body CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1 of 2339

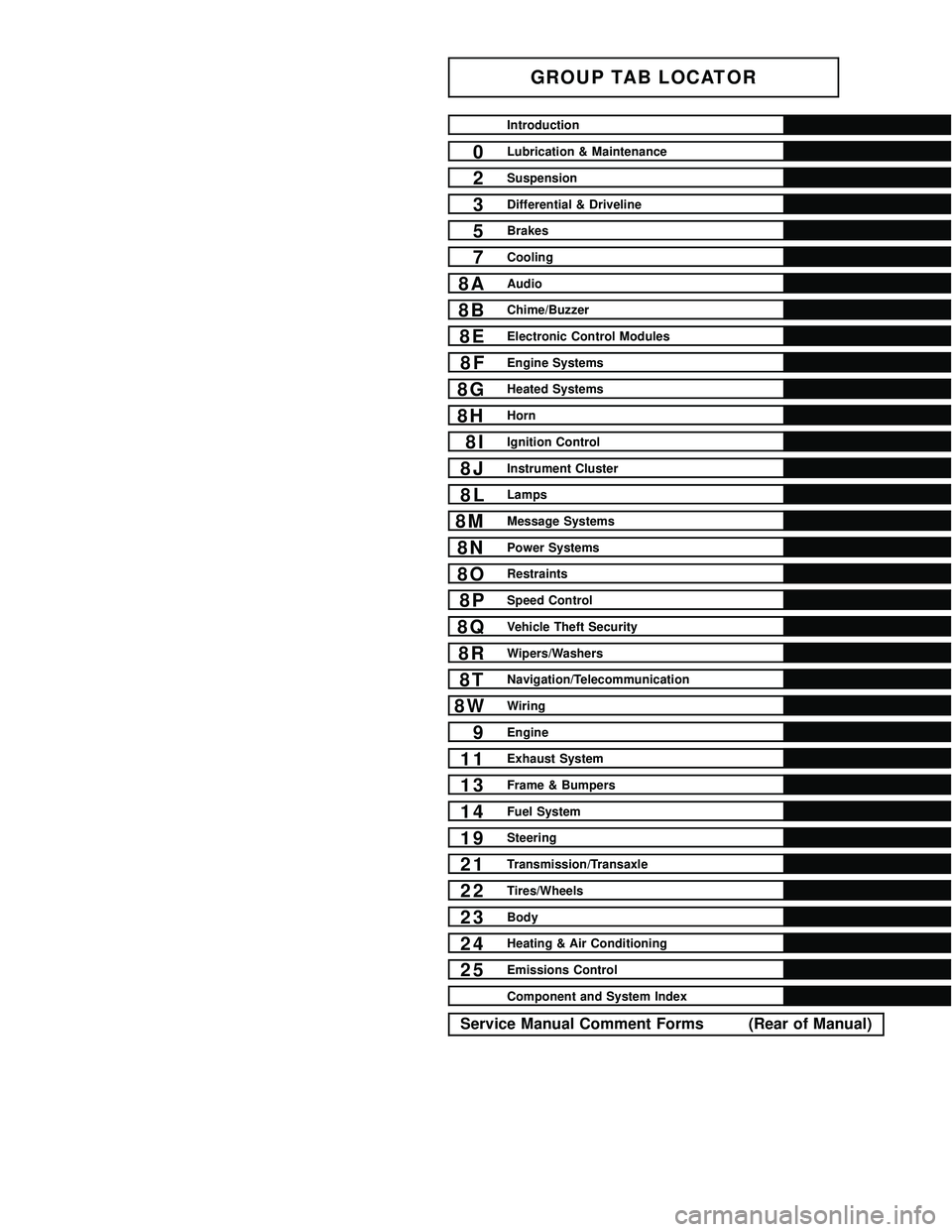

GROUP TAB LOCATOR

Introduction

0Lubrication & Maintenance

2Suspension

3Differential & Driveline

5Brakes

7Cooling

8AAudio

8BChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8LLamps

8MMessage Systems

8NPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8TNavigation/Telecommunication

8WWiring

9Engine

11Exhaust System

13Frame & Bumpers

14Fuel System

19Steering

21Transmission/Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

25Emissions Control

Component and System Index

Service Manual Comment Forms (Rear of Manual)

