tow CHRYSLER CARAVAN 2003 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 253 of 2177

(10) Using Tool 6638A, disconnect clutch master

cylinder ªquick connectº fitting (Fig. 17). Disengage

plumbing retainer from body stud.

(11) Remove master cylinder reservoir-to-strut

tower nuts (Fig. 18). Reposition reservoir off to side.

(12) Remove clutch master cylinder from dash

panel by rotating clockwise 45É and removing from

dash panel (Fig. 18).(13) Remove master cylinder and plumbing from

engine compartment. Use care not to bend or kink

plumbing. Note plumbing routing to aid in installa-

tion.

INSTALLATION

(1) Install master cylinder into position, while

routing plumbing as originally installed.

(2) Insert master cylinder pushrod through dash

panel (Fig. 18) and rotate 45É counter-clockwise to

secure.

(3) Connect master cylinder plumbing quick-con-

nect fitting. An audible ªclickº should be heard. Ver-

ify connection by pulling outward.

(4) Install master cylinder reservoir onto strut

tower. Install and tighten two (2) master cylinder

reservoir-to-strut tower nuts to 11 N´m (100 in. lbs.)

(Fig. 18).

(5) Install windshield wiper module assembly

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION).

(6) Install battery tray.

(7) Install battery.

(8) Install battery shield.

(9) Connect master cylinder pushrod to clutch

pedal lever (Fig. 16). Install retainer clip.

(10) Install knee bolster and instrument panel

lower silencer (Fig. 15) (Fig. 14).

(11) Connect battery cables.

Fig. 16 Master Cylinder Pushrod at Pedal

1 - MASTER CYLINDER PUSHROD

2 - CLUTCH/BRAKE PEDAL ASSEMBLY

3 - PUSHROD RETAINER

Fig. 17 Disconnect Quick-Connect Using Tool 6638A

1 - QUICK CONNECT FITTING

2 - TOOL 6638A

Fig. 18 Clutch Master Cylinder Removal/Installation

1 - CLUTCH MASTER CYLINDER

2 - RESERVOIR

3 - NUT (2)

6 - 10 CLUTCHRS

MASTER CYLINDER - LHD (Continued)

