tow bar CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 346 of 2339

HEATED SYSTEMS

TABLE OF CONTENTS

page page

HEATED GLASS........................... 1

HEATED MIRRORS......................... 6HEATED SEAT SYSTEM..................... 7

HEATED GLASS

TABLE OF CONTENTS

page page

HEATED GLASS

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

ELECTRIC BACKLIGHT (EBL) SYSTEM.....2

REAR WINDOW DEFOGGER RELAY

DESCRIPTION..........................3

OPERATION............................3REMOVAL.............................4

INSTALLATION..........................4

REAR WINDOW DEFOGGER SWITCH

DESCRIPTION..........................4

OPERATION............................4

REAR WINDOW DEFOGGER GRID

STANDARD PROCEDURE

GRID REPAIR PROCEDURE..............5

HEATED GLASS

DESCRIPTION

CAUTION: Grid lines can be damaged or scraped

off with sharp instruments. Care should be taken in

cleaning glass or removing foreign materials,

decals or stickers. Normal glass cleaning solvents

or hot water used with rags or toweling is recom-

mended.

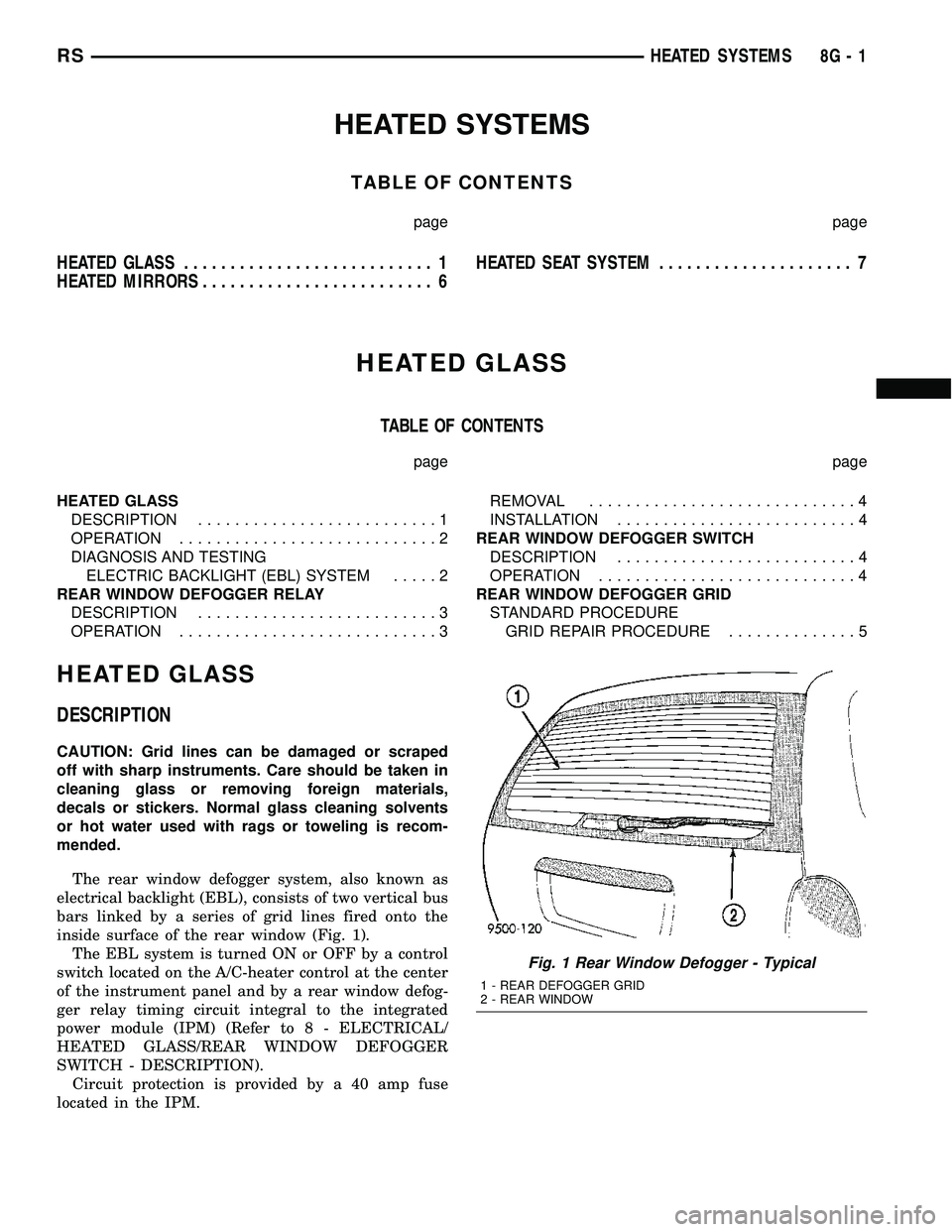

The rear window defogger system, also known as

electrical backlight (EBL), consists of two vertical bus

bars linked by a series of grid lines fired onto the

inside surface of the rear window (Fig. 1).

The EBL system is turned ON or OFF by a control

switch located on the A/C-heater control at the center

of the instrument panel and by a rear window defog-

ger relay timing circuit integral to the integrated

power module (IPM) (Refer to 8 - ELECTRICAL/

HEATED GLASS/REAR WINDOW DEFOGGER

SWITCH - DESCRIPTION).

Circuit protection is provided by a 40 amp fuse

located in the IPM.

