fuel CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1405 of 2339

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the PCM.

REMOVAL

(1) Disconnect negative cable from battery cable.

(2) Remove air inlet to throttle body hose clamp.

(3) Remove throttle and the speed control (if

equipped) cables from lever and bracket.

(4) Disconnect electrical connectors from the idle

air control motor and throttle position sensor (TPS)

(Fig. 28) or (Fig. 29).

(5) Remove throttle body to intake manifold

attaching bolts.

(6) Remove throttle body and gasket.

INSTALLATION

(1) Install a new gasket, if required.

(2) Install throttle body.

(3) Tighten throttle body mounting bolts. The 2.4L

to 28.2 N´m (250 50 in. lbs.) torque, The 3.3/3.8L to

11.6 N´m (105 20 in. lbs.) torque.

(4) Connect electrical connectors to the idle air

control motor and throttle position sensor (TPS) (Fig.

28) or (Fig. 29).

(5) Install air inlet to throttle body hose clamp and

tighten.

(6) Connect negative cable to battery cable.

THROTTLE CONTROL CABLE

REMOVAL

(1) Working from the engine compartment, hold

the throttle body throttle lever in the wide open posi-

tion.

(2) Remove the throttle cable from the throttle

body cam.

(3) From inside the vehicle, hold up the pedal and

remove the cable retainer and throttle cable from the

upper end of the pedal shaft.

(4) Remove retainer clip from throttle cable and

grommet at dash panel.

(5) From the engine compartment, pull the throttle

cable and gromment out of the dash panel.

(6) Remove the throttle cable from throttle bracket

by carefully compressing both retaining ears simulta-

neously then gently pull the throttle cable from

throttle bracket or if it is the slide snap design you

have to slide the locking tab out of the hole and then

slide the cable assembly out of the bracket.

INSTALLATION

(1) From the engine compartment, push the hous-

ing end fitting and grommet into the dash panel.In-

stall gromment into the dash panel.

(2) Install the cable housing (throttle body end)

into the cable mounting bracket on the engine.

(3) From inside the vehicle, hold up the pedal and

install throttle cable and cable retainer in the upper

end of the pedal shaft.

(4) At the dash panel, install the cable retainer

clip between the end of the throttle cable fitting and

grommet

(5) From the engine compartment, rotate the

throttle lever wide open and install the throttle

cable.

THROTTLE POSITION SENSOR

DESCRIPTION

The throttle position sensor mounts to the side of

the throttle body (Fig. 30) or (Fig. 31).The sensor

connects to the throttle blade shaft. The TPS is a

variable resistor that provides the Powertrain Con-

trol Module (PCM) with an input signal (voltage).

Fig. 30 Throttle Position SensorÐ2.4L Engine

1 - Idle Air Control Valve

2 - Throttle Position Sensor

14 - 40 FUEL INJECTIONRS

THROTTLE BODY (Continued)

Page 1406 of 2339

OPERATION

The signal represents throttle blade position. As

the position of the throttle blade changes, the resis-

tance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.6 volt at minimum throttle

opening (idle) to a maximum of 4.5 volts at wide open

throttle.Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

REMOVAL - 3.3/3.8L

(1) Disconnect the negative battery cable.

(2) Remove the electrical connector from the Inlet

Air Temperature sensor.

(3) Remove the air cleaner box lid. Remove hose

from throttle body.

(4) Disconnect the electrical connector at TPS.

(5) Disconnect the electrical connector at IAC.

(6) Remove the throttle and speed control cables

from throttle body.

(7) Remove 3 mounting bolts from throttle body.

(8) Remove throttle body.

(9) Disconnect the purge vacuum line from the

throttle body.

(10) Remove TPS from throttle body.

INSTALLATION - 3.3/3.8L

(1) Install TPS to throttle body.

(2) Disconnect the purge vacuum line from the

throttle body.

(3) Install throttle body.

(4) Install 3 mounting bolts from throttle body.

Tighten bolts.

(5) Install the throttle and speed control cables to

throttle body.

(6) Connect the electrical connector at TPS.

