parking brake CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 6 of 2339

FASTENER USAGE

DESCRIPTION

FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

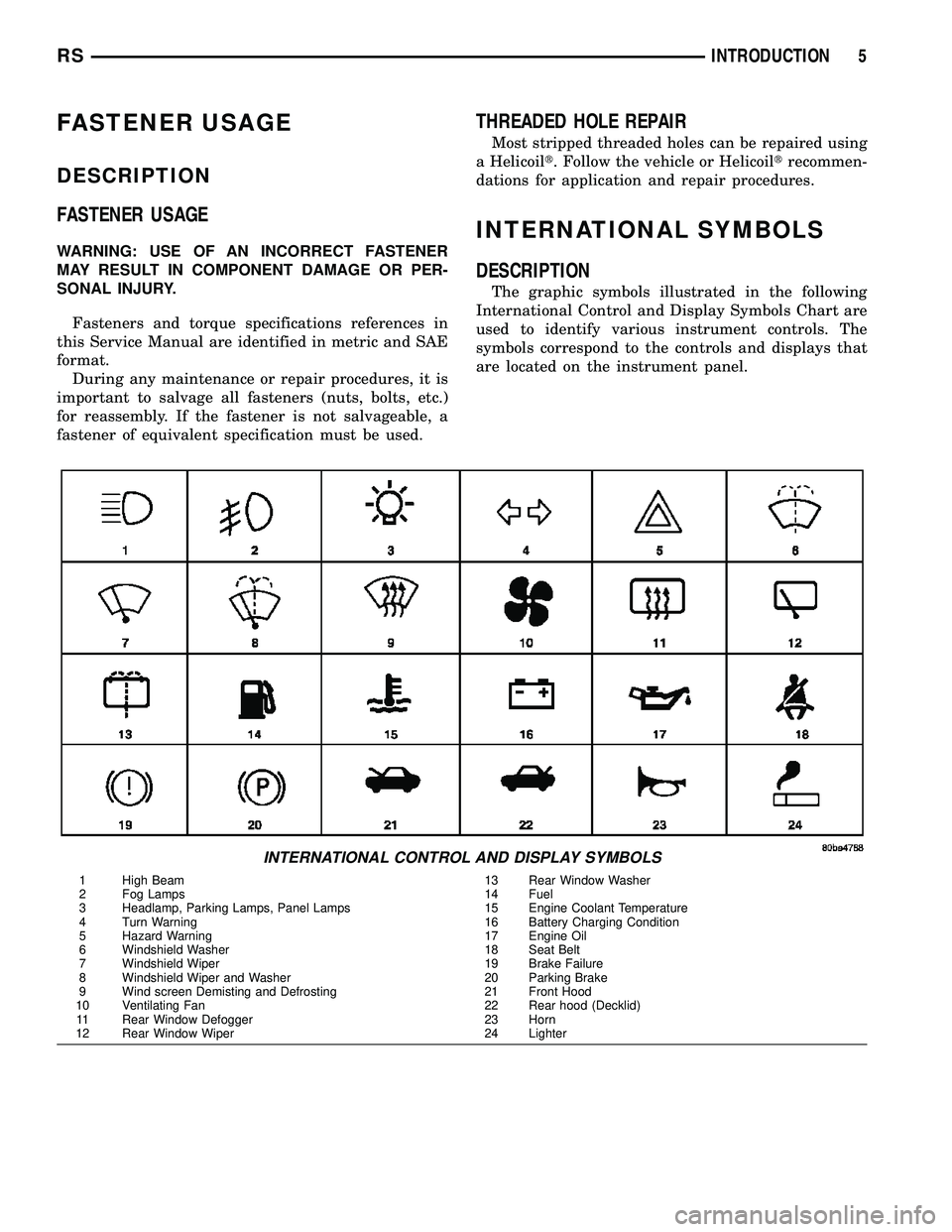

INTERNATIONAL SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Wind screen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

Page 38 of 2339

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS. (Refer to 8 - ELECTRICAL/BAT-

TERY SYSTEM/BATTERY - STANDARD PROCE-

DURE).

WARNING: DO NOT JUMP START A FROZEN BAT-

TERY, PERSONAL INJURY CAN RESULT.

WARNING: DO NOT JUMP START WHEN MAINTE-

NANCE FREE BATTERY INDICATOR DOT IS BRIGHT

COLOR.

WARNING: DO NOT ALLOW JUMPER CABLE

CLAMPS TO TOUCH EACH OTHER WHEN CON-

NECTED TO A BOOSTER SOURCE.

WARNING: DO NOT USE OPEN FLAME NEAR BAT-

TERYWARNING: REMOVE METALLIC JEWELRY WORN

ON HANDS OR WRISTS TO AVOID INJURY BY

ACCIDENTAL ARCING OF BATTERY CURRENT.

WARNING: WHEN USING A HIGH OUTPUT BOOST-

ING DEVICE, DO NOT ALLOW BATTERY VOLTAGE

TO EXCEED 16 VOLTS.

WARNING: REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: DO NOT ATTEMPT TO PUSH OR TOW

THE VEHICLE TO START IT. THE VEHICLE CANNOT

BE STARTED THIS WAY. PUSHING WITH ANOTHER

VEHICLE MAY DAMAGE THE TRANSAXLE OR THE

REAR OF THE VEHICLE.

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Clear or bright color test indicator, if equipped.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 6).