ProCarManuals.com

Page 254 of 2177

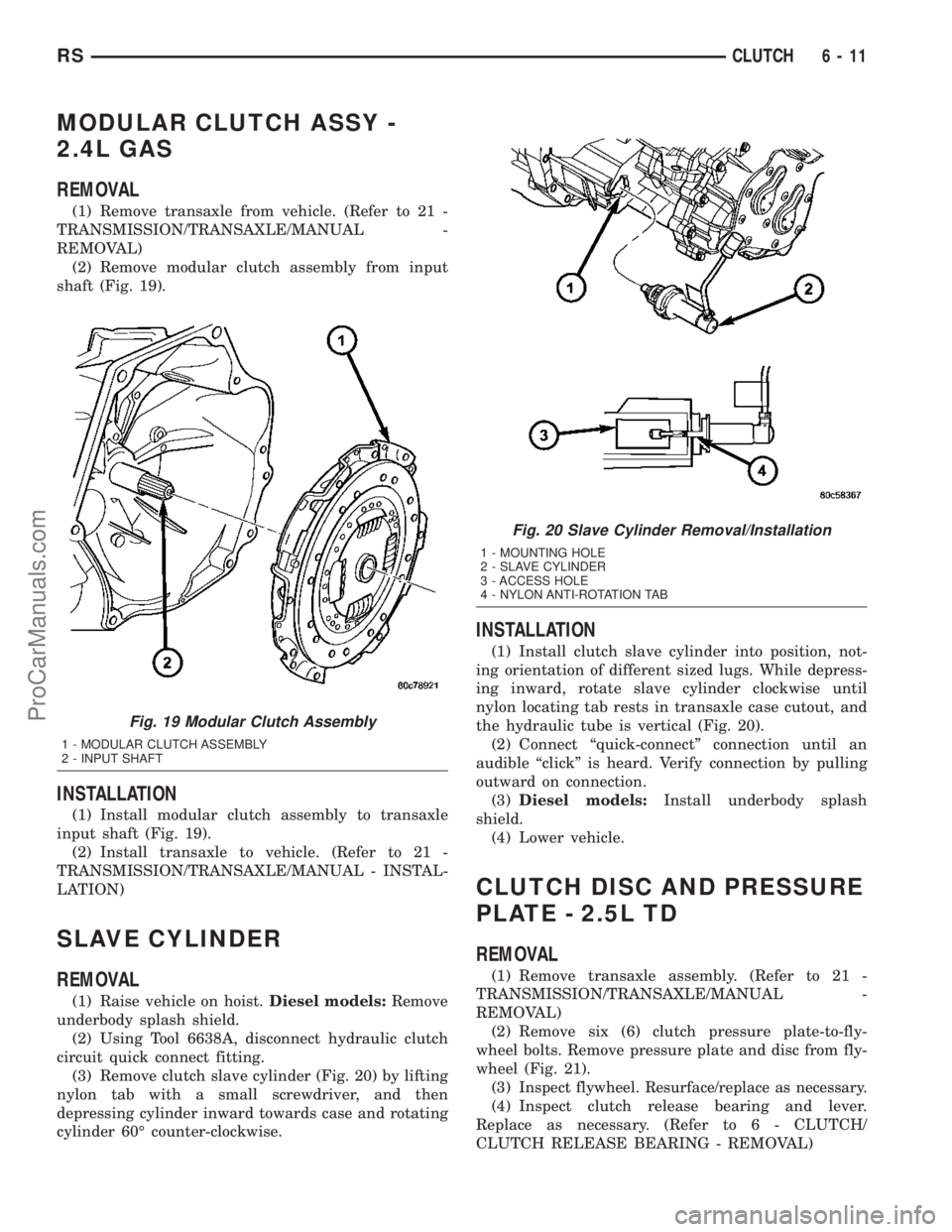

MODULAR CLUTCH ASSY -

2.4L GAS

REMOVAL

(1) Remove transaxle from vehicle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove modular clutch assembly from input

shaft (Fig. 19).

INSTALLATION

(1) Install modular clutch assembly to transaxle

input shaft (Fig. 19).

(2) Install transaxle to vehicle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

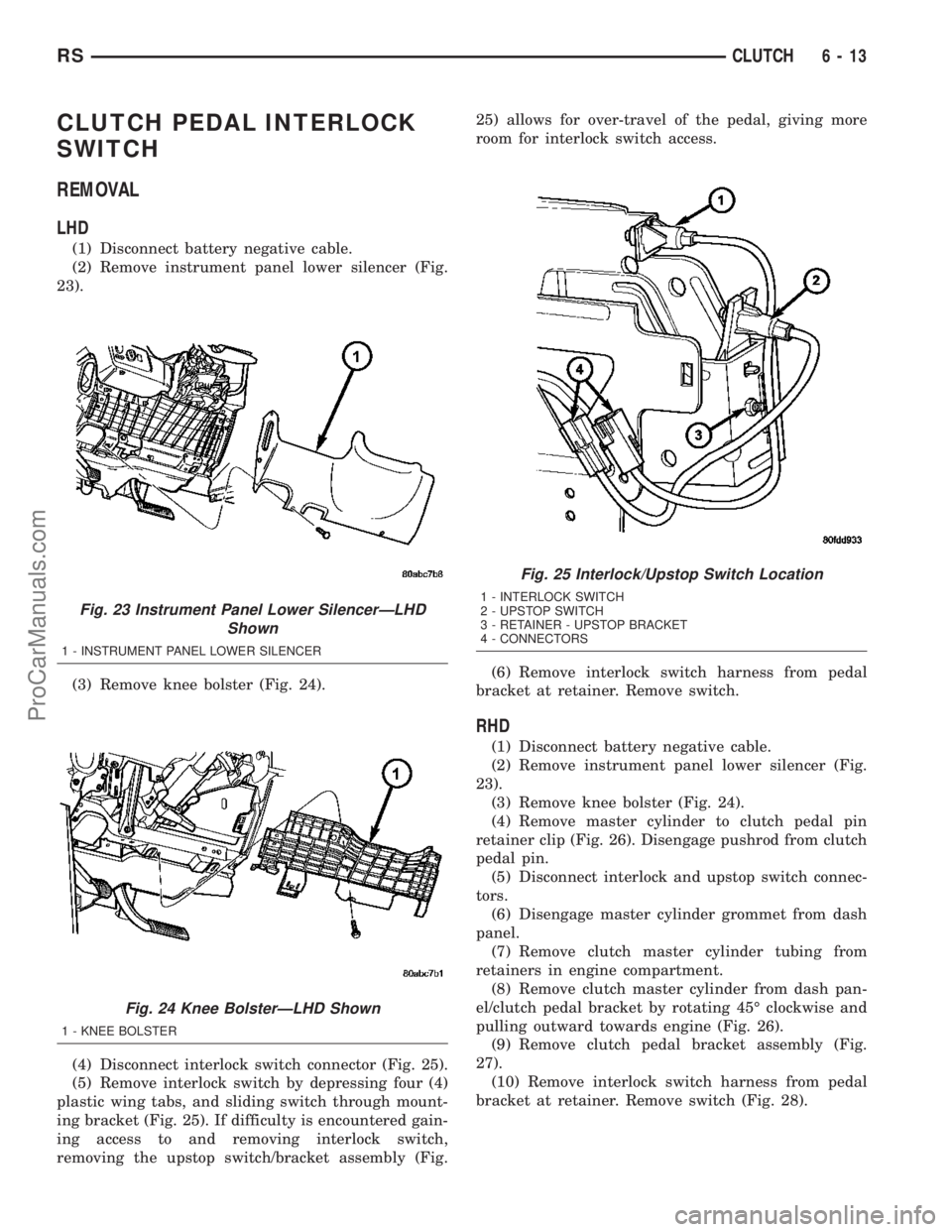

SLAVE CYLINDER

REMOVAL

(1) Raise vehicle on hoist.Diesel models:Remove

underbody splash shield.