(7) Connect the electrical connector at IAC.

(8) Install the air cleaner box lid. Install hose to

throttle body.

(9) Install the electrical connector to the Inlet Air

Temperature sensor.

(10) Connect the negative battery cable.

Fig. 31 Throttle Position SensorÐ3.3/3.8L Engine

1 - Idle Air Control Valve

2 - Throttle Position Sensor

RSFUEL INJECTION14-41

THROTTLE POSITION SENSOR (Continued)

Page 1585 of 2339

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 297) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

Fig. 297 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21 - 124 40TE AUTOMATIC TRANSAXLERS

Page 1736 of 2339

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 321) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

Fig. 321 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

RS41TE AUTOMATIC TRANSAXLE21 - 275

Page 1774 of 2339

Inflation pressures specified on the Tire Inflation

Pressure Label are always the cold inflation pressure

of the tire. Cold inflation pressure is obtained after

the vehicle has not been operated for at least 3

hours, or the vehicle is driven less than one mile

after being inoperative for 3 hours. Tire inflation

pressures may increase from 2 to 6 pounds per

square inch (psi) (14 to 41 kPa) during operation. Do

not reduce this normal pressure buildup.

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²The vehicle to drift.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING. THE TIRE CAN FAIL

SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 24).

Over inflation causes rapid center wear and loss of

the tire's ability to cushion shocks (Fig. 25).

STANDARD PROCEDURE - TIRE PRESSURE

FOR HIGH SPEED OPERATION

DaimlerChrysler Corporation advocates driving at

safe speeds within posted speed limits. Where speed

limits allow the vehicle to be driven at high speeds,

correct tire inflation pressure is very important.

Vehicles loaded to maximum capacity should not be

driven at continuous speeds over 120 km/h (75 mph).

Never exceed the maximum speed capacity of the

tire. For information on tire identification and speed

ratings, (Refer to 22 - TIRES/WHEELS/TIRES -

DESCRIPTION).

STANDARD PROCEDURE - TIRE LEAK

REPAIRING

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

defect, or puncture, is in the tread area (Fig. 26). The

tire should be replaced if the puncture is located in

the sidewall.

Deflate tire completely before attempting to dis-

mount the tire from the wheel.Use a lubricant

such as a mild soap solution when dismounting

or mounting tire.Use tools free of burrs or sharp

edges which could damage the tire or wheel rim.

Before mounting tire on wheel, make sure all rust

is removed from the rim bead and repaint if neces-

sary.

Install wheel on vehicle, and progressively tighten

the 5 wheel nuts to a torque of 135 N´m (100 ft. lbs.).

Fig. 24 Under Inflation Wear

1 - THIN TIRE TREAD AREAS

Fig. 25 Over Inflation Wear

1 - THIN TIRE TREAD AREA

RSTIRES/WHEELS22-17

TIRES (Continued)

Page 1791 of 2339

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track guide to seat riser 3.5 Ð 31

Sunroof opening panel to lifter arm screws 5 44

Sunroof opening panel motor screws 4 35

Sunroof trough bracket to roof bolts 6 53

Sunroof trough to trough bracket bolts 6 53

Sunroof trough bracket bolts 6 53

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door Hinges ± Hinge Pin and Pivot Contact

Areas

²Hood Hinges ± Pivot Points

²Liftgate Hinges

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Liftgate Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Liftgate Lock Cylinder

23 - 12 BODYRS

BODY (Continued)

