wheel alignment CHRYSLER CARAVAN 2003 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 255 of 2177

INSTALLATION

(1) Install clutch release bearing and lever (if

removed). (Refer to 6 - CLUTCH/CLUTCH RELEASE

BEARING - INSTALLATION)

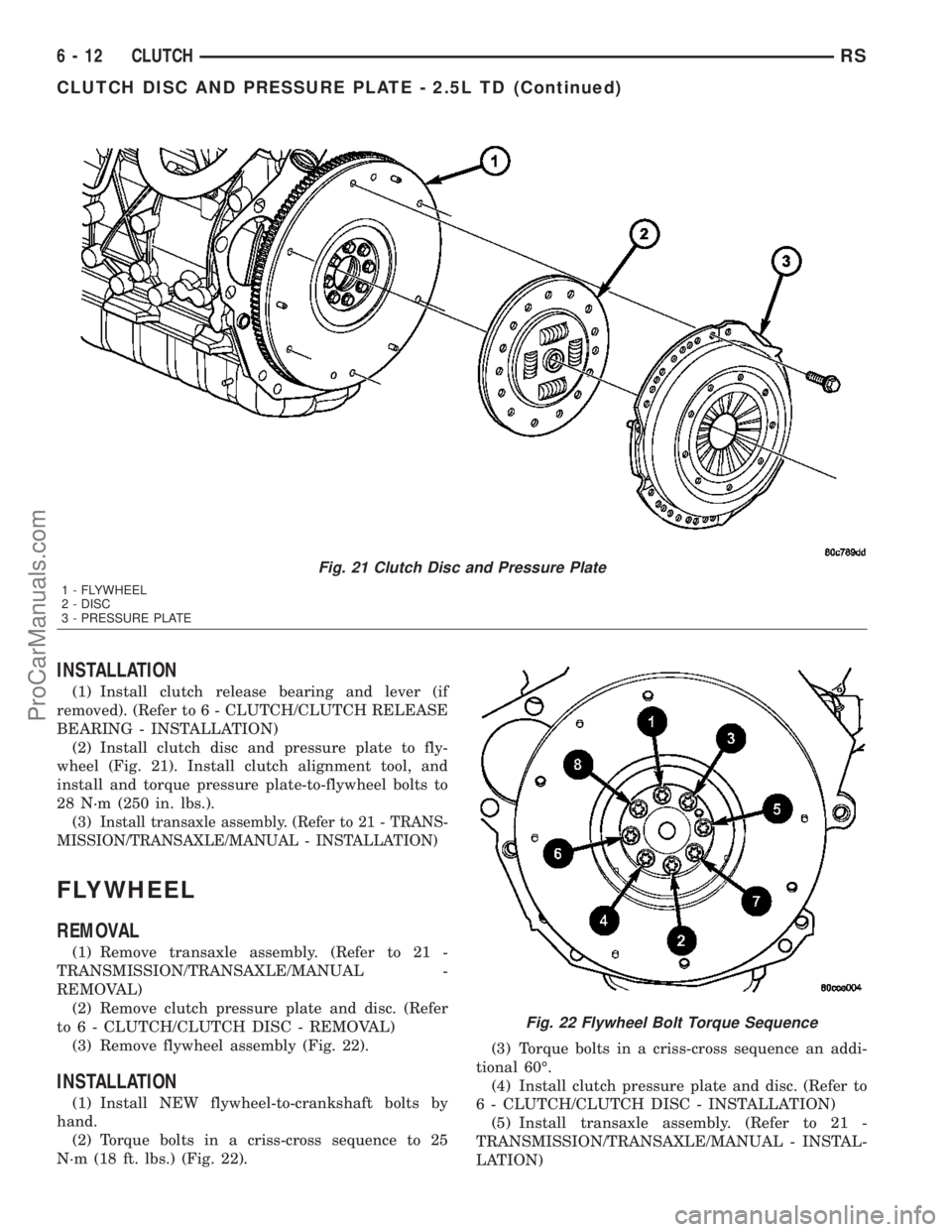

(2) Install clutch disc and pressure plate to fly-

wheel (Fig. 21). Install clutch alignment tool, and

install and torque pressure plate-to-flywheel bolts to

28 N´m (250 in. lbs.).

(3)

Install transaxle assembly. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/MANUAL - INSTALLATION)

FLYWHEEL

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove clutch pressure plate and disc. (Refer

to 6 - CLUTCH/CLUTCH DISC - REMOVAL)

