tires CHRYSLER CARAVAN 2005 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1777 of 2339

(2) Grasp the wheel cover at the edges in line with

the remaining installed wheel nuts and pull straight

outward from the wheel. This will pop the wheel

cover retaining tabs over the two remaining wheel

nuts, removing the wheel cover from the wheel.

INSTALLATION

NOTE: Wheel mounting nuts must be installed on

the studs as shown to allow installation of the

wheel cover (Fig. 30).

(1) Place the wheel cover on the wheel in the fol-

lowing fashion:(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 31).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 31).

This will hold the wheel cover in place.

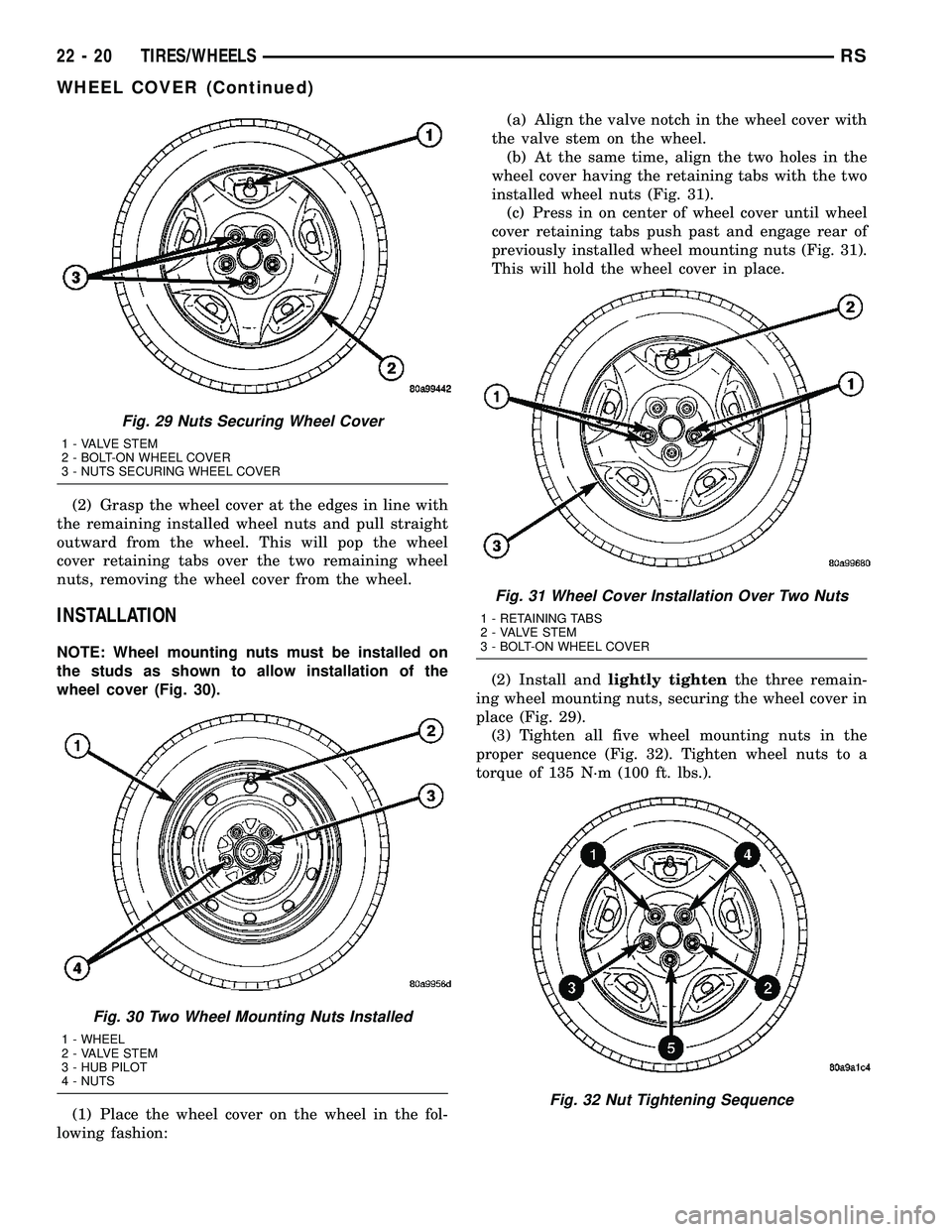

(2) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 29).

(3) Tighten all five wheel mounting nuts in the

proper sequence (Fig. 32). Tighten wheel nuts to a

torque of 135 N´m (100 ft. lbs.).

Fig. 29 Nuts Securing Wheel Cover

1 - VALVE STEM

2 - BOLT-ON WHEEL COVER

3 - NUTS SECURING WHEEL COVER

Fig. 30 Two Wheel Mounting Nuts Installed

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 31 Wheel Cover Installation Over Two Nuts

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 32 Nut Tightening Sequence

22 - 20 TIRES/WHEELSRS

WHEEL COVER (Continued)

Page 1778 of 2339

WHEEL MOUNTING STUDS -

FRONT

REMOVAL

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION).

CAUTION: Wheel mounting studs MUST NOT be

hammered out of hub flange of hub and bearing

assembly. If a stud is removed by hammering it out,

damage to hub and bearing assembly will occur

leading to premature bearing failure.

