oil level CHRYSLER CARAVAN 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 585 of 2339

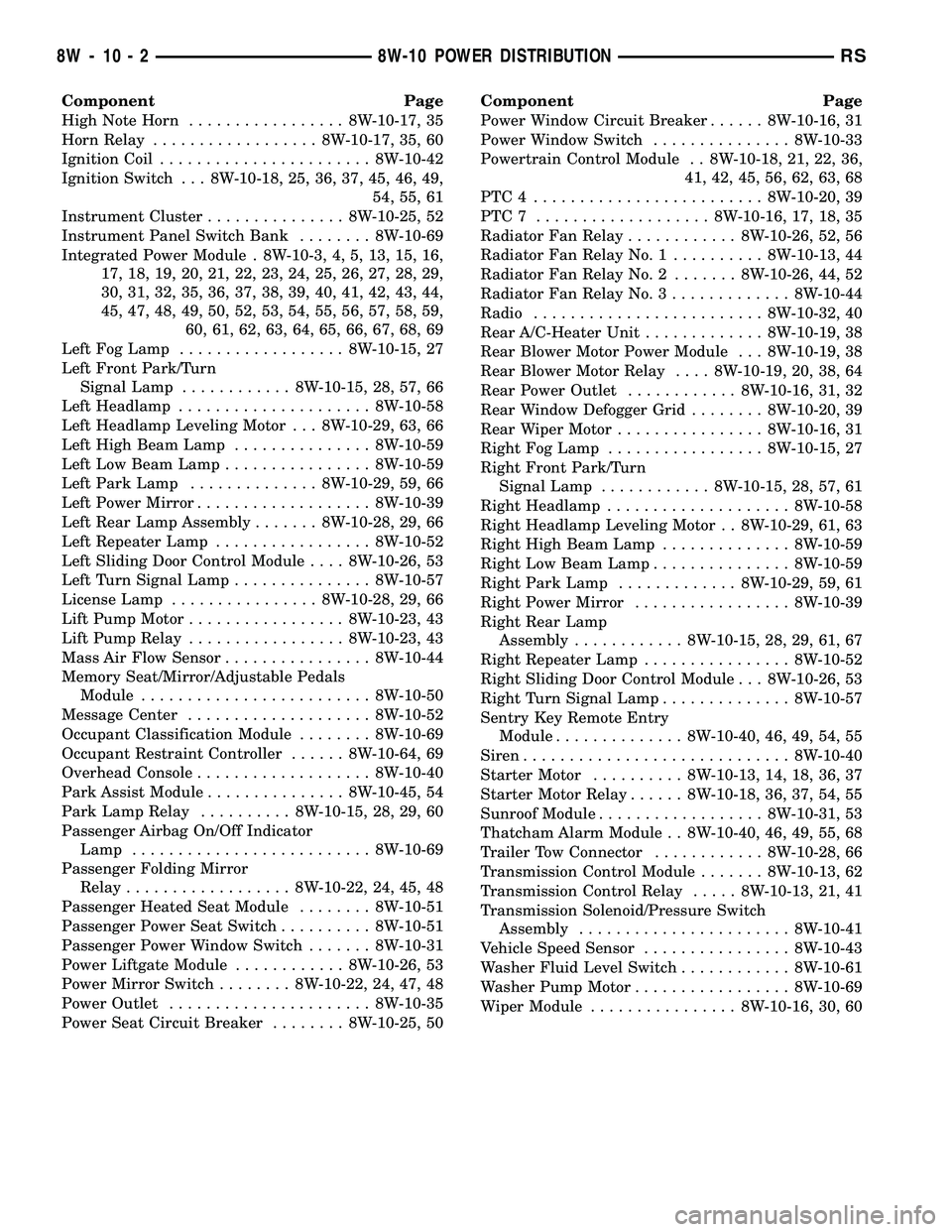

Component Page

High Note Horn................. 8W-10-17, 35

Horn Relay.................. 8W-10-17, 35, 60

Ignition Coil....................... 8W-10-42

Ignition Switch . . . 8W-10-18, 25, 36, 37, 45, 46, 49,

54, 55, 61

Instrument Cluster............... 8W-10-25, 52

Instrument Panel Switch Bank........ 8W-10-69

Integrated Power Module . 8W-10-3, 4, 5, 13, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29,

