CD player CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 260 of 2339

AUDIO/VIDEO

TABLE OF CONTENTS

page page

AUDIO/VIDEO

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

AUDIO/VIDEO.........................2

AMPLIFIER

REMOVAL.............................7

INSTALLATION..........................7

ANTENNA BODY AND CABLE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING

ANTENNA BODY AND CABLE.............8

REMOVAL.............................8

INSTALLATION..........................8

ANTENNA MODULE - EXPORT

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING

ANTENNA MODULE - EXPORT...........10

REMOVAL.............................10

INSTALLATION.........................10

ANTENNA - NAVIGATION RADIO

REMOVAL.............................11

INSTALLATION.........................11

CD CHANGER

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................11

INSTALLATION.........................11

DVD PLAYER

DESCRIPTION.........................12

REMOVAL.............................12

INSTALLATION.........................12

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................12INSTALLATION.........................12

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT............................13

RADIO

DESCRIPTION.........................13

OPERATION...........................14

DIAGNOSIS AND TESTING

RADIO..............................14

REMOVAL.............................14

INSTALLATION.........................15

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION.........................15

OPERATION...........................15

REMOTE SWITCHES

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING

REMOTE SWITCHES..................16

REMOVAL.............................17

INSTALLATION.........................17

SPEAKER

DIAGNOSIS AND TESTING

SPEAKER...........................18

REMOVAL.............................18

INSTALLATION.........................19

VIDEO SCREEN

DESCRIPTION.........................20

OPERATION...........................20

REMOVAL.............................20

INSTALLATION.........................20

AUDIO/VIDEO

DESCRIPTION

An audio system is standard on this model. A rear

seat video system is an available option. Several com-

binations of radio receivers are offered on this model.

The audio/video system uses an ignition switched

source of battery current so that the system will only

operate when the ignition switch is in the RUN or

ACCESSORY/ACCESSORY DELAY positions.

The audio system includes the following compo-

nents:²Amplifier

²Antenna

²CD changer (if equipped)

²DVD player (if equipped)

²Radio noise suppression components

²Radio receiver

²Speakers

²Video screen (if equipped)

Certain functions and features of the audio/video

system rely upon resources shared with other elec-

tronic modules in the vehicle over the Programmable

Communication Interface (PCI) bus network. The

data bus network allows the sharing of sensor infor-

RSAUDIO/VIDEO8A-1

Page 264 of 2339

VIDEO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO VIDEO (DVD PLAYER

WILL NOT LOAD OR

EJECT)1. FUSE INOPERATIVE. 1. CHECK FUSES. REPLACE FUSES IF

REQUIRED.

2. LOOSE OR DAMAGED DVD

PLAYER CONNECTOR2. CHECK FOR LOOSE OR CORRODED

DVD PLAYER CONNECTOR (16 PIN).

REPAIR OR REPLACE AS REQUIRED.

3. LOOSE OR DAMAGED

WIRING/DVD PLAYER

INOPERATIVE3. CHECK PIN 1 (B+) AND PIN 9

(GROUND) OF THE 16 PIN CONNECTOR,

THEN CHECK PIN 1 (B+) AND PIN 7

(GROUND) OF THE 12 PIN CONNECTOR.

IF THE 16 PIN CONNECTOT DOES NOT

SHOW VOLTAGE, THE 12 PIN

CONNECTOR WILL NOT SHOW VOLTAGE

(THE 12 PIN IS FED FROM THE 16 PIN). IF

VOLTAGE IS OK ON THE 16 PIN, BUT NOT

PRESENT ON THE 12 PIN, UNPLUG THE

12 PIN HARNESS FROM THE PLAYER

AND CHECK THE CONNECTOR PINSON

THE BACK OF THE PLAYER. IF VOLTAGE

IS PRESENT ON THE 12 PIN

CONNECTOR, THE SCREEN OR THE 12

PIN HARNESS SHOULD BE REPLACED. IF

THERE IS STILL NO VOLTAGE ON THE 12

PIN CONNECTOR, THE DVD PLAYER

SHOULD BE REPLACED.

4. GROUND CONNECTION

DAMAGED4. CHECK FOR CONTINUITY BETWEEN

DVD PLAYER AND A KNOWN GOOD

GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND IF

REQUIRED.

5. DVD PLAYER DAMAGED 5. EXCHANGE OR REPLACE DVD PLAYER

IF REQUIRED.

6. DVD DAMAGED.

AVOID USING CD'S OR DVD'S

THAT HAVE ADHESIVE TYPE

LABELS, AS THEY MAY CAUSE

THE DISC TO BECOME

JAMMED.6. INSERT KNOWN GOOD DVD AND TEST

OPERATION.

NO DISPLAY. AUDIO

HEARD THROUGH

SPEAKERS1. LOOSE OR DAMAGED

CONNECTORS1. CHECK FOR LOOSE OR CORRODED

DVD PLAYER CONNECTOR (12 PIN).

CHECK FOR LOOSE OR CORRODED

VIDEO SCREEN CONNECTOR. REPAIR IF

REQUIRED. CHECK FOR LOOSE OR

DAMAGED IN-LINE CONNECTOR.

RSAUDIO/VIDEO8A-5

AUDIO/VIDEO (Continued)

Page 265 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

2. WIRING DAMAGED 2. WITH HARNESS CONNECTED, CHECK

FOR VIDEO SIGNAL VOLTAGE AT DVD

PLAYER AND AT VIDEO SCREEN

HARNESS. PLACE KNOWN GOOD DVD

INTO DVD PLAYER. PLACE POSITIVE

LEAD OF VOLTMETER ON PIN 5 (VIDEO

SIGNAL) OF THE 12 PIN CONNECTOR.

PLACE NEGATIVE LEAD ON PIN 6 (VIDEO

GROUND). READINGS SHOULD BE

BETWEEN 0.1V TO 2V DC.

3. VIDEO SCREEN DAMAGED 3. EXCHANGE OR REPLACE VIDEO

SCREEN IF REQUIRED.

WHITE DISPLAY 1. LOW VOLTAGE 1. CHECK FOR BATTERY VOLTAGE

(9V-16V) AT DVD PLAYER 12 PIN

CONNECTOR (PIN 1-BATTERY, PIN

7-GROUND). DISPLAY WILL BE WHITE IF

VOLTAGE DROPS BELOW 6V.

2. VIDEO SCREEN DAMAGED 2. EXCHANGE OR REPLACE VIDEO

SCREEN IF REQUIRED.

DARK OR BRIGHT SPOTS

ON SCREEN1. BRIGHTNESS SETTING

REQUIRES ADJUSTMENT.1. ADJUST BRIGHTNESS SETTING OF

VIDEO SCREEN BY PRESSING BUTTONS

ON SIDE OF VIDEO SCREEN UNTIL

DESIRED LEVEL IS REACHED. START

WITH A BLACK SCREEN, THEN PRESS

BUTTON UP 16-20 TIMES. THERE ARE 64

TOTAL STEPS OF BRIGHTNESS.

BRIGHT OR DARK DISPLAY 1. VIDEO SCREEN DISPLAY

PIXEL DEFECT.1. THE ACCEPTABLE LEVEL OF DOTS ON

THE SCREEN IS (GREEN-1, RED-2) OR A

TOTAL

(GREEN+RED+BLUE+WHITE+BLACK) = 8.

REPLACE OR EXCHANGE VIDEO

SCREEN IF NECESSARY.

VIDEO SELECTIONS DO

NOT APPEAR FULL

SCREEN WIDTH1. ASPECT RATIO IS SET

INCORRECTLY.1. USING MODE BUTTON, ADJUST UNTIL

VIDEO APPEARS CORRECTLY.