(Refer to 8 - ELECTRICAL/BATTERY SYSTEM/BAT-

TERY - STANDARD PROCEDURE).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

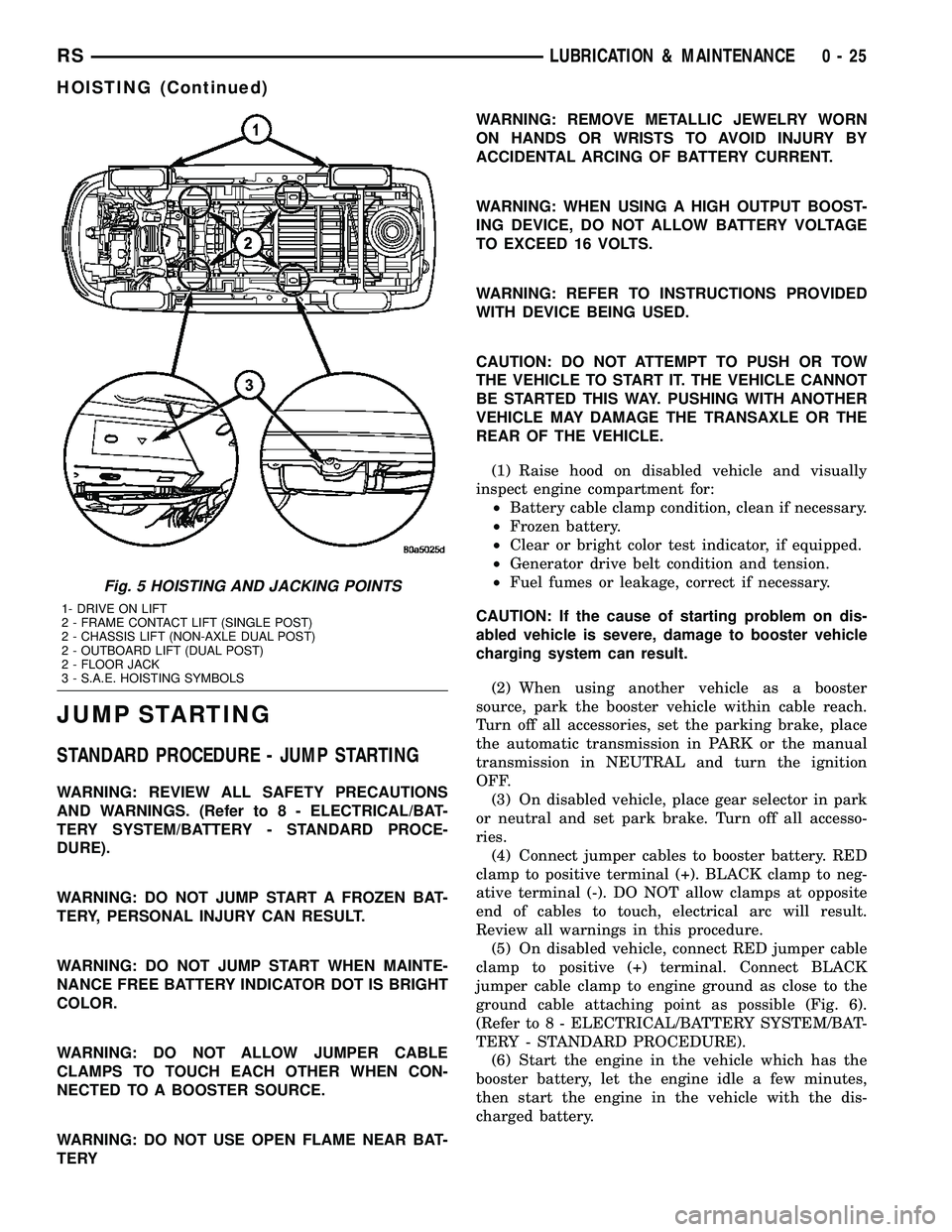

Fig. 5 HOISTING AND JACKING POINTS

1- DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

2 - CHASSIS LIFT (NON-AXLE DUAL POST)

2 - OUTBOARD LIFT (DUAL POST)

2 - FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

RSLUBRICATION & MAINTENANCE0-25

HOISTING (Continued)

Page 73 of 2339

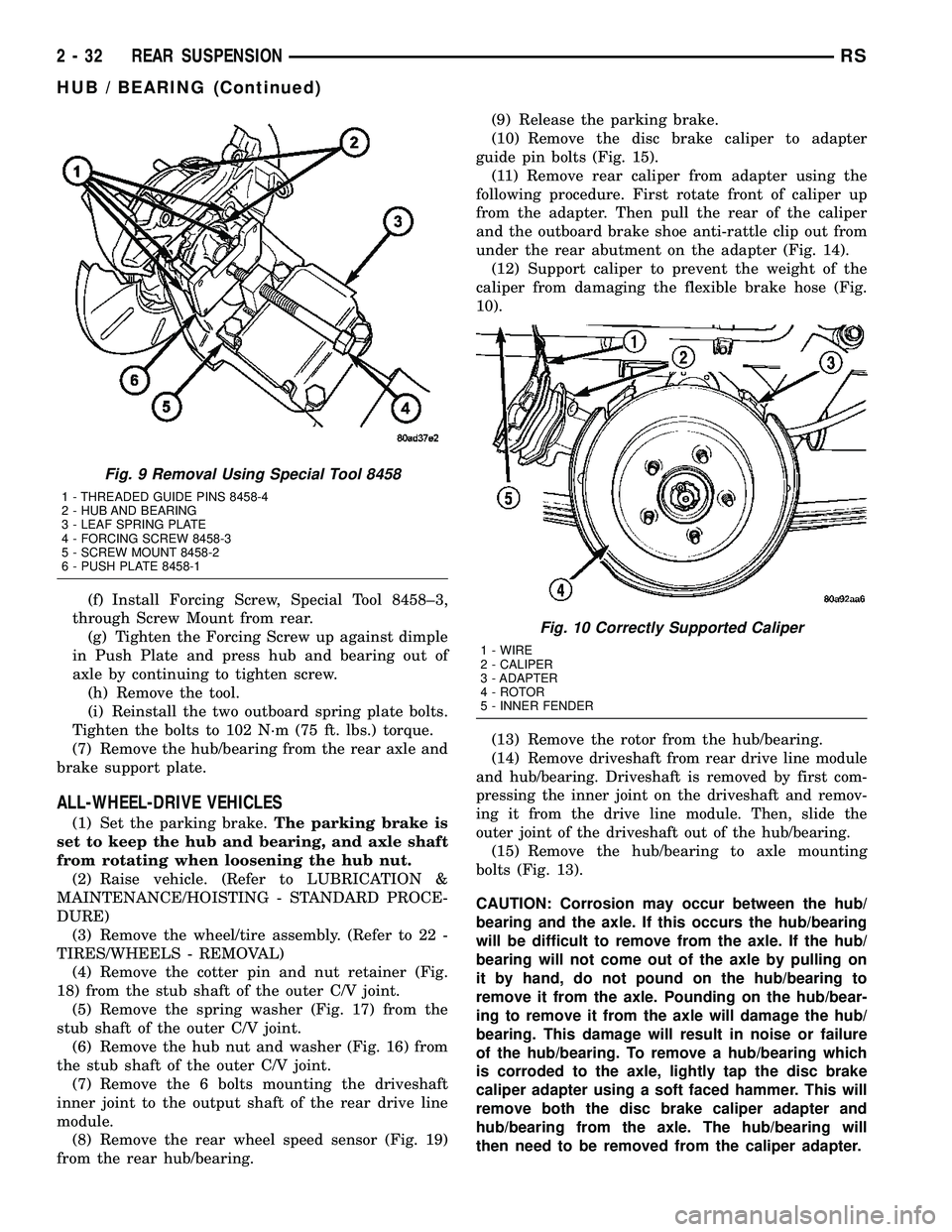

(f) Install Forcing Screw, Special Tool 8458±3,

through Screw Mount from rear.

(g) Tighten the Forcing Screw up against dimple

in Push Plate and press hub and bearing out of

axle by continuing to tighten screw.

(h) Remove the tool.

(i) Reinstall the two outboard spring plate bolts.

Tighten the bolts to 102 N´m (75 ft. lbs.) torque.

(7) Remove the hub/bearing from the rear axle and

brake support plate.

ALL-WHEEL-DRIVE VEHICLES

(1) Set the parking brake.The parking brake is

set to keep the hub and bearing, and axle shaft

from rotating when loosening the hub nut.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(3) Remove the wheel/tire assembly. (Refer to 22 -

TIRES/WHEELS - REMOVAL)

(4) Remove the cotter pin and nut retainer (Fig.

18) from the stub shaft of the outer C/V joint.

(5) Remove the spring washer (Fig. 17) from the

stub shaft of the outer C/V joint.

(6) Remove the hub nut and washer (Fig. 16) from

the stub shaft of the outer C/V joint.

(7) Remove the 6 bolts mounting the driveshaft

inner joint to the output shaft of the rear drive line

module.

(8) Remove the rear wheel speed sensor (Fig. 19)

from the rear hub/bearing.(9) Release the parking brake.

(10) Remove the disc brake caliper to adapter

guide pin bolts (Fig. 15).

(11) Remove rear caliper from adapter using the

following procedure. First rotate front of caliper up

from the adapter. Then pull the rear of the caliper

and the outboard brake shoe anti-rattle clip out from

under the rear abutment on the adapter (Fig. 14).

(12) Support caliper to prevent the weight of the

caliper from damaging the flexible brake hose (Fig.

10).

(13) Remove the rotor from the hub/bearing.

(14)

Remove driveshaft from rear drive line module

and hub/bearing. Driveshaft is removed by first com-

pressing the inner joint on the driveshaft and remov-

ing it from the drive line module. Then, slide the

outer joint of the driveshaft out of the hub/bearing.

(15) Remove the hub/bearing to axle mounting

bolts (Fig. 13).

