water pump CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 238 of 2339

COOLANT

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.

DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION TESTING

Coolant concentration should be checked when any

additional coolant was added to system or after a

coolant drain, flush and refill. The coolant mixture

offers optimum engine cooling and protection against

corrosion when mixed to a freeze point of -37ÉC

(-34ÉF) to -46ÉC (-50ÉF). The use of a hydrometer or a

refractometer can be used to test coolant concentra-

tion.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mix-

ture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, and

higher the freeze protection (up to a maximum of

60% by volume glycol).

A refractometer (Special Tool 8286)(Refer to 7 -

COOLING - SPECIAL TOOLS) will test the amount

of glycol in a coolant mixture by measuring the

amount a beam of light bends as it passes through

the fluid.

Some coolant manufactures use other types of gly-

cols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freez-

ing protection and corrosion protection and is not rec-

ommended.

CAUTION: Do not mix types of coolantÐcorrosion

protection will be severely reduced.

STANDARD PROCEDURE - COOLANT SERVICE

For engine coolant recommended service schedule,

(Refer to LUBRICATION & MAINTENANCE/MAIN-

TENANCE SCHEDULES - DESCRIPTION).

RSENGINE7-19

Page 242 of 2339

INSTALLATION

(1) Install engine coolant temperature sensor (Fig.

6). Tighten sensor to 7 N´m (60 in. lbs.).

(2) Connect electrical connector to sensor (Fig. 6).

(3) Install ignition coil bracket (Fig. 5).

(4) Install ignition coil (Fig. 5).

(5) Install power steering reservoir (Fig. 4).

(6) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

ENGINE COOLANT

THERMOSTAT

DESCRIPTION

The engine cooling thermostats are a wax pellet

driven, reverse poppet choke type. The thermostat is

mounted in a housing on the coolant outlet of the

engine (Fig. 8) or (Fig. 10).

OPERATION

The engine cooling thermostat is a wax pellet

driven, reverse poppet choke type. The thermostat is

designed to provide the fastest warm up possible by

preventing leakage through it and to guarantee a

minimum engine operating temperature of 88 to

93ÉC (192 to 199ÉF). The thermostat also will auto-

matically reach wide open so it will not restrict flow

to the radiator as temperature of the coolant rises in

hot weather to around 104ÉC (220ÉF). Above this

temperature the coolant temperature is controlled by

the radiator, fan, and ambient temperature, not the

thermostat.

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolant

reaches a predetermined temperature, the wax

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

DIAGNOSIS AND TESTING - ENGINE COOLANT

THERMOSTAT

The thermostat is operated by a wax filled cham-

ber (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.

Thermostat diagnostics is included in powertrain

control module's (PCM) programing for on-board

diagnosis. The malfunction indicator light (MIL) will

illuminate and a diagnostic trouble code (DTC) will

be set when an ªopen too soonº condition occurs. Do

not change a thermostat for lack of heater perfor-

mance or temperature gauge position, unless a DTC

is present. For other probable causes, (Refer to 7 -

COOLING/ENGINE - DIAGNOSIS AND TESTING).

Thermostat failing shut is the normal long term

mode of failure, and normally, only on high mileage

vehicles. The temperature gauge will indicate this

(Refer to 7 - COOLING/ENGINE - DIAGNOSIS AND

TESTING).Fig. 6 Engine Coolant Temperature Sensor

1 - ENGINE COOLANT TEMPERATURE SENSOR

2 - CONNECTOR - ENGINE COOLANT SENSOR

3 - FITTING - HEATER SUPPLY

RSENGINE7-23

ENGINE COOLANT TEMPERATURE SENSOR - 3.3/3.8L (Continued)