2. SOME DVD'S ARE TWO

SIDED. ONE SIDE IS WIDE

SCREEN FORMAT AND THE

OTHER IS FULL SCREEN OR

THERE MAY BE A WIDE

SCREEN OR STANDARD

SCREEN FORMAT ON THE

DISC.2. ENSURE THAT DVD IS INSERTED

CORRECTLY.

8A - 6 AUDIO/VIDEORS

AUDIO/VIDEO (Continued)

Page 266 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

BUTTONS ON VIDEO

SCREEN INOPERATIVE1. VIDEO SCREEN DAMAGED. 1. PLACE KNOWN GOOD DVD INTO DVD

PLAYER. ONCE IMAGE APPEARS ON

VIDEO SCREEN, PRESS TOP BUTTON ON

SIDE OF VIDEO SCREEN TO ADJUST

WIDTH OF DISPLAY. PRESS BOTTOM

BUTTONS TO ADJUST BRIGHTNESS.

ONCE DVD MENU APPEARS ON VIDEO

SCREEN, PRESS MIDDLE BUTTON ON

VIDEO SCREEN. HIGHLIGHTED

SELECTION WILL BEGIN TO PLAY. IF ANY

OF THE BUTTONS DO NOT FUNCTION,

REPLACE OR EXCHANGE VIDEO

SCREEN.

AMPLIFIER

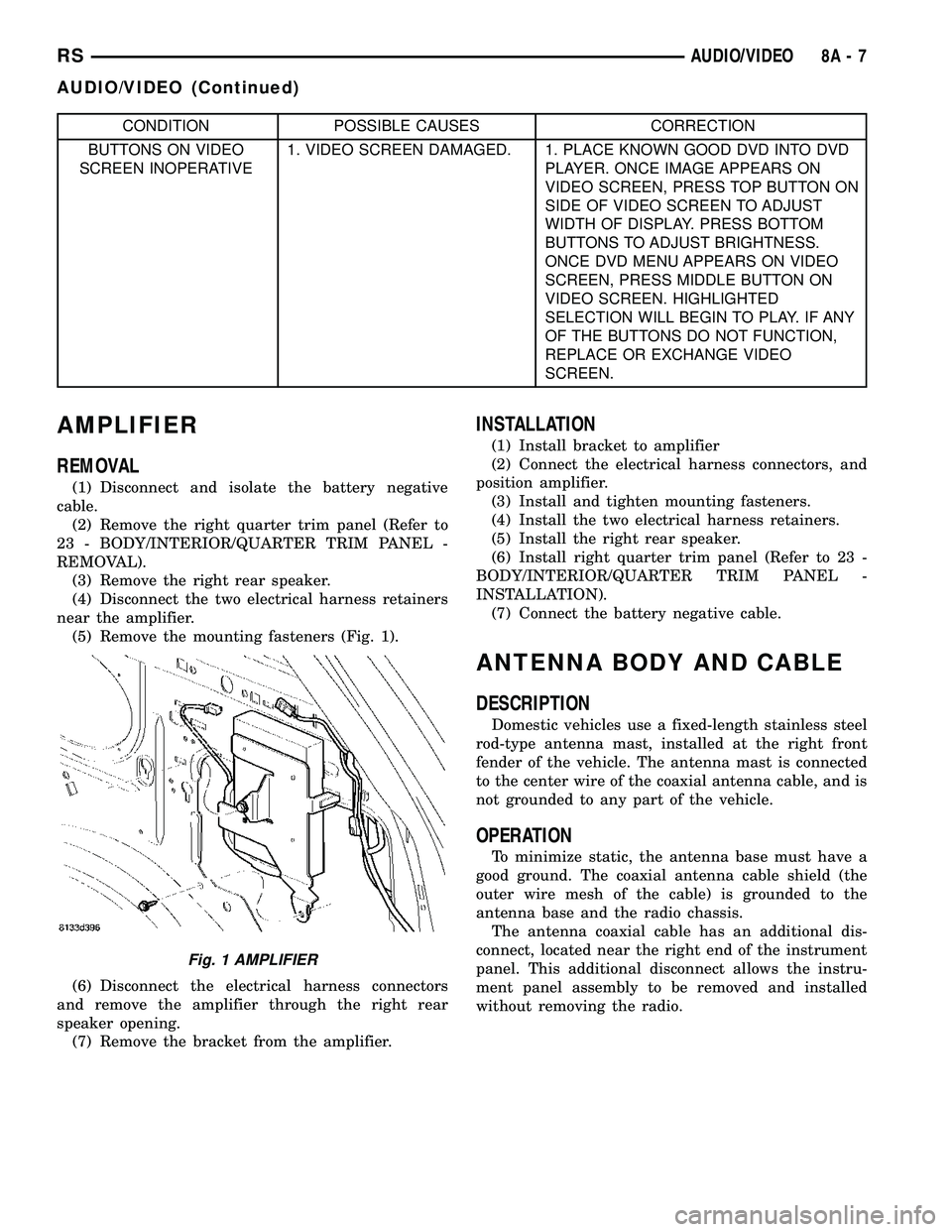

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right quarter trim panel (Refer to

23 - BODY/INTERIOR/QUARTER TRIM PANEL -

REMOVAL).

(3) Remove the right rear speaker.

(4) Disconnect the two electrical harness retainers

near the amplifier.

(5) Remove the mounting fasteners (Fig. 1).

(6) Disconnect the electrical harness connectors

and remove the amplifier through the right rear

speaker opening.

(7) Remove the bracket from the amplifier.

INSTALLATION

(1) Install bracket to amplifier

(2) Connect the electrical harness connectors, and

position amplifier.

(3) Install and tighten mounting fasteners.

(4) Install the two electrical harness retainers.

(5) Install the right rear speaker.

(6) Install right quarter trim panel (Refer to 23 -

BODY/INTERIOR/QUARTER TRIM PANEL -

INSTALLATION).

(7) Connect the battery negative cable.

ANTENNA BODY AND CABLE

DESCRIPTION

Domestic vehicles use a fixed-length stainless steel

rod-type antenna mast, installed at the right front

fender of the vehicle. The antenna mast is connected

to the center wire of the coaxial antenna cable, and is

not grounded to any part of the vehicle.

OPERATION

To minimize static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

Fig. 1 AMPLIFIER

RSAUDIO/VIDEO8A-7

AUDIO/VIDEO (Continued)

Page 271 of 2339

(3) Install screws holding CD changer.

(4) Reconnect the battery negative cable.

