remove seats CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 462 of 2339

(2) Remove the appropriate seat from the vehicle

and place it on a clean work surface, (Refer to 23 -

BODY/SEATS/SEAT - REMOVAL).

(3) Remove the Memory Seat/Mirror Module

(MSMM) mounting fasteners (if equipped).

(4) Disconnect the MSMM electrical harness con-

nectors and remove the MSMM from the power seat

track (if equipped).

(5) Remove the front seat track rear cover, (Refer

to 23 - BODY/SEATS/SEAT TRACK REAR COVER -

REMOVAL).

(6) Remove the seat side cover and power seat

switch as an assembly (Refer to 23 - BODY/SEATS/

SEAT CUSHION SIDE COVERS - REMOVAL).

(7) Disconnect all electrical connectors connecting

the power seat track to the seat assembly.

(8) Pull the seat back trim cover up slightly to

access and remove the two seat back frame mounting

bolts and also remove two seat back recliner bolts.

(9) Remove four seat track mounting bolts from

the seat cushion pan.

(10) Remove the power seat track from the seat.INSTALLATION

(1) Position the seat cushion on the seat track.

(2) Install the four seat track retaining bolts in the

seat cushion pan. Torque the bolts to 28.5 N´m (21 ft-

lbs.).

(3) Position the seat back and install the two seat

back frame mounting bolts and the two seat back

recliner bolts. Torque the bolts to 55 N´m (40.5

ft-lbs.).

(4) Route and connect the electrical connectors

between the power seat track and the seat assembly.

(5) Install the seat side cover and power seat

switch as an assembly (Refer to 23 - BODY/SEATS/

SEAT CUSHION SIDE COVERS - INSTALLATION).

(6) Install the front seat track rear cover, (Refer to

23 - BODY/SEATS/SEAT TRACK REAR COVER -

INSTALLATION).

(7) Position the Memory Seat/Mirror Module

(MSMM) and connect the MSMM electrical connec-

tors (if equipped).

(8) Install the MSMM mounting fasteners (if

equipped).

(9) Install the seat assembly in the vehicle (Refer

to 23 - BODY/SEATS/SEAT - INSTALLATION).

(10) Connect the battery negative cable.

RSPOWER SEAT SYSTEM8N-39

POWER SEAT TRACK (Continued)

Page 477 of 2339

INSTALLATION

(1) Position the lower drive unit near the lower

hinge.

(2) Connect the flex drive assembly on the lower

drive unit. Push the flex drive collar straight on until

the it snaps in place (Fig. 14).It may be necessary

to rotate the drive unit slightly until the flex

drive seats in place.

(3) Install the lower drive unit retaining fasteners

(Fig. 15). Torque the larger allen headed center stud

to 9 N´m (80 in. lbs.). Torque the smaller screw to 3

N´m (28 in. lbs.).

(4) Install the lower drive unit cover and retaining

screws (Fig. 16).

(5) Connect the battery negative cable.

Fig. 14 LOWER DRIVE UNIT

1 - LOWER DRIVE UNIT

2 - FLEX DRIVE ASSEMBLY

Fig. 15 LOWER DRIVE UNIT RETAINING

FASTENERS

1 - LOWER DRIVE UNIT RETAINING SCREW

2 - DO NOT REMOVE

3 - LOWER DRIVE UNIT RETAINING BOLT

Fig. 16 SLIDING DOOR LOWER HINGE ASSEMBLY

1 - LOWER DRIVE UNIT COVER

2 - LOWER DRIVE UNIT COVER RETAINING SCREWS

3 - SLIDING DOOR

4 - LOWER HINGE ARM BRACKET

8N - 54 POWER SLIDING DOOR SYSTEMRS

LOWER DRIVE UNIT (Continued)

