wiring CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 2188 of 2339

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(ATC heater-A/C control) through a fuse in the IPM

on the fused rear blower motor relay output circuit

only when the blower motor relay coil is energized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the rear blower

motor relay coil is de-energized.

Refer to the appropriate wiring information for

diagnosis and testing of the micro-relay and for com-

plete HVAC wiring diagrams.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

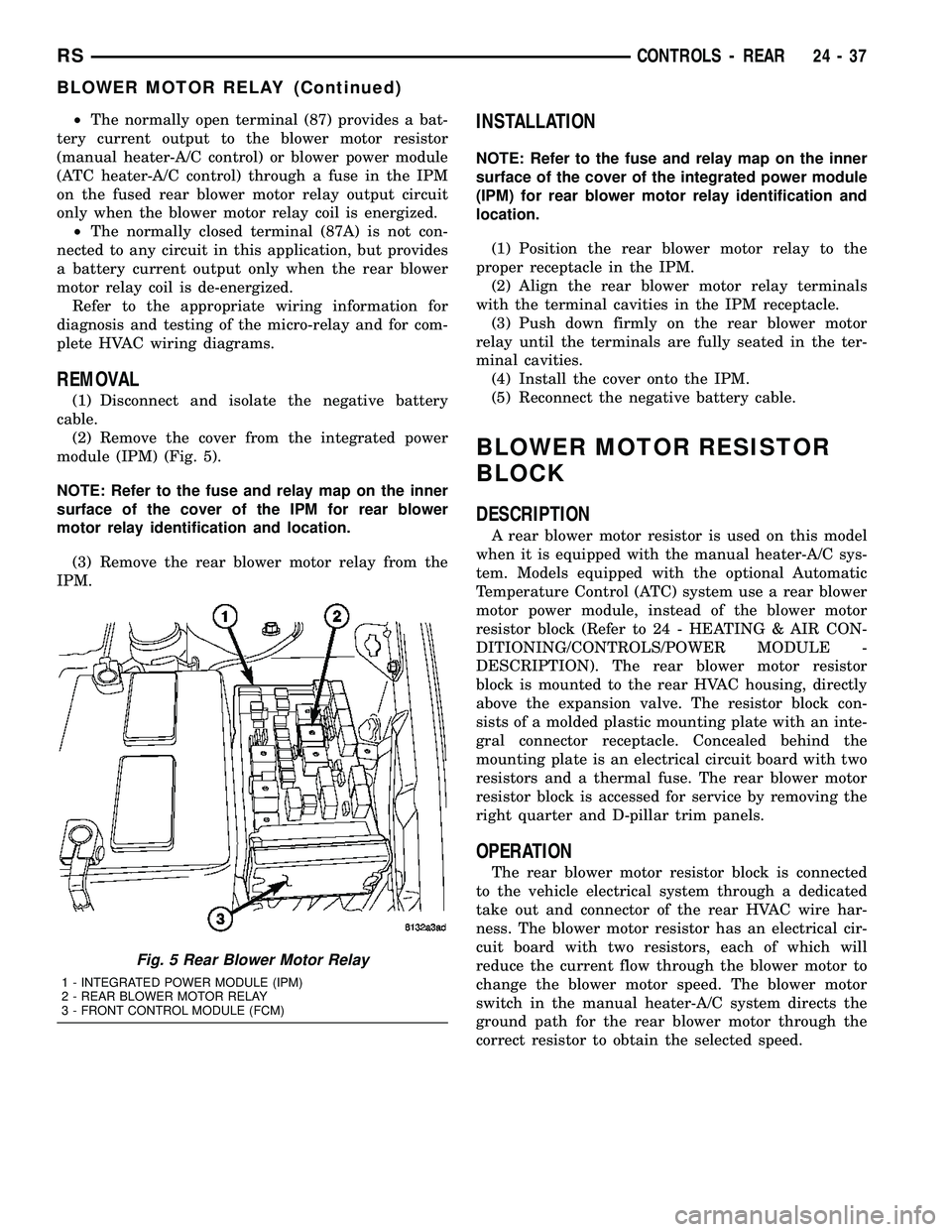

(2) Remove the cover from the integrated power

module (IPM) (Fig. 5).

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the IPM for rear blower

motor relay identification and location.

(3) Remove the rear blower motor relay from the

IPM.

INSTALLATION

NOTE: Refer to the fuse and relay map on the inner

surface of the cover of the integrated power module

(IPM) for rear blower motor relay identification and

location.

(1) Position the rear blower motor relay to the

proper receptacle in the IPM.

(2) Align the rear blower motor relay terminals

with the terminal cavities in the IPM receptacle.