Page 2 of 2339

INTRODUCTION

TABLE OF CONTENTS

page page

BODY CODE PLATE

DESCRIPTION..........................1

FASTENER IDENTIFICATION

DESCRIPTION..........................2

FASTENER USAGE

DESCRIPTION

FASTENER USAGE.....................5

THREADED HOLE REPAIR...............5

INTERNATIONAL SYMBOLS

DESCRIPTION..........................5

METRIC SYSTEM

DESCRIPTION..........................6TORQUE REFERENCES

DESCRIPTION..........................8

VEHICLE IDENTIFICATION NUMBER

DESCRIPTION..........................9

VEHICLE CERTIFICATION LABEL

DESCRIPTION.........................11

E-MARK LABEL

DESCRIPTION.........................11

VECI LABEL

DESCRIPTION.........................11

MANUFACTURER PLATE

DESCRIPTION.........................11

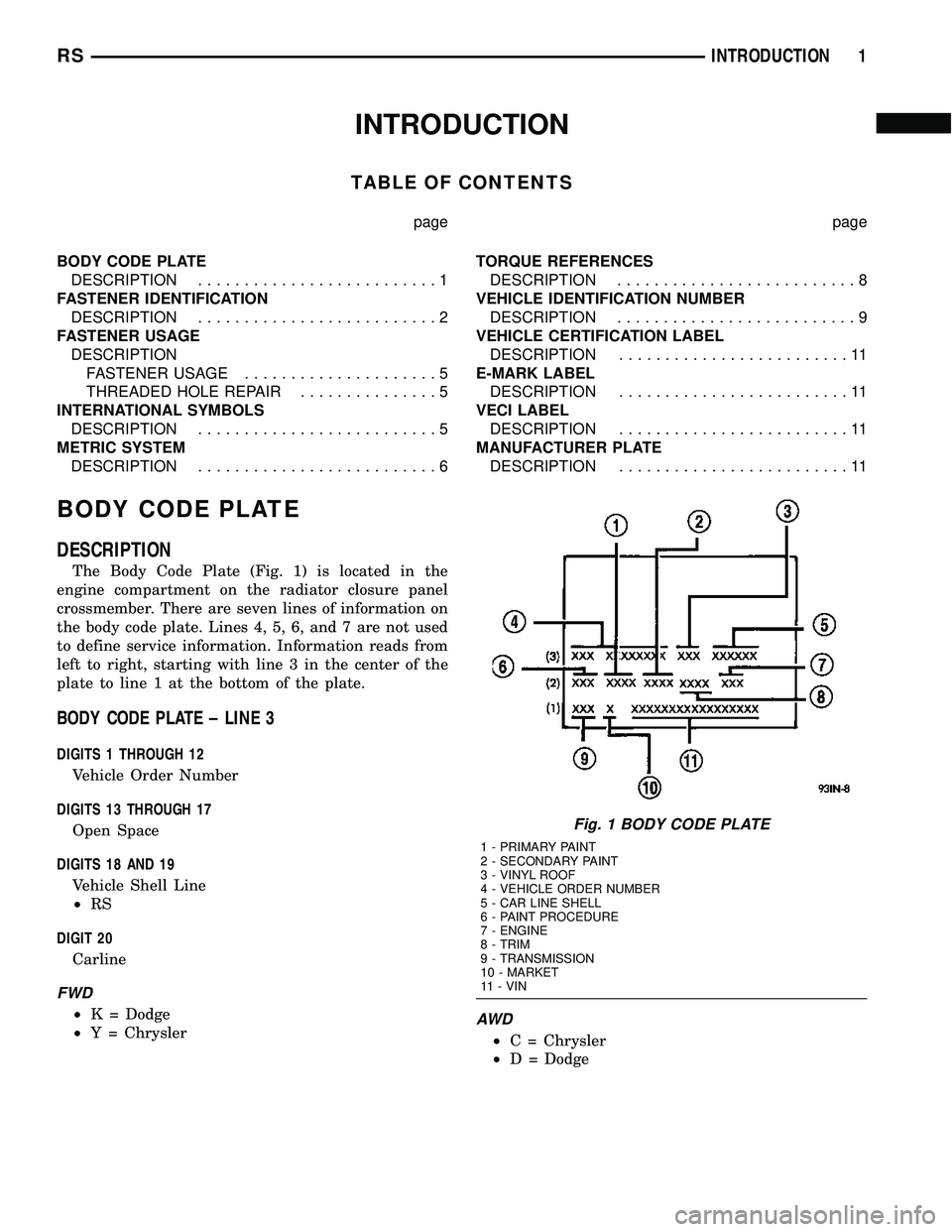

BODY CODE PLATE

DESCRIPTION

The Body Code Plate (Fig. 1) is located in the

engine compartment on the radiator closure panel

crossmember. There are seven lines of information on

the body code plate. Lines 4, 5, 6, and 7 are not used

to define service information. Information reads from

left to right, starting with line 3 in the center of the

plate to line 1 at the bottom of the plate.

BODY CODE PLATE ± LINE 3

DIGITS 1 THROUGH 12

Vehicle Order Number

DIGITS 13 THROUGH 17

Open Space

DIGITS 18 AND 19

Vehicle Shell Line

²RS

DIGIT 20

Carline

FWD

²K = Dodge

²Y = ChryslerAW D

²C = Chrysler

²D = Dodge

Fig. 1 BODY CODE PLATE

1 - PRIMARY PAINT

2 - SECONDARY PAINT

3 - VINYL ROOF

4 - VEHICLE ORDER NUMBER

5 - CAR LINE SHELL

6 - PAINT PROCEDURE

7 - ENGINE

8 - TRIM

9 - TRANSMISSION

10 - MARKET

11 - VIN

RSINTRODUCTION1

Page 3 of 2339

DIGIT 21

Price Class

²H = Highline

²L = Lowline

²P = Premium

²S = Luxury

²X = Premium

DIGITS 22 AND 23

Body Type

²52 = Short Wheel Base

²53 = Long Wheel Base

BODY CODE PLATE LINE 2

DIGITS 1, 2 AND 3

Paint Procedure

DIGIT 4

Open Space

DIGITS 5 THROUGH 7

Primary Paint (Refer to 23 - BODY/PAINT - SPEC-

IFICATIONS).

DIGIT 8 AND 9

Open Space

DIGITS 10 THROUGH 12

Secondary Paint

DIGIT 13 AND 14

Open Space

DIGITS 15 THROUGH 18

Interior Trim Code

DIGIT 19

Open Space

DIGITS 20, 21, AND 22

Engine Code

²EDZ = 2.4L 4 cyl. 16-Valve DOHC Gasoline

(MPI)

²EGA = 3.3L 6 cyl. Gasoline (SMPI)

²EGH = 3.8L 6 cyl. Gasoline (SMPI)

²EGM = 3.3L 6 cyl. Ethanol Flexible Fuel

²ENJ = 2.5L 4 cyl. 16-Valve Turbo Diesel

DIGIT 23

Open Space

BODY CODE PLATE LINE 1

DIGITS 1, 2, AND 3

Transaxle Codes

²DGC = 31TH 3-Speed Automatic Transaxle

²DGL = 41AE/TE 4-Speed Electronic Automatic

²DDR = T850 5-Speed Manual Transaxle

DIGIT 4

Open Space

DIGIT 5

Market Code

²C = Canada

²B = International

²M = Mexico

²U = United States

DIGIT 6

Open Space

DIGITS 7 THROUGH 23

Vehicle Identification Number

²Refer to Vehicle Identification Number (VIN)

paragraph for proper breakdown of VIN code.