CAUTION: Corrosion may occur between the hub/

bearing and the axle. If this occurs the hub/bearing

will be difficult to remove from the axle. If the hub/

bearing will not come out of the axle by pulling on

it by hand, do not pound on the hub/bearing to

remove it from the axle. Pounding on the hub/bear-

ing to remove it from the axle will damage the hub/

bearing. This damage will result in noise or failure

of the hub/bearing. To remove a hub/bearing which

is corroded to the axle, lightly tap the disc brake

caliper adapter using a soft faced hammer. This will

remove both the disc brake caliper adapter and

hub/bearing from the axle. The hub/bearing will

then need to be removed from the caliper adapter.

Fig. 9 Removal Using Special Tool 8458

1 - THREADED GUIDE PINS 8458-4

2 - HUB AND BEARING

3 - LEAF SPRING PLATE

4 - FORCING SCREW 8458-3

5 - SCREW MOUNT 8458-2

6 - PUSH PLATE 8458-1

Fig. 10 Correctly Supported Caliper

1 - WIRE

2 - CALIPER

3 - ADAPTER

4 - ROTOR

5 - INNER FENDER

2 - 32 REAR SUSPENSIONRS

HUB / BEARING (Continued)

Page 113 of 2339

DISASSEMBLY - CALIPER PISTON AND

SEAL...............................24

CLEANING - CALIPER...................25

INSPECTION - CALIPER..................25

ASSEMBLY

ASSEMBLY - CALIPER GUIDE PIN

BUSHINGS (CONTINENTAL TEVES

BRAKES)............................25

ASSEMBLY - CALIPER PISTON AND SEAL . . 26

INSTALLATION

INSTALLATION - FRONT DISC BRAKE

CALIPER (CONTINENTAL TEVES

BRAKES)............................27

INSTALLATION - FRONT DISC BRAKE

CALIPER (TRW BRAKES)...............27

DISC BRAKE CALIPER - REAR

REMOVAL - REAR DISC BRAKE CALIPER....28

DISASSEMBLY - CALIPER PISTON AND SEAL..28

CLEANING - CALIPER...................29

INSPECTION - CALIPER..................29

ASSEMBLY - CALIPER PISTON AND SEAL . . . 30

INSTALLATION - REAR DISC BRAKE CALIPER..30

DISC BRAKE CALIPER ADAPTER

REMOVAL - FRONT DISC BRAKE CALIPER

ADAPTER...........................31

INSTALLATION - FRONT DISC BRAKE

CALIPER ADAPTER....................31

DISC BRAKE CALIPER GUIDE PINS

REMOVAL - DISC BRAKE CALIPER GUIDE

PINS (TRW BRAKES)..................31

INSTALLATION - DISC BRAKE CALIPER

GUIDE PINS (TRW BRAKES).............32

DRUM

REMOVAL.............................32

INSTALLATION.........................32

FLUID

DIAGNOSIS AND TESTING - BRAKE FLUID

CONTAMINATION.....................33

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING.....................33

SPECIFICATIONS

BRAKE FLUID........................33

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK..33

OPERATION - NON-ABS JUNCTION BLOCK . . 33

REMOVAL - NON-ABS JUNCTION BLOCK....34

INSTALLATION - NON-ABS JUNCTION BLOCK..34

MASTER CYLINDER

DESCRIPTION

DESCRIPTION........................35

DESCRIPTION - RHD..................35

OPERATION...........................36

STANDARD PROCEDURE - MASTER

CYLINDER BLEEDING..................36

REMOVAL

REMOVAL - LHD......................36

REMOVAL - RHD......................37DISASSEMBLY - MASTER CYLINDER (FLUID

RESERVOIR).........................38

ASSEMBLY - MASTER CYLINDER (FLUID

RESERVOIR).........................39

INSTALLATION

INSTALLATION - LHD..................39

INSTALLATION - RHD..................39

PEDALS - ADJUSTABLE

REMOVAL.............................40

INSTALLATION.........................43

PEDAL TORQUE SHAFT - RHD

REMOVAL.............................44

INSTALLATION.........................44

POWER BRAKE BOOSTER

DESCRIPTION.........................45

OPERATION...........................46

DIAGNOSIS AND TESTING - POWER BRAKE

BOOSTER...........................46

REMOVAL

REMOVAL - LHD......................46

REMOVAL - RHD......................48

INSTALLATION

INSTALLATION - LHD..................50

INSTALLATION - RHD..................51

PROPORTIONING VALVE

DESCRIPTION - PROPORTIONING VALVE

(HEIGHT SENSING)....................53

OPERATION - PROPORTIONING VALVE

(HEIGHT SENSING)....................53

DIAGNOSIS AND TESTING -

PROPORTIONING VALVE (HEIGHT

SENSING)...........................54

REMOVAL - PROPORTIONING VALVE

(HEIGHT SENSING)....................55

INSTALLATION - PROPORTIONING VALVE

(HEIGHT SENSING)....................55

ROTOR

DIAGNOSIS AND TESTING - BRAKE ROTOR . . 55

STANDARD PROCEDURE - BRAKE ROTOR

MACHINING..........................58

REMOVAL - FRONT BRAKE ROTOR........59

INSTALLATION - FRONT BRAKE ROTOR.....59

SPECIFICATIONS

BRAKE ROTOR.......................60

BRAKE ROTOR - EXPORT..............60

SUPPORT PLATE - DRUM BRAKE

REMOVAL.............................61

INSTALLATION.........................61

WHEEL CYLINDERS

REMOVAL.............................62

INSPECTION..........................62

INSTALLATION.........................62

PARKING BRAKE

DESCRIPTION

DESCRIPTION........................62

DESCRIPTION - EXPORT...............63

OPERATION...........................63

5 - 2 BRAKES - BASERS

Page 114 of 2339

STANDARD PROCEDURE

STANDARD PROCEDURE - PARKING

BRAKE AUTOMATIC ADJUSTER TENSION

RELEASE...........................63

STANDARD PROCEDURE - PARKING

BRAKE AUTOMATIC ADJUSTER TENSION

RESET.............................64

STANDARD PROCEDURE - CABLE END

CLEANING AND LUBRICATION...........65

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE

CABLES............................65

CABLE - PARKING BRAKE FRONT

REMOVAL

REMOVAL...........................66

REMOVAL - FOLD-IN-FLOOR SEATING.....66

REMOVAL - EXPORT..................67

INSTALLATION

INSTALLATION.......................67

INSTALLATION - FOLD-IN-FLOOR SEATING . 68

INSTALLATION - EXPORT...............68

CABLE - PARKING BRAKE INTERMEDIATE

REMOVAL.............................69

INSTALLATION.........................69CABLE - PARKING BRAKE REAR

REMOVAL

REMOVAL - RIGHT REAR...............70

REMOVAL - LEFT REAR................71

REMOVAL - FOLD-IN-FLOOR SEATING.....72

INSTALLATION

INSTALLATION - RIGHT REAR...........74

INSTALLATION - LEFT REAR............75

INSTALLATION - FOLD-IN-FLOOR

SEATING............................75

LEVER - PARKING BRAKE

REMOVAL.............................75

INSTALLATION.........................76

LEVER - PARKING BRAKE (EXPORT)