(3) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities.

(4) Install the cover onto the IPM.

(5) Reconnect the negative battery cable.

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

A rear blower motor resistor is used on this model

when it is equipped with the manual heater-A/C sys-

tem. Models equipped with the optional Automatic

Temperature Control (ATC) system use a rear blower

motor power module, instead of the blower motor

resistor block (Refer to 24 - HEATING & AIR CON-

DITIONING/CONTROLS/POWER MODULE -

DESCRIPTION). The rear blower motor resistor

block is mounted to the rear HVAC housing, directly

above the expansion valve. The resistor block con-

sists of a molded plastic mounting plate with an inte-

gral connector receptacle. Concealed behind the

mounting plate is an electrical circuit board with two

resistors and a thermal fuse. The rear blower motor

resistor block is accessed for service by removing the

right quarter and D-pillar trim panels.

OPERATION

The rear blower motor resistor block is connected

to the vehicle electrical system through a dedicated

take out and connector of the rear HVAC wire har-

ness. The blower motor resistor has an electrical cir-

cuit board with two resistors, each of which will

reduce the current flow through the blower motor to

change the blower motor speed. The blower motor

switch in the manual heater-A/C system directs the

ground path for the rear blower motor through the

correct resistor to obtain the selected speed.

Fig. 5 Rear Blower Motor Relay

1 - INTEGRATED POWER MODULE (IPM)

2 - REAR BLOWER MOTOR RELAY

3 - FRONT CONTROL MODULE (FCM)

RSCONTROLS - REAR24-37

BLOWER MOTOR RELAY (Continued)

Page 2189 of 2339

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through both resistors. Each higher speed selected

with the blower motor switch applies the blower

motor ground path through fewer of the resistors,

increasing the blower motor speed. When the blower

motor switch is in the highest speed position, the

blower motor resistors are bypassed and the blower

motor receives a direct path to ground through the

blower motor switch.

The rear blower motor resistor block cannot be

adjusted or repaired and, if faulty or damaged, it

must be replaced.

DIAGNOSIS AND TESTING

REAR BLOWER MOTOR RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the rear HVAC wire harness con-

nector from the rear blower motor resistor.

(3) Check for continuity between each of the

blower motor switch input terminals of the blower

motor resistor and the resistor output terminal. In

each case there should be continuity. If OK, repair

the wire harness circuits between the blower motor

switch and the blower motor resistor, blower motor or

blower motor relay as required. If not OK, replace

the faulty blower motor resistor block.

REMOVAL

WARNING: THE REAR BLOWER MOTOR RESISTOR

BLOCK MAY GET VERY HOT DURING NORMAL

OPERATION. IF THE BLOWER MOTOR WAS

TURNED ON PRIOR TO SERVICING THE BLOWER

MOTOR RESISTOR BLOCK, WAIT FIVE MINUTES

TO ALLOW THE BLOWER MOTOR RESISTORS TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.CAUTION: Do not operate the blower motor with the

blower motor resistor block removed from the cir-

cuit. Failure to take this precaution can result in

vehicle damage.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right quarter trim panel and right