(2) Using Tool 6638A, disconnect hydraulic clutch

circuit quick connect fitting.

(3) Remove clutch slave cylinder (Fig. 20) by lifting

nylon tab with a small screwdriver, and then

depressing cylinder inward towards case and rotating

cylinder 60É counter-clockwise.

INSTALLATION

(1) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs. While depress-

ing inward, rotate slave cylinder clockwise until

nylon locating tab rests in transaxle case cutout, and

the hydraulic tube is vertical (Fig. 20).

(2) Connect ªquick-connectº connection until an

audible ªclickº is heard. Verify connection by pulling

outward on connection.

(3)Diesel models:Install underbody splash

shield.

(4) Lower vehicle.

CLUTCH DISC AND PRESSURE

PLATE - 2.5L TD

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove six (6) clutch pressure plate-to-fly-

wheel bolts. Remove pressure plate and disc from fly-

wheel (Fig. 21).

(3)

Inspect flywheel. Resurface/replace as necessary.

(4) Inspect clutch release bearing and lever.

Replace as necessary. (Refer to 6 - CLUTCH/

CLUTCH RELEASE BEARING - REMOVAL)

Fig. 19 Modular Clutch Assembly

1 - MODULAR CLUTCH ASSEMBLY

2 - INPUT SHAFT

Fig. 20 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

RSCLUTCH6-11

ProCarManuals.com

Page 256 of 2177

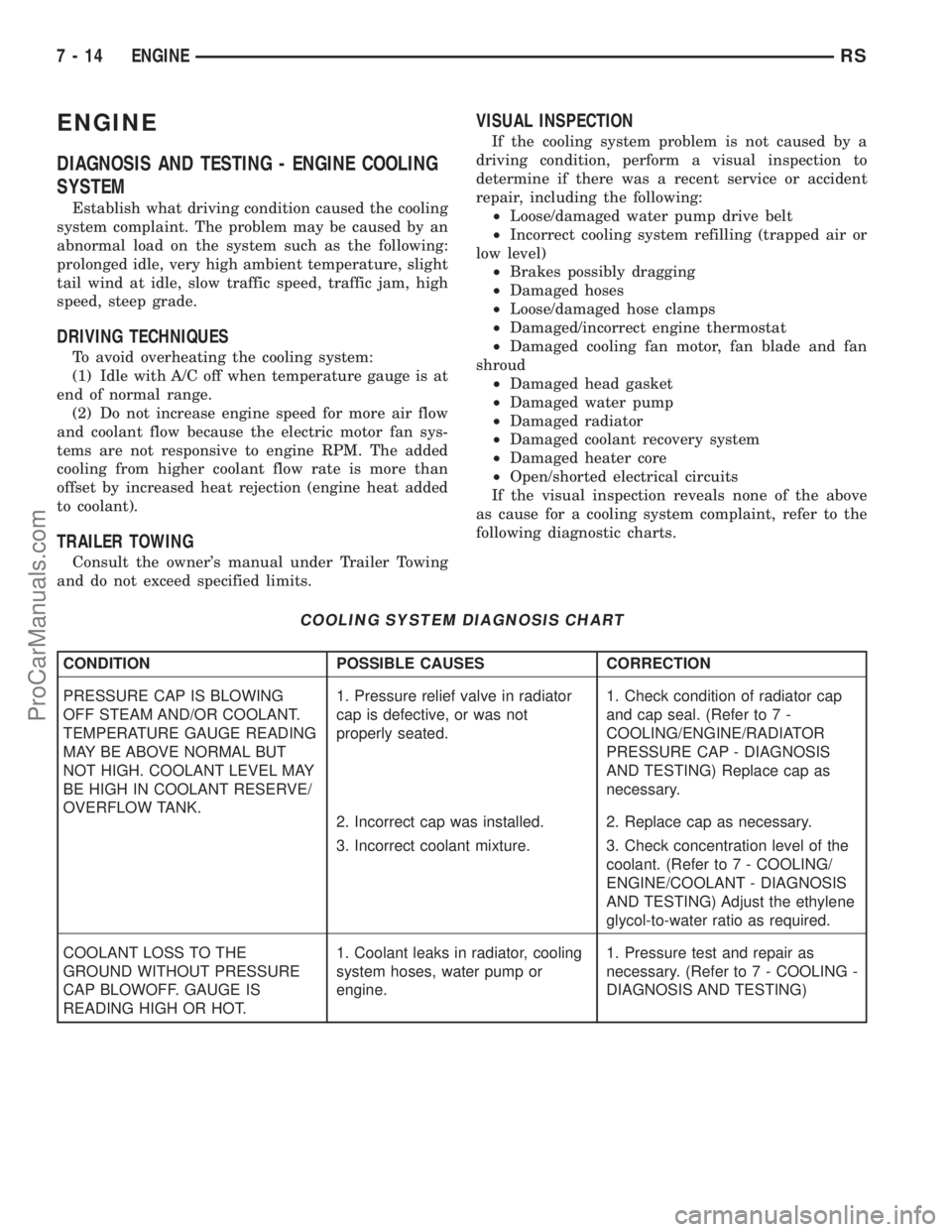

CLUTCH PEDAL INTERLOCK

SWITCH

REMOVAL

LHD

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower silencer (Fig.

23).

(3) Remove knee bolster (Fig. 24).

(4) Disconnect interlock switch connector (Fig. 25).

(5) Remove interlock switch by depressing four (4)

plastic wing tabs, and sliding switch through mount-

ing bracket (Fig. 25). If difficulty is encountered gain-

ing access to and removing interlock switch,

removing the upstop switch/bracket assembly (Fig.25) allows for over-travel of the pedal, giving more

room for interlock switch access.

(6) Remove interlock switch harness from pedal

bracket at retainer. Remove switch.

RHD

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower silencer (Fig.

23).

(3) Remove knee bolster (Fig. 24).

(4) Remove master cylinder to clutch pedal pin

retainer clip (Fig. 26). Disengage pushrod from clutch

pedal pin.

(5) Disconnect interlock and upstop switch connec-

tors.

(6) Disengage master cylinder grommet from dash

panel.

(7) Remove clutch master cylinder tubing from

retainers in engine compartment.

(8) Remove clutch master cylinder from dash pan-

el/clutch pedal bracket by rotating 45É clockwise and