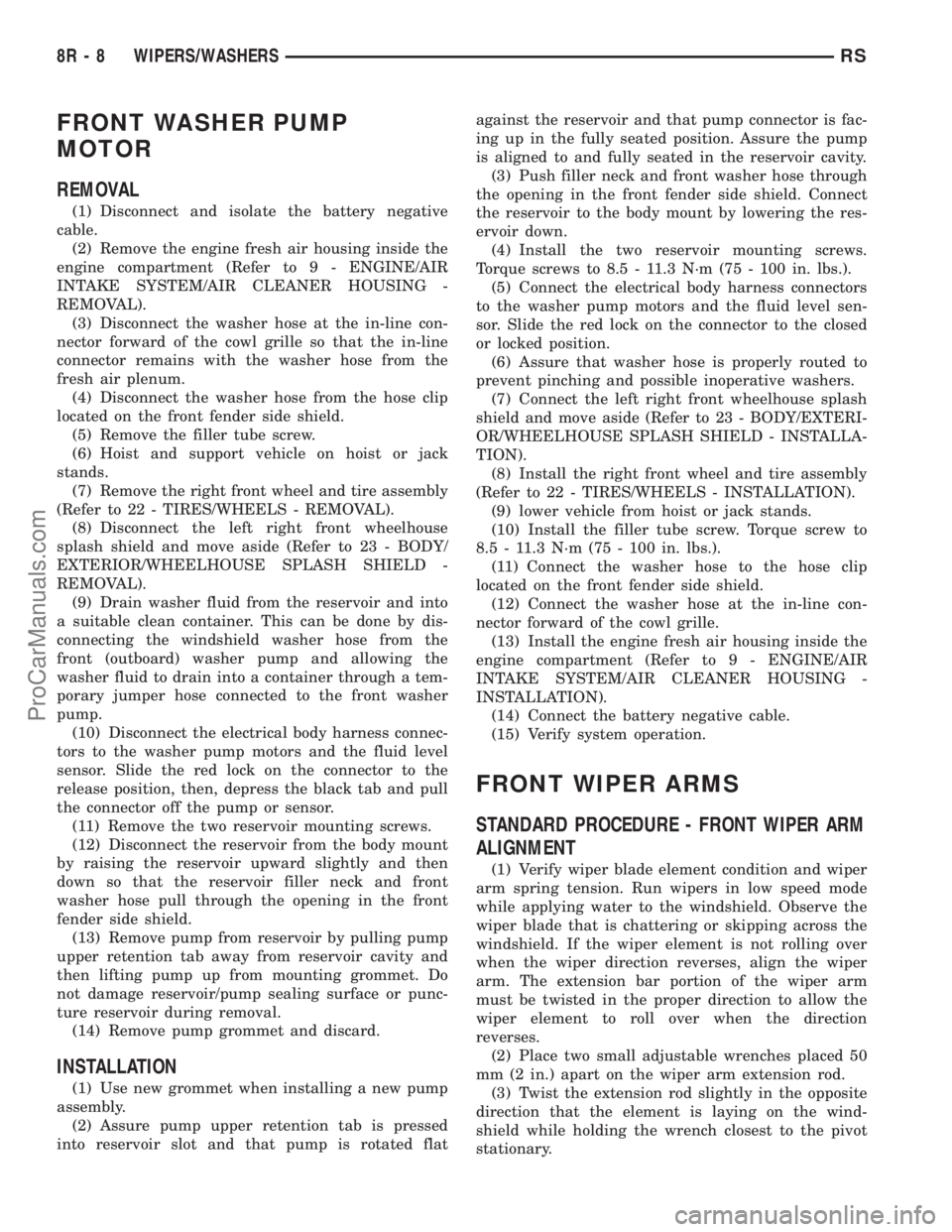

(3) Remove flywheel assembly (Fig. 22).

INSTALLATION

(1) Install NEW flywheel-to-crankshaft bolts by

hand.

(2) Torque bolts in a criss-cross sequence to 25

N´m (18 ft. lbs.) (Fig. 22).(3) Torque bolts in a criss-cross sequence an addi-

tional 60É.

(4) Install clutch pressure plate and disc. (Refer to

6 - CLUTCH/CLUTCH DISC - INSTALLATION)

(5) Install transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

Fig. 21 Clutch Disc and Pressure Plate

1 - FLYWHEEL

2 - DISC

3 - PRESSURE PLATE

Fig. 22 Flywheel Bolt Torque Sequence

6 - 12 CLUTCHRS

CLUTCH DISC AND PRESSURE PLATE - 2.5L TD (Continued)

ProCarManuals.com

Page 559 of 2177

FRONT WASHER PUMP

MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the washer hose at the in-line con-

nector forward of the cowl grille so that the in-line

connector remains with the washer hose from the

fresh air plenum.

(4) Disconnect the washer hose from the hose clip

located on the front fender side shield.

(5) Remove the filler tube screw.

(6) Hoist and support vehicle on hoist or jack

stands.

(7) Remove the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - REMOVAL).

(8) Disconnect the left right front wheelhouse

splash shield and move aside (Refer to 23 - BODY/

EXTERIOR/WHEELHOUSE SPLASH SHIELD -

REMOVAL).

(9) Drain washer fluid from the reservoir and into

a suitable clean container. This can be done by dis-

connecting the windshield washer hose from the

front (outboard) washer pump and allowing the

washer fluid to drain into a container through a tem-

porary jumper hose connected to the front washer

pump.

(10) Disconnect the electrical body harness connec-

tors to the washer pump motors and the fluid level

sensor. Slide the red lock on the connector to the

release position, then, depress the black tab and pull

the connector off the pump or sensor.

(11) Remove the two reservoir mounting screws.

(12) Disconnect the reservoir from the body mount

by raising the reservoir upward slightly and then

down so that the reservoir filler neck and front

washer hose pull through the opening in the front

fender side shield.

(13) Remove pump from reservoir by pulling pump

upper retention tab away from reservoir cavity and

then lifting pump up from mounting grommet. Do

not damage reservoir/pump sealing surface or punc-

ture reservoir during removal.

(14) Remove pump grommet and discard.

INSTALLATION

(1) Use new grommet when installing a new pump

assembly.

(2) Assure pump upper retention tab is pressed

into reservoir slot and that pump is rotated flatagainst the reservoir and that pump connector is fac-

ing up in the fully seated position. Assure the pump

is aligned to and fully seated in the reservoir cavity.

(3) Push filler neck and front washer hose through

the opening in the front fender side shield. Connect

the reservoir to the body mount by lowering the res-

ervoir down.

(4) Install the two reservoir mounting screws.

Torque screws to 8.5 - 11.3 N´m (75 - 100 in. lbs.).

(5) Connect the electrical body harness connectors

to the washer pump motors and the fluid level sen-

sor. Slide the red lock on the connector to the closed

or locked position.

(6) Assure that washer hose is properly routed to

prevent pinching and possible inoperative washers.

(7) Connect the left right front wheelhouse splash

shield and move aside (Refer to 23 - BODY/EXTERI-

OR/WHEELHOUSE SPLASH SHIELD - INSTALLA-

TION).

(8) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(9) lower vehicle from hoist or jack stands.

(10) Install the filler tube screw. Torque screw to

8.5 - 11.3 N´m (75 - 100 in. lbs.).

(11) Connect the washer hose to the hose clip

located on the front fender side shield.

(12) Connect the washer hose at the in-line con-

nector forward of the cowl grille.

(13) Install the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(14) Connect the battery negative cable.

(15) Verify system operation.

FRONT WIPER ARMS

STANDARD PROCEDURE - FRONT WIPER ARM

ALIGNMENT

(1) Verify wiper blade element condition and wiper

arm spring tension. Run wipers in low speed mode

while applying water to the windshield. Observe the

wiper blade that is chattering or skipping across the

windshield. If the wiper element is not rolling over

when the wiper direction reverses, align the wiper

arm. The extension bar portion of the wiper arm

must be twisted in the proper direction to allow the

wiper element to roll over when the direction

reverses.

(2) Place two small adjustable wrenches placed 50

mm (2 in.) apart on the wiper arm extension rod.

(3) Twist the extension rod slightly in the opposite

direction that the element is laying on the wind-

shield while holding the wrench closest to the pivot

stationary.

8R - 8 WIPERS/WASHERSRS

ProCarManuals.com

Page 1179 of 2177

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET

For complete circuit diagrams, refer toCigar

Lighter/Power Outletin Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO RESTRAINTS BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN,

SEAT OR INSTRUMENT PANEL COMPONENT DIAG-

NOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Check the fused B(+) fuse in the Integrated

Power Module (IPM). If OK, go to Step 2. If not OK,

repair the shorted circuit or component as required

and replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the IPM. If OK, go to Step 3. If not OK, repair the

open fused B(+) circuit to the IPM fuse as required.

(3)

Open the power outlet door. Check for continuity

between the inside circumference of the power outlet

receptacle and a good ground. There should be continu-

ity. If OK, go to Step 4. If not OK, go to Step 5.

(4) Check for battery voltage at the insulated con-

tact located at the back of the power outlet recepta-

cle. If not OK, go to Step 5.

(5) Disconnect and isolate the battery negative

cable. Remove the appropriate bezel. Check for conti-

nuity between the ground circuit cavity of the power

outlet wire harness connector and a good ground.

There should be continuity. If OK, go to Step 6. If not

OK, repair the open ground circuit to ground as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

power outlet wire harness connector. If OK, replace

the faulty power outlet receptacle. If not OK, repair

the open fused B(+) circuit to the IPM fuse as

required.