D-pillar trim panel from the quarter inner panel

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

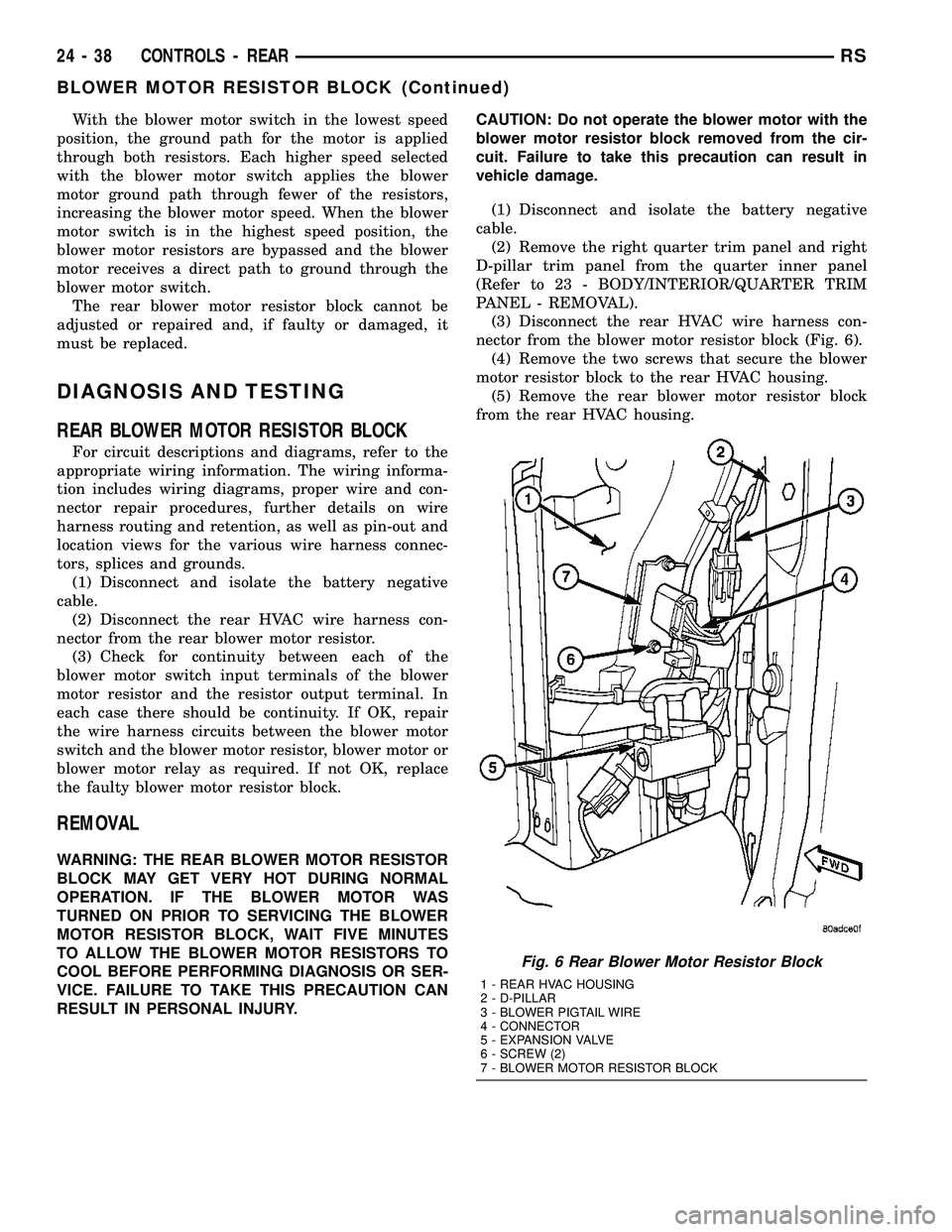

(3) Disconnect the rear HVAC wire harness con-

nector from the blower motor resistor block (Fig. 6).

(4) Remove the two screws that secure the blower

motor resistor block to the rear HVAC housing.

(5) Remove the rear blower motor resistor block

from the rear HVAC housing.

Fig. 6 Rear Blower Motor Resistor Block

1 - REAR HVAC HOUSING

2 - D-PILLAR

3 - BLOWER PIGTAIL WIRE

4 - CONNECTOR

5 - EXPANSION VALVE

6 - SCREW (2)

7 - BLOWER MOTOR RESISTOR BLOCK

24 - 38 CONTROLS - REARRS

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2197 of 2339

whenever the ignition switch is in the On position

and the A/C-heater control power is turned on.

The blower motor receives battery current when-

ever the front blower motor relay is energized. The

front blower motor relay output circuit is protected

by a fuse in the Integrated Power Module (IPM)

located in the engine compartment near the battery.

In the manual heater-A/C system, the blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the blower motor

speed is controlled by an electronic blower motor

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING

FRONT BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) or

the front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

24 - 46 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)

Page 2203 of 2339

(5) Disconnect the HVAC wire harness connector

from the blower motor.

(6) Disengage the HVAC wire harness from the

routing clips molded into the outside of the HVAC

housing.

