charging CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 6 of 2339

FASTENER USAGE

DESCRIPTION

FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

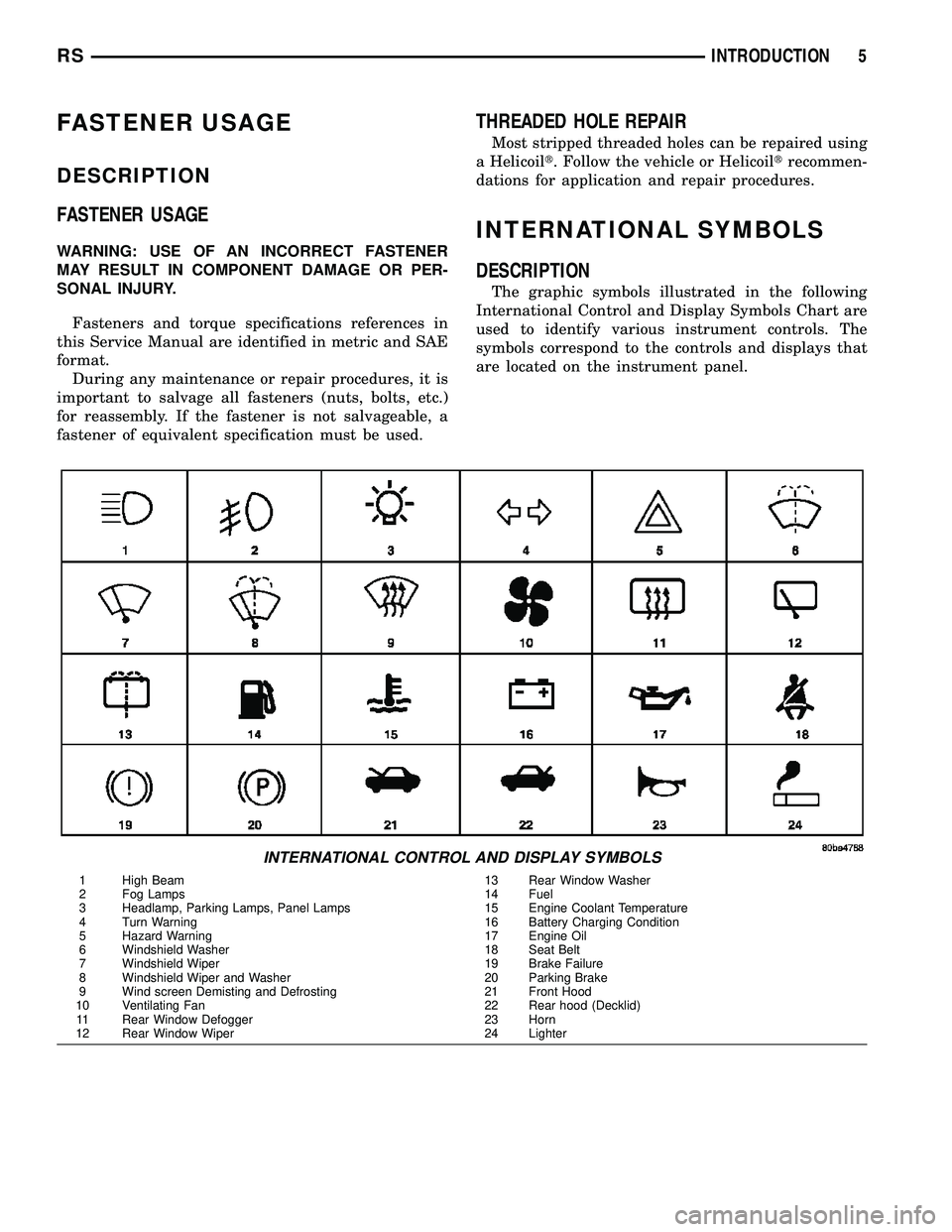

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Wind screen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

Page 38 of 2339

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS. (Refer to 8 - ELECTRICAL/BAT-

TERY SYSTEM/BATTERY - STANDARD PROCE-

DURE).

WARNING: DO NOT JUMP START A FROZEN BAT-

TERY, PERSONAL INJURY CAN RESULT.

WARNING: DO NOT JUMP START WHEN MAINTE-

NANCE FREE BATTERY INDICATOR DOT IS BRIGHT

COLOR.

