amp CHRYSLER PACIFICA 2020 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2020, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2020Pages: 516, PDF Size: 28.69 MB

Page 318 of 516

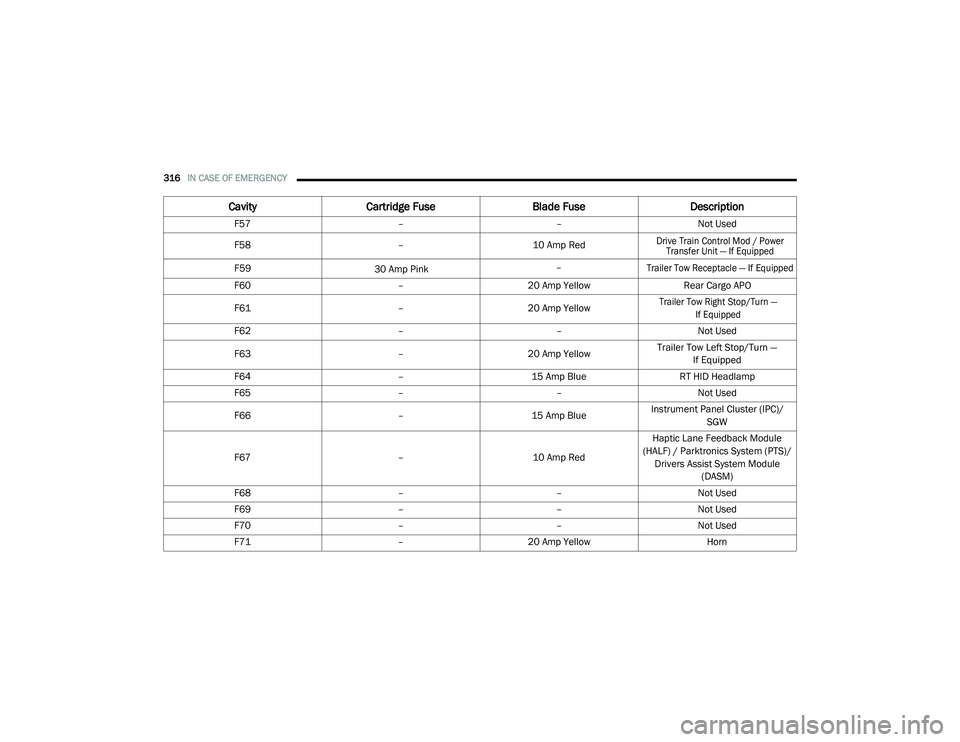

316IN CASE OF EMERGENCY

F57 ––Not Used

F58 – 10 Amp Red

Drive Train Control Mod / Power

Transfer Unit — If Equipped

F59

30 Amp Pink –

Trailer Tow Receptacle — If Equipped

F60

–20 Amp Yellow Rear Cargo APO

F61 –20 Amp Yellow

Trailer Tow Right Stop/Turn —

If Equipped

F62––Not Used

F63 –20 Amp Yellow Trailer Tow Left Stop/Turn —

If Equipped

F64–15 Amp Blue RT HID Headlamp

F65 ––Not Used

F66 –15 Amp BlueInstrument Panel Cluster (IPC)/

SGW

F67 –10 Amp RedHaptic Lane Feedback Module

(HALF) / Parktronics System (PTS)/ Drivers Assist System Module (DASM)

