body CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1190 of 2339

(9) Using a blade or suitable hose cutter, cut trans-

axle oil cooler lines off flush with fittings. Plug cooler

lines and fittings to prevent debris from entering

transaxle or cooler circuit. A service splice kit will be

installed upon reassembly.

(10) Disconnect transmission shift linkage and

electrical connectors.

(11) Disconnect throttle body linkage.

(12) Disconnect engine wiring harness.

(13) Disconnect heater hoses from heater (Fig. 5).

(14) Discharge air conditioning system. (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING

- STANDARD PROCEDURE)

(15) Hoist vehicle and remove front wheels and

tires.

(16) Remove accessory drive belt splash shield.

(17) Remove accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(18) Remove axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - REMOVAL)(19) Drain engine oil and remove oil filter. (Refer

to 9 - ENGINE/LUBRICATION/OIL - STANDARD

PROCEDURE)

(20) Remove crossmember cradle plate (Fig. 6).

Fig. 5 HEATER HOSES - 2.4L

1 - HEATER HOSES TO HEATER 3 - HEATER HOSE TO ENGINE - SUPPLY AND RETURN

2 - BOLT - HEATER TUBE SUPPORT

Fig. 6 Crossmember Cradle Plate

1 - CRADLE PLATE

RSENGINE 2.4L9-13

ENGINE 2.4L (Continued)

Page 1191 of 2339

(21) Disconnect exhaust pipe from manifold (Fig.

7).

(22) Remove engine front mount and bracket from

engine. (Refer to 9 - ENGINE/ENGINE MOUNTING/

FRONT MOUNT - REMOVAL)

(23) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

(24) Remove rear engine mount bracket. (Refer to

9 - ENGINE/ENGINE MOUNTING/REAR MOUNT -

REMOVAL)

(25) Mark flex plate to torque converter and

remove torque converter bolts.

(26) Pinch-off power steering supply hose at pump.

Remove hose from pump.

(27) Remove and set aside the power steering

pump and bracket. Do not disconnect pressure line.

(28) Lower vehicle.

(29) Remove A/C lines at compressor and cap open-

ings.

(30) Remove engine ground straps (strap at engine

right mount and at starter).

(31) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 to be installed under vehicle

(Fig. 8).

(32) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

oil pan rails (Fig. 8). Lower vehicle and position cra-

dle mounts until the engine is resting on mounts.Tighten mounts to cradle frame. This will keep

mounts from moving when removing or installing

engine and transmission.

(33) Install safety straps around the engine to cra-

dle. Tighten straps and lock.

(34) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(35) Remove engine and transmission mount bolts.

(36) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly with the

dolly to allow for removal around the body.

INSTALLATION - ENGINE ASSEMBLY

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

(Fig. 9) and left mounts (Fig. 10).

(3) Remove safety straps.

(4) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(5) Install rear mount bracket and rear mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/REAR MOUNT - INSTALLATION)

(6) Install the flex plate to torque converter bolts.

(7) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(8) Install front mount bracket and front mount

through bolt. (Refer to 9 - ENGINE/ENGINE

MOUNTING/FRONT MOUNT - INSTALLATION)

(9) Connect exhaust system to manifold (Fig. 7).

(10) Install crossmember cradle plate (Fig. 6).

(11) Install new oil filter.

(12) Install power steering pump and bracket.

(13) Connect power steering supply line to pump

and remove pinch-off pliers.

(14) Connect A/C compressor hoses to compressor.

(15) Install accessory drive belts. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(16) Install axle shafts. (Refer to 3 - DIFFEREN-

TIAL & DRIVELINE/HALF SHAFT - INSTALLA-

TION)

(17) Install accessory drive belt splash shield.

(18) Install front wheels and tires.

(19) Remove plugs from transmission cooler hoses

and install transaxle oil cooler line service splice kit.

Refer to instructions included with kit.

(20) Connect the transaxle shift linkage and elec-

trical connectors.

(21) Connect heater hoses (Fig. 5).

(22) Install ground straps.

(23) Connect all engine and throttle body electrical

connections.

Fig. 7 Catalytic Converter to Exhaust Manifold

1 - CATALYTIC CONVERTER

2 - BOLT

3 - GASKET

4 - FLAG NUT

9 - 14 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1195 of 2339

CRANKSHAFT

DESCRIPTION SPECIFICATION

Metric Standard

Connecting Rod

Journal

Diameter49.984 - 50.000

mm1.968 - 1.9685

in.