IF TWO BODY CODE PLATES ARE REQUIRED

The last code shown on either plate will be fol-

lowed by END. When two plates are required, the

last code space on the first plate will indicate (CTD)

When a second plate is required, the first four

spaces of each line will not be used due to overlap of

the plates.

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts.

2 INTRODUCTIONRS

BODY CODE PLATE (Continued)

Page 11 of 2339

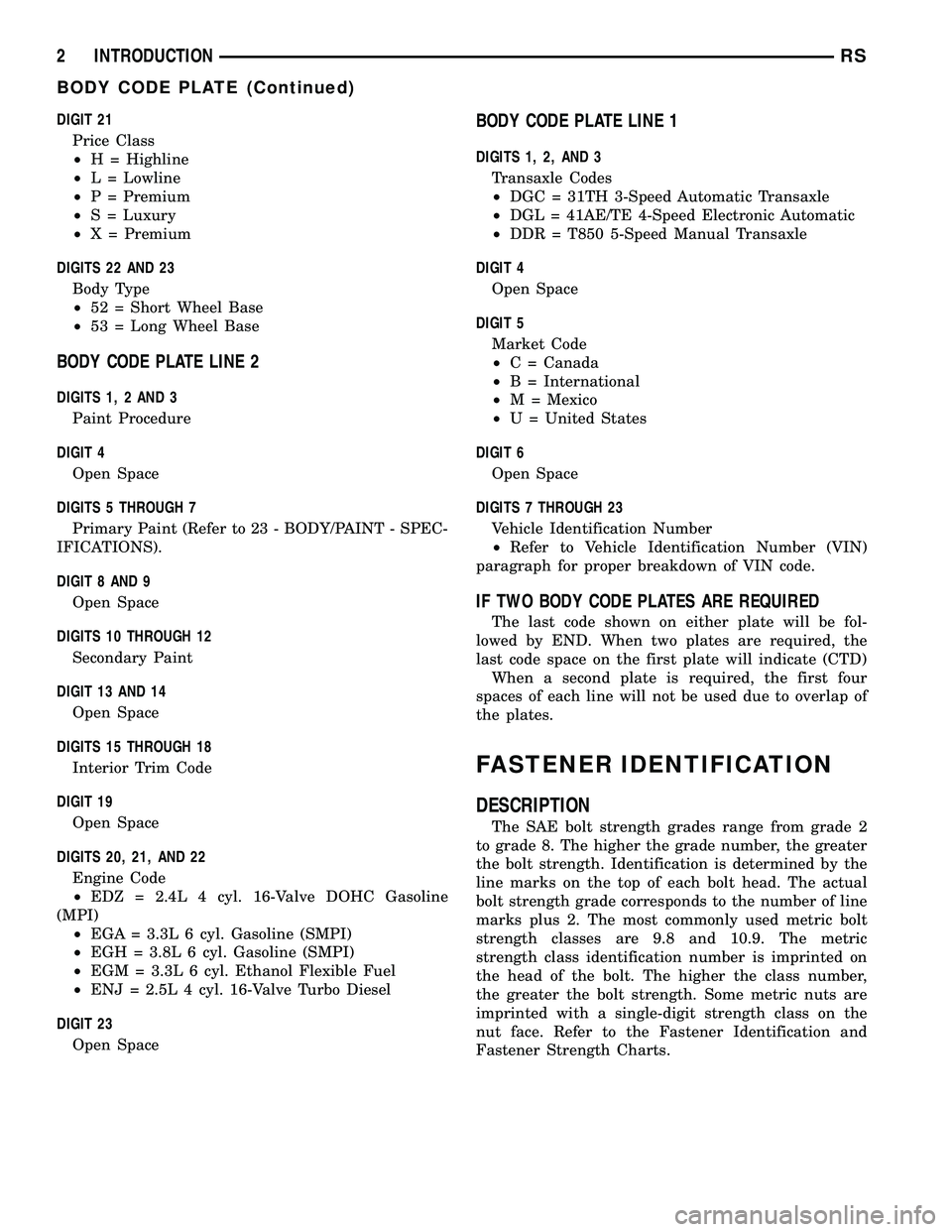

POSITION INTERPRETATION CODE = DESCRIPTION

6 Series2 = Low Line

3 = Medium

4 = High Line

5 = Premium

6 = Sport

7 = Special

6 - Export Series B = 4-Speed Automatic Transaxle

N = 5-Speed Manual Transaxle

7 Body Style1 = Van - Caravan C/V

3 = Extended Van - Grand Caravan C/V

4 = Extended Wagon - Grand Caravan/Town & Country

5 = Wagon - Caravan, Voyager, Town & Country

7 - Export Body Style1 = EURO Wagon - Long Wheelbase (RG - 53 - S Series)

2 = EURO Wagon - Short Wheelbase (RG - 52 - H Series)

3 = EURO Wagon - Short Wheelbase (RG - 52 - P Series)

4 = EURO Wagon - Long Wheelbase (RG - 53 - P Series)

5 = EURO Wagon - Long Wheelbase (RG - 53 - H Series)

6 = Commercial Van - Short Wheelbase (with- Sales Code -

CYX Less AS8)

7 = Commercial Van - Short Wheelbase (with Sales Code -

AS8)

8 = Commercial Van-Long Wheelbase (H - Series with Sales

Code - CYX)

9 = Commercial Van - Long Wheelbase (P - Series with

Sales Code - CYX)

8 EngineB = 2.4L I4 Cyl. 16-Valve Gasoline DOHC (MPI)

E = 3.3L V6 Cyl. OHV Flex Fuel

L = 3.8L V6 Cyl. Gasoline (SMPI)

R = 3.3L V6 Cyl. OHV Gasoline

5 = 2.8L I4 Cyl. Turbo Diesel

7 = 2.5L I4 Cyl. 16 Valve Turbo Diesel

9 Check Digit See explanation in this section.

10 Model Year 5 = 2005

11 Assembly Plant B = St. Louis Assembly South

R = Windsor Assembly

U = Eurostar Gesellschaftz Assembly

12 through 17 Sequence Number A six digit number assigned by assembly plant.