Page 479 of 2339

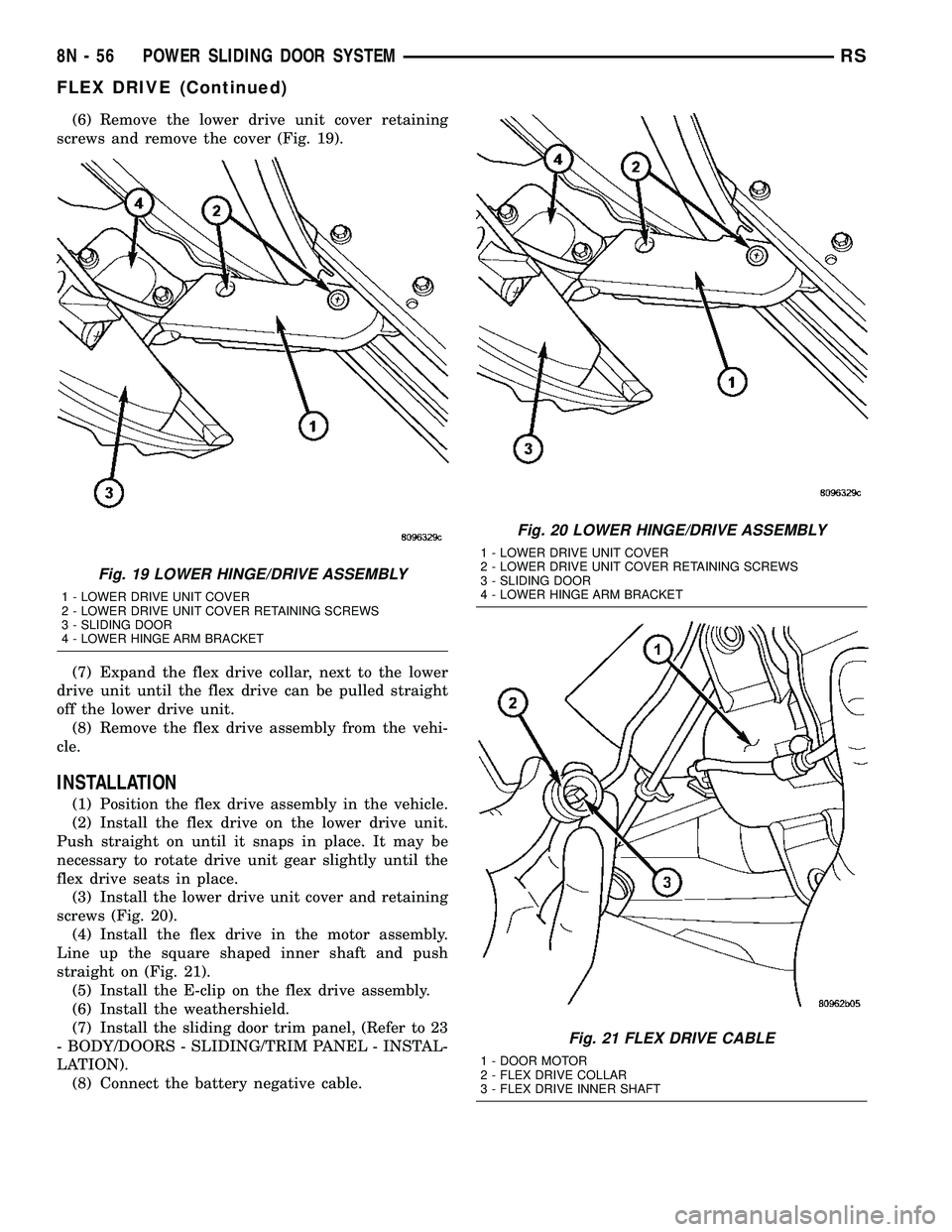

(6) Remove the lower drive unit cover retaining

screws and remove the cover (Fig. 19).

(7) Expand the flex drive collar, next to the lower

drive unit until the flex drive can be pulled straight

off the lower drive unit.

(8) Remove the flex drive assembly from the vehi-

cle.

INSTALLATION

(1) Position the flex drive assembly in the vehicle.

(2) Install the flex drive on the lower drive unit.

Push straight on until it snaps in place. It may be

necessary to rotate drive unit gear slightly until the

flex drive seats in place.