WARNING: DO NOT ALLOW JUMPER CABLE

CLAMPS TO TOUCH EACH OTHER WHEN CON-

NECTED TO A BOOSTER SOURCE.

WARNING: DO NOT USE OPEN FLAME NEAR BAT-

TERYWARNING: REMOVE METALLIC JEWELRY WORN

ON HANDS OR WRISTS TO AVOID INJURY BY

ACCIDENTAL ARCING OF BATTERY CURRENT.

WARNING: WHEN USING A HIGH OUTPUT BOOST-

ING DEVICE, DO NOT ALLOW BATTERY VOLTAGE

TO EXCEED 16 VOLTS.

WARNING: REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: DO NOT ATTEMPT TO PUSH OR TOW

THE VEHICLE TO START IT. THE VEHICLE CANNOT

BE STARTED THIS WAY. PUSHING WITH ANOTHER

VEHICLE MAY DAMAGE THE TRANSAXLE OR THE

REAR OF THE VEHICLE.

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Clear or bright color test indicator, if equipped.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 6).

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

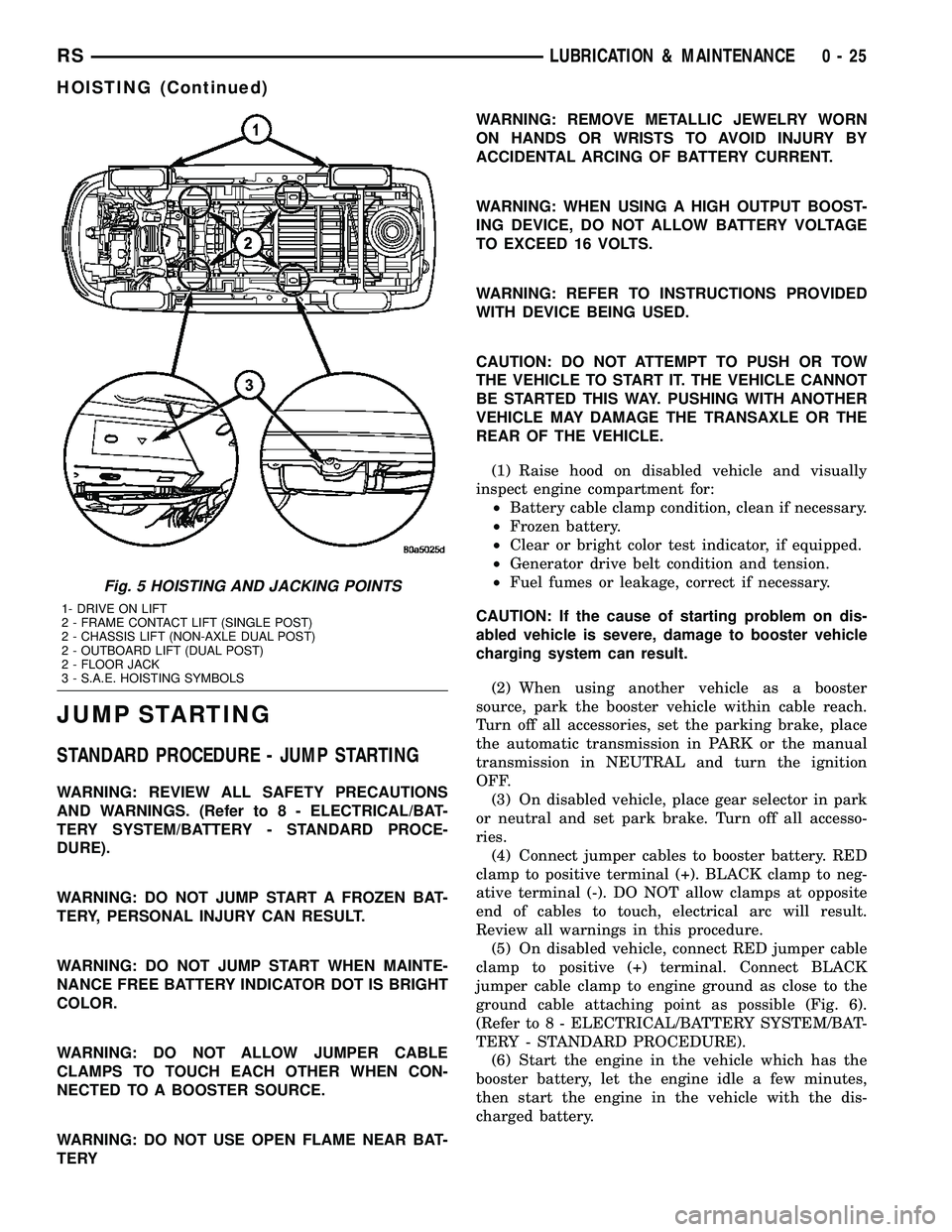

Fig. 5 HOISTING AND JACKING POINTS

1- DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

2 - CHASSIS LIFT (NON-AXLE DUAL POST)