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove front wheel and tire assembly. (Refer

to 22 - TIRES/WHEELS - REMOVAL)

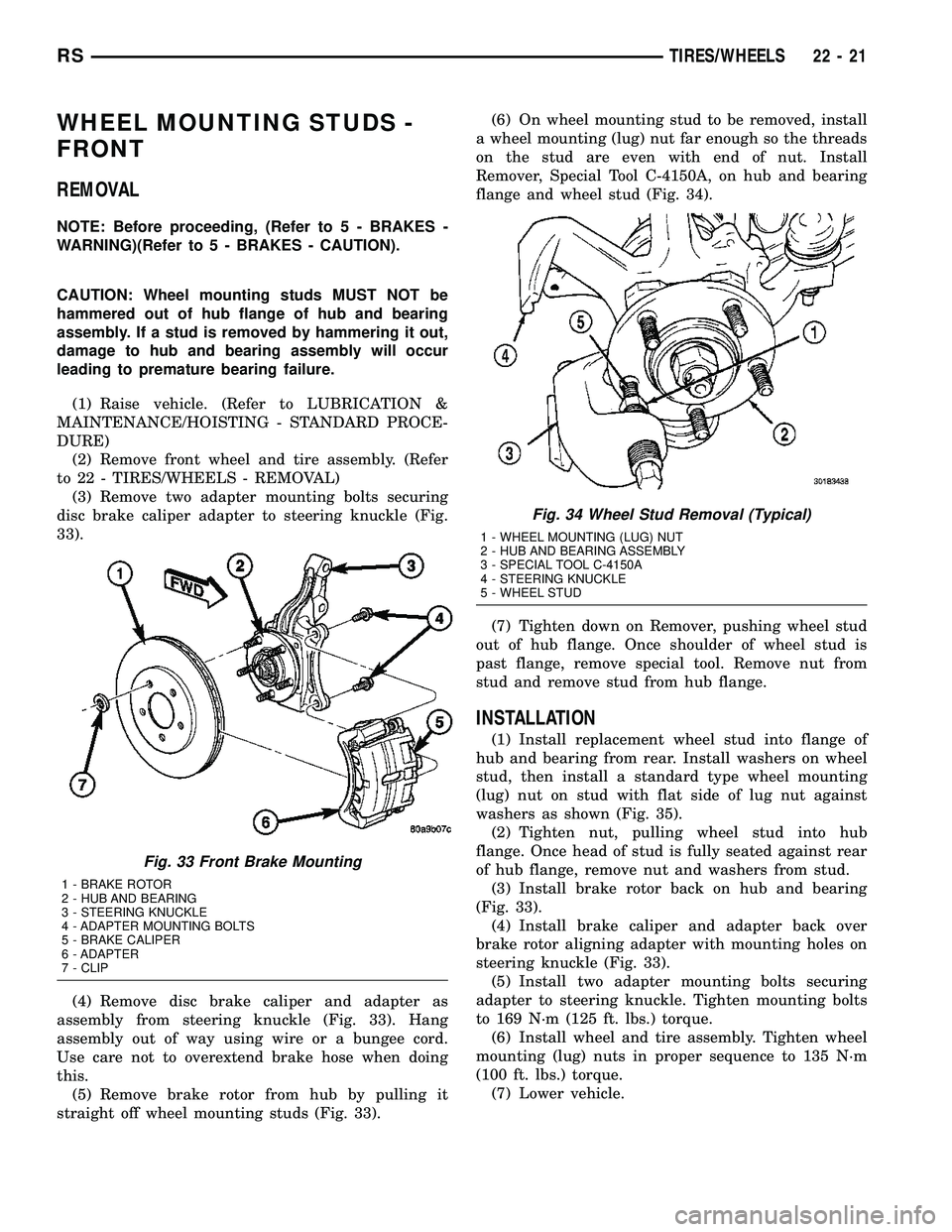

(3) Remove two adapter mounting bolts securing

disc brake caliper adapter to steering knuckle (Fig.

33).

(4) Remove disc brake caliper and adapter as

assembly from steering knuckle (Fig. 33). Hang

assembly out of way using wire or a bungee cord.

Use care not to overextend brake hose when doing

this.

(5) Remove brake rotor from hub by pulling it

straight off wheel mounting studs (Fig. 33).(6) On wheel mounting stud to be removed, install

a wheel mounting (lug) nut far enough so the threads

on the stud are even with end of nut. Install

Remover, Special Tool C-4150A, on hub and bearing

flange and wheel stud (Fig. 34).

(7) Tighten down on Remover, pushing wheel stud

out of hub flange. Once shoulder of wheel stud is

past flange, remove special tool. Remove nut from

stud and remove stud from hub flange.