Page 247 of 2339

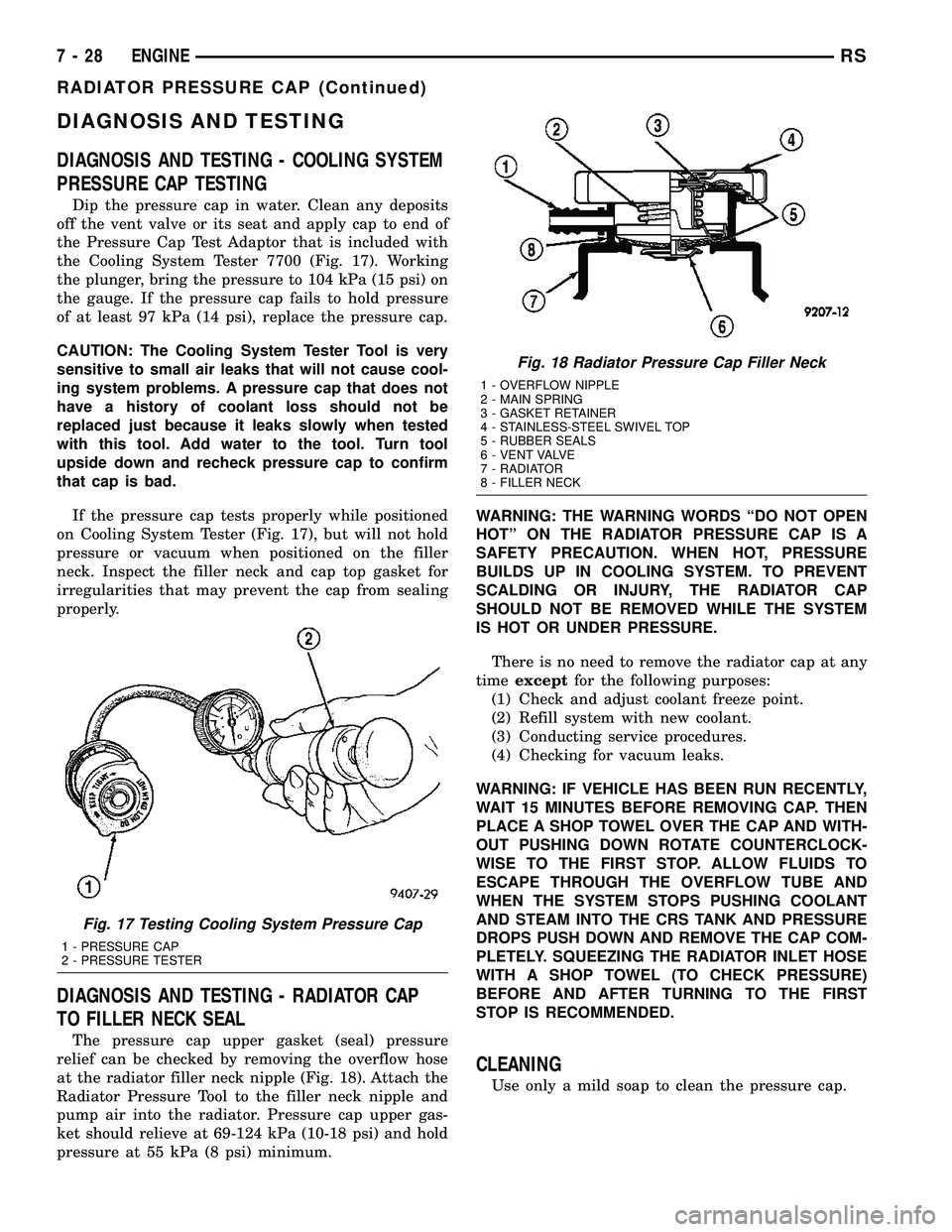

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - COOLING SYSTEM

PRESSURE CAP TESTING

Dip the pressure cap in water. Clean any deposits

off the vent valve or its seat and apply cap to end of

the Pressure Cap Test Adaptor that is included with

the Cooling System Tester 7700 (Fig. 17). Working

the plunger, bring the pressure to 104 kPa (15 psi) on

the gauge. If the pressure cap fails to hold pressure

of at least 97 kPa (14 psi), replace the pressure cap.

CAUTION: The Cooling System Tester Tool is very

sensitive to small air leaks that will not cause cool-

ing system problems. A pressure cap that does not

have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to the tool. Turn tool

upside down and recheck pressure cap to confirm

that cap is bad.

If the pressure cap tests properly while positioned

on Cooling System Tester (Fig. 17), but will not hold

pressure or vacuum when positioned on the filler

neck. Inspect the filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

DIAGNOSIS AND TESTING - RADIATOR CAP

TO FILLER NECK SEAL

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 18). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gas-

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.WARNING: THE WARNING WORDS ªDO NOT OPEN

HOTº ON THE RADIATOR PRESSURE CAP IS A

SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.

WARNING: IF VEHICLE HAS BEEN RUN RECENTLY,

WAIT 15 MINUTES BEFORE REMOVING CAP. THEN

PLACE A SHOP TOWEL OVER THE CAP AND WITH-

OUT PUSHING DOWN ROTATE COUNTERCLOCK-

WISE TO THE FIRST STOP. ALLOW FLUIDS TO

ESCAPE THROUGH THE OVERFLOW TUBE AND

WHEN THE SYSTEM STOPS PUSHING COOLANT

AND STEAM INTO THE CRS TANK AND PRESSURE

DROPS PUSH DOWN AND REMOVE THE CAP COM-

PLETELY. SQUEEZING THE RADIATOR INLET HOSE

WITH A SHOP TOWEL (TO CHECK PRESSURE)

BEFORE AND AFTER TURNING TO THE FIRST

STOP IS RECOMMENDED.

CLEANING

Use only a mild soap to clean the pressure cap.

Fig. 17 Testing Cooling System Pressure Cap

1 - PRESSURE CAP

2 - PRESSURE TESTER

Fig. 18 Radiator Pressure Cap Filler Neck

1 - OVERFLOW NIPPLE

2 - MAIN SPRING

3 - GASKET RETAINER

4 - STAINLESS-STEEL SWIVEL TOP

5 - RUBBER SEALS

6 - VENT VALVE

7 - RADIATOR

8 - FILLER NECK

7 - 28 ENGINERS

RADIATOR PRESSURE CAP (Continued)