Fig. 1 Rear Window Defogger - Typical

1 - REAR DEFOGGER GRID

2 - REAR WINDOW

RSHEATED SYSTEMS8G-1

Page 1187 of 2339

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

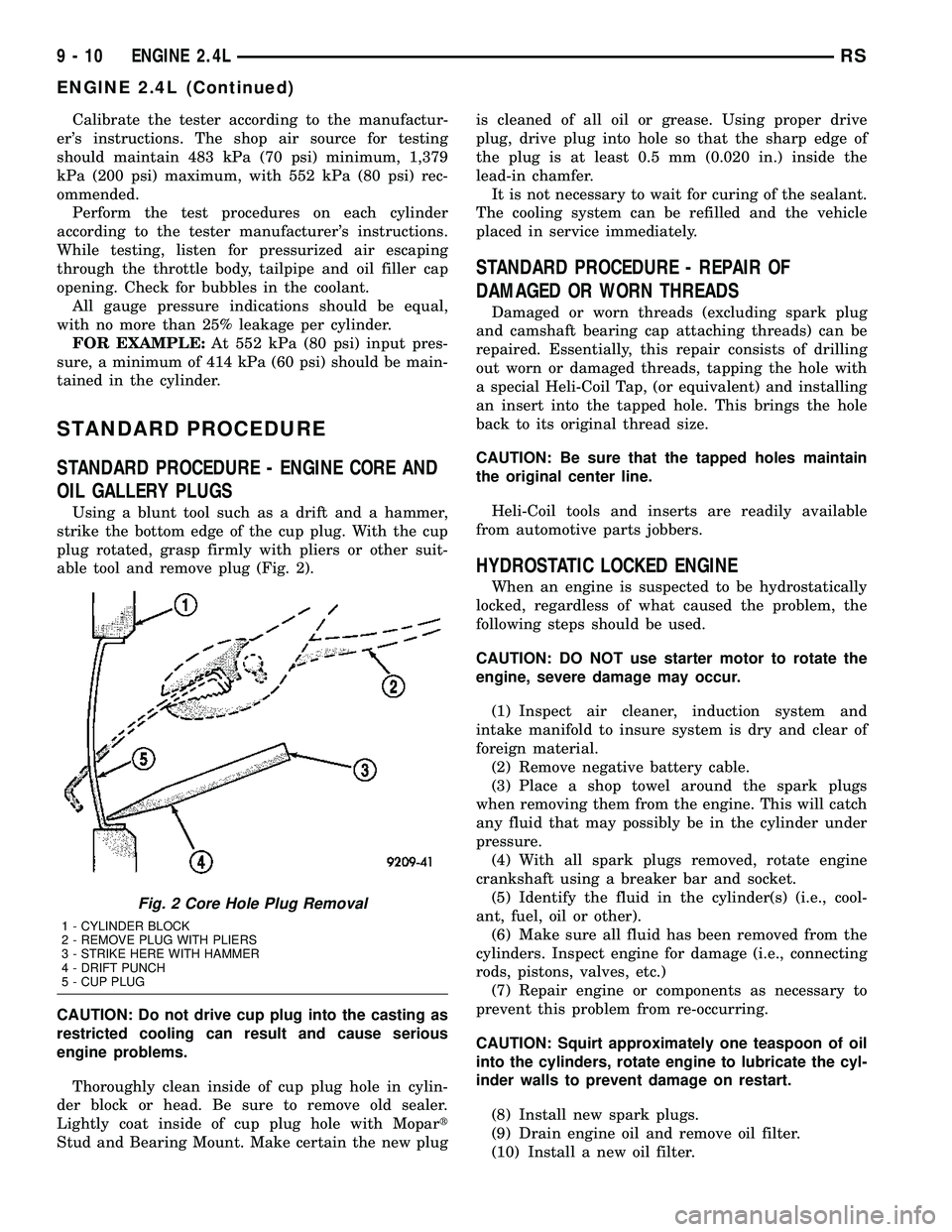

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 2).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plugis cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS

Damaged or worn threads (excluding spark plug

and camshaft bearing cap attaching threads) can be

repaired. Essentially, this repair consists of drilling

out worn or damaged threads, tapping the hole with

a special Heli-Coil Tap, (or equivalent) and installing

an insert into the tapped hole. This brings the hole

back to its original thread size.

CAUTION: Be sure that the tapped holes maintain

the original center line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

Fig. 2 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

9 - 10 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1265 of 2339

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

STANDARD PROCEDURE - REPAIR OF

DAMAGED OR WORN THREADS

Damaged or worn threads (excluding spark plug

and camshaft bearing cap attaching threads) can be

repaired. Essentially, this repair consists of drilling

out worn or damaged threads, tapping the hole with

a special Heli-Coil Tap, (or equivalent) and installing

an insert into the tapped hole. This brings the hole

back to its original thread size.

CAUTION: Be sure that the tapped holes maintain

the original center line.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 5).

CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plugis cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL - ENGINE ASSEMBLY

(1) Perform fuel pressure release procedure (Refer

to 14 - FUEL SYSTEM/FUEL DELIVERY - STAN-

DARD PROCEDURE).

(2) Disconnect negative battery cable.

(3) Remove air cleaner and hoses.

(4) Disconnect the fuel line from fuel rail (Refer to

14 - FUEL SYSTEM/FUEL DELIVERY/QUICK

CONNECT FITTING - STANDARD PROCEDURE).

(5) Remove the wiper module (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

REMOVAL).

(6) Block off heater hoses to the rear heater sys-

tem using pinch-off pliers (if equipped).

(7) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(8) Disconnect the heater hoses.

(9) Remove the radiator upper support crossmem-

ber (Refer to 23 - BODY/EXTERIOR/GRILLE OPEN-

ING REINFORCEMENT - REMOVAL).

(10) Remove the radiator fans (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - REMOVAL).

(11) Disconnect the throttle cables from the throt-

tle body.

(12) Disconnect the MAP, IAC, and TPS electrical

connectors.

Fig. 5 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

9 - 88 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 1411 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

4. Loose lower control arm mounting

bolts at front suspension

crossmember.4. Tighten control arm mounting bolts to

the specified torques.

5. Lower control arm pivot bushing

worn.5. Replace lower control arm pivot

bushing.

6. Loose strut assembly mounting

fasteners at tower or knuckle.6. Tighten strut assembly fasteners to

the specified torque.

7. Power steering fluid hose touching

the body of the vehicle.7. Adjust hose to proper position by

loosening, repositioning, and tightening

attachments to specified torque. Do not

bend tubing.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

9. Stabilizer bar link ball joints worn. 9. Replace stabilizer bar link.

10. Lug nuts loose. 10. Tighten lug nuts to specifications.

11. Excessive Wheel bearing

free-play.11. Verify correct halfshaft hub nut

torque. Replace hub and bearing if

torque is okay.

12. Internal power steering gear

noise.12. Replace power steering gear.

POPPING NOISE 1. Worn outer tie rod. 1. Check ball joint for free-play;

Replace outer tie rod.

2. Loose inner tie rod. 2. Replace power steering gear.

CHIRP OR SQUEAL

(POWER STEERING

PUMP)1. Loose power steering pump drive

belt.1. Check and adjust power steering

pump drive belt to specifications or

replace automatic tensioner where

applicable. Replace belt if worn or

glazed.

2. Malfuctioning belt auto-tensioner 2. Replace belt auto-tensioner.

WHINE, GROWL, MOAN

OR GROAN (POWER

STEERING PUMP)***1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level and check for leaks (make

sure all air is bled from the system

fluid).

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing. Replace hose if damaged.

3. Extremely low ambient

temperature.3. Some noise can be expected, but will

go away as vehicle warms. Replace

pump if noise is excessive.

4. Extreme wear of power steering

pump internal components.4. Replace power steering pump and

flush system as necessary.

19 - 4 STEERINGRS

STEERING (Continued)

Page 1798 of 2339

(10) Verify door latch and power door lock opera-

tion.

(11) Install watershield and front door trim panel.

LATCH STRIKER

REMOVAL

(1) Mark outline of door striker on B-pillar to aid

in installation.

(2) Remove screws attaching door latch striker to

B-pillar (Fig. 10).

(3) Remove door latch striker from vehicle.

(4) Retrieve any shims found between latch striker

and B-pillar.

INSTALLATION

(1) Position latch striker and any shims retrieved

on vehicle.

(2) Loosely install screws attaching latch striker to

B-pillar.

(3) Align latch striker to outline on B-pillar made

previously.

(4) Tighten fasteners to 28 N´m (21 ft. lbs.) torque.

(5) Verify door fit and operation. Adjust latch

striker as necessary.

LOCK CYLINDER

REMOVAL

(1) Roll door glass up.

(2) Remove front door watershield as necessary to

gain access to the outside door handle. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(3) Through access hole at rear of inner door

panel, disconnect Vehicle Theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch (Fig. 11).

(6) Remove latch linkage from latch.

(7) Disengage clip holding door lock linkage to

door latch.

(8) Remove lock linkage from latch.

(9) Remove nuts attaching outside door handle to

door outer panel.

(10) Remove outside door handle from vehicle.

(11) Disengage clip holding lock cylinder into out-

side handle.

(12) Pull lock cylinder from door handle.

INSTALLATION

(1) Engage clip into outside handle to hold lock

cylinder (Fig. 11).

(2) With link arm toward rear of vehicle, push lock

cylinder into door handle until clip snaps into place.