F68 ––Not Used

F69 ––Not Used

F70 ––Not Used

F71 –20 Amp Yellow Horn

CavityCartridge Fuse Blade FuseDescription

20_RU_OM_EN_US_t.book Page 316

Page 319 of 516

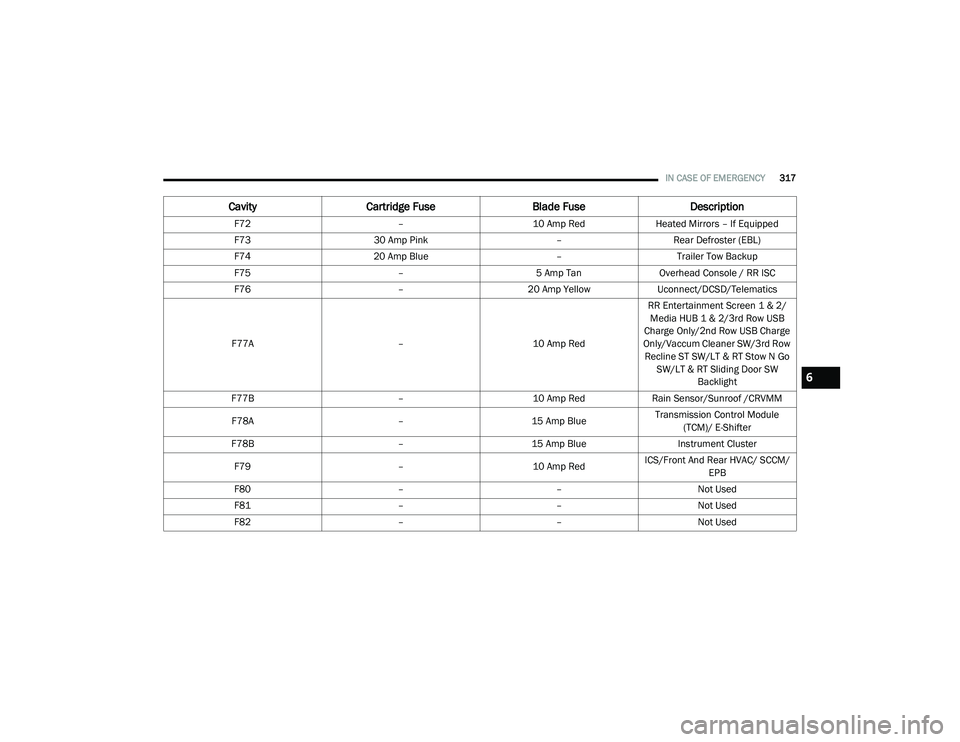

IN CASE OF EMERGENCY317

F72 –10 Amp RedHeated Mirrors – If Equipped

F73 30 Amp Pink –Rear Defroster (EBL)

F74 20 Amp Blue –Trailer Tow Backup

F75 –5 Amp TanOverhead Console / RR ISC

F76 –20 Amp YellowUconnect/DCSD/Telematics

F77A –10 Amp RedRR Entertainment Screen 1 & 2/

Media HUB 1 & 2/3rd Row USB

Charge Only/2nd Row USB Charge

Only/Vaccum Cleaner SW/3rd Row Recline ST SW/LT & RT Stow N Go SW/LT & RT Sliding Door SW Backlight