INSTALLATION

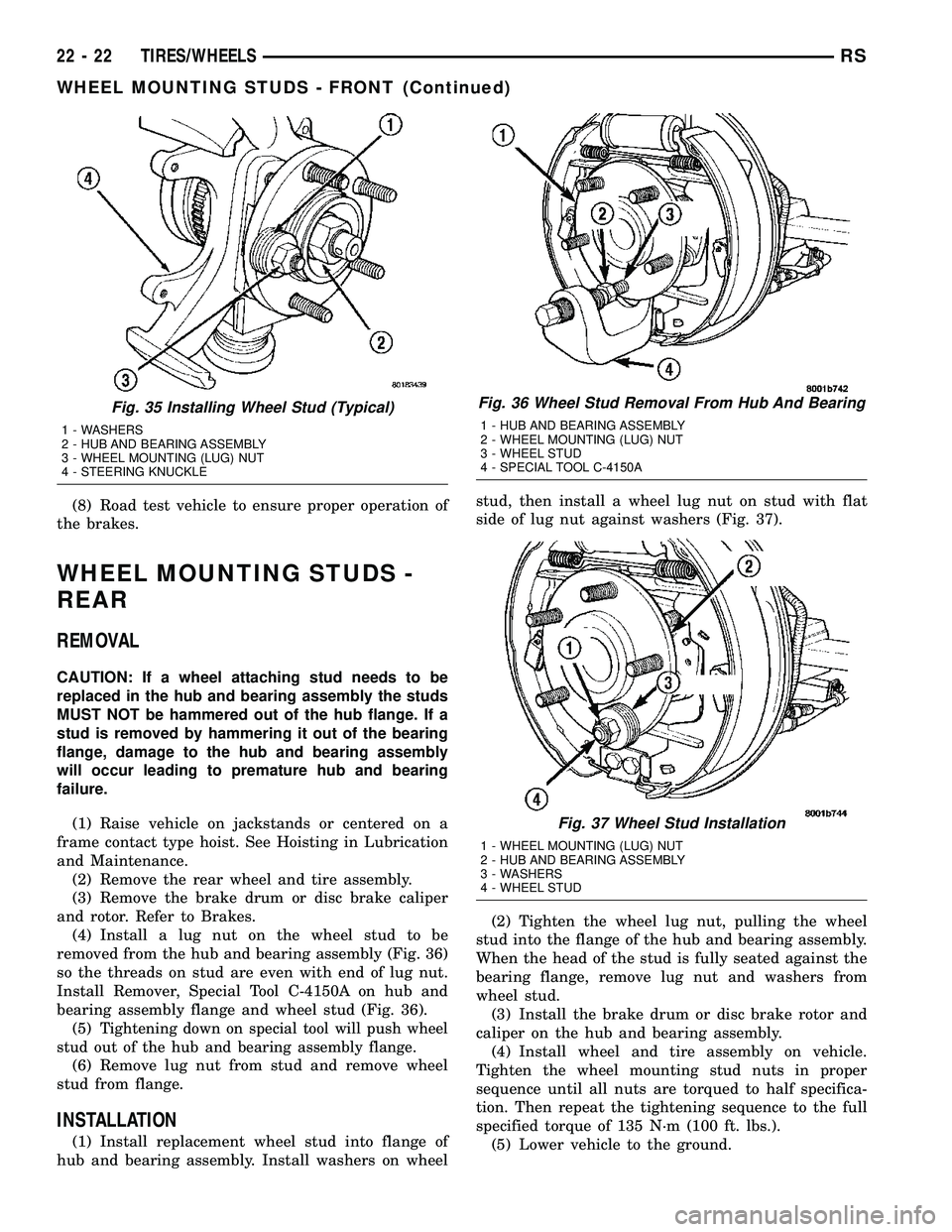

(1) Install replacement wheel stud into flange of

hub and bearing from rear. Install washers on wheel

stud, then install a standard type wheel mounting

(lug) nut on stud with flat side of lug nut against

washers as shown (Fig. 35).

(2) Tighten nut, pulling wheel stud into hub

flange. Once head of stud is fully seated against rear

of hub flange, remove nut and washers from stud.

(3) Install brake rotor back on hub and bearing

(Fig. 33).

(4) Install brake caliper and adapter back over

brake rotor aligning adapter with mounting holes on

steering knuckle (Fig. 33).

(5) Install two adapter mounting bolts securing

adapter to steering knuckle. Tighten mounting bolts

to 169 N´m (125 ft. lbs.) torque.

(6) Install wheel and tire assembly. Tighten wheel

mounting (lug) nuts in proper sequence to 135 N´m

(100 ft. lbs.) torque.

(7) Lower vehicle.

Fig. 33 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 34 Wheel Stud Removal (Typical)

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - SPECIAL TOOL C-4150A

4 - STEERING KNUCKLE

5 - WHEEL STUD

RSTIRES/WHEELS22-21

Page 1779 of 2339

(8) Road test vehicle to ensure proper operation of

the brakes.

WHEEL MOUNTING STUDS -

REAR

REMOVAL

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

MUST NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature hub and bearing

failure.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the rear wheel and tire assembly.

(3) Remove the brake drum or disc brake caliper

and rotor. Refer to Brakes.

(4) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly (Fig. 36)

so the threads on stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 36).

(5)

Tightening down on special tool will push wheel

stud out of the hub and bearing assembly flange.

(6) Remove lug nut from stud and remove wheel

stud from flange.

INSTALLATION

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheelstud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 37).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the brake drum or disc brake rotor and

caliper on the hub and bearing assembly.

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(5) Lower vehicle to the ground.

Fig. 35 Installing Wheel Stud (Typical)

1 - WASHERS

2 - HUB AND BEARING ASSEMBLY

3 - WHEEL MOUNTING (LUG) NUT

4 - STEERING KNUCKLE

Fig. 36 Wheel Stud Removal From Hub And Bearing

1 - HUB AND BEARING ASSEMBLY

2 - WHEEL MOUNTING (LUG) NUT

3 - WHEEL STUD

4 - SPECIAL TOOL C-4150A

Fig. 37 Wheel Stud Installation

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - WASHERS

4 - WHEEL STUD

22 - 22 TIRES/WHEELSRS

WHEEL MOUNTING STUDS - FRONT (Continued)

