wheel CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 330 of 2339

(9) Remove accessory drive belt, refer to the Cool-

ing System section for proper procedures.

(10) Remove the generator.

REMOVAL - 2.5L

(1) Disconnect the negative battery cable (Fig. 1).

(2) Remove the engine cover (Fig. 2).(3) Raise vehicle and support.

(4) Turn wheels to the right. Remove the right

front splash shield (Fig. 3).

(5) Remove the generator drive belt (Fig. 4).

Fig. 1 BATTERY CONNECTION

Fig. 2 ENGINE COVER

Fig. 3 SPLASH SHIELD

Fig. 4 GENERATOR BELT

RSCHARGING8F-25

GENERATOR (Continued)

Page 336 of 2339

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................31

OPERATION...........................31

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST.......................31

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST........................33

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST....................35

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST...............................36SPECIFICATIONS

Torques.............................36

STARTER ...........................37

STARTER MOTOR

REMOVAL

REMOVAL - 2.4L......................37

REMOVAL - 3.3/3.8L...................38

REMOVAL - 2.5L......................38

INSTALLATION

INSTALLATION - 2.4L..................39

INSTALLATION - 3.3/3.8L................39

INSTALLATION - 2.5L..................39

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

RSSTARTING8F-31

Page 337 of 2339

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor or Park/Neu-

tral Switch- Visually inspect the transmission

range sensor for indications of physical damage and

loose or corroded wire harness connections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