2 - OUTBOARD LIFT (DUAL POST)

2 - FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

RSLUBRICATION & MAINTENANCE0-25

HOISTING (Continued)

Page 274 of 2339

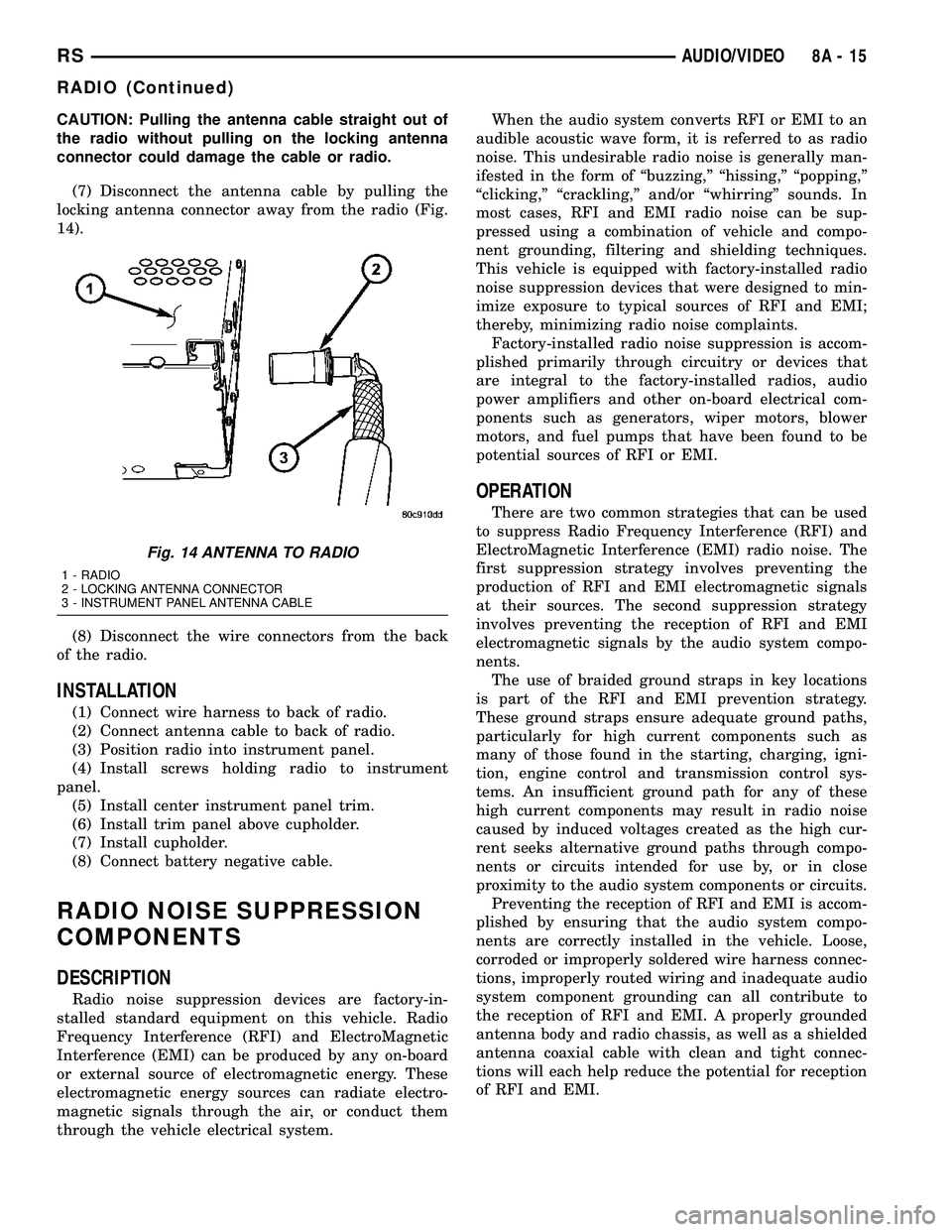

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(7) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

14).