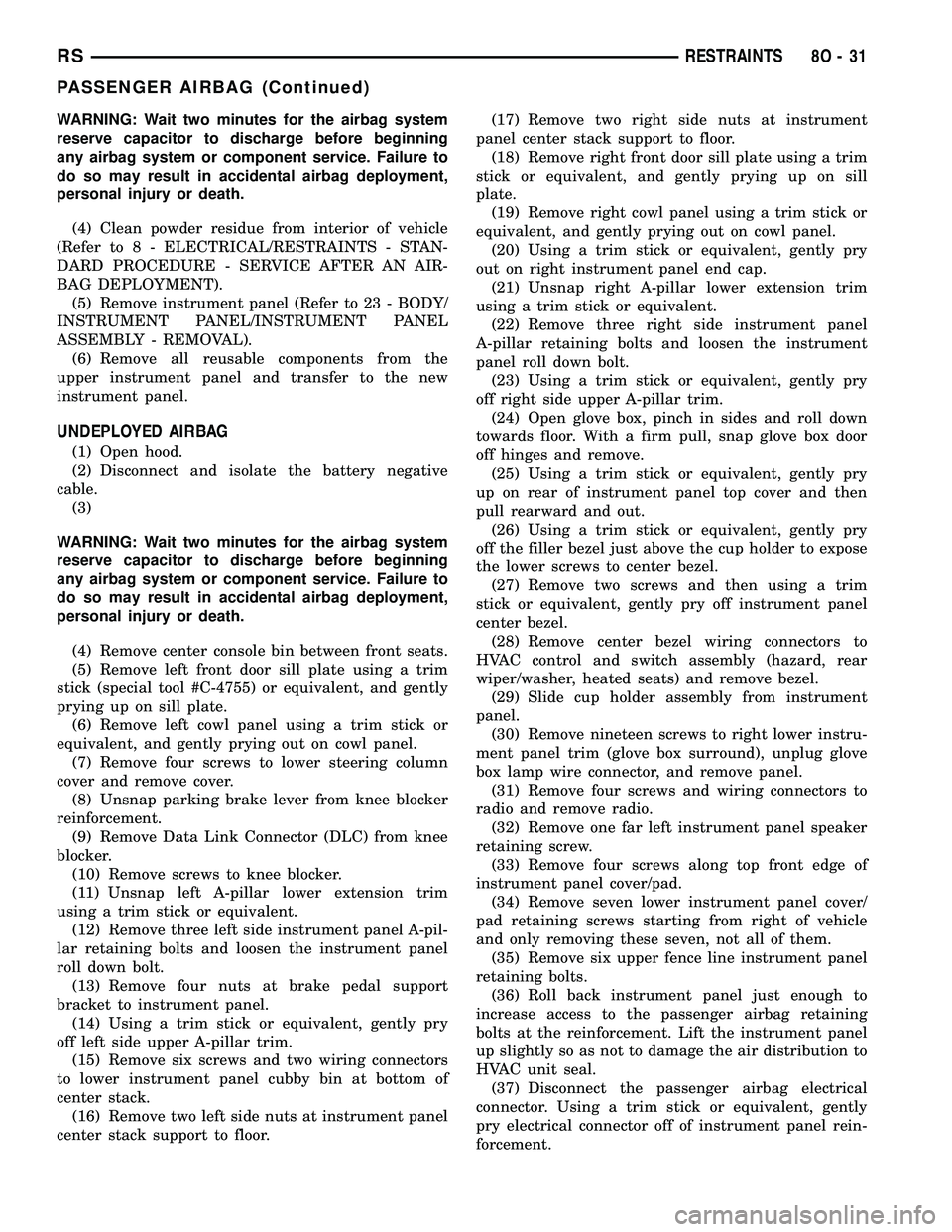

(3) Install the lower drive unit cover and retaining

screws (Fig. 20).

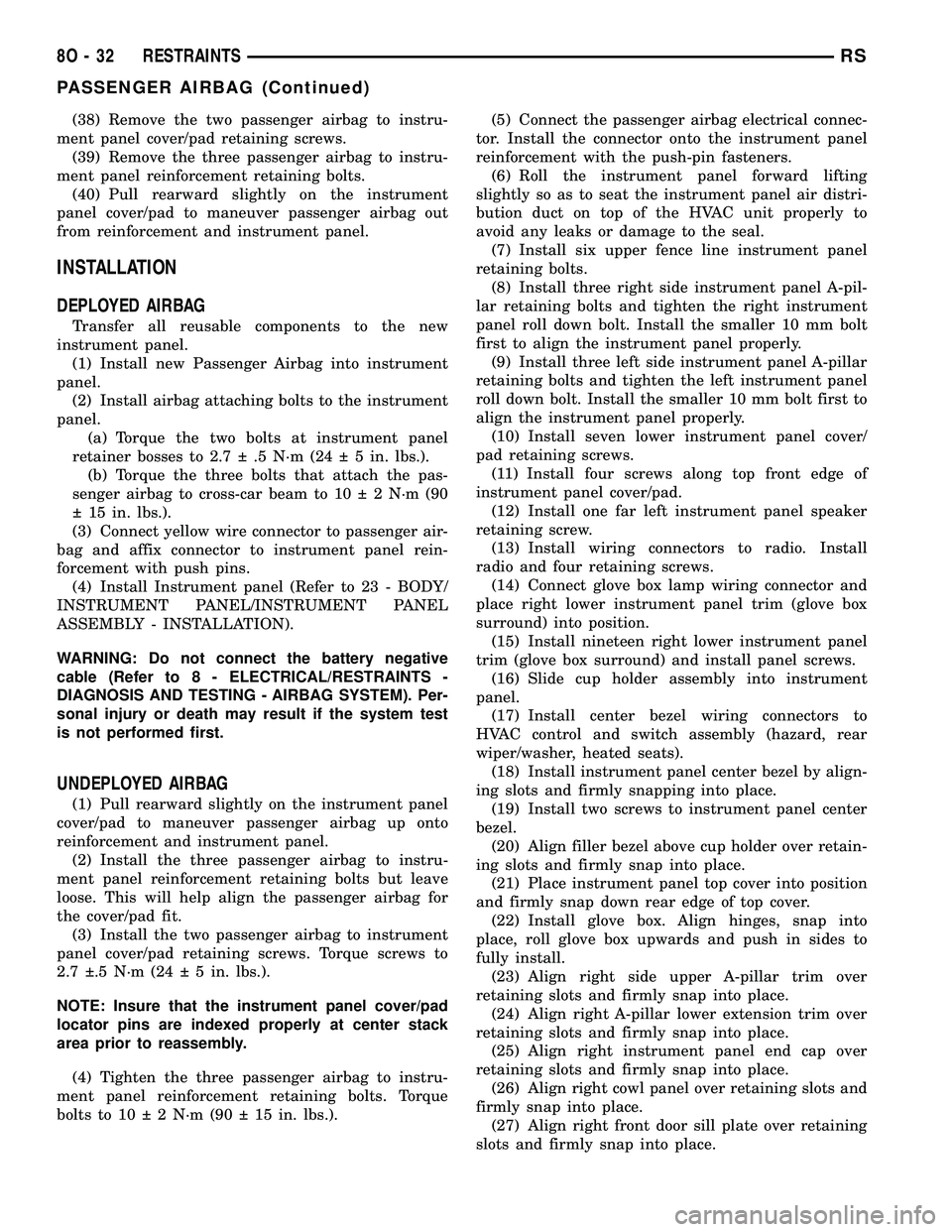

(4) Install the flex drive in the motor assembly.