Page 1809 of 2339

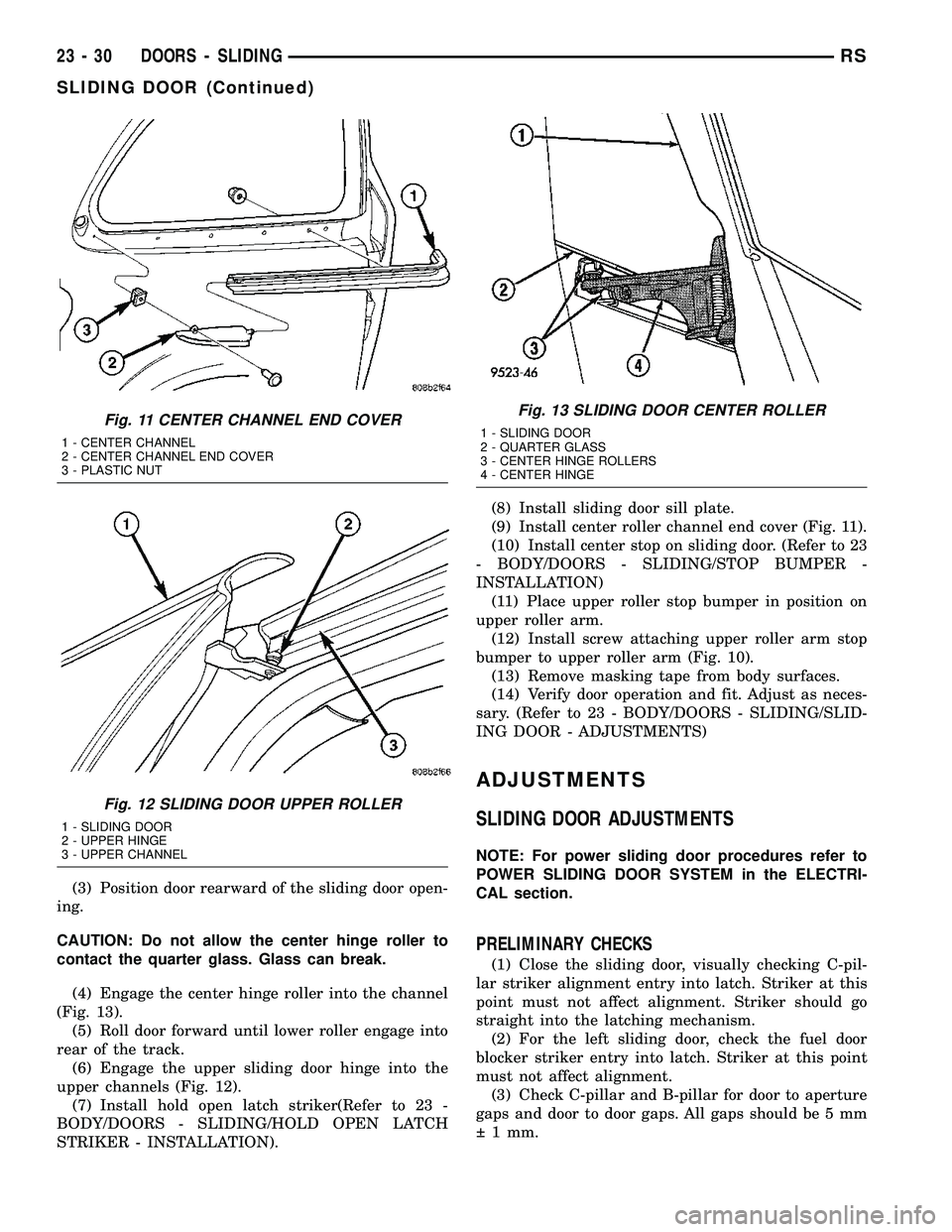

(3) Position door rearward of the sliding door open-

ing.

CAUTION: Do not allow the center hinge roller to

contact the quarter glass. Glass can break.

(4) Engage the center hinge roller into the channel

(Fig. 13).

(5) Roll door forward until lower roller engage into

rear of the track.

(6) Engage the upper sliding door hinge into the

upper channels (Fig. 12).

(7) Install hold open latch striker(Refer to 23 -

BODY/DOORS - SLIDING/HOLD OPEN LATCH

STRIKER - INSTALLATION).(8) Install sliding door sill plate.

(9) Install center roller channel end cover (Fig. 11).

(10) Install center stop on sliding door. (Refer to 23

- BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(11) Place upper roller stop bumper in position on

upper roller arm.

(12) Install screw attaching upper roller arm stop

bumper to upper roller arm (Fig. 10).

(13) Remove masking tape from body surfaces.