Page 2326 of 2339

QUAD BUCKET - REMOVAL, BUCKETSEAT BACK ........................ 23-140

QUAD BUCKET - REMOVAL, SEAT BELT BUCKLE - FIRST ROW INBOARD ........8O-35

QUAD BUCKET, 50/50 SPLIT, BENCH - INSTALLATION, SEAT BACK HINGE

COVERS ........................... 23-146

QUAD BUCKET, 50/50 SPLIT, BENCH - INSTALLATION, SEAT CUSHION COVER . . 23-144

QUAD BUCKET, 50/50 SPLIT, BENCH - REMOVAL, SEAT BACK HINGE COVERS . . 23-146

QUAD BUCKET, 50/50 SPLIT, BENCH - REMOVAL, SEAT CUSHION COVER ......23-144

QUAD BUCKET SEAT RISER - INSTALLATION ...................... 23-143

QUAD BUCKET SEAT RISER - REMOVAL . 23-143

QUAD BUCKET SEAT SIDE SHIELD - NO CUP HOLDER - INSTALLATION .........23-143

QUAD BUCKET SEAT SIDE SHIELD - NO CUP HOLDER - REMOVAL .............23-143

QUAD BUCKET SEAT SIDE SHIELD/CUP HOLDER - FLAP AND SPRING

ASSEMBLY - INSTALLATION ...........23-151

QUAD BUCKET SEAT SIDE SHIELD/CUP HOLDER - FLAP AND SPRING

ASSEMBLY - REMOVAL ...............23-151

QUAD BUCKET SEAT SIDE SHIELD/CUP HOLDER - INSTALLATION .............23-142

QUAD BUCKET SEAT SIDE SHIELD/CUP HOLDER - REMOVAL .................23-141

QUAD CHILD SEAT - INSTALLATION .....23-106

QUAD CHILD SEAT - REMOVAL ........23-106

QUAD SEAT CUSHION - INSTALLATION . . 23-141

QUAD SEAT CUSHION - REMOVAL ......23-141

QUARTER GLASS INTEGRAL ANTENNA - EXPORT - DESCRIPTION ...............8A-13

QUARTER GLASS INTEGRAL ANTENNA - EXPORT - OPERATION ................8A-13

QUARTER GLASS INTEGRAL ANTENNA, EXPORT ............................ 8A-13

QUARTER PANEL/FENDER AIR EXHAUSTER - DESCRIPTION, REAR ......23-59

QUARTER PANEL/FENDER AIR EXHAUSTER - INSTALLATION, REAR .....23-60

QUARTER PANEL/FENDER AIR EXHAUSTER - REMOVAL, REAR .........23-59

QUARTER TRIM BOLSTER - INSTALLATION ....................... 23-95

QUARTER TRIM BOLSTER - REMOVAL ....23-95

QUARTER TRIM PANEL - INSTALLATION, LEFT .............................. 23-94

QUARTER TRIM PANEL - INSTALLATION, RIGHT ............................. 23-97

QUARTER TRIM PANEL - REMOVAL, LEFT .............................. 23-94

QUARTER TRIM PANEL - REMOVAL, RIGHT ............................. 23-97

QUARTER WINDOW - INSTALLATION ....23-164

QUARTER WINDOW - REMOVAL ........23-164

QUICK CONNECT FITTING DISASSEMBLY/ASSEMBLY -

STANDARD PROCEDURE,

TRANSMISSION COOLER LINE ...........7-38

QUICK LEARN PROCEDURE - STANDARD PROCEDURE ........................ 8E-15

QUICK-CONNECT FITTINGS - STANDARD PROCEDURE ........................ 14-18

RACK - DESCRIPTION, LOWER DRIVE UNIT TRACK ........................ 8N-57

RACK - INSTALLATION, LOWER DRIVE UNIT TRACK ........................ 8N-58

RACK - OPERATION, LOWER DRIVE UNIT TRACK ............................. 8N-57

RACK - REMOVAL, LOWER DRIVE UNIT TRACK ............................. 8N-57

RACK CROSSBAR - INSTALLATION, LUGGAGE .......................... 23-59

RACK CROSSBAR - REMOVAL, LUGGAGE . 23-58

RACK RISER - INSTALLATION, LUGGAGE . . 23-58

RACK RISER - REMOVAL, LUGGAGE .....23-57

RADIAL-PLY TIRES - DESCRIPTION ......22-13

RADIATOR - INSTALLATION .............7-27

RADIATOR - REMOVAL .................7-26

RADIATOR CAP TO FILLER NECK SEAL - DIAGNOSIS AND TESTING ..............7-28

RADIATOR CROSSMEMBER - INSTALLATION, UPPER ................23-56RADIATOR CROSSMEMBER - REMOVAL,

UPPER ............................. 23-56

RADIATOR DRAINCOCK - INSTALLATION . . . 7-27

RADIATOR DRAINCOCK - REMOVAL .......7-27

RADIATOR FAN - DESCRIPTION ..........7-29

RADIATOR FAN - INSTALLATION ..........7-30

RADIATOR FAN - OPERATION ............7-29

RADIATOR FAN - REMOVAL .............7-30

RADIATOR FAN MOTOR - DIAGNOSIS AND TESTING ........................ 7-30

RADIATOR FAN RELAY - DESCRIPTION ....7-31

RADIATOR FAN RELAY - INSTALLATION ....7-31

RADIATOR FAN RELAY - OPERATION ......7-31

RADIATOR FAN RELAY - REMOVAL .......7-31