Line up the square shaped inner shaft and push

straight on (Fig. 21).

(5) Install the E-clip on the flex drive assembly.

(6) Install the weathershield.

(7) Install the sliding door trim panel, (Refer to 23

- BODY/DOORS - SLIDING/TRIM PANEL - INSTAL-

LATION).

(8) Connect the battery negative cable.

Fig. 19 LOWER HINGE/DRIVE ASSEMBLY

1 - LOWER DRIVE UNIT COVER

2 - LOWER DRIVE UNIT COVER RETAINING SCREWS

3 - SLIDING DOOR

4 - LOWER HINGE ARM BRACKET

Fig. 20 LOWER HINGE/DRIVE ASSEMBLY

1 - LOWER DRIVE UNIT COVER

2 - LOWER DRIVE UNIT COVER RETAINING SCREWS

3 - SLIDING DOOR

4 - LOWER HINGE ARM BRACKET

Fig. 21 FLEX DRIVE CABLE

1 - DOOR MOTOR

2 - FLEX DRIVE COLLAR

3 - FLEX DRIVE INNER SHAFT

8N - 56 POWER SLIDING DOOR SYSTEMRS

FLEX DRIVE (Continued)

Page 513 of 2339

anchor. The OCM then monitors the return voltage

from each of the sensors. The bladder pressure sen-

sor input allows the OCM to determine whether the

passenger front seat is occupied and the relative size

of the occupant by providing a weight-sensing refer-

ence to the load on the seat cushion. The belt tension

sensor provides an additional logic input to the OCM

microprocessor that allows it to distinguish between

the lower seat belt cinch loads of a belted occupant

and the higher loads associated with a belted child

seat.

Pre-programmed decision algorithms and OCS cal-

ibration allow the OCM microprocessor to determine

when the seat cushion load as signaled by the blad-

der pressure sensor and the seat belt cinch load as

signaled by the belt tension sensor indicate that pas-

senger airbag protection is appropriate. When the

programmed conditions are met, the OCM sends the

proper electronic occupant classification messages

over the PCI data bus to the Occupant Restraint

Controller (ORC), and the ORC enables or disables

the deployment circuits for the passenger front sup-

plemental restraints. The ORC also provides a con-

trol output for the Passenger Airbag Disabled (PAD)

indicator in the instrument panel center stack, based

upon the electronic occupant classification messages

it receives from the OCM.

The OCM microprocessor continuously monitors all

of the OCS electrical circuits and components to

determine the system readiness. If the OCM detects

a monitored system fault, it sets an active and stored

Diagnostic Trouble Code (DTC) and sends the appro-

priate electronic messages to the ORC over the PCI

data bus. Then the ORC sets a DTC and sends mes-

sages to control the airbag indicator operation

accordingly. An active fault only remains for the

duration of the fault, or in some cases for the dura-

tion of the current ignition switch cycle, while a

stored fault causes a DTC to be stored in memory by

the OCM and the ORC. For some DTC's, if a fault

does not recur for a number of ignition cycles, the

OCM will automatically erase the stored DTC. For

other internal faults, the stored DTC is latched for-

ever.

The OCM receives battery current from an IPM

high side driver (Run/Start). The OCM receives

ground through a ground circuit of the body wire

harness, which it shares with the ORC. These con-

nections allow the OCM to be operational whenever

the ignition switch is in the Start or ON positions.

To diagnose and test the OCS, use a scan tool and

the appropriate diagnostic information.

REMOVAL

Once any of the original factory-installed compo-

nents except the Occupant Classification Module(OCM) have been replaced with the service replace-

ment package components, the OCM can only be ser-

viced by replacing the entire passenger front seat

cushion unit with another complete service replace-

ment package (Refer to 23 - BODY/SEATS/SEAT

CUSHION - FRONT - REMOVAL).

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAG

SYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion and result in personal injury or death.

(1) Disconnect and isolate the battery negative

cable.

(2)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(3) Reach under the front edge of the passenger

side front seat cushion to access and remove the lock

pin from the connector lock tower on the Occupant

Classification Module (OCM) (Fig. 36).

(4) Disconnect the passenger front seat wire har-

ness connector for the OCM.

(5) Remove the two screws that secure the OCM to

the OCM bracket.

(6) Remove the OCM from under the passenger

front seat.

INSTALLATION

WARNING: To avoid personal injury or death on

vehicles equipped with the Occupant Classification

System (OCS), only the Occupant Classification

Module (OCM) and the seat cushion trim may be

serviced separately. All other components of the

passenger front seat cushion must be serviced only

as a complete factory-calibrated, assembled and

tamper-evident service replacement package.

