power steering CHRYSLER PACIFICA 2021 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2021, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2021Pages: 401, PDF Size: 26.88 MB

Page 237 of 401

SAFETY235

If the ABS Warning Light is on, the brake system

should be serviced as soon as possible to restore

the benefits of anti-lock brakes. If the ABS Warning

Light does not come on when the ignition is placed

in the ON/RUN mode, have the light repaired as

soon as possible.

ELECTRONIC BRAKE CONTROL (EBC)

S

YSTEM

Your vehicle is equipped with an advanced

Electronic Brake Control (EBC) system. This system

includes Anti-Lock Brake System (ABS), Brake

Assist System (BAS), Electronic Brake Force

Distribution (EBD), Electronic Roll Mitigation

(ERM), Electronic Stability Control (ESC), Hill Start

Assist (HSA), and Traction Control System

(TCS).These systems work together to enhance

both vehicle stability and control in various driving

conditions.

Your vehicle may also be equipped with Dynamic

Steering Torque (DST), Ready Alert Braking (RAB),

Rain Brake Support (RBS) and Trailer Sway Control

(TSC).

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s

braking capability during emergency braking

maneuvers. The system detects an emergency

braking situation by sensing the rate and amount

of brake application and then applies optimum

pressure to the brakes. This can help reduce

braking distances. The BAS complements the

Anti-Lock Brake System (ABS). Applying the brakes

very quickly results in the best BAS assistance. To

receive the benefit of the system, you must apply

continuous braking pressure during the stopping

sequence (do not “pump” the brakes). Do not

reduce brake pedal pressure unless braking is no

longer desired. Once the brake pedal is released,

the BAS is deactivated.

Brake System Warning Light

The red Brake System Warning Light will turn on

when the ignition is placed in the ON/RUN mode

and may stay on for as long as four seconds.

If the Brake System Warning Light remains on or

comes on while driving, it indicates that the brake

system is not functioning properly and that

immediate service is required. If the Brake System

Warning Light does not come on when the ignition

is placed in the ON/RUN mode, have the light

repaired as soon as possible.

Dynamic Steering Torque (DST)

DST is a feature of the ESC and Electric Power

Steering (EPS) modules that provides torque at the

steering wheel for certain driving conditions in

which the ESC module is detecting vehicle

instability. The torque that the steering wheel

receives is only meant to help the driver realize

optimal steering behavior in order to reach/

maintain vehicle stability. The only notification the

driver receives that the feature is active, is the

torque applied to the steering wheel.

WARNING!

The Brake Assist System (BAS) cannot prevent

the natural laws of physics from acting on the

vehicle, nor can it increase the traction afforded

by prevailing road conditions. BAS cannot

prevent collisions, including those resulting from

excessive speed in turns, driving on very slippery

surfaces, or hydroplaning. The capabilities of a

BAS-equipped vehicle must never be exploited in

a reckless or dangerous manner, which could

jeopardize the user's safety or the safety of

others.

6

21_RUP_OM_EN_USC_t.book Page 235

Page 238 of 401

236SAFETY

NOTE:The DST feature is only meant to help the driver

realize the correct course of action through small

torques on the steering wheel, which means the

effectiveness of the DST feature is highly

dependent on the driver’s sensitivity and overall

reaction to the applied torque. It is very important

to realize that this feature will not steer the vehicle,

meaning the driver is still responsible for steering

the vehicle.

Electronic Brake Force Distribution (EBD)

The EBD function manages the distribution of the

braking torque between the front and rear axles by

limiting braking pressure to the rear axle. This is

done to prevent overslip of the rear wheels to avoid

vehicle instability, and to prevent the rear axle from

entering the Anti-Lock Brake System (ABS) before

the front axle.

Electronic Roll Mitigation (ERM)

ERM anticipates the potential for wheel lift by

monitoring the driver’s steering wheel input and

the speed of the vehicle. When ERM determines

that the rate of change of the steering wheel angle

and vehicle’s speed are sufficient to potentially

cause wheel lift, it then applies the appropriate

brake and may also reduce engine power to lessen

the chance that wheel lift will occur. ERM can only

reduce the chance of wheel lift occurring during

severe or evasive driving maneuvers; it cannot

prevent wheel lift due to other factors, such as

road conditions, leaving the roadway, striking

objects or other vehicles.