30, 31, 32, 35, 36, 37, 38, 39, 40, 41, 42, 43, 44,

45, 47, 48, 49, 50, 52, 53, 54, 55, 56, 57, 58, 59,

60, 61, 62, 63, 64, 65, 66, 67, 68, 69

Left Fog Lamp.................. 8W-10-15, 27

Left Front Park/Turn

Signal Lamp............ 8W-10-15, 28, 57, 66

Left Headlamp..................... 8W-10-58

Left Headlamp Leveling Motor . . . 8W-10-29, 63, 66

Left High Beam Lamp............... 8W-10-59

Left Low Beam Lamp................ 8W-10-59

Left Park Lamp.............. 8W-10-29, 59, 66

Left Power Mirror................... 8W-10-39

Left Rear Lamp Assembly....... 8W-10-28, 29, 66

Left Repeater Lamp................. 8W-10-52

Left Sliding Door Control Module.... 8W-10-26, 53

Left Turn Signal Lamp............... 8W-10-57

License Lamp................ 8W-10-28, 29, 66

Lift Pump Motor................. 8W-10-23, 43

Lift Pump Relay................. 8W-10-23, 43

Mass Air Flow Sensor................ 8W-10-44

Memory Seat/Mirror/Adjustable Pedals

Module......................... 8W-10-50

Message Center.................... 8W-10-52

Occupant Classification Module........ 8W-10-69

Occupant Restraint Controller...... 8W-10-64, 69

Overhead Console................... 8W-10-40

Park Assist Module............... 8W-10-45, 54

Park Lamp Relay.......... 8W-10-15, 28, 29, 60

Passenger Airbag On/Off Indicator

Lamp.......................... 8W-10-69

Passenger Folding Mirror

Relay.................. 8W-10-22, 24, 45, 48

Passenger Heated Seat Module........ 8W-10-51

Passenger Power Seat Switch.......... 8W-10-51

Passenger Power Window Switch....... 8W-10-31

Power Liftgate Module............ 8W-10-26, 53

Power Mirror Switch........ 8W-10-22, 24, 47, 48

Power Outlet...................... 8W-10-35

Power Seat Circuit Breaker........ 8W-10-25, 50Component Page

Power Window Circuit Breaker...... 8W-10-16, 31

Power Window Switch............... 8W-10-33

Powertrain Control Module . . 8W-10-18, 21, 22, 36,

41, 42, 45, 56, 62, 63, 68

PTC4 ......................... 8W-10-20, 39

PTC7 ................... 8W-10-16, 17, 18, 35

Radiator Fan Relay............ 8W-10-26, 52, 56

Radiator Fan Relay No. 1.......... 8W-10-13, 44

Radiator Fan Relay No. 2....... 8W-10-26, 44, 52

Radiator Fan Relay No. 3............. 8W-10-44

Radio......................... 8W-10-32, 40

Rear A/C-Heater Unit............. 8W-10-19, 38

Rear Blower Motor Power Module . . . 8W-10-19, 38

Rear Blower Motor Relay.... 8W-10-19, 20, 38, 64

Rear Power Outlet............ 8W-10-16, 31, 32

Rear Window Defogger Grid........ 8W-10-20, 39

Rear Wiper Motor................ 8W-10-16, 31

Right Fog Lamp................. 8W-10-15, 27

Right Front Park/Turn

Signal Lamp............ 8W-10-15, 28, 57, 61

Right Headlamp.................... 8W-10-58

Right Headlamp Leveling Motor . . 8W-10-29, 61, 63

Right High Beam Lamp.............. 8W-10-59

Right Low Beam Lamp............... 8W-10-59

Right Park Lamp............. 8W-10-29, 59, 61

Right Power Mirror................. 8W-10-39

Right Rear Lamp

Assembly............ 8W-10-15, 28, 29, 61, 67

Right Repeater Lamp................ 8W-10-52

Right Sliding Door Control Module . . . 8W-10-26, 53

Right Turn Signal Lamp.............. 8W-10-57

Sentry Key Remote Entry

Module.............. 8W-10-40, 46, 49, 54, 55

Siren............................. 8W-10-40

Starter Motor.......... 8W-10-13, 14, 18, 36, 37

Starter Motor Relay...... 8W-10-18, 36, 37, 54, 55

Sunroof Module.................. 8W-10-31, 53

Thatcham Alarm Module . . 8W-10-40, 46, 49, 55, 68

Trailer Tow Connector............ 8W-10-28, 66

Transmission Control Module....... 8W-10-13, 62

Transmission Control Relay..... 8W-10-13, 21, 41

Transmission Solenoid/Pressure Switch

Assembly....................... 8W-10-41

Vehicle Speed Sensor................ 8W-10-43

Washer Fluid Level Switch............ 8W-10-61

Washer Pump Motor................. 8W-10-69

Wiper Module................ 8W-10-16, 30, 60

8W - 10 - 2 8W-10 POWER DISTRIBUTIONRS

Page 972 of 2339

Component Page

Evaporator Temperature Sensor........ 8W-80-70

Floor Console Lamp................. 8W-80-70

Floor Console Power Outlet (Export).... 8W-80-70

Front Blower Module C1 (ATC)........ 8W-80-71

Front Blower Module C2 (ATC)........ 8W-80-71

Front Cigar Lighter................. 8W-80-71