Main Bearing

Journal

Diameter59.992 - 60.008

mm2.362 - 2.3625

in.

Journal

Out-of-Round

(Max.)0.0035 mm 0.0003 in.

Journal Taper

(Max.)0.007 mm 0.0001 in.

End Play 0.09 - 0.24 mm 0.0035 - 0.0094

in.

Wear Limit 0.38 mm 0.015 in.

Main Bearing

Diametrical

Clearance0.018 - 0.062

mm0.0007 - 0.0024

in.

HYDRAULIC LASH ADJUSTER

DESCRIPTION SPECIFICATION

Metric Standard

Body Diameter 15.901 - 15.913

mm0.626 - 0.6264

in.

Plunger Travel

Minimum (Dry)3.0 mm 0.118 in.

CYLINDER HEAD CAMSHAFT BEARING BORE

DIAMETER

DSECRIPTION SPECIFICATION

Metric Standard

Journals No.1 -

626.020 - 26.041

mm1.024 - 1.025 in.

CAMSHAFT

DESCRIPTION SPECIFICATION

Metric Standard

Journal

Diameter No. 1

-625.951 - 25.970

mm1.021 - 1.022 in.

Bearing

Clearance -

Diametrical0.069 - 0.071

mm0.0027 - 0.003

in.

End Play 0.05 - 0.17 mm 0.0019 - 0.0066

in.

Lift (Zero Lash)

Intake 8.25 mm 0.324 in.

Exhaust 6.60 mm 0.259 in.

Intake Valve

Timing*

Closes (ABDC) 51É

Opens (BTDC) 1É

Duration 232É

Exhaust Valve

Timing*

Closes (ATDC) 7É

Opens (BBDC) 47É

Duration 234É

Valve Overlap 8É

*

All reading in degrees. Timing points @4É from top of

ramp.

CYLINDER HEAD

DESCRIPTION SPECIFICATION

Metric Standard

Material Cast Aluminum

Gasket

Thickness

(Compressed)0.71 mm 0.028 in.

9 - 18 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1202 of 2339

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.

(2) Disconnect the inlet air temperature sensor

(Fig. 12).

(3) Remove the inlet hose to throttle body (Fig. 11).

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.

(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

12).

(5) Connect the negative battery cable.

CYLINDER HEAD

DESCRIPTION

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 13). The valves are arranged in two

in-line banks. The intake valves face toward the

front of the vehicle. The exhaust valves face the dash

panel. The cylinder head incorporates powdered

metal valve guides and seats. The cylinder head is

sealed to the block using a multi-layer steel head

gasket and retaining bolts.Integral oil galleries provide lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

DIAGNOSIS AND TESTINGÐCYLINDER HEAD

GASKET

A cylinder head gasket leak can be located between

adjacent cylinders or between a cylinder and the

adjacent water jacket.

Possible indications of the cylinder head gasket

leaking between adjacent cylinders are:

²Loss of engine power

²Engine misfiring

²Poor fuel economy

Possible indications of the cylinder head gasket

leaking between a cylinder and an adjacent water

jacket are:

²Engine overheating

²Loss of coolant

²Excessive steam (white smoke) emitting from

exhaust

²Coolant foaming

Fig. 12 IAT Sensor 2.4L

Fig. 13 Cylinder Head and Camshafts

1 - CAMSHAFT BEARING CAPS

2 - PLUG

3 - CAMSHAFT

4 - CYLINDER HEAD

5 - CAMSHAFT OIL SEAL

RSENGINE 2.4L9-25

Page 1229 of 2339

INSTALLATION

(1) Install rear mount bracket, if removed (Fig.

84).

(2) Install the rear mount and bolts (Fig. 83).

Tighten bolts to 54 N´m (40 ft. lbs.).

(3) Install the mount through bolt to the mount

and bracket (Fig. 83). Tighten through bolt to 54 N´m

(40 ft. lbs.).

(4) Install the rear mount heat shield (Fig. 82).

(5) Lower vehicle on hoist.

RIGHT MOUNT

REMOVAL

(1) Remove air cleaner housing lid and clean air

hose from throttle body.

(2) Remove air cleaner element and housing.

(3) Disconnect make-up air hose from cylinder

head cover.

(4) Remove the load on the right engine mount by

carefully supporting the engine assembly with a floor

jack.