pulling outward towards engine (Fig. 26).

(9) Remove clutch pedal bracket assembly (Fig.

27).

(10) Remove interlock switch harness from pedal

bracket at retainer. Remove switch (Fig. 28).

Fig. 23 Instrument Panel Lower SilencerÐLHD

Shown

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 24 Knee BolsterÐLHD Shown

1 - KNEE BOLSTER

Fig. 25 Interlock/Upstop Switch Location

1 - INTERLOCK SWITCH

2 - UPSTOP SWITCH

3 - RETAINER - UPSTOP BRACKET

4 - CONNECTORS

RSCLUTCH6-13

ProCarManuals.com

Page 273 of 2177

ENGINE

DIAGNOSIS AND TESTING - ENGINE COOLING

SYSTEM

Establish what driving condition caused the cooling

system complaint. The problem may be caused by an

abnormal load on the system such as the following:

prolonged idle, very high ambient temperature, slight

tail wind at idle, slow traffic speed, traffic jam, high

speed, steep grade.

DRIVING TECHNIQUES

To avoid overheating the cooling system:

(1) Idle with A/C off when temperature gauge is at

end of normal range.

(2) Do not increase engine speed for more air flow

and coolant flow because the electric motor fan sys-

tems are not responsive to engine RPM. The added

cooling from higher coolant flow rate is more than

offset by increased heat rejection (engine heat added

to coolant).

TRAILER TOWING

Consult the owner's manual under Trailer Towing

and do not exceed specified limits.

VISUAL INSPECTION

If the cooling system problem is not caused by a

driving condition, perform a visual inspection to

determine if there was a recent service or accident

repair, including the following:

²Loose/damaged water pump drive belt

²Incorrect cooling system refilling (trapped air or

low level)

²Brakes possibly dragging

²Damaged hoses

²Loose/damaged hose clamps

²Damaged/incorrect engine thermostat

²Damaged cooling fan motor, fan blade and fan

shroud

²Damaged head gasket

²Damaged water pump

²Damaged radiator

²Damaged coolant recovery system

²Damaged heater core

²Open/shorted electrical circuits

If the visual inspection reveals none of the above

as cause for a cooling system complaint, refer to the

following diagnostic charts.

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT.

TEMPERATURE GAUGE READING

MAY BE ABOVE NORMAL BUT

NOT HIGH. COOLANT LEVEL MAY

BE HIGH IN COOLANT RESERVE/

OVERFLOW TANK.1. Pressure relief valve in radiator

cap is defective, or was not

properly seated.1. Check condition of radiator cap

and cap seal. (Refer to 7 -

COOLING/ENGINE/RADIATOR

PRESSURE CAP - DIAGNOSIS

AND TESTING) Replace cap as

necessary.