Front Control Module................ 8W-80-72

Front Intrusion Sensor (United

Kingdom)....................... 8W-80-73

Front Reading Lamps/Switch.......... 8W-80-73

Fuel Heater (Diesel)................. 8W-80-73

Fuel Injector No. 1 (2.4L/3.3L/3.8L)..... 8W-80-73

Fuel Injector No. 1 (Diesel)............ 8W-80-73

Fuel Injector No. 2 (2.4L/3.3L/3.8L)..... 8W-80-74

Fuel Injector No. 2 (Diesel)............ 8W-80-74

Fuel Injector No. 3 (2.4L/3.3L/3.8L)..... 8W-80-74

Fuel Injector No. 3 (Diesel)............ 8W-80-74

Fuel Injector No. 4 (2.4L/3.3L/3.8L)..... 8W-80-75

Fuel Injector No. 4 (Diesel)............ 8W-80-75

Fuel Injector No. 5 (3.3L/3.8L)......... 8W-80-75

Fuel Injector No. 6 (3.3L/3.8L)......... 8W-80-75

Fuel Pressure Sensor (Diesel).......... 8W-80-76

Fuel Pressure Solenoid (Diesel)........ 8W-80-76

Fuel Pump Module.................. 8W-80-76

Generator......................... 8W-80-76

Glow Plug Relay (Diesel)............. 8W-80-77

Hands Free Module C1............... 8W-80-77

Hands Free Module C2............... 8W-80-77

Hands Free Module C3............... 8W-80-78

Headlamp Switch................... 8W-80-78

Headlamp Washer Pump Motor (Export) . 8W-80-78

High Note Horn.................... 8W-80-79

Hood Ajar Switch (Export)............ 8W-80-79

Idle Air Control Motor (Gas)........... 8W-80-79

Ignition Coil (2.4L).................. 8W-80-79

Ignition Coil (3.3L/3.8L).............. 8W-80-80

Ignition Switch..................... 8W-80-80

Inlet Air Temperature Sensor.......... 8W-80-80

Input Speed Sensor................. 8W-80-80

Instrument Cluster.................. 8W-80-81

Instrument Panel Switch Bank

(Except Heated Seats)............. 8W-80-81

Instrument Panel Switch Bank

(Heated Seats)................... 8W-80-81

Integrated Power Module C1.......... 8W-80-82

Integrated Power Module C2.......... 8W-80-82

Integrated Power Module C3.......... 8W-80-83

Integrated Power Module C4.......... 8W-80-83

Integrated Power Module C5.......... 8W-80-84

Integrated Power Module C6.......... 8W-80-84

Integrated Power Module C7.......... 8W-80-84

Integrated Power Module C8.......... 8W-80-85

Integrated Power Module C9.......... 8W-80-85

Knock Sensor (Except Export)......... 8W-80-85Component Page

Left B-Pillar Switch (Power Sliding

Door).......................... 8W-80-86

Left Cinch/Release Motor (Power Sliding

Door).......................... 8W-80-86

Left Curtain Airbag Squib............ 8W-80-86

Left Cylinder Lock Switch (Export)..... 8W-80-86

Left Door Speaker.................. 8W-80-87

Left Fog Lamp..................... 8W-80-87

Left Front Door Ajar Switch (Base)..... 8W-80-87

Left Front Door Lock Motor/Ajar Switch

(Except Base).................... 8W-80-87

Left Front Impact Sensor (Export)...... 8W-80-87

Left Front Impact Sensor (Except

Export)......................... 8W-80-88

Left Front Park/Turn Signal Lamp...... 8W-80-88

Left Front Wheel Speed Sensor........ 8W-80-88

Left Full Open Switch (Power Sliding

Door).......................... 8W-80-88

Left Headlamp (Caravan/Voyager Except

Export)......................... 8W-80-89

Left Headlamp (Town And Country)..... 8W-80-89

Left Headlamp Leveling Motor (Export) . . 8W-80-89

Left High Beam Lamp (Export)........ 8W-80-89

Left Instrument Panel Speaker........ 8W-80-90

Left Liftgate Flood Lamp (Export)...... 8W-80-90

Left Low Beam Lamp (Export)......... 8W-80-90

Left Mid Reading Lamp (Premium/

Luxury)........................ 8W-80-90

Left Park Lamp (Export)............. 8W-80-91

Left Power Mirror................... 8W-80-91

Left Rear Lamp Assembly............ 8W-80-91

Left Rear Pillar Speaker (Highline

Audio).......................... 8W-80-92

Left Rear Reading Lamp (Luxury)...... 8W-80-92

Left Rear Speaker.................. 8W-80-92

Left Rear Vent Motor................ 8W-80-92

Left Rear Wheel Speed Sensor......... 8W-80-93

Left Remote Radio Switch............ 8W-80-93

Left Repeater Lamp (Export).......... 8W-80-93

Left Side Impact Sensor 1 (Export)..... 8W-80-93

Left Side Impact Sensor 1 (Except

Export)......................... 8W-80-94

Left Side Impact Sensor 2............ 8W-80-94

Left Side Impact Sensor 3............ 8W-80-94