(3) Insert lock linkage into door latch.

(4) Engage clip to hold door lock linkage to latch.

(5) Insert latch linkage into door latch.

(6) Engage clip to hold door latch linkage to latch.

(7) Install push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(8) Connect VTSS switch connector into door har-

ness, if equipped.

(9) Verify door latch operation.

(10) Install watershield and door trim panel.

Fig. 10 DOOR LATCH STRIKER

1 - B-PILLAR

2 - SHIM

3 - DOOR LATCH STRIKER

RSDOOR - FRONT23-19

LATCH (Continued)

Page 1800 of 2339

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

(19) Install switch bezel.

WATERSHIELD

REMOVAL

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL)

(2) Remove the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the shield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Install the front door speaker. (Refer to 8 -

ELECTRICAL/AUDIO/SPEAKER - INSTALLATION)

(4) Install door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - INSTALLATION)

WINDOW CRANK

REMOVAL

(1) Using a window crank removal tool, disengage

clip attaching window crank to regulator shaft (Fig.

13).

NOTE: Wrap a shop towel around the window crank

to catch the clip when it springs out.

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Place the clip on to the window crank handle.

(2) Position window crank to regulator shaft.

(3) Push window crank onto regulator shaft to

engage retaining clip.

EXTERIOR HANDLE

REMOVAL

(1) Roll door glass up.

(2) Remove the watershield as necessary to gain

access to the outside door handle. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(3) Through access hole at rear of inner door

panel, disconnect Vehicle Theft Security System

(VTSS) switch connector from door harness, if

equipped.

(4) Disengage push in fasteners attaching VTSS

switch harness to inner door reinforcement bar, if

equipped.

(5) Disengage clip holding door latch linkage to

door latch (Fig. 11).

(6) Remove latch linkage from latch.

Fig. 13 WINDOW CRANK - TYPICAL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

RSDOOR - FRONT23-21

TRIM PANEL (Continued)

Page 1838 of 2339

INSTALLATION

NOTE: The crossbar assemblies are designed to be

installed in only one way. Check top and bottom

surfaces of the crossbar for the word FRONT and

directional arrows. The directional arrows must

point toward the front of the vehicle.

(1) Place crossbar in position on vehicle.

(2) Work from side to side sliding the crossbar

assembly back a little at a time to ensure it remains

perpendicular to the side rails.

(3) Position first crossbar assembly crossbar at the

second most rearward locator holes. Press the top of

the stanchion lever to lock it into position.

(4) Position the second crossbar assembly in the

second hole from the front. Lock into place.

(5) Place luggage rack riser into position.

(6) Install two fasteners into riser. Tighten fasten-

ers to 4 mm (35 in. lbs.) torque.

REAR QUARTER PANEL/

FENDER AIR EXHAUSTER

DESCRIPTION

Air exhausters, designed to conform to the body

structure, allow air entering at the front of the vehi-

cle to flow out the back. By reducing air pressure

within the vehicle, the exhausters also reduce blower

noise at any given air flow level compared to operat-

ing without them and help reduce door closing effort.

They are located in the lower rear comers of the

body.

REMOVAL

SHORT WHEELBASE

(1) Remove the rear fascia from the body. (Refer to

13 - FRAMES & BUMPERS/BUMPERS/REAR FAS-

CIA - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 21).

(3) Remove the air exhauster from the hole in the

lower aperture panel.

LONG WHEELBASE

NOTE: Models with the optional rear heater and air

conditioner do not have an air exhauster on the

right side of the vehicle, but have a plastic plug

installed in the right lower aperture panel. This plug

is removed using the same procedure used toremove the air exhauster from the short wheelbase

model. Refer to SHORT WHEELBASE.

(1) Remove the quarter trim panel from the inside

of the left or right quarter inner panel (Refer to 23 -

BODY/INTERIOR/RIGHT QUARTER TRIM PANEL

- REMOVAL) or (Refer to 23 - BODY/INTERIOR/

LEFT QUARTER TRIM PANEL - REMOVAL).

(2) Using a trim stick or another suitable wide flat

bladed tool, carefully pry the air exhauster away

from the opening in the lower aperture panel until

the snap features release (Fig. 22).

(1) Remove the air exhauster from the hole in the

lower aperture panel.

Fig. 21 AIR EXHAUSTER - SWB

1 - LOWER APERTURE PANEL

2 - AIR EXHAUSTER

Fig. 22 AIR EXHAUSTER - LWB

1 - AIR EXHAUSTER

2 - PLUG

3 - LOWER APERTURE PANEL

RSEXTERIOR23-59

LUGGAGE RACK CROSSBAR (Continued)