REMOVAL - PARKING BRAKE LEVER AND

FRONT CABLE.......................77

INSTALLATION - PARKING BRAKE LEVER

AND FRONT CABLE...................77

SHOES - PARKING BRAKE

REMOVAL.............................78

INSTALLATION.........................84

ADJUSTMENTS

ADJUSTMENT - PARKING BRAKE SHOES . . 85

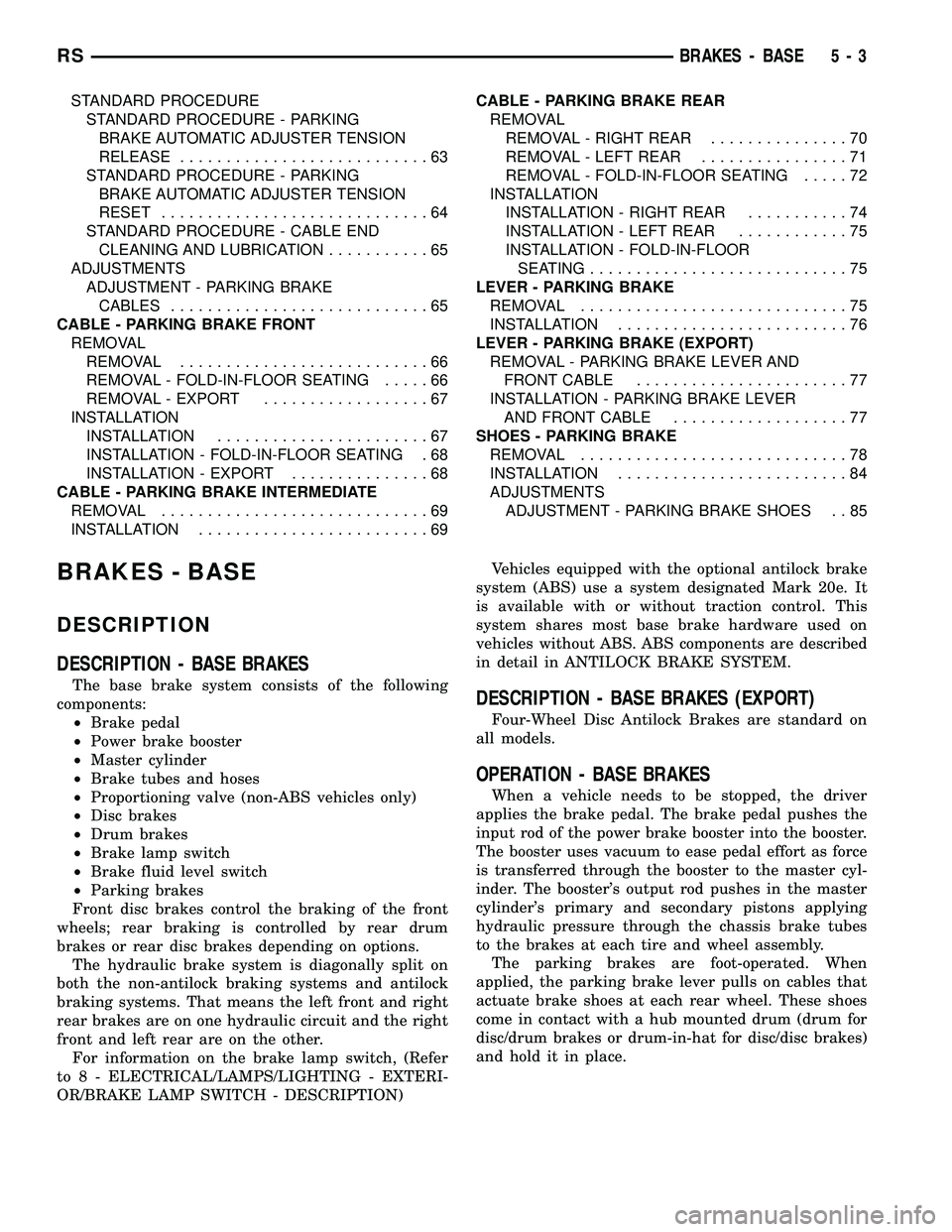

BRAKES - BASE

DESCRIPTION

DESCRIPTION - BASE BRAKES

The base brake system consists of the following

components:

²Brake pedal

²Power brake booster

²Master cylinder

²Brake tubes and hoses

²Proportioning valve (non-ABS vehicles only)

²Disc brakes

²Drum brakes

²Brake lamp switch

²Brake fluid level switch

²Parking brakes

Front disc brakes control the braking of the front

wheels; rear braking is controlled by rear drum

brakes or rear disc brakes depending on options.

The hydraulic brake system is diagonally split on

both the non-antilock braking systems and antilock

braking systems. That means the left front and right

rear brakes are on one hydraulic circuit and the right

front and left rear are on the other.

For information on the brake lamp switch, (Refer

to 8 - ELECTRICAL/LAMPS/LIGHTING - EXTERI-

OR/BRAKE LAMP SWITCH - DESCRIPTION)Vehicles equipped with the optional antilock brake

system (ABS) use a system designated Mark 20e. It

is available with or without traction control. This

system shares most base brake hardware used on

vehicles without ABS. ABS components are described

in detail in ANTILOCK BRAKE SYSTEM.DESCRIPTION - BASE BRAKES (EXPORT)

Four-Wheel Disc Antilock Brakes are standard on

all models.

OPERATION - BASE BRAKES

When a vehicle needs to be stopped, the driver

applies the brake pedal. The brake pedal pushes the

input rod of the power brake booster into the booster.

The booster uses vacuum to ease pedal effort as force

is transferred through the booster to the master cyl-

inder. The booster's output rod pushes in the master

cylinder's primary and secondary pistons applying

hydraulic pressure through the chassis brake tubes

to the brakes at each tire and wheel assembly.

The parking brakes are foot-operated. When

applied, the parking brake lever pulls on cables that

actuate brake shoes at each rear wheel. These shoes

come in contact with a hub mounted drum (drum for

disc/drum brakes or drum-in-hat for disc/disc brakes)

and hold it in place.

RSBRAKES - BASE5-3

Page 115 of 2339

WARNING

WARNING: DUST AND DIRT ACCUMULATING ON

BRAKE PARTS DURING NORMAL USE MAY CON-

TAIN ASBESTOS FIBERS FROM PRODUCTION OR

AFTERMARKET BRAKE LININGS. BREATHING

EXCESSIVE CONCENTRATIONS OF ASBESTOS

FIBERS CAN CAUSE SERIOUS BODILY HARM.

EXERCISE CARE WHEN SERVICING BRAKE

PARTS. DO NOT SAND OR GRIND BRAKE LINING

UNLESS EQUIPMENT USED IS DESIGNED TO CON-

TAIN THE DUST RESIDUE. DO NOT CLEAN BRAKE

PARTS WITH COMPRESSED AIR OR BY DRY

BRUSHING. CLEANING SHOULD BE DONE BY

DAMPENING THE BRAKE COMPONENTS WITH A

FINE MIST OF WATER, THEN WIPING THE BRAKE

COMPONENTS CLEAN WITH A DAMPENED CLOTH.

DISPOSE OF CLOTH AND ALL RESIDUE CONTAIN-

ING ASBESTOS FIBERS IN AN IMPERMEABLE

CONTAINER WITH THE APPROPRIATE LABEL. FOL-

LOW PRACTICES PRESCRIBED BY THE OCCUPA-

TIONAL SAFETY AND HEALTH ADMINISTRATION

(OSHA) AND THE ENVIRONMENTAL PROTECTION

AGENCY (EPA) FOR THE HANDLING, PROCESSING,

AND DISPOSING OF DUST OR DEBRIS THAT MAY

CONTAIN ASBESTOS FIBERS.

CAUTION

CAUTION: During service procedures, grease or

any other foreign material must be kept off brake

shoes and braking surfaces of brake rotor or drum,

and external surfaces of hub and bearing assembly.

CAUTION: Brake rotor and caliper handling must be

done in such a way as to avoid damage to the rotor,

especially the machined surfaces, and scratching or

nicking of the brake linings.