2. Incorrect cap was installed. 2. Replace cap as necessary.

3. Incorrect coolant mixture. 3. Check concentration level of the

coolant. (Refer to 7 - COOLING/

ENGINE/COOLANT - DIAGNOSIS

AND TESTING) Adjust the ethylene

glycol-to-water ratio as required.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING)

7 - 14 ENGINERS

ProCarManuals.com

Page 287 of 2177

WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE COUNTERCLOCK-

WISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

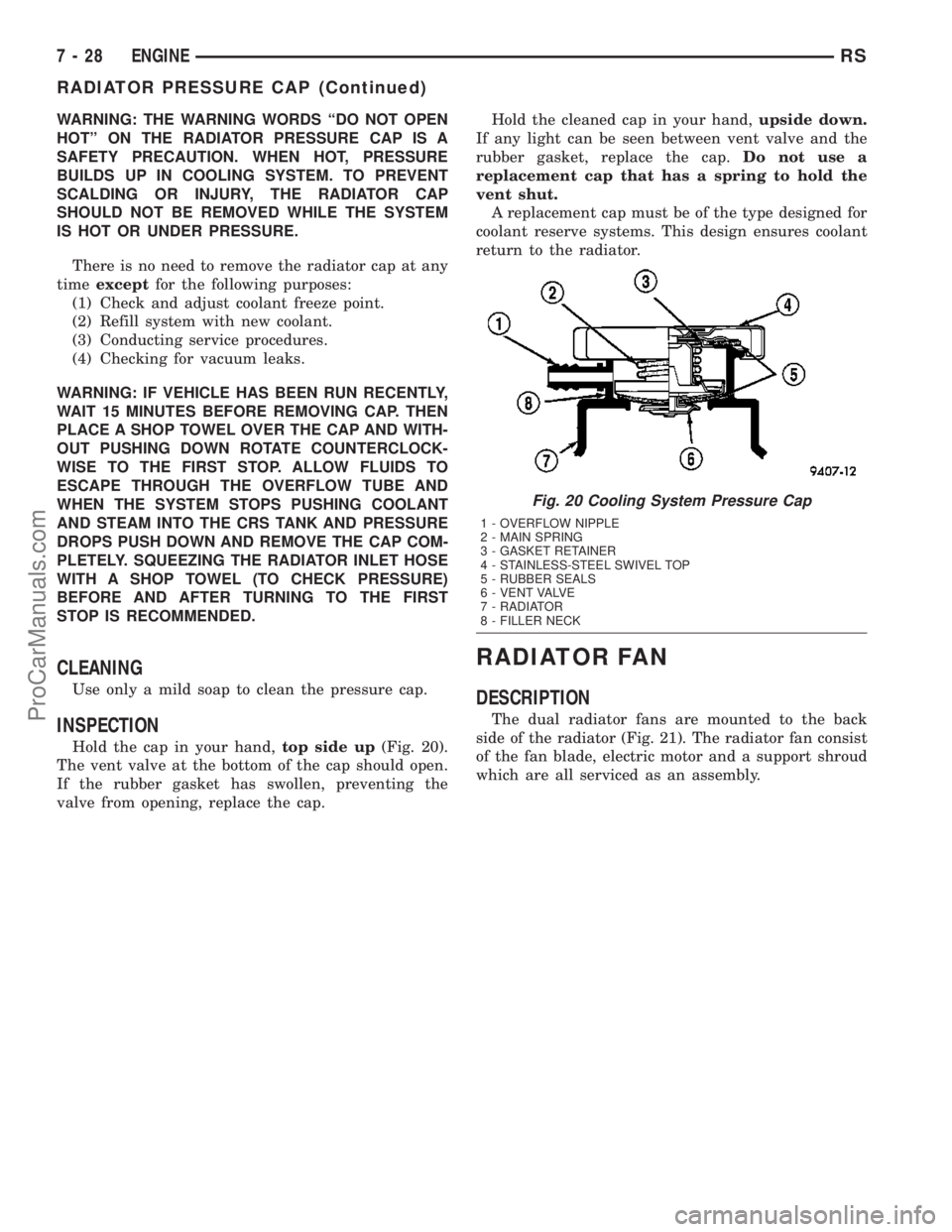

INSPECTION

Hold the cap in your hand,top side up(Fig. 20).

The vent valve at the bottom of the cap should open.

If the rubber gasket has swollen, preventing the

valve from opening, replace the cap.Hold the cleaned cap in your hand,upside down.

If any light can be seen between vent valve and the

rubber gasket, replace the cap.Do not use a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures coolant

return to the radiator.

RADIATOR FAN

DESCRIPTION

The dual radiator fans are mounted to the back

side of the radiator (Fig. 21). The radiator fan consist

of the fan blade, electric motor and a support shroud

which are all serviced as an assembly.

Fig. 20 Cooling System Pressure Cap

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

7 - 28 ENGINERS

RADIATOR PRESSURE CAP (Continued)

ProCarManuals.com

Page 301 of 2177

CONDITION POSSIBLE CAUSE CORRECTION

HEADPHONES

WILL NOT HOLD

A CHANNEL OR

HAVE STATIC1. WEAK BATTERIES IN

THE HEADPHONES.1. REPLACE BATTERIES.