RADIATOR PRESSURE CAP - DESCRIPTION ........................ 7-27

RADIATOR PRESSURE CAP - OPERATION . . 7-27

RADIO - DESCRIPTION ................8A-13

RADIO - INSTALLATION, ANTENNA - NAVIGATION ........................ 8A-11

RADIO - OPERATION ..................8A-14

RADIO - REMOVAL, ANTENNA - NAVIGATION ........................ 8A-11

RADIO, DIAGNOSIS AND TESTING .......8A-14

RADIO NOISE SUPPRESSION COMPONENTS - DESCRIPTION ..........8A-15

RADIO NOISE SUPPRESSION COMPONENTS - OPERATION ...........8A-15

RANGE - SPECIFICATIONS, TRANSMITTER ...................... 8N-24

RANGE SENSOR - DESCRIPTION, TRANSMISSION ............... 21-130,21-281

RANGE SENSOR - INSTALLATION, TRANSMISSION ............... 21-131,21-282

RANGE SENSOR - OPERATION, TRANSMISSION ............... 21-131,21-282

RANGE SENSOR - REMOVAL, TRANSMISSION ............... 21-131,21-282

READING LAMP - INSTALLATION ........8L-23

READING LAMP - REMOVAL ............8L-22

RECEIVER / DRIER - DESCRIPTION ......24-92

RECEIVER / DRIER - INSTALLATION ......24-93

RECEIVER / DRIER - OPERATION ........24-92

RECEIVER / DRIER - REMOVAL .........24-92

RECIRCULATION DOOR ACTUATOR - DESCRIPTION ....................... 24-31

RECIRCULATION DOOR ACTUATOR - INSTALLATION ....................... 24-32

RECIRCULATION DOOR ACTUATOR - OPERATION ......................... 24-31

RECIRCULATION DOOR ACTUATOR - REMOVAL .......................... 24-32

RECLINER HANDLE - INSTALLATION ....23-108

RECLINER HANDLE - REMOVAL ........23-108

RECLINER/FOLD FORWARD MECHANISM -THIRD ROW -FOLD-IN-FLOOR -

INSTALLATION, SEAT .................23-160

RECLINER/FOLD FORWARD MECHANISM -THIRD ROW -FOLD-IN-FLOOR -

REMOVAL, SEAT .................... 23-160

RECLINER/FORWARD FOLDING MECHANISM -SECOND ROW

-FOLD-IN-FLOOR - INSTALLATION,

SEAT ............................. 23-137

RECLINER/FORWARD FOLDING MECHANISM -SECOND ROW

-FOLD-IN-FLOOR - REMOVAL, SEAT .....23-137

RECOVERY CONTAINER - DESCRIPTION, COOLANT ............................ 7-20

RECOVERY CONTAINER - INSTALLATION, COOLANT ............................ 7-20

RECOVERY CONTAINER - OPERATION, COOLANT ............................ 7-20

RECOVERY CONTAINER - REMOVAL, COOLANT ............................ 7-20

RECOVERY, STANDARD PROCEDURE - REFRIGERANT SYSTEM ...............24-70

RECOVERY SYSTEM - DIAGNOSIS AND TESTING, COOLANT ................... 7-20

REFACING VALVES AND VALVE SEATS - STANDARD PROCEDURE ...............9-107

REFRIGERANT - DESCRIPTION ..........24-93

REFRIGERANT - OPERATION ............24-94

REFRIGERANT LINES, INSTALLATION - UNDERBODY ....................... 24-112

REFRIGERANT LINES, REMOVAL - UNDERBODY ....................... 24-110

REFRIGERANT OIL - DESCRIPTION ......24-94 REFRIGERANT OIL - OPERATION

........24-94

REFRIGERANT OIL LEVEL, STANDARD PROCEDURE ........................ 24-94

REFRIGERANT SYSTEM CHARGE, STANDARD PROCEDURE ...............24-71

REFRIGERANT SYSTEM EVACUATE, STANDARD PROCEDURE ...............24-70

REFRIGERANT SYSTEM LEAKS, DIAGNOSIS AND TESTING .............24-67

REFRIGERANT SYSTEM RECOVERY, STANDARD PROCEDURE ...............24-70

REFRIGERANT SYSTEM SERVICE EQUIPMENT, STANDARD PROCEDURE ....24-69

REGULATOR - DESCRIPTION, VOLTAGE . . . 8F-30

REGULATOR - INSTALLATION, FUEL PRESSURE .......................... 14-7

REGULATOR - MANUAL - INSTALLATION, WINDOW ........................... 23-23

REGULATOR - MANUAL - REMOVAL, WINDOW ........................... 23-22

REGULATOR - OPERATION, FUEL PRESSURE .......................... 14-7

REGULATOR - OPERATION, VOLTAGE .....8F-30

REGULATOR - POWER - INSTALLATION, WINDOW ........................... 23-22

REGULATOR - POWER - REMOVAL, WINDOW ........................... 23-22

REGULATOR - REMOVAL, FUEL PRESSURE .......................... 14-7

REINFORCEMENT - INSTALLATION, FRONT BUMPER ...................... 13-3

