warning CHRYSLER CARAVAN 2005 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 375 of 2339

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic

problems. Prior to any test, perform the Self-Diag-

nostic Test. The self diagnostic system displays

instrument cluster stored fault codes in the odometer

display, sweeps the gauges to the calibration points,

and bulb checks the warning indicators. When the

key is in the ON position with the engine not run-

ning, the MIL will remain illuminated for regulatory

purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

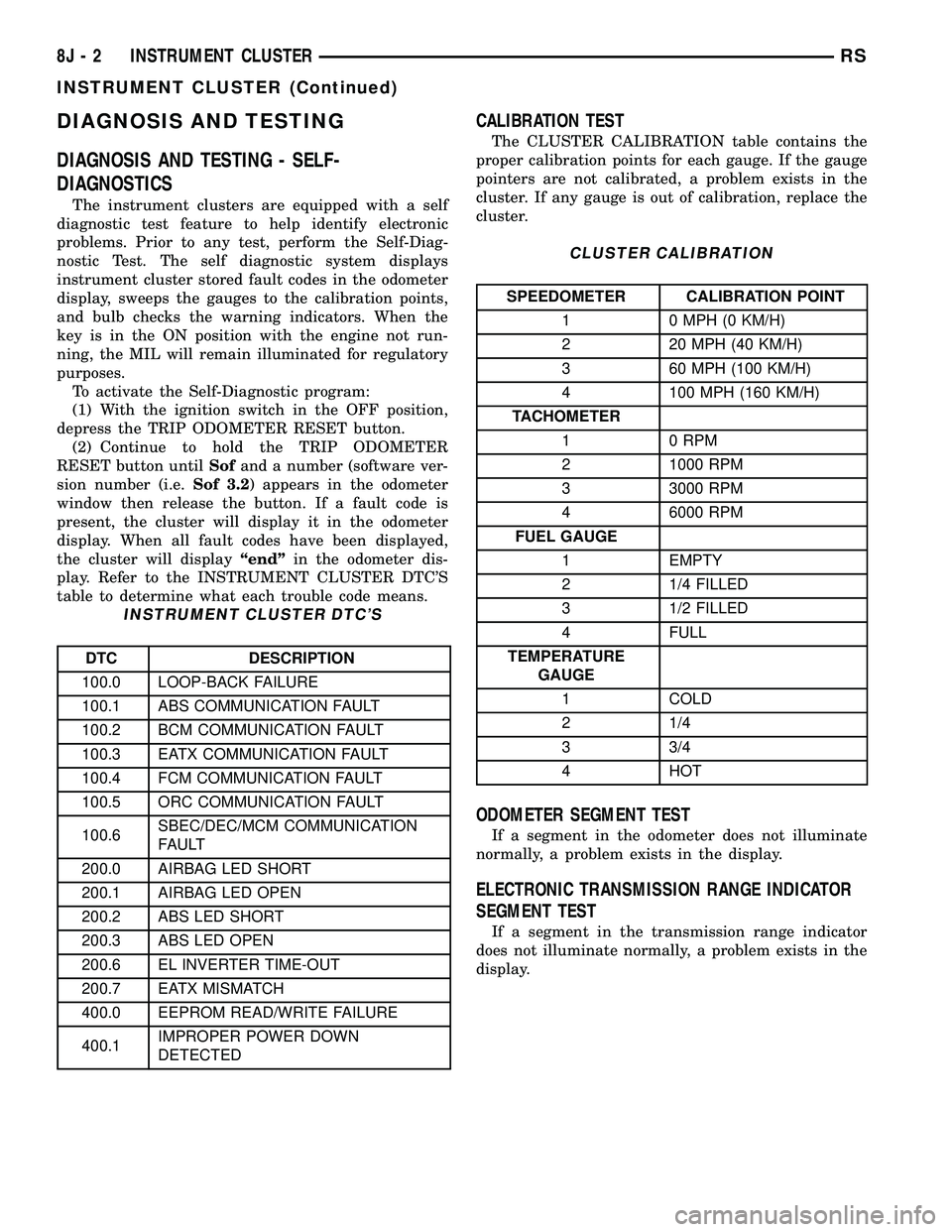

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

400.0 EEPROM READ/WRITE FAILURE

400.1IMPROPER POWER DOWN

DETECTED

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 386 of 2339

LAMPS

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR............... 1LAMPS/LIGHTING - INTERIOR............... 20

LAMPS/LIGHTING - EXTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION..........................2

OPERATION............................2

WARNING.............................3

SPECIFICATIONS

EXTERIOR LAMPS.....................3

BRAKE LAMP SWITCH

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - BRAKE LAMP

SWITCH.............................4

REMOVAL.............................5

INSTALLATION..........................5

CENTER HIGH MOUNTED STOP LAMP

REMOVAL.............................6

INSTALLATION..........................6

CENTER HIGH MOUNTED STOP LAMP UNIT

REMOVAL.............................6

INSTALLATION..........................6

FRONT FOG LAMP

DIAGNOSIS AND TESTING - FRONT FOG

LAMP...............................7

REMOVAL.............................8

INSTALLATION..........................8

FRONT FOG LAMP UNIT

STANDARD PROCEDURE

STANDARD PROCEDURE - FRONT FOG

LAMP UNIT ALIGNMENT.................9

STANDARD PROCEDURE - FRONT FOG

LAMP UNIT ALIGNMENT - EXPORT........9

REMOVAL.............................10

INSTALLATION.........................10

HEADLAMP

DIAGNOSIS AND TESTING - HEADLAMP.....11

REMOVAL.............................12INSTALLATION.........................13

HEADLAMP SWITCH

DIAGNOSIS AND TESTING - HEADLAMP

SWITCH............................13

REMOVAL.............................13

INSTALLATION.........................13

HEADLAMP UNIT

STANDARD PROCEDURE - HEADLAMP UNIT

ALIGNMENT.........................14

REMOVAL.............................15

INSTALLATION.........................15

HEADLAMP UNIT - EXPORT

STANDARD PROCEDURE - HEADLAMP UNIT

ALIGNMENT - EXPORT.................15

REMOVAL.............................17

INSTALLATION.........................17

LICENSE LAMP

REMOVAL.............................17

INSTALLATION.........................17

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM.....17

OPERATION - TURN SIGNAL SYSTEM.......17

DIAGNOSIS AND TESTING - MULTI-

FUNCTION SWITCH...................18

REMOVAL.............................18

INSTALLATION.........................18

PARK/TURN SIGNAL LAMP

REMOVAL.............................18

INSTALLATION.........................18

TAIL LAMP

REMOVAL.............................18

INSTALLATION.........................19

TAIL LAMP UNIT

REMOVAL.............................19

INSTALLATION.........................19

RSLAMPS8L-1

Page 388 of 2339

DAYTIME RUNNING LAMPS

Power is reduced using pulse-width modulation to

the high beams, where by the power is switched on

and off rapidly instead of remaining on continuously.