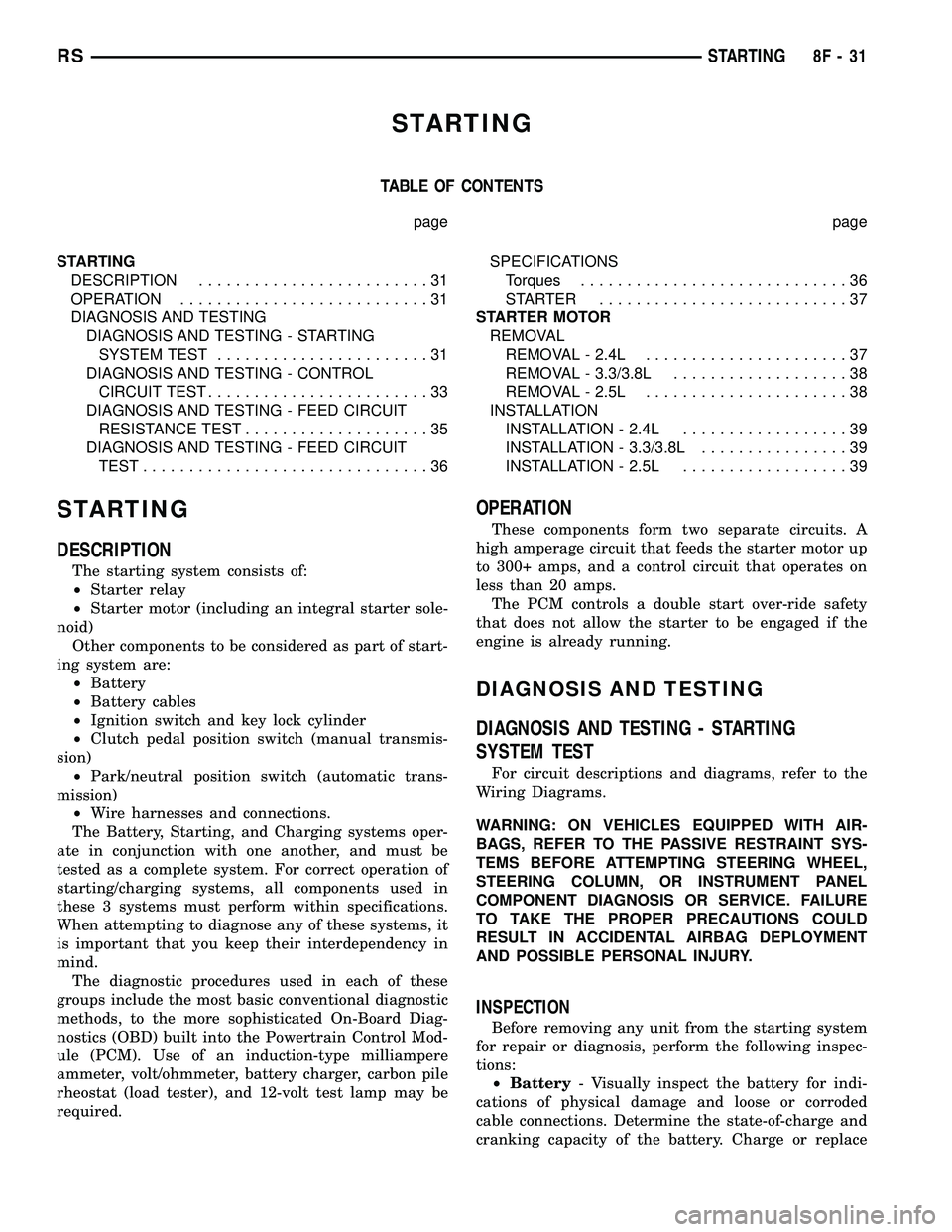

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH INTERLOCK

SWITCH (MAN TRANS)

FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE.10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

8F - 32 STARTINGRS

STARTING (Continued)

Page 338 of 2339

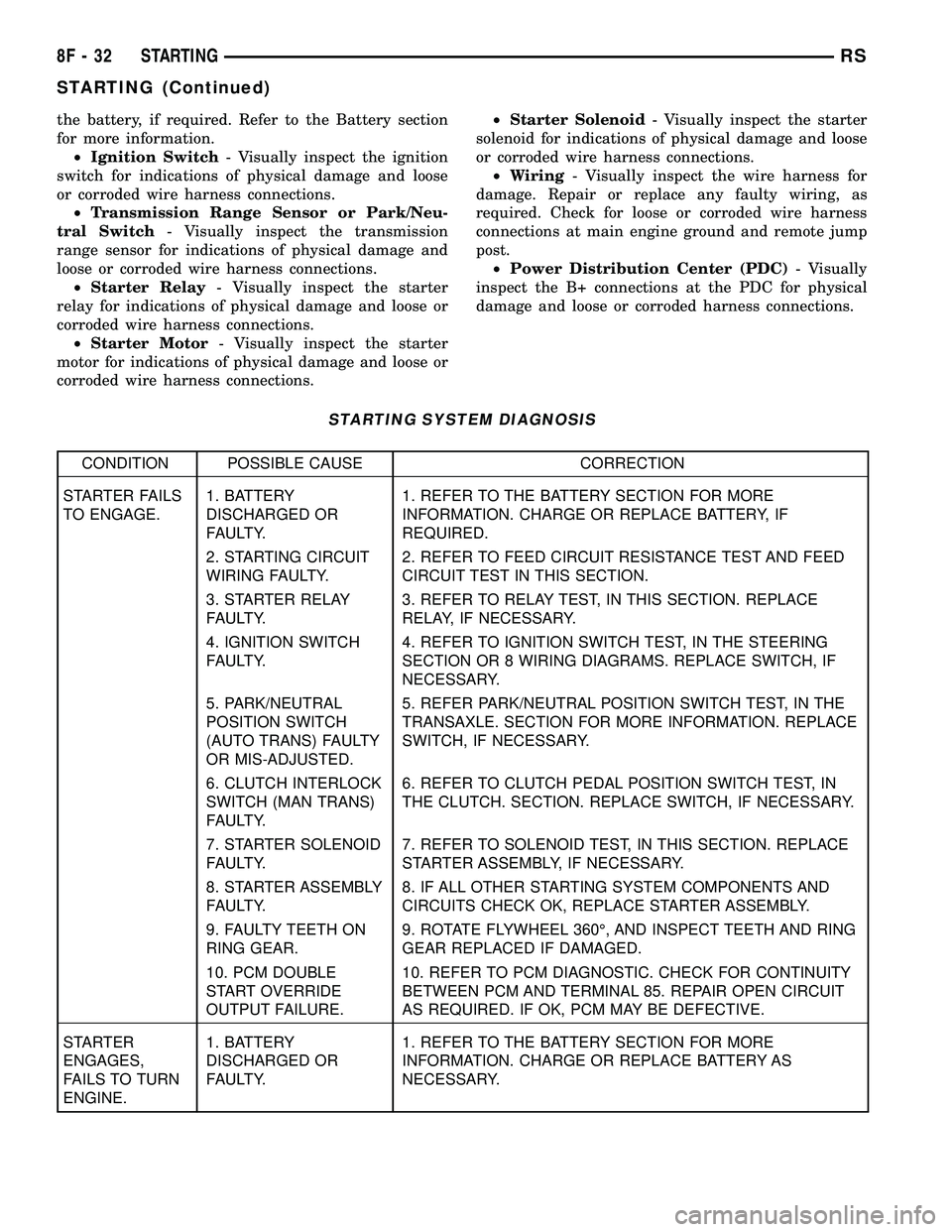

CONDITION POSSIBLE CAUSE CORRECTION

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO THE FEED CIRCUIT RESISTANCE TEST AND