CAUTION: Only the recommended jacking or hoist-

ing procedures for this vehicle are to be used

whenever it is necessary to lift a vehicle. Failure to

raise a vehicle utilizing the recommended lift points

can result in damage to the vehicle. (Refer to

LUBRICATION & MAINTENANCE/HOISTING - STAN-

DARD PROCEDURE)

DIAGNOSIS AND TESTING - BASE BRAKE

SYSTEM

NOTE: There are three diagnosis charts following

that cover the RED BRAKE WARNING INDICATOR

LAMP, BRAKE NOISE and OTHER BRAKE CONDI-

TIONS.

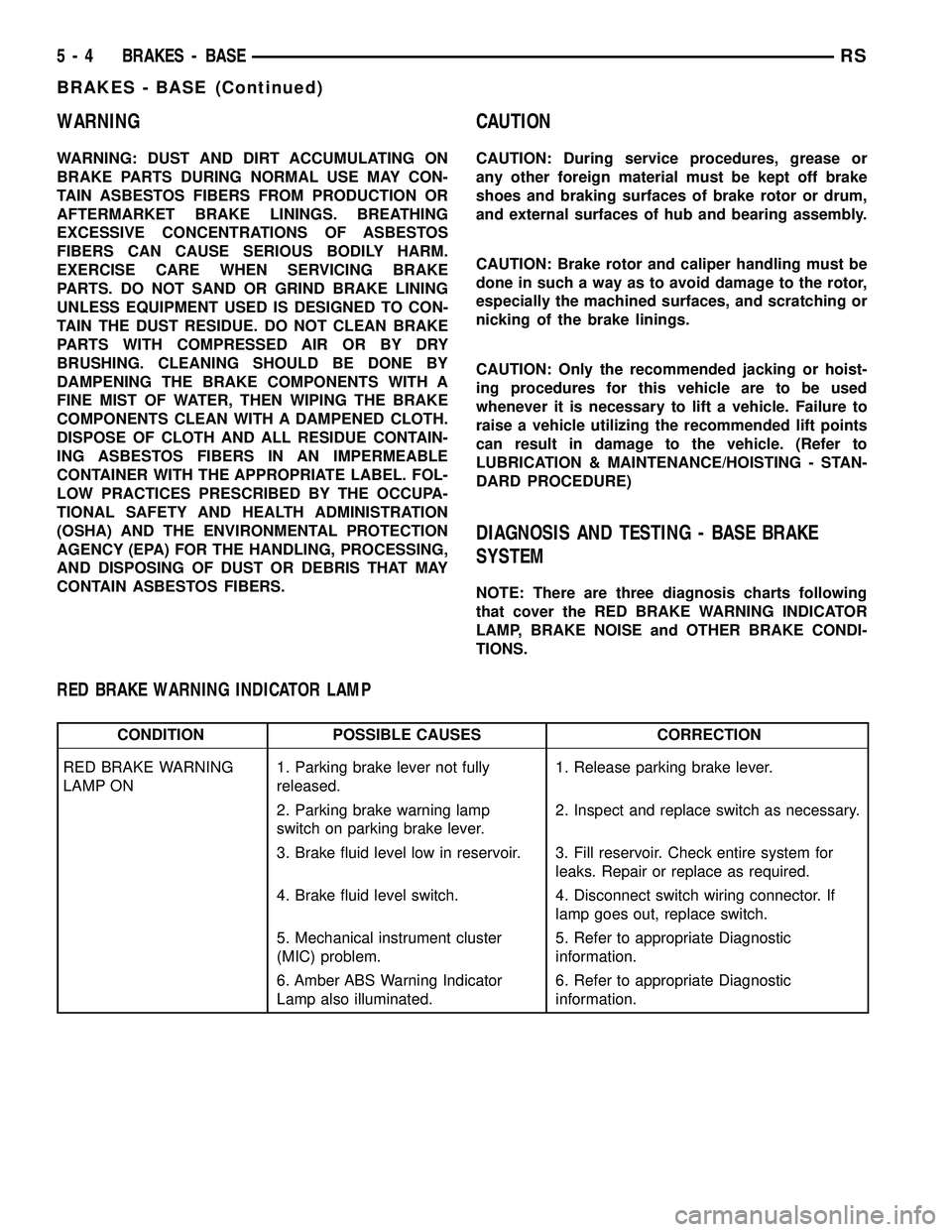

RED BRAKE WARNING INDICATOR LAMP

CONDITION POSSIBLE CAUSES CORRECTION

RED BRAKE WARNING

LAMP ON1. Parking brake lever not fully

released.1. Release parking brake lever.

2. Parking brake warning lamp

switch on parking brake lever.2. Inspect and replace switch as necessary.

3. Brake fluid level low in reservoir. 3. Fill reservoir. Check entire system for

leaks. Repair or replace as required.

4. Brake fluid level switch. 4. Disconnect switch wiring connector. If

lamp goes out, replace switch.

5. Mechanical instrument cluster

(MIC) problem.5. Refer to appropriate Diagnostic

information.

6. Amber ABS Warning Indicator

Lamp also illuminated.6. Refer to appropriate Diagnostic

information.

5 - 4 BRAKES - BASERS

BRAKES - BASE (Continued)

Page 117 of 2339

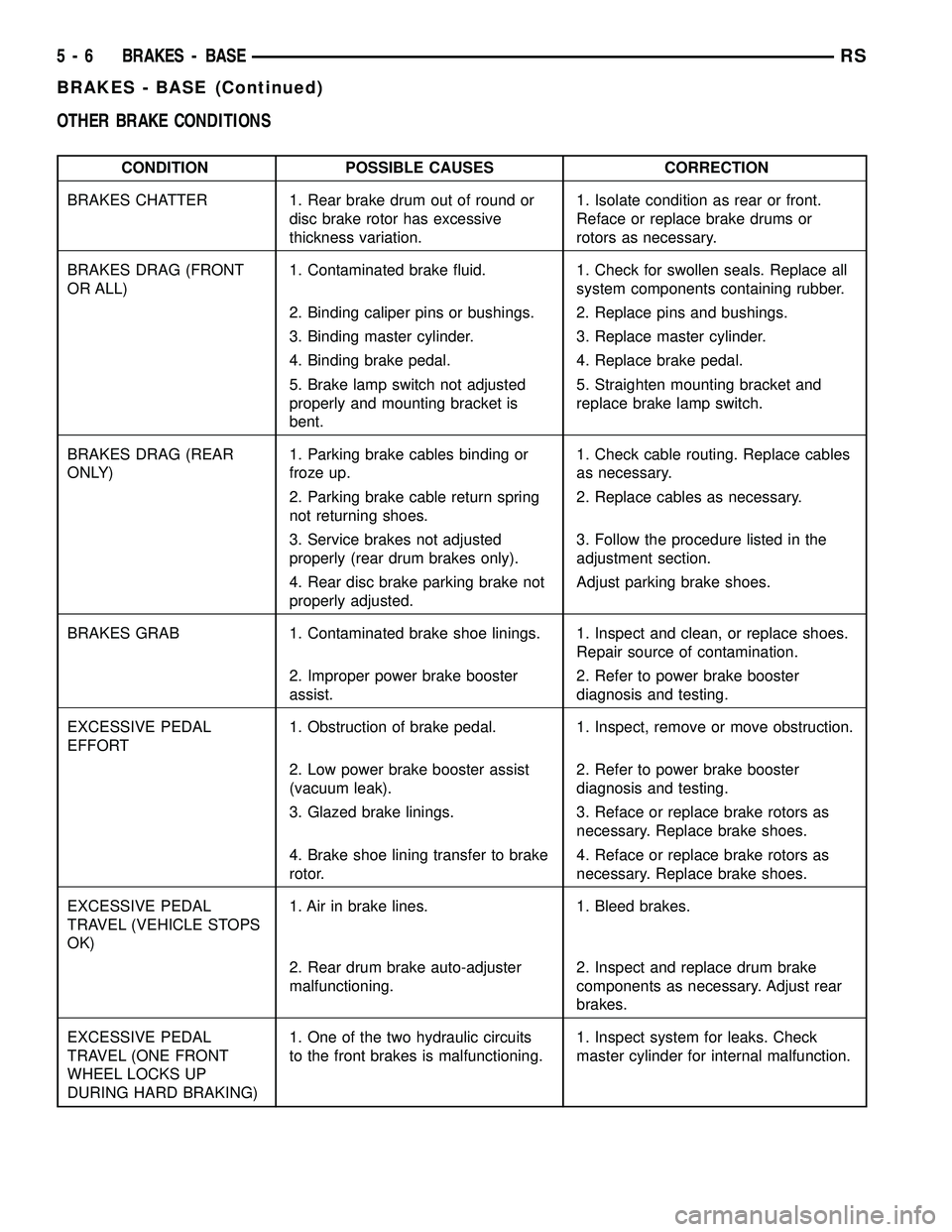

OTHER BRAKE CONDITIONS

CONDITION POSSIBLE CAUSES CORRECTION

BRAKES CHATTER 1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or

rotors as necessary.