Page 2304 of 2339

BACKLIGHT (EBL) SYSTEM, DIAGNOSISAND TESTING - ELECTRIC ..............8G-2

BACKSTOW STRAP - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-158

BACKSTOW STRAP - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-158

BAG RETAINER - INSTALLATION, PLASTIC GROCERY .................. 23-149

BAG RETAINER - REMOVAL, PLASTIC GROCERY ......................... 23-149

BALANCE - STANDARD PROCEDURE, TIRE AND WHEEL ..................... 22-5

BALANCE SHAFTS AND CARRIER ASSEMBLY - DESCRIPTION .............9-71

BALANCE SHAFTS AND CARRIER ASSEMBLY - INSTALLATION .............9-73

BALANCE SHAFTS AND CARRIER ASSEMBLY - OPERATION ...............9-71

BALANCE SHAFTS AND CARRIER ASSEMBLY - REMOVAL .................9-71

BALL JOINT - DESCRIPTION, LOWER ......2-10

BALL JOINT - DIAGNOSIS AND TESTING, LOWER ............................. 2-10

BALL JOINT - OPERATION, LOWER .......2-10

BAR - DESCRIPTION, STABILIZER ....2-16,2-44

BAR - DESCRIPTION, TRACK ............2-45

BAR - INSPECTION, STABILIZER ..........2-17

BAR - INSTALLATION, STABILIZER ........2-17

BAR - INSTALLATION, TRACK ............2-46

BAR - OPERATION, STABILIZER ......2-16,2-44

BAR - OPERATION, TRACK ................2-46

BAR - REMOVAL, STABILIZER ...........2-17

BAR - REMOVAL, TRACK ...............2-46

BAR CUSHION - INSTALLATION, STABILIZER ...........................2-4

BAR CUSHION - REMOVAL, STABILIZER ....2-4

BASE BRAKE BLEEDING - STANDARD PROCEDURE ..........................5-8

BASE BRAKE SYSTEM - DIAGNOSIS AND TESTING .............................5-4

BASE BRAKE SYSTEM, SPECIAL TOOLS ....5-10

BASE BRAKES - DESCRIPTION ............5-3

BASE BRAKES - OPERATION ..............5-3

BASE BRAKES (EXPORT) - DESCRIPTION . . . 5-3

BASE COAT/CLEARCOAT FINISH - DESCRIPTION ...................... 23-101

BASE RISER - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-135

BASE RISER - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-134

BASE TRAY - INSTALLATION, FLOOR CONSOLE ........................... 23-89

BASE TRAY - REMOVAL, FLOOR CONSOLE ........................... 23-89

BATTERY - DESCRIPTION ...............8F-7

BATTERY - OPERATION .................8F-9

BATTERY - REMOVAL .................8F-16

BATTERY - SPECIFICATIONS ............8N-24

BATTERY CABLES - DESCRIPTION .......8F-16

BATTERY CABLES - OPERATION .........8F-17

BATTERY CABLES, DIAGNOSIS AND TESTING ........................... 8F-17

BATTERY CHARGING, STANDARD PROCEDURE - CONVENTIONAL ..........8F-11

BATTERY CHARGING, STANDARD PROCEDURE - SPIRAL PLATE ...........8F-10

BATTERY, DIAGNOSIS AND TESTING ......8F-9

BATTERY ELECTROLYTE LEVEL, STANDARD PROCEDURE - CHECKING ....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-16

BATTERY HOLDDOWN - REMOVAL .......8F-16

BATTERY REPLACEMENT - STANDARD PROCEDURE ........................ 8N-24

BATTERY, SPECIFICATIONS ..............8F-6

BATTERY SYSTEM - DESCRIPTION ........8F-1

BATTERY SYSTEM - OPERATION .........8F-2

BATTERY SYSTEM, DIAGNOSIS AND TESTING ............................ 8F-2

BATTERY SYSTEM SPECIAL TOOLS, SPECIAL TOOLS ...................... 8F-7

BATTERY TEMPERATURE SENSOR - DESCRIPTION ....................... 8F-24

BATTERY TEMPERATURE SENSOR - OPERATION ......................... 8F-24

BATTERY TEMPERATURE SENSOR - REMOVAL .......................... 8F-24

BATTERY TEMPERATURE SENSOR - SPECIFICATIONS ..................... 8F-23BATTERY TESTER, STANDARD

PROCEDURE - MICRO 420 .............8F-15

BATTERY TRAY - DESCRIPTION .........8F-19

BATTERY TRAY - INSTALLATION .........8F-20

BATTERY TRAY - REMOVAL ............8F-19

BEARING - DESCRIPTION, HUB .......2-30,2-5

BEARING - DIAGNOSIS AND TESTING, HUB............................. 2-31,2-5

BEARING - INSTALLATION, HUB .......2-33,2-5

BEARING - OPERATION, HUB .........2-30,2-5

BEARING - REMOVAL, HUB ..........2-31,2-5

BEARING CLEARANCE - STANDARD PROCEDURE, MEASURING

CONNECTING ROD ................... 9-123

BEARING CLEARANCE USING PLASTIGAGE - STANDARD

PROCEDURE, MEASURING ..........9-12,9-86

BEARING FITTING - STANDARD PROCEDURE, MAIN ................... 9-125

BEARING PRELOAD - ADJUSTMENT, DIFFERENTIAL ...................... 21-228

BEARING PRELOAD MEASUREMENT AND ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL ....................... 21-79

BEARINGS - INSTALLATION, CRANKSHAFT MAIN .................. 9-127

BEARINGS - REMOVAL, CRANKSHAFT MAIN .............................. 9-127

BEARINGS (IN BLOCK) - DESCRIPTION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - INSPECTION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - INSTALLATION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - OPERATION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - REMOVAL, CAMSHAFT ......................... 9-118

BELLCRANK - INSTALLATION ...........23-35

BELLCRANK - REMOVAL ...............23-35

BELT - DIAGNOSIS AND TESTING, ACCESSORY DRIVE .....................7-7

BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER LAP ..............23-157

BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER LAP ..............23-157

BELT - INSTALLATION, TIMING ...........9-67

BELT - REMOVAL, TIMING ..............9-65

BELT & RETRACTOR - FIRST ROW - OUTBOARD - INSTALLATION, SEAT ......8O-40

BELT & RETRACTOR - FIRST ROW - OUTBOARD - REMOVAL, SEAT ..........8O-39

BELT & RETRACTOR - OUTBOARD - FRONT - INSTALLATION, SEAT ..........8O-39

BELT & RETRACTOR - OUTBOARD - FRONT - REMOVAL, SEAT ..............8O-38

BELT & RETRACTOR - SECOND ROW - LEFT OUTBOARD - INSTALLATION,

SEAT .............................. 8O-42

BELT & RETRACTOR - SECOND ROW - LEFT OUTBOARD - REMOVAL, SEAT .....8O-42

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD - INSTALLATION,

SEAT .............................. 8O-40

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD - REMOVAL, SEAT ....8O-40

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD WITH REAR HVAC -

LWB - INSTALLATION, SEAT ............8O-41

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD WITH REAR HVAC -

LWB - REMOVAL, SEAT ...............8O-41

BELT BUCKLE - FIRST ROW - BENCH - INSTALLATION, SEAT .................8O-37

BELT BUCKLE - FIRST ROW - BENCH - REMOVAL, SEAT ..................... 8O-36

BELT BUCKLE - FIRST ROW INBOARD - QUAD BUCKET - INSTALLATION, SEAT ....8O-36

BELT BUCKLE - FIRST ROW INBOARD - QUAD BUCKET - REMOVAL, SEAT .......8O-35

BELT BUCKLE - FRONT INBOARD - INSTALLATION, SEAT .................8O-35

BELT BUCKLE - FRONT INBOARD - REMOVAL, SEAT ..................... 8O-35

BELT BUCKLE - SECOND ROW - THREE PASSENGER BENCH - INSTALLATION,

SEAT .............................. 8O-40BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH - REMOVAL, SEAT . . . 8O-40