THE FEED CIRCUIT TEST IN THIS SECTION. REPAIR AS

NECESSARY.

3. STARTER ASSEMBLY

FAULTY.3. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

4. ENGINE SEIZED. 4. REFER TO THE ENGINE SECTION, FOR DIAGNOSTIC AND

SERVICE PROCEDURES.

5. LOOSE

CONNECTION AT

BATTERY, PDC,

STARTER, OR ENGINE

GROUND.5. INSPECT FOR LOOSE CONNECTIONS.

6. FAULTY TEETH ON

RING GEAR.6. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

STARTER

ENGAGES,

SPINS OUT

BEFORE

ENGINE

STARTS.1. BROKEN TEETH ON

STARTER RING GEAR.1. REMOVE STARTER. INSPECT RING GEAR AND REPLACE

IF NECESSARY.

2. STARTER ASSEMBLY

FAULTY.2. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

STARTER DOES

NOT

DISENGAGE.1. STARTER

IMPROPERLY

INSTALLED.1. INSTALL STARTER. TIGHTEN STARTER MOUNTING

HARDWARE TO CORRECT TORQUE SPECIFICATIONS.

2. STARTER RELAY

FAULTY.2. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

3. IGNITION SWITCH

FAULTY.3. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION. REPLACE SWITCH, IF NECESSARY.

4. STARTER ASSEMBLY

FAULTY.4. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

5. FAULTY TEETH ON

RING GEAR.5. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST

The starter control circuit has:

²Starter motor with integral solenoid

²Starter relay

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Powertrain Control Module (PCM)

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for the proper relay location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED. THIS MAY RESULT IN

PERSONAL INJURY OR DEATH.

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

RSSTARTING8F-33

STARTING (Continued)

Page 343 of 2339

(8) Remove starter.

REMOVAL - 3.3/3.8L

(1) Release hood latch and open hood.

(2) Disconnect and isolate the battery negative

cable.

(3) Hoist and support vehicle on safety stands.

(4) Remove nut holding B+ terminal to starter

solenoid (Fig. 5).

(5) Disconnect solenoid connector from starter.

(6) Remove bolts holding starter to transaxle bell-

housing (Fig. 6).(7) Remove starter from bellhousing (Fig. 7).

(8) Separate starter spacer from transaxle bell-

housing.

REMOVAL - 2.5L

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) Remove the lower engine splash shield.

(4) Remove the electrical connectors from the

starter (Fig. 8).Fig. 5 Starter

1 - SOLENOID CONNECTOR

2 - B+ CONNECTOR

Fig. 6 Starter Bolts

1-STARTER

2 - STARTER BOLTS

3 - TRANSAXLE

4 - ENGINE MOUNT

Fig. 7 STARTER 3.3/3.8L

1 - BELL HOUSING PLATE

2 - FLYWHEEL

3 - ENGINE MOUNT

4-STARTER

5 - SPACER

Fig. 8 STARTER LOCATION

8F - 38 STARTINGRS

STARTER MOTOR (Continued)

Page 344 of 2339

(5) Remove the starter mounting bolts (Fig. 9).

(6) Remove the starter.

INSTALLATION

INSTALLATION - 2.4L

(1) Place starter in position on vehicle.

(2) Install the lower bolts to hold starter to trans-

axle bellhousing.(3) Install the upper bolt and ground wire (Fig. 4).

(4) Place solenoid and B+ wires in position on

starter terminals (Fig. 3).

(5) Install nut to hold B+ wire to terminal.

(6) Connect solenoid wire connector onto terminal.

(7) Connect battery negative cable.

(8) Verify starter operation.

INSTALLATION - 3.3/3.8L

(1) Place starter spacer in position on transaxle

bellhousing, flange toward flywheel.