BRAKES DRAG (FRONT

OR ALL)1. Contaminated brake fluid. 1. Check for swollen seals. Replace all

system components containing rubber.

2. Binding caliper pins or bushings. 2. Replace pins and bushings.

3. Binding master cylinder. 3. Replace master cylinder.

4. Binding brake pedal. 4. Replace brake pedal.

5. Brake lamp switch not adjusted

properly and mounting bracket is

bent.5. Straighten mounting bracket and

replace brake lamp switch.

BRAKES DRAG (REAR

ONLY)1. Parking brake cables binding or

froze up.1. Check cable routing. Replace cables

as necessary.

2. Parking brake cable return spring

not returning shoes.2. Replace cables as necessary.

3. Service brakes not adjusted

properly (rear drum brakes only).3. Follow the procedure listed in the

adjustment section.

4. Rear disc brake parking brake not

properly adjusted.Adjust parking brake shoes.

BRAKES GRAB 1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Improper power brake booster

assist.2. Refer to power brake booster

diagnosis and testing.

EXCESSIVE PEDAL

EFFORT1. Obstruction of brake pedal. 1. Inspect, remove or move obstruction.

2. Low power brake booster assist

(vacuum leak).2. Refer to power brake booster

diagnosis and testing.

3. Glazed brake linings. 3. Reface or replace brake rotors as

necessary. Replace brake shoes.

4. Brake shoe lining transfer to brake

rotor.4. Reface or replace brake rotors as

necessary. Replace brake shoes.

EXCESSIVE PEDAL

TRAVEL (VEHICLE STOPS

OK)1. Air in brake lines. 1. Bleed brakes.

2. Rear drum brake auto-adjuster

malfunctioning.2. Inspect and replace drum brake

components as necessary. Adjust rear

brakes.

EXCESSIVE PEDAL

TRAVEL (ONE FRONT

WHEEL LOCKS UP

DURING HARD BRAKING)1. One of the two hydraulic circuits

to the front brakes is malfunctioning.1. Inspect system for leaks. Check

master cylinder for internal malfunction.

5 - 6 BRAKES - BASERS

BRAKES - BASE (Continued)

Page 118 of 2339

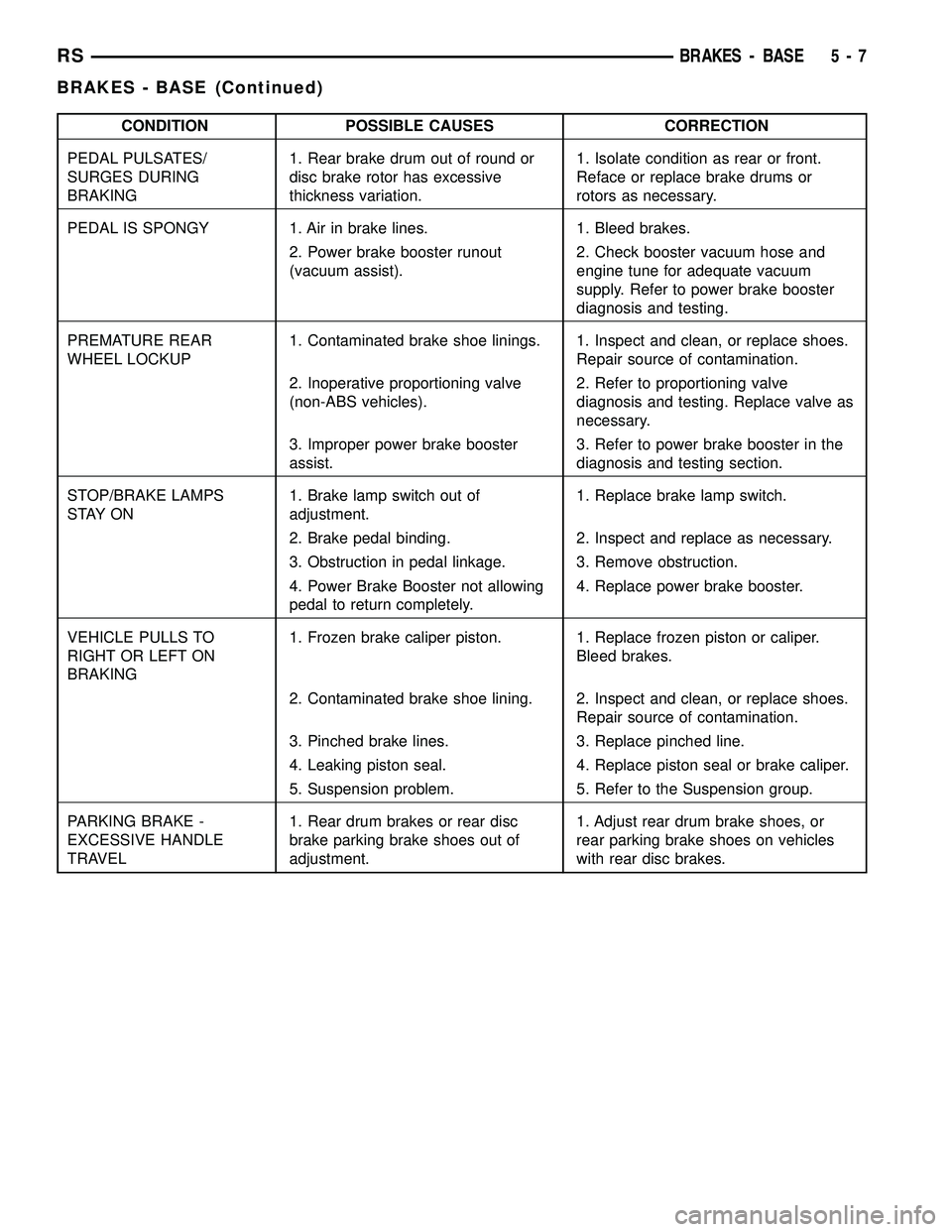

CONDITION POSSIBLE CAUSES CORRECTION

PEDAL PULSATES/

SURGES DURING

BRAKING1. Rear brake drum out of round or

disc brake rotor has excessive

thickness variation.1. Isolate condition as rear or front.

Reface or replace brake drums or

rotors as necessary.

PEDAL IS SPONGY 1. Air in brake lines. 1. Bleed brakes.

2. Power brake booster runout

(vacuum assist).2. Check booster vacuum hose and

engine tune for adequate vacuum

supply. Refer to power brake booster

diagnosis and testing.

PREMATURE REAR

WHEEL LOCKUP1. Contaminated brake shoe linings. 1. Inspect and clean, or replace shoes.

Repair source of contamination.