REINFORCEMENT - INSTALLATION, REAR BUMPER .............................. 13-5

REINFORCEMENT - REMOVAL, FRONT BUMPER ............................ 13-3

REINFORCEMENT - REMOVAL, REAR BUMPER ............................ 13-5

RELAY - DESCRIPTION, A/C COMPRESSOR CLUTCH ...............24-18

RELAY - DESCRIPTION, AUTO SHUT DOWN .............................. 8I-3

RELAY - DESCRIPTION, BLOWER MOTOR ....................... 24-23,24-36

RELAY - DESCRIPTION, FUEL PUMP .....14-32

RELAY - DESCRIPTION, RADIATOR FAN ....7-31

RELAY - DESCRIPTION, REAR WINDOW DEFOGGER .......................... 8G-3

RELAY - DESCRIPTION, TRANSMISSION CONTROL ................... 21-130,21-281

RELAY - INSTALLATION, A/C COMPRESSOR CLUTCH ...............24-19

RELAY - INSTALLATION, BLOWER MOTOR ....................... 24-24,24-37

RELAY - INSTALLATION, RADIATOR FAN . . . 7-31

RELAY - INSTALLATION, REAR WINDOW DEFOGGER .......................... 8G-4

RELAY - OPERATION, A/C COMPRESSOR CLUTCH ............................ 24-18

RELAY - OPERATION, AUTO SHUT DOWN . . . 8I-3

RELAY - OPERATION, BLOWER MOTOR . . 24-23, 24-36

RELAY - OPERATION, FUEL PUMP .......14-32

RELAY - OPERATION, RADIATOR FAN ......7-31

RELAY - OPERATION, REAR WINDOW DEFOGGER .......................... 8G-3

RELAY - OPERATION, TRANSMISSION CONTROL ................... 21-130,21-281

RELAY - REMOVAL, A/C COMPRESSOR CLUTCH ............................ 24-19

RELAY - REMOVAL, BLOWER MOTOR ....24-24,

24-37

RELAY - REMOVAL, RADIATOR FAN .......7-31

RELAY - REMOVAL, REAR WINDOW DEFOGGER .......................... 8G-4

RELEASE - STANDARD PROCEDURE, PARKING BRAKE AUTOMATIC

ADJUSTER TENSION ................... 5-63

RELEASE CABLE - INSTALLATION, LATCH . 23-64

RELEASE CABLE - REMOVAL, LATCH .....23-63

RELEASE PROCEDURE - STANDARD PROCEDURE, FUEL SYSTEM

PRESSURE .......................... 14-2

RELIEF VALVE - INSTALLATION, OIL PRESSURE ......................... 9-144

RELIEF VALVE - REMOVAL, OIL PRESSURE ......................... 9-143

RELIEF VALVE, DESCRIPTION - HIGH PRESSURE ......................... 24-72

RS INDEX25

Description Group-Page Description Group-Page Description Group-Page

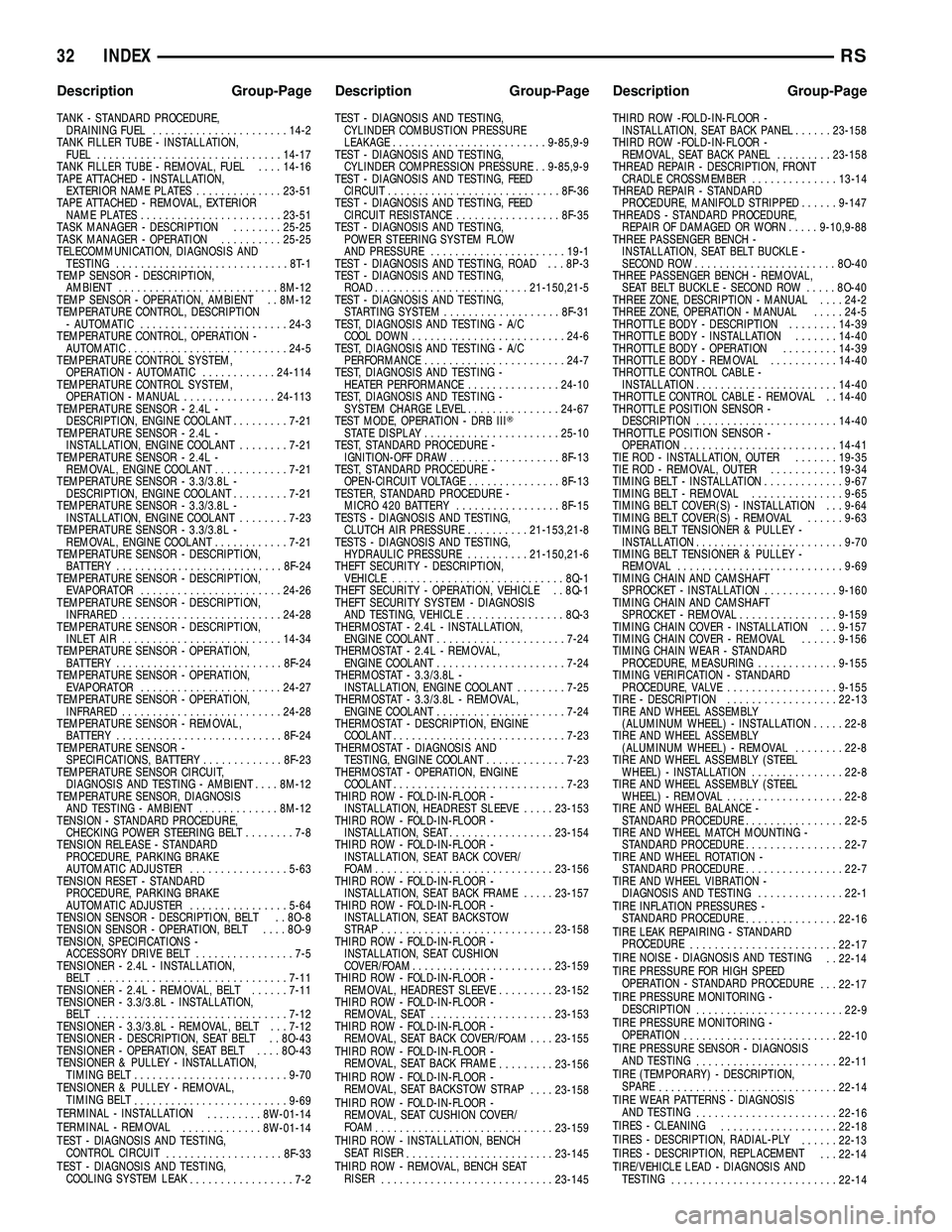

Page 2333 of 2339

TANK - STANDARD PROCEDURE,DRAINING FUEL ...................... 14-2

TANK FILLER TUBE - INSTALLATION, FUEL .............................. 14-17

TANK FILLER TUBE - REMOVAL, FUEL ....14-16

TAPE ATTACHED - INSTALLATION, EXTERIOR NAME PLATES ..............23-51

TAPE ATTACHED - REMOVAL, EXTERIOR NAME PLATES ....................... 23-51

TASK MANAGER - DESCRIPTION ........25-25

TASK MANAGER - OPERATION ..........25-25

TELECOMMUNICATION, DIAGNOSIS AND TESTING ............................8T-1

TEMP SENSOR - DESCRIPTION, AMBIENT .......................... 8M-12

TEMP SENSOR - OPERATION, AMBIENT . . 8M-12

TEMPERATURE CONTROL, DESCRIPTION - AUTOMATIC ........................ 24-3

TEMPERATURE CONTROL, OPERATION - AUTOMATIC .......................... 24-5

TEMPERATURE CONTROL SYSTEM, OPERATION - AUTOMATIC ............24-114

TEMPERATURE CONTROL SYSTEM, OPERATION - MANUAL ...............24-113

TEMPERATURE SENSOR - 2.4L - DESCRIPTION, ENGINE COOLANT .........7-21

TEMPERATURE SENSOR - 2.4L - INSTALLATION, ENGINE COOLANT ........7-21

TEMPERATURE SENSOR - 2.4L - REMOVAL, ENGINE COOLANT ............7-21

TEMPERATURE SENSOR - 3.3/3.8L - DESCRIPTION, ENGINE COOLANT .........7-21

TEMPERATURE SENSOR - 3.3/3.8L - INSTALLATION, ENGINE COOLANT ........7-23

TEMPERATURE SENSOR - 3.3/3.8L - REMOVAL, ENGINE COOLANT ............7-21

TEMPERATURE SENSOR - DESCRIPTION, BATTERY ........................... 8F-24

TEMPERATURE SENSOR - DESCRIPTION, EVAPORATOR ....................... 24-26

TEMPERATURE SENSOR - DESCRIPTION, INFRARED .......................... 24-28