2. CLOSENESS TO

RADIO TRANSMITTER

SUCH AS A RADIO

TOWER, AIRPORT

TRANSMITTER OR

SOME MOBILE

RADIOS.2. MOVE TO AN AREA AWAY FREE FROM THESE

CONDITIONS.

REMOTE

CONTROL

INOPERATIVE1. WEAK BATTERIES IN

THE REMOTE

CONTROL.1. REPLACE BATTERIES.

2. OPERATION

CONSTRAINT OF

SYSTEM2. MAKE SURE THAT REAR AUDIO IS IN A DIFFERENT MODE

THAN FRONT SPEAKERS. REMOTE CONTROL WILL NOT

WORK WHEN BOTH ARE IN THE SAME MODE.

ANTENNA BODY AND CABLE

DESCRIPTION

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front fender

of the vehicle. The antenna mast is connected to the

center wire of the coaxial antenna cable, and is not

grounded to any part of the vehicle.

OPERATION

To minimize static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

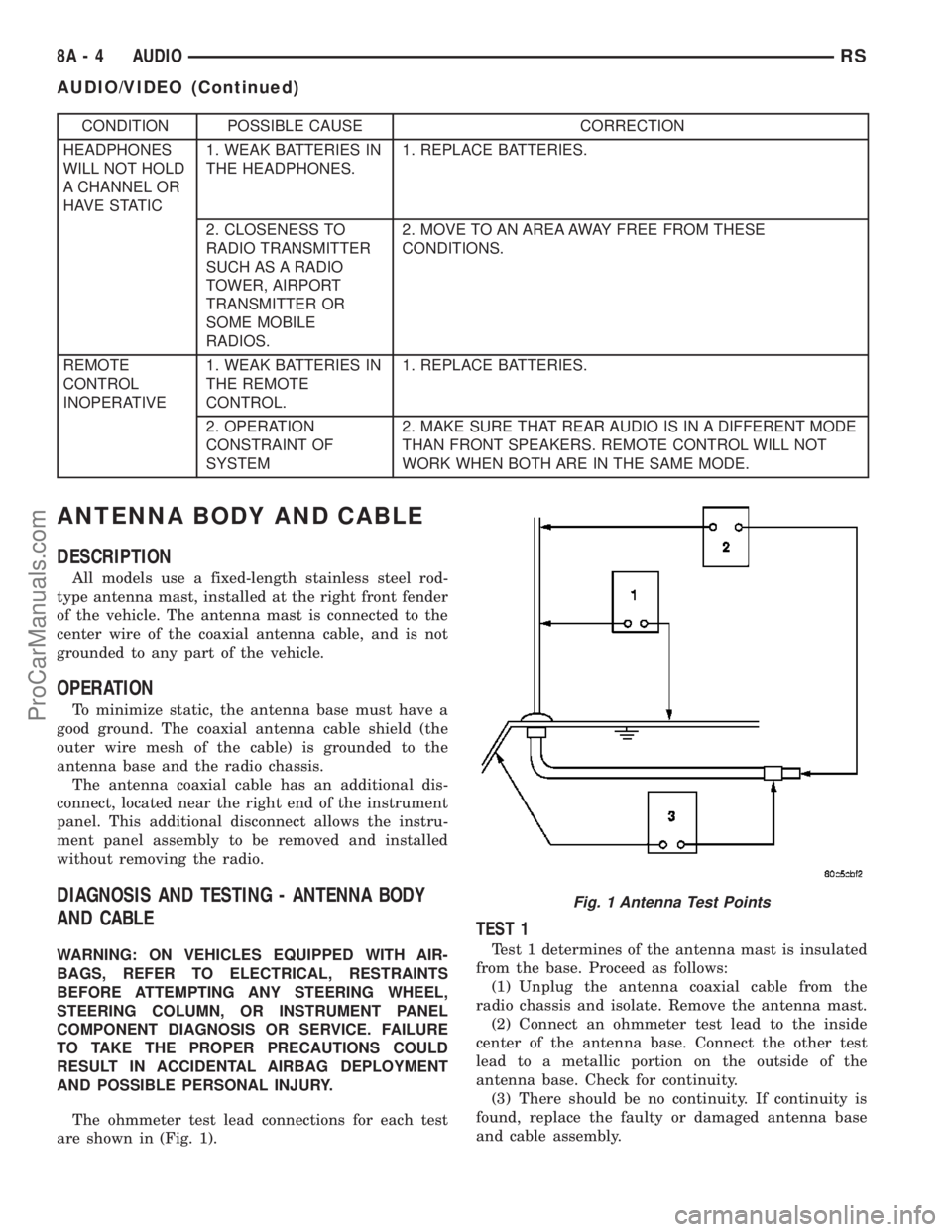

The ohmmeter test lead connections for each test

are shown in (Fig. 1).