The duration and interval of the power pulses is pro-

grammed into the FCM. Daytime running lamps are

functional when 450 rpm's are reached.

HEADLAMP SYSTEM

The headlamp system will default to headlamps

ON position when ignition switch is ON and when an

open or short circuit failure occurs on the headlamp

switch input or PCI data bus communication between

the BCM and the FCM fails. The system will return

to normal operation when the open or short is

repaired. A fault will be reported by the BCM when a

failure occurs on the dimmer or headlamp switch

input.

If the exterior lamps are ON and the headlamp

switch is in any position other than OFF or AUTO

and with the ignition switch OFF (LOCK) after 3

minutes the BCM sends a message via PCI bus to

the FCM informing the FCM to turn off the head-

lamps, park lamps and fog lamps. This feature pre-

vents the vehicle battery from being discharged when

the vehicle lights have been left ON.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is activated by

turning the headlamps ON (high or low beam) while

the engine is running, turning the ignition switch

OFF, and then turning the headlamp switch OFF

within 45 seconds. The system will not activate if

more than 45 seconds elapse between ignition switch

OFF and headlamp switch OFF. The BCM will allow

the headlamps to remain ON for 90 seconds (config-

urable) before they automatically turn off (If the key

is in the ignition during the headlamp time delay

mode, then both the headlamps and park lamps

(including panel dimming) will be ON). Refer to the

Owner's Manual for more information.

If the headlamp switch is in the Auto Headlamp

Position, the headlamps are ON due to the night sig-

nal from the CMTC and the ignition switch is in any

position other than run/start, the BCM shall enter a

90 second (configurable) Auto Headlamps time delay

mode. If the key is in the ignition during the head-

lamp time delay mode, then both the headlamps and

park lamps (including panel dimming) will be ON. If

the key is not in the ignition, then only the head-

lamps will be ON. The BCM will allow the head-

lamps to remain ON for 90 seconds before they

automatically turn OFF. Refer to the Owner's Man-

ual for more information.

OPTICAL HORN/HIGH BEAMS

When the multi-function switch is pulled to the

first detent (optical horn) signal, the headlamps are

ON, key-in the ignition the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers to illuminate all four filaments (Low

and High beams). When the multi-function switch is

pulled to the second detent (high beam) signal and

the headlamps are ON, the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers. The High Beams are illuminated and

the Low Beams and Fog Lamps (if ON) are extin-

guished. If the headlamps were in the high beam

configuration when power was removed from the

headlamps, the headlamps will be configured as low

beam the next time they are activated.

NOTE: For RG - Export vehicles, the low beams and

front fog lamps will remain ON when high beams

are activated.

WARNING

Eye protection should be used when servicing

glass components. Personal injury or death can

result.

Do not touch the glass of halogen bulbs with

fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other

than those indicated in the Bulb Application

table. Damage to lamp and/or Daytime Running

Lamp Module can result. Do not use fuses, cir-

cuit breakers or relays having greater amper-

age value than indicated on the fuse panel or in

the Owners Manual.

Do not use bulbs other than those listed in

the Bulb Application Table. Damage to lamp

can result. Do not touch halogen bulbs with fin-

gers or other oily surfaces. Bulb life will be

reduced.

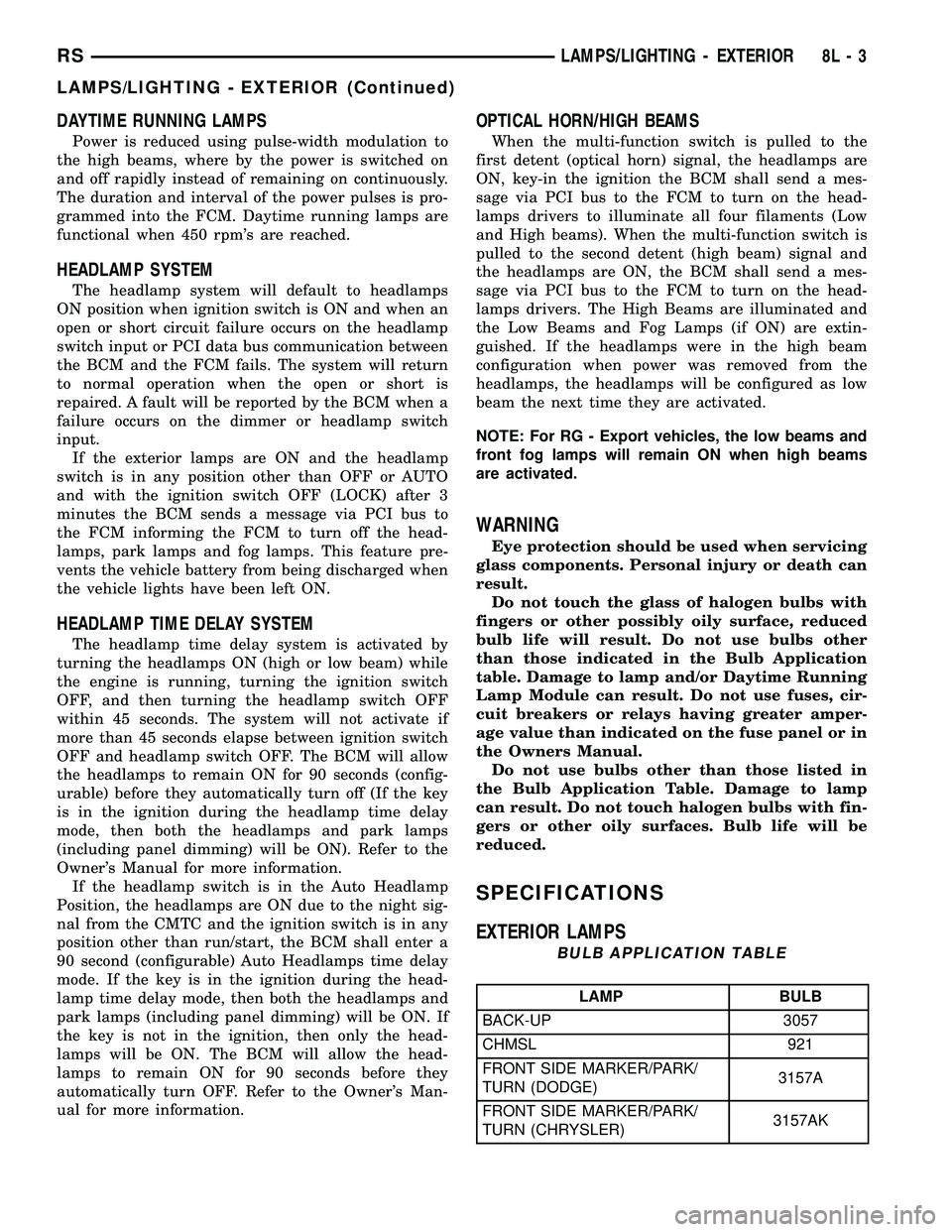

SPECIFICATIONS

EXTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

BACK-UP 3057

CHMSL 921

FRONT SIDE MARKER/PARK/

TURN (DODGE)3157A

FRONT SIDE MARKER/PARK/

TURN (CHRYSLER)3157AK

RSLAMPS/LIGHTING - EXTERIOR8L-3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 405 of 2339