(2) Place starter in position on bellhousing.

(3) Install bolts and ground wire (Fig. 4) to hold

starter to transaxle bellhousing.

(4) Connect solenoid connector into starter.

(5) Install nut to hold B+ terminal to starter sole-

noid.

(6) Lower vehicle.

(7) Connect battery negative cable.

(8) Verify starter operation.

INSTALLATION - 2.5L

(1) Raise vehicle and support.

(2) Install the starter.

(3) Install the starter mounting bolts (Fig. 9).

(4) Install the electrical connectors to the starter

(Fig. 8).

(5) Install the lower engine splash shield.

(6) Connect the negative battery cable.

(7) Lower vehicle.

Fig. 9 STARTER MOUNTING BOLTS

1 - Starter

2 - Mounting Bolts

RSSTARTING8F-39

STARTER MOTOR (Continued)

Page 354 of 2339

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the low

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the high position LED indi-

cator illuminates. When the switch rocker is moved

to its neutral position (middle), Off is selected and

both LED indicators are extinguished.

Each switch provides separate resistor, hard wire

inputs to its respective Heated Seat Module (HSM) to

indicate the selected switch position. The heated seat

module responds to the heated seat switch status

messages by controlling the output to the seat heater

elements of the selected seat. The Low heat position

set point is about 36É C (97É F), and the High heat

position set point is about 41É C (105É F).

DIAGNOSIS AND TESTING

DRIVER HEATED SEAT SWITCH

Refer to the appropriate wiring information for

complete circuit schematic or connector pin-out infor-

mation.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

CHECKING SWITCH SIGNAL AND WIRING AT THE

MODULE

(1) Disconnect and isolate the battery negative

cable.

(2) Access and disconnect the gray 4-way connector

from the heated seat module. Visually inspect wiring

terminals for damage that would prevent positive

connection. If not OK, repair or replace the necessary

components.(3) Connect the battery negative cable. Place the

heated seat switch in the LO position. Using an

Ohmmeter, check the resistance between cavities 2

and 3 of the gray connector noted above. Resistance

should be about 3.5 kilohms (3500 ohms). If not OK,

check resistance directly at switch, as noted below. If

OK, proceed to the next step. If not OK, replace the

faulty switch.

(4) Place the heated seat switch in the HI position.

Using an ohmmeter, check the resistance between

cavities 2 and 3 of the gray connector noted above.

Resistance should be about 1.4 kilohms (1400 ohms).

If not OK, check resistance directly at the switch, as

indicated in the Heated Seat Switch Test Table. If

OK, proceed. If not OK replace the faulty switch.

(5) With the system ON in the HI position, check

for battery voltage and ground at cavities 4 and 1. If

OK, proceed with testing remaining components. If

not OK, repair open or shorted wiring.

CHECKING SWITCH ONLY

(1) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL). Check for continuity between the

ground circuit cavity (#10) of the instrument panel

center bezel switch electrical connector and a good

ground. There should be continuity. If OK, go to Step

2. If not OK, repair the open ground circuit to ground

as required.

(2) Connect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel center bezel

switch electrical connector (#4). If OK, turn the igni-

tion switch to the Off position, and go to Step 3. If

not OK, repair the open fused ignition switch output

(run) circuit as required.