2. Inoperative proportioning valve

(non-ABS vehicles).2. Refer to proportioning valve

diagnosis and testing. Replace valve as

necessary.

3. Improper power brake booster

assist.3. Refer to power brake booster in the

diagnosis and testing section.

STOP/BRAKE LAMPS

S TAY O N1. Brake lamp switch out of

adjustment.1. Replace brake lamp switch.

2. Brake pedal binding. 2. Inspect and replace as necessary.

3. Obstruction in pedal linkage. 3. Remove obstruction.

4. Power Brake Booster not allowing

pedal to return completely.4. Replace power brake booster.

VEHICLE PULLS TO

RIGHT OR LEFT ON

BRAKING1. Frozen brake caliper piston. 1. Replace frozen piston or caliper.

Bleed brakes.

2. Contaminated brake shoe lining. 2. Inspect and clean, or replace shoes.

Repair source of contamination.

3. Pinched brake lines. 3. Replace pinched line.

4. Leaking piston seal. 4. Replace piston seal or brake caliper.

5. Suspension problem. 5. Refer to the Suspension group.

PARKING BRAKE -

EXCESSIVE HANDLE

TRAVEL1. Rear drum brakes or rear disc

brake parking brake shoes out of

adjustment.1. Adjust rear drum brake shoes, or

rear parking brake shoes on vehicles

with rear disc brakes.

RSBRAKES - BASE5-7

BRAKES - BASE (Continued)

Page 120 of 2339

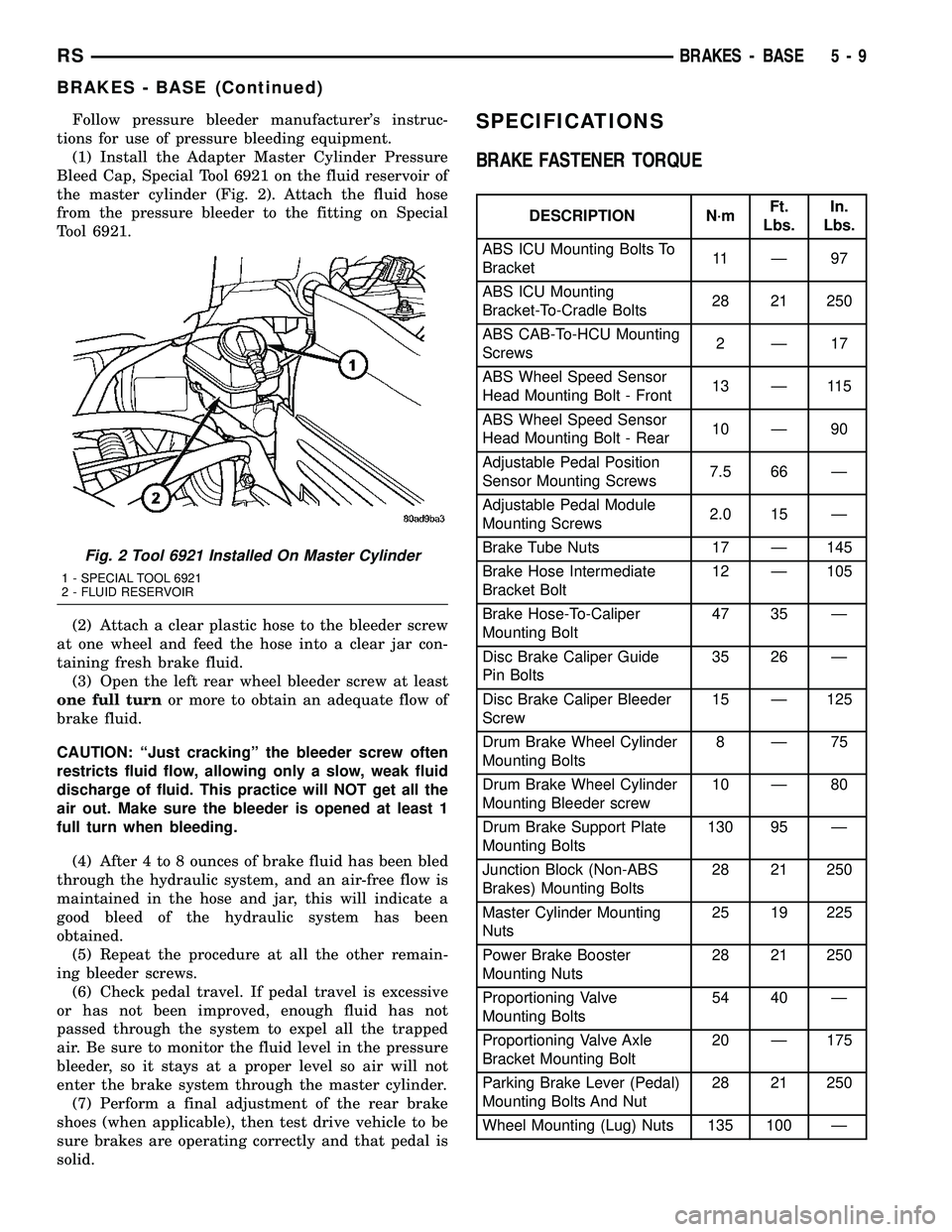

Follow pressure bleeder manufacturer's instruc-

tions for use of pressure bleeding equipment.

(1) Install the Adapter Master Cylinder Pressure

Bleed Cap, Special Tool 6921 on the fluid reservoir of

the master cylinder (Fig. 2). Attach the fluid hose

from the pressure bleeder to the fitting on Special

Tool 6921.

(2) Attach a clear plastic hose to the bleeder screw

at one wheel and feed the hose into a clear jar con-

taining fresh brake fluid.

(3) Open the left rear wheel bleeder screw at least

one full turnor more to obtain an adequate flow of

brake fluid.

CAUTION: ªJust crackingº the bleeder screw often

restricts fluid flow, allowing only a slow, weak fluid

discharge of fluid. This practice will NOT get all the

air out. Make sure the bleeder is opened at least 1

full turn when bleeding.

(4) After 4 to 8 ounces of brake fluid has been bled

through the hydraulic system, and an air-free flow is

maintained in the hose and jar, this will indicate a

good bleed of the hydraulic system has been

obtained.

(5) Repeat the procedure at all the other remain-

ing bleeder screws.

(6) Check pedal travel. If pedal travel is excessive

or has not been improved, enough fluid has not

passed through the system to expel all the trapped

air. Be sure to monitor the fluid level in the pressure

bleeder, so it stays at a proper level so air will not

enter the brake system through the master cylinder.

(7) Perform a final adjustment of the rear brake

shoes (when applicable), then test drive vehicle to be

sure brakes are operating correctly and that pedal is

solid.SPECIFICATIONS

BRAKE FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

ABS ICU Mounting Bolts To

Bracket11 Ð 9 7

ABS ICU Mounting

Bracket-To-Cradle Bolts28 21 250

ABS CAB-To-HCU Mounting

Screws2Ð17

ABS Wheel Speed Sensor

Head Mounting Bolt - Front13 Ð 115

ABS Wheel Speed Sensor

Head Mounting Bolt - Rear10 Ð 90

Adjustable Pedal Position

Sensor Mounting Screws7.5 66 Ð

Adjustable Pedal Module

Mounting Screws2.0 15 Ð

Brake Tube Nuts 17 Ð 145

Brake Hose Intermediate

Bracket Bolt12 Ð 105

Brake Hose-To-Caliper

Mounting Bolt47 35 Ð

Disc Brake Caliper Guide

Pin Bolts35 26 Ð

Disc Brake Caliper Bleeder

Screw15 Ð 125

Drum Brake Wheel Cylinder

Mounting Bolts8Ð75

Drum Brake Wheel Cylinder

Mounting Bleeder screw10 Ð 80

Drum Brake Support Plate

Mounting Bolts130 95 Ð

Junction Block (Non-ABS

Brakes) Mounting Bolts28 21 250

Master Cylinder Mounting

Nuts25 19 225

Power Brake Booster

Mounting Nuts28 21 250

Proportioning Valve

Mounting Bolts54 40 Ð

Proportioning Valve Axle

Bracket Mounting Bolt20 Ð 175

Parking Brake Lever (Pedal)