REMOVAL

(1)Disconnect and isolate the battery negative cable.

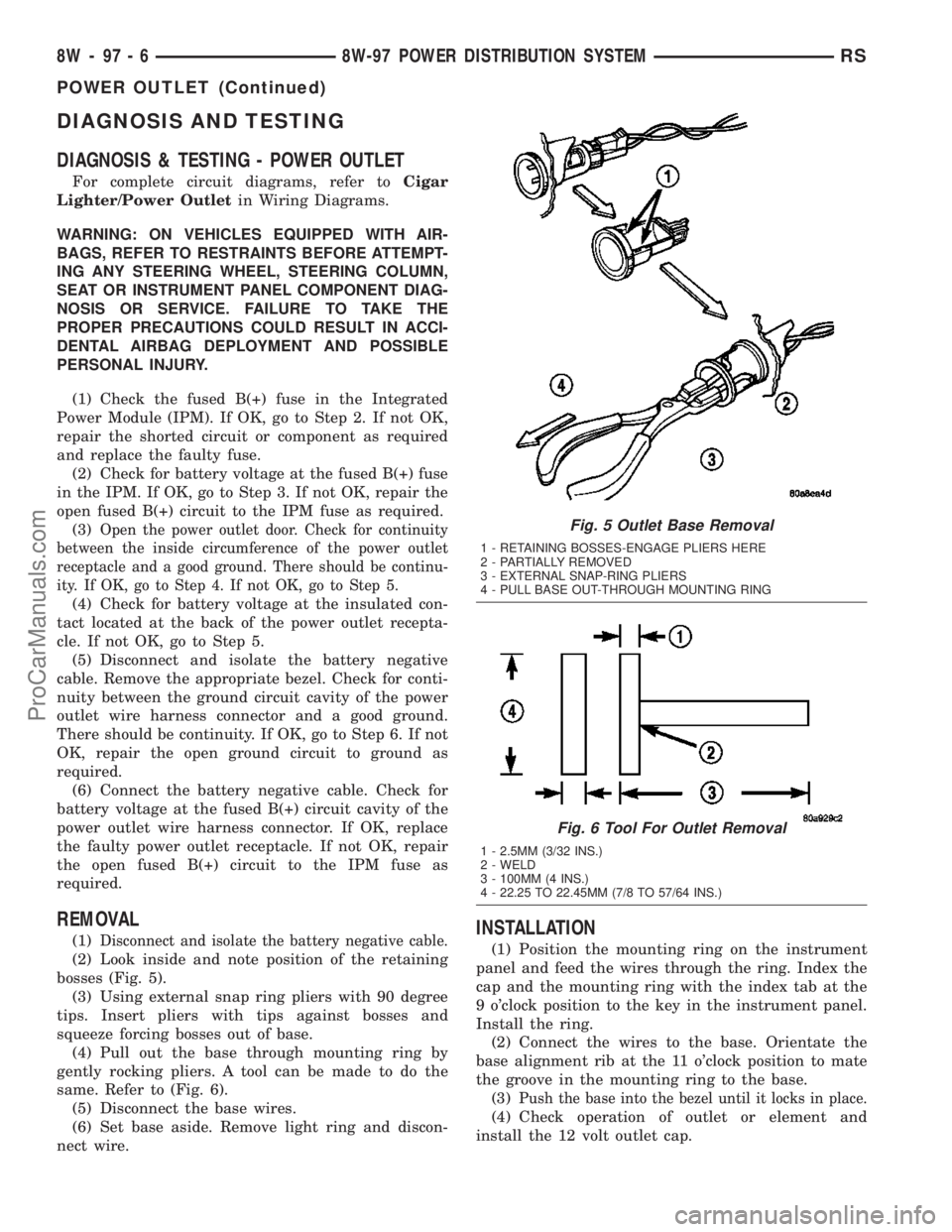

(2) Look inside and note position of the retaining

bosses (Fig. 5).

(3) Using external snap ring pliers with 90 degree

tips. Insert pliers with tips against bosses and

squeeze forcing bosses out of base.

(4) Pull out the base through mounting ring by

gently rocking pliers. A tool can be made to do the

same. Refer to (Fig. 6).

(5) Disconnect the base wires.

(6) Set base aside. Remove light ring and discon-

nect wire.

INSTALLATION

(1) Position the mounting ring on the instrument

panel and feed the wires through the ring. Index the

cap and the mounting ring with the index tab at the

9 o'clock position to the key in the instrument panel.

Install the ring.

(2) Connect the wires to the base. Orientate the

base alignment rib at the 11 o'clock position to mate

the groove in the mounting ring to the base.

(3)

Push the base into the bezel until it locks in place.

(4) Check operation of outlet or element and

install the 12 volt outlet cap.

Fig. 5 Outlet Base Removal

1 - RETAINING BOSSES-ENGAGE PLIERS HERE

2 - PARTIALLY REMOVED

3 - EXTERNAL SNAP-RING PLIERS

4 - PULL BASE OUT-THROUGH MOUNTING RING

Fig. 6 Tool For Outlet Removal

1 - 2.5MM (3/32 INS.)

2 - WELD

3 - 100MM (4 INS.)

4 - 22.25 TO 22.45MM (7/8 TO 57/64 INS.)

8W - 97 - 6 8W-97 POWER DISTRIBUTION SYSTEMRS

POWER OUTLET (Continued)

ProCarManuals.com

Page 1216 of 2177

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Engine Specifica-

tions.

REMOVAL - CRANKSHAFT

NOTE: Crankshaft can not be removed when engine

is in vehicle.

(1) Remove engine assembly from vehicle (Refer to

9 - ENGINE - REMOVAL).

(2) Separate transaxle from engine.

(3) Remove drive plate/flex plate.

(4) Remove crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

(5) Mount engine on a suitable repair stand.

(6) Drain engine oil and remove oil filter.

(7) Remove crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(8) Remove engine mount support bracket.

(9) Remove front timing belt covers (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- REMOVAL).

(10) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

REMOVAL).

(11) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(12) Remove oil pump pick-up tube.

(13) Remove the crankshaft sprocket and oil pump

(Refer to 9 - ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

(14) Remove balance shafts and housing assembly

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - REMOVAL).

(15) Remove crankshaft position sensor.NOTE: If piston/connecting rod replacement is nec-

essary, remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

(16) Using a permanent ink or paint marker, iden-

tify cylinder number on each connecting rod cap (Fig.

44).

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(17) Remove all connecting rod bolts and caps.

Care should be taken not to damage the fracture rod

and cap surfaces.

NOTE: Do not reuse connecting rod bolts.

(18) Remove all bedplate bolts from the engine

block (Fig. 45).

(19) Using a mallet gently tap the bedplate loose

from the engine block dowel pins.

CAUTION: Do not pry up on one side of the bed-

plate. Damage may occur to cylinder block to bed-

plate alignment and thrust bearing.

(20) Bedplate should be removed evenly from the

cylinder block dowel pins to prevent damage to the

dowel pins and thrust bearing.