F77B –10 Amp RedRain Sensor/Sunroof /CRVMM

F78A –15 Amp BlueTransmission Control Module

(TCM)/ E-Shifter

F78B –15 Amp Blue Instrument Cluster

F79 –10 Amp RedICS/Front And Rear HVAC/ SCCM/

EPB

F80 ––Not Used

F81 ––Not Used

F82 ––Not Used

CavityCartridge Fuse Blade FuseDescription

6

20_RU_OM_EN_US_t.book Page 317

Page 320 of 516

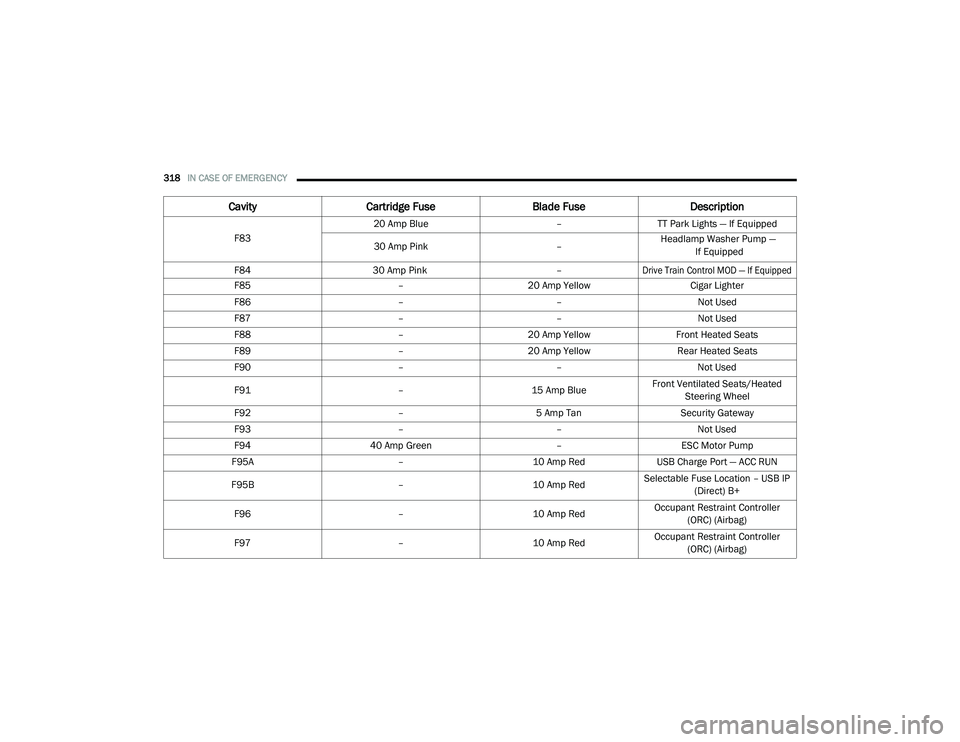

318IN CASE OF EMERGENCY

F83 20 Amp Blue

–TT Park Lights — If Equipped

30 Amp Pink – Headlamp Washer Pump —

If Equipped F84 30 Amp Pink

–

Drive Train Control MOD — If Equipped

F85

–20 Amp Yellow Cigar Lighter

F86 ––Not Used

F87 ––Not Used

F88 –20 Amp Yellow Front Heated Seats

F89 –20 Amp Yellow Rear Heated Seats

F90 ––Not Used

F91 –15 Amp BlueFront Ventilated Seats/Heated

Steering Wheel

F92 –5 Amp Tan Security Gateway

F93 ––Not Used

F94 40 Amp Green –ESC Motor Pump

F95A –10 Amp RedUSB Charge Port — ACC RUN

F95B –10 Amp RedSelectable Fuse Location – USB IP

(Direct) B+

F96 –10 Amp RedOccupant Restraint Controller

(ORC) (Airbag)

F97 –10 Amp RedOccupant Restraint Controller

(ORC) (Airbag)

Cavity Cartridge Fuse Blade FuseDescription

20_RU_OM_EN_US_t.book Page 318

Page 321 of 516

IN CASE OF EMERGENCY319

* 30 Amp mini fuse is substituted for 25 Amp Circuit Breaker.F98

–15 Amp Blue Left HID Headlamp

F99 30 Amp Pink –Trailer Tow Module - If Equipped

F100A –10 Amp Red AHLM

F100B –10 Amp RedRear Camera/LBSS/RBSS/CVPM/

Humidity Sensor/In Vehicle Temperature Sensor

Circuit Breakers

CB1 25 AmpPower Seats (Driver)

CB2 25 Amp *Power Seats (Pass)