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS.....................20

CENTER CONSOLE LAMP

REMOVAL.............................21

INSTALLATION.........................21

CENTER CONSOLE LAMP SWITCH

REMOVAL.............................21

INSTALLATION.........................21

CLUSTER ILLUMINATION LAMPS

REMOVAL.............................21

INSTALLATION.........................21

COURTESY LAMP

REMOVAL.............................21

INSTALLATION.........................21DOME/CARGO LAMP

REMOVAL.............................22

INSTALLATION.........................22

GLOVE BOX LAMP SWITCH

REMOVAL.............................22

INSTALLATION.........................22

LIFTGATE LAMP

REMOVAL.............................22

INSTALLATION.........................22

READING LAMP

REMOVAL.............................22

INSTALLATION.........................23

VANITY LAMP

REMOVAL.............................24

INSTALLATION.........................24

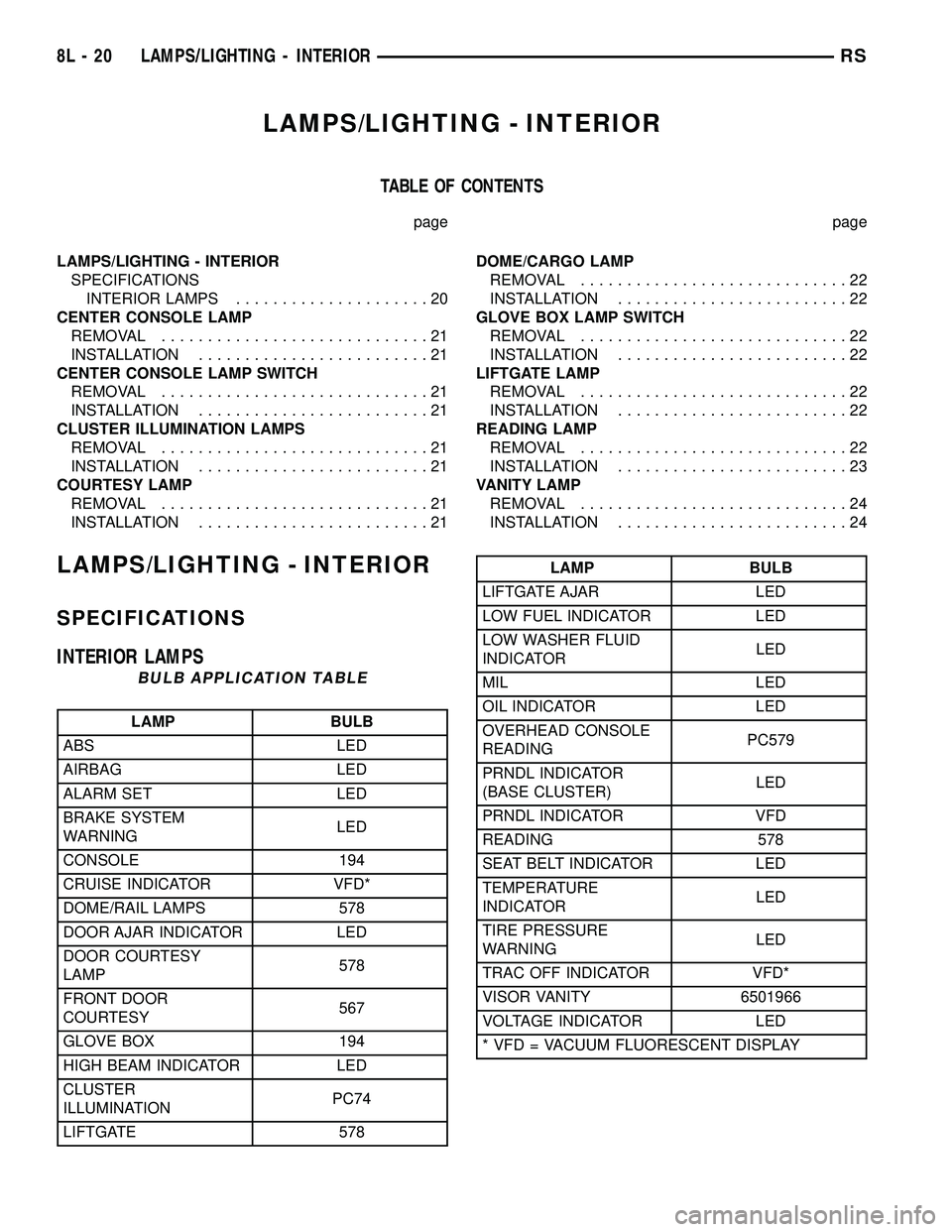

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET LED

BRAKE SYSTEM

WARNINGLED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY

LAMP578

FRONT DOOR

COURTESY567

GLOVE BOX 194

HIGH BEAM INDICATOR LED

CLUSTER

ILLUMINATIONPC74

LIFTGATE 578

LAMP BULB

LIFTGATE AJAR LED

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MIL LED

OIL INDICATOR LED

OVERHEAD CONSOLE

READINGPC579

PRNDL INDICATOR

(BASE CLUSTER)LED

PRNDL INDICATOR VFD

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE

INDICATORLED

TIRE PRESSURE

WARNINGLED

TRAC OFF INDICATOR VFD*

VISOR VANITY 6501966

VOLTAGE INDICATOR LED

* VFD = VACUUM FLUORESCENT DISPLAY

8L - 20 LAMPS/LIGHTING - INTERIORRS

Page 417 of 2339

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE/ELEC-

TRONIC VEHICLE INFO CENTER - STANDARD

PROCEDURE).

DIAGNOSIS AND TESTING

ELECTRONIC VEHICLE INFORMATION CENTER

Electronic Vehicle Information Center (EVIC) data

is obtained from the Body Control Module (BCM) on

the Programmable Communications Interface (PCI)

Data Bus circuit. The EVIC will display dashes (- -)

for any of the screens it did not receive the bus mes-

sages. The label corresponding to the missing infor-

mation will be lit. If no EVIC data is displayed,

check the PCI Data Bus circuit communications and

the BCM. If the dimming level is improper check the

PCI Data Bus circuit.

The use of a DRBIIItscan tool and the proper

diagnostic procedures information are recommended

for further testing of the EVIC module and the PCI

data bus circuit. Perform the SELF-DIAGNOSTIC

TEST before replacing the EVIC module (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - DIAGNO-

SIS AND TESTING).