Once any of the original factory-installed compo-

nents except the OCM have been replaced with the

service replacement package components, the OCM

can only be serviced by replacing the entire passen-

8O - 26 RESTRAINTSRS

OCCUPANT CLASSIFICATION MODULE (Continued)

Page 514 of 2339

ger side front seat cushion unit with another com-

plete service replacement package. (Refer to 23 -

BODY/SEATS/SEAT CUSHION - FRONT -

REMOVAL).

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAG

SYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion may result in personal injury or death.

(1) Carefully position the Occupant Classification

Module (OCM) to the OCM bracket (Fig. 36). When

the OCM is correctly positioned, the connector on the

module will be pointed to right side of the vehicle.

(2) Install the two screws to the OCM. Torque the

screws to 2 N´m (20 in. lbs.).

(3) Connect the seat wire harness connector for the

OCM. Be certain that the latches on the connector

are each fully engaged.(4) Install the lock pin into the connector lock

tower on the OCM.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

WARNING: Following successful completion of the

Airbag System test procedure, the Occupant Classi-

fication System Verification Test must be done

using a scan tool and the appropriate diagnostic

information.

(5) Verify vehicle and system operation.

(6) Close hood.

OCCUPANT RESTRAINT

CONTROLLER

DESCRIPTION

The Occupant Restraint Controller (ORC) (Fig. 37)

is also sometimes referred to as the Airbag Control

Module (ACM).

Fig. 36 OCM - REMOVE/INSTALL

1 - OCCUPANT CLASSIFICATION MODULE (OCM)

2 - LOCK TOWER

3 - LOCK PIN

4 - CONNECTOR

5 - SCREW (2)

6 - BRACKET

Fig. 37 OCCUPANT RESTRAINT CONTROLLER -

TYPICAL

1 - ORC

2 - ORIENTATION ARROW UPON INSTALLATION

3 - LABEL

4 - ORC ELECTRICAL CONNECTORS

RSRESTRAINTS8O-27

OCCUPANT CLASSIFICATION MODULE (Continued)

Page 518 of 2339

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(4) Clean powder residue from interior of vehicle

(Refer to 8 - ELECTRICAL/RESTRAINTS - STAN-

DARD PROCEDURE - SERVICE AFTER AN AIR-

BAG DEPLOYMENT).

(5) Remove instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - REMOVAL).

(6) Remove all reusable components from the

upper instrument panel and transfer to the new

instrument panel.

UNDEPLOYED AIRBAG

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(4) Remove center console bin between front seats.

(5) Remove left front door sill plate using a trim

stick (special tool #C-4755) or equivalent, and gently

prying up on sill plate.

(6) Remove left cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(7) Remove four screws to lower steering column

cover and remove cover.

(8) Unsnap parking brake lever from knee blocker

reinforcement.

(9) Remove Data Link Connector (DLC) from knee

blocker.

(10) Remove screws to knee blocker.

(11) Unsnap left A-pillar lower extension trim

using a trim stick or equivalent.

(12) Remove three left side instrument panel A-pil-

lar retaining bolts and loosen the instrument panel

roll down bolt.

(13) Remove four nuts at brake pedal support

bracket to instrument panel.

(14) Using a trim stick or equivalent, gently pry

off left side upper A-pillar trim.

(15) Remove six screws and two wiring connectors

to lower instrument panel cubby bin at bottom of

center stack.

(16) Remove two left side nuts at instrument panel

center stack support to floor.(17) Remove two right side nuts at instrument

panel center stack support to floor.

(18) Remove right front door sill plate using a trim

stick or equivalent, and gently prying up on sill

plate.

(19) Remove right cowl panel using a trim stick or

equivalent, and gently prying out on cowl panel.

(20) Using a trim stick or equivalent, gently pry

out on right instrument panel end cap.

(21) Unsnap right A-pillar lower extension trim

using a trim stick or equivalent.

(22) Remove three right side instrument panel

A-pillar retaining bolts and loosen the instrument

panel roll down bolt.

(23) Using a trim stick or equivalent, gently pry

off right side upper A-pillar trim.

(24) Open glove box, pinch in sides and roll down

towards floor. With a firm pull, snap glove box door

off hinges and remove.

(25) Using a trim stick or equivalent, gently pry

up on rear of instrument panel top cover and then

pull rearward and out.

(26) Using a trim stick or equivalent, gently pry

off the filler bezel just above the cup holder to expose

the lower screws to center bezel.

(27) Remove two screws and then using a trim

stick or equivalent, gently pry off instrument panel

center bezel.

(28) Remove center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats) and remove bezel.

(29) Slide cup holder assembly from instrument

panel.

(30) Remove nineteen screws to right lower instru-

ment panel trim (glove box surround), unplug glove

box lamp wire connector, and remove panel.

(31) Remove four screws and wiring connectors to

radio and remove radio.

(32) Remove one far left instrument panel speaker

retaining screw.

(33) Remove four screws along top front edge of

instrument panel cover/pad.