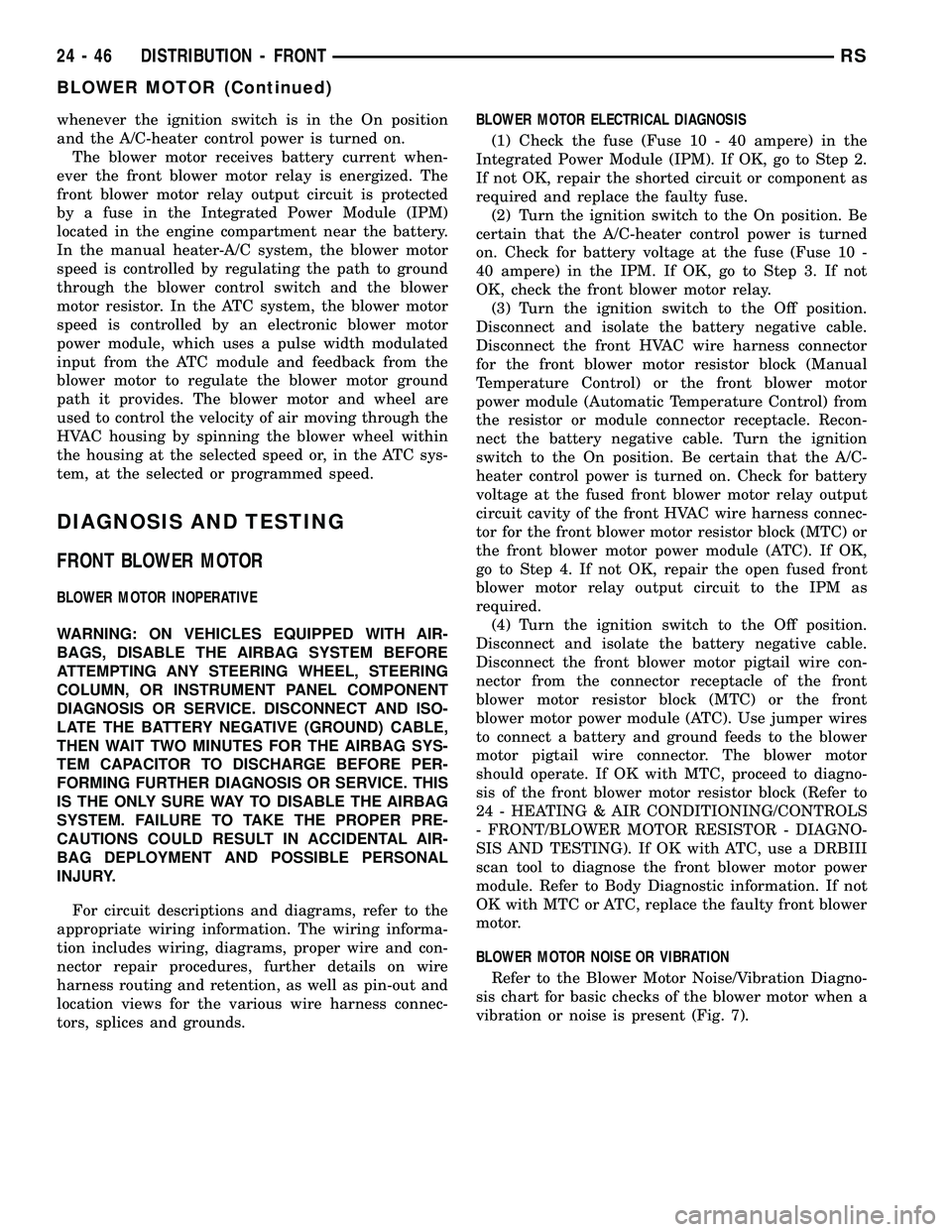

(7) Remove the four screws that secure the top of

the distribution housing to the HVAC housing (Fig.

15).(8) Pull the top of the distribution housing away

from the HVAC housing far enough to disengage the

two hook retainers on the bottom of the distribution

housing from the two receptacles on the HVAC hous-

ing (Fig. 16).

(9) Remove the two screws that secure the upper

air inlet housing to the lower air inlet housing.

(10) Remove the three screws that secure the

upper air inlet housing to the top of the HVAC hous-

ing. Be certain to remove the screw located just

inside the inboard side of the fresh air intake open-

ing.

(11) Remove the upper air inlet housing from the

top of the HVAC housing to expose the recirculation

air door and the blower motor and wheel (Fig. 17).

Fig. 15 Distribution Housing - LHD Shown,

RHD Typical

1 - DISTRIBUTION HOUSING

2 - SCREWS (3)