(8) Disconnect the wire connectors from the back

of the radio.

INSTALLATION

(1) Connect wire harness to back of radio.

(2) Connect antenna cable to back of radio.

(3) Position radio into instrument panel.

(4) Install screws holding radio to instrument

panel.

(5) Install center instrument panel trim.

(6) Install trim panel above cupholder.

(7) Install cupholder.

(8) Connect battery negative cable.

RADIO NOISE SUPPRESSION

COMPONENTS

DESCRIPTION

Radio noise suppression devices are factory-in-

stalled standard equipment on this vehicle. Radio

Frequency Interference (RFI) and ElectroMagnetic

Interference (EMI) can be produced by any on-board

or external source of electromagnetic energy. These

electromagnetic energy sources can radiate electro-

magnetic signals through the air, or conduct them

through the vehicle electrical system.When the audio system converts RFI or EMI to an

audible acoustic wave form, it is referred to as radio

noise. This undesirable radio noise is generally man-

ifested in the form of ªbuzzing,º ªhissing,º ªpopping,º

ªclicking,º ªcrackling,º and/or ªwhirringº sounds. In

most cases, RFI and EMI radio noise can be sup-

pressed using a combination of vehicle and compo-

nent grounding, filtering and shielding techniques.

This vehicle is equipped with factory-installed radio

noise suppression devices that were designed to min-

imize exposure to typical sources of RFI and EMI;

thereby, minimizing radio noise complaints.

Factory-installed radio noise suppression is accom-

plished primarily through circuitry or devices that

are integral to the factory-installed radios, audio

power amplifiers and other on-board electrical com-

ponents such as generators, wiper motors, blower

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

Fig. 14 ANTENNA TO RADIO

1 - RADIO

2 - LOCKING ANTENNA CONNECTOR

3 - INSTRUMENT PANEL ANTENNA CABLE

RSAUDIO/VIDEO8A-15

RADIO (Continued)

Page 306 of 2339

ENGINE SYSTEMS

TABLE OF CONTENTS

page page

BATTERY SYSTEM......................... 1

CHARGING.............................. 21STARTING............................... 31

BATTERY SYSTEM

TABLE OF CONTENTS

page page

BATTERY SYSTEM

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING

BATTERY SYSTEM.....................2

CLEANING.............................5

INSPECTION...........................5

SPECIFICATIONS

BATTERY............................6

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS.......7

BATTERY

DESCRIPTION..........................7

OPERATION............................9

DIAGNOSIS AND TESTING

BATTERY............................9

STANDARD PROCEDURE

SPIRAL PLATE BATTERY CHARGING......10

CONVENTIONAL BATTERY CHARGING....11

OPEN-CIRCUIT VOLTAGE TEST..........13IGNITION-OFF DRAW TEST.............13

CHECKING BATTERY ELECTROLYTE

LEVEL..............................14

MICRO 420 BATTERY TESTER...........15

REMOVAL - BATTERY...................16

INSTALLATION.........................16

BATTERY HOLDDOWN

REMOVAL.............................16

INSTALLATION.........................16

BATTERY CABLES

DESCRIPTION.........................16

OPERATION...........................17

DIAGNOSIS AND TESTING

BATTERY CABLES....................17

REMOVAL.............................19

INSTALLATION.........................19

BATTERY TRAY

DESCRIPTION.........................19

REMOVAL.............................19

INSTALLATION.........................20

BATTERY SYSTEM

DESCRIPTION

This vehicle is equipped with a single 12-volt bat-

tery. All of the components of the battery system are

located within the engine compartment. The battery

system for this vehicle contains the following related

components:

²Battery- The storage battery provides a reli-

able means of storing a renewable source of electrical

energy within the vehicle.

²Battery Cable- The battery cables connect the

battery terminal posts to the vehicle electrical sys-

tem.²Battery Holddown- The battery holddown

hardware secures the battery in the battery tray in

the engine compartment.

²Battery Thermowrap- The battery thermow-

rap insulates the battery to protect it from engine

compartment temperature extremes.

²Battery Tray- The battery tray provides a

secure mounting location in the vehicle for the bat-

tery and an anchor point for the battery holddown

hardware.