Page 251 of 2339

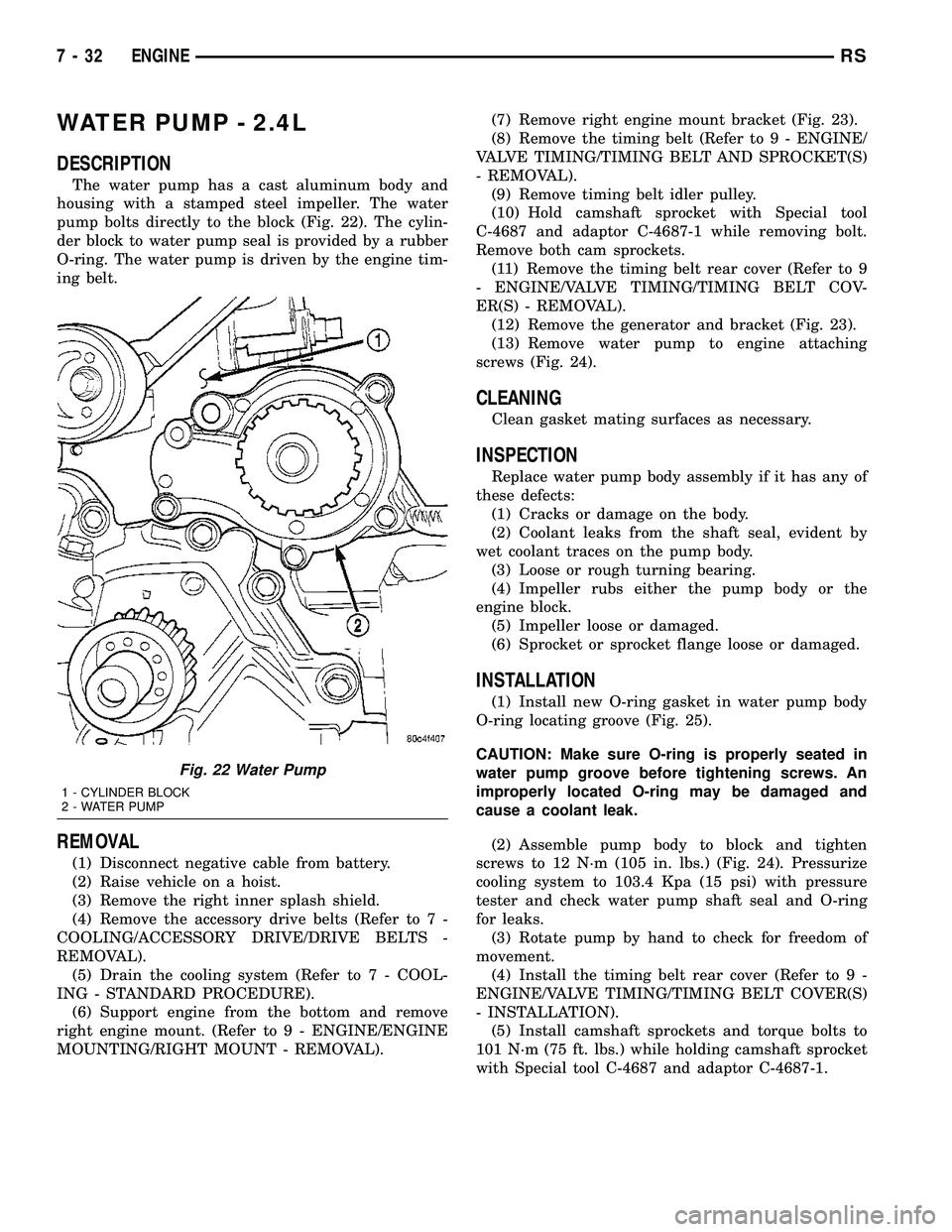

WATER PUMP - 2.4L

DESCRIPTION

The water pump has a cast aluminum body and

housing with a stamped steel impeller. The water

pump bolts directly to the block (Fig. 22). The cylin-

der block to water pump seal is provided by a rubber

O-ring. The water pump is driven by the engine tim-

ing belt.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on a hoist.

(3) Remove the right inner splash shield.

(4) Remove the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(6) Support engine from the bottom and remove