3 - HVAC WIRING HARNESS

4 - ROUTING CLIP

5 - HVAC HOUSING

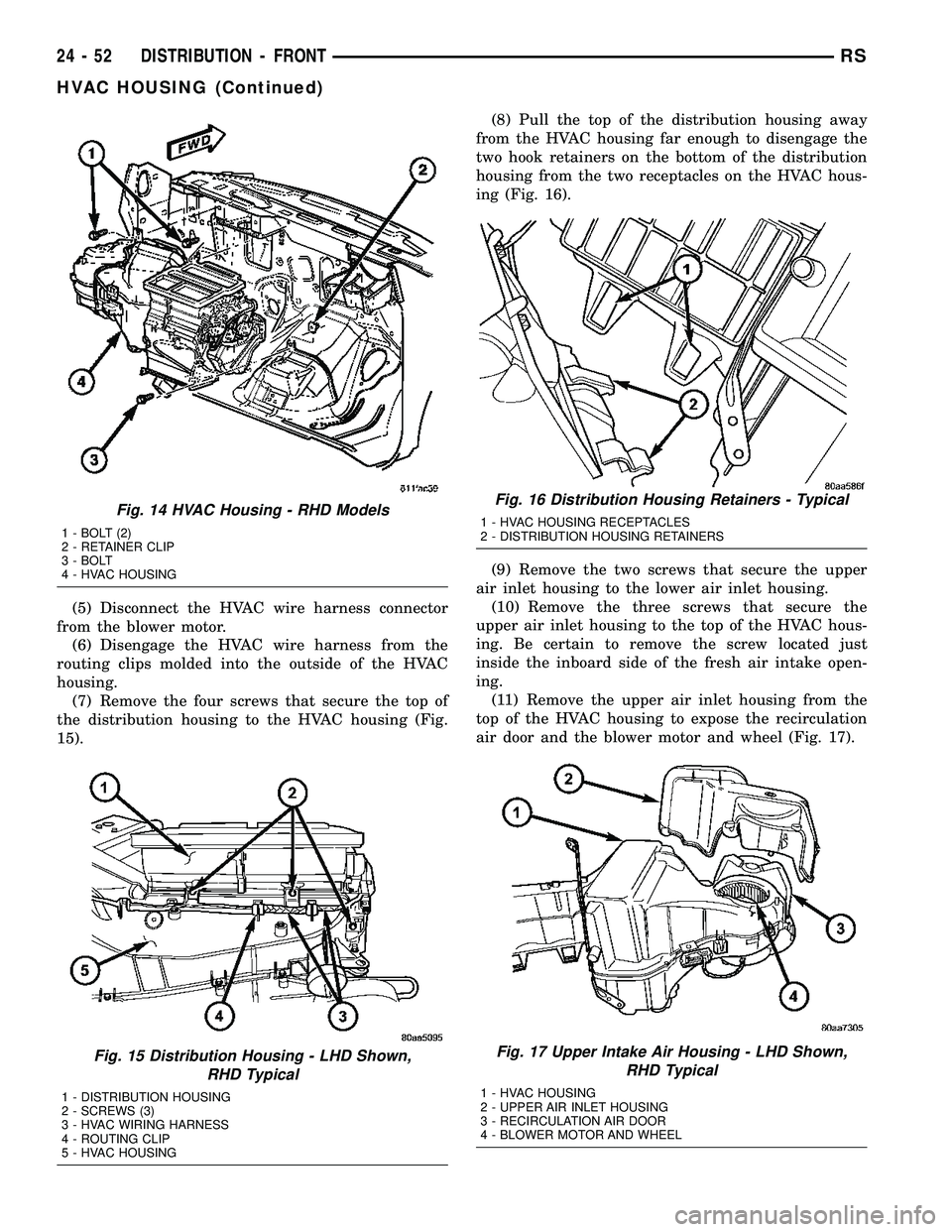

Fig. 14 HVAC Housing - RHD Models

1 - BOLT (2)

2 - RETAINER CLIP

3 - BOLT

4 - HVAC HOUSING

Fig. 16 Distribution Housing Retainers - Typical

1 - HVAC HOUSING RECEPTACLES

2 - DISTRIBUTION HOUSING RETAINERS

Fig. 17 Upper Intake Air Housing - LHD Shown,

RHD Typical

1 - HVAC HOUSING

2 - UPPER AIR INLET HOUSING

3 - RECIRCULATION AIR DOOR

4 - BLOWER MOTOR AND WHEEL

24 - 52 DISTRIBUTION - FRONTRS

HVAC HOUSING (Continued)

Page 2209 of 2339

DIAGNOSIS AND TESTING

REAR BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.

BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear A/C-heater control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, check the rear blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector

from the rear blower motor resistor block (Manual

Temperature Control) or the rear blower motor power

module (Automatic Temperature Control). Reconnect

the battery negative cable. Turn the ignition switch

to the On position. Be certain that the rear A/C-

heater control power is turned on. Check for battery

voltage at the fused rear blower motor relay output

circuit cavity of the rear HVAC wire harness connec-

tor for the rear blower motor resistor block (MTC) or

the rear blower motor power module (ATC). If OK, go

to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.Disconnect the rear blower motor pigtail wire connec-

tor from the rear HVAC wire harness (MTC) or the

rear blower power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The rear blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the rear blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- REAR/BLOWER MOTOR RESISTOR - DIAGNOSIS

AND TESTING). If OK with ATC, use a DRBIII scan

tool to diagnose the rear blower motor power module.

Refer to the appropriate diagnostic information. If

not OK with MTC or ATC, replace the faulty rear

blower motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 3).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING) and (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING - CAUTION).