RSENGINE SYSTEMS8F-1

Page 307 of 2339

OPERATION

The battery system is designed to provide a safe,

efficient, reliable and mobile means of delivering and

storing electrical energy. This electrical energy is

required to operate the engine starting system, as

well as to operate many of the other vehicle acces-

sory systems for limited durations while the engine

and/or the charging system are not operating. The

battery system is also designed to provide a reserve

of electrical energy to supplement the charging sys-

tem for short durations while the engine is running

and the electrical current demands of the vehicle

exceed the output of the charging system. In addition

to delivering, and storing electrical energy for the

vehicle, the battery system serves as a capacitor and

voltage stabilizer for the vehicle electrical system. It

absorbs most abnormal or transient voltages caused

by the switching of any of the electrical components

or circuits in the vehicle.

DIAGNOSIS AND TESTING

BATTERY SYSTEM

The battery, starting, and charging systems in the

vehicle operate with one another and must be tested

as a complete system. In order for the engine to start

and the battery to maintain its charge properly, all of

the components that are used in these systems must

perform within specifications. It is important that

the battery, starting, and charging systems be thor-

oughly tested and inspected any time a battery needs

to be charged or replaced. The cause of abnormal bat-

tery discharge, overcharging or early battery failuremust be diagnosed and corrected before a battery is

replaced and before a vehicle is returned to service.

The service information for these systems has been

separated within this service manual to make it eas-

ier to locate the specific information you are seeking.

However, when attempting to diagnose any of these

systems, it is important that you keep their interde-

pendency in mind.

The diagnostic procedures used for the battery,

starting, and charging systems include the most

basic conventional diagnostic methods, to the more

sophisticated On-Board Diagnostics (OBD) built into

the Powertrain Control Module (PCM). Use of an

induction-type milliampere ammeter, a volt/ohmme-

ter, a battery charger, a carbon pile rheostat (load

tester) and a 12-volt test lamp may be required. All

OBD-sensed systems are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for any failure it detects. (Refer to 8 -

ELECTRICAL/CHARGING - DIAGNOSIS AND

TESTING) for the proper charging system on-board

diagnostic test procedures.MICRO 420 BATTERY TESTER

The Micro 420 automotive battery tester is

designed to help the dealership technicians diagnose

the cause of a defective battery. Follow the instruc-

tion manual supplied with the tester to properly

diagnose a vehicle. If the instruction manual is not

available refer to the standard procedure in this sec-

tion, which includes the directions for using the

Micro 420 battery tester.

8F - 2 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

Page 308 of 2339

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY SEEMS

WEAK OR DEAD WHEN

ATTEMPTING TO START

THE ENGINE.1. The electrical system

ignition-off draw is excessive.1. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE

- IGNITION-OFF DRAW TEST) for the proper test

procedures. Repair the excessive ignition-off

draw, as required.

2. The charging system is

inoperative.2. Determine if the charging system is performing

to specifications. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND TESTING) for

additional charging system diagnosis and testing

procedures. Repair the inoperative charging

system, as required.

3. The battery is discharged. 3. Determine the battery state-of-charge using the

Micro 420 battery tester. Refer to the Standard

Procedures in this section for additional test

procedures. Charge the inoperative battery, as

required.

4. The battery terminal

connections are loose or

corroded.4. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/CABLES - DIAGNOSIS AND TESTING)

for the proper battery cable diagnosis and testing

procedures. Clean and tighten the battery

terminal connections, as required.

5. The battery has an

incorrect size or rating for

this vehicle.5. (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- SPECIFICATIONS) for the proper size and

rating. Replace an incorrect battery, as required.

6. The battery is inoperative. 6. Test the battery using the Micro 420 battery

tester. Refer to the Standard Procedures in this

section for additional test procedures. Replace

the inoperative battery, as required.

7. The starting system is

inoperative.7. Determine if the starting system is performing

to specifications. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND TESTING) for the

proper starting system diagnosis and testing

procedures. Repair the inoperative starting

system, as required.

8. The battery is physically

damaged.8. Inspect the battery for loose terminal posts or a

cracked and leaking case. Replace the damaged

battery, as required.