right engine mount. (Refer to 9 - ENGINE/ENGINE

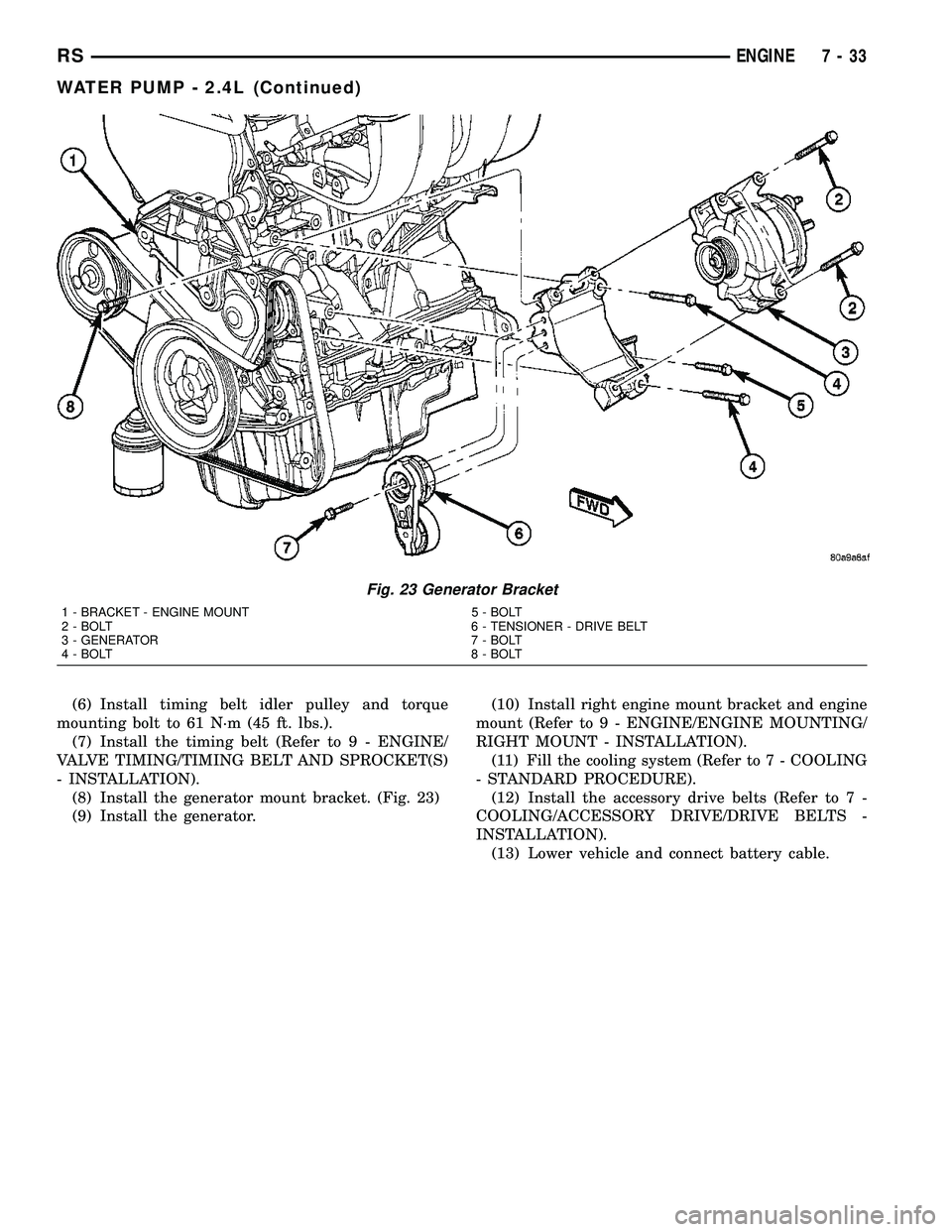

MOUNTING/RIGHT MOUNT - REMOVAL).(7) Remove right engine mount bracket (Fig. 23).

(8) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- REMOVAL).

(9) Remove timing belt idler pulley.

(10) Hold camshaft sprocket with Special tool

C-4687 and adaptor C-4687-1 while removing bolt.

Remove both cam sprockets.

(11) Remove the timing belt rear cover (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - REMOVAL).

(12) Remove the generator and bracket (Fig. 23).

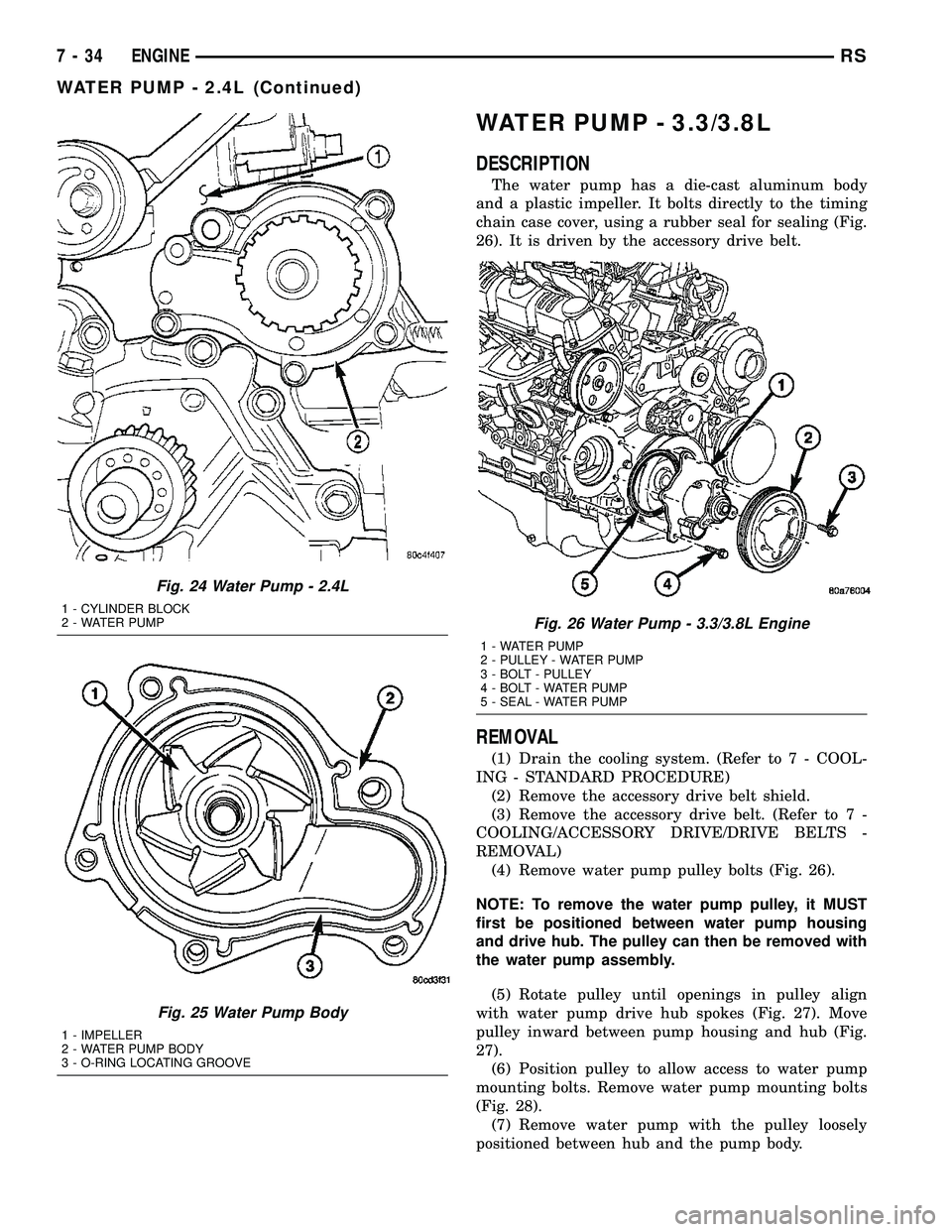

(13) Remove water pump to engine attaching

screws (Fig. 24).