(5) Disconnect electrical harness support clips from

engine mount bracket.(6) Remove the vertical bolts attaching the engine

mount to the frame rail (Fig. 85).

(7) Loosen the horizontal bolt attaching the engine

mount to the frame rail (Fig. 85).

(8) Remove the bolts attaching the engine mount

to the engine bracket (Fig. 85).

(9) Remove the right engine mount (Fig. 85).

INSTALLATION

(1) Position right engine mount and install frame

rail to mount vertical bolts (Fig. 85).

(2) Tighten engine right mount to rail horizontal

bolt (Fig. 85).

(3) Install mount to engine bracket bolts (Fig. 85).

(4) Connect electrical harness support clips to

engine mount bracket.

(5) Remove jack from under engine.

(6) Connect make-up air hose to cylinder head

cover.

(7) Install air cleaner housing and element.

(8) Install air cleaner housing lid and clean air

tube to throttle body.

Fig. 84 Rear Mount Bracket - (all engines)

1 - BOLT - VERTICAL 102 N´m (75 ft. lbs.)

2 - BRACKET - REAR MOUNT3 - BOLT - HORIZONTAL 102 N´m (75 ft. lbs.)

9 - 52 ENGINE 2.4LRS

REAR MOUNT (Continued)

Page 1234 of 2339

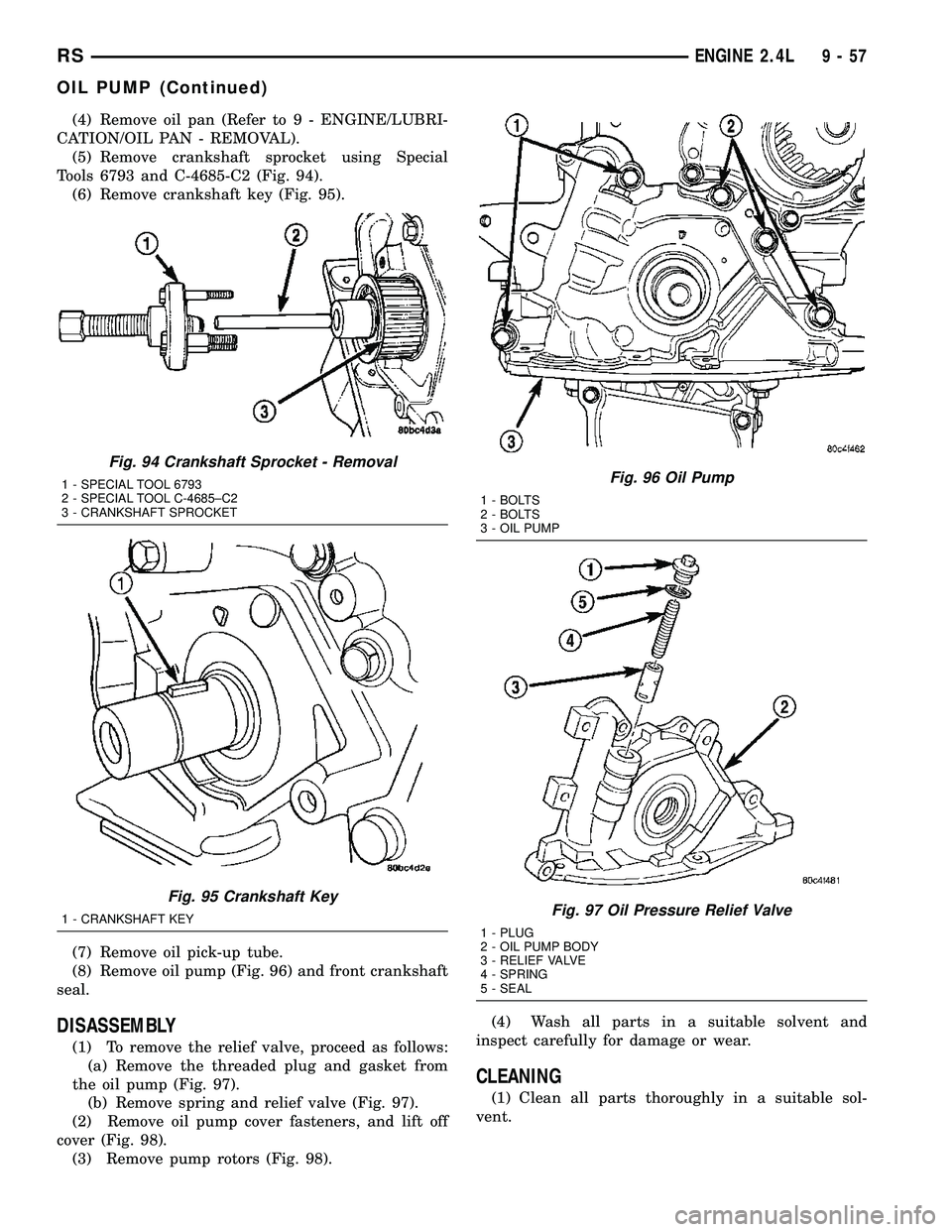

(4) Remove oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(5) Remove crankshaft sprocket using Special

Tools 6793 and C-4685-C2 (Fig. 94).

(6) Remove crankshaft key (Fig. 95).

(7) Remove oil pick-up tube.

(8) Remove oil pump (Fig. 96) and front crankshaft

seal.

DISASSEMBLY

(1) To remove the relief valve, proceed as follows:

(a) Remove the threaded plug and gasket from

the oil pump (Fig. 97).

(b) Remove spring and relief valve (Fig. 97).

(2) Remove oil pump cover fasteners, and lift off

cover (Fig. 98).

(3) Remove pump rotors (Fig. 98).(4) Wash all parts in a suitable solvent and

inspect carefully for damage or wear.