RSBATTERY SYSTEM8F-3

BATTERY SYSTEM (Continued)

Page 309 of 2339

BATTERY SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

THE BATTERY STATE OF

CHARGE CANNOT BE

MAINTAINED.1. The battery has an

incorrect size or rating for

this vehicle.1. (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- SPECIFICATIONS) for the proper specifications.

Replace an incorrect battery, as required.

2. The battery terminal

connections are loose or

corroded.2. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/CABLES - DIAGNOSIS AND TESTING)

for the proper cable diagnosis and testing

procedures. Clean and tighten the battery

terminal connections, as required.

3. The electrical system

ignition-off draw is excessive.3. (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE

- IGNITION-OFF DRAW TEST) for the proper test

procedures. Repair the inoperative electrical

system, as required.

4. The battery is inoperative. 4. Test the battery using the Micro 420 battery

tester. Refer to Standard Procedures for

additional test procedures. Replace the

inoperative battery, as required.

5. The starting system is

inoperative.5. Determine if the starting system is performing

to specifications. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND TESTING) for the

proper starting system diagnosis and testing

procedures. Repair the inoperative starting

system, as required.

6. The charging system is

inoperative.6. Determine if the charging system is performing

to specifications. (Refer to 8 - ELECTRICAL/

CHARGING - DIAGNOSIS AND TESTING) for

charging system diagnosis and testing

procedures. Repair the inoperative charging

system, as required.

7. Electrical loads exceed the

output of the charging

system.7. Inspect the vehicle for aftermarket electrical

equipment which might cause excessive electrical

loads.

8. Slow driving or prolonged

idling with high-amperage

draw loads in use.8. Advise the vehicle operator, as required.

THE BATTERY WILL NOT

ACCEPT A CHARGE.1. The battery is inoperative. 1. Test the battery using the Micro 420 battery

tester.. Charge or replace the inoperative battery,

as required.