BELT BUCKLE - SECOND ROW INBOARD - 50/50 BENCH - INSTALLATION, SEAT . . . 8O-38

BELT BUCKLE - SECOND ROW INBOARD - 50/50 BENCH - REMOVAL, SEAT .......8O-37

BELT CENTER LAP BELT - FOLD-IN- FLOOR - INSTALLATION, SEAT .........23-157

BELT CENTER LAP BELT - FOLD-IN- FLOOR - REMOVAL, SEAT .............23-157

BELT COVER(S) - INSTALLATION, TIMING ............................. 9-64

BELT COVER(S) - REMOVAL, TIMING ......9-63

BELT HEIGHT ADJUSTE R-BOR

C-PILLAR - INSTALLATION, SEAT ........8O-38

BELT HEIGHT ADJUSTE R-BOR

C-PILLAR - REMOVAL, SEAT ...........8O-38

BELT HEIGHT ADJUSTER KNOB - INSTALLATION, SEAT .................8O-38

BELT HEIGHT ADJUSTER KNOB - REMOVAL, SEAT ..................... 8O-38

BELT MOLDING - INSTALLATION, FRONT DOOR INNER ....................... 23-168

BELT MOLDING - INSTALLATION, FRONT DOOR OUTER ...................... 23-167

BELT MOLDING - REMOVAL, FRONT DOOR INNER ....................... 23-168

BELT MOLDING - REMOVAL, FRONT DOOR OUTER ...................... 23-167

BELT TENSION - STANDARD PROCEDURE, CHECKING POWER

STEERING ............................7-8

BELT TENSION SENSOR - DESCRIPTION . . . 8O-8

BELT TENSION SENSOR - OPERATION .....8O-9

BELT TENSION, SPECIFICATIONS - ACCESSORY DRIVE .....................7-5

BELT TENSIONER - 2.4L - INSTALLATION . . 7-11

BELT TENSIONER - 2.4L - REMOVAL ......7-11

BELT TENSIONER - 3.3/3.8L - INSTALLATION ........................ 7-12

BELT TENSIONER - 3.3/3.8L - REMOVAL . . . 7-12

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-43

BELT TENSIONER - OPERATION, SEAT ....8O-43

BELT TENSIONER & PULLEY - INSTALLATION, TIMING .................9-70

BELT TENSIONER & PULLEY - REMOVAL, TIMING .................... 9-69

BELTS - 2.4L - ADJUSTMENTS, DRIVE .....7-10

BELTS - 2.4L - INSTALLATION, DRIVE ......7-9

BELTS - 2.4L - REMOVAL, DRIVE ..........7-9

BELTS - 3.3/3.8L - INSTALLATION, DRIVE . . 7-12

BELTS - 3.3/3.8L - REMOVAL, DRIVE ......7-11

BELTS - CLEANING, DRIVE ...............7-8

BELTS - INSPECTION, DRIVE .............7-8

BENCH - INSTALLATION, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50

SPLIT ............................. 23-146

BENCH - INSTALLATION, SEAT BELT BUCKLE - FIRST ROW ................8O-37

BENCH - INSTALLATION, SEAT BELT BUCKLE - SECOND ROW - THREE

PASSENGER ........................ 8O-40

BENCH - INSTALLATION, SEAT BELT BUCKLE - SECOND ROW INBOARD -

50/50 .............................. 8O-38

BENCH - INSTALLATION, SEAT CUSHION COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-144

BENCH - REMOVAL, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50 SPLIT . . 23-146

BENCH - REMOVAL, SEAT BELT BUCKLE - FIRST ROW ....................... 8O-36

BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW - THREE PASSENGER ....8O-40

BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW INBOARD - 50/50 .......8O-37

BENCH - REMOVAL, SEAT CUSHION COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-144

BENCH SEAT - REMOVAL, CHILD SEAT MODULE .......................... 23-104

BENCH SEAT BACK - INSTALLATION .....23-147

BENCH SEAT BACK - REMOVAL ........23-147

BENCH SEAT BACK COVER - INSTALLATION ...................... 23-148

BENCH SEAT BACK COVER - REMOVAL . . 23-148

BENCH SEAT BACK HINGE - REMOVAL . . 23-146

BENCH SEAT BACK PANEL - INSTALLATION ...................... 23-144

BENCH SEAT BACK PANEL - REMOVAL . . 23-143

RS INDEX3

Description Group-Page Description Group-Page Description Group-Page

Page 2332 of 2339

STORAGE BIN GUIDE - INSTALLATION,UNDER SEAT ....................... 23-150

STORAGE BIN GUIDE - REMOVAL, UNDER SEAT ....................... 23-150

STORAGE BIN LOCK/LATCH - INSTALLATION, UNDER SEAT ..........23-150

STORAGE BIN LOCK/LATCH - REMOVAL, UNDER SEAT ....................... 23-150

STRAP - INSTALLATION, CHECK .........23-15

STRAP - INSTALLATION, FRONT SEAT BACK ASSIST ...................... 23-112

STRAP - REMOVAL, CHECK ............23-15

STRAP - REMOVAL, FRONT SEAT BACK ASSIST ........................... 23-112

STRAP - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACKSTOW .....23-158

STRAP - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACKSTOW .........23-158

STRIKER - INSTALLATION, CENTER ......23-28

STRIKER - INSTALLATION, FUEL FILL DOOR BLOCKER LATCH ...............23-53

STRIKER - INSTALLATION, GLOVE BOX LATCH ............................. 23-66

STRIKER - INSTALLATION, HOLD OPEN LATCH ............................. 23-26

STRIKER - INSTALLATION, LATCH . . 23-19,23-42, 23-64

STRIKER - INSTALLATION, REAR LATCH . . 23-29

STRIKER - REMOVAL, CENTER ..........23-28

STRIKER - REMOVAL, FUEL FILL DOOR BLOCKER LATCH ..................... 23-53

STRIKER - REMOVAL, GLOVE BOX LATCH ............................. 23-66

STRIKER - REMOVAL, HOLD OPEN LATCH ............................. 23-26

STRIKER - REMOVAL, LATCH . 23-19,23-41,23-64

STRIKER - REMOVAL, REAR LATCH ......23-29

STRIPPED THREAD REPAIR - STANDARD PROCEDURE, MANIFOLD ..............9-147

STRUCTURAL ADHESIVE LOCATIONS - FOLD-IN-FLOOR ONLY -

SPECIFICATIONS .................... 23-228

STRUCTURAL ADHESIVE LOCATIONS - SPECIFICATIONS .................... 23-218

STRUCTURAL COLLAR - INSTALLATION ....9-49

STRUCTURAL COLLAR - REMOVAL .......9-49

STRUT - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION, SEAT GAS .....23-139