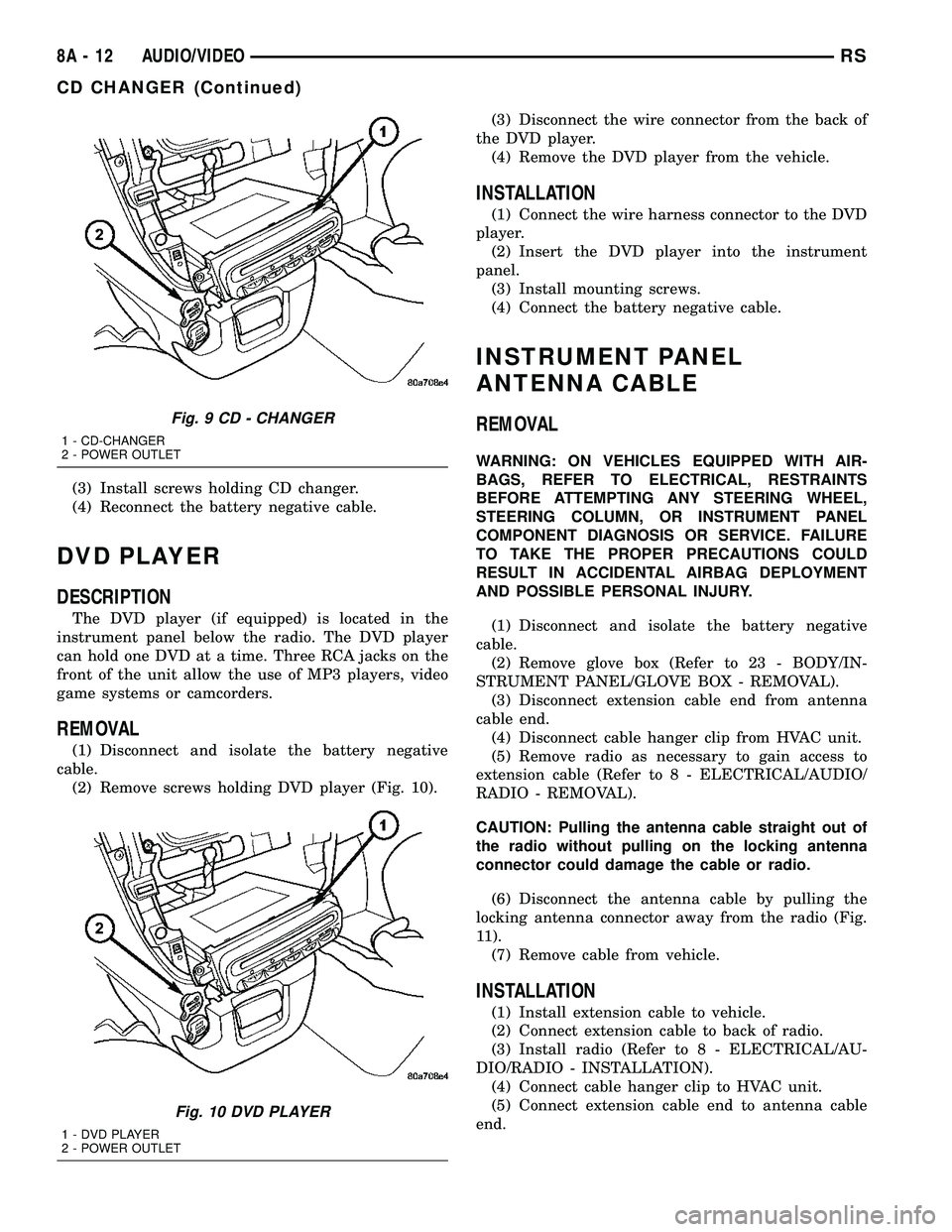

DVD PLAYER

DESCRIPTION

The DVD player (if equipped) is located in the

instrument panel below the radio. The DVD player

can hold one DVD at a time. Three RCA jacks on the

front of the unit allow the use of MP3 players, video

game systems or camcorders.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove screws holding DVD player (Fig. 10).(3) Disconnect the wire connector from the back of

the DVD player.

(4) Remove the DVD player from the vehicle.

INSTALLATION

(1) Connect the wire harness connector to the DVD

player.

(2) Insert the DVD player into the instrument

panel.

(3) Install mounting screws.

(4) Connect the battery negative cable.

INSTRUMENT PANEL

ANTENNA CABLE

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box (Refer to 23 - BODY/IN-

STRUMENT PANEL/GLOVE BOX - REMOVAL).

(3) Disconnect extension cable end from antenna

cable end.

(4) Disconnect cable hanger clip from HVAC unit.

(5) Remove radio as necessary to gain access to

extension cable (Refer to 8 - ELECTRICAL/AUDIO/

RADIO - REMOVAL).

CAUTION: Pulling the antenna cable straight out of

the radio without pulling on the locking antenna

connector could damage the cable or radio.

(6) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

11).

(7) Remove cable from vehicle.

INSTALLATION

(1) Install extension cable to vehicle.

(2) Connect extension cable to back of radio.

(3) Install radio (Refer to 8 - ELECTRICAL/AU-

DIO/RADIO - INSTALLATION).

(4) Connect cable hanger clip to HVAC unit.

(5) Connect extension cable end to antenna cable

end.

Fig. 9 CD - CHANGER

1 - CD-CHANGER

2 - POWER OUTLET

Fig. 10 DVD PLAYER

1 - DVD PLAYER

2 - POWER OUTLET

8A - 12 AUDIO/VIDEORS

CD CHANGER (Continued)

Page 273 of 2339

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory/Accessory Delay

positions. The electronic digital clock function of the

radio operates on fused battery current supplied

through the IOD fuse, regardless of the ignition

switch position.

For complete circuit diagrams, refer to the appro-

priate wiring information.

DIAGNOSIS AND TESTING

RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.

(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Turn the ignition switch to the OFF position.

Check for battery voltage at the fused B(+) circuit

cavity of the radio wire harness connector. If OK,

replace the faulty radio. If not OK, repair the open

circuit to the Ignition-Off Draw (IOD) fuse as

required.

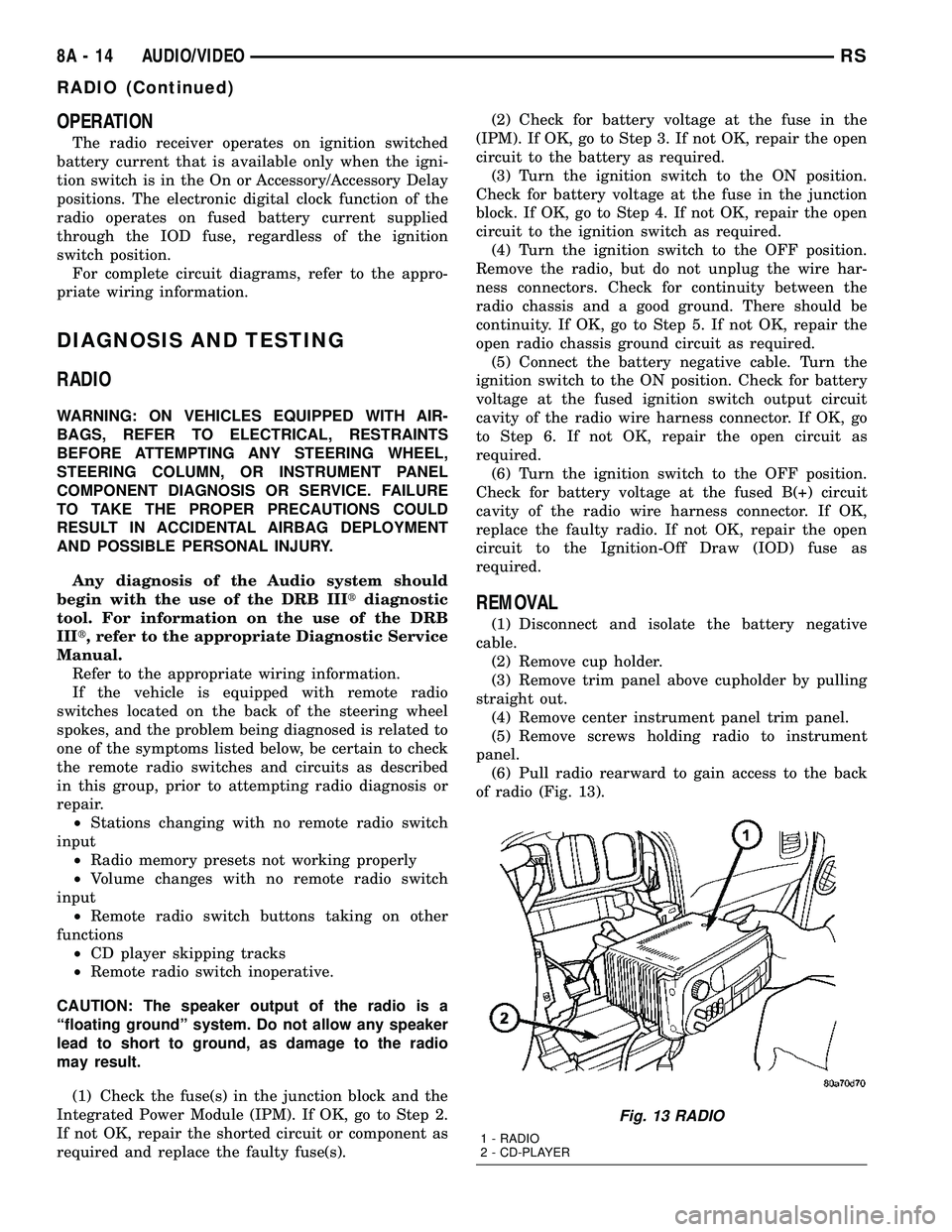

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cup holder.