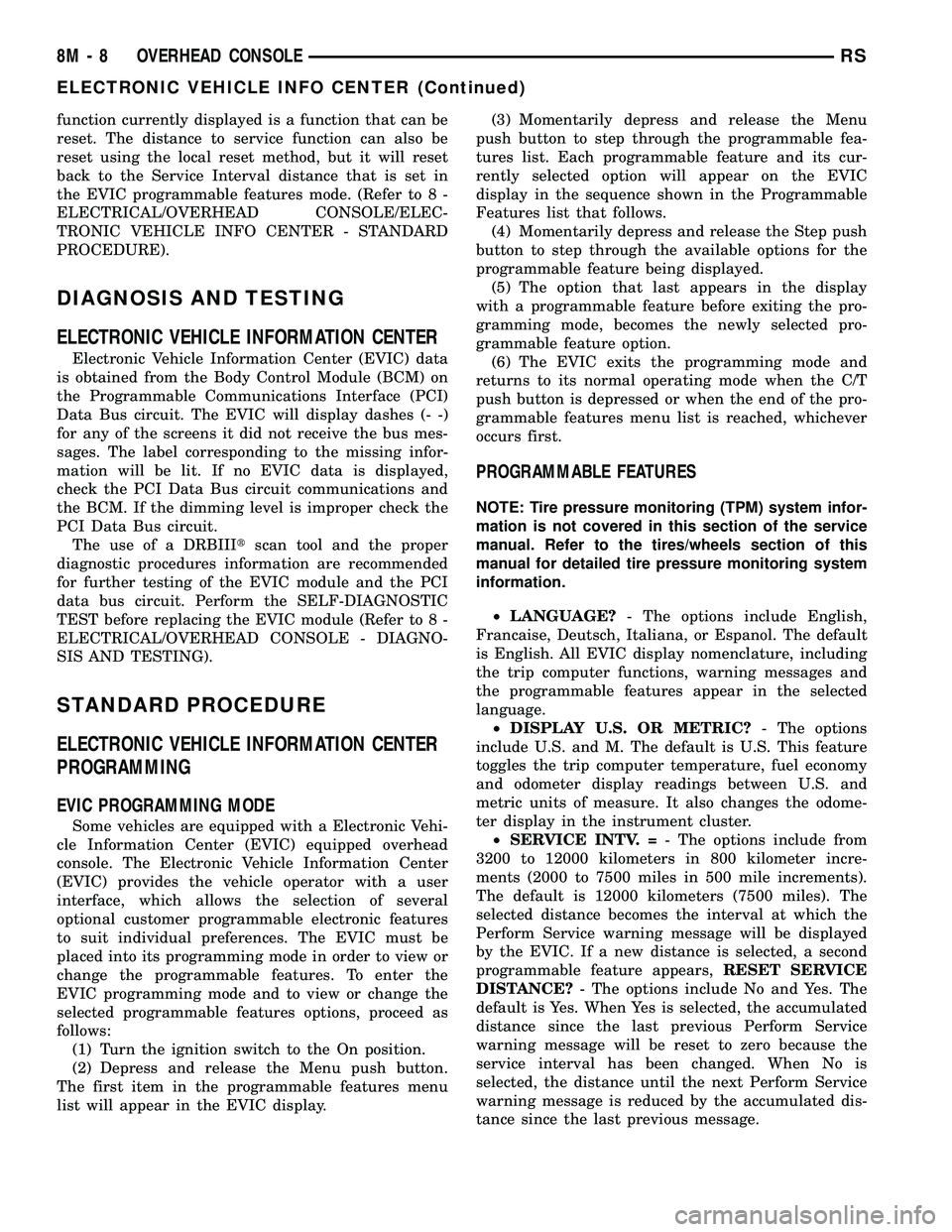

STANDARD PROCEDURE

ELECTRONIC VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

Some vehicles are equipped with a Electronic Vehi-

cle Information Center (EVIC) equipped overhead

console. The Electronic Vehicle Information Center

(EVIC) provides the vehicle operator with a user

interface, which allows the selection of several

optional customer programmable electronic features

to suit individual preferences. The EVIC must be

placed into its programming mode in order to view or

change the programmable features. To enter the

EVIC programming mode and to view or change the

selected programmable features options, proceed as

follows:

(1) Turn the ignition switch to the On position.

(2) Depress and release the Menu push button.

The first item in the programmable features menu

list will appear in the EVIC display.(3) Momentarily depress and release the Menu

push button to step through the programmable fea-

tures list. Each programmable feature and its cur-

rently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(4) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(5) The option that last appears in the display

with a programmable feature before exiting the pro-

gramming mode, becomes the newly selected pro-

grammable feature option.

(6) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the pro-

grammable features menu list is reached, whichever

occurs first.

PROGRAMMABLE FEATURES

NOTE: Tire pressure monitoring (TPM) system infor-

mation is not covered in this section of the service

manual. Refer to the tires/wheels section of this

manual for detailed tire pressure monitoring system

information.

²LANGUAGE?- The options include English,

Francaise, Deutsch, Italiana, or Espanol. The default

is English. All EVIC display nomenclature, including

the trip computer functions, warning messages and

the programmable features appear in the selected

language.

²DISPLAY U.S. OR METRIC?- The options

include U.S. and M. The default is U.S. This feature

toggles the trip computer temperature, fuel economy

and odometer display readings between U.S. and

metric units of measure. It also changes the odome-

ter display in the instrument cluster.

²SERVICE INTV. =- The options include from

3200 to 12000 kilometers in 800 kilometer incre-

ments (2000 to 7500 miles in 500 mile increments).

The default is 12000 kilometers (7500 miles). The

selected distance becomes the interval at which the

Perform Service warning message will be displayed

by the EVIC. If a new distance is selected, a second

programmable feature appears,RESET SERVICE

DISTANCE?- The options include No and Yes. The

default is Yes. When Yes is selected, the accumulated

distance since the last previous Perform Service

warning message will be reset to zero because the

service interval has been changed. When No is

selected, the distance until the next Perform Service

warning message is reduced by the accumulated dis-

tance since the last previous message.

8M - 8 OVERHEAD CONSOLERS

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 418 of 2339

²RETRAIN TIRE SENSORS?- This program-

mable feature only applies to vehicles equipped with

the optional Tire Pressure Monitoring System. The

options include Yes and No. The default is No. When

Yes is selected, and the menu button is depressed the

EVIC will enter the training mode, starting with the

left front tire.

²USE FACTORY SETTINGS?- The options

include Yes and No. The default is Yes. When yes is

selected all the programmable features will return to

there defaults and the rest of the programmable fea-

tures will not be displayed. If No is selected the rest

of the programmable features will be displayed at

there current chosen values. This feature will auto-

matically return to the Yes default under two condi-

tions. First, if no programmable features are changed

from there defaults. Second, if all the programmable

features equal there defaults.