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

wet coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring locating groove (Fig. 25).

CAUTION: Make sure O-ring is properly seated in

water pump groove before tightening screws. An

improperly located O-ring may be damaged and

cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.) (Fig. 24). Pressurize

cooling system to 103.4 Kpa (15 psi) with pressure

tester and check water pump shaft seal and O-ring

for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install the timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(5) Install camshaft sprockets and torque bolts to

101 N´m (75 ft. lbs.) while holding camshaft sprocket

with Special tool C-4687 and adaptor C-4687-1.

Fig. 22 Water Pump

1 - CYLINDER BLOCK

2 - WATER PUMP

7 - 32 ENGINERS

Page 252 of 2339

(6) Install timing belt idler pulley and torque

mounting bolt to 61 N´m (45 ft. lbs.).

(7) Install the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKET(S)

- INSTALLATION).

(8) Install the generator mount bracket. (Fig. 23)

(9) Install the generator.(10) Install right engine mount bracket and engine

mount (Refer to 9 - ENGINE/ENGINE MOUNTING/

RIGHT MOUNT - INSTALLATION).

(11) Fill the cooling system (Refer to 7 - COOLING

- STANDARD PROCEDURE).

(12) Install the accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Lower vehicle and connect battery cable.

Fig. 23 Generator Bracket

1 - BRACKET - ENGINE MOUNT 5 - BOLT

2 - BOLT 6 - TENSIONER - DRIVE BELT

3 - GENERATOR 7 - BOLT

4 - BOLT 8 - BOLT

RSENGINE7-33

WATER PUMP - 2.4L (Continued)

Page 253 of 2339

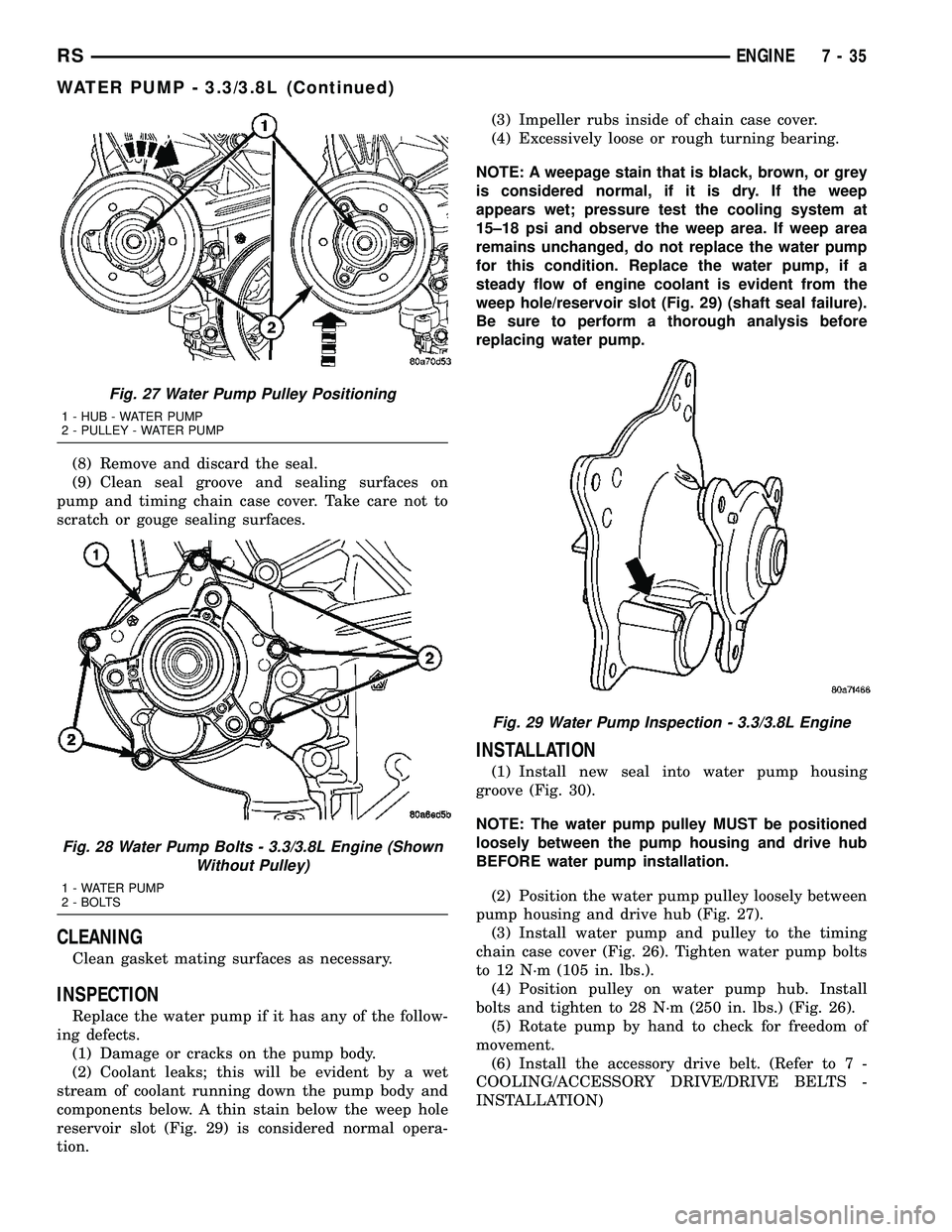

WATER PUMP - 3.3/3.8L

DESCRIPTION

The water pump has a die-cast aluminum body

and a plastic impeller. It bolts directly to the timing

chain case cover, using a rubber seal for sealing (Fig.