(3) Remove trim panel above cupholder by pulling

straight out.

(4) Remove center instrument panel trim panel.

(5) Remove screws holding radio to instrument

panel.

(6) Pull radio rearward to gain access to the back

of radio (Fig. 13).

Fig. 13 RADIO

1 - RADIO

2 - CD-PLAYER

8A - 14 AUDIO/VIDEORS

RADIO (Continued)

Page 275 of 2339

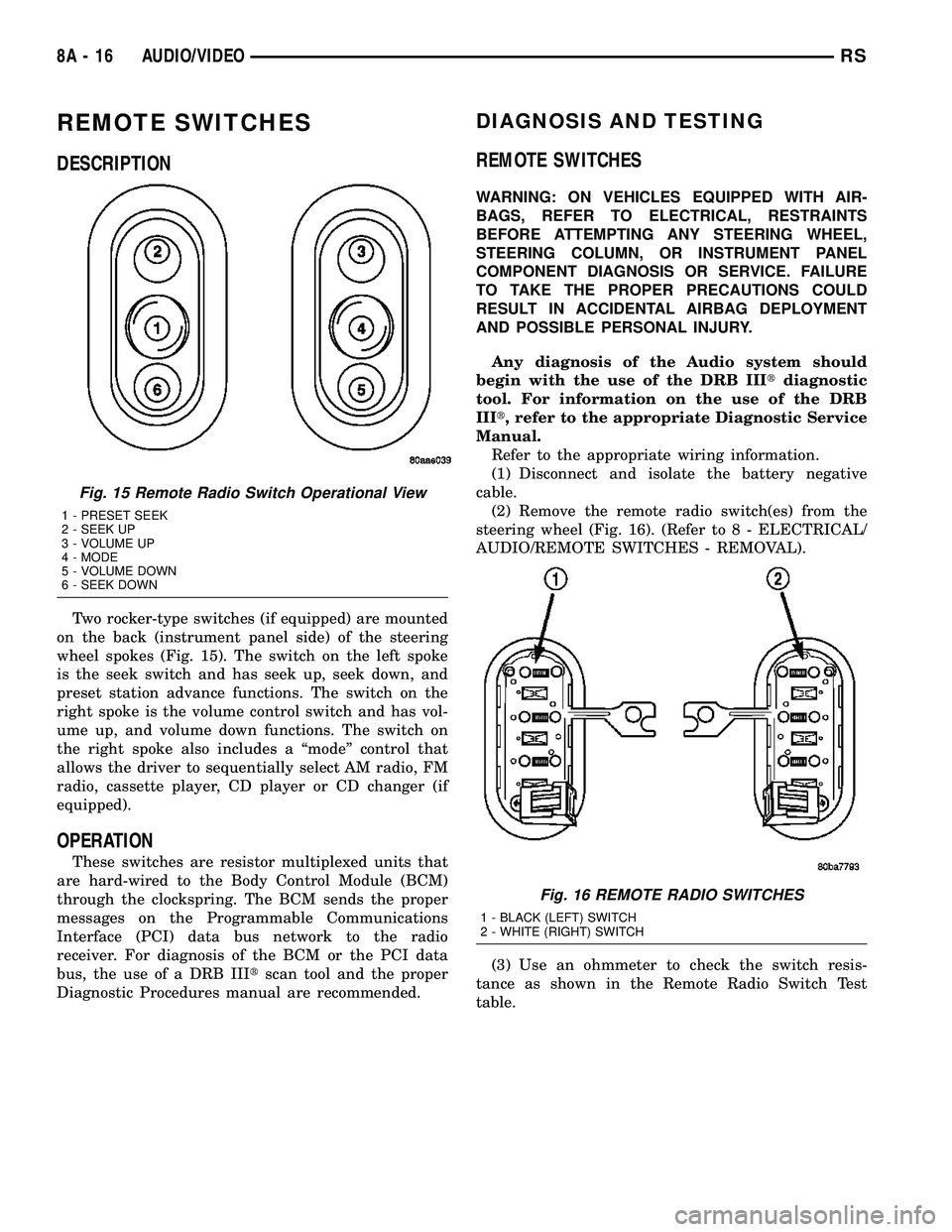

REMOTE SWITCHES

DESCRIPTION

Two rocker-type switches (if equipped) are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 15). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended.

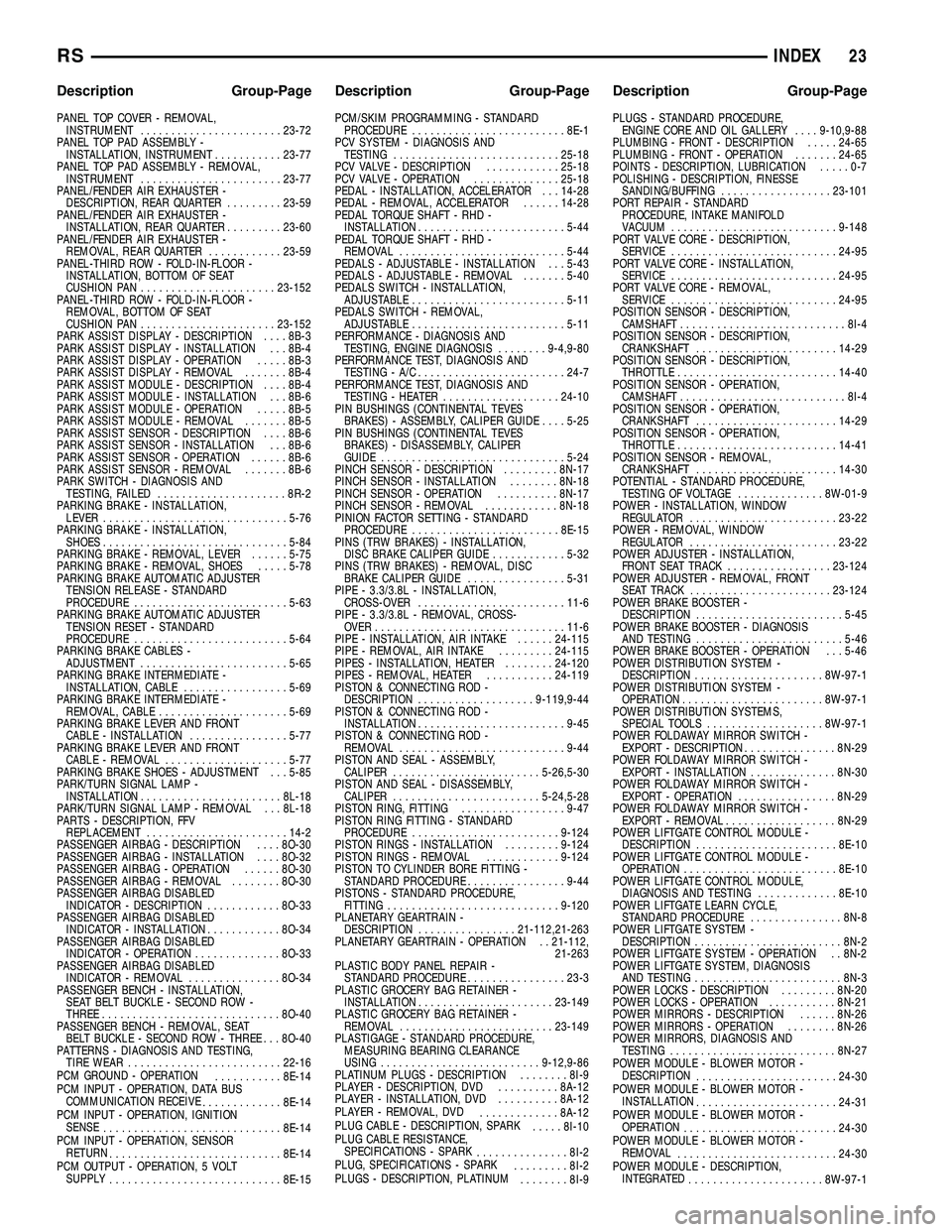

DIAGNOSIS AND TESTING

REMOTE SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the remote radio switch(es) from the

steering wheel (Fig. 16). (Refer to 8 - ELECTRICAL/

AUDIO/REMOTE SWITCHES - REMOVAL).