CB3 25 AmpFRT PWR Window W/O Door Nodes

+ RR PWR Window Lockout

Cavity Cartridge Fuse Blade FuseDescription

6

20_RU_OM_EN_US_t.book Page 319

Page 323 of 516

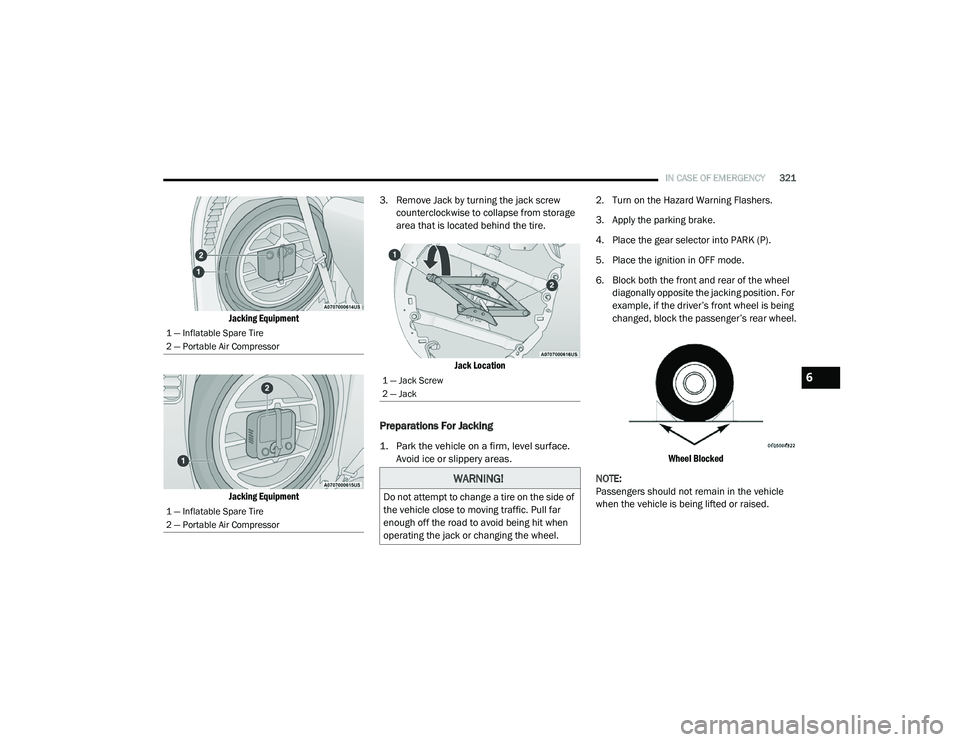

IN CASE OF EMERGENCY321

Jacking Equipment

Jacking Equipment

3. Remove Jack by turning the jack screw

counterclockwise to collapse from storage

area that is located behind the tire.

Jack Location

Preparations For Jacking

1. Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

2. Turn on the Hazard Warning Flashers.

3. Apply the parking brake.

4. Place the gear selector into PARK (P).

5. Place the ignition in OFF mode.

6. Block both the front and rear of the wheel

diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being lifted or raised.

1 — Inflatable Spare Tire

2 — Portable Air Compressor

1 — Inflatable Spare Tire

2 — Portable Air Compressor

1 — Jack Screw

2 — Jack

WARNING!

Do not attempt to change a tire on the side of

the vehicle close to moving traffic. Pull far

enough off the road to avoid being hit when

operating the jack or changing the wheel.

6

20_RU_OM_EN_US_t.book Page 321

Page 334 of 516

332IN CASE OF EMERGENCY

(Continued)

(Continued)

Tire Service Kit Usage Precautions

Replace the Tire Service Kit Sealant Bottle

prior to the expiration date (printed at the

lower right hand corner on the bottle label) to

assure optimum operation of the system.

Refer to “Sealant Bottle Replacement” in this

section for further information.

The Sealant Bottle is a one tire application use

and needs to be replaced after each use.

Always replace these components immedi -

ately at your original equipment vehicle dealer.

When the Tire Service Kit sealant is in a liquid

form, clean water, and a damp cloth will

remove the material from the vehicle or tire

and wheel components. Once the sealant

dries, it can easily be peeled off and properly

discarded.

For optimum performance, make sure the

valve stem on the wheel is free of debris

before connecting the Tire Service Kit.

The Tire Service Kit Sealant is only intended

to seal punctures less than 1/4 inch (6 mm)

diameter in the tread/contact surface of your

vehicle’s tires.

The Tire Service Kit Sealant is not intended to

seal punctures on the tires' side walls.

You can use the Tire Service Kit air pump to

inflate bicycle tires. The kit also comes with

two needles, located in the Accessory

Storage Compartment (on the bottom of the

air pump) for inflating sport balls, rafts, or

similar inflatable items. However, use only

the Air Pump and make sure the Mode Select

Knob is in the Air Mode when inflating such

items to avoid injecting sealant into them.

Do not lift or carry the Tire Service Kit by the

hoses.

WARNING!

Do not attempt to seal a tire on the side of

the vehicle closest to traffic. Pull far enough

off the road to avoid the danger of being hit

when using the Tire Service Kit.

Do not use Tire Service Kit or drive the

vehicle under the following circumstances:

If the puncture in the tire tread is

approximately 1/4 inch (6 mm) or

larger.

If the tire has any sidewall damage.

If the tire has any damage from driving

with extremely low tire pressure.

If the tire has any damage from driving

on a flat tire.