(14) Verify door operation and fit. Adjust as neces-

sary. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS)

ADJUSTMENTS

SLIDING DOOR ADJUSTMENTS

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

PRELIMINARY CHECKS

(1) Close the sliding door, visually checking C-pil-

lar striker alignment entry into latch. Striker at this

point must not affect alignment. Striker should go

straight into the latching mechanism.

(2) For the left sliding door, check the fuel door

blocker striker entry into latch. Striker at this point

must not affect alignment.

(3) Check C-pillar and B-pillar for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

1 mm.

Fig. 11 CENTER CHANNEL END COVER

1 - CENTER CHANNEL

2 - CENTER CHANNEL END COVER

3 - PLASTIC NUT

Fig. 12 SLIDING DOOR UPPER ROLLER

1 - SLIDING DOOR

2 - UPPER HINGE

3 - UPPER CHANNEL

Fig. 13 SLIDING DOOR CENTER ROLLER

1 - SLIDING DOOR

2 - QUARTER GLASS

3 - CENTER HINGE ROLLERS

4 - CENTER HINGE

23 - 30 DOORS - SLIDINGRS

SLIDING DOOR (Continued)

Page 1824 of 2339

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL.............................45

INSTALLATION.........................46

COWL GRILLE

REMOVAL.............................50

INSTALLATION.........................50

EXTERIOR NAME PLATES - TAPE ATTACHED

REMOVAL.............................51

INSTALLATION.........................51

EXTERIOR NAME PLATES - ADHESIVE

ATTACHED

REMOVAL.............................51

INSTALLATION.........................51

FRONT FENDER

REMOVAL.............................51

INSTALLATION.........................52

FUEL FILL DOOR

REMOVAL.............................52

INSTALLATION.........................52

FUEL FILL DOOR BLOCKER LATCH

REMOVAL.............................53

INSTALLATION.........................53

FUEL FILL DOOR BLOCKER LATCH STRIKER

REMOVAL.............................53

INSTALLATION.........................53

FUEL FILL DOOR BLOCKER LOCKOUT LINK

REMOVAL.............................54

INSTALLATION.........................54

GRILLE

DESCRIPTION.........................55REMOVAL.............................55

INSTALLATION.........................55

UPPER RADIATOR CROSSMEMBER

REMOVAL.............................56

INSTALLATION.........................56

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL.............................57

INSTALLATION.........................57

LUGGAGE RACK RISER

REMOVAL.............................57

INSTALLATION.........................58

LUGGAGE RACK CROSSBAR

REMOVAL.............................58

INSTALLATION.........................59

REAR QUARTER PANEL/FENDER AIR

EXHAUSTER

DESCRIPTION.........................59

REMOVAL.............................59

INSTALLATION.........................60

ROOF JOINT MOLDING

REMOVAL.............................60

INSTALLATION.........................60

SIDE VIEW MIRROR

REMOVAL.............................60

INSTALLATION.........................60

GLASS-OUTSIDE REARVIEW MIRROR

REMOVAL.............................61

INSTALLATION.........................61

BODY SIDE MOLDINGS

REMOVAL

Refer to (Fig. 1), (Fig. 2), (Fig. 3), (Fig. 4) or (Fig.

5)for proper location of fasteners holding the molding

to the wheelhouse lip and rocker panels.

(1) Warm the affected stick on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.(2) If equipped, remove pop rivets holding molding

edge to wheelhouse lip.

(3) Pull stick on molding from painted surface.

(4) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Disc, or equivalent, to

clean adhesive residue from painted surfaces. These

products are available from automotive paint suppli-

ers. Refer to instructions supplied with the specific

product for proper usage.

RSEXTERIOR23-45

Page 1831 of 2339

(6) Remove outboard cowl grille/fender bracket

screw and antenna right side only.

(7) Remove fender bolt to lower rocker panel.

(8) Remove fender bolt to lower cowl.

(9) Support/remove hood.

(10) Pull fascia away from fender.

(11) Remove bolts attaching fender to upper rail.

(12) Remove fender from vehicle (Fig. 8).