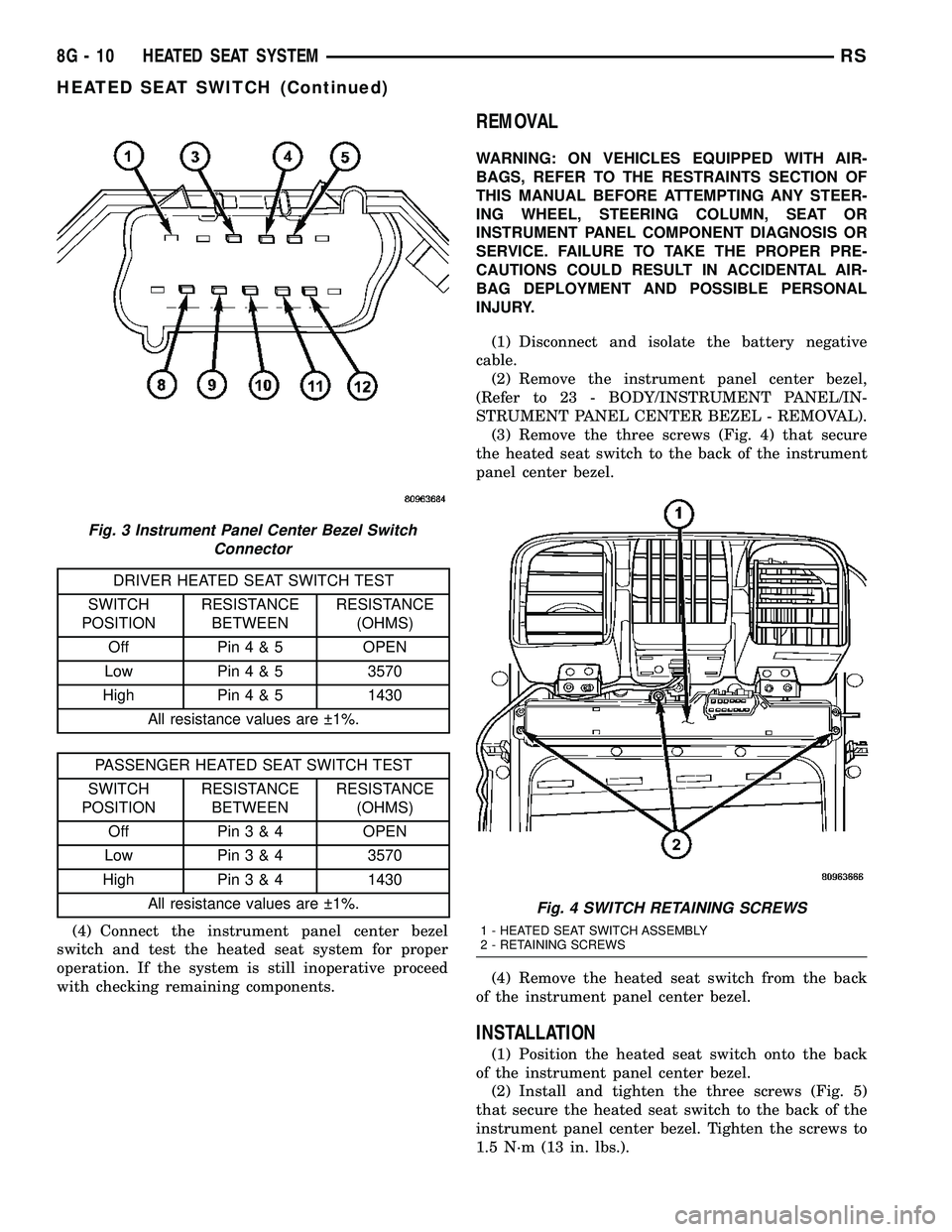

(3) Test the heated seat switch as shown in the

Heated Seat Switch Test chart and the connector pin-

out below (Fig. 3). If OK, go to Step 4. If not OK,

replace the instrument panel center bezel switch

assembly.

RSHEATED SEAT SYSTEM8G-9

HEATED SEAT SWITCH (Continued)