CAUTION: Use extreme care when handling crank-

shaft. Tone wheel damage can occur if crankshaft is

mis-handled.

(21) Lift out crankshaft from cylinder block. Do

not damage the main bearings or journals when

removing the crankshaft.

INSPECTION

For crankshaft specifications (Refer to 9 - ENGINE

- SPECIFICATIONS).

Fig. 43 CHECKING CRANKSHAFT END PLAY

Fig. 44 Identify Connecting Rod to Cylinder

RSENGINE 2.4L9-37

CRANKSHAFT (Continued)

ProCarManuals.com

Page 1402 of 2177

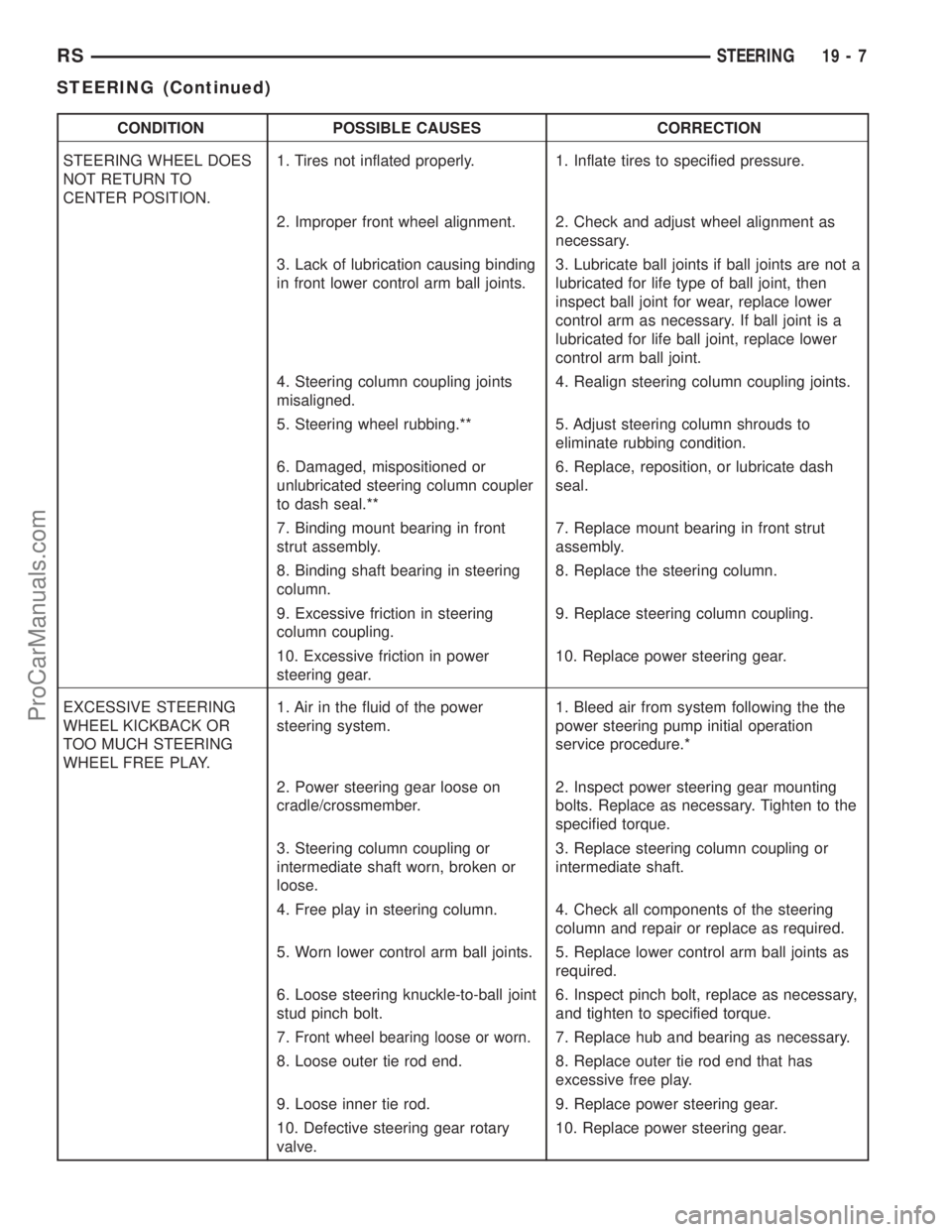

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES

NOT RETURN TO

CENTER POSITION.1. Tires not inflated properly. 1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust wheel alignment as

necessary.

3. Lack of lubrication causing binding

in front lower control arm ball joints.3. Lubricate ball joints if ball joints are not a

lubricated for life type of ball joint, then

inspect ball joint for wear, replace lower

control arm as necessary. If ball joint is a

lubricated for life ball joint, replace lower

control arm ball joint.

4. Steering column coupling joints

misaligned.4. Realign steering column coupling joints.

5. Steering wheel rubbing.** 5. Adjust steering column shrouds to

eliminate rubbing condition.

6. Damaged, mispositioned or

unlubricated steering column coupler

to dash seal.**6. Replace, reposition, or lubricate dash

seal.

7. Binding mount bearing in front

strut assembly.7. Replace mount bearing in front strut

assembly.

8. Binding shaft bearing in steering

column.8. Replace the steering column.

9. Excessive friction in steering

column coupling.9. Replace steering column coupling.

10. Excessive friction in power

steering gear.10. Replace power steering gear.

EXCESSIVE STEERING

WHEEL KICKBACK OR

TOO MUCH STEERING

WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Bleed air from system following the the

power steering pump initial operation

service procedure.*

2. Power steering gear loose on

cradle/crossmember.2. Inspect power steering gear mounting

bolts. Replace as necessary. Tighten to the

specified torque.

3. Steering column coupling or

intermediate shaft worn, broken or

loose.3. Replace steering column coupling or

intermediate shaft.

4. Free play in steering column. 4. Check all components of the steering

column and repair or replace as required.

5. Worn lower control arm ball joints. 5. Replace lower control arm ball joints as

required.

6. Loose steering knuckle-to-ball joint

stud pinch bolt.6. Inspect pinch bolt, replace as necessary,

and tighten to specified torque.

7.

Front wheel bearing loose or worn.7. Replace hub and bearing as necessary.

8. Loose outer tie rod end. 8. Replace outer tie rod end that has

excessive free play.

9. Loose inner tie rod. 9. Replace power steering gear.

10. Defective steering gear rotary

valve.10. Replace power steering gear.

RSSTEERING19-7

STEERING (Continued)

ProCarManuals.com

Page 1418 of 2177

SHROUD - UPPER

REMOVAL

(1) Remove the two shroud-to-shroud mounting

screws from the lower shroud (Fig. 32).

(2) Unsnap the upper shroud from the lower on

the left side as follows:

(a) Hook a finger on the left hand around the

rear of the shrouds at the seam (Fig. 33), near the

snap points.

(b) Grasp the upper shroud at the rear using the

right hand (Fig. 33).