TEST 1

Test 1 determines of the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable from the

radio chassis and isolate. Remove the antenna mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to a metallic portion on the outside of the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

Fig. 1 Antenna Test Points

8A - 4 AUDIORS

AUDIO/VIDEO (Continued)

ProCarManuals.com

Page 325 of 2177

INSTALLATION

(1) Connect the module wire harness connectors.

(2) Snap the module on the seat cushion pan.

(3) Install the appropriate front seat in the vehicle

(Refer to 23 - BODY/SEATS/SEAT - INSTALLA-

TION).

(4) Connect and isolate the negative battery cable.

MEMORY SEAT/MIRROR

MODULE

DESCRIPTION

Vehicles equipped with the memory seat/mirror

option, utilize a memory module located under the

drivers front seat. This module is basically wired in-

line between the power seat switch and the power

seat track/adjuster motors, or in-line between the

power mirror switch and the power side view mir-

ror(s) motor(s). The MSMM contains a central pro-

cessing unit that communicates with other modules

on the Programmable Communications Interface

(PCI) data bus network.

The Memory Seat/Mirror Module (MSMM) receives

hard wired inputs from the driver power seat switch

and the potentiometers on each of the driver side

power seat track motors, or from the power mirror

switch and the potentiometers on the side view mir-

ror. The MSMM receives messages over the PCI data

bus from the Body Control Module (BCM) (memory

switch status), the Powertrain Control Module (PCM)

(vehicle speed status). The MSMM will prevent the

seat memory recall function from being initiated if

the driver side seat belt is buckled, if the transmis-

sion gear selector lever is not in the Park or Neutral

positions, or if the vehicle is moving.

For diagnosis of the MSMM or the PCI data bus, a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual are recommended. The MSMM cannot

be repaired and, if faulty or damaged, it must be

replaced. Refer toMemory Systemin the Power

Seat or Power Mirror section of this manual for more

information on the memory system option.

OPERATION

When memory system operation is requested

(depressing of the memory switch), a resistor multi-

plexed signal is sent from the memory switch to the

body control module (BCM). The body control module

will then send the appropriate signals out to the

memory/mirror seat module, the memory/mirror seat

module then applies the voltage supply to the power

seat track or side-view mirror if the proper require-

ments are met. The vehicle speed must equal zero

and the transmission must be in park or neutral in

order for the memory system to function.

DIAGNOSIS AND TESTING - MEMORY

SEAT/MIRROR MODULE

Visually inspect the related wiring harness connec-

tors. Look for broken, bent, pushed out, or corroded

terminals. If any of the above conditions are present,

repair as necessary. If not, use a DRB IIItscan tool

and the proper Diagnostic Procedures Manual to test

the memory/mirror seat module. For complete circuit

diagrams, refer toWiring Diagrams.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front bucket seat

retaining nuts from under the vehicle (Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(3) Lift the drivers seat up and out of the mount-

ing holes in the floor pan and lay the seat rearward

to access the module located under the seat. It is not

necessary to disconnect the seat electrical, just use

care not to damage the wiring by over-extending.

(4) Disconnect the memory/mirror seat module

electrical connectors. Depress the retaining tab and

pull straight apart.

(5) Remove the module retaining bolts and remove

the module from the bracket.

INSTALLATION

(1) Position and install the module retaining bolts.

(2) Connect the memory/mirror seat module elec-

trical connectors.

(3) Position the drivers seat in the mounting holes

in the floor pan.

(4) Install the driver side front bucket seat retain-

ing nuts from under the vehicle (Refer to 23 - BODY/

SEATS/SEAT - INSTALLATION).

(5) Connect the battery negative cable.

POWER LIFTGATE CONTROL

MODULE

DESCRIPTION

Vehicles equipped with a power liftgate (PLG) uti-

lize a PLG control module. This module is located on

the vehicles left side D-pillar just below the motor

assembly (Fig. 8) and contains a microprocessor,

which is used to communicate to the vehicles body

control module. The PLG control module receives and

monitors logic inputs from all the PLG system

switches except for the outside handle switch. This

module also contains the software technology to

detect liftgate obstructions and stop and/or reverse

the door accordingly.

8E - 10 ELECTRONIC CONTROL MODULESRS

HEATED SEAT MODULE (Continued)

ProCarManuals.com

Page 334 of 2177

(6) Rotate the SKIM upwards and then to the side

away from the steering column to slide the SKIM

antenna ring from around the ignition switch lock

cylinder housing.

(7) Remove the SKIM from the vehicle.

INSTALLATION

(1) Slip the SKIM antenna ring around the igni-

tion switch lock cylinder housing. Rotate the SKIM

downwards and then towards the steering column.

(2) Install the one screws securing the SKIM to

the steering column.