Left Sliding Door Control Module C1

(Power Sliding Door).............. 8W-80-94

Left Sliding Door Control Module C2

(Power Sliding Door).............. 8W-80-95

Left Sliding Door Latch Sensing Switch

(Power Sliding Door).............. 8W-80-95

Left Sliding Door Lock Motor (Power Sliding

Door).......................... 8W-80-95

Left Sliding Door Lock Motor/Ajar Switch

(Manual Sliding Door)............. 8W-80-96

RS8W-80 CONNECTOR PIN-OUTS8W-80-3

Page 1179 of 2339

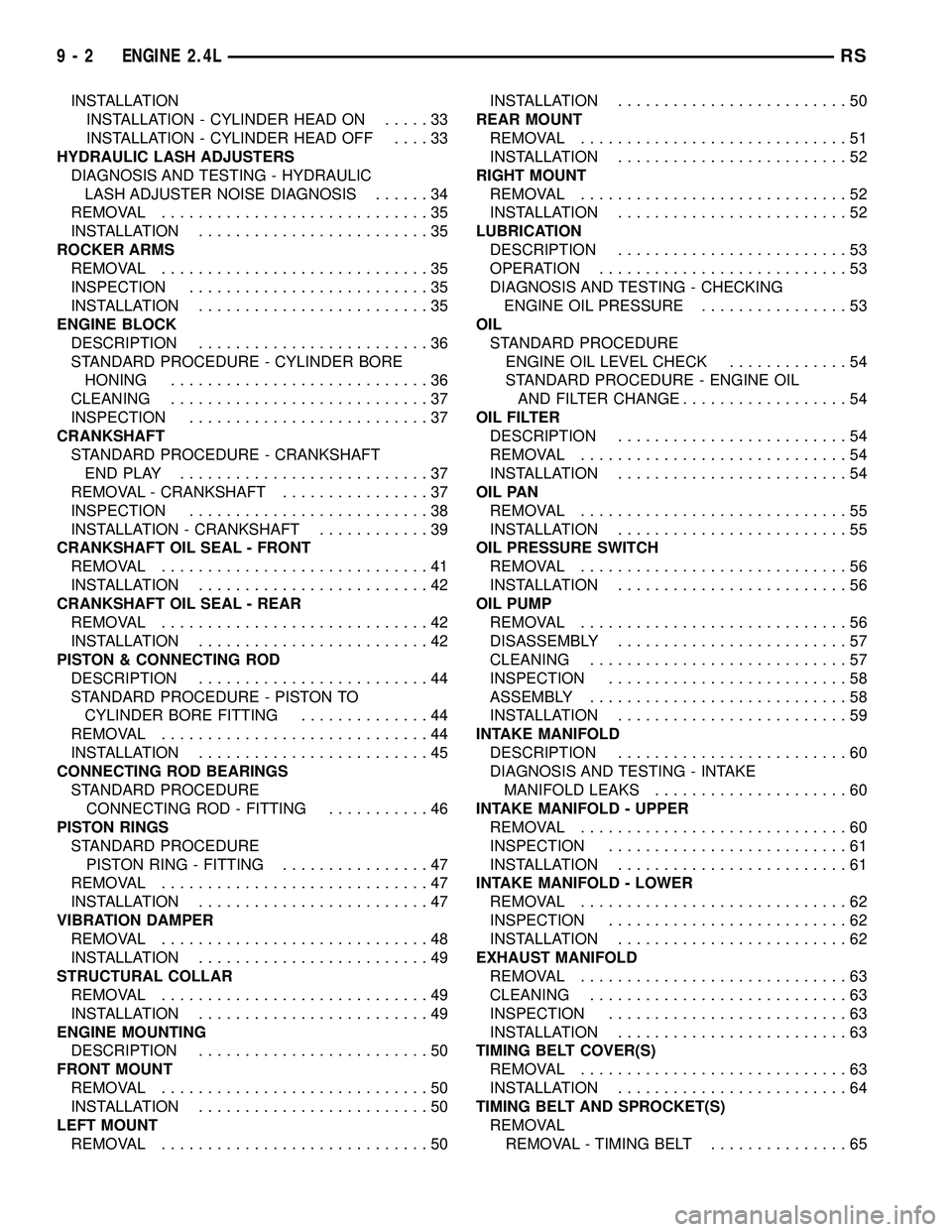

INSTALLATION

INSTALLATION - CYLINDER HEAD ON.....33

INSTALLATION - CYLINDER HEAD OFF....33

HYDRAULIC LASH ADJUSTERS

DIAGNOSIS AND TESTING - HYDRAULIC

LASH ADJUSTER NOISE DIAGNOSIS......34

REMOVAL.............................35

INSTALLATION.........................35

ROCKER ARMS

REMOVAL.............................35

INSPECTION..........................35

INSTALLATION.........................35

ENGINE BLOCK

DESCRIPTION.........................36

STANDARD PROCEDURE - CYLINDER BORE

HONING............................36

CLEANING............................37

INSPECTION..........................37

CRANKSHAFT

STANDARD PROCEDURE - CRANKSHAFT

ENDPLAY ...........................37

REMOVAL - CRANKSHAFT................37

INSPECTION..........................38

INSTALLATION - CRANKSHAFT............39

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................41

INSTALLATION.........................42

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................42

INSTALLATION.........................42

PISTON & CONNECTING ROD

DESCRIPTION.........................44

STANDARD PROCEDURE - PISTON TO

CYLINDER BORE FITTING..............44

REMOVAL.............................44

INSTALLATION.........................45

CONNECTING ROD BEARINGS

STANDARD PROCEDURE

CONNECTING ROD - FITTING...........46

PISTON RINGS

STANDARD PROCEDURE

PISTON RING - FITTING................47

REMOVAL.............................47

INSTALLATION.........................47

VIBRATION DAMPER

REMOVAL.............................48

INSTALLATION.........................49

STRUCTURAL COLLAR

REMOVAL.............................49

INSTALLATION.........................49

ENGINE MOUNTING

DESCRIPTION.........................50

FRONT MOUNT

REMOVAL.............................50

INSTALLATION.........................50

LEFT MOUNT

REMOVAL.............................50INSTALLATION.........................50

REAR MOUNT

REMOVAL.............................51

INSTALLATION.........................52

RIGHT MOUNT

REMOVAL.............................52

INSTALLATION.........................52

LUBRICATION

DESCRIPTION.........................53

OPERATION...........................53

DIAGNOSIS AND TESTING - CHECKING

ENGINE OIL PRESSURE................53

OIL

STANDARD PROCEDURE

ENGINE OIL LEVEL CHECK.............54

STANDARD PROCEDURE - ENGINE OIL

AND FILTER CHANGE..................54

OIL FILTER

DESCRIPTION.........................54

REMOVAL.............................54

INSTALLATION.........................54

OIL PAN

REMOVAL.............................55

INSTALLATION.........................55

OIL PRESSURE SWITCH

REMOVAL.............................56

INSTALLATION.........................56

OIL PUMP

REMOVAL.............................56

DISASSEMBLY.........................57

CLEANING............................57

INSPECTION..........................58

ASSEMBLY............................58

INSTALLATION.........................59

INTAKE MANIFOLD

DESCRIPTION.........................60

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS.....................60

INTAKE MANIFOLD - UPPER

REMOVAL.............................60

INSPECTION..........................61

INSTALLATION.........................61

INTAKE MANIFOLD - LOWER

REMOVAL.............................62

INSPECTION..........................62

INSTALLATION.........................62

EXHAUST MANIFOLD

REMOVAL.............................63

CLEANING............................63

INSPECTION..........................63

INSTALLATION.........................63

TIMING BELT COVER(S)

REMOVAL.............................63

INSTALLATION.........................64

TIMING BELT AND SPROCKET(S)