10 INTRODUCTIONRS

VEHICLE IDENTIFICATION NUMBER (Continued)

Page 44 of 2339

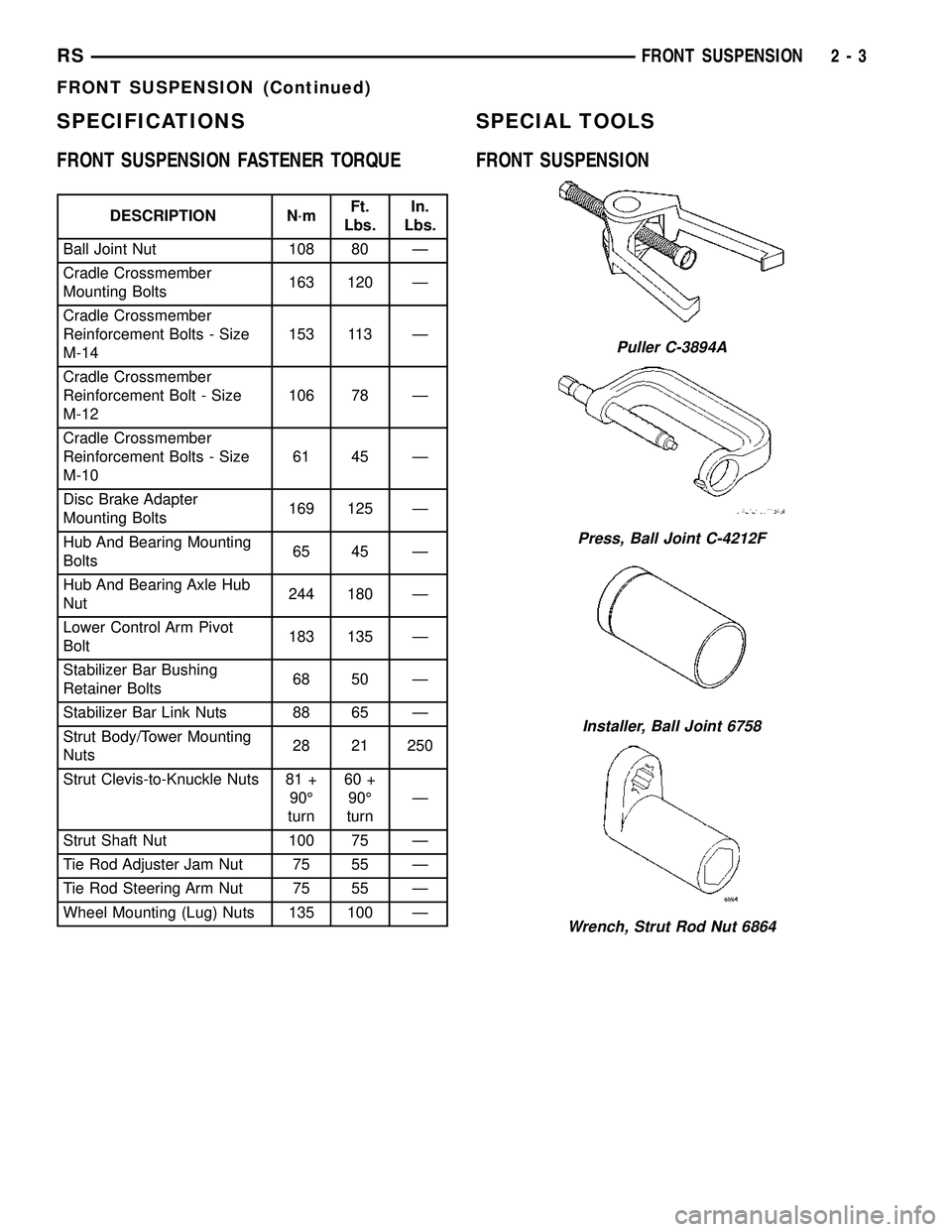

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Ball Joint Nut 108 80 Ð

Cradle Crossmember

Mounting Bolts163 120 Ð

Cradle Crossmember

Reinforcement Bolts - Size

M-14153 113 Ð

Cradle Crossmember

Reinforcement Bolt - Size

M-12106 78 Ð

Cradle Crossmember

Reinforcement Bolts - Size

M-1061 45 Ð

Disc Brake Adapter

Mounting Bolts169 125 Ð

Hub And Bearing Mounting

Bolts65 45 Ð

Hub And Bearing Axle Hub

Nut244 180 Ð

Lower Control Arm Pivot

Bolt183 135 Ð

Stabilizer Bar Bushing

Retainer Bolts68 50 Ð

Stabilizer Bar Link Nuts 88 65 Ð

Strut Body/Tower Mounting

Nuts28 21 250

Strut Clevis-to-Knuckle Nuts 81 +

90É

turn60 +

90É

turnÐ

Strut Shaft Nut 100 75 Ð

Tie Rod Adjuster Jam Nut 75 55 Ð

Tie Rod Steering Arm Nut 75 55 Ð

Wheel Mounting (Lug) Nuts 135 100 Ð

SPECIAL TOOLS

FRONT SUSPENSION

Puller C-3894A

Press, Ball Joint C-4212F

Installer, Ball Joint 6758

Wrench, Strut Rod Nut 6864

RSFRONT SUSPENSION2-3

FRONT SUSPENSION (Continued)