²AUTO DOOR LOCKS?- The options include

Yes and No. The default is Yes. When Yes is selected,

all doors and the liftgate lock automatically when

vehicle speed reaches 25 kilometers-per-hour (15

miles-per-hour). If YES is selected, a second program-

mable feature appears,AUTO UNLOCK ON EXIT?

- The options again include Yes and No. The default

is No. When Yes is selected, following each Auto Door

Lock event all doors and the liftgate will automati-

cally unlock when the driver door is opened, if the

vehicle is stopped and the transmission gear selector

is in Park or Neutral. The Auto Door Unlock event

will only occur once following each Auto Door Lock

event.

²REMOTE UNLOCK- The options include

Driver Door 1st and All Doors. The default is Driver

Door 1st. When Diver Door 1st is selected, only the

driver door unlocks when the Unlock button of the

Remote Keyless Entry (RKE) transmitter is

depressed once. The Unlock button of the RKE trans-

mitter must be depressed twice to unlock all doors.

When All Doors is selected, all doors unlock when the

Unlock button of the RKE transmitter is depressed

once.

²REMOTE LINKED TO MEMORY?- This pro-

grammable feature only applies to vehicles equipped

with the optional memory / heated system. The

options include Yes and No. The default is No. When

Yes is selected, the memory system will recall the

Driver 1 or Driver 2 memory settings assigned to the

RKE transmitter being used to unlock the vehicle.

When No is selected, the memory system will only

recall memory settings when the Driver 1 or Driver 2

push buttons of the memory switch on the driver side

front door trim panel are depressed.

²SOUND HORN ON LOCK?- The options

include Yes and No. The default is No. When Yes is

selected, a short horn chirp will provide an audibleconfirmation when the RKE receiver recognizes a

valid Lock signal from an RKE transmitter. When No

is selected, no horn chirp will occur with the RKE

Lock event. This feature may be selected indepen-

dent of theFLASH LIGHTS WITH LOCKS?pro-

grammable feature.

²FLASH LIGHTS WITH LOCKS?- The options

include Yes and No. The default is Yes. When Yes is

selected, a single flash of the hazard warning lamps

will provide an optical confirmation when the RKE

receiver recognizes a valid Lock signal from an RKE

transmitter, and two flashes of the same lamps will

occur when the RKE receiver recognizes a valid

Unlock signal from an RKE transmitter. When No is

selected, no lamp flash will occur with the RKE Lock

or Unlock event. This feature may be selected inde-

pendent of theSOUND HORN ON LOCK?pro-

grammable feature.

²HEADLAMP DELAY =- The options include

Off, 30 Sec, 60 Sec, and 90 Sec. The default is 90 Sec.

When a time interval is selected, the headlamps will

remain on for that length of time when the head-

lamps are turned off after the ignition is turned off,

or if the Auto mode is selected on vehicles with the

Auto Headlamps option. When Off is selected, the

headlamp delay feature is disabled.

²HEADLAMPS ON WITH WIPERS?- This pro-

grammable feature only applies to vehicles equipped

with the optional Auto Headlamps. The options

include Yes and No. The default is No. When Yes is

selected, the headlamps will turn on automatically

when the windshield wipers are turned on. The head-

lamps will turn off when the wipers are turned off,

as long as the headlamp switch is in the Auto or Off

positions. When No is selected, the headlamps will

only turn on if manually selected or if the Auto mode

is selected and the outside ambient light levels dic-

tate that they should be on.

²POWER ACCESSORY DELAY?- The options

include Yes and No. The default is Yes. When No is

selected, the accessory powered components will turn

off automatically when the ignition key is turned off.

When Yes is selected, the accessory powered compo-

nents will remain on for 45 seconds when the igni-

tion key is turned off.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove overhead console. (Refer to 8 - ELEC-

TRICAL/OVERHEAD CONSOLE - REMOVAL).

(3) Remove the ten screws holding the Electronic

Vehicle Information Center (EVIC) module in the

overhead console.

(4) Remove EVIC module from console assembly.

RSOVERHEAD CONSOLE8M-9

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 425 of 2339

POWER LIFTGATE SYSTEM

DESCRIPTION

the components of the power liftgate system are:

²Liftgate gear motor assembly

²Latch assembly

²Lift gear and rod

²Power liftgate control module

²Chime/thermistor

²Full open switch

²Engage actuator

²Pinch sensor

²Liftgate handle switch

²Overhead console switch

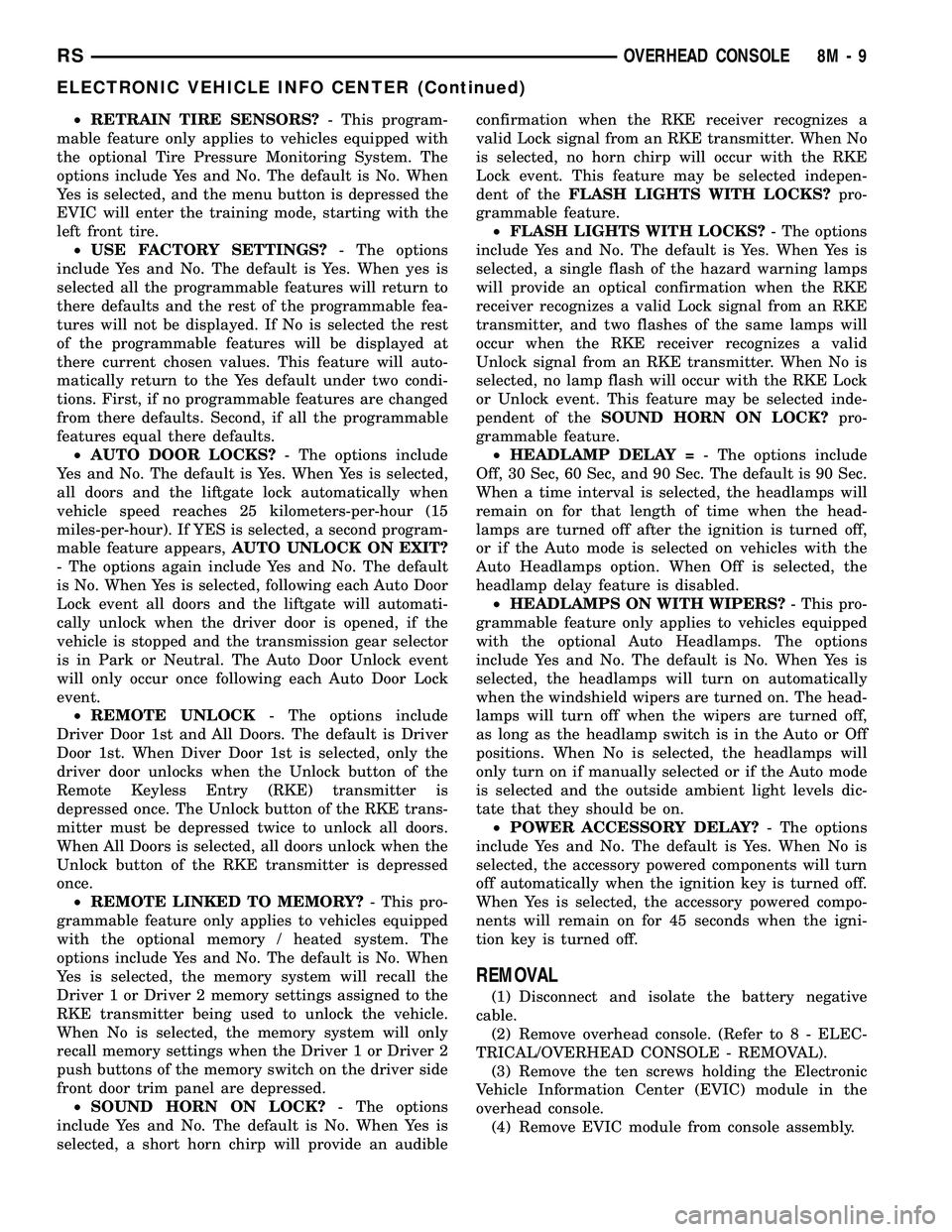

²Key fob switches (Fig. 1)

²Pawl switch

²Ratchet switch

The power liftgate system has its own power lift-

gate control module, located on the vehicles left body

D-pillar behind the trim panel. The power liftgate

gear motor assembly is located just above the control

module. The latch assembly is located in the bottom

center of the power liftgate, below the exterior lift-

gate handle switch. The power liftgate full open

switch, engage actuator, lift gear and rod are part of

the liftgate gear motor assembly. The pawl and

ratchet switches are part of the latch assembly. The

pinch sensors are located along the right and left

sides of the power liftgate, just above the body line.The liftgate handle switch is a power release switch

and is located in the rear light bar assembly, just

above the license plate. The overhead console switch

is a power open and close command switch located in

the vehicles overhead console.

Software technology has enabled the power liftgate

control module to detect resistance to liftgate travel,

which allows the power liftgate to stop and reverse

direction anytime an obstruction is felt or any of the

command switches are operated (only in closing

direction). Battery voltage is supplied to the power

liftgate system through a 40 amp fuse, located in the

Integrated Power Module (IPM) assembly. If the

power liftgate system develops a fault, the power lift-

gate can still be operated manually with a key, sim-

ilar to a manual liftgate.

The power liftgate control module communicates

on the Programmable Communication Interface (PCI)

Bus Circuit. Therefore, the power liftgate control

module can generate and store its own Diagnostic

Trouble Codes (DTC). The vehicles Body Control

Module (BCM) receives and supplies messages to the

power liftgate control module via the PCI bus circuit.

A diagnostic scan tool, such as the DRB IIItor equiv-

alent, is used to read and troubleshoot these DTCs.

Refer to the Body Diagnostic Manual for a complete

list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). Refer to the

appropriate wiring information for complete circuit

schematic or connector pin-out information.

WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS BEFORE ATTEMPTING ANY SER-

VICE OF THE POWER LIFTGATE SYSTEM OR COM-

PONENTS.

OPERATION

With the push of a power liftgate open/close com-

mand switch (key fob or overhead console mounted) a

signal is sent out on the Programmable Communica-

tion Interface (PCI) Data Bus circuit. This signal is

detected at the Body Control Module (BCM). The

BCM then sends a signal out on the PCI Data Bus

circuit to the power liftgate control module. The

power liftgate control module then signals the power

liftgate motor to start an open or close cycle, depend-

ing on what position the liftgate is in.

During a liftgate open or close cycle, if the power

liftgate module detects sufficient resistance to liftgate

travel, such as an obstruction in the path of the lift-

gate, the power liftgate control module will immedi-

ately stop the liftgate movement and reverse travel

to the full open or closed position. The ability for the

power liftgate module to detect resistance to liftgate

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR SWITCH

2 - RIGHT SLIDING DOOR SWITCH

3 - LIFTGATE SWITCH

8N - 2 POWER LIFTGATE SYSTEMRS

Page 426 of 2339

travel is accomplished by hall effect sensors, drive

motor speed and pinch sensors (tape switches).

Anytime the liftgate is opened or closed using the

power liftgate system the power liftgate control mod-

ule learns from the cycle. If a replacement power lift-

gate component is installed or a liftgate adjustment

is made, the module will relearn the effort and/or

time required to open or close the liftgate. This learn

cycle can be performed with a DRB IIIt, or equiva-

lent scan tool, or with a complete cycle of the liftgate,

using any one of the command switches. (Refer to 8 -

ELECTRICAL/POWER DOORS - STANDARD PRO-

CEDURE) for detailed instructions.

The power liftgate system is designed with a num-

ber of system inhibitors. These inhibitors are neces-

sary for safety and / or feasibility of the power

liftgate system. The power liftgate system inhibitors

are:

²The Power Liftgate may not operate in extreme

temperatures. These extreme temperatures will be

approximately less than -12É F (-24.4É C) or greater

than 143É F (61.6É C). A chime/thermister assembly

in the rear light bar assembly monitors the outside

temperature.

²The vehicle transmission must be in Park or

Neutral for the power liftgate to start a cycle.

²If multiple obstacles are detected during the

same power open or close cycle, the liftgate goes into

manual operation.

²If severe problems occur, Diagnostic Trouble

Codes (DTC) are stored in the power liftgate control

module.

POWER LIFTGATE SYSTEM CAUTIONS AND

WARNINGS

WARNING: ALWAYS DISCONNECT THE BATTERY

NEGATIVE CABLE BEFORE ATTEMPTING ANY

POWER LIFTGATE SYSTEM SERVICE.

WARNING: THERE IS A SMALL AREA ON BOTH

SIDES OF THE LOWER POWER LIFTGATE WHICH

IS NOT PROTECTED BY PINCH SENSORS.

EXTREME CARE MUST BE TAKEN TO PREVENT

OBJECTS FROM ENTERING THIS AREA ONCE THELIFTGATE REACHES THE SECONDARY LATCH

CONTACT (APPROXIMATELY 1/2 INCH BEFORE

FULLY CLOSED).

WARNING: NEVER ATTEMPT TO ENTER OR EXIT

THE VEHICLE WITH THE LIFTGATE IN MOTION.

YOU COULD DAMAGE THE POWER LIFTGATE SYS-

TEM AND/OR COMPONENTS AND/OR CAUSE PER-

SONAL INJURY.

WARNING: NEVER STICK OBJECTS IN THE POWER

LIFTGATE WHEN CINCHING CLOSED. YOU COULD

DAMAGE THE VEHICLE, POWER LIFTGATE SYS-

TEM COMPONENTS AND/OR CAUSE PERSONAL

INJURY.