(34) Remove seven lower instrument panel cover/

pad retaining screws starting from right of vehicle

and only removing these seven, not all of them.

(35) Remove six upper fence line instrument panel

retaining bolts.

(36) Roll back instrument panel just enough to

increase access to the passenger airbag retaining

bolts at the reinforcement. Lift the instrument panel

up slightly so as not to damage the air distribution to

HVAC unit seal.

(37) Disconnect the passenger airbag electrical

connector. Using a trim stick or equivalent, gently

pry electrical connector off of instrument panel rein-

forcement.

RSRESTRAINTS8O-31

PASSENGER AIRBAG (Continued)

Page 519 of 2339

(38) Remove the two passenger airbag to instru-

ment panel cover/pad retaining screws.

(39) Remove the three passenger airbag to instru-

ment panel reinforcement retaining bolts.

(40) Pull rearward slightly on the instrument

panel cover/pad to maneuver passenger airbag out

from reinforcement and instrument panel.

INSTALLATION

DEPLOYED AIRBAG

Transfer all reusable components to the new

instrument panel.

(1) Install new Passenger Airbag into instrument

panel.

(2) Install airbag attaching bolts to the instrument

panel.

(a) Torque the two bolts at instrument panel

retainer bosses to 2.7 .5 N´m (24 5 in. lbs.).

(b) Torque the three bolts that attach the pas-

senger airbag to cross-car beam to 10 2 N´m (90

15 in. lbs.).

(3) Connect yellow wire connector to passenger air-

bag and affix connector to instrument panel rein-

forcement with push pins.

(4) Install Instrument panel (Refer to 23 - BODY/

INSTRUMENT PANEL/INSTRUMENT PANEL

ASSEMBLY - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

UNDEPLOYED AIRBAG

(1) Pull rearward slightly on the instrument panel

cover/pad to maneuver passenger airbag up onto

reinforcement and instrument panel.

(2) Install the three passenger airbag to instru-

ment panel reinforcement retaining bolts but leave

loose. This will help align the passenger airbag for

the cover/pad fit.

(3) Install the two passenger airbag to instrument

panel cover/pad retaining screws. Torque screws to

2.7 .5 N´m (24 5 in. lbs.).

NOTE: Insure that the instrument panel cover/pad

locator pins are indexed properly at center stack

area prior to reassembly.

(4) Tighten the three passenger airbag to instru-

ment panel reinforcement retaining bolts. Torque

bolts to 10 2 N´m (90 15 in. lbs.).(5) Connect the passenger airbag electrical connec-

tor. Install the connector onto the instrument panel

reinforcement with the push-pin fasteners.

(6) Roll the instrument panel forward lifting

slightly so as to seat the instrument panel air distri-

bution duct on top of the HVAC unit properly to

avoid any leaks or damage to the seal.

(7) Install six upper fence line instrument panel

retaining bolts.

(8) Install three right side instrument panel A-pil-

lar retaining bolts and tighten the right instrument

panel roll down bolt. Install the smaller 10 mm bolt

first to align the instrument panel properly.

(9) Install three left side instrument panel A-pillar

retaining bolts and tighten the left instrument panel

roll down bolt. Install the smaller 10 mm bolt first to

align the instrument panel properly.

(10) Install seven lower instrument panel cover/

pad retaining screws.

(11) Install four screws along top front edge of

instrument panel cover/pad.

(12) Install one far left instrument panel speaker

retaining screw.

(13) Install wiring connectors to radio. Install

radio and four retaining screws.

(14) Connect glove box lamp wiring connector and

place right lower instrument panel trim (glove box

surround) into position.

(15) Install nineteen right lower instrument panel

trim (glove box surround) and install panel screws.

(16) Slide cup holder assembly into instrument

panel.

(17) Install center bezel wiring connectors to

HVAC control and switch assembly (hazard, rear

wiper/washer, heated seats).

(18) Install instrument panel center bezel by align-

ing slots and firmly snapping into place.

(19) Install two screws to instrument panel center

bezel.

(20) Align filler bezel above cup holder over retain-

ing slots and firmly snap into place.

(21) Place instrument panel top cover into position

and firmly snap down rear edge of top cover.

(22) Install glove box. Align hinges, snap into

place, roll glove box upwards and push in sides to

fully install.

(23) Align right side upper A-pillar trim over

retaining slots and firmly snap into place.

(24) Align right A-pillar lower extension trim over

retaining slots and firmly snap into place.

(25) Align right instrument panel end cap over

retaining slots and firmly snap into place.

(26) Align right cowl panel over retaining slots and

firmly snap into place.

(27) Align right front door sill plate over retaining

slots and firmly snap into place.

8O - 32 RESTRAINTSRS

PASSENGER AIRBAG (Continued)

Page 526 of 2339

(10) Remove the lower seat belt anchor bolt (Fig.

49).

(11) Disconnect the electrical connector if equipped

with OCS (Fig. 49).

(12) Remove front door sill plate (Fig. 48).

(13) Remove sliding door sill plate (Fig. 48).