(3) Use an ohmmeter to check the switch resis-

tance as shown in the Remote Radio Switch Test

table.

Fig. 15 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

Fig. 16 REMOTE RADIO SWITCHES

1 - BLACK (LEFT) SWITCH

2 - WHITE (RIGHT) SWITCH

8A - 16 AUDIO/VIDEORS

Page 2184 of 2339

CONTROLS - REAR

TABLE OF CONTENTS

page page

A/C-HEATER CONTROL

DESCRIPTION.........................33

OPERATION...........................33

REMOVAL.............................33

INSTALLATION.........................34

BLEND DOOR ACTUATOR

DESCRIPTION.........................34

OPERATION...........................35

REMOVAL.............................35

INSTALLATION.........................35

BLOWER MOTOR RELAY

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL.............................37

INSTALLATION.........................37

BLOWER MOTOR RESISTOR BLOCK

DESCRIPTION.........................37OPERATION...........................37

DIAGNOSIS AND TESTING

REAR BLOWER MOTOR RESISTOR

BLOCK.............................38

REMOVAL.............................38

INSTALLATION.........................39

MODE DOOR ACTUATOR - REAR

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................39

INSTALLATION.........................40

POWER MODULE - REAR BLOWER MOTOR

DESCRIPTION.........................40

OPERATION...........................40

REMOVAL.............................41

INSTALLATION.........................41

A/C-HEATER CONTROL

DESCRIPTION

The rear heating-A/C system is controlled by rota-

ry-type blower motor and temperature controls, cen-

trally mounted directly into the headliner, or if

equipped with the available DVD player, located in

the player housing. The rear A/C-heater control

allows selection of three blower motor speeds and an

Off position when the center knob on the front A/C-

heater control is set to the Rear position, otherwise

the front unit controls both front and rear heater-A/C

operation.

OPERATION

With the rear A/C-heater control active, tempera-

ture selection dictates the air distribution mode (floor

or overhead air) of the rear unit. A cool temperature

setting directs flow to the overhead outlets and a

warm temperature setting to the floor. Refer to Body

Diagnostic Procedures for further diagnostic informa-

tion.

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) If the rear A/C-heater control is mounted in the

headliner, use a trim stick or another suitable wide

flat bladed tool and gently pry the top edge of the

control bezel away from the headliner far enough to

release the two snap clip retainers (Fig. 1).

(3) Pull the rear A/C-heater control and bezel

assembly rearward far enough to access the wire har-

ness connector on the back of the control.

(4) Disconnect the wire harness connector from the

rear A/C-heater control.

(5) Remove the rear A/C-heater control and bezel

assembly from the headliner.

(6) If the rear A/C-heater control is mounted in the

video screen housing, remove the housing from the

headliner (Refer to 8 - ELECTRICAL/AUDIO/VIDEO

SCREEN - REMOVAL).

(7) Remove the three screws that secure the rear

A/C-heater control to the bezel or video screen hous-

ing, depending on application and remove the control

(Fig. 2).