If the wheel has any damage.

If you are unsure of the condition of the

tire or the wheel.

Keep Tire Service Kit away from open

flames or heat source.

A loose Tire Service Kit thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

Tire Service Kit in the place provided.

Failure to follow these warnings can result

in injuries that are serious or fatal to you,

your passengers, and others around you.

WARNING! (Continued)

20_RU_OM_EN_US_t.book Page 332

Page 352 of 516

350SERVICING AND MAINTENANCE

Checking Oil Level

To assure proper engine lubrication, the engine

oil must be maintained at the correct level.

Check the oil level at regular intervals, such as

every fuel stop. The best time to check the

engine oil level is about five minutes after a fully

warmed engine is shut off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Maintain the oil level between the

MIN and MAX markings on the dipstick. Adding

one quart or one liter of oil when the reading is

at the MIN mark will result in a MAX reading on

these engines.

Adding Washer Fluid

The fluid reservoir is located in the front of the

engine compartment. Be sure to check the fluid

level in the reservoir at regular intervals. Fill the

reservoir with windshield washer solvent (not

radiator antifreeze) and operate the system for

a few seconds to flush out the residual washer

fluid.

When refilling the washer fluid reservoir, take

some washer fluid, apply it to a cloth or towel,

and wipe clean the wiper blades; this will help

blade performance.

To prevent freeze-up of your windshield washer

system in cold weather, select a solution or

mixture that meets or exceeds the temperature

range of your climate. This rating information

can be found on most washer fluid containers.

Maintenance-Free Battery

Your vehicle is equipped with a

maintenance-free battery. You will never have

to add water, nor is periodic maintenance

required.

CAUTION!

Overfilling or underfilling will cause oil aera -

tion, or loss of oil pressure. This could

damage your engine.

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling

or working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps. If acid splashes in eyes

or on skin, flush the area immediately with

large amounts of water. Refer to “Jump

Starting Procedure” in “In Case Of Emer -

gency” for further information.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or any

other booster source with an output greater

than 12 Volts. Do not allow cable clamps to

touch each other.

Battery posts, terminals, and related acces -

sories contain lead and lead compounds.

Wash hands after handling.

20_RU_OM_EN_US_t.book Page 350

Page 353 of 516

SERVICING AND MAINTENANCE351

Pressure Washing

DEALER SERVICE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:

Intentional tampering with emissions control

systems may void your warranty and could

result in civil penalties being assessed against

you.

Engine Oil

Change Engine Oil

Refer to “Scheduled Servicing” in this section

for the proper maintenance intervals.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Gasoline Engine Oil Selection

For best performance and maximum protection

under all types of operating conditions, the

manufacturer only recommends engine oils

that are API Certified and meet the

requirements of FCA Material Standard

MS-6395.

CAUTION!

It is essential when replacing the cables on

the battery that the positive cable is

attached to the positive post and the nega -

tive cable is attached to the negative post.

Battery posts are marked positive (+) and

negative (-) and are identified on the battery

case. Cable clamps should be tight on the

terminal posts and free of corrosion.

If a “fast charger” is used while the battery

is in the vehicle, disconnect both vehicle

battery cables before connecting the

charger to the battery. Do not use a “fast

charger” to provide starting voltage.

CAUTION!

Cleaning the engine compartment with a high

pressure washer is not recommended.

Precautions have been taken to safeguard all

parts and connections however, the

pressures generated by these machines is

such that complete protection against water

ingress cannot be guaranteed.

WARNING!

You can be badly injured working on or

around a motor vehicle. Only do service work

for which you have the knowledge and the

proper equipment. If you have any doubt

about your ability to perform a service job,

take your vehicle to a competent mechanic.7

20_RU_OM_EN_US_t.book Page 351

Page 362 of 516

360SERVICING AND MAINTENANCE

(Continued)

Under normal operating conditions, the catalytic

converter will not require maintenance. However,

it is important to keep the engine properly tuned

to ensure proper catalyst operation and prevent

possible catalyst damage.

NOTE:

Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you. In unusual situations involving grossly

malfunctioning engine operation, a scorching

odor may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn

off the engine and allow it to cool. Service,

including a tune-up to manufacturer's

specifications, should be obtained immediately.