(1) Remove the rear HVAC housing from the vehi-

cle (Refer to 24 - HEATING & AIR CONDITIONING/

DISTRIBUTION/HVAC HOUSING - REMOVAL).

(2) Disconnect the rear blower motor pigtail wire

connector.

NOTE: With the Manual Temperature Control sys-

tem, the blower motor pigtail wire is connected to a

take out and connector of the rear HVAC wire har-

ness. With the Automatic Temperature Control sys-

tem , the blower pigtail wire is connected to a

receptacle on the blower motor power module.

24 - 58 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)

Page 2264 of 2339

CABIN HEATER

TABLE OF CONTENTS

page page

CABIN HEATER

DESCRIPTION........................113

OPERATION

MANUAL TEMPERATURE CONTROL

SYSTEM...........................113

AUTOMATIC TEMPERATURE CONTROL

SYSTEM...........................114

WARNING............................114

DIAGNOSIS AND TESTING

SUPPLEMENTAL CABIN HEATER........114

AIR INTAKE PIPE

REMOVAL............................115

INSTALLATION........................115

EXHAUST TUBE

REMOVAL............................116

INSTALLATION........................116

FUEL DOSING PUMP

DESCRIPTION........................117

OPERATION..........................117REMOVAL............................117

INSTALLATION........................117

FUEL LINE

STANDARD PROCEDURE

CLEANING..........................118

REMOVAL............................118

INSTALLATION........................118

HEATER HOSES

REMOVAL............................119

INSTALLATION........................119

HEATER PIPES

REMOVAL............................119

INSTALLATION........................120

HEATER UNIT

REMOVAL............................121

INSTALLATION........................122

HEATER WIRING

REMOVAL............................122

INSTALLATION........................122

CABIN HEATER

DESCRIPTION

Vehicles equipped with the diesel engine are also

equipped with a supplemental cabin heater. This

cabin heater is mounted under the vehicle and oper-

ates similar to an oil fired furnace. The heater burns

small amounts of fuel to provide additional heat to

the coolant. Coolant is routed from the engine, to the

supplemental cabin heater and then to the front

heater core. This provides additional heat to the pas-

senger compartment. The supplemental cabin heater

system is interfaced to the vehicles on-board com-

puter systems and DRBIIItdiagnostics.

The supplemental cabin heater has an electronic

control module that monitors the heat output of the

heater. The cabin heater operates at full load (5 kW),

half load or idle mode (no additional heat) depending

on engine coolant temperature.

When ambient temperatures are lower than 15É C

(60É F), the supplemental cabin heater automatically

operates once each ignition cycle for five minutes.

This assures a good fuel supply is always present for

the supplemental cabin heater.

OPERATION

MANUAL TEMPERATURE CONTROL SYSTEM

The supplemental cabin heater is activated via the

temperature slide control or knob on the A/C-heater

control when equipped with the manual temperature

control (MTC) system. If the slide control or knob is

moved to or above the upper set point the cabin

heater is activated. The cabin heater can operate in a

full or partial load range as well as an idle mode all

dependent on the engine coolant temperature. The

cabin heater will also turn off if the A/C-heater tem-

perature control is lowered to less than the lower set

point. The cabin heater can take up to three minutes

to completely shut down when either the heater tem-

perature is set below the lower set point or the vehi-

cle ignition is shut down.

NOTE: Do not apply a strong vacuum source such

as a garage ventilation system directly on the sup-

plemental cabin heater exhaust line. Too strong of a

vacuum can prevent the supplemental cabin heater

from starting. If required, place the vacuum source

at least 75 mm (3 in.) away from the exhaust line.

RSCABIN HEATER24 - 113

Page 2268 of 2339

FUEL DOSING PUMP

DESCRIPTION

The dosing pump is a combined delivery, dosing

and shut-off system for the fuel supply to the supple-

mental cabin heater from the vehicle fuel tank.

OPERATION

The dosing pump is an electrically operated pump

that receives its operation instructions from the sup-

plemental cabin heater control module. The pump

supplies diesel fuel from the vehicle fuel tank to the

cabin heater.

REMOVAL

NOTE: The dosing pump is serviceable without

removing the supplemental cabin heater from the

vehicle.

(1) Disconnect and isolate the negative battery

cable.

CAUTION: Make sure that the hoist is properly posi-

tioned under the vehicle to prevent damage to the

flexible section of the cabin heater exhaust tube.

(2) Raise and support the vehicle.

(3) Disconnect the wiring harness connector to the

dosing pump by depressing the integral spring and

pulling the connector away from the pump.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel that may drain from the

heater fuel hose or the dosing pump.

(4) Remove the clamp that secures the heater fuel

hose to the dosing pump (Fig. 4).