Page 355 of 2339

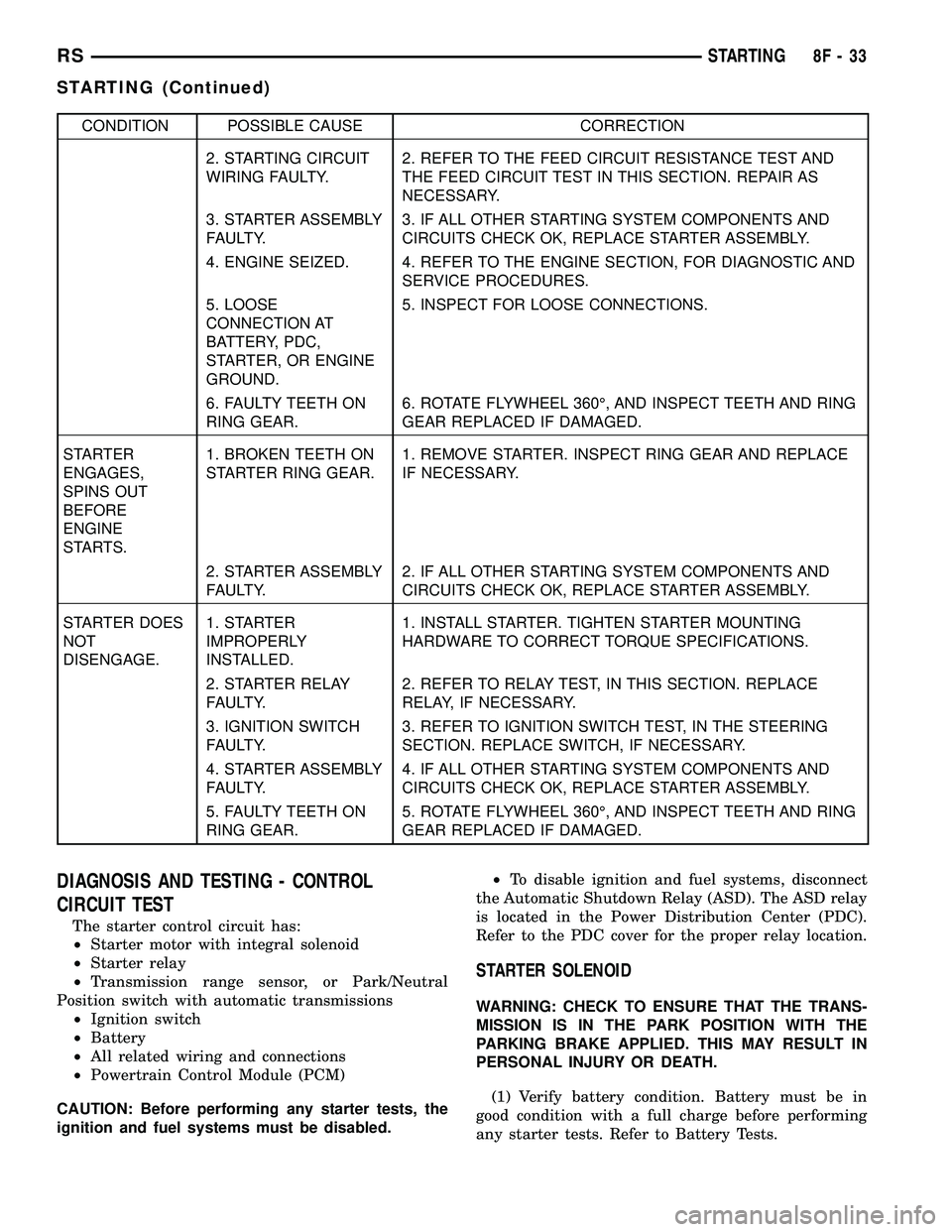

DRIVER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin4&5OPEN

Low Pin4&53570

High Pin4&51430

All resistance values are 1%.

PASSENGER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin3&4OPEN

Low Pin3&43570

High Pin3&41430

All resistance values are 1%.

(4) Connect the instrument panel center bezel

switch and test the heated seat system for proper

operation. If the system is still inoperative proceed

with checking remaining components.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel center bezel,

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL CENTER BEZEL - REMOVAL).

(3) Remove the three screws (Fig. 4) that secure

the heated seat switch to the back of the instrument

panel center bezel.

(4) Remove the heated seat switch from the back

of the instrument panel center bezel.

INSTALLATION

(1) Position the heated seat switch onto the back

of the instrument panel center bezel.

(2) Install and tighten the three screws (Fig. 5)

that secure the heated seat switch to the back of the

instrument panel center bezel. Tighten the screws to

1.5 N´m (13 in. lbs.).

Fig. 3 Instrument Panel Center Bezel Switch

Connector

Fig. 4 SWITCH RETAINING SCREWS

1 - HEATED SEAT SWITCH ASSEMBLY

2 - RETAINING SCREWS

8G - 10 HEATED SEAT SYSTEMRS

HEATED SEAT SWITCH (Continued)

Page 360 of 2339

HORN

TABLE OF CONTENTS

page page

HORN SYSTEM

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

HORN SYSTEM........................1

HORN

DIAGNOSIS AND TESTING

HORN...............................3REMOVAL.............................4

INSTALLATION..........................4

HORN SWITCH

DESCRIPTION..........................4

HORN SYSTEM

DESCRIPTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, REFER TO ELECTRICAL, RESTRAINTS FOR

SAFETY PRECAUTIONS. DISCONNECT THE NEGA-

TIVE CABLE FROM THE BATTERY BEFORE SER-

VICING COMPONENTS INVOLVING THE AIRBAG

SYSTEM. ACCIDENTAL DEPLOYMENT OF AIRBAG

AND PERSONAL INJURY CAN RESULT.