(c) As the left hand's hooked finger is pulled out-

ward against the seam, pull the upper shroud

upward using the right hand, disconnecting the

shroud snaps.

(3) Unsnap the upper shroud from the lower on

the right side as follows:

(a) Hook a finger on the right hand around the

rear of the shrouds at the seam (Fig. 34), near the

snap points.

(b) Grasp the upper shroud at the rear using the

left hand (Fig. 34).

(c) As the right hand's hooked finger is pulled

outward against the seam, pull the upper shroud

upward using the left hand, disconnecting the

shroud snaps.

(4) Lift the upper shroud straight up off the steer-

ing column. If vehicle is equipped with traction con-

trol, disconnect wiring connector at traction control

switch pig tail. If vehicle is equipped with power fold-

away mirrors (Export), disconnect wiring connector

at mirror switch pig tail. Remove upper shroud.

(5) If vehicle is equipped with traction control,

remove traction control switch from shroud.

(6) If vehicle is equipped with power foldaway mir-

rors (Export), remove power fold-away switch from

upper shroud.

INSTALLATION

(1) If the vehicle is equipped with power foldaway

mirrors (Export), install the power fold-away switch

in the upper shroud.

(2) If vehicle is equipped with traction control,

install the traction control switch in the upper

shroud.

(3) Place the upper shroud over the lower shroud,

aligning the snap clips and alignment tabs. If the

vehicle is equipped with traction control, connect the

wiring connector at the traction control switch pig

tail before lining the shrouds up to one another.

(4) Snap the upper shroud to the lower shroud.

Once snapped into place, verify there are no gaps

between the two mating surfaces of the shrouds.(5) Install the two shroud-to-shroud mounting

screws (Fig. 32). Tighten the screws to 2 N´m (17 in.

lbs.) torque.

(6) Ensure that the shrouds are snug and fit is

acceptable.

STEERING WHEEL

REMOVAL

NOTE: Before proceeding, (Refer to 19 - STEERING/

COLUMN - WARNING)(Refer to 8 - ELECTRICAL/RE-

STRAINTS - WARNING).

(1) Adjust the steering wheel so that the tires are

in thestraight-aheadposition.

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the two bolts from the rear of the

steering wheel attaching the driver airbag. Lift the

airbag from the steering wheel.

(4) Disconnect airbag squib wiring connectors from

the airbag and the horn/speed control switch pigtail

connector from the clockspring (Fig. 35). If the steer-

ing wheel is equipped with remote radio controls, dis-

connect the connector from the clockspring (Fig. 36).

Properly store the driver airbag out of the way.

(Refer to 8 - ELECTRICAL/RESTRAINTS - WARN-

ING)

(5) Remove the steering wheel retaining nut from

the steering column shaft (Fig. 36).

(6) Remove the steering wheel damper from the

steering wheel (Fig. 36).

Fig. 35 Airbag Wiring Connections

1 - AIRBAG FEED SQUIB CONNECTORS

2 - DRIVER AIRBAG

3 - HORN/SPEED CONTROL CONNECTOR

4 - CLOCKSPRING

RSCOLUMN19-23

ProCarManuals.com

Page 1428 of 2177

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.

(7) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 6). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).

(8) Install the lower control arm rear bushing

retainer bolts (M-10 size) through reinforcement on

each side of each lower control arm rear bushing.

Tighten bolts to a torque of 61 N´m (45 ft. lbs.).

(9) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 6). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

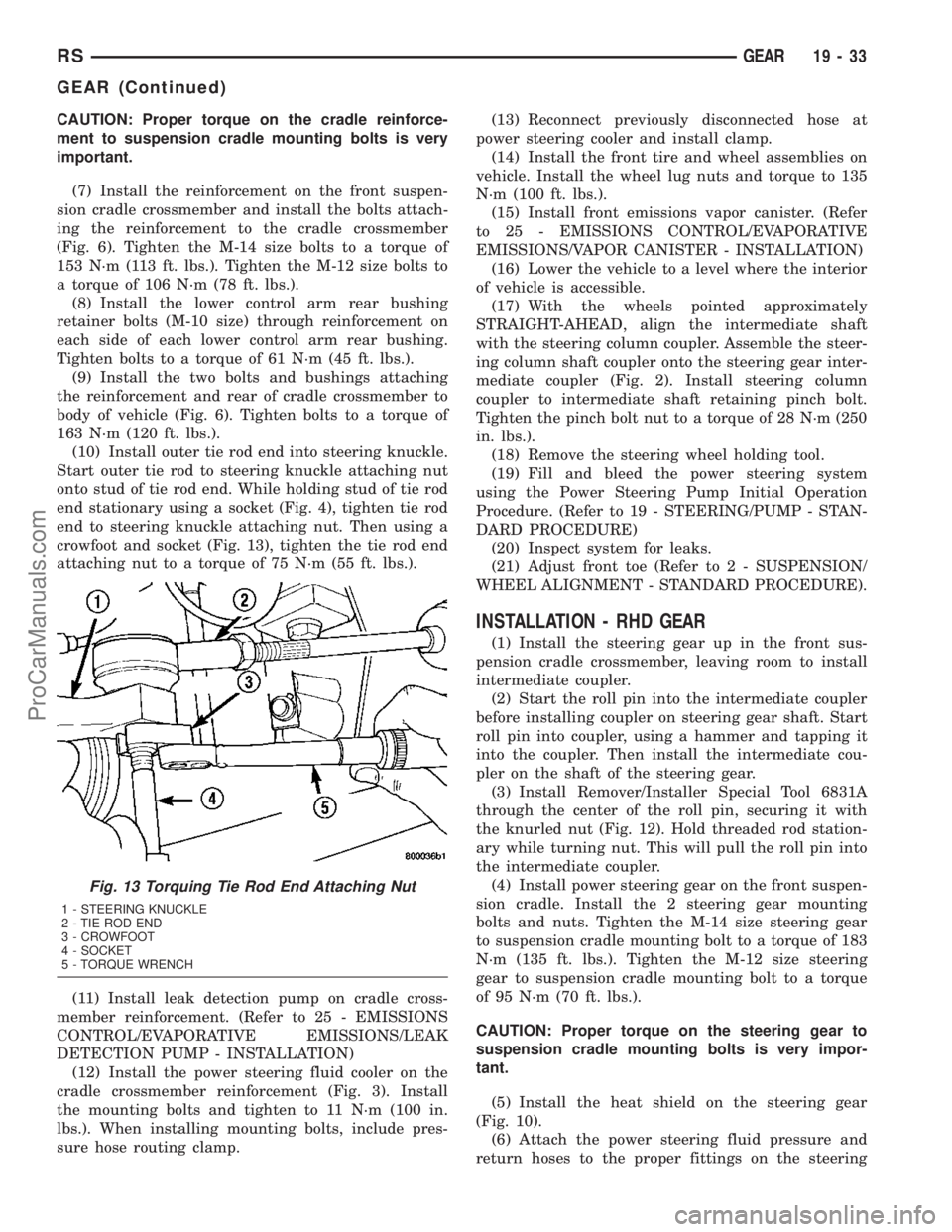

(10) Install outer tie rod end into steering knuckle.