CLEANING

(1) Clean all parts thoroughly in a suitable sol-

vent.

Fig. 94 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - SPECIAL TOOL C-4685±C2

3 - CRANKSHAFT SPROCKET

Fig. 95 Crankshaft Key

1 - CRANKSHAFT KEY

Fig. 96 Oil Pump

1 - BOLTS

2 - BOLTS

3 - OIL PUMP

Fig. 97 Oil Pressure Relief Valve

1 - PLUG

2 - OIL PUMP BODY

3 - RELIEF VALVE

4 - SPRING

5 - SEAL

RSENGINE 2.4L9-57

OIL PUMP (Continued)

Page 1235 of 2339

INSPECTION

(1) Inspect the mating surfaces of the oil pump

cover. Surface should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 99). If a 0.025 mm (0.001 in.) feeler gauge

can be inserted between cover and straight edge,

cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 9.40 mm (0.370 in.)

or less (Fig. 100), or if the diameter is 79.95 mm

(3.148 in.) or less, replace outer rotor.

(4) If inner rotor measures 9.40 mm (0.370 in.) or

less replace inner rotor (Fig. 101).

ASSEMBLY

(1) Assemble pump, using new parts as required.

Install the inner rotor with chamfer facing the

cast iron oil pump cover.

(2) Prime oil pump before installation by filling

rotor cavity with engine oil.

(3) Install cover and tighten fasteners to 12 N´m

(105 in. lbs.) (Fig. 98).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 97) or serious engine

damage may occur.

(4) Install relief valve, spring, gasket and cap as

shown in (Fig. 97). Tighten cap to 41 N´m (30 ft.

lbs.).

Fig. 98 Oil Pump

1 - O-RING

2 - SEAL

3 - INNER ROTOR

4 - OIL PUMP COVER

5 - FASTENER

6 - OUTER ROTOR

7 - OIL PUMP BODY

Fig. 99 Checking Oil Pump Cover Flatness

1 - STRAIGHT EDGE

2 - FEELER GAUGE

3 - OIL PUMP COVER

Fig. 100 Measuring Outer Rotor Thickness

Fig. 101 Measuring Inner Rotor Thickness

9 - 58 ENGINE 2.4LRS

OIL PUMP (Continued)