The horn circuit consists of a horn switch, clock-

spring, horn relay, horns and Integrated Power Mod-

ule (IPM). The horn switch is a membrane switch

located in the airbag trim cover. The horns are

located forward of the left front wheel behind the

bumper fascia.

OPERATION

The horn relay plugs into the Integrated Power

Module (IPM) which is located in the engine com-

partment. For circuit information and component

locations, refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, details

of wire harness routing and retention, connector pin-

out information and location views for the various

wire harness connectors, splices and grounds.

The horns will not function if the switch is

ªCLOSEDº for more than 30 seconds. Once the

switch is ªOPENº, a 20±30 second delay will occur

before the horns are functional again.

DIAGNOSIS AND TESTING

HORN SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Refer to Horn System Test below. If the horn does

not sound, check horn fuse located in the Integrated

Power Module (IPM). If the fuse is blown, replace

with the correct fuse. If the horns fail to sound and

the new fuse blows when depressing the horn switch,

a short circuit in the horn or the horn wiring

between the fuse terminal and the horn is responsi-

ble, or a defective horn switch allowed the horn to

burn out is responsible.

If the fuse is OK, test horn relay.

If the relay is OK, test horn.

CAUTION: Continuous sounding of horn may

cause horn failure.

Should the horn sound continuously, unplug the

horn relay from IPM.

Refer to the appropriate wiring information.