REMOVAL

REMOVAL - TIMING BELT...............65

9 - 2 ENGINE 2.4LRS

Page 1183 of 2339

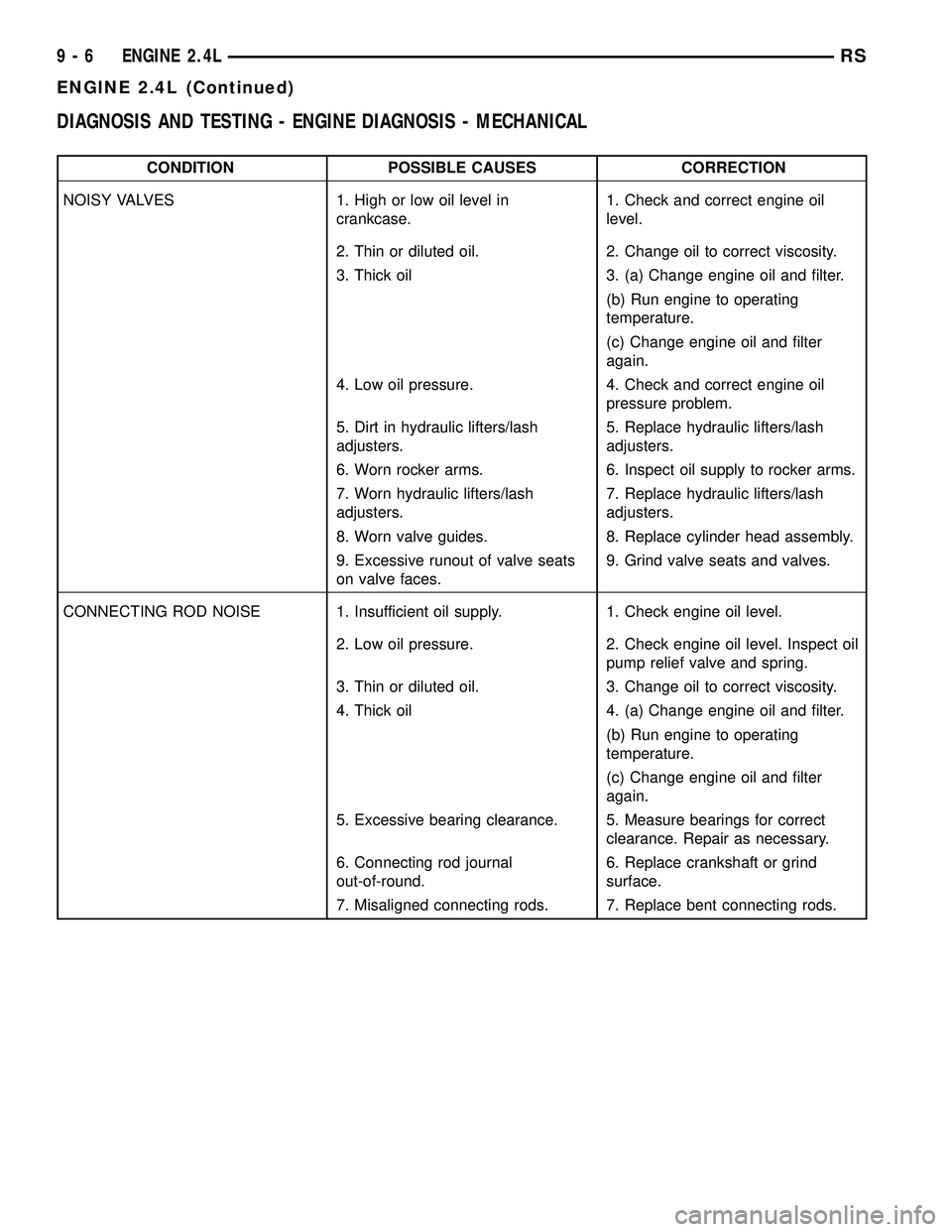

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

4. Low oil pressure. 4. Check and correct engine oil

pressure problem.

5. Dirt in hydraulic lifters/lash

adjusters.5. Replace hydraulic lifters/lash

adjusters.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn hydraulic lifters/lash

adjusters.7. Replace hydraulic lifters/lash

adjusters.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Connecting rod journal

out-of-round.6. Replace crankshaft or grind

surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

9 - 6 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1184 of 2339

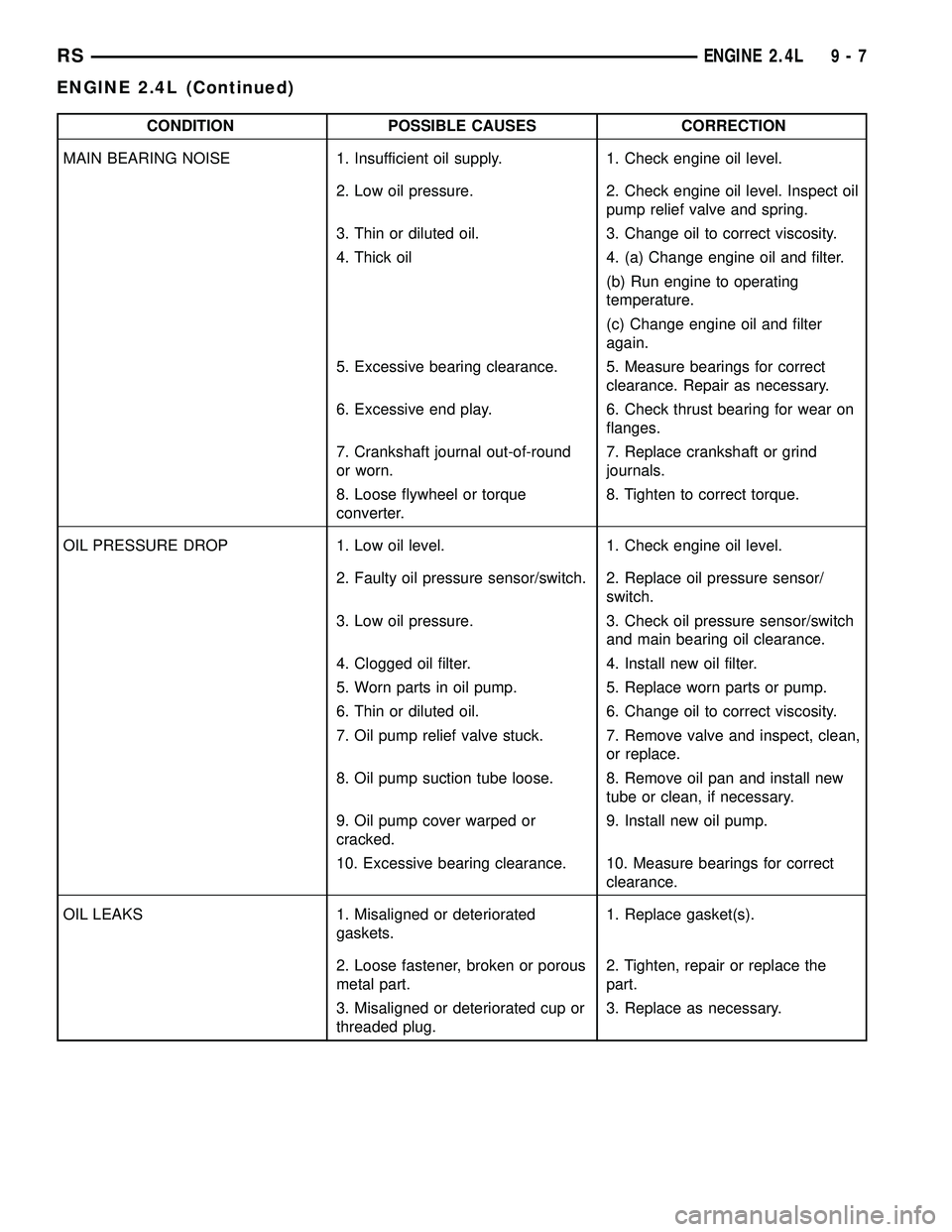

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on

flanges.

7. Crankshaft journal out-of-round

or worn.7. Replace crankshaft or grind

journals.

8. Loose flywheel or torque

converter.8. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sensor/switch. 2. Replace oil pressure sensor/

switch.

3. Low oil pressure. 3. Check oil pressure sensor/switch

and main bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

RSENGINE 2.4L9-7

ENGINE 2.4L (Continued)

Page 1186 of 2339

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

Page 1193 of 2339

(24) Connect all vacuum lines.

(25) Connect the throttle cables.