To minimize the possibility of catalytic converter

damage:

Do not interrupt the ignition when the trans

-

mission is in gear and the vehicle is in

motion.

Do not try to start the vehicle by pushing or

towing the vehicle.

Do not idle the engine with any ignition

components disconnected or removed, such

as when diagnostic testing, or for prolonged

periods during very rough idle or malfunc -

tioning operating conditions.

A hot exhaust system can start a fire if you

park over materials that can burn. Such

materials might be grass or leaves coming

into contact with your exhaust system. Do

not park or operate your vehicle in areas

where your exhaust system can contact

anything that can burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as

an emissions control device and may seri -

ously reduce engine performance and

cause serious damage to the engine.

WARNING! (Continued)

Damage to the catalytic converter can

result if your vehicle is not kept in proper

operating condition. In the event of engine

malfunction, particularly involving engine

misfire or other apparent loss of perfor -

mance, have your vehicle serviced

promptly. Continued operation of your

vehicle with a severe malfunction could

cause the converter to overheat, resulting

in possible damage to the converter and

vehicle.

CAUTION! (Continued)

20_RU_OM_EN_US_t.book Page 360

Page 368 of 516

366SERVICING AND MAINTENANCE

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not

required. However, change the fluid and filter if

the fluid becomes contaminated (with water,

etc.), or if the transmission is disassembled for

any reason.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

Tire Safety Information

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

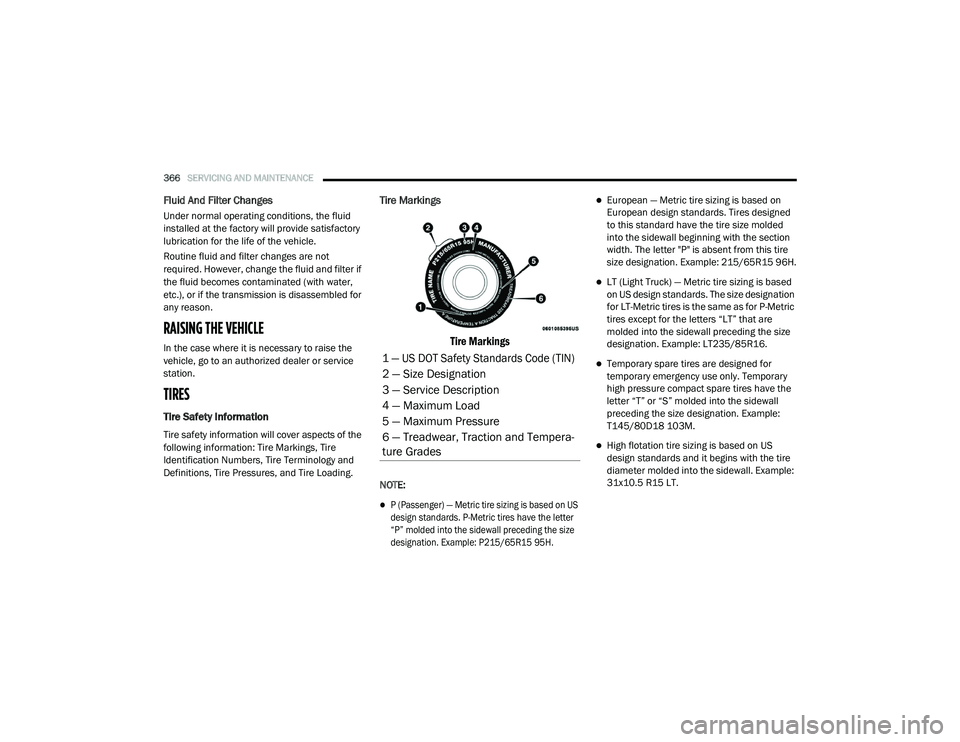

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on

European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section

width. The letter "P" is absent from this tire

size designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based

on US design standards. The size designation

for LT-Metric tires is the same as for P-Metric

tires except for the letters “LT” that are

molded into the sidewall preceding the size

designation. Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US

design standards and it begins with the tire

diameter molded into the sidewall. Example:

31x10.5 R15 LT.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

20_RU_OM_EN_US_t.book Page 366