DIAGNOSIS AND TESTING

POWER LIFTGATE SYSTEM

The power liftgate system contains many compo-

nents and modules. In order to obtain conclusive

testing the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the power liftgate system must be checked.

The power liftgate system can be diagnosed with

an appropriate scan tool, such as the DRB IIItor

equivalent. The DRB IIItcan be used to observe var-

ious switch statuses throughout the power liftgate

system to help diagnose an inoperative switch or

component. The DRB IIItcan also be used to actuate

various components throughout the power liftgate

system to help diagnose an inoperative component.

Before any testing of the power liftgate system is

attempted, the battery should be fully charged, all

built-in power liftgate system inhibitors read and

understood, and all wire harness and ground connec-

tions inspected around the affected areas on the vehi-

cle.

The following are quick reference diagnostic tables

to help when diagnosing and testing the power lift-

gate system.

RSPOWER LIFTGATE SYSTEM8N-3

POWER LIFTGATE SYSTEM (Continued)

Page 441 of 2339

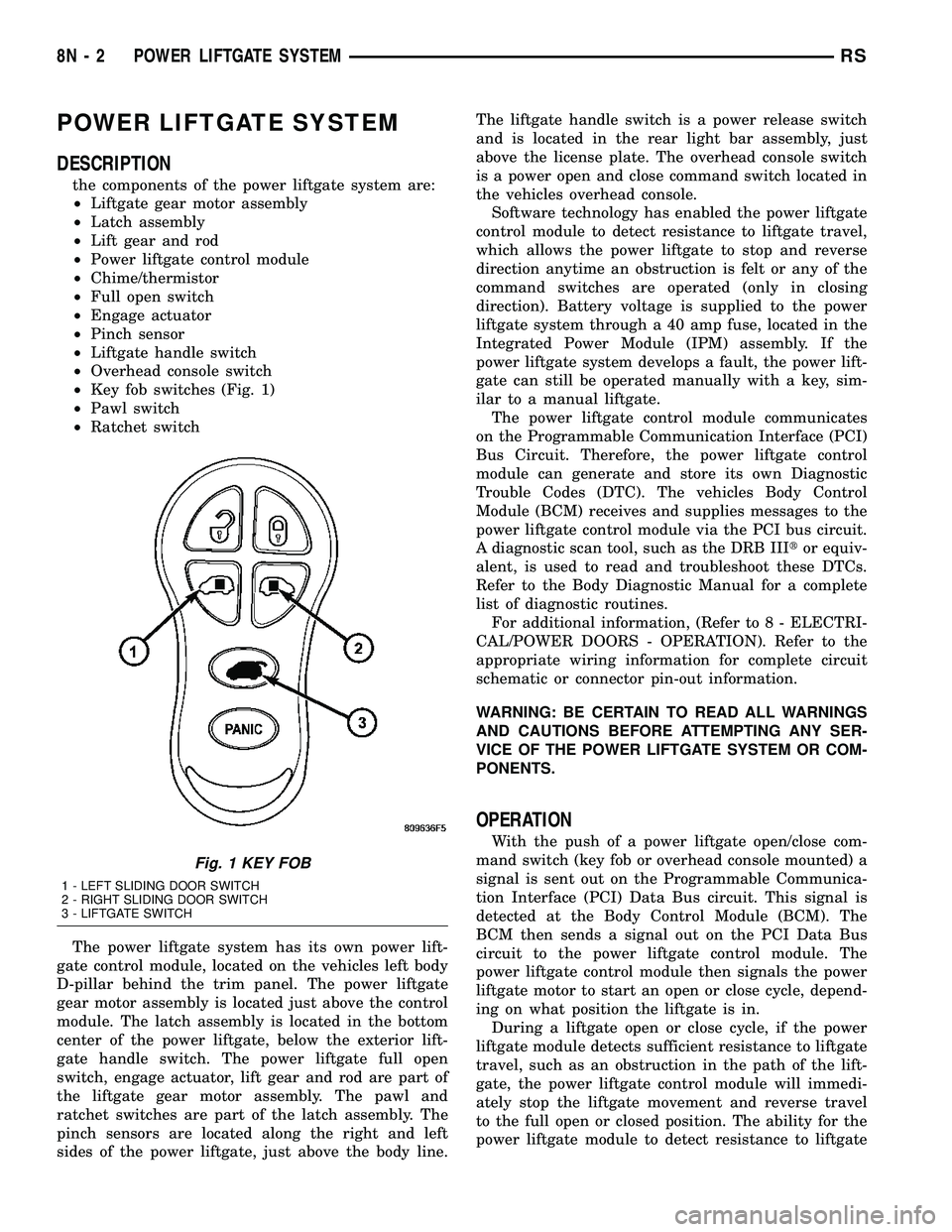

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove trim panel from liftgate, (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL).

(3) Disconnect the pinch sensor wire harness con-

nector (Fig. 20).

(4) Remove screws holding the pinch sensor to lift-

gate.

(5) Feed the pinch sensor wire harness out of the

liftgate and remove the sensor from the vehicle.

INSTALLATION

WARNING: USE EXTREME CAUTION WHEN TEST-

ING PINCH SENSOR OPERATION.

CAUTION: Ensure liftgate surface is clean and dry

prior to pinch sensor installation. Failure to do so

will inhibit the adhesive backings ability to adhere

to the liftgate and cause improper system operation

or premature component failure.