RSCONTROLS - REAR24-33

Page 2312 of 2339

DOOR WEATHERSTRIP - INSTALLATION,SLIDING ........................... 23-168

DOOR WEATHERSTRIP - REMOVAL, FRONT ............................ 23-168

DOOR WEATHERSTRIP - REMOVAL, SLIDING ........................... 23-168

DOSING PUMP - DESCRIPTION, FUEL . . . 24-117

DOSING PUMP - INSTALLATION, FUEL . . . 24-117

DOSING PUMP - OPERATION, FUEL .....24-117

DOSING PUMP - REMOVAL, FUEL ......24-117

DOWNSTREAM 1/2 - 2.4/3.3/3.8L - REMOVAL .......................... 14-38

DOWNSTREAM 2/1, 2.4/3.3/3.8L - INSTALLATION ....................... 14-39

D-PILLAR TRIM PANEL - INSTALLATION, LEFT .............................. 23-94

D-PILLAR TRIM PANEL - INSTALLATION, RIGHT ............................. 23-98

D-PILLAR TRIM PANEL - REMOVAL, LEFT .............................. 23-94

D-PILLAR TRIM PANEL - REMOVAL, RIGHT ............................. 23-97

DRAIN TUBE - INSTALLATION ..........23-172

DRAIN TUBE - REMOVAL .............23-172

DRAINCOCK - INSTALLATION, RADIATOR . . . 7-27

DRAINCOCK - REMOVAL, RADIATOR ......7-27

DRAINING - STANDARD PROCEDURE, COOLING SYSTEM .....................7-4

DRAINING FUEL TANK - STANDARD PROCEDURE ......................... 14-2

DRAW TEST, STANDARD PROCEDURE - IGNITION-OFF ....................... 8F-13

DRB III TSTATE DISPLAY TEST MODE,

OPERATION ......................... 25-10

DRIER - DESCRIPTION, RECEIVER .......24-92

DRIER - INSTALLATION, RECEIVER ......24-93

DRIER - OPERATION, RECEIVER .........24-92

DRIER - REMOVAL, RECEIVER ..........24-92

DRIVE - ASSEMBLY, FINAL .......21-224,21-78

DRIVE - DESCRIPTION, FINAL ....21-219,21-74

DRIVE - DESCRIPTION, FLEX ...........8N-55

DRIVE - DISASSEMBLY, FINAL ....21-220,21-75

DRIVE - INSTALLATION, FLEX ..........8N-56

DRIVE - OPERATION, FINAL ......21-220,21-75

DRIVE - OPERATION, FLEX .............8N-55

DRIVE - REMOVAL, FLEX ..............8N-55

DRIVE BELT - DIAGNOSIS AND TESTING, ACCESSORY ..........................7-7

DRIVE BELT TENSION, SPECIFICATIONS - ACCESSORY ..........................7-5

DRIVE BELTS - 2.4L - ADJUSTMENTS .....7-10

DRIVE BELTS - 2.4L - INSTALLATION .......7-9

DRIVE BELTS - 2.4L - REMOVAL ..........7-9

DRIVE BELTS - 3.3/3.8L - INSTALLATION . . . 7-12

DRIVE BELTS - 3.3/3.8L - REMOVAL ......7-11

DRIVE BELTS - CLEANING ...............7-8

DRIVE BELTS - INSPECTION ..............7-8

DRIVE UNIT - DESCRIPTION, LOWER ....8N-53

DRIVE UNIT - INSTALLATION, LOWER ....8N-54

DRIVE UNIT - OPERATION, LOWER ......8N-53

DRIVE UNIT - REMOVAL, LOWER .......8N-53

DRIVE UNIT TRACK & RACK - DESCRIPTION, LOWER ................8N-57

DRIVE UNIT TRACK & RACK - INSTALLATION, LOWER ...............8N-58

DRIVE UNIT TRACK & RACK - OPERATION, LOWER .................. 8N-57

DRIVE UNIT TRACK & RACK - REMOVAL, LOWER ................... 8N-57

DRIVELINE MODULE FLUIDS - DESCRIPTION, AWD REAR ...............0-6

DRIVER AIRBAG - DESCRIPTION ........8O-16

DRIVER AIRBAG - INSTALLATION .......8O-18

DRIVER AIRBAG - OPERATION ..........8O-16

DRIVER AIRBAG - REMOVAL ...........8O-17

DRIVER HEATED SEAT SWITCH, DIAGNOSIS AND TESTING ..............8G-9

DRIVER SEAT SWITCH, DIAGNOSIS AND TESTING ........................... 8N-34

DRIVING CLUTCHES - DESCRIPTION ....21-219,

21-74

DRIVING CLUTCHES - OPERATION . 21-219,21-74

DROP - STANDARD PROCEDURE, TESTING FOR A VOLTAGE ...........8W-01-10

DRUM - INSTALLATION .................5-32

DRUM - REMOVAL .................... 5-32

DRUM BRAKE - INSTALLATION, SUPPORT PLATE ...................... 5-61DRUM BRAKE - REMOVAL, SUPPORT

PLATE .............................. 5-61

DRUM BRAKE AUTOMATIC ADJUSTER - DIAGNOSIS AND TESTING ..............5-14

DRUM BRAKE SHOE LINING - INSPECTION, REAR .................... 5-22

DRUM BRAKE SHOES - ADJUSTMENT, REAR ............................... 5-23

DRUM BRAKE SHOES - INSTALLATION, REAR ............................... 5-22

DRUM BRAKE SHOES - REMOVAL, REAR . . 5-19

DRUM BRAKES (REAR) - DESCRIPTION ....5-13

DUAL ZONE, DESCRIPTION - MANUAL .....24-2

DUAL ZONE, OPERATION - MANUAL ......24-5

DUCT - INSTALLATION, DEFROSTER .....24-50

DUCT - INSTALLATION, DISTRIBUTION . . . 24-57

DUCT - INSTALLATION, REAR FLOOR HEAT .............................. 24-63

DUCT - REMOVAL, DEFROSTER .........24-49

DUCT - REMOVAL, DISTRIBUTION .......24-57

DUCT - REMOVAL, REAR FLOOR HEAT . . . 24-63

DUCTS - INSTALLATION, FLOOR DISTRIBUTION ....................... 24-50

DUCTS - INSTALLATION, INSTRUMENT PANEL ............................. 24-55

DUCTS - INSTALLATION, INSTRUMENT PANEL DEMISTER .................... 24-54

DUCTS - REMOVAL, FLOOR DISTRIBUTION ....................... 24-50

DUCTS - REMOVAL, INSTRUMENT PANEL .............................. 24-55

DUCTS - REMOVAL, INSTRUMENT PANEL DEMISTER .................... 24-54

DUTY, CARGO - INSTALLATION, AWD, HEAVY.............................. 2-36

DUTY, CARGO - REMOVAL, AWD, HEAVY . . . 2-36

DVD PLAYER - DESCRIPTION ...........8A-12

DVD PLAYER - INSTALLATION ..........8A-12

DVD PLAYER - REMOVAL ..............8A-12

ELECTRIC BACKLIGHT (EBL) SYSTEM, DIAGNOSIS AND TESTING ..............8G-2

ELECTROLYTE LEVEL, STANDARD PROCEDURE - CHECKING BATTERY ......8F-14

ELECTRONIC VARIABLE BRAKE PROPORTIONING - DESCRIPTION ........5-88

ELECTRONIC VARIABLE BRAKE PROPORTIONING - OPERATION ..........5-89

ELECTRONIC VEHICLE INFO CENTER - DESCRIPTION ........................ 8M-7

ELECTRONIC VEHICLE INFO CENTER - OPERATION ......................... 8M-7

ELECTRONIC VEHICLE INFORMATION CENTER, DIAGNOSIS AND TESTING ......8M-8

ELECTRONIC VEHICLE INFORMATION CENTER PROGRAMMING, STANDARD

PROCEDURE ......................... 8M-8

ELECTROSTATIC DISCHARGE (ESD) SENSITIVE DEVICES - STANDARD

PROCEDURE ......................8W -01-8

ELEMENT - INSTALLATION, AIR CLEANER ....................... 9-101,9-24

ELEMENT - REMOVAL, AIR CLEANER . 9-101,9-24

ELEMENTS - DESCRIPTION, HEATED SEAT .............................. 8G-11

ELEMENTS - OPERATION, HEATED SEAT . . 8G-11

ELEMENTS, DIAGNOSIS AND TESTING - HEATED SEAT ....................... 8G-11

EMISSION CONTROL INFORMATION LABEL, DESCRIPTION - VEHICLE .........25-1

END CAP - INSTALLATION, INSTRUMENT PANEL RIGHT ....................... 23-72

END CAP - REMOVAL, INSTRUMENT PANEL RIGHT ....................... 23-72

END CLEANING AND LUBRICATION - STANDARD PROCEDURE, CABLE .........5-65

END PLAY - STANDARD PROCEDURE, CRANKSHAFT ........................ 9-37

END PLAY - STANDARD PROCEDURE, MEASURING CAMSHAFT ................9-29

END PLAY - STANDARD PROCEDURE, MEASURING CRANKSHAFT .............9-128

ENGAGE ACTUATOR - DESCRIPTION ......8N-9

ENGAGE ACTUATOR - INSTALLATION .....8N-10

ENGAGE ACTUATOR - OPERATION ........8N-9

ENGAGE ACTUATOR - REMOVAL .........8N-9

ENGINE - A/C COMPRESSOR MOUNTING BRACKET, 2.4L ................. 24-74,24-75

ENGINE - CLEANING ................... 7-18ENGINE - DESCRIPTION, 2.4L/3.3L/3.8L . . . 19-52

ENGINE - DESCRIPTION, FUEL

REQUIREMENTS - DIESEL ...............0-6

ENGINE - INSPECTION .................7-18

ENGINE - INSTALLATION, 2.4L .....19-47,19-50,

19-51,19-53

ENGINE - INSTALLATION, 3.3L/3.8L . 19-48,19-50, 19-52,19-53

ENGINE - REMOVAL, 2.4L . . . 19-46,19-49,19-51, 19-52

ENGINE - REMOVAL, 3.3L/3.8L ....19-46,19-49,

19-51,19-52