Page 54 of 2339

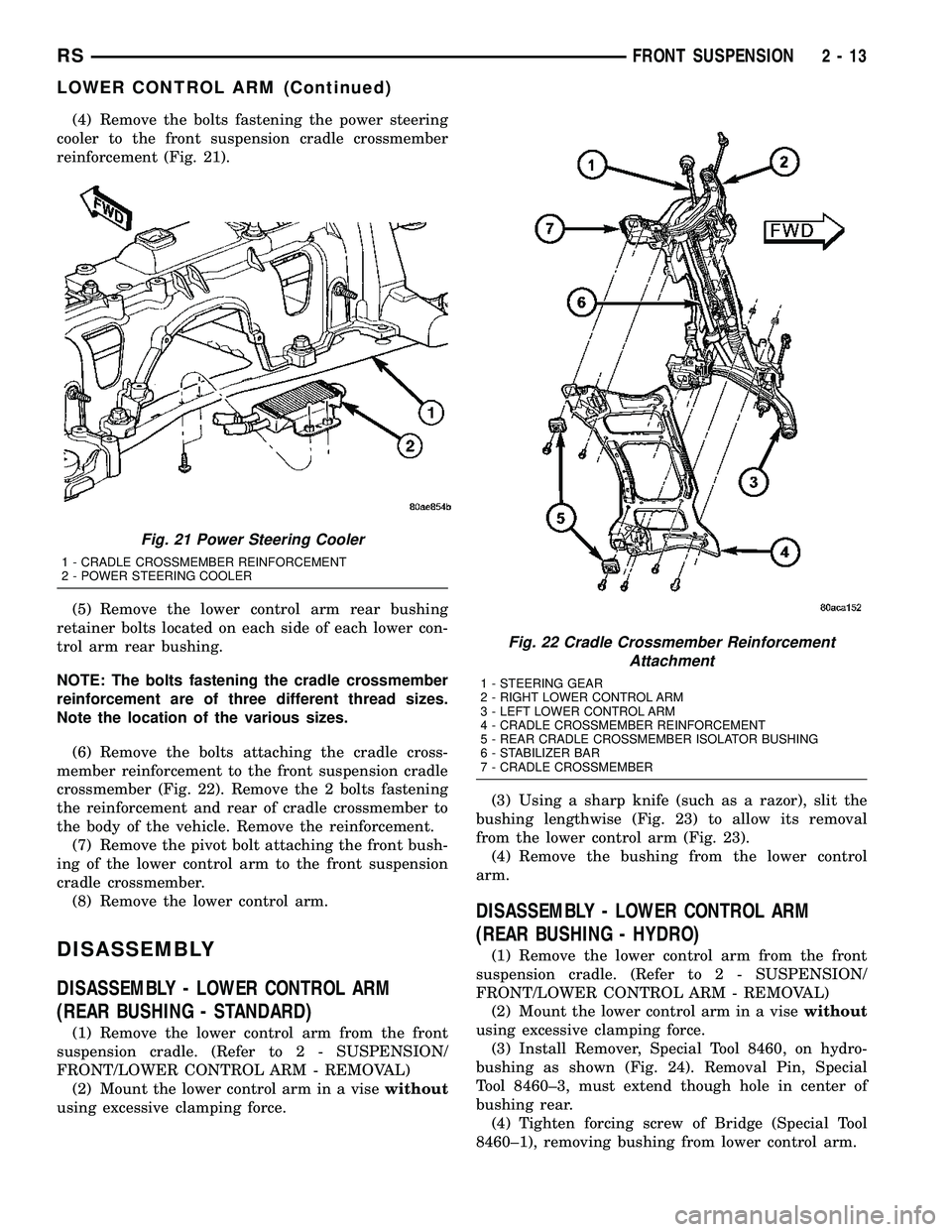

(4) Remove the bolts fastening the power steering

cooler to the front suspension cradle crossmember

reinforcement (Fig. 21).

(5) Remove the lower control arm rear bushing

retainer bolts located on each side of each lower con-

trol arm rear bushing.

NOTE: The bolts fastening the cradle crossmember

reinforcement are of three different thread sizes.

Note the location of the various sizes.

(6) Remove the bolts attaching the cradle cross-

member reinforcement to the front suspension cradle

crossmember (Fig. 22). Remove the 2 bolts fastening

the reinforcement and rear of cradle crossmember to

the body of the vehicle. Remove the reinforcement.

(7) Remove the pivot bolt attaching the front bush-

ing of the lower control arm to the front suspension

cradle crossmember.

(8) Remove the lower control arm.

DISASSEMBLY

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - STANDARD)

(1) Remove the lower control arm from the front

suspension cradle. (Refer to 2 - SUSPENSION/

FRONT/LOWER CONTROL ARM - REMOVAL)

(2) Mount the lower control arm in a visewithout

using excessive clamping force.(3) Using a sharp knife (such as a razor), slit the

bushing lengthwise (Fig. 23) to allow its removal

from the lower control arm (Fig. 23).

(4) Remove the bushing from the lower control

arm.

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - HYDRO)

(1) Remove the lower control arm from the front

suspension cradle. (Refer to 2 - SUSPENSION/

FRONT/LOWER CONTROL ARM - REMOVAL)

(2) Mount the lower control arm in a visewithout

using excessive clamping force.

(3) Install Remover, Special Tool 8460, on hydro-

bushing as shown (Fig. 24). Removal Pin, Special

Tool 8460±3, must extend though hole in center of

bushing rear.

(4) Tighten forcing screw of Bridge (Special Tool

8460±1), removing bushing from lower control arm.

Fig. 21 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

Fig. 22 Cradle Crossmember Reinforcement

Attachment

1 - STEERING GEAR

2 - RIGHT LOWER CONTROL ARM

3 - LEFT LOWER CONTROL ARM

4 - CRADLE CROSSMEMBER REINFORCEMENT

5 - REAR CRADLE CROSSMEMBER ISOLATOR BUSHING

6 - STABILIZER BAR

7 - CRADLE CROSSMEMBER

RSFRONT SUSPENSION2-13

LOWER CONTROL ARM (Continued)

Page 57 of 2339

(3) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 22). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).