STRUT - SECOND ROW - FOLD-IN- FLOOR - REMOVAL, SEAT GAS .........23-138

STRUT ASSEMBLY - ASSEMBLY ..........2-23

STRUT ASSEMBLY - DESCRIPTION .......2-19

STRUT ASSEMBLY - DIAGNOSIS AND TESTING ............................ 2-20

STRUT ASSEMBLY - DISASSEMBLY .......2-21

STRUT ASSEMBLY - INSTALLATION .......2-25

STRUT ASSEMBLY - OPERATION .........2-19

STRUT ASSEMBLY - REMOVAL ...........2-20

STUDS - FRONT - INSTALLATION, WHEEL MOUNTING ................... 22-21

STUDS - FRONT - REMOVAL, WHEEL MOUNTING ......................... 22-21

STUDS - REAR - INSTALLATION, WHEEL MOUNTING ......................... 22-22

STUDS - REAR - REMOVAL, WHEEL MOUNTING ......................... 22-22

SUCTION LINE - INSTALLATION . . . 24-107,24-97

SUCTION LINE - REMOVAL .......24-106,24-96

SUN VISOR - INSTALLATION ...........23-99

SUN VISOR - REMOVAL ...............23-99

SUN VISOR SUPPORT - INSTALLATION . . . 23-99

SUN VISOR SUPPORT - REMOVAL .......23-99

SUNROOF - DESCRIPTION ............23-169

SUNROOF ASSEMBLY - INSTALLATION . . 23-173

SUNROOF ASSEMBLY - REMOVAL ......23-173

SUNROOF DIAGNOSIS AND TESTING, DIAGNOSIS AND TESTING ............23-169

SUNROOF GLASS PANEL ADJUSTMENT, ADJUSTMENTS ..................... 23-173

SUNROOF MOTOR - INSTALLATION .....23-174

SUNROOF MOTOR - REMOVAL .........23-174

SUNROOF SWITCH - INSTALLATION .....23-176

SUNROOF SWITCH - REMOVAL ........23-176

SUNSHADE - INSTALLATION ...........23-173

SUNSHADE - REMOVAL ..............23-173

SUPPLEMENTAL CABIN HEATER, DIAGNOSIS AND TESTING ............24-114SUPPLY - PCM OUTPUT - OPERATION, 5

VOLT .............................. 8E-15

SUPPORT - INSTALLATION, LUMBAR ....23-150

SUPPORT - INSTALLATION, SUN VISOR . . . 23-99

SUPPORT - REMOVAL, LUMBAR .......23-150

SUPPORT - REMOVAL, SUN VISOR ......23-99

SUPPORT CYLINDER - INSTALLATION ....23-43

SUPPORT CYLINDER - REMOVAL ........23-42

SUPPORT PLATE - DRUM BRAKE - INSTALLATION ........................ 5-61

SUPPORT PLATE - DRUM BRAKE - REMOVAL ........................... 5-61

SUPPRESSION COMPONENTS - DESCRIPTION, RADIO NOISE ...........8A-15

SUPPRESSION COMPONENTS - OPERATION, RADIO NOISE .............8A-15

SURFACE PREPARATION - STANDARD PROCEDURE, ENGINE GASKET .......9-11,9-87

SUSPENSION - DESCRIPTION, FRONT ......2-2

SUSPENSION - DESCRIPTION, REAR ......2-26

SUSPENSION - OPERATION, FRONT ........2-2

SUSPENSION AND STEERING - DIAGNOSIS AND TESTING ..............2-50

SUSPENSION FASTENER TORQUE, SPECIFICATIONS - FRONT ................2-3

SUSPENSION FASTENER TORQUE, SPECIFICATIONS - REAR ................2-28

SUSPENSION, SPECIAL TOOLS - FRONT ....2-3

SUSPENSION, SPECIAL TOOLS - REAR ....2-28

SWITCH - DESCRIPTION .................8P-5

SWITCH - DESCRIPTION, B-PILLAR ......8N-52

SWITCH - DESCRIPTION, BRAKE FLUID LEVEL .............................. 5-10

SWITCH - DESCRIPTION, BRAKE LAMP ....8L-4

SWITCH - DESCRIPTION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - DESCRIPTION, FULL OPEN ....8N-11,

8N-52

SWITCH - DESCRIPTION, HEATED SEAT . . . 8G-8

SWITCH - DESCRIPTION, HORN ..........8H-4

SWITCH - DESCRIPTION, MEMORY ......8N-36

SWITCH - DESCRIPTION, OIL PRESSURE . 9-144

SWITCH - DESCRIPTION, REAR WINDOW DEFOGGER .................. 8G-4

SWITCH - DESCRIPTION, REAR WIPER/WASHER ..................... 8R-10

SWITCH - DESCRIPTION, SEAT .........8N-34

SWITCH - DIAGNOSIS AND TESTING, BRAKE LAMP ........................ 8L-4

SWITCH - DIAGNOSIS AND TESTING, FAILED PARK ........................ 8R-2

SWITCH - DIAGNOSIS AND TESTING, FRONT WIPER/WASHER ................8R-2

SWITCH - DIAGNOSIS AND TESTING, HEADLAMP ......................... 8L-13

SWITCH - DIAGNOSIS AND TESTING, MULTI-FUNCTION .................... 8L-18

SWITCH - DIAGNOSIS AND TESTING, TRACTION CONTROL ................... 5-94

SWITCH - EXPORT - DESCRIPTION, DOOR CYLINDER LOCK ...............8N-22

SWITCH - EXPORT - DESCRIPTION, POWER FOLDAWAY MIRROR ...........8N-29

SWITCH - EXPORT - INSTALLATION, HOOD AJAR ......................... 8Q-3

SWITCH - EXPORT - INSTALLATION, POWER FOLDAWAY MIRROR ...........8N-30

SWITCH - EXPORT - OPERATION, DOOR CYLINDER LOCK ..................... 8N-22

SWITCH - EXPORT - OPERATION, POWER FOLDAWAY MIRROR ...........8N-29

SWITCH - EXPORT - REMOVAL, HOOD AJAR ............................... 8Q-3

SWITCH - EXPORT - REMOVAL, POWER FOLDAWAY MIRROR .................. 8N-29

SWITCH - INSTALLATION ...............8P-6

SWITCH - INSTALLATION, ADJUSTABLE PEDALS ............................. 5-11

SWITCH - INSTALLATION, B-PILLAR .....8N-52

SWITCH - INSTALLATION, BRAKE FLUID LEVEL .............................. 5-11

SWITCH - INSTALLATION, BRAKE LAMP . . . 8L-5

SWITCH - INSTALLATION, CENTER CONSOLE LAMP ..................... 8L-21

SWITCH - INSTALLATION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - INSTALLATION, FULL OPEN ....8N-11 SWITCH - INSTALLATION, GLOVE BOX