(14) Remove lower B-pillar trim cover (Fig. 48).

(15) Disconnect the seat belt retractor electrical

connector (Fig. 48).

(16) Remove seat belt retractor attaching bolt (Fig.

48).

(17) Remove the seat belt and retractor from vehi-

cle.

INSTALLATION

WARNING: Inspect the condition of the shoulder

belt and lap belt. Replace any belt that is cut,

frayed, torn, or damaged in any way. Also, replace

the shoulder belt if the retractor is either damaged

or inoperative.

(1) Place seat belt and retractor into position (Fig.

48).

(2) Install bolt attaching seat belt retractor to

B-pillar (Fig. 48). Torque bolt to 39 N´m (29 ft. lbs.).

(3) Connect the seat belt retractor electrical con-

nector (Fig. 48).

(4) Install the lower B-pillar trim cover (Fig. 48).

(5) Install the sliding door sill plate (Fig. 48).

(6) Install the front door sill plate (Fig. 48).(7) Install the lower seat belt anchor bolt (Fig. 49).

Torque bolt to 39 N´m (29 ft. lbs.).

NOTE: If equipped with the Occupant Classification

System (OCS), there is a Belt Tension Sensor

located on the lower seat belt anchor on the pas-

senger front seat belt.

(8) Connect the belt tension sensor connector (if

equipped with OCS) (Fig. 49).

(9) Install the upper B-pillar trim cover (Fig. 48).

(10) Install the bolt attaching turning loop to

shoulder belt height adjuster (Fig. 48). Torque bolt to

39 N´m (29 ft. lbs.).

(11) Install the cover to the seat belt turning loop

(Fig. 48).

(12) Install the shoulder harness height adjuster

knob by pushing it straight onto the adjuster (Fig.

48).

(13) Move seat back to approximate customer posi-

tion.

WARNING: If equipped with the OCS, do not con-

nect the battery negative cable (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - DIAGNOSIS AND TESTING -

AIRBAG SYSTEM). Personal injury or death may

result if the system test is not performed first.

WARNING: If equipped with the OCS, following suc-

cessful completion of the Airbag System test proce-

dure, the Occupant Classification System

Verification Test must be done using a scan tool

and the appropriate diagnostic information.

(14) Verify vehicle and system operation.

(15) Close hood.

SEAT BELT & RETRACTOR -

FIRST ROW - OUTBOARD

REMOVAL

(1) Remove first and second row seats.

(2) Remove first row seat belt lower anchor bolt.

(3) Remove first row seat belt upper turning loop

anchor bolt.

(4) Remove liftgate sill plate.

(5) Remove upper liftgate trim.

(6) Remove second seat lower anchor bolt.

(7) Remove second seat upper turning loop anchor

bolt.

(8) Remove D-pillar trim cover.

(9) Disconnect speaker connector. The left side has

the speaker mounted in the D-pillar trim cover and

the right side will have the speaker mounted in the

rear of the quarter trim panel, but the connector is

Fig. 49 BELT TENSION SENSOR/LOWER SEAT

BELT ANCHOR

1 - A-PILLAR

2 - SEAT BELT ANCHOR/BELT TENSION SENSOR

3 - BELT TENSION SENSOR CONNECTOR

RSRESTRAINTS8O-39

SEAT BELT & RETRACTOR - OUTBOARD - FRONT (Continued)

Page 527 of 2339

accessible from the rear after the D-pillar trim is

removed.

(10) Remove quarter trim bolster.

(11) Remove quarter trim panel screws.

(12) Remove quarter trim panel.

(13) Remove first row seat belt and retractor

retaining bolt.

(14) Remove first row seat belt and retractor from

vehicle.

INSTALLATION

(1) Install first row seat belt and retractor. Torque

bolt to 39 N´m (29 ft. lbs.).

(2) Install quarter trim panel.

(3) Install quarter trim panel screws.

(4) Install quarter trim bolster.

(5) Connect speaker connector. The left side has

the speaker mounted in the D-pillar trim cover and

the right side will have the speaker mounted in the

rear of the quarter trim panel, but the connector is

accessible from the rear after the D-pillar trim is

removed.

(6) Install D-pillar trim cover.

(7) Install second seat belt lower anchor bolt.

Torque bolt to 39 N´m (29 ft. lbs.).

(8) Install second seat belt upper turning loop

anchor bolt. Torque bolt to 39 N´m (29 ft. lbs.).

(9) Install upper liftgate trim.

(10) Install liftgate sill plate.

(11) Install first row seat belt upper turning loop

anchor bolt. Torque bolt to 39 N´m (29 ft. lbs.).

(12) Install first row seat belt lower anchor bolt.

Torque bolt to 39 N´m (29 ft. lbs.).

(13) Install first and second row seats.

SEAT BELT BUCKLE - SECOND

ROW - THREE PASSENGER

BENCH

REMOVAL

(1) Remove bolt attaching seat belt buckle to seat

rear frame rail (Fig. 50).

(2) Remove seat belt buckle from seat.

INSTALLATION

(1) Place seat belt buckle in position on seat.