Page 1236 of 2339

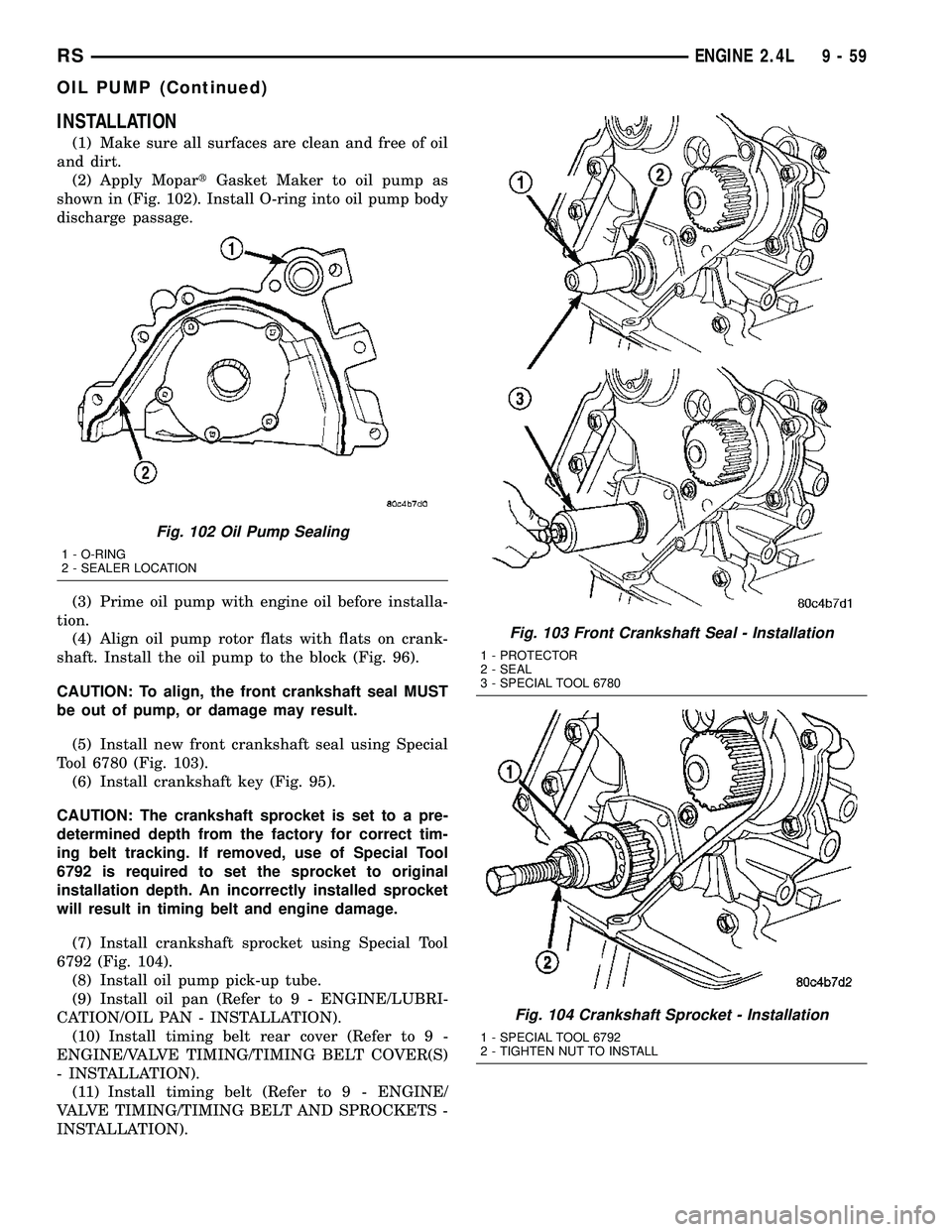

INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 102). Install O-ring into oil pump body

discharge passage.

(3) Prime oil pump with engine oil before installa-

tion.

(4) Align oil pump rotor flats with flats on crank-

shaft. Install the oil pump to the block (Fig. 96).

CAUTION: To align, the front crankshaft seal MUST

be out of pump, or damage may result.

(5) Install new front crankshaft seal using Special

Tool 6780 (Fig. 103).

(6) Install crankshaft key (Fig. 95).

CAUTION: The crankshaft sprocket is set to a pre-

determined depth from the factory for correct tim-

ing belt tracking. If removed, use of Special Tool

6792 is required to set the sprocket to original

installation depth. An incorrectly installed sprocket

will result in timing belt and engine damage.

(7) Install crankshaft sprocket using Special Tool

6792 (Fig. 104).

(8) Install oil pump pick-up tube.

(9) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(10) Install timing belt rear cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- INSTALLATION).

(11) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

INSTALLATION).