LAMP .............................. 8L-22

SWITCH - INSTALLATION, HEADLAMP ....8L-13

SWITCH - INSTALLATION, IGNITION ......19-19

SWITCH - INSTALLATION, MULTI- FUNCTION .......................... 8L-18

SWITCH - INSTALLATION, OIL PRESSURE ..................... 9-144,9-56

SWITCH - INSTALLATION, SUNROOF ....23-176

SWITCH - INSTALLATION, TRACTION CONTROL ........................... 5-95

SWITCH - INSTALLATION, WASHER FLUID LEVEL ........................ 8R-11

SWITCH - OPERATION .................8P-5

SWITCH - OPERATION, B-PILLAR ........8N-52

SWITCH - OPERATION, BRAKE FLUID LEVEL .............................. 5-10

SWITCH - OPERATION, BRAKE LAMP ......8L-4

SWITCH - OPERATION, EXTERIOR HANDLE ........................... 8N-10

SWITCH - OPERATION, FULL OPEN . 8N-11,8N-52

SWITCH - OPERATION, HEATED SEAT .....8G-9

SWITCH - OPERATION, MEMORY ........8N-36

SWITCH - OPERATION, OIL PRESSURE . . . 9-144

SWITCH - OPERATION, REAR WINDOW DEFOGGER .......................... 8G-4

SWITCH - OPERATION, REAR WIPER/ WASHER ........................... 8R-11

SWITCH - OPERATION, SEAT ...........8N-34

SWITCH - REMOVAL .................... 8P-5

SWITCH - REMOVAL, ADJUSTABLE PEDALS ............................. 5-11

SWITCH - REMOVAL, B-PILLAR .........8N-52

SWITCH - REMOVAL, BRAKE FLUID LEVEL .............................. 5-11

SWITCH - REMOVAL, BRAKE LAMP .......8L-5

SWITCH - REMOVAL, CENTER CONSOLE LAMP .............................. 8L-21

SWITCH - REMOVAL, EXTERIOR HANDLE . 8N-10

SWITCH - REMOVAL, FULL OPEN .......8N-11

SWITCH - REMOVAL, GLOVE BOX LAMP . . 8L-22

SWITCH - REMOVAL, HEADLAMP ........8L-13

SWITCH - REMOVAL, IGNITION .........19-17

SWITCH - REMOVAL, MULTI-FUNCTION . . . 8L-18

SWITCH - REMOVAL, OIL PRESSURE ....9-144,

9-56

SWITCH - REMOVAL, SUNROOF ........23-176

SWITCH - REMOVAL, TRACTION CONTROL ........................... 5-95

SWITCH - REMOVAL, WASHER FLUID LEVEL ............................. 8R-11

SWITCH ASSY - DESCRIPTION, SOLENOID/PRESSURE ..........21-117,21-268

SWITCH ASSY - INSTALLATION, SOLENOID/PRESSURE ..........21-119,21-270

SWITCH ASSY - OPERATION, SOLENOID/ PRESSURE .................. 21-118,21-268

SWITCH ASSY - REMOVAL, SOLENOID/ PRESSURE .................. 21-118,21-269

SWITCH, DIAGNOSIS AND TESTING - DOOR LOCK ........................ 8N-23

SWITCH, DIAGNOSIS AND TESTING - DRIVER HEATED SEAT .................8G-9

SWITCH, DIAGNOSIS AND TESTING - DRIVER SEAT ....................... 8N-34

SWITCH, DIAGNOSIS AND TESTING - MEMORY ........................... 8N-37

SWITCH, DIAGNOSIS AND TESTING - REMOTE ........................... 8N-30

SWITCH, DIAGNOSIS AND TESTING - WINDOW ........................... 8N-63

SWITCH, EXPORT - DOOR CYLINDER LOCK .............................. 8N-22

SWITCHES - DESCRIPTION, REMOTE .....8A-16

SWITCHES - OPERATION, REMOTE ......8A-16

SWITCHES, DIAGNOSIS AND TESTING - REMOTE ........................... 8A-16

SYMBOLS - DESCRIPTION, INTERNATIONAL .......................0-1

SYNCHRONIZING CABLE ADJUSTMENT, INSTALLATION ................ 23-105,23-147

TAIL LAMP - INSTALLATION ............8L-19

TAIL LAMP - REMOVAL ................8L-18

TAIL LAMP UNIT - INSTALLATION .......8L-19

TAIL LAMP UNIT - REMOVAL ...........8L-19

TANK - DESCRIPTION, FUEL ............14-12

TANK - OPERATION, FUEL ..............14-12

RS INDEX31

Description Group-Page Description Group-Page Description Group-Page

Page 2334 of 2339

TO CYLINDER BORE FITTING -STANDARD PROCEDURE, PISTON ........9-44

TO FILLER NECK SEAL - DIAGNOSIS AND TESTING, RADIATOR CAP ...........7-28

TO GROUND - STANDARD PROCEDURE, TESTING FOR A SHORT .............8W-01-9

TO GROUND ON FUSES POWERING SEVERAL LOADS - STANDARD

PROCEDURE, TESTING FOR A SHORT . 8W-01-10

TO USE WIRING DIAGRAMS - DESCRIPTION, HOW ................8W -01-1

TONE WHEEL - INSPECTION .............5-94

TONE WHEEL RUNOUT, SPECIFICATIONS . . . 5-91

TOOLS - 2.4L ENGINE, SPECIAL ..........9-21

TOOLS - 3.3/3.8L ENGINE, SPECIAL .......9-98

TOOLS - 41TE AUTOMATIC TRANSAXLE, SPECIAL .......................... 21-213

TOOLS - BASE BRAKE SYSTEM, SPECIAL . . 5-10

TOOLS - BATTERY SYSTEM SPECIAL TOOLS, SPECIAL ...................... 8F-7

TOOLS - BODY, SPECIAL ...............23-13

TOOLS - COOLING SYSTEM, SPECIAL ......7-6

TOOLS - EXHAUST SYSTEM, SPECIAL .....11-4

TOOLS - FRONT SUSPENSION, SPECIAL ....2-3

TOOLS - FUEL, SPECIAL ...........14-27,14-4

TOOLS - OVERHEAD CONSOLE, SPECIAL . . 8M-7

TOOLS - POWER DISTRIBUTION SYSTEMS, SPECIAL ................8W -97-1

TOOLS - POWER STEERING GEAR, SPECIAL ........................... 19-34

TOOLS - POWER STEERING PUMP, SPECIAL ........................... 19-44

TOOLS - POWER STEERING, SPECIAL .....19-9

TOOLS - REAR SUSPENSION, SPECIAL ....2-28

TOOLS - WIRING/TERMINAL, SPECIAL . 8W-01-10

TOOLS, SCHEMATICS AND DIAGRAMS - SPECIAL ........................... 21-68

TOOLS, SPECIAL TOOLS - BATTERY SYSTEM SPECIAL ..................... 8F-7

TOOLS, SPECIFICATIONS - SPECIAL ......8F-24

TOP COVER - INSTALLATION, INSTRUMENT PANEL .................. 23-72

TOP COVER - REMOVAL, INSTRUMENT PANEL ............................. 23-72

TOP PAD ASSEMBLY - INSTALLATION, INSTRUMENT PANEL .................. 23-77

TOP PAD ASSEMBLY - REMOVAL, INSTRUMENT PANEL .................. 23-77

TORQUES, SPECIFICATIONS ............8F-36

TOUCH-UP - DESCRIPTION, PAINTED ....23-101

TOWING - STANDARD PROCEDURE .......0-26

TPM - CAUTION, SENSOR ..............22-11

TPM - DESCRIPTION, SENSOR ..........22-10

TPM - INSTALLATION, SENSOR .........22-11

TPM - OPERATION, SENSOR ............22-10

TPM - REMOVAL, SENSOR .............22-11

TRACK - DESCRIPTION, POWER SEAT ....8N-37

TRACK - INSTALLATION, BENCH SEAT . . . 23-148

TRACK - OPERATION, POWER SEAT .....8N-38

TRACK & RACK - DESCRIPTION, LOWER DRIVE UNIT ........................ 8N-57

TRACK & RACK - INSTALLATION, LOWER DRIVE UNIT .................. 8N-58

TRACK & RACK - OPERATION, LOWER DRIVE UNIT ........................ 8N-57

TRACK & RACK - REMOVAL, LOWER DRIVE UNIT ........................ 8N-57

TRACK - REAR COVER - INSTALLATION, FRONT SEAT ....................... 23-128

TRACK - REAR COVER - REMOVAL, FRONT SEAT ....................... 23-128

TRACK - REMOVAL, BENCH SEAT .......23-148

TRACK ADJUSTER/MANUAL - OCS - INSTALLATION, FRONT SEAT ..........23-128

TRACK ADJUSTER/MANUAL - OCS - REMOVAL, FRONT SEAT ..............23-126

TRACK ADJUSTER/POWER - OCS - INSTALLATION, FRONT SEAT ..........23-125

TRACK ADJUSTER/POWER - OCS - REMOVAL, FRONT SEAT ..............23-124

TRACK BAR - DESCRIPTION .............2-45

TRACK BAR - INSTALLATION ............2-46

TRACK BAR - OPERATION ...............2-46

TRACK BAR - REMOVAL ................2-46