(26) Connect the fuel line. (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY/QUICK CONNECT FIT-

TING - STANDARD PROCEDURE)

(27) Connect radiator lower and upper hoses.

(28) Install radiator fans. (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - INSTALLATION)

(29) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(30) Connect battery cables.

(31) Install air cleaner and inlet hose.

(32) Fill engine crankcase with proper oil to cor-

rect level.

(33) Start engine and run until operating temper-

ature is reached.

(34) Adjust transmission linkage, if necessary.

SPECIFICATIONS

SPECIFICATIONS - 2.4L ENGINE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Type In-Line OHV, DOHC

Number of

Cylinders4

Firing Order 1-3-4-2

Compression

Ratio9.5:1

Max. Variation

Between

Cylinders25%

Metric Standard

Displacement 2.4 Liters 148 cu. in.

Bore 87.5 mm 3.445 in.

Stroke 101.0 mm 3.976 in.

Compression

Pressure1172-1551 kPa 170-225 psi

CYLINDER BLOCK

DESCRIPTION SPECIFICATIONS

Metric Standard

Cylinder Bore

Diameter87.4924 -

87.5076 mm3.4446 - 3.4452

in.

Out-of-Round

(Max.)0.051 mm 0.002 in.

Taper (Max.) 0.051 mm 0.002 in.

Fig. 9 RIGHT MOUNT TO RAIL AND ENGINE

1 - BOLT - MOUNT TO RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO ENGINE 54 N´m (40 ft. lbs.)

3 - BOLT - MOUNT TO RAIL (HORIZONTAL) 68 N´m (50 ft. lbs.)

4 - RIGHT ENGINE MOUNT

5 - RIGHT FRAME RAIL

Fig. 10 LEFT MOUNT TO FRAME BRACKET

1 - FRAME BRACKET

2 - FRAME RAIL - LEFT

3 - BOLT

4 - TRANSAXLE MOUNT

9 - 16 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 1211 of 2339

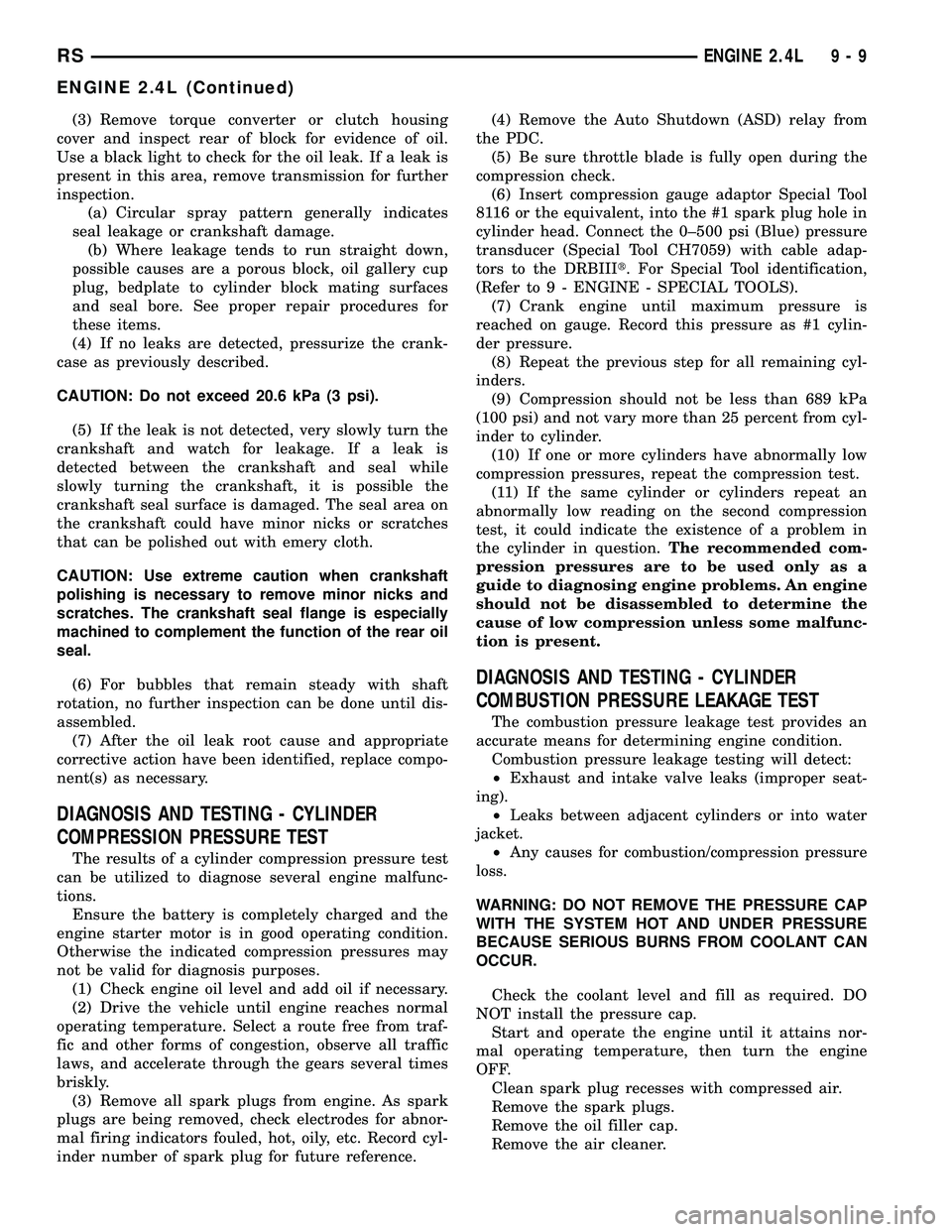

CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring retain-

ers with valve spring compressor the locks can

become dislocated. Ensure both locks are in the

correct location after removing tool.