26). It is driven by the accessory drive belt.

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Remove the accessory drive belt shield.

(3) Remove the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove water pump pulley bolts (Fig. 26).

NOTE: To remove the water pump pulley, it MUST

first be positioned between water pump housing

and drive hub. The pulley can then be removed with

the water pump assembly.

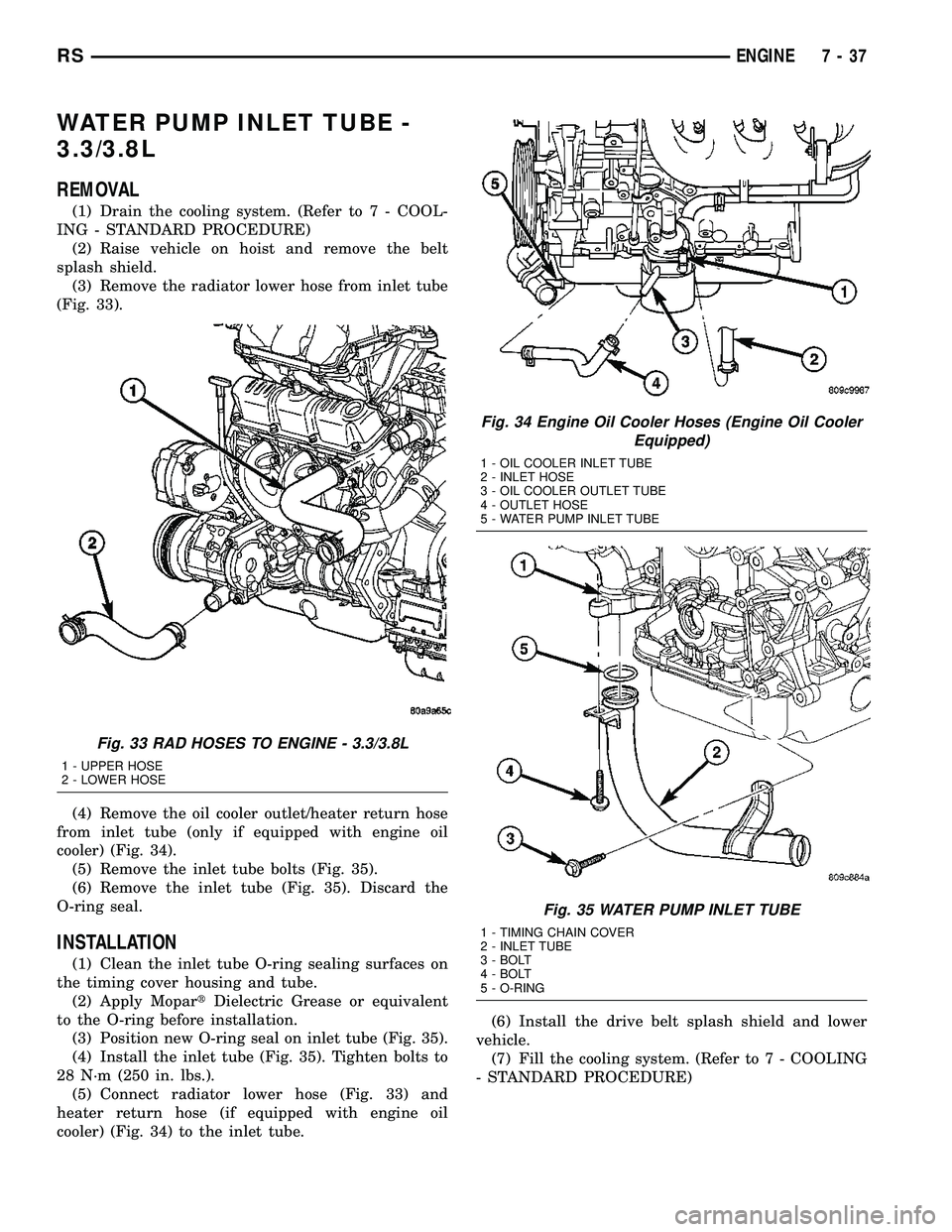

(5) Rotate pulley until openings in pulley align

with water pump drive hub spokes (Fig. 27). Move

pulley inward between pump housing and hub (Fig.

27).

(6) Position pulley to allow access to water pump

mounting bolts. Remove water pump mounting bolts

(Fig. 28).

(7) Remove water pump with the pulley loosely

positioned between hub and the pump body.

Fig. 24 Water Pump - 2.4L

1 - CYLINDER BLOCK

2 - WATER PUMP

Fig. 25 Water Pump Body

1 - IMPELLER

2 - WATER PUMP BODY

3 - O-RING LOCATING GROOVE

Fig. 26 Water Pump - 3.3/3.8L Engine

1 - WATER PUMP

2 - PULLEY - WATER PUMP

3 - BOLT - PULLEY

4 - BOLT - WATER PUMP

5 - SEAL - WATER PUMP

7 - 34 ENGINERS

WATER PUMP - 2.4L (Continued)

Page 254 of 2339

(8) Remove and discard the seal.