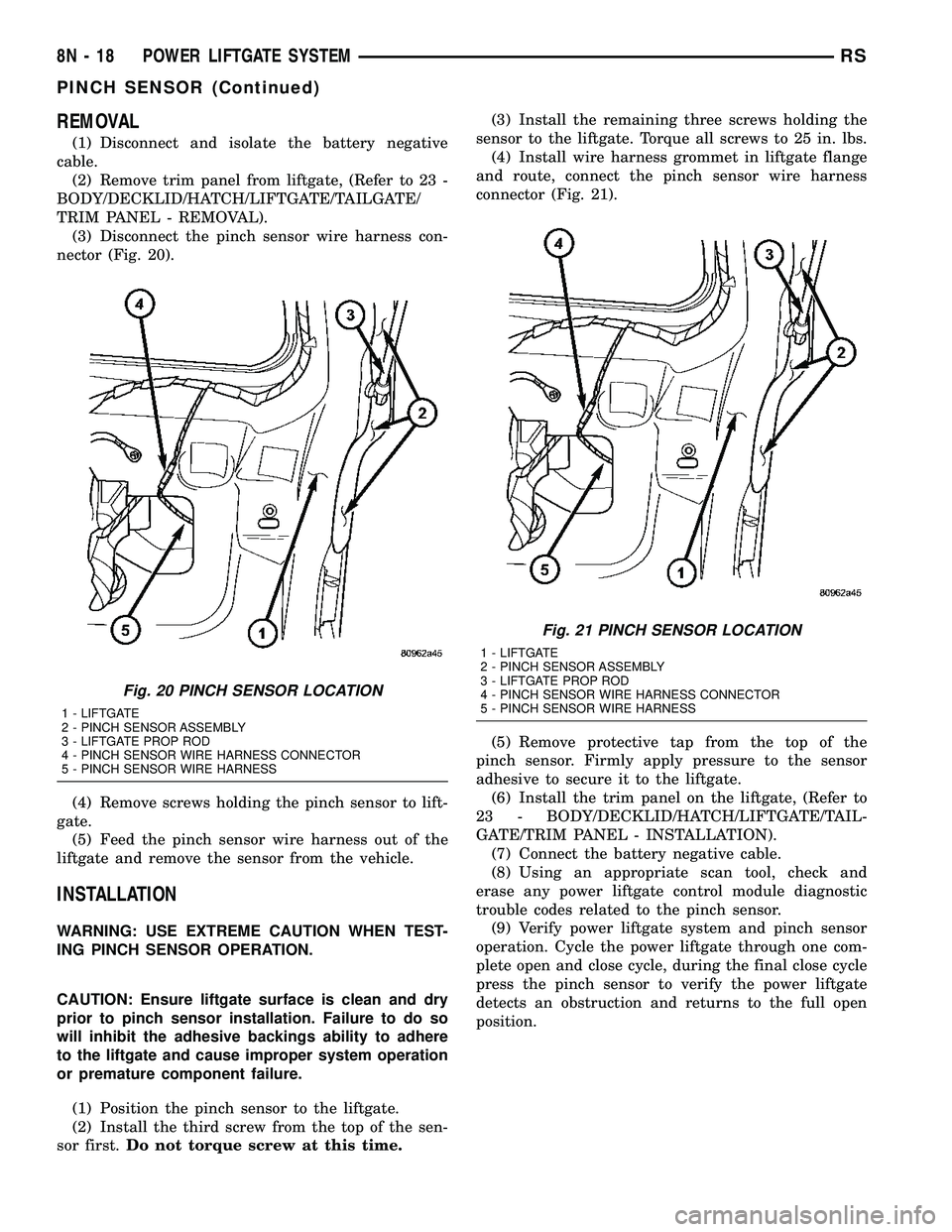

(1) Position the pinch sensor to the liftgate.

(2) Install the third screw from the top of the sen-

sor first.Do not torque screw at this time.(3) Install the remaining three screws holding the

sensor to the liftgate. Torque all screws to 25 in. lbs.

(4) Install wire harness grommet in liftgate flange

and route, connect the pinch sensor wire harness

connector (Fig. 21).

(5) Remove protective tap from the top of the

pinch sensor. Firmly apply pressure to the sensor

adhesive to secure it to the liftgate.

(6) Install the trim panel on the liftgate, (Refer to

23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/TRIM PANEL - INSTALLATION).

(7) Connect the battery negative cable.

(8) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the pinch sensor.

(9) Verify power liftgate system and pinch sensor

operation. Cycle the power liftgate through one com-

plete open and close cycle, during the final close cycle

press the pinch sensor to verify the power liftgate

detects an obstruction and returns to the full open

position.

Fig. 20 PINCH SENSOR LOCATION

1 - LIFTGATE

2 - PINCH SENSOR ASSEMBLY

3 - LIFTGATE PROP ROD

4 - PINCH SENSOR WIRE HARNESS CONNECTOR

5 - PINCH SENSOR WIRE HARNESS

Fig. 21 PINCH SENSOR LOCATION

1 - LIFTGATE

2 - PINCH SENSOR ASSEMBLY

3 - LIFTGATE PROP ROD

4 - PINCH SENSOR WIRE HARNESS CONNECTOR

5 - PINCH SENSOR WIRE HARNESS

8N - 18 POWER LIFTGATE SYSTEMRS

PINCH SENSOR (Continued)

Page 452 of 2339

OFF and back ON with the forward-facing light sen-

sor still covered. This defeats the day-detect logic. If

OK, go to Step 8. If not OK, replace the faulty mirror

unit.

(8) With the mirror darkened, place the transmis-

sion gear selector lever in the Reverse position. The

automatic day/night mirror should return to its nor-

mal reflectance. If not OK, replace the faulty mirror

unit.

Bench testing both mirrors can be done, of care is

exercised. For an inside mirror, the pin closest to he

mount is 12V (+), the next is 12V (-). The third is

reverse override. The fourth is outside mirror (+), and

the fifth is outside mirror (-).Do not apply 12 volts to

the fourth and fifth pins.With 12 volts on pins 1 and

2, the mirror can be tested by blocking the rear sensor

and shining a light into the forward sensor. For an out-

side mirror, there is a 2±pin connector. Applying 1.2

volts will cause the mirror to dim. If the mirror does not

dim, the entire glass assembly can be replaced just as it

is when the glass is broken.

WARNING: Do not apply 12 volts to the outside mir-

ror. Damage to the mirror will result.

POWER FOLDAWAY MIRROR

SWITCH - EXPORT

DESCRIPTION

These vehicles may be equipped with Power Fold-

away Mirrors. This feature allows both the driver

and passenger side view mirrors to fold inward

(retract) on demand. The vehicle has an additional

switch located on the steering column that controls

the folding function of the mirror assembly (Fig. 2).

The fold-away side view mirror is attached to the

vehicle's door in the same manner as mirrors without

the fold-away option. The fold-away mirrors unique

option is the internal motor which allows the mirrors to

fold inward on demand. The fold-away mirror motor is

not serviceable separately and if a motor is found to be

faulty the entire side view mirror must be replaced.

OPERATION

When the mirror retract switch is depressed, both

of the side view mirrors will fold inward, Thus mak-

ing the overall width of the vehicle the smallest pos-

sible. This can be helpful were parking space is a

absolute minimum.

When the driver's door is opened, only the driver's

door mirror will unfold. If the passenger door is

opened, both mirrors will unfold.

The power fold away mirror system consists of the fol-

lowing components: mirror switch, side view mirror,relay, wires and fuse. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair procedures,

details of wire harness routing and retention, connector

pin-out information and location views for the various

wire harness connectors, splices and grounds.

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove the upper and lower steering column

shroud (Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(3) Disconnect electrical harness connector.

(4) Remove switch from steering column shroud

(Fig. 3).

Fig. 2 POWER FOLDAWAY MIRROR SWITCH

1 - POWER FOLDAWAY MIRROR SWITCH

2 - STEERING COLUMN

Fig. 3 POWER FOLDING MIRROR SWITCH

1 - STEERING COLUMN SHROUD

2 - POWER FOLDAWAY SWITCH

RSPOWER MIRRORS8N-29

AUTOMATIC DAY / NIGHT MIRROR (Continued)