8F - 4 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

Page 311 of 2339

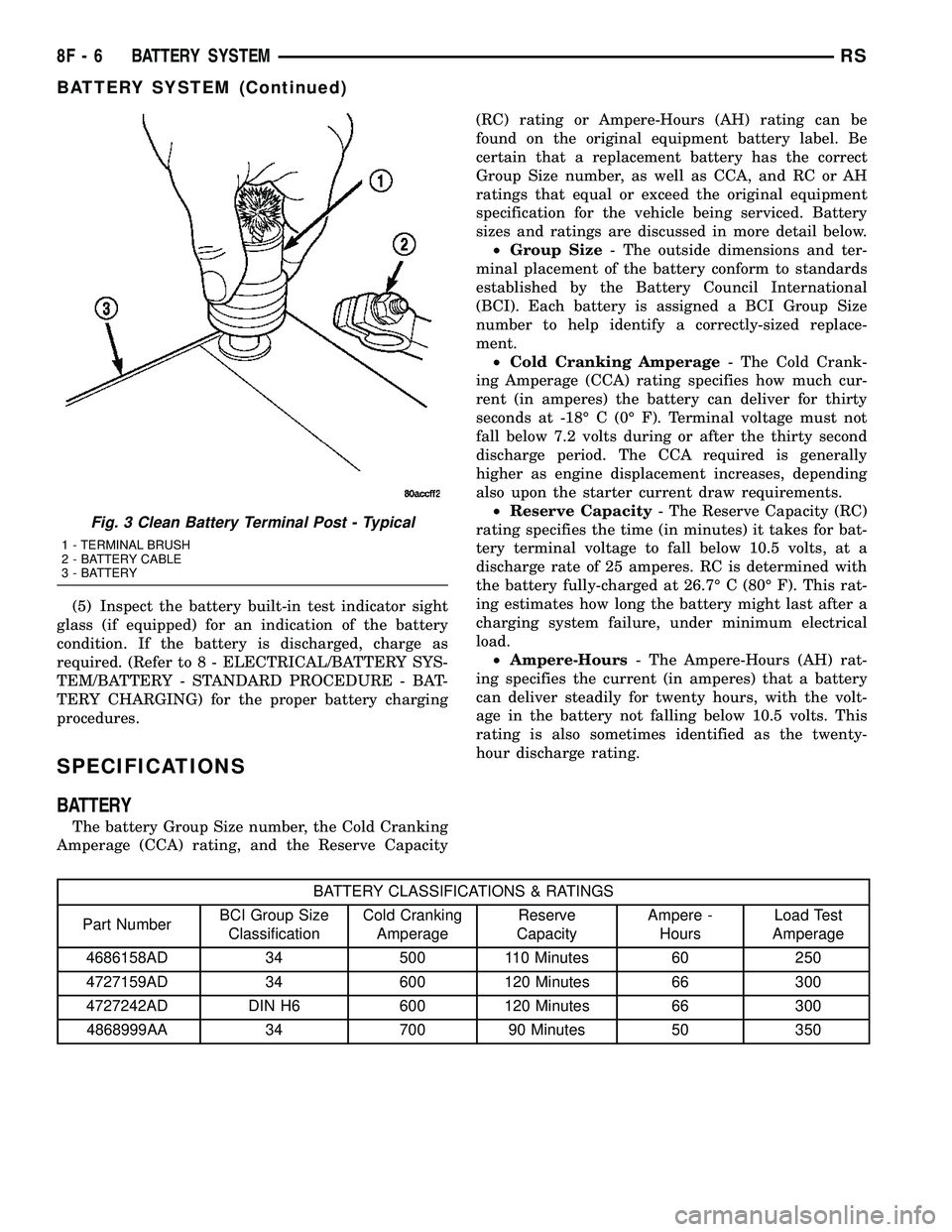

(5) Inspect the battery built-in test indicator sight

glass (if equipped) for an indication of the battery

condition. If the battery is discharged, charge as

required. (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE - BAT-

TERY CHARGING) for the proper battery charging

procedures.

SPECIFICATIONS

BATTERY

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity(RC) rating or Ampere-Hours (AH) rating can be

found on the original equipment battery label. Be

certain that a replacement battery has the correct

Group Size number, as well as CCA, and RC or AH

ratings that equal or exceed the original equipment

specification for the vehicle being serviced. Battery

sizes and ratings are discussed in more detail below.

²Group Size- The outside dimensions and ter-

minal placement of the battery conform to standards

established by the Battery Council International

(BCI). Each battery is assigned a BCI Group Size

number to help identify a correctly-sized replace-

ment.

²Cold Cranking Amperage- The Cold Crank-

ing Amperage (CCA) rating specifies how much cur-

rent (in amperes) the battery can deliver for thirty

seconds at -18É C (0É F). Terminal voltage must not

fall below 7.2 volts during or after the thirty second

discharge period. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

²Reserve Capacity- The Reserve Capacity (RC)

rating specifies the time (in minutes) it takes for bat-

tery terminal voltage to fall below 10.5 volts, at a

discharge rate of 25 amperes. RC is determined with

the battery fully-charged at 26.7É C (80É F). This rat-

ing estimates how long the battery might last after a

charging system failure, under minimum electrical

load.

²Ampere-Hours- The Ampere-Hours (AH) rat-

ing specifies the current (in amperes) that a battery

can deliver steadily for twenty hours, with the volt-

age in the battery not falling below 10.5 volts. This

rating is also sometimes identified as the twenty-

hour discharge rating.

BATTERY CLASSIFICATIONS & RATINGS

Part NumberBCI Group Size

ClassificationCold Cranking

AmperageReserve

CapacityAmpere -

HoursLoad Test

Amperage

4686158AD 34 500 110 Minutes 60 250

4727159AD 34 600 120 Minutes 66 300

4727242AD DIN H6 600 120 Minutes 66 300

4868999AA 34 700 90 Minutes 50 350

Fig. 3 Clean Battery Terminal Post - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

3 - BATTERY

8F - 6 BATTERY SYSTEMRS

BATTERY SYSTEM (Continued)

Page 312 of 2339

SPECIAL TOOLS

BATTERY SYSTEM SPECIAL TOOLS

BATTERY

DESCRIPTION

There are three different batteries available for

this vehicle. Vehicles equipped with a diesel engine

utilize a spiral wound plate designed battery with

recombination technology. This is a maintenance-free

battery that is capable of delivering more power than

a conventional battery. This additional power is

required by a diesel engine during cold cranking.

Vehicles equipped with a gasoline engine utilize a

conventional battery. Refer to the following informa-

tion for detailed differences and descriptions of these

batteries.

SPIRAL PLATE BATTERY - DIESEL ENGINE

By tightly winding layers of spiral grids and acid-

permeated vitreous separators into cells, the battery

has more power and service life than conventional

batteries of the same size. The spiral plate battery is

permanently sealed. Through gas recombination,

hydrogen and oxygen within the battery are captured

during normal charging and reunited to form thewater within the electrolyte, eliminating the need to

add distilled water. Therefore, these batteries have

non-removable battery vent caps (Fig. 4).