TRACK, DIAGNOSIS AND TESTING - POWER SEAT ....................... 8N-38

TRACK MANUAL ADJUSTER - INSTALLATION, FRONT SEAT ..........23-126TRACK MANUAL ADJUSTER - REMOVAL,

FRONT SEAT ....................... 23-125

TRACK POWER ADJUSTER - INSTALLATION, FRONT SEAT ..........23-124

TRACK POWER ADJUSTER - REMOVAL, FRONT SEAT ....................... 23-124

TRACK REAR COVER - OCS - INSTALLATION, FRONT SEAT ..........23-129

TRACK REAR COVER - OCS - REMOVAL, FRONT SEAT ....................... 23-129

TRACTION CONTROL SWITCH - DIAGNOSIS AND TESTING ..............5-94

TRACTION CONTROL SWITCH - INSTALLATION ........................ 5-95

TRACTION CONTROL SWITCH - REMOVAL ........................... 5-95

TRACTION CONTROL SYSTEM - DESCRIPTION ........................ 5-88

TRACTION CONTROL SYSTEM - OPERATION .......................... 5-89

TRANSAXLE - DESCRIPTION, 40TE AUTOMATIC .......................... 21-2

TRANSAXLE - DESCRIPTION, 41TE AUTOMATIC ........................ 21-147

TRANSAXLE - OPERATION, 40TE AUTOMATIC .......................... 21-4

TRANSAXLE - OPERATION, 41TE AUTOMATIC ........................ 21-149

TRANSAXLE - SPECIFICATIONS, 41TE . . . 21-211, 21-66

TRANSAXLE FLUID - DESCRIPTION, AUTOMATIC/MANUAL ...................0-4

TRANSAXLE GENERAL DIAGNOSIS - DIAGNOSIS AND TESTING, 4XTE .....21-149,21-5

TRANSAXLE HYDRAULIC SCHEMATICS, SCHEMATICS AND DIAGRAMS - 4XTE . . . 21-199, 21-54

TRANSAXLE, SPECIAL TOOLS - 41TE AUTOMATIC ........................ 21-213

TRANSDUCER - DESCRIPTION, A/C PRESSURE ......................... 24-20

TRANSDUCER - OPERATION, A/C PRESSURE ......................... 24-20

TRANSDUCER, DIAGNOSIS AND TESTING - A/C PRESSURE .............24-21

TRANSFER UNIT FLUID - DESCRIPTION, AWD POWER ..........................0-6

TRANSMISSION CONTROL RELAY - DESCRIPTION ................ 21-130,21-281

TRANSMISSION CONTROL RELAY - OPERATION .................. 21-130,21-281

TRANSMISSION COOLER LINE QUICK CONNECT FITTING DISASSEMBLY/

ASSEMBLY - STANDARD PROCEDURE .....7-38

TRANSMISSION OIL COOLER - DESCRIPTION ........................ 7-39

TRANSMISSION OIL COOLER - INSPECTION ......................... 7-39

TRANSMISSION OIL COOLER LINES - INSTALLATION ........................ 7-40

TRANSMISSION OIL COOLER LINES - REMOVAL ........................... 7-39

TRANSMISSION RANGE SENSOR - DESCRIPTION ................ 21-130,21-281

TRANSMISSION RANGE SENSOR - INSTALLATION ................ 21-131,21-282

TRANSMISSION RANGE SENSOR - OPERATION .................. 21-131,21-282

TRANSMISSION RANGE SENSOR - REMOVAL ................... 21-131,21-282

TRANSMITTER - DESCRIPTION, UNIVERSAL ........................ 8M-11

TRANSMITTER CODES, STANDARD PROCEDURE - ERASING ..............8M-12

TRANSMITTER CODES, STANDARD PROCEDURE - SETTING ...............8M-12

TRANSMITTER, DIAGNOSIS AND TESTING - KEYLESS ENTRY ............8N-24

TRANSMITTER, DIAGNOSIS AND TESTING - UNIVERSAL ...............8M-11

TRANSMITTER PROGRAMMING - STANDARD PROCEDURE, REMOTE

KEYLESS ENTRY ..................... 8N-24

TRANSMITTER RANGE - SPECIFICATIONS ..................... 8N-24

TRANSPONDER KEY - DESCRIPTION ......8Q-6

TRANSPONDER KEY - OPERATION ........8Q-6TRANSPONDER PROGRAMMING -

STANDARD PROCEDURE ...............8Q-6

TRANSVERSE BRACKET - DESCRIPTION . . 8N-19

TRANSVERSE BRACKET - INSTALLATION . . 8N-19

TRANSVERSE BRACKET - OPERATION ....8N-19

TRANSVERSE BRACKET - REMOVAL .....8N-19

TRAY - DESCRIPTION, BATTERY .........8F-19

TRAY - INSTALLATION, BATTERY ........8F-20

TRAY - INSTALLATION, FLOOR CONSOLE BASE .............................. 23-89

TRAY - REMOVAL, BATTERY ............8F-19

TRAY - REMOVAL, FLOOR CONSOLE BASE .............................. 23-89

TREAD WEAR INDICATORS - DIAGNOSIS AND TESTING ....................... 22-16

TRIM - INSTALLATION, A-PILLAR ........23-79

TRIM - INSTALLATION, A-PILLAR LOWER EXTENSION .................. 23-79

TRIM - INSTALLATION, B-PILLAR LOWER ............................ 23-80

TRIM - INSTALLATION, B-PILLAR UPPER . . 23-80

TRIM - INSTALLATION, COWL ..........23-88

TRIM - INSTALLATION, C-PILLAR ........23-88

TRIM - INSTALLATION, REAR HEADER ....23-96

TRIM - REMOVAL, A-PILLAR ...........23-79

TRIM - REMOVAL, A-PILLAR LOWER EXTENSION ......................... 23-79

TRIM - REMOVAL, B-PILLAR LOWER .....23-79

TRIM - REMOVAL, B-PILLAR UPPER .......23-80

TRIM - REMOVAL, COWL ..............23-88

TRIM - REMOVAL, C-PILLAR ...........23-88

TRIM - REMOVAL, REAR HEADER .......23-96

TRIM BOLSTER - INSTALLATION, QUARTER .......................... 23-95

TRIM BOLSTER - REMOVAL, QUARTER . . . 23-95

TRIM CARE, CLEANING - WHEEL AND WHEEL ............................ 22-19

TRIM PANEL - INSTALLATION .....23-20,23-34,

23-43

TRIM PANEL - INSTALLATION, LEFT D-PILLAR ........................... 23-94

TRIM PANEL - INSTALLATION, LEFT QUARTER .......................... 23-94

TRIM PANEL - INSTALLATION, RIGHT D-PILLAR ........................... 23-98

TRIM PANEL - INSTALLATION, RIGHT QUARTER .......................... 23-97

TRIM PANEL - REMOVAL ....23-20,23-34,23-43

TRIM PANEL - REMOVAL, LEFT D-PILLAR ........................... 23-94

TRIM PANEL - REMOVAL, LEFT QUARTER .......................... 23-94

TRIM PANEL - REMOVAL, RIGHT D-PILLAR ........................... 23-97

TRIM PANEL - REMOVAL, RIGHT QUARTER .......................... 23-97

TRIM PLATE - INSTALLATION, DOOR SILL ............................... 23-89

TRIM PLATE - REMOVAL, DOOR SILL ....23-89

TRIM RING AND COVER - FOLD-IN- FLOOR - INSTALLATION, CARPET ........23-84

TRIM RING AND COVER - FOLD-IN- FLOOR - REMOVAL, CARPET ...........23-84

TRIP DEFINITION, DESCRIPTION .........25-1

TROUBLE CODES - STANDARD PROCEDURE, OBTAINING DIAGNOSTIC . . . 8E-15

TUB CARPET INSERT - FOLD-IN-FLOOR - INSTALLATION, SECOND ROW FLOOR ....23-98

TUB CARPET INSERT - FOLD-IN-FLOOR - REMOVAL, SECOND ROW FLOOR ........23-98

TUB CARPETS INSERT - FOLD-IN-FLOOR - INSTALLATION, REAR FLOOR ..........23-96

TUB CARPETS INSERT - FOLD-IN-FLOOR - REMOVAL, REAR FLOOR .............23-95

TUBE - 2.4L - DESCRIPTION, WATER PUMP INLET ......................... 7-36

TUBE - 2.4L - INSTALLATION, WATER PUMP INLET ......................... 7-36

TUBE - 2.4L - REMOVAL, WATER PUMP INLET ............................... 7-36

TUBE - 3.3/3.8L - INSTALLATION, WATER PUMP INLET ......................... 7-37

TUBE - 3.3/3.8L - REMOVAL, WATER PUMP INLET ......................... 7-37

TUBE - INSTALLATION, DRAIN .........23-172

TUBE - INSTALLATION, EXHAUST .......24-116

TUBE - INSTALLATION, FUEL TANK FILLER ............................. 14-17

RS INDEX33

Description Group-Page Description Group-Page Description Group-Page