TEMPERATURE SENSOR - DESCRIPTION, INLET AIR .......................... 14-34

TEMPERATURE SENSOR - OPERATION, BATTERY ........................... 8F-24

TEMPERATURE SENSOR - OPERATION, EVAPORATOR ....................... 24-27

TEMPERATURE SENSOR - OPERATION, INFRARED .......................... 24-28

TEMPERATURE SENSOR - REMOVAL, BATTERY ........................... 8F-24

TEMPERATURE SENSOR - SPECIFICATIONS, BATTERY .............8F-23

TEMPERATURE SENSOR CIRCUIT, DIAGNOSIS AND TESTING - AMBIENT ....8M-12

TEMPERATURE SENSOR, DIAGNOSIS AND TESTING - AMBIENT .............8M-12

TENSION - STANDARD PROCEDURE, CHECKING POWER STEERING BELT ........7-8

TENSION RELEASE - STANDARD PROCEDURE, PARKING BRAKE

AUTOMATIC ADJUSTER ................5-63

TENSION RESET - STANDARD PROCEDURE, PARKING BRAKE

AUTOMATIC ADJUSTER ................5-64

TENSION SENSOR - DESCRIPTION, BELT . . 8O-8

TENSION SENSOR - OPERATION, BELT ....8O-9

TENSION, SPECIFICATIONS - ACCESSORY DRIVE BELT ................7-5

TENSIONER - 2.4L - INSTALLATION, BELT ............................... 7-11

TENSIONER - 2.4L - REMOVAL, BELT ......7-11

TENSIONER - 3.3/3.8L - INSTALLATION, BELT ............................... 7-12

TENSIONER - 3.3/3.8L - REMOVAL, BELT . . . 7-12

TENSIONER - DESCRIPTION, SEAT BELT . . 8O-43

TENSIONER - OPERATION, SEAT BELT ....8O-43

TENSIONER & PULLEY - INSTALLATION, TIMING BELT ......................... 9-70

TENSIONER & PULLEY - REMOVAL, TIMING BELT ......................... 9-69

TERMINAL - INSTALLATION .........8W-01-14

TERMINAL - REMOVAL .............8W-01-14

TEST - DIAGNOSIS AND TESTING, CONTROL CIRCUIT ................... 8F-33

TEST - DIAGNOSIS AND TESTING, COOLING SYSTEM LEAK .................7-2 TEST - DIAGNOSIS AND TESTING,

CYLINDER COMBUSTION PRESSURE

LEAKAGE ......................... 9-85,9-9

TEST - DIAGNOSIS AND TESTING, CYLINDER COMPRESSION PRESSURE . . 9-85,9-9

TEST - DIAGNOSIS AND TESTING, FEED CIRCUIT ............................ 8F-36

TEST - DIAGNOSIS AND TESTING, FEED CIRCUIT RESISTANCE .................8F-35

TEST - DIAGNOSIS AND TESTING, POWER STEERING SYSTEM FLOW

AND PRESSURE ...................... 19-1

TEST - DIAGNOSIS AND TESTING, ROAD . . . 8P-3

TEST - DIAGNOSIS AND TESTING, ROAD ......................... 21-150,21-5

TEST - DIAGNOSIS AND TESTING, STARTING SYSTEM ................... 8F-31

TEST, DIAGNOSIS AND TESTING - A/C COOL DOWN ......................... 24-6

TEST, DIAGNOSIS AND TESTING - A/C PERFORMANCE ....................... 24-7

TEST, DIAGNOSIS AND TESTING - HEATER PERFORMANCE ...............24-10

TEST, DIAGNOSIS AND TESTING - SYSTEM CHARGE LEVEL ...............24-67

TEST MODE, OPERATION - DRB III T

STATE DISPLAY ...................... 25-10

TEST, STANDARD PROCEDURE - IGNITION-OFF DRAW .................. 8F-13

TEST, STANDARD PROCEDURE - OPEN-CIRCUIT VOLTAGE ...............8F-13

TESTER, STANDARD PROCEDURE - MICRO 420 BATTERY .................8F-15

TESTS - DIAGNOSIS AND TESTING, CLUTCH AIR PRESSURE ..........21-153,21-8

TESTS - DIAGNOSIS AND TESTING, HYDRAULIC PRESSURE ..........21-150,21-6

THEFT SECURITY - DESCRIPTION, VEHICLE ............................ 8Q-1

THEFT SECURITY - OPERATION, VEHICLE . . 8Q-1

THEFT SECURITY SYSTEM - DIAGNOSIS AND TESTING, VEHICLE ................8Q-3

THERMOSTAT - 2.4L - INSTALLATION, ENGINE COOLANT ..................... 7-24

THERMOSTAT - 2.4L - REMOVAL, ENGINE COOLANT ..................... 7-24

THERMOSTAT - 3.3/3.8L - INSTALLATION, ENGINE COOLANT ........7-25

THERMOSTAT - 3.3/3.8L - REMOVAL, ENGINE COOLANT ..................... 7-24

THERMOSTAT - DESCRIPTION, ENGINE COOLANT ............................ 7-23

THERMOSTAT - DIAGNOSIS AND TESTING, ENGINE COOLANT .............7-23

THERMOSTAT - OPERATION, ENGINE COOLANT ............................ 7-23

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, HEADREST SLEEVE .....23-153