INSTALLATION

(1) Place fender in position on vehicle.

(2) From inside engine compartment, start the

center upper rail bolt. install all the bolts attaching

fender to upper rail and tighten.

(3) Install fender to lower cowl panel bolt.

(4) Install fender to rocker panel bolt.

(5) Place fascia into position.

(6) Install hood/remove support.

(7) Install outboard cowl grille/fender bracket

screw and install antenna right side only.

(8) Install fender to fascia nuts.

(9) Install inner splash shield.

(10) Install mud guard.

(11) Install headlamp assembly. (Refer to 8 -

ELECTRICAL/LAMPS/LIGHTING - EXTERIOR/

HEADLAMP UNIT - INSTALLATION)

(12) Check fender for flush and gap. (Refer to 23 -

BODY/BODY STRUCTURE/GAP AND FLUSH -

SPECIFICATIONS).

FUEL FILL DOOR

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12).

(4) Open fuel fill door.

(5) Remove screws holding fuel fill neck to fuel

filler housing.

(6) Position fuel fill neck out of the way.

(7) Reaching inside fuel filler housing, release clips

holding housing to quarter panel (Fig. 9).

(8) Remove fuel fill door from vehicle.

(9) Disengage clip holding link to fuel fill door

(Fig. 13).

(10) Remove link from fuel fill door.

INSTALLATION

(1) Install spring to housing and door

(2) Snap door into housing.

(3) Insert lockout link into clip on fuel fill door.

(4) Engage clip to hold link to fuel fill door.

(5) Insert lockout link through grommet in panel

between inner and outer quarter panel.

(6) Close fuel fill door.

(7) Install fuel filler housing to outer quarter

panel.

(8) Verify that all clips on fuel filler housing are

fully engaged to outer quarter panel.

(9) Place fuel fill neck in position.

(10) Install screws to hold fuel fill neck to fuel

filler housing.

Fig. 8 FENDER

1 - FASTENERS

2 - FENDER

3 - FASTENERS

Fig. 9 FUEL FILLER HOUSING AND DOOR

1 - FUEL FILLER HOUSING W/LATCH

2 - CLIP

3 - FUEL FILLER HOUSING DOOR

4 - CLIPS

5 - FIX CLIP

23 - 52 EXTERIORRS

FRONT FENDER (Continued)

Page 1832 of 2339

(11) Engage latch release link into clip on fuel fill

blocker latch arm.

(12) Verify fuel fill blocker latch operation.

(13) Install water shield patch to cover access hole

in C-pillar.

(14) Install left quarter trim panel.