ENGINE - SPECIFICATIONS, 2.4L .........9-16

ENGINE 2.4L - DESCRIPTION .............9-3

ENGINE 3.3/3.8L - DESCRIPTION .........9-78

ENGINE ASSEMBLY - INSTALLATION . . 9-14,9-91

ENGINE ASSEMBLY - REMOVAL ......9-12,9-88

ENGINE BLOCK - CLEANING ........9-115,9-37

ENGINE BLOCK - DESCRIPTION .....9-115,9-36

ENGINE BLOCK - INSPECTION ......9-115,9-37

ENGINE BLOCK HEATER - DESCRIPTION . . . 7-20

ENGINE BLOCK HEATER - INSTALLATION . . . 7-21

ENGINE BLOCK HEATER - OPERATION .....7-20

ENGINE BLOCK HEATER - REMOVAL ......7-21

ENGINE BLOCK HEATER TESTING - DIAGNOSIS AND TESTING ..............7-21

ENGINE COOLANT - DESCRIPTION ........7-19

ENGINE COOLANT - DESCRIPTION .........0-3

ENGINE COOLANT TEMPERATURE SENSOR - 2.4L - DESCRIPTION ..........7-21

ENGINE COOLANT TEMPERATURE SENSOR - 2.4L - INSTALLATION ..........7-21

ENGINE COOLANT TEMPERATURE SENSOR - 2.4L - REMOVAL .............7-21

ENGINE COOLANT TEMPERATURE SENSOR - 3.3/3.8L - DESCRIPTION .......7-21

ENGINE COOLANT TEMPERATURE SENSOR - 3.3/3.8L - INSTALLATION .......7-23

ENGINE COOLANT TEMPERATURE SENSOR - 3.3/3.8L - REMOVAL ..........7-21

ENGINE COOLANT THERMOSTAT - 2.4L - INSTALLATION ........................ 7-24

ENGINE COOLANT THERMOSTAT - 2.4L - REMOVAL ........................... 7-24

ENGINE COOLANT THERMOSTAT - 3.3/3.8L - INSTALLATION ...............7-25

ENGINE COOLANT THERMOSTAT - 3.3/3.8L - REMOVAL ................... 7-24

ENGINE COOLANT THERMOSTAT - DESCRIPTION ........................ 7-23

ENGINE COOLANT THERMOSTAT - DIAGNOSIS AND TESTING ..............7-23

ENGINE COOLANT THERMOSTAT - OPERATION .......................... 7-23

ENGINE COOLING SYSTEM - DIAGNOSIS AND TESTING ........................ 7-14

ENGINE COOLING SYSTEM REQUIREMENTS, DESCRIPTION ..........24-1

ENGINE COOLING SYSTEM, WARNING ....24-65

ENGINE CORE AND OIL GALLERY PLUGS - STANDARD PROCEDURE ..........9-10,9-88

ENGINE DIAGNOSIS - INTRODUCTION - DIAGNOSIS AND TESTING ...........9-3,9-78

ENGINE DIAGNOSIS - MECHANICAL - DIAGNOSIS AND TESTING ...........9-6,9-82

ENGINE DIAGNOSIS - PERFORMANCE - DIAGNOSIS AND TESTING ...........9-4,9-80

ENGINE GASKET SURFACE PREPARATION - STANDARD

PROCEDURE ..................... 9-11,9-87

ENGINE MOUNTING - DESCRIPTION . 9-134,9-50

ENGINE OIL - DESCRIPTION, FLEXIBLE FUEL ................................0-3

ENGINE OIL - DIESEL ENGINES - DESCRIPTION .........................0-6

ENGINE OIL AND FILTER CHANGE - STANDARD PROCEDURE ...........9-139,9-54

ENGINE OIL AND LUBRICANTS - DESCRIPTION .........................0-1

ENGINE OIL LEAK INSPECTION - DIAGNOSIS AND TESTING ...........9-8,9-84

ENGINE OIL LEVEL CHECK - STANDARD PROCEDURE ........................ 9-140

ENGINE OIL LEVEL CHECK, STANDARD PROCEDURE ......................... 9-54

ENGINE OIL PRESSURE - DIAGNOSIS AND TESTING ....................... 9-138

RS INDEX11

Description Group-Page Description Group-Page Description Group-Page

Page 2324 of 2339

PANEL TOP COVER - REMOVAL,INSTRUMENT ....................... 23-72

PANEL TOP PAD ASSEMBLY - INSTALLATION, INSTRUMENT ...........23-77

PANEL TOP PAD ASSEMBLY - REMOVAL, INSTRUMENT ....................... 23-77

PANEL/FENDER AIR EXHAUSTER - DESCRIPTION, REAR QUARTER .........23-59

PANEL/FENDER AIR EXHAUSTER - INSTALLATION, REAR QUARTER .........23-60

PANEL/FENDER AIR EXHAUSTER - REMOVAL, REAR QUARTER ............23-59

PANEL-THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, BOTTOM OF SEAT

CUSHION PAN ...................... 23-152

PANEL-THIRD ROW - FOLD-IN-FLOOR - REMOVAL, BOTTOM OF SEAT

CUSHION PAN ...................... 23-152

PARK ASSIST DISPLAY - DESCRIPTION ....8B-3

PARK ASSIST DISPLAY - INSTALLATION . . . 8B-4

PARK ASSIST DISPLAY - OPERATION .....8B-3

PARK ASSIST DISPLAY - REMOVAL .......8B-4

PARK ASSIST MODULE - DESCRIPTION ....8B-4

PARK ASSIST MODULE - INSTALLATION . . . 8B-6

PARK ASSIST MODULE - OPERATION .....8B-5

PARK ASSIST MODULE - REMOVAL .......8B-5

PARK ASSIST SENSOR - DESCRIPTION ....8B-6

PARK ASSIST SENSOR - INSTALLATION . . . 8B-6

PARK ASSIST SENSOR - OPERATION ......8B-6

PARK ASSIST SENSOR - REMOVAL .......8B-6

PARK SWITCH - DIAGNOSIS AND TESTING, FAILED ..................... 8R-2

PARKING BRAKE - INSTALLATION, LEVER .............................. 5-76

PARKING BRAKE - INSTALLATION, SHOES .............................. 5-84

PARKING BRAKE - REMOVAL, LEVER ......5-75

PARKING BRAKE - REMOVAL, SHOES .....5-78

PARKING BRAKE AUTOMATIC ADJUSTER TENSION RELEASE - STANDARD

PROCEDURE ......................... 5-63

PARKING BRAKE AUTOMATIC ADJUSTER TENSION RESET - STANDARD

PROCEDURE ......................... 5-64

PARKING BRAKE CABLES - ADJUSTMENT ........................ 5-65

PARKING BRAKE INTERMEDIATE - INSTALLATION, CABLE .................5-69

PARKING BRAKE INTERMEDIATE - REMOVAL, CABLE ..................... 5-69

PARKING BRAKE LEVER AND FRONT CABLE - INSTALLATION ................5-77

PARKING BRAKE LEVER AND FRONT CABLE - REMOVAL .................... 5-77

PARKING BRAKE SHOES - ADJUSTMENT . . . 5-85

PARK/TURN SIGNAL LAMP - INSTALLATION ....................... 8L-18

PARK/TURN SIGNAL LAMP - REMOVAL . . . 8L-18

PARTS - DESCRIPTION, FFV REPLACEMENT ....................... 14-2

PASSENGER AIRBAG - DESCRIPTION ....8O-30

PASSENGER AIRBAG - INSTALLATION ....8O-32

PASSENGER AIRBAG - OPERATION ......8O-30

PASSENGER AIRBAG - REMOVAL ........8O-30

PASSENGER AIRBAG DISABLED INDICATOR - DESCRIPTION ............8O-33

PASSENGER AIRBAG DISABLED INDICATOR - INSTALLATION ............8O-34

PASSENGER AIRBAG DISABLED INDICATOR - OPERATION ..............8O-33

PASSENGER AIRBAG DISABLED INDICATOR - REMOVAL ...............8O-34

PASSENGER BENCH - INSTALLATION, SEAT BELT BUCKLE - SECOND ROW -

THREE ............................. 8O-40

PASSENGER BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW - THREE . . . 8O-40

PATTERNS - DIAGNOSIS AND TESTING, TIRE WEAR ......................... 22-16

PCM GROUND - OPERATION ...........8E-14

PCM INPUT - OPERATION, DATA BUS COMMUNICATION RECEIVE .............8E-14

PCM INPUT - OPERATION, IGNITION SENSE ............................. 8E-14

PCM INPUT - OPERATION, SENSOR RETURN ............................ 8E-14

PCM OUTPUT - OPERATION, 5 VOLT SUPPLY ............................ 8E-15PCM/SKIM PROGRAMMING - STANDARD

PROCEDURE ......................... 8E-1

PCV SYSTEM - DIAGNOSIS AND TESTING ........................... 25-18

PCV VALVE - DESCRIPTION ............25-18

PCV VALVE - OPERATION ..............25-18

PEDAL - INSTALLATION, ACCELERATOR . . . 14-28

PEDAL - REMOVAL, ACCELERATOR ......14-28

PEDAL TORQUE SHAFT - RHD - INSTALLATION ........................ 5-44

PEDAL TORQUE SHAFT - RHD - REMOVAL ........................... 5-44

PEDALS - ADJUSTABLE - INSTALLATION . . . 5-43

PEDALS - ADJUSTABLE - REMOVAL .......5-40

PEDALS SWITCH - INSTALLATION, ADJUSTABLE ......................... 5-11

PEDALS SWITCH - REMOVAL, ADJUSTABLE ......................... 5-11

PERFORMANCE - DIAGNOSIS AND TESTING, ENGINE DIAGNOSIS ........9-4,9-80

PERFORMANCE TEST, DIAGNOSIS AND TESTING - A/C ........................ 24-7

PERFORMANCE TEST, DIAGNOSIS AND TESTING - HEATER ................... 24-10

PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - ASSEMBLY, CALIPER GUIDE ....5-25