RSHORN8H-1

Page 361 of 2339

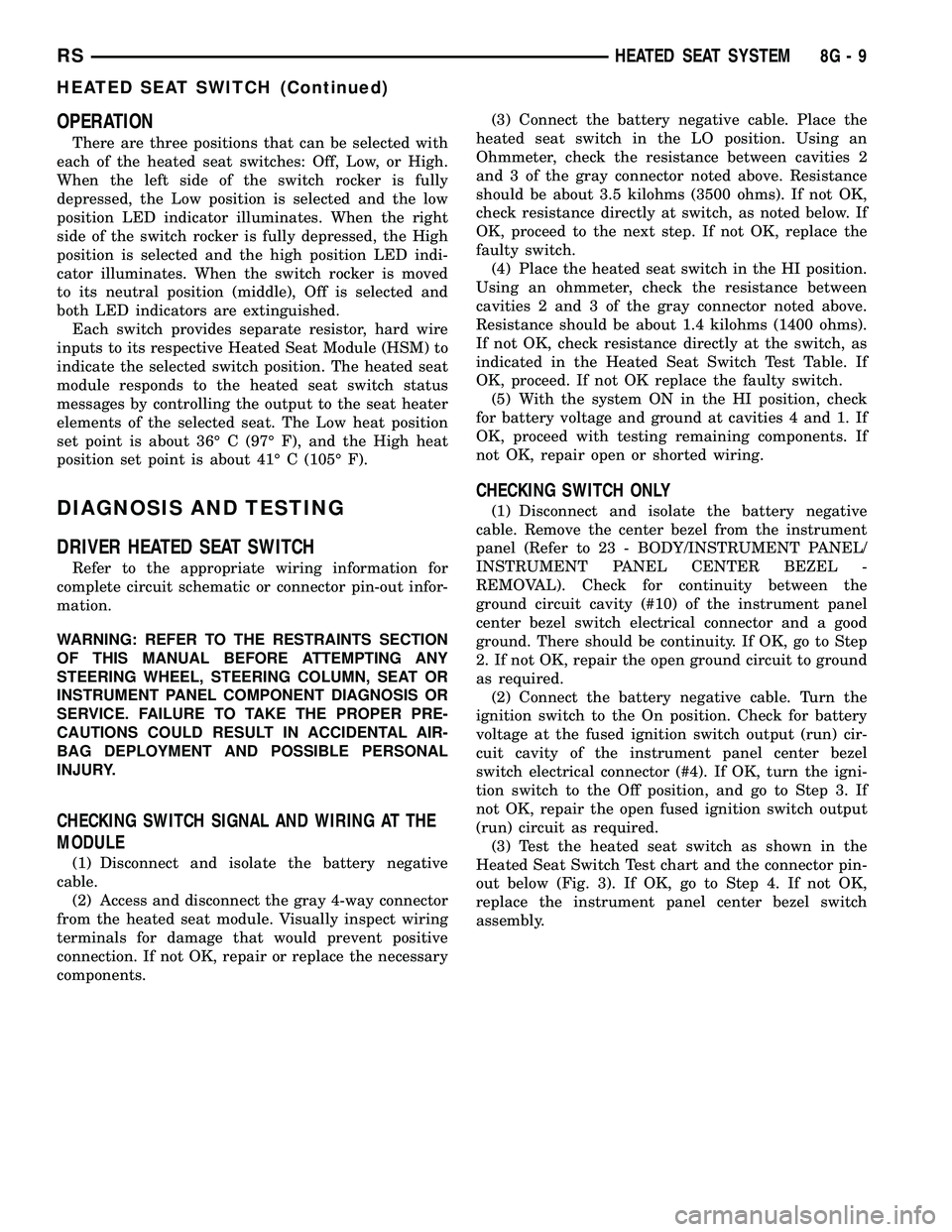

HORN SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

HORN SOUNDS CONTINUOUSLY.

NOTE: IMMEDIATELY UNPLUG HORN

RELAY IN THE IPM.(1) HORN RELAY

INOPERATIVE.(1) REPLACE RELAY.

(2) HORN CONTROL

CIRCUIT TO RELAY

SHORTED TO GROUND.(2) CHECK TERMINAL 85 IN IPM FOR

CONTINUITY TO GROUND. IF

CONTINUITY TO GROUND INDICATES:

(A) STEERING WHEEL HORN SWITCH/

LEAD SHORTED TO GROUND.

(B) WIRING HARNESS SHORTED TO

GROUND. FIND THE SHORT AND

REPAIR AS NECESSARY.

(3) PINCHED HORN SWITCH

WIRE UNDER DRIVER

AIRBAG MODULE.(3) REPLACE DRIVER AIRBAG TRIM

COVER.

(4) HORN SWITCH

INOPERATIVE.(4) REPLACE DRIVER AIRBAG TRIM

COVER.

(5) CLOCKSPRING

INOPERATIVE.(5) REPLACE CLOCKSPRING.

(6) FRONT CONTROL

MODULE INOPERATIVE.(6) REFER TO ELECTRONIC CONTROL

MODULES/FRONT CONTROL MODULE.

HORN SOUND INTERMITTENTLY AS

THE STEERING WHEEL IS TURNED.(1) HORN RELAY CONTROL

CIRCUIT X3 IS SHORTED TO

GROUND INSIDE STEERING

COLUMN OR WHEEL.(1) REMOVE DRIVER AIRBAG AND/OR

WHEEL. CHECK FOR RUBBING OR

LOOSE WIRE/CONNECTOR, REPAIR AS

NECESSARY.

(2) PINCHED HORN SWITCH

WIRE UNDER DRIVER

AIRBAG MODULE.(2) REPLACE DRIVER AIRBAG TRIM

COVER.

(3) HORN SWITCH

INOPERATIVE.(3) REPLACE DRIVER AIRBAG TRIM

COVER.

(4) CLOCKSPRING

INOPERATIVE.(4) REPLACE CLOCKSPRING.

HORN DOES NOT SOUND (1) CHECK FUSE 8 IN

INTELLIGENT POWER

MODULE.(1) REPLACE FUSE IF BLOWN REPAIR

AS NECESSARY.

(2) NO VOLTAGE AT HORN

RELAY TERMINALS 30 & 86,

AND FUSE IS OK.(2) NO VOLTAGE, REPAIR THE CIRCUIT

AS NECESSARY.

(3) OPEN CIRCUIT FROM

TERMINAL 85 OF THE HORN

RELAY TO HORN SWITCH,

X3 CIRCUIT.(3) REPAIR CIRCUIT AS NECESSARY.

(4) HORN INOPERATIVE OR

DAMAGED.(4) CHECK VOLTAGE AT HORN WHEN

HORN SWITCH IS PRESSED. IF NO

VOLTAGE, REPLACE HORN.

(5) HORN SWITCH

INOPERATIVE.(5) REPLACE DRIVER AIRBAG TRIM

COVER.

8H - 2 HORNRS

HORN SYSTEM (Continued)