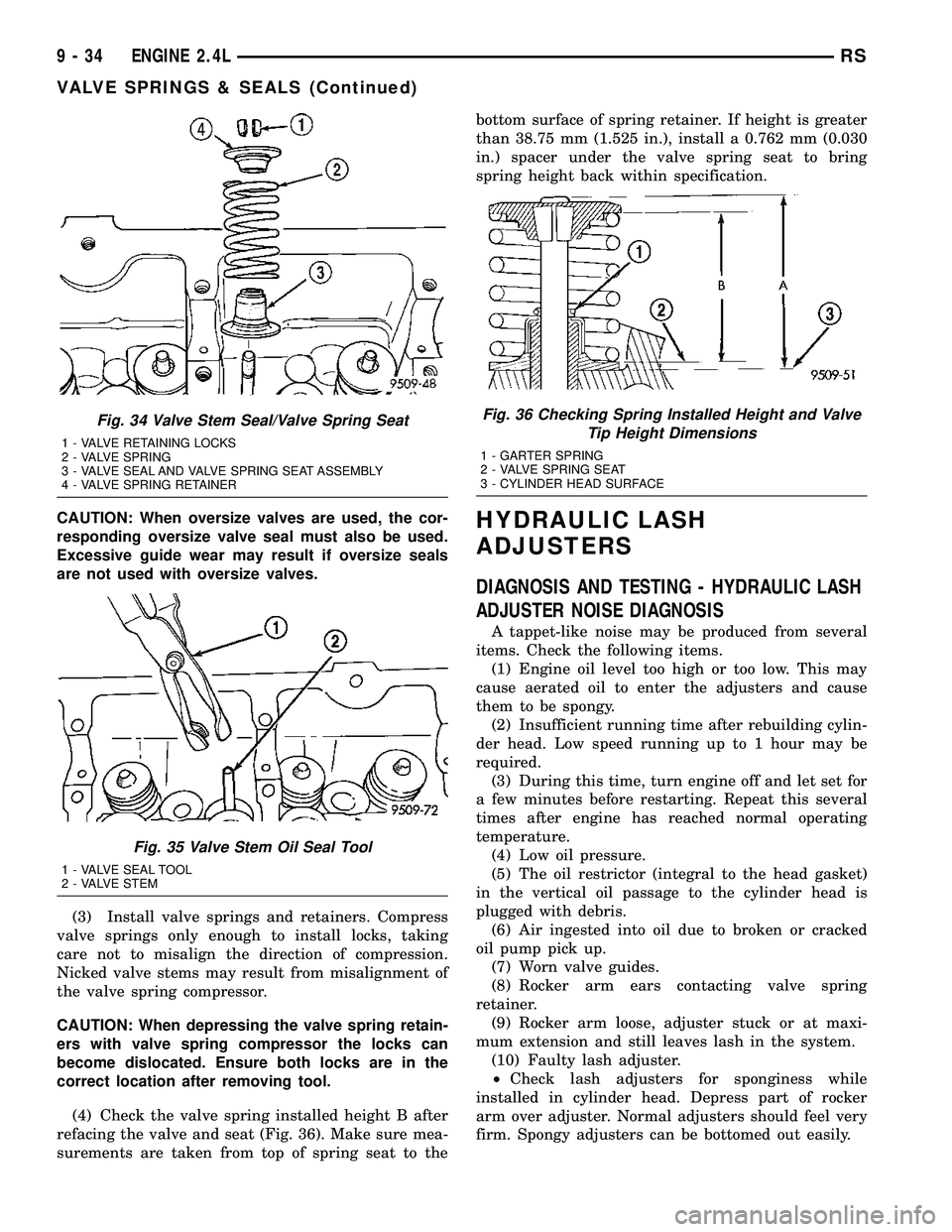

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 36). Make sure mea-

surements are taken from top of spring seat to thebottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a 0.762 mm (0.030

in.) spacer under the valve spring seat to bring

spring height back within specification.HYDRAULIC LASH

ADJUSTERS

DIAGNOSIS AND TESTING - HYDRAULIC LASH

ADJUSTER NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor (integral to the head gasket)

in the vertical oil passage to the cylinder head is

plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

²Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

Fig. 34 Valve Stem Seal/Valve Spring Seat

1 - VALVE RETAINING LOCKS

2 - VALVE SPRING

3 - VALVE SEAL AND VALVE SPRING SEAT ASSEMBLY

4 - VALVE SPRING RETAINER

Fig. 35 Valve Stem Oil Seal Tool

1 - VALVE SEAL TOOL

2 - VALVE STEM

Fig. 36 Checking Spring Installed Height and Valve

Tip Height Dimensions

1 - GARTER SPRING

2 - VALVE SPRING SEAT

3 - CYLINDER HEAD SURFACE

9 - 34 ENGINE 2.4LRS

VALVE SPRINGS & SEALS (Continued)

Page 1214 of 2339

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

CLEANING

Clean cylinder block thoroughly using a suitable

cleaning solvent.

INSPECTION

ENGINE BLOCK

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are to be installed, (Refer to 9

- ENGINE - STANDARD PROCEDURE - ENGINE

CORE AND OIL GALLERY PLUGS).

(3) Examine block and cylinder bores for cracks or

fractures.

(4) Check block deck surfaces for flatness. Deck

surface must be within service limit of 0.1 mm (0.004

in.).

CYLINDER BORE

NOTE: The cylinder bores should be measured at

normal room temperature, 21ÉC (70ÉF).

The cylinder walls should be checked for out-of-

round and taper with Tool C119 or equivalent (Fig.

42) (Refer to 9 - ENGINE - SPECIFICATIONS). If

the cylinder walls are badly scuffed or scored, the

cylinder block should be replaced, and new pistons

and rings fitted.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 42). Top measurement should be

10 mm (3/8 in.) down and bottom measurement

should be 10 mm (3/8 in.) up from bottom of bore.

(Refer to 9 - ENGINE - SPECIFICATIONS).

CRANKSHAFT

STANDARD PROCEDURE - CRANKSHAFT END

PLAY

(1) Using Dial Indicator C-3339 and Mounting

Post L-4438, attach to front of engine, locating probe

perpendicular on nose of crankshaft (Fig. 43).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Engine Specifica-

tions.

REMOVAL - CRANKSHAFT

NOTE: Crankshaft can not be removed when engine

is in vehicle.

(1) Remove engine assembly from vehicle (Refer to

9 - ENGINE - REMOVAL).

(2) Separate transaxle from engine.

(3) Remove drive plate/flex plate.

(4) Remove crankshaft rear oil seal (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL).

(5) Mount engine on a suitable repair stand.