PIN BUSHINGS (CONTINENTAL TEVES BRAKES) - DISASSEMBLY, CALIPER

GUIDE .............................. 5-24

PINCH SENSOR - DESCRIPTION .........8N-17

PINCH SENSOR - INSTALLATION ........8N-18

PINCH SENSOR - OPERATION ..........8N-17

PINCH SENSOR - REMOVAL ............8N-18

PINION FACTOR SETTING - STANDARD PROCEDURE ........................ 8E-15

PINS (TRW BRAKES) - INSTALLATION, DISC BRAKE CALIPER GUIDE ............5-32

PINS (TRW BRAKES) - REMOVAL, DISC BRAKE CALIPER GUIDE ................5-31

PIPE - 3.3/3.8L - INSTALLATION, CROSS-OVER ........................ 11-6

PIPE - 3.3/3.8L - REMOVAL, CROSS- OVER ............................... 11-6

PIPE - INSTALLATION, AIR INTAKE ......24-115

PIPE - REMOVAL, AIR INTAKE .........24-115

PIPES - INSTALLATION, HEATER ........24-120

PIPES - REMOVAL, HEATER ...........24-119

PISTON & CONNECTING ROD - DESCRIPTION ................... 9-119,9-44

PISTON & CONNECTING ROD - INSTALLATION ........................ 9-45

PISTON & CONNECTING ROD - REMOVAL ........................... 9-44

PISTON AND SEAL - ASSEMBLY, CALIPER ........................ 5-26,5-30

PISTON AND SEAL - DISASSEMBLY, CALIPER ........................ 5-24,5-28

PISTON RING, FITTING .................9-47

PISTON RING FITTING - STANDARD PROCEDURE ........................ 9-124

PISTON RINGS - INSTALLATION .........9-124

PISTON RINGS - REMOVAL ............9-124

PISTON TO CYLINDER BORE FITTING - STANDARD PROCEDURE ................9-44

PISTONS - STANDARD PROCEDURE, FITTING ............................ 9-120

PLANETARY GEARTRAIN - DESCRIPTION ................ 21-112,21-263

PLANETARY GEARTRAIN - OPERATION . . 21-112, 21-263

PLASTIC BODY PANEL REPAIR - STANDARD PROCEDURE ................23-3

PLASTIC GROCERY BAG RETAINER - INSTALLATION ...................... 23-149

PLASTIC GROCERY BAG RETAINER - REMOVAL ......................... 23-149

PLASTIGAGE - STANDARD PROCEDURE, MEASURING BEARING CLEARANCE

USING .......................... 9-12,9-86

PLATINUM PLUGS - DESCRIPTION ........8I-9

PLAYER - DESCRIPTION, DVD ..........8A-12

PLAYER - INSTALLATION, DVD ..........8A-12

PLAYER - REMOVAL, DVD .............8A-12

PLUG CABLE - DESCRIPTION, SPARK .....8I-10

PLUG CABLE RESISTANCE, SPECIFICATIONS - SPARK ...............8I-2

PLUG, SPECIFICATIONS - SPARK .........8I-2

PLUGS - DESCRIPTION, PLATINUM ........8I-9PLUGS - STANDARD PROCEDURE,

ENGINE CORE AND OIL GALLERY ....9-10,9-88

PLUMBING - FRONT - DESCRIPTION .....24-65

PLUMBING - FRONT - OPERATION .......24-65

POINTS - DESCRIPTION, LUBRICATION .....0-7

POLISHING - DESCRIPTION, FINESSE SANDING/BUFFING .................. 23-101

PORT REPAIR - STANDARD PROCEDURE, INTAKE MANIFOLD

VACUUM ........................... 9-148

PORT VALVE CORE - DESCRIPTION, SERVICE ........................... 24-95

PORT VALVE CORE - INSTALLATION, SERVICE ........................... 24-95

PORT VALVE CORE - REMOVAL, SERVICE ........................... 24-95

POSITION SENSOR - DESCRIPTION, CAMSHAFT ........................... 8I-4

POSITION SENSOR - DESCRIPTION, CRANKSHAFT ....................... 14-29

POSITION SENSOR - DESCRIPTION, THROTTLE .......................... 14-40

POSITION SENSOR - OPERATION, CAMSHAFT ........................... 8I-4

POSITION SENSOR - OPERATION, CRANKSHAFT ....................... 14-29

POSITION SENSOR - OPERATION, THROTTLE .......................... 14-41

POSITION SENSOR - REMOVAL, CRANKSHAFT ....................... 14-30

POTENTIAL - STANDARD PROCEDURE, TESTING OF VOLTAGE ..............8W-01-9

POWER - INSTALLATION, WINDOW REGULATOR ........................ 23-22

POWER - REMOVAL, WINDOW REGULATOR ........................ 23-22

POWER ADJUSTER - INSTALLATION, FRONT SEAT TRACK .................23-124

POWER ADJUSTER - REMOVAL, FRONT SEAT TRACK ....................... 23-124

POWER BRAKE BOOSTER - DESCRIPTION ........................ 5-45

POWER BRAKE BOOSTER - DIAGNOSIS AND TESTING ........................ 5-46

POWER BRAKE BOOSTER - OPERATION . . . 5-46

POWER DISTRIBUTION SYSTEM - DESCRIPTION .....................8W -97-1

POWER DISTRIBUTION SYSTEM - OPERATION .......................8W -97-1

POWER DISTRIBUTION SYSTEMS, SPECIAL TOOLS ...................8W -97-1

POWER FOLDAWAY MIRROR SWITCH - EXPORT - DESCRIPTION ...............8N-29

POWER FOLDAWAY MIRROR SWITCH - EXPORT - INSTALLATION ..............8N-30

POWER FOLDAWAY MIRROR SWITCH - EXPORT - OPERATION ................8N-29

POWER FOLDAWAY MIRROR SWITCH - EXPORT - REMOVAL .................. 8N-29

POWER LIFTGATE CONTROL MODULE - DESCRIPTION ....................... 8E-10

POWER LIFTGATE CONTROL MODULE - OPERATION ......................... 8E-10

POWER LIFTGATE CONTROL MODULE, DIAGNOSIS AND TESTING .............8E-10

POWER LIFTGATE LEARN CYCLE, STANDARD PROCEDURE ...............8N-8

POWER LIFTGATE SYSTEM - DESCRIPTION ........................ 8N-2

POWER LIFTGATE SYSTEM - OPERATION . . 8N-2

POWER LIFTGATE SYSTEM, DIAGNOSIS AND TESTING ........................ 8N-3

POWER LOCKS - DESCRIPTION .........8N-20

POWER LOCKS - OPERATION ...........8N-21

POWER MIRRORS - DESCRIPTION ......8N-26

POWER MIRRORS - OPERATION ........8N-26

POWER MIRRORS, DIAGNOSIS AND TESTING ........................... 8N-27

POWER MODULE - BLOWER MOTOR - DESCRIPTION ....................... 24-30

POWER MODULE - BLOWER MOTOR - INSTALLATION ....................... 24-31

POWER MODULE - BLOWER MOTOR - OPERATION ......................... 24-30

POWER MODULE - BLOWER MOTOR - REMOVAL .......................... 24-30

POWER MODULE - DESCRIPTION, INTEGRATED ......................8W -97-1

RS INDEX23

Description Group-Page Description Group-Page Description Group-Page