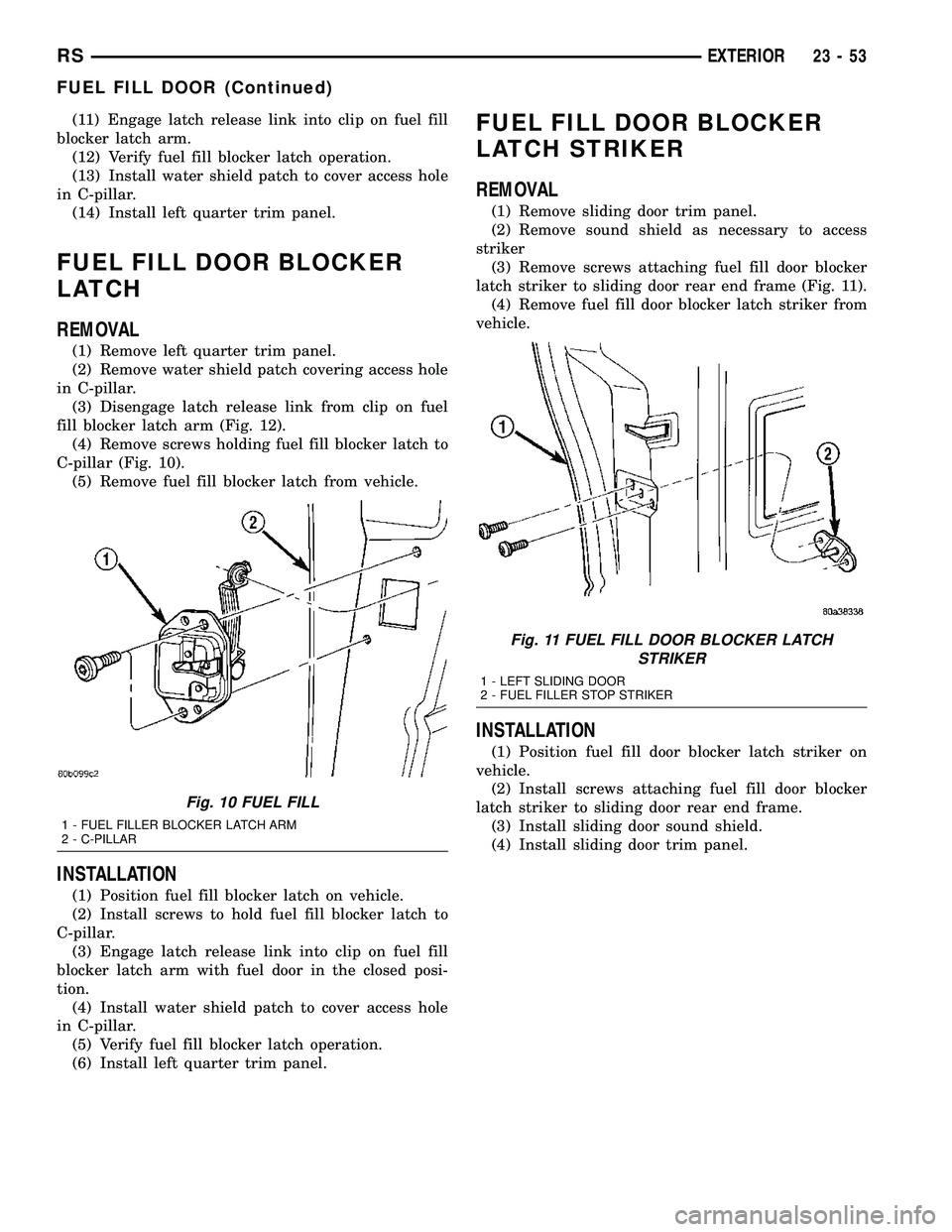

FUEL FILL DOOR BLOCKER

LATCH

REMOVAL

(1) Remove left quarter trim panel.

(2) Remove water shield patch covering access hole

in C-pillar.

(3) Disengage latch release link from clip on fuel

fill blocker latch arm (Fig. 12).

(4) Remove screws holding fuel fill blocker latch to

C-pillar (Fig. 10).

(5) Remove fuel fill blocker latch from vehicle.

INSTALLATION

(1) Position fuel fill blocker latch on vehicle.

(2) Install screws to hold fuel fill blocker latch to

C-pillar.

(3) Engage latch release link into clip on fuel fill

blocker latch arm with fuel door in the closed posi-

tion.

(4) Install water shield patch to cover access hole

in C-pillar.

(5) Verify fuel fill blocker latch operation.

(6) Install left quarter trim panel.

FUEL FILL DOOR BLOCKER

LATCH STRIKER

REMOVAL

(1) Remove sliding door trim panel.

(2) Remove sound shield as necessary to access

striker

(3) Remove screws attaching fuel fill door blocker

latch striker to sliding door rear end frame (Fig. 11).

(4) Remove fuel fill door blocker latch striker from

vehicle.

INSTALLATION

(1) Position fuel fill door blocker latch striker on

vehicle.

(2) Install screws attaching fuel fill door blocker

latch striker to sliding door rear end frame.

(3) Install sliding door sound shield.

(4) Install sliding door trim panel.

Fig. 10 FUEL FILL

1 - FUEL FILLER BLOCKER LATCH ARM

2 - C-PILLAR

Fig. 11 FUEL FILL DOOR BLOCKER LATCH

STRIKER

1 - LEFT SLIDING DOOR

2 - FUEL FILLER STOP STRIKER

RSEXTERIOR23-53

FUEL FILL DOOR (Continued)