(5) Disconnect the heater fuel hose from the dosing

pump.

NOTE: Position and retain the heater fuel line to

prevent fuel leakage from the cabin heater unit

while servicing the dosing pump.

(6) Disconnect the fuel line between the dosing

pump and the cabin heater unit.

NOTE: Have an approved fuel storage container

ready to catch any residual fuel that may drain from

the fuel line or the cabin heater unit.(7) Remove the dosing pump from the rubber iso-

lator and the vehicle.

INSTALLATION

(1) Position the dosing pump to the vehicle and

onto the rubber isolator.

(2) Connect the fuel line between the dosing pump

and the cabin heater unit.

NOTE: The connectors should point towards the

cabin heater fuel line.

(3) Connect the heater fuel hose to the dosing

pump.

(4) Install the clamp that secures the heater fuel

hose to the dosing pump. Tighten the clamp securely.

(5) Connect the wire harness connector to the dos-

ing pump by depressing the integral spring and

pushing the connector toward the pump. Verify con-

nector installation.

(6) Lower the vehicle

(7) Reconnect the negative battery cable.

(8) Verify function of the supplemental cabin

heater.

Fig. 4 Dosing Pump Fuel Line

1 - HEATER FUEL LINE

2 - HEATER FUEL HOSE

3 - HEATER AIR INTAKE PIPE

4 - RETAINING CLAMP (2)

5 - DOSING PUMP

RSCABIN HEATER24 - 117

Page 2272 of 2339

(7) Connect the heater lines to the heater hoses at

the heater core and EGR port. Position spring clamps

onto the hoses.

(8) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

HEATER UNIT

REMOVAL

WARNING: DO NOT OPERATE THE DIESEL SUP-

PLEMENTAL CABIN HEATER IN AN ENCLOSED

AREA SUCH AS A GARAGE THAT DOES NOT HAVE

EXHAUST VENTILATION FACILITIES. ALWAYS VENT

THE CABIN HEATER EXHAUST WHEN OPERATING

THE CABIN HEATER. ALLOW THE DIESEL SUPPLE-

MENTAL CABIN HEATER TO COOL BEFORE PER-

FORMING ANY SERVICE PROCEDURES TO THE

CABIN HEATER. VERIFY THAT ALL DIESEL SUP-

PLEMENTAL CABIN HEATER FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE PERFORMING ANY SER-

VICE PROCEDURES TO THE CABIN HEATER. FAIL-

URE TO FOLLOW THESE INSTRUCTION MAY

RESULT IN PERSONAL INJURY OR DEATH.(1) Raise and support the vehicle. Take note of the

location of the flexible section of the cabin heater

exhaust tube.

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Carefully open one hose to the underbody tube

assembly and drain the remaining coolant. A salvage

hose is a good idea to control the residual coolant, as

flow will occur from both the cabin heater and the

hose and tube assemblies.

(4) Remove the second hose from the underbody

hose and tube assembly.

(5) Loosen the hose and tube assembly from the

toe-board crossmember at two locations.

(6) Disconnect the electrical connector from the

body harness near the toe-board crossmember and

rail.

(7) Remove the wiring harness from the toe-board

crossmember (Refer to 24 - HEATING & AIR CON-

DITIONING/CABIN HEATER/HEATER UNIT -

REMOVAL).

(8) Open the fuel filler cap. Disconnect the rubber

fuel hose between the body tube assembly and the

fuel pump nipple at the body tube joint. A minimal

amount of fuel may flow from the open port.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel.

(9) Loosen the two fasteners at the rail. Take care

to notice that the exhaust tube bracket tab is on top

of the heater bracket and that there are two spacer

washers installed between the rubber grommets.

(10) Remove the flexible section of the cabin

heater exhaust tube from the exhaust tube by loos-

ening the clamp. Remove the hose from the exhaust

tube. Removal of the rail tube assembly may aid in

this service operation (Refer to 24 - HEATING & AIR

CONDITIONING/CABIN HEATER/EXHAUST TUBE

- REMOVAL).

(11) Remove seat hex nut at the heater mounting

flange to crossmember.

(12) Loosen the remaining fasteners which mount

the exhaust tube assembly to the vehicle.

(a) Install a suitable support device under the

cabin heater and secure the cabin heater to the

support.

(13) Loosen the remaining three fasteners to the

crossmembers.

(14) Remove the loosened fasteners that support

the cabin heater while supporting the weight of the

heater.

(15) Swing the cabin heater mounting bracket

from between the exhaust bracket and rail mounting

location. Drain any residual coolant from the cabin

heater.