Start outer tie rod to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary using a socket (Fig. 4), tighten tie rod

end to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 13), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(11) Install leak detection pump on cradle cross-

member reinforcement. (Refer to 25 - EMISSIONS

CONTROL/EVAPORATIVE EMISSIONS/LEAK

DETECTION PUMP - INSTALLATION)

(12) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 3). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.). When installing mounting bolts, include pres-

sure hose routing clamp.(13) Reconnect previously disconnected hose at

power steering cooler and install clamp.

(14) Install the front tire and wheel assemblies on

vehicle. Install the wheel lug nuts and torque to 135

N´m (100 ft. lbs.).

(15) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(16) Lower the vehicle to a level where the interior

of vehicle is accessible.

(17) With the wheels pointed approximately

STRAIGHT-AHEAD, align the intermediate shaft

with the steering column coupler. Assemble the steer-

ing column shaft coupler onto the steering gear inter-

mediate coupler (Fig. 2). Install steering column

coupler to intermediate shaft retaining pinch bolt.

Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

(18) Remove the steering wheel holding tool.

(19) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(20) Inspect system for leaks.

(21) Adjust front toe (Refer to 2 - SUSPENSION/

WHEEL ALIGNMENT - STANDARD PROCEDURE).

INSTALLATION - RHD GEAR

(1) Install the steering gear up in the front sus-

pension cradle crossmember, leaving room to install

intermediate coupler.

(2) Start the roll pin into the intermediate coupler

before installing coupler on steering gear shaft. Start

roll pin into coupler, using a hammer and tapping it

into the coupler. Then install the intermediate cou-

pler on the shaft of the steering gear.

(3) Install Remover/Installer Special Tool 6831A

through the center of the roll pin, securing it with

the knurled nut (Fig. 12). Hold threaded rod station-

ary while turning nut. This will pull the roll pin into

the intermediate coupler.

(4) Install power steering gear on the front suspen-

sion cradle. Install the 2 steering gear mounting

bolts and nuts. Tighten the M-14 size steering gear

to suspension cradle mounting bolt to a torque of 183

N´m (135 ft. lbs.). Tighten the M-12 size steering

gear to suspension cradle mounting bolt to a torque

of 95 N´m (70 ft. lbs.).

CAUTION: Proper torque on the steering gear to

suspension cradle mounting bolts is very impor-

tant.

(5) Install the heat shield on the steering gear

(Fig. 10).

(6) Attach the power steering fluid pressure and

return hoses to the proper fittings on the steering

Fig. 13 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

RSGEAR19-33

GEAR (Continued)

ProCarManuals.com

Page 1429 of 2177

gear (Fig. 10). Do not fully tighten the fittings at this

time.

(7) Install the routing clamp with the bolt securing

the power steering fluid hoses to the rear of the cra-

dle crossmember (Fig. 11).

(8) Using a crowfoot wrench on a torque wrench,

tighten the power steering fluid hose tube nuts at the

gear to a torque of 31 N´m (275 in. lbs.).

(9) Install tie rod end into steering knuckle. Start

tie rod end to steering knuckle attaching nut onto

stud of tie rod end. While holding stud of tie rod end

stationary using a socket (Fig. 4), tighten tie rod end

to steering knuckle attaching nut. Then using a

crowfoot and socket (Fig. 13), tighten the tie rod end

attaching nut to a torque of 75 N´m (55 ft. lbs.).

(10) If the vehicle is equipped with All-Wheel-

Drive, install the power transfer unit (Refer to 21 -

TRANSMISSION/TRANSAXLE/POWER TRANSFER

UNIT - INSTALLATION).

CAUTION: Proper torque on the cradle reinforce-

ment to suspension cradle mounting bolts is very

important.

(11) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 6). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(12) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(13) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 6). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(14) If power steering cooler equipped, install the

previously disconnected power steering cooler hose on

the cooler. Install the clamp.

(15) If power steering cooler equipped, install the

power steering fluid cooler on the cradle crossmem-

ber reinforcement (Fig. 3). Install the mounting bolts

and tighten to 11 N´m (100 in. lbs.).

(16) Install the front tire and wheel assemblies on

vehicle. Install the wheel mounting lug nuts and

tighten to a torque to 135 N´m (100 ft. lbs.).

(17) Lower the vehicle to a level were the interior

of vehicle is accessible (keeping tires off the ground).

(18) With the wheels pointed approximately

STRAIGHT-AHEAD, align the intermediate shaft

with the steering column coupler. Assemble the steer-

ing column shaft coupler onto the steering gear inter-

mediate coupler (Fig. 2). Install steering column

coupler to intermediate shaft retaining pinch bolt.Tighten the pinch bolt nut to a torque of 28 N´m (250

in. lbs.).

(19) Remove the steering wheel holding tool.

(20) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(21) Inspect for leaks.

(22) Adjust front wheel toe (Refer to 2 - SUSPEN-

SION/WHEEL ALIGNMENT - STANDARD PROCE-

DURE).