Fig. 42 Checking Cylinder Bore Size

Fig. 43 Checking Crankshaft End Play - Typical

RSENGINE 2.4L9-37

ENGINE BLOCK (Continued)

Page 1231 of 2339

(6) Install oil pressure switch and connector. (Refer

to 9 - ENGINE/LUBRICATION/OIL PRESSURE

SENSOR/SWITCH - INSTALLATION)

OIL

STANDARD PROCEDURE

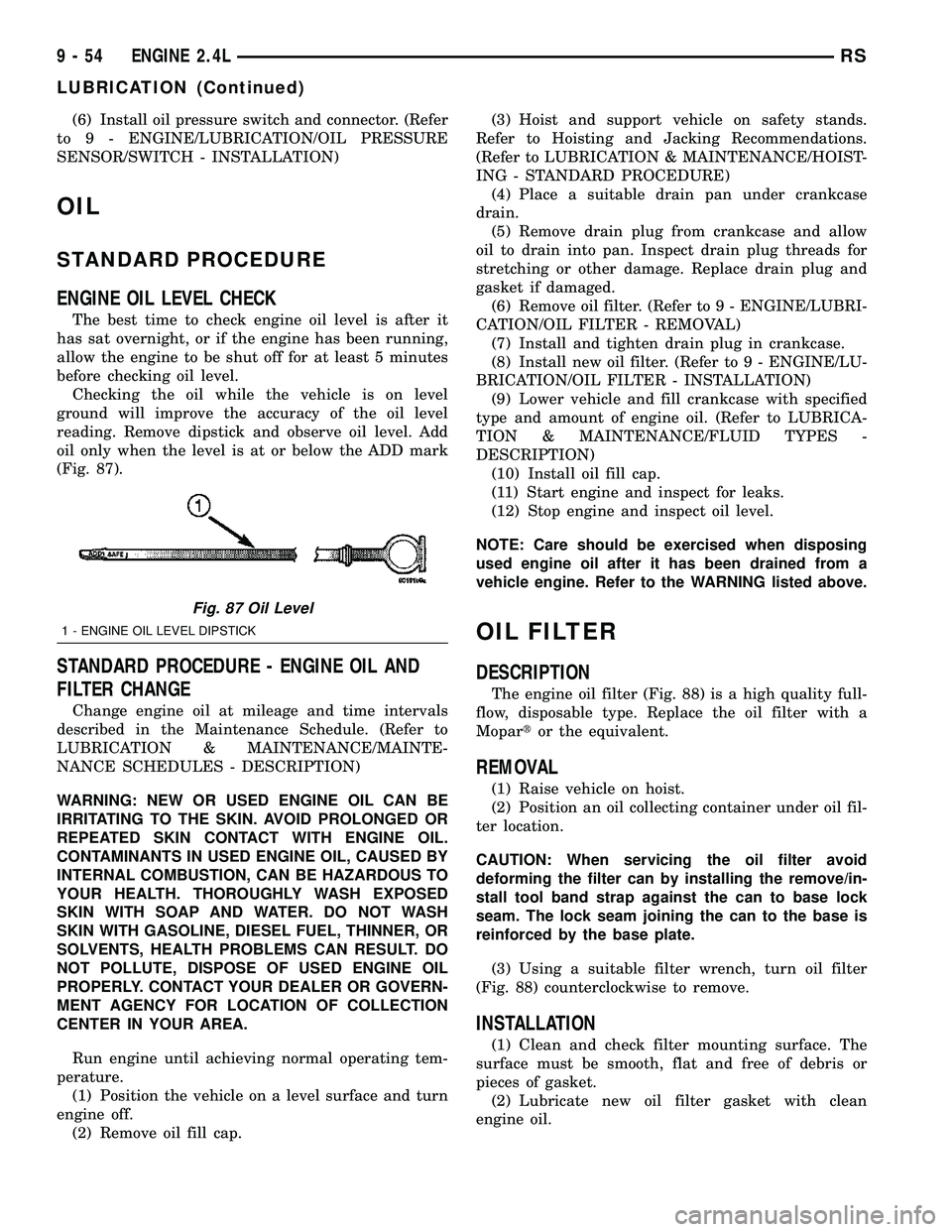

ENGINE OIL LEVEL CHECK

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick and observe oil level. Add

oil only when the level is at or below the ADD mark

(Fig. 87).

STANDARD PROCEDURE - ENGINE OIL AND

FILTER CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. (Refer to

LUBRICATION & MAINTENANCE/MAINTE-

NANCE SCHEDULES - DESCRIPTION)

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Remove oil fill cap.(3) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(Refer to LUBRICATION & MAINTENANCE/HOIST-

ING - STANDARD PROCEDURE)

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Remove oil filter. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL FILTER - REMOVAL)

(7) Install and tighten drain plug in crankcase.

(8) Install new oil filter. (Refer to 9 - ENGINE/LU-

BRICATION/OIL FILTER - INSTALLATION)

(9) Lower vehicle and fill crankcase with specified

type and amount of engine oil. (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES -

DESCRIPTION)

(10) Install oil fill cap.

(11) Start engine and inspect for leaks.

(12) Stop engine and inspect oil level.

NOTE: Care should be exercised when disposing

used engine oil after it has been drained from a

vehicle engine. Refer to the WARNING listed above.

OIL FILTER

DESCRIPTION

The engine oil filter (Fig. 88) is a high quality full-

flow, disposable type. Replace the oil filter with a

Mopartor the equivalent.

REMOVAL

(1) Raise vehicle on hoist.

(2) Position an oil collecting container under oil fil-

ter location.

CAUTION: When servicing the oil filter avoid

deforming the filter can by installing the remove/in-

stall tool band strap against the can to base lock

seam. The lock seam joining the can to the base is

reinforced by the base plate.

(3) Using a suitable filter wrench, turn oil filter

(Fig. 88) counterclockwise to remove.

INSTALLATION

(1) Clean and check filter mounting surface. The

surface must be smooth, flat and free of debris or

pieces of gasket.

(2) Lubricate new oil filter gasket with clean

engine oil.

Fig. 87 Oil Level

1 - ENGINE OIL LEVEL DIPSTICK

9 - 54 ENGINE 2.4LRS

LUBRICATION (Continued)