Fig. 7 Cabin Heater Air Intake And Heater Pipe

Assembly

1 - INTAKE TUBE AIR INTAKE

2 - INTAKE PIPE

3 - RETAINING SCREWS

4 - INTAKE HEATER LINE

5 - RETURN HEATER LINE

RSCABIN HEATER24 - 121

HEATER PIPES (Continued)

Page 2273 of 2339

(16) Remove the cabin heater from the vehicle.

INSTALLATION

(1) Install the cabin heater mounting bracket

between the exhaust bracket and the rail mounting

location.

(2) Support the cabin heater and install the fasten-

ers that secure the cabin heater to the mounting

bracket.

(3) Install the three fasteners to the crossmem-

bers. Tighten the M6 fasteners to 7 N´m (62 in. lbs.).

(4) Position the two spacer washers between the

body and the rubber grommets for the two mounting

points on the rail.

(5) Tighten the remaining M6 fasteners to 7 N´m

(62 in. lbs.) and the M8 fasteners to 23 N´m (17 ft.

lbs.) which mount the exhaust tube assembly to the

vehicle.

(6) Install the seat hex nut at the heater mounting

flange to the crossmembers. Tighten the nut to 60

N´m (44 ft. lbs.)

(7) Install the flexible section of the cabin heater

exhaust tube to the exhaust tube. Tighten the M6

bolt of the clamp securley. Install the hose to the

exhaust tube.

(8) Tighten the two M8 fasteners at the rail to 23

N´m (17 ft. lbs.). Taking care so that the exhaust

tube bracket tab is on the top of the heater bracket.

(9) Install the wiring harness (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CABIN HEATER/

HEATER UNIT - INSTALLATION).

(10) Tighten the hose and tube assembly to the

toe-board crossmember at two locations.

(11) Install the second hose to the underbody hose

and tube assembly.

(12) Connect the rubber fuel hose between the

body tube assembly and the fuel pump nipple at the

body tube joint. Close the fuel fill cap.

(13) Remove the cabin heater support device from

under the vehicle.

(14) Lower the vehicle.(15) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Verify function of the cabin heater.

HEATER WIRING

REMOVAL

(1) Elevate vehicle on a lift taking note of the

exhaust tube flexible section.

(2) Unplug connector from vehicle wiring harness

to cabin heater harness.

(3) Unplug connector from cabin heater harness to

dosing pump connector.

(4) Unplug two connectors from cabin heater har-

ness to cabin heater controller connectors.

(5) Remove two wiring harness connectors from

underbody.

(6) Remove two wiring harness connectors from

cabin heater shield.

(7) Carefully route the cabin heater harness to the

left side between the cabin heater unit and the cabin

heater shield.

INSTALLATION

(1) Carefully route the cabin heater harness from

the left side of the cabin heater between the cabin

heater unit and the cabin heater shield.

(2) Install the two wiring harness retaining con-

nectors to the cabin heater shield.

(3) Route the wiring harness along the underside

of the vehicle and install the two wiring harness

retaining connectors.

(4) Plug the two connectors from the cabin heater

harness to the cabin heater controller.

(5) Plug the connector to the cabin heater harness

to the dosing pump connector.

(6) Plug the connector from the vehicle wiring har-

ness to the cabin heater harness.

(7) Lower the vehicle.

(8) Verify function of the cabin heater.

24 - 122 CABIN HEATERRS

HEATER UNIT (Continued)

Page 2285 of 2339

SPECIFICATIONS

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

PCV VAlve 3.3/3.8L 6.3 55

Fig. 1 ORVR System Schematic (PZEV)

1 - FUEL TANK (PLASTIC) 11 - NATURAL VACUUM LEAD DETECTION (NVLD)

2 - FUEL FILLER TUBE 12 - LIQUID SEPARATOR (IF EQUIPPED)

3 - FUEL CAP (PRESSURE/RELIEF) 13 - ENGINE WIRING HARNESS TO NVLD

4 - FILL TUBE TO FUEL TANK CONNECTOR (ELASTOMERIC) 14 - VAPOR CANISTER

5 - TANK VENT/ROLLOVER VALVE(S) 15 - PURGE LINE

6 - VAPOR RECIRCULATION LINE 16 - PURGE DEVICE

7 - TANK VAPOR LINE 17 - WITHOUT NVLD

8 - VAPOR LINE TO CANISTER 18 - BREATHER ELEMENT

9 - CHECK VALVE (N/C) 19 - FLOW CONTROL ORIFICE

10 - CONTROL VALVE 20 - SERVICE PORT

21 - WITH NVLD

25 - 12 EVAPORATIVE EMISSIONSRS

EVAPORATIVE EMISSIONS (Continued)