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT .................23-154

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACK COVER/

FOAM ............................. 23-156

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACK FRAME .....23-157

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT BACKSTOW

STRAP ............................ 23-158

THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT CUSHION

COVER/FOAM ....................... 23-159

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, HEADREST SLEEVE .........23-152

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT .................... 23-153

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACK COVER/FOAM ....23-155

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACK FRAME .........23-156

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT BACKSTOW STRAP ....23-158

THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT CUSHION COVER/

FOAM ............................. 23-159

THIRD ROW - INSTALLATION, BENCH SEAT RISER ........................ 23-145

THIRD ROW - REMOVAL, BENCH SEAT RISER ............................ 23-145THIRD ROW -FOLD-IN-FLOOR -

INSTALLATION, SEAT BACK PANEL ......23-158

THIRD ROW -FOLD-IN-FLOOR - REMOVAL, SEAT BACK PANEL .........23-158

THREAD REPAIR - DESCRIPTION, FRONT CRADLE CROSSMEMBER ..............13-14

THREAD REPAIR - STANDARD PROCEDURE, MANIFOLD STRIPPED ......9-147

THREADS - STANDARD PROCEDURE, REPAIR OF DAMAGED OR WORN .....9-10,9-88

THREE PASSENGER BENCH - INSTALLATION, SEAT BELT BUCKLE -

SECOND ROW ....................... 8O-40

THREE PASSENGER BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW .....8O-40

THREE ZONE, DESCRIPTION - MANUAL ....24-2

THREE ZONE, OPERATION - MANUAL .....24-5

THROTTLE BODY - DESCRIPTION ........14-39

THROTTLE BODY - INSTALLATION .......14-40

THROTTLE BODY - OPERATION .........14-39

THROTTLE BODY - REMOVAL ...........14-40

THROTTLE CONTROL CABLE - INSTALLATION ....................... 14-40

THROTTLE CONTROL CABLE - REMOVAL . . 14-40

THROTTLE POSITION SENSOR - DESCRIPTION ....................... 14-40

THROTTLE POSITION SENSOR - OPERATION ......................... 14-41

TIE ROD - INSTALLATION, OUTER .......19-35

TIE ROD - REMOVAL, OUTER ...........19-34

TIMING BELT - INSTALLATION .............9-67

TIMING BELT - REMOVAL ...............9-65

TIMING BELT COVER(S) - INSTALLATION . . . 9-64

TIMING BELT COVER(S) - REMOVAL ......9-63

TIMING BELT TENSIONER & PULLEY - INSTALLATION ........................ 9-70

TIMING BELT TENSIONER & PULLEY - REMOVAL ........................... 9-69

TIMING CHAIN AND CAMSHAFT SPROCKET - INSTALLATION ............9-160

TIMING CHAIN AND CAMSHAFT SPROCKET - REMOVAL ................9-159

TIMING CHAIN COVER - INSTALLATION . . . 9-157

TIMING CHAIN COVER - REMOVAL ......9-156

TIMING CHAIN WEAR - STANDARD PROCEDURE, MEASURING .............9-155

TIMING VERIFICATION - STANDARD PROCEDURE, VALVE .................. 9-155

TIRE - DESCRIPTION ..................22-13

TIRE AND WHEEL ASSEMBLY (ALUMINUM WHEEL) - INSTALLATION .....22-8

TIRE AND WHEEL ASSEMBLY (ALUMINUM WHEEL) - REMOVAL ........22-8

TIRE AND WHEEL ASSEMBLY (STEEL WHEEL) - INSTALLATION ...............22-8

TIRE AND WHEEL ASSEMBLY (STEEL WHEEL) - REMOVAL ................... 22-8

TIRE AND WHEEL BALANCE - STANDARD PROCEDURE ................22-5

TIRE AND WHEEL MATCH MOUNTING - STANDARD PROCEDURE ................22-7

TIRE AND WHEEL ROTATION - STANDARD PROCEDURE ................22-7

TIRE AND WHEEL VIBRATION - DIAGNOSIS AND TESTING ..............22-1

TIRE INFLATION PRESSURES - STANDARD PROCEDURE ...............22-16

TIRE LEAK REPAIRING - STANDARD PROCEDURE ........................ 22-17

TIRE NOISE - DIAGNOSIS AND TESTING . . 22-14

TIRE PRESSURE FOR HIGH SPEED OPERATION - STANDARD PROCEDURE . . . 22-17

TIRE PRESSURE MONITORING - DESCRIPTION ........................ 22-9

TIRE PRESSURE MONITORING - OPERATION ......................... 22-10

TIRE PRESSURE SENSOR - DIAGNOSIS AND TESTING ....................... 22-11

TIRE (TEMPORARY) - DESCRIPTION, SPARE ............................. 22-14

TIRE WEAR PATTERNS - DIAGNOSIS AND TESTING ....................... 22-16

TIRES - CLEANING ................... 22-18

TIRES - DESCRIPTION, RADIAL-PLY ......22-13

TIRES - DESCRIPTION, REPLACEMENT . . . 22-14

TIRE/VEHICLE LEAD - DIAGNOSIS AND TESTING ........................... 22-14

32 INDEXRS

Description Group-Page Description Group-Page Description Group-Page