SPECIAL TOOLS

POWER STEERING GEAR

OUTER TIE ROD

REMOVAL

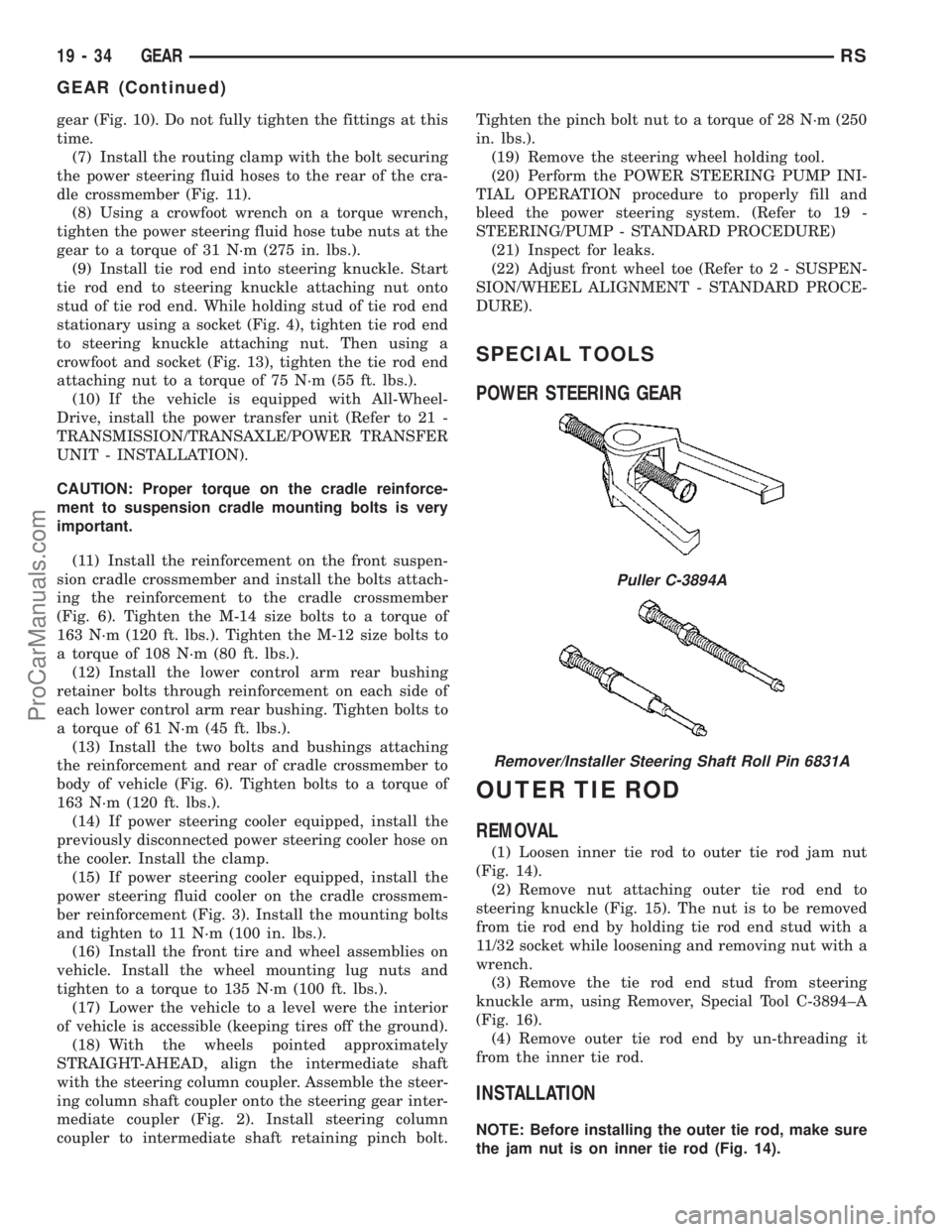

(1) Loosen inner tie rod to outer tie rod jam nut

(Fig. 14).

(2) Remove nut attaching outer tie rod end to

steering knuckle (Fig. 15). The nut is to be removed

from tie rod end by holding tie rod end stud with a

11/32 socket while loosening and removing nut with a

wrench.

(3) Remove the tie rod end stud from steering

knuckle arm, using Remover, Special Tool C-3894±A

(Fig. 16).

(4) Remove outer tie rod end by un-threading it

from the inner tie rod.

INSTALLATION

NOTE: Before installing the outer tie rod, make sure

the jam nut is on inner tie rod (Fig. 14).

Puller C-3894A

Remover/Installer Steering Shaft Roll Pin 6831A

19 - 34 GEARRS

GEAR (Continued)

ProCarManuals.com

Page 1430 of 2177

(1) Install outer tie rod onto inner tie rod.

(2) Do not tighten jam nut.

(3) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 15). Then using a crow-

foot and 11/32 socket (Fig. 17), torque tie rod end

attaching nut to 75 N´m (55 ft. lbs.).

(4) Tighten tie rod jam nut (Fig. 14) to 75 N´m (55

ft. lbs.) torque.CAUTION: During this procedure do not allow the

steering gear boot to become twisted.

(5) Adjust the front toe setting on the vehicle

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE).

Fig. 14 Inner To Outer Tie Rod Jam Nut

1 - INNER TIE ROD SERRATION

2 - OUTER TIE ROD JAM NUT

3 - OUTER TIE ROD END

4 - INNER TIE ROD

5 - STEERING KNUCKLE

Fig. 15 Tie Rod End Attaching Nut (Typical)

1 - TIE ROD END

2 - STEERING KNUCKLE

3 - WRENCH

4 - SOCKET

5 - TIE ROD END STUD

Fig. 16 TIE ROD REMOVAL WITH TOOL C-3894-A

1 - OUTER TIE ROD

2 - SPECIAL TOOL C-3894-A

3 - STEERING KNUCKLE

Fig. 17 Torquing Tie Rod End Attaching Nut

1 - STEERING KNUCKLE

2 - TIE ROD END

3 - CROWFOOT

4 - SOCKET

5 - TORQUE WRENCH

RSGEAR19-35

OUTER TIE ROD (Continued)

ProCarManuals.com

Page 1729 of 2177

white letters. To remove the protective coating, apply

warm water and let it soak for a few minutes. After-

wards, scrub the coating away with a soft bristle

brush. Steam cleaning may also be used to remove

the coating.

CAUTION: DO NOT use gasoline, mineral oil, oil-

based solvent or a wire brush for cleaning.