(9) Clean seal groove and sealing surfaces on

pump and timing chain case cover. Take care not to

scratch or gouge sealing surfaces.

CLEANING

Clean gasket mating surfaces as necessary.

INSPECTION

Replace the water pump if it has any of the follow-

ing defects.

(1) Damage or cracks on the pump body.

(2) Coolant leaks; this will be evident by a wet

stream of coolant running down the pump body and

components below. A thin stain below the weep hole

reservoir slot (Fig. 29) is considered normal opera-

tion.(3) Impeller rubs inside of chain case cover.

(4) Excessively loose or rough turning bearing.

NOTE: A weepage stain that is black, brown, or grey

is considered normal, if it is dry. If the weep

appears wet; pressure test the cooling system at

15±18 psi and observe the weep area. If weep area

remains unchanged, do not replace the water pump

for this condition. Replace the water pump, if a

steady flow of engine coolant is evident from the

weep hole/reservoir slot (Fig. 29) (shaft seal failure).

Be sure to perform a thorough analysis before

replacing water pump.

INSTALLATION

(1) Install new seal into water pump housing

groove (Fig. 30).

NOTE: The water pump pulley MUST be positioned

loosely between the pump housing and drive hub

BEFORE water pump installation.

(2) Position the water pump pulley loosely between

pump housing and drive hub (Fig. 27).

(3) Install water pump and pulley to the timing

chain case cover (Fig. 26). Tighten water pump bolts

to 12 N´m (105 in. lbs.).

(4) Position pulley on water pump hub. Install

bolts and tighten to 28 N´m (250 in. lbs.) (Fig. 26).

(5) Rotate pump by hand to check for freedom of

movement.

(6) Install the accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

Fig. 27 Water Pump Pulley Positioning

1 - HUB - WATER PUMP

2 - PULLEY - WATER PUMP

Fig. 28 Water Pump Bolts - 3.3/3.8L Engine (Shown

Without Pulley)

1 - WATER PUMP

2 - BOLTS

Fig. 29 Water Pump Inspection - 3.3/3.8L Engine

RSENGINE7-35

WATER PUMP - 3.3/3.8L (Continued)

Page 255 of 2339

(7) Install drive belt shield.

(8) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

WATER PUMP INLET TUBE -

2.4L

DESCRIPTION

The 2.4L engine uses a metal tube to connect the

engine block to the lower radiator hose and heater

return (Fig. 31). The tube has an O-ring for block to

tube sealing and bolts attach the tube to the engine

block.

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Remove radiator upper hose to access the hose

connections at the inlet tube.

(3) Remove radiator lower (Fig. 7) and heater

hoses from the inlet tube (Fig. 32).

(4) Remove the two fasteners that hold the inlet

tube to the block.

(5) Rotate tube while removing the tube from the

engine block.

INSTALLATION

(1) Inspect the O-ring for damage before installing

the tube into the cylinder block (Fig. 31).

(2) Lube O-ring with coolant and install inlet tube

into the cylinder block opening (Fig. 31).(3) Install the two inlet tube fasteners and tighten

to 12 N´m (105 in. lbs.).

(4) Connect the radiator lower hose (Fig. 7) and

heater hose to inlet tube (Fig. 32).

(5) Install the radiator upper hose.

(6) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

Fig. 30 Water Pump Seal

1 - WATER PUMP HOUSING

2 - SEAL

3 - IMPELLER

Fig. 31 Water Pump Inlet Tube - 2.4L Engine

1 - O-RING

2 - WATER PUMP INLET TUBE

Fig. 32 Water Pump Inlet Tube Hose Connections

1 - WATER PUMP INLET TUBE

2 - HOSE - HEATER RETURN

3 - COOLANT INLET

7 - 36 ENGINERS

WATER PUMP - 3.3/3.8L (Continued)

Page 256 of 2339

WATER PUMP INLET TUBE -

3.3/3.8L

REMOVAL

(1) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(2) Raise vehicle on hoist and remove the belt

splash shield.

(3) Remove the radiator lower hose from inlet tube

(Fig. 33).

(4) Remove the oil cooler outlet/heater return hose

from inlet tube (only if equipped with engine oil

cooler) (Fig. 34).

(5) Remove the inlet tube bolts (Fig. 35).

(6) Remove the inlet tube (Fig. 35). Discard the

O-ring seal.

INSTALLATION

(1) Clean the inlet tube O-ring sealing surfaces on

the timing cover housing and tube.

(2) Apply MopartDielectric Grease or equivalent

to the O-ring before installation.

(3) Position new O-ring seal on inlet tube (Fig. 35).

(4) Install the inlet tube (Fig. 35). Tighten bolts to

28 N´m (250 in. lbs.).

(5) Connect radiator lower hose (Fig. 33) and

heater return hose (if equipped with engine oil

cooler) (Fig. 34) to the inlet tube.(6) Install the drive belt splash shield and lower

vehicle.