(4) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten these

M-10 size bolts to a torque of 61 N´m (45 ft. lbs.).

(5) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 22). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(6) Install the power steering cooler (Fig. 21).

Tighten bolts to a torque of 11 N´m (100 in. lbs.).

(7) Reinstall steering knuckle, brake rotor and cal-

iper. (Refer to 2 - SUSPENSION/FRONT/KNUCKLE

- INSTALLATION)

CAUTION: When locating jack stands under lower

control arms, do not place the jack stands under

the ball joints (Fig. 30).

(8) Position jack stands under the lower control

arms as close to the ball joints as possible (Fig. 30).

Lower the vehicle onto the jack stands until the jack

stands are supporting the total weight of the vehicle.

(9) Tighten front lower control arm pivot bolt to a

torque of 183 N´m (135 ft. lbs.).

(10) Install the wheel and tire assembly. Install

and tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).(11) Raise vehicle, remove jack stands and lower

vehicle to the ground.

(12) Perform front wheel alignment as necessary.

(Refer to 2 - SUSPENSION/WHEEL ALIGNMENT -

STANDARD PROCEDURE)

STABILIZER BAR

DESCRIPTION

The stabilizer bar interconnects both front struts of

the vehicle and is attached to the front crossmember

(Fig. 1).

Attachment of the stabilizer bar to the front cross-

member is through 2 rubber-isolator cushion bush-

ings and retainers. A double ball jointed stabilizer

bar link is used to attach each end of the stabilizer

bar to the front strut assemblies. All parts of the sta-

bilizer bar are replaceable as individual components.

The stabilizer bar to front crossmember cushion

bushings are split for easy removal and installation.

The split in the bushings should be positioned toward

the rear of the vehicle, with the square corner facing

down, when the stabilizer bar is installed.

OPERATION

Jounce and rebound movements affecting one

wheel are partially transmitted to the opposite wheel

of the vehicle through the stabilizer bar. This helps

to minimize the body roll of the vehicle during sus-

pension movement.

Connecting the stabilizer bar links to the strut

assemblies helps reduce the fore-and-aft rate of the

stabilizer bar from the rest of the front suspension.

Fig. 29 Lower Control Arm Bushing Pivot Bolt

Correctly Installed

1 - PIVOT BOLT

2 - LOWER CONTROL ARM

3 - FRONT SUSPENSION CRADLE CROSSMEMBER

Fig. 30 Jack Stands Supporting Vehicle Weight

1 - LOWER CONTROL ARMS

2 - BALL JOINT

3 - JACK STANDS

4 - BALL JOINT

2 - 16 FRONT SUSPENSIONRS

LOWER CONTROL ARM (Continued)

Page 58 of 2339

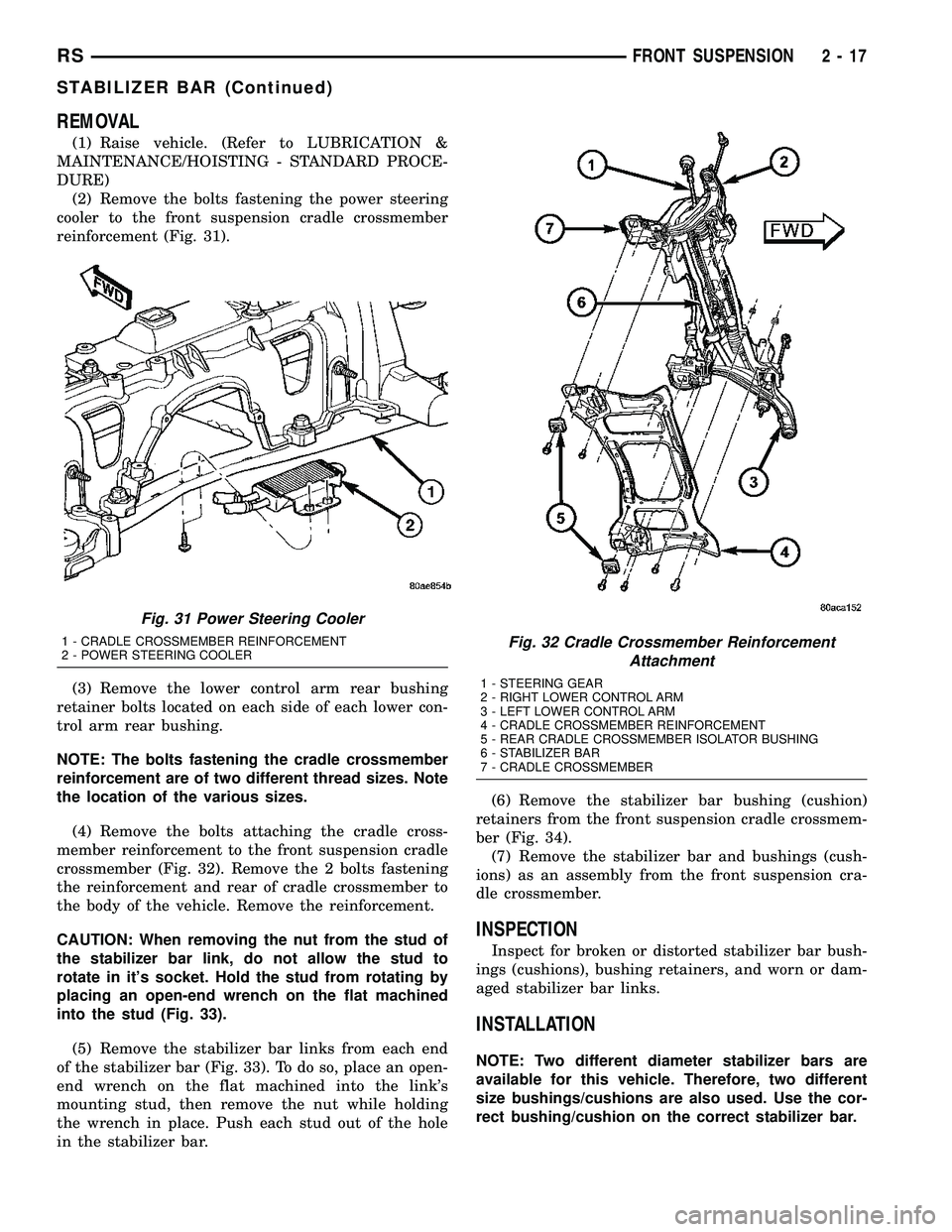

REMOVAL

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove the bolts fastening the power steering

cooler to the front suspension cradle crossmember

reinforcement (Fig. 31).