The acid inside a spiral plate battery is bound

within the vitreous separators, ending the threat of

acid leaks. This feature allows the battery to be

installed in any position anywhere in the vehicle.

Spiral plate technology is the process by which the

plates holding the active material in the battery are

wound tightly in coils instead of hanging flat, like

conventional batteries. This design has a lower inter-

nal resistance and also increases the active material

surface area.

WARNING: NEVER EXCEED 14.4 VOLTS WHEN

CHARGING A SPIRAL PLATE BATTERY. PERSONAL

INJURY AND/OR BATTERY DAMAGE MAY RESULT.

Due to the maintanance-free design, distilled water

cannot be added to this battery. Therefore, if more

than 14.4 volts are used during the spiral plate bat-

tery charging process, water vapor can be exhausted

through the pressure-sensitive battery vents and lost

for good. This can permanently damage the spiral

plate battery.

Micro 420 Battery Tester

Fig. 4 MAINTENANCE-FREE DIESEL ENGINE

BATTERY

RSBATTERY SYSTEM8F-7

BATTERY SYSTEM (Continued)

Page 313 of 2339

CONVENTIONAL BATTERY - GASOLINE ENGINE

Low-maintenance batteriesare used on export

vehicles equipped with a gasoline engine, these bat-

teries have removable battery cell caps (Fig. 5).

Watercanbe added to this battery. Under normal

service, the composition of this battery reduces gas-

sing and water loss at normal charge rates. However

these batteries may require additional distilled water

after years of service.

Maintenance-free batteriesare standard facto-

ry-installed equipment on all domestic vehicles. Male

post type terminals made of a soft lead material pro-

trude from the top of the molded plastic battery case

(Fig. 6)to provide the means for connecting the bat-

tery to the vehicle electrical system. The battery pos-

itive terminal post is visibly larger in diameter than

the negative terminal post, for easy identification.

The lettersPOSandNEGare also molded into the

top of the battery case adjacent to their respective

positive and negative terminal posts for additional

identification confirmation.

This battery is designed to provide a safe, efficient

and reliable means of storing electrical energy in a

chemical form. This means of energy storage allows

the battery to produce the electrical energy required

to operate the engine starting system, as well as to

operate many of the other vehicle accessory systems

for limited durations while the engine and/or thecharging system are not operating. The battery is

made up of six individual cells that are connected in

series. Each cell contains positively charged plate

groups that are connected with lead straps to the

positive terminal post, and negatively charged plate

groups that are connected with lead straps to the

negative terminal post. Each plate consists of a stiff

mesh framework or grid coated with lead dioxide

(positive plate) or sponge lead (negative plate). Insu-

lators or plate separators made of a non-conductive

material are inserted between the positive and nega-

tive plates to prevent them from contacting or short-

ing against one another. These dissimilar metal

plates are submerged in a sulfuric acid and water

solution called an electrolyte.

Some factory-installed batteries have a built-in test

indicator (hydrometer). The color visible in the sight

glass of the indicator will reveal the battery condi-

tion. For more information on the use of the built-in

test indicator, refer toStandard Procedures. The

chemical composition of the metal coated plates

within the low-maintenance battery used in export

models reduces battery gassing and water loss at

normal charge and discharge rates. Therefore, the

battery should not require additional water in nor-

mal service. If the electrolyte level in this battery

does become low, distilled water must be added. How-

ever, rapid loss of electrolyte can be caused by an

overcharging condition. Be certain to diagnose the

charging system after replenishing the water in the

Fig. 5 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTANANCE GASOLINE

ENGINE BATTERY - EXPORT

1 - BATTERY CELL CAP

2 - BATTERY CASE

Fig. 6 Maintenance-Free Battery - Domestic

1 - POSITIVE POST

2 - VENT

3 - CELL CAP

4 - VENT

5 - CELL CAP

6 - VENT

7 - NEGATIVE POST

8 - INDICATOR EYE (if equipped)

9 - ELECTROLYTE LEVEL

10 - PLATE GROUPS

11 - MAINTENANCE-FREE BATTERY

8F - 8 BATTERY SYSTEMRS

BATTERY (Continued)