(7) Fill the cooling system. (Refer to 7 - COOLING

- STANDARD PROCEDURE)

Fig. 33 RAD HOSES TO ENGINE - 3.3/3.8L

1 - UPPER HOSE

2 - LOWER HOSE

Fig. 34 Engine Oil Cooler Hoses (Engine Oil Cooler

Equipped)

1 - OIL COOLER INLET TUBE

2 - INLET HOSE

3 - OIL COOLER OUTLET TUBE

4 - OUTLET HOSE

5 - WATER PUMP INLET TUBE

Fig. 35 WATER PUMP INLET TUBE

1 - TIMING CHAIN COVER

2 - INLET TUBE

3 - BOLT

4 - BOLT

5 - O-RING

RSENGINE7-37

Page 583 of 2339

Component Page

Ignition Coil......................... 8W-30

Ignition Switch....................... 8W-10

Impact Sensors....................... 8W-43

Inlet Air Temperature Sensor............ 8W-30

Instrument Cluster.................... 8W-40

Instrument Panel Switch

Bank.................. 8W-43, 44, 52, 53, 63

Integrated Power Module............... 8W-10

Knock Sensor........................ 8W-30

Lamp Assemblies...................... 8W-51

License Lamp..................... 8W-51, 61

Lift Pump Motor...................... 8W-30

Lift Pump Relay...................... 8W-30

Liftgate Ajar Switch................ 8W-39, 61

Liftgate Cinch/Release Motor............ 8W-61

Liftgate Flood Lamps.................. 8W-44

Liftgate Pinch Sensors................. 8W-61

Low Beam Lamps..................... 8W-50

Manifold Absolute Pressure Sensor........ 8W-30

Mass Air Flow Sensor.................. 8W-30

Memory Seat/Mirror/Adjustable Pedals

Module...................... 8W-56, 62, 63

Memory Set Switch.................... 8W-63

Message Center.................... 8W-40, 46

Mode Door Actuator................... 8W-42

Multi-Function Switch............ 8W-50, 52, 53

Natural Vacuum Leak Detection Assembly . . 8W-30

Occupant Classification Module.......... 8W-43

Occupant Restraint Controller........... 8W-43

Overhead Console..................... 8W-49

Oxygen Sensors....................... 8W-30

Park Assist Display.................... 8W-56

Park Assist Module.................... 8W-56

Park Assist Sensors.................... 8W-56

Park Lamp Relay..................... 8W-10

Park Lamps.......................... 8W-50

Park/Turn Signal Lamps................ 8W-50

Parking Brake Switch.................. 8W-40

Power Folding Mirror Switch............ 8W-62

Power Liftgate Module................. 8W-61

Power Liftgate Motor.................. 8W-61

Power Mirror Switch................... 8W-62

Power Mirrors........................ 8W-62

Power Outlets........................ 8W-41

Power Seat Circuit Breaker.............. 8W-10

Power Seat Motors.................... 8W-63

Power Seat Position Sensors............. 8W-63

Power Seat Switches................... 8W-63

Power Window Circuit Breaker........... 8W-10

Power Window Motors.................. 8W-60

Power Window Switches................ 8W-60

Powertrain Control Module........... 8W-30, 31

PTCs............................... 8W-10

Radiator Fan Relaies................... 8W-42Component Page

Radiator Fans........................ 8W-42

Radio............................... 8W-47

Reading Lamps....................... 8W-44

Rear A/C-Heater Unit.................. 8W-42

Rear Auto Temp Control Switch.......... 8W-42

Rear Blower Control Switches............ 8W-42

Rear Blower Motor Power Module......... 8W-42

Rear Dome Lamp..................... 8W-44

Rear Intrusion Sensor.................. 8W-39

Rear Mode Motor..................... 8W-42

Rear Temperature Motor................ 8W-42

Rear View Mirror................ 8W-49, 55, 62

Rear Window Defogger Grid............. 8W-48

Rear Wiper Motor..................... 8W-53

Recirculation Door Actuator............. 8W-42

Remote Radio Switches................. 8W-47

Repeater Lamps...................... 8W-52

Seat Belt Switches.................... 8W-43

Seat Belt Tensioners................... 8W-43

Seat Weight Sensor.................... 8W-43

Sentry Key Remote Entry Module......... 8W-39

Siren............................... 8W-39

Sliding Door Control Modules............ 8W-61

Sliding Door Latch Sensing Switches...... 8W-61

Sliding Door Lock Motors............... 8W-61

Sliding Door Motors................... 8W-61

Speakers............................ 8W-47

Speed Control Servo................... 8W-33

Speed Control Switches................. 8W-33

Speed Sensors........................ 8W-31

Splices.............................. 8W-70

Starter Motor........................ 8W-21

Starter Motor Relay................... 8W-21

Sunroof Module....................... 8W-64

Sunroof Switch....................... 8W-64

Thatcham Alarm Indicator.............. 8W-39

Thatcham Alarm Module................ 8W-39

Throttle Position Sensor................ 8W-30

Traction Control Switch................. 8W-35

Trailer Tow Connector.................. 8W-54

Transmission Control Module............ 8W-31

Transmission Control Relay............. 8W-31

Transmission Range Sensor.............. 8W-31

Transmission Solenoid/Pressure Switch

Assembly.......................... 8W-31

Turn Signal Lamps.................... 8W-52

Vehicle Speed Sensor................... 8W-30

Vent Motors.......................... 8W-60

Visor/Vanity Lamps.................... 8W-44

Washer Fluid Level Switch.............. 8W-53

Washer Pump Motor................... 8W-53

Water In Fuel Sensor.................. 8W-30

Wheel Speed Sensors................... 8W-35

Wiper Module........................ 8W-53

8W - 02 - 2 8W-02 COMPONENT INDEXRS