Fig. 102 Oil Pump Sealing

1 - O-RING

2 - SEALER LOCATION

Fig. 103 Front Crankshaft Seal - Installation

1 - PROTECTOR

2 - SEAL

3 - SPECIAL TOOL 6780

Fig. 104 Crankshaft Sprocket - Installation

1 - SPECIAL TOOL 6792

2 - TIGHTEN NUT TO INSTALL

RSENGINE 2.4L9-59

OIL PUMP (Continued)

Page 1237 of 2339

INTAKE MANIFOLD

DESCRIPTION

The intake manifold is a two piece aluminum cast-

ing (Fig. 105) that attaches to the cylinder head with

fasteners. The manifold is a long branch design to

enhance low and mid-range torque

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

INTAKE MANIFOLD - UPPER

REMOVAL

(1) Disconnect negative cable from battery.(2) Disconnect connector from inlet air tempera-

ture sensor (Fig. 106).

(3) Disconnect air intake tube at throttle body and

remove upper air cleaner housing.

(4) Disconnect connector from throttle position

sensor (TPS) (Fig. 108).

(5) Disconnect connector from idle air control (IAC)

motor (Fig. 108).

(6) Disconnect connector from MAP sensor (Fig.

107).

(7) Remove vacuum lines for purge solenoid and

PCV valve at intake manifold.

(8) Remove vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at upper intake manifold fittings.

Fig. 105 Intake Manifold - Upper and Lower

1 - UPPER INTAKE MANIFOLD

2 - LOWER INTAKE MANIFOLD

Fig. 106 Inlet Air Temperature Sensor - 2.4L

Fig. 107 Map Sensor - 2.4L

1 - MAP SENSOR

9 - 60 ENGINE 2.4LRS

Page 1238 of 2339

(9) Disconnect throttle and speed control (if

equipped) cables from throttle lever and bracket.

(Refer to 14 - FUEL SYSTEM/FUEL INJECTION/

THROTTLE CONTROL CABLE - REMOVAL)

(10) Remove the EGR tube. (Refer to 25 - EMIS-

SIONS CONTROL/EXHAUST GAS RECIRCULA-

TION/TUBE - REMOVAL)

(11) Remove the upper manifold support bracket

bolt to manifold (Fig. 109).

(12) Remove engine oil dipstick from tube.

(13) Remove upper intake manifold bolts (Fig.

110). Remove upper intake manifold.

CAUTION: Cover intake manifold to prevent foreign

material from entering engine.

INSPECTION

(1) Check manifold surfaces for flatness with

straight edge. Surface must be flat within 0.15 mm

per 300 mm (0.006 in. per foot) of manifold length.

(2) Inspect manifold for cracks or distortion.

Replace manifold if necessary.

INSTALLATION

(1) Clean manifold sealing surfaces.

(2) Apply a 1.5 mm (0.060 in.) bead MopartGas-

ket Maker to the perimeter of the lower intake man-

ifold runner openings.

(3) Install upper intake manifold and tighten fas-

teners to 28 N´m (250 in. lbs.) in sequence shown in

(Fig. 110). Repeat this procedures until all fasteners

are at specified torque.

(4) Install engine oil dipstick.

(5) Install upper bolt in intake manifold to front

support bracket (Fig. 109). Torque to 28 N´m (250 in.

lbs.).

(6) Install EGR tube. (Refer to 25 - EMISSIONS

CONTROL/EXHAUST GAS RECIRCULATION/

TUBE - INSTALLATION)

(7) Install throttle cables in bracket.

(8) Connect throttle and speed control (if equipped)

cables to throttle lever.

(9) Connect vacuum lines for power brake booster,

LDP, EGR transducer, and speed control vacuum res-

ervoir (if equipped) at upper intake manifold fittings.

(10) Connect vacuum lines for purge solenoid and

PCV valve.

(11) Connect electrical connectors for MAP sensor,

throttle position sensor (TPS), and idle air control

(IAC) motor.

(12) Install air cleaner upper housing and air

intake tube to throttle body.

(13) Connect inlet air temperature sensor connec-

tor (Fig. 106).

(14) Connect negative cable to battery.

Fig. 108 Throttle Body Electrical Connectors -

Typical

1 - IDLE AIR CONTROL MOTOR CONNECTOR

2 - TPS CONNECTOR

Fig. 109 Upper Intake Manifold Support Bracket

1 - NUT - BRACKET TO CYLINDER HEAD COVER

2 - BOLT - BRACKET TO UPPER INTAKE MANIFOLD

3 - UPPER INTAKE MANIFOLD SUPPORT BRACKET

Fig. 110 Upper Intake Manifold Tightening Sequence

- 2.4L

RSENGINE 2.4L9-61

INTAKE MANIFOLD - UPPER (Continued)