(3) Engage the steering column wire harness from

the Sentry Key Immobilizer Module (SKIM).

(4) Install the steering column upper and lower

shrouds. Refer to Steering, Column, Column Shroud,

Installation.

(5) Install the Lower Instrument Panel Cover.

Refer to Body, Instrument Panel, Lower Instrument

Panel Cover, Installation.

(6) Connect the battery negative cable.

SLIDING DOOR CONTROL

MODULE

DESCRIPTION

Vehicles equipped with a power sliding door utilize

a sliding door control module. The sliding door con-

trol module is located behind the sliding door trim

panel in the center of the door, just above the sliding

door motor (Fig. 15). This module controls the opera-

tion of the door through the Programmable Commu-

nication Interface (PCI) J1850 data bus circuit and

the Body Control Module. The sliding door control

module contains software technology which enables it

to detect resistance to door travel and to reverse door

travel in order to avoid damage to the door or to

avoid possible personal injury if the obstruction is a

person. This feature functions in both the opening

and closing cycles. If the power sliding door system

develops any problems the control module will store

and recall Diagnostic Trouble Codes (DTC). The use

of a diagnostic scan tool, such as the DRB IIItis

required to read and troubleshoot these trouble

codes. The sliding door control module can be

reflashed if necessary. Refer to the latest Technical

Service Bulletin (TSB) Information for any updates.

The power door control module is a replaceable

component and cannot be repaired, if found to be

faulty it must be replaced. Consult your MoparŸ

parts catalog for a specific part number.

OPERATION

The power sliding door control module serves as

the main computer for the power sliding side doorsystem. All power door functions are processed

through the power door control module and/or the

vehicles body control module (BCM). At the start of a

power open command, a signal is sent to the BCM

and then to the power door control module via the

J1850 data bus circuit. This signal, generated by any

of the power door command switches, tells the power

door control module to activate a power latch release,

engage the clutch assembly and drive the door into

the full open position. If an obstacle is felt during

this power open cycle, the module will reverse direc-

tion and close the door. This process is also enabled

during a power close cycle. This process will repeat

three times, and if a fourth obstacle is detected, the

door will go into full manual mode. Once the full

open position is obtained, a hold open latch assembly

mounted full open switch tells the control module

that the door has reached the full open position. If

the power sliding door system develops any problems

the control module will store and recall Diagnostic

Trouble Codes (DTC). The use of a diagnostic scan

tool, such as the DRB IIItis required to read and

troubleshoot these trouble codes.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

Fig. 15 Power Side Door Components

1 - SLIDING DOOR CONTROL MODULE

2 - MODULE RETAINING SCREW

3 - MODULE ELECTRICAL CONNECTORS

4 - DOOR MOTOR ASSEMBLY

5 - FLEX DRIVE ASSEMBLY

6 - DOOR MOTOR RETAINING FASTENERS

7 - DOOR MOTOR ELECTRICAL CONNECTOR

RSELECTRONIC CONTROL MODULES8E-19

SENTRY KEY IMMOBILIZER MODULE (Continued)

ProCarManuals.com

Page 355 of 2177

NOTE: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit.

(3) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

(1) Install the battery hold down bracket in the

battery tray and support unit.

(2) Install the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. Torque to 20 N´m (180 in. lbs.).

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

Refer toWiring Diagramsin the index of this ser-

vice manual for the location of the proper battery

cable wire gauge information.

A clamping type female battery terminal made of

stamped metal is attached to one end of the battery

cable wire. A square headed pinch-bolt and hex nut

are installed at the open end of the female battery

terminal clamp. Large eyelet type terminals are

crimped onto the opposite end of the battery cable

wire and then solder-dipped. The battery positive

cable wires have a red insulating jacket to provide

visual identification and feature a larger female bat-

tery terminal clamp to allow connection to the larger

battery positive terminal post. The battery negative

cable wires have a black insulating jacket and a

smaller female battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsin theindex of this service manual for the location of more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is

attached to the ends of two wires. One wire has an

eyelet terminal that connects the battery positive

cable to the B(+) terminal stud of the Integrated

Power Module (IPM), and the other wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the engine starter motor

solenoid. The battery negative cable terminal clamp

is also attached to the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the left front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLE

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

8F - 16 BATTERY SYSTEMRS

BATTERY HOLDDOWN (Continued)

ProCarManuals.com

Page 375 of 2177

(7) Connect battery negative cable.

(8) Verify starter operation.

INSTALLATION - 3.3/3.8L

(1) Place starter spacer in position on transaxle

bellhousing, flange toward flywheel.

(2) Place starter in position on bellhousing.(3) Install bolts and ground wire (Fig. 4) to hold

starter to transaxle bellhousing.

(4) Connect solenoid connector into starter.

(5) Install nut to hold B+ terminal to starter sole-

noid.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

8F - 36 STARTINGRS

STARTER MOTOR (Continued)

ProCarManuals.com