(3) Remove the lower control arm rear bushing

retainer bolts located on each side of each lower con-

trol arm rear bushing.

NOTE: The bolts fastening the cradle crossmember

reinforcement are of two different thread sizes. Note

the location of the various sizes.

(4) Remove the bolts attaching the cradle cross-

member reinforcement to the front suspension cradle

crossmember (Fig. 32). Remove the 2 bolts fastening

the reinforcement and rear of cradle crossmember to

the body of the vehicle. Remove the reinforcement.

CAUTION: When removing the nut from the stud of

the stabilizer bar link, do not allow the stud to

rotate in it's socket. Hold the stud from rotating by

placing an open-end wrench on the flat machined

into the stud (Fig. 33).

(5) Remove the stabilizer bar links from each end

of the stabilizer bar (Fig. 33). To do so, place an open-

end wrench on the flat machined into the link's

mounting stud, then remove the nut while holding

the wrench in place. Push each stud out of the hole

in the stabilizer bar.(6) Remove the stabilizer bar bushing (cushion)

retainers from the front suspension cradle crossmem-

ber (Fig. 34).

(7) Remove the stabilizer bar and bushings (cush-

ions) as an assembly from the front suspension cra-

dle crossmember.

INSPECTION

Inspect for broken or distorted stabilizer bar bush-

ings (cushions), bushing retainers, and worn or dam-

aged stabilizer bar links.

INSTALLATION

NOTE: Two different diameter stabilizer bars are

available for this vehicle. Therefore, two different

size bushings/cushions are also used. Use the cor-

rect bushing/cushion on the correct stabilizer bar.

Fig. 31 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLERFig. 32 Cradle Crossmember Reinforcement

Attachment

1 - STEERING GEAR

2 - RIGHT LOWER CONTROL ARM

3 - LEFT LOWER CONTROL ARM

4 - CRADLE CROSSMEMBER REINFORCEMENT

5 - REAR CRADLE CROSSMEMBER ISOLATOR BUSHING

6 - STABILIZER BAR

7 - CRADLE CROSSMEMBER

RSFRONT SUSPENSION2-17

STABILIZER BAR (Continued)