(2) Install bolt to attach seat belt buckle to seat

rear frame rail. Tighten all seat belt bolts to 39 N´m

(29 ft. lbs.) torque.

SEAT BELT & RETRACTOR -

SECOND ROW - RIGHT

OUTBOARD

REMOVAL

(1) Remove first and second row seats.

(2) Remove first row seat belt lower anchor bolt.

(3) Remove first row seat belt upper anchor bolt.

(4) Remove liftgate sill plate.

(5) Remove upper liftgate trim.

(6) Remove second seat belt lower anchor bolt.

(7) Remove second seat belt upper anchor bolt.

(8) Remove D-pillar trim cover.

(9) Disconnect speaker connector. The left side has

the speaker mounted in the D-pillar trim cover and

the right side will have the speaker mounted in the

rear of the quarter trim panel, but the connector is

accessible from the rear after the D-pillar trim is

removed.

(10) Remove quarter trim bolster.

(11) Remove quarter trim panel screws.

(12) Remove quarter trim panel.

(13) Remove retractor retaining bolt.

(14) Remove second row seat belt and retractor.

INSTALLATION

(1) Install second row seat belt and retractor.

Torque bolt to 39 N´m (29 ft. lbs.).

(2) Install quarter trim panel.

(3) Install quarter trim panel screws.

(4) Install quarter trim bolster.

(5) Connect speaker connector. The left side has

the speaker mounted in the D-pillar trim cover and

Fig. 50 SEAT BELT BUCKLE - SECOND ROW -

THREE PASSENGER BENCH

1 - ANCHOR BOLT

2 - SEAT BELTS

3 - ANCHOR

4 - RISER

8O - 40 RESTRAINTSRS

SEAT BELT & RETRACTOR - FIRST ROW - OUTBOARD (Continued)

Page 528 of 2339

the right side will have the speaker mounted in the

rear of the quarter trim panel, but the connector is

accessible from the rear after the D-pillar trim is

removed.

(6) Install D-pillar trim cover.

(7) Install second seat belt lower anchor bolt.

Torque bolt to 39 N´m (29 ft. lbs.).

(8) Install second seat belt upper turning loop

anchor bolt. Torque bolt to 39 N´m (29 ft. lbs.).

(9) Install upper liftgate trim.

(10) Install liftgate sill plate.

(11) Install first row seat belt upper turning loop

anchor bolt. Torque bolt to 39 N´m (29 ft. lbs.).

(12) Install first row seat belt lower anchor bolt.

Torque bolt to 39 N´m (29 ft. lbs.).

(13) Install first and second row seats.

SEAT BELT & RETRACTOR -

SECOND ROW - RIGHT

OUTBOARD WITH REAR HVAC

-LWB

REMOVAL

(1) Remove first and second row seats.

(2) Remove first row seat belt lower anchor bolt.

(3) Remove first row seat belt upper anchor bolt.

(4) Remove liftgate sill plate.

(5) Remove upper liftgate trim.

(6) Remove second seat belt lower anchor bolt.

(7) Remove second seat belt upper anchor bolt.

(8) Remove D-pillar trim cover.

(9) Disconnect speaker connector. The left side has

the speaker mounted in the D-pillar trim cover and

the right side will have the speaker mounted in the

rear of the quarter trim panel, but the connector is

accessible from the rear after the D-pillar trim is

removed.

(10) Remove quarter trim bolster.

(11) Remove quarter trim panel screws.

(12) Remove quarter trim panel.

(13) Loosen HVAC unit enough to gain access to

seat belt retractor fasteners.

(a) Remove bracket around HVAC unit (Fig. 51).

(b) Remove air duct (Fig. 52).

(c) Remove fasteners attaching HVAC unit to

inner quarter panel (Fig. 53).

(d) Gently pry out on rear HVAC unit to gain

access to the seat belt and retractor.

(14) Remove bolts attaching seat belt guide loop to

inner quarter panel.

(15) Pull outward on HVAC unit and remove bolt

attaching retractor to inner quarter panel.

(16) Remove second row seat belt and retractor

from vehicle.

INSTALLATION

(1) Position second row seat belt and retractor to

vehicle.

(2) Pull outward on HVAC unit and install bolt

attaching retractor to inner quarter panel. Torque

bolt to 39 N´m (29 ft. lbs.).

(3) Install bolts attaching seat belt guide loop to

inner quarter panel.

(4) Install fasteners attaching HVAC unit to inner

quarter panel.

(5) Install air duct.

(6) Install trim panel retaining bracket around

HVAC unit.

(7) Install quarter trim panel.

(8) Install quarter trim panel screws.

(9) Install quarter trim bolster.

(10) Connect speaker connector. The left side has

the speaker mounted in the D-pillar trim cover and

Fig. 51 TRIM PANEL MOUNTING BRACKET

1 - TRIM PANEL MOUNTING BRACKET

Fig. 52 LOWER HEATER DUCT

1 - LOWER HEAT DUCT MOUNTING

RSRESTRAINTS8O-41

SEAT BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD (Continued)