Mounting Bolts And Nut28 21 250

Wheel Mounting (Lug) Nuts 135 100 Ð

Fig. 2 Tool 6921 Installed On Master Cylinder

1 - SPECIAL TOOL 6921

2 - FLUID RESERVOIR

RSBRAKES - BASE5-9

BRAKES - BASE (Continued)

Page 124 of 2339

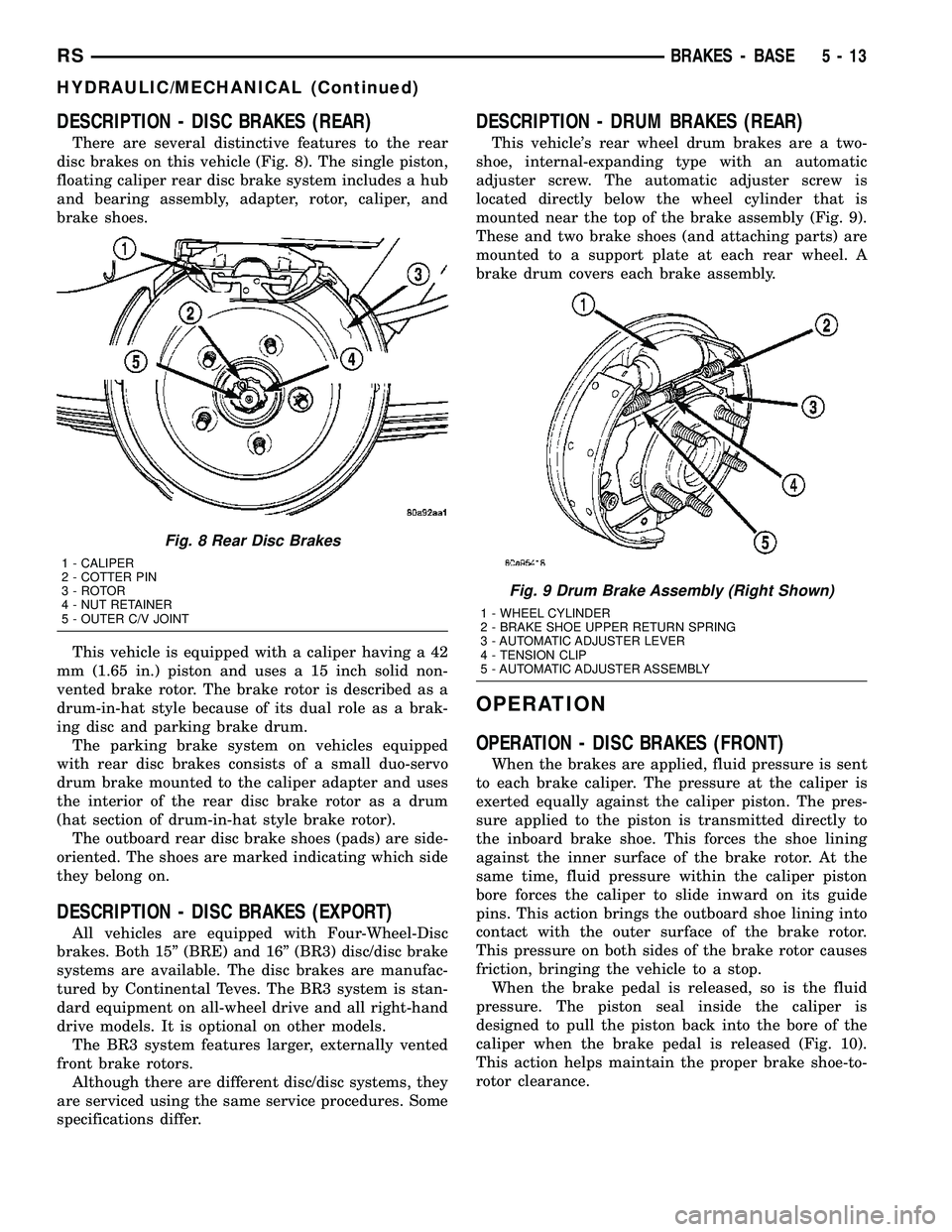

DESCRIPTION - DISC BRAKES (REAR)

There are several distinctive features to the rear

disc brakes on this vehicle (Fig. 8). The single piston,

floating caliper rear disc brake system includes a hub

and bearing assembly, adapter, rotor, caliper, and

brake shoes.

This vehicle is equipped with a caliper having a 42

mm (1.65 in.) piston and uses a 15 inch solid non-

vented brake rotor. The brake rotor is described as a

drum-in-hat style because of its dual role as a brak-

ing disc and parking brake drum.

The parking brake system on vehicles equipped

with rear disc brakes consists of a small duo-servo

drum brake mounted to the caliper adapter and uses

the interior of the rear disc brake rotor as a drum

(hat section of drum-in-hat style brake rotor).

The outboard rear disc brake shoes (pads) are side-

oriented. The shoes are marked indicating which side

they belong on.

DESCRIPTION - DISC BRAKES (EXPORT)

All vehicles are equipped with Four-Wheel-Disc

brakes. Both 15º (BRE) and 16º (BR3) disc/disc brake

systems are available. The disc brakes are manufac-

tured by Continental Teves. The BR3 system is stan-

dard equipment on all-wheel drive and all right-hand

drive models. It is optional on other models.

The BR3 system features larger, externally vented

front brake rotors.

Although there are different disc/disc systems, they

are serviced using the same service procedures. Some

specifications differ.

DESCRIPTION - DRUM BRAKES (REAR)

This vehicle's rear wheel drum brakes are a two-

shoe, internal-expanding type with an automatic

adjuster screw. The automatic adjuster screw is

located directly below the wheel cylinder that is

mounted near the top of the brake assembly (Fig. 9).

These and two brake shoes (and attaching parts) are

mounted to a support plate at each rear wheel. A

brake drum covers each brake assembly.

OPERATION

OPERATION - DISC BRAKES (FRONT)

When the brakes are applied, fluid pressure is sent

to each brake caliper. The pressure at the caliper is

exerted equally against the caliper piston. The pres-

sure applied to the piston is transmitted directly to

the inboard brake shoe. This forces the shoe lining

against the inner surface of the brake rotor. At the

same time, fluid pressure within the caliper piston

bore forces the caliper to slide inward on its guide

pins. This action brings the outboard shoe lining into

contact with the outer surface of the brake rotor.

This pressure on both sides of the brake rotor causes

friction, bringing the vehicle to a stop.

When the brake pedal is released, so is the fluid

pressure. The piston seal inside the caliper is

designed to pull the piston back into the bore of the

caliper when the brake pedal is released (Fig. 10).

This action helps maintain the proper brake shoe-to-

rotor clearance.

Fig. 8 Rear Disc Brakes

1 - CALIPER

2 - COTTER PIN

3 - ROTOR

4 - NUT RETAINER

5 - OUTER C/V JOINT

Fig. 9 Drum Brake Assembly (Right Shown)

1 - WHEEL CYLINDER

2 - BRAKE SHOE UPPER RETURN SPRING

3 - AUTOMATIC ADJUSTER LEVER

4 - TENSION CLIP

5 - AUTOMATIC ADJUSTER ASSEMBLY

RSBRAKES - BASE5-13

HYDRAULIC/MECHANICAL (Continued)