WHEELS

DESCRIPTION - WHEEL

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

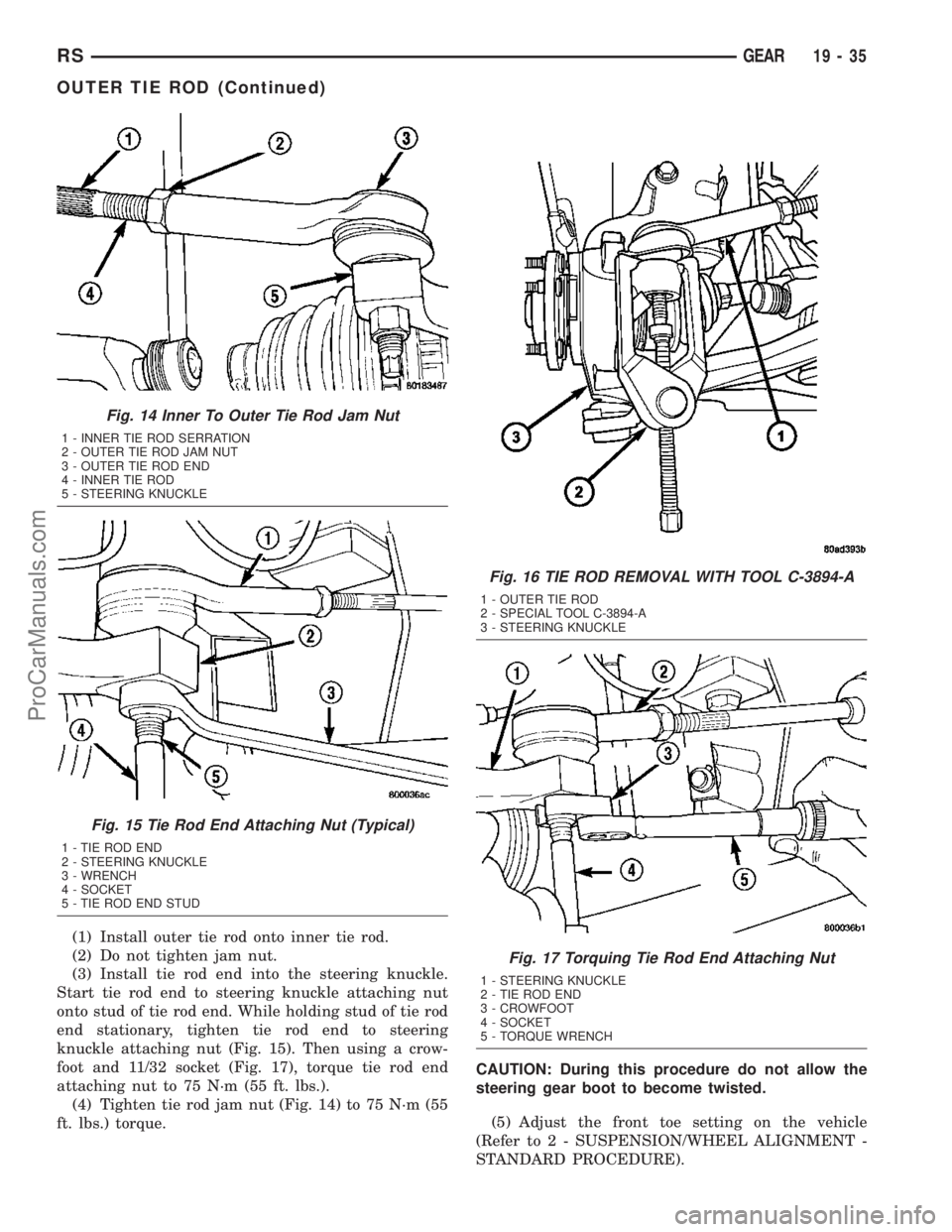

All models use either steel or aluminum drop-cen-

ter wheels. Every wheel has raised sections between

the rim flanges and rim drop well called safety

humps (Fig. 28). Initial inflation of the tires forces

the bead over these raised sections. In case of air

loss, the safety humps hold the tire in position on the

wheel until the vehicle can be brought to a safe stop.

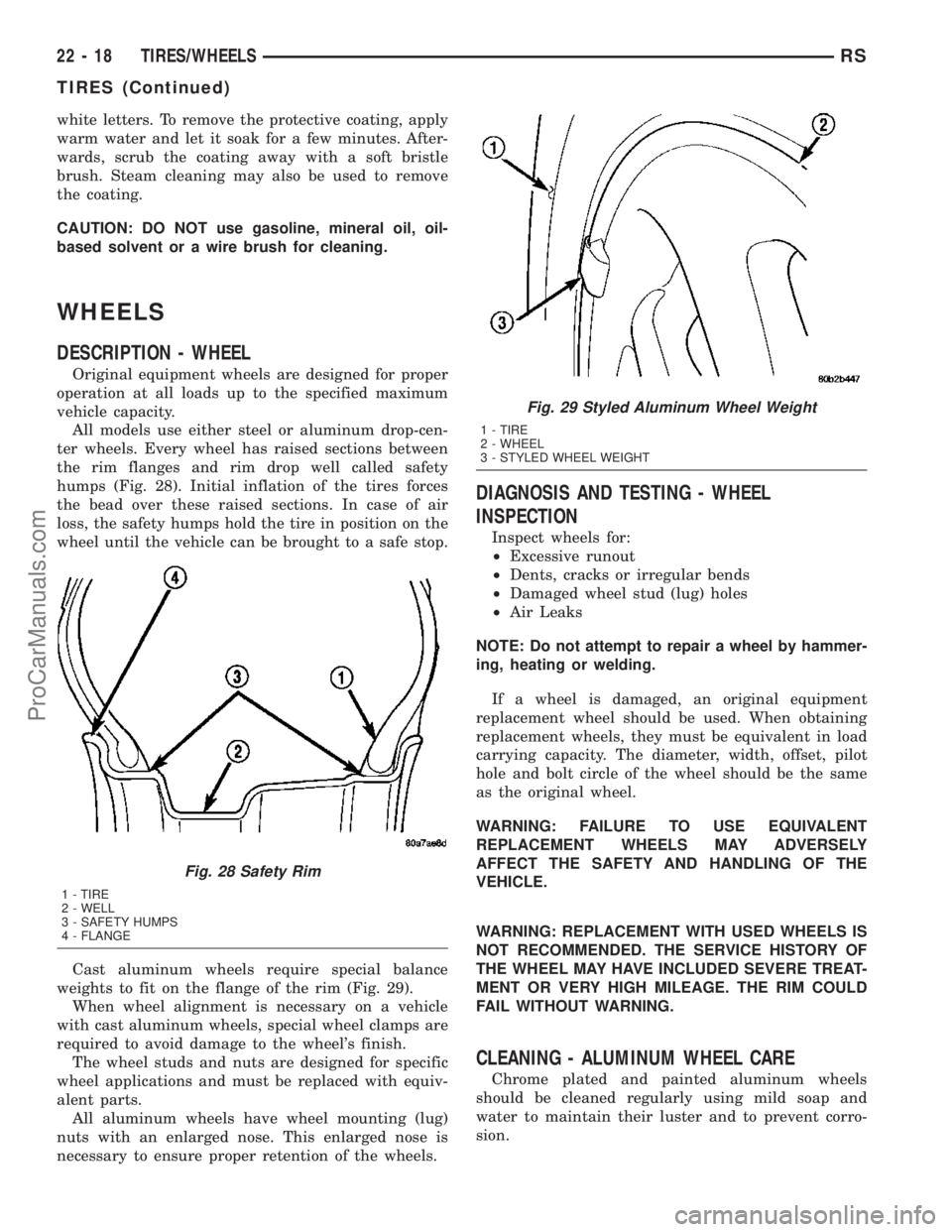

Cast aluminum wheels require special balance

weights to fit on the flange of the rim (Fig. 29).

When wheel alignment is necessary on a vehicle

with cast aluminum wheels, special wheel clamps are

required to avoid damage to the wheel's finish.

The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts.

All aluminum wheels have wheel mounting (lug)

nuts with an enlarged nose. This enlarged nose is

necessary to ensure proper retention of the wheels.

DIAGNOSIS AND TESTING - WHEEL

INSPECTION

Inspect wheels for:

²Excessive runout

²Dents, cracks or irregular bends

²Damaged wheel stud (lug) holes

²Air Leaks

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged, an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they must be equivalent in load

carrying capacity. The diameter, width, offset, pilot

hole and bolt circle of the wheel should be the same

as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE.

WARNING: REPLACEMENT WITH USED WHEELS IS

NOT RECOMMENDED. THE SERVICE HISTORY OF

THE WHEEL MAY HAVE INCLUDED SEVERE TREAT-

MENT OR VERY HIGH MILEAGE. THE RIM COULD

FAIL WITHOUT WARNING.

CLEANING - ALUMINUM WHEEL CARE

Chrome plated and painted aluminum wheels

should be cleaned regularly using mild soap and

water to maintain their luster and to prevent corro-

sion.

Fig. 28 Safety Rim

1 - TIRE

2 - WELL

3 - SAFETY HUMPS

4 - FLANGE

Fig. 29 Styled Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - STYLED WHEEL WEIGHT

22 - 18 TIRES/WHEELSRS

TIRES (Continued)

ProCarManuals.com