Page 60 of 2339

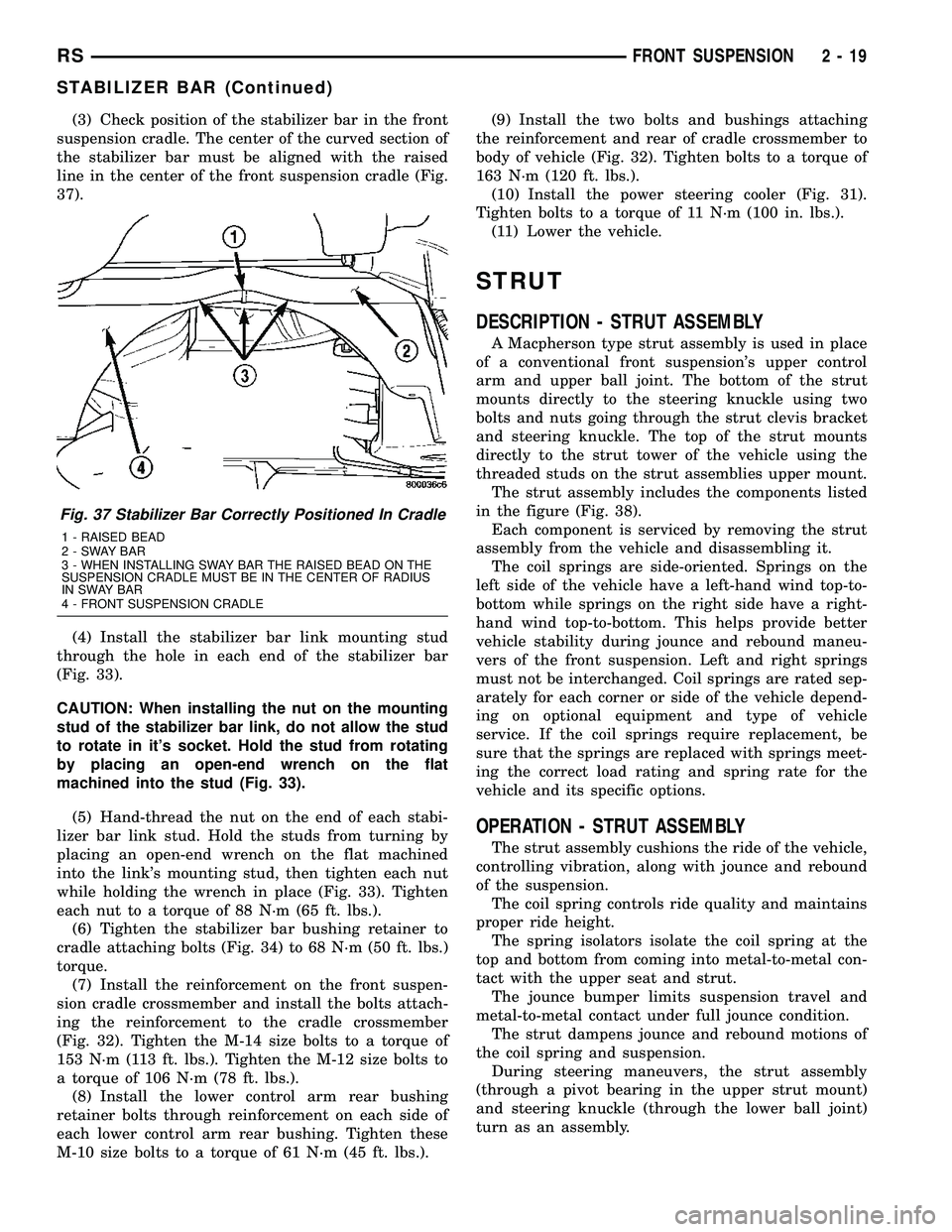

(3) Check position of the stabilizer bar in the front

suspension cradle. The center of the curved section of

the stabilizer bar must be aligned with the raised

line in the center of the front suspension cradle (Fig.

37).

(4) Install the stabilizer bar link mounting stud

through the hole in each end of the stabilizer bar

(Fig. 33).

CAUTION: When installing the nut on the mounting

stud of the stabilizer bar link, do not allow the stud

to rotate in it's socket. Hold the stud from rotating

by placing an open-end wrench on the flat

machined into the stud (Fig. 33).

(5) Hand-thread the nut on the end of each stabi-

lizer bar link stud. Hold the studs from turning by

placing an open-end wrench on the flat machined

into the link's mounting stud, then tighten each nut

while holding the wrench in place (Fig. 33). Tighten

each nut to a torque of 88 N´m (65 ft. lbs.).

(6) Tighten the stabilizer bar bushing retainer to

cradle attaching bolts (Fig. 34) to 68 N´m (50 ft. lbs.)

torque.

(7) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 32). Tighten the M-14 size bolts to a torque of

153 N´m (113 ft. lbs.). Tighten the M-12 size bolts to

a torque of 106 N´m (78 ft. lbs.).

(8) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten these

M-10 size bolts to a torque of 61 N´m (45 ft. lbs.).(9) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 32). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(10) Install the power steering cooler (Fig. 31).

Tighten bolts to a torque of 11 N´m (100 in. lbs.).

(11) Lower the vehicle.

STRUT

DESCRIPTION - STRUT ASSEMBLY

A Macpherson type strut assembly is used in place

of a conventional front suspension's upper control

arm and upper ball joint. The bottom of the strut

mounts directly to the steering knuckle using two

bolts and nuts going through the strut clevis bracket

and steering knuckle. The top of the strut mounts

directly to the strut tower of the vehicle using the

threaded studs on the strut assemblies upper mount.

The strut assembly includes the components listed

in the figure (Fig. 38).

Each component is serviced by removing the strut

assembly from the vehicle and disassembling it.

The coil springs are side-oriented. Springs on the

left side of the vehicle have a left-hand wind top-to-

bottom while springs on the right side have a right-

hand wind top-to-bottom. This helps provide better

vehicle stability during jounce and rebound maneu-

vers of the front suspension. Left and right springs

must not be interchanged. Coil springs are rated sep-

arately for each corner or side of the vehicle depend-

ing on optional equipment and type of vehicle

service. If the coil springs require replacement, be

sure that the springs are replaced with springs meet-

ing the correct load rating and spring rate for the

vehicle and its specific options.

OPERATION - STRUT ASSEMBLY

The strut assembly cushions the ride of the vehicle,

controlling vibration, along with jounce and rebound

of the suspension.

The coil spring controls ride quality and maintains

proper ride height.

The spring isolators isolate the coil spring at the

top and bottom from coming into metal-to-metal con-

tact with the upper seat and strut.

The jounce bumper limits suspension travel and

metal-to-metal contact under full jounce condition.

The strut dampens jounce and rebound motions of

the coil spring and suspension.

During steering maneuvers, the strut assembly

(through a pivot bearing in the upper strut mount)

and steering knuckle (through the lower ball joint)

turn as an assembly.

Fig. 37 Stabilizer Bar Correctly Positioned In Cradle

1 - RAISED BEAD

2-SWAYBAR

3 - WHEN INSTALLING SWAY BAR THE RAISED BEAD ON THE

SUSPENSION CRADLE MUST BE IN THE CENTER OF RADIUS

IN SWAY BAR

4 - FRONT SUSPENSION CRADLE

RSFRONT SUSPENSION2-19

STABILIZER BAR (Continued)

Page 69 of 2339

SPECIFICATIONS

REAR SUSPENSION FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Hub And Bearing Mounting

Bolts129 95 Ð

Hub And Bearing Axle Hub

Nut244 180 Ð

Jounce Bumper Mounting

Bolt33 24 290

Leaf Spring Front Mount-To-

Body Bolts61 45 Ð

Leaf Spring Front Pivot Bolt 156 115 Ð

Leaf Spring Plate-To-Axle

Bolts95 70 Ð

Leaf Spring Rear Mount-To-

Body Bolts61 45 Ð

Leaf Spring Shackle Plate

Nuts61 45 Ð

Shock Absorber Mounting

Bolts88 65 Ð

Stabilizer Bar Bushing

Retainer Bolts61 45 Ð

Stabilizer Bar Link Nuts 61 45 Ð

Stabilizer Bar Link Frame

Bracket Mounting Bolts61 45 Ð

Track Bar Bracket-To-Body

Mount Bolts61 45 Ð

Track Bar Pivot Bolts 95 70 Ð

Wheel Mounting (Lug) Nut 135 100 Ð

SPECIAL TOOLS

REAR SUSPENSION

Remover, Hub/Bearing 8458

Remover/Installer, Bushing 8459

Remover/Installer, Bushing 8526

Press, Ball Joint C-4212F

2 - 28 REAR SUSPENSIONRS

REAR SUSPENSION (Continued)