Electronic Stability Control (ESC)

ESC enhances directional control and stability of

the vehicle under various driving conditions. ESC

corrects for oversteering or understeering of the

vehicle by applying the brake of the appropriate

wheel(s) to assist in counteracting the above

conditions. Engine power may also be reduced to

help the vehicle maintain the desired path.

Oversteer — when the vehicle is turning more

than appropriate for the steering wheel position.

Understeer — when the vehicle is turning less

than appropriate for the steering wheel position.

ESC uses sensors in the vehicle to determine the

vehicle path intended by the driver and compares

it to the actual path of the vehicle. When the actual

path does not match the intended path, ESC

applies the brake of the appropriate wheel to

assist in counteracting the oversteer or understeer

condition.

WARNING!

Many factors, such as vehicle loading, road

conditions and driving conditions, influence the

chance that wheel lift or rollover may occur. ERM

cannot prevent all wheel lift or rollovers,

especially those that involve leaving the roadway

or striking objects or other vehicles. The

capabilities of an ERM-equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

21_RUP_OM_EN_USC_t.book Page 236

Page 263 of 401

SAFETY261

SUPPLEMENTAL RESTRAINT SYSTEMS

(SRS)

Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on others. If

you are not sure, ask an authorized dealer.

The air bag system must be ready to protect you in

a collision. The Occupant Restraint Controller

(ORC) monitors the internal circuits and

interconnecting wiring associated with the

electrical Air Bag System Components. Your

vehicle may be equipped with the following Air Bag

System Components:

Air Bag System Components

Occupant Restraint Controller (ORC)

Air Bag Warning Light

Steering Wheel and Column

Instrument Panel

Knee Impact Bolsters

Driver and Front Passenger Air Bags

Seat Belt Buckle Switch

Supplemental Side Air Bags

Supplemental Knee Air Bags

Front and Side Impact Sensors

Seat Belt Pretensioners

Seat Track Position Sensors

Occupant Classification System

Air Bag Warning Light

The Occupant Restraint Controller (ORC)

monitors the readiness of the electronic

parts of the air bag system whenever the

ignition switch is in the START or ON/RUN

position. If the ignition switch is in the OFF position

or in the ACC position, the air bag system is not on

and the air bags will not inflate.

The ORC contains a backup power supply system

that may deploy the air bag system even if the

battery loses power or it becomes disconnected

prior to deployment. The ORC turns on the Air Bag Warning Light in the

instrument panel for approximately four to eight

seconds for a self-check when the ignition switch is

first in the ON/RUN position. After the self-check,

the Air Bag Warning Light will turn off. If the ORC

detects a malfunction in any part of the system, it

turns on the Air Bag Warning Light, either

momentarily or continuously. A single chime will

sound to alert you if the light comes on again after

initial startup.

The ORC also includes diagnostics that will

illuminate the instrument panel Air Bag Warning

Light if a malfunction is detected that could affect

the air bag system. The diagnostics also record the

nature of the malfunction. While the air bag system

is designed to be maintenance free, if any of the

following occurs, have an authorized dealer

service the air bag system immediately.

The Air Bag Warning Light does not come on

during the four to eight seconds when the igni

-

tion switch is first in the ON/RUN position.

The Air Bag Warning Light remains on after the

four to eight-second interval.

The Air Bag Warning Light comes on intermit -

tently or remains on while driving.

6

21_RUP_OM_EN_USC_t.book Page 261

Page 275 of 401

SAFETY273

Your vehicle may also be designed to perform any of

these other functions in response to the Enhanced

Accident Response System:

Turn off the Fuel Filter Heater, Turn off the HVAC

Blower Motor, Close the HVAC Circulation Door

Cut off battery power to the:

Engine

Electric Motor (if equipped)

Electric power steering

Brake booster

Electric park brake

Automatic transmission gear selector

Horn

Front wiper

Headlamp washer pump

NOTE:

After an accident, remember to cycle the ignition to

the STOP (OFF/LOCK) position and remove the key

from the ignition switch to avoid draining the battery.

Carefully check the vehicle for fuel leaks in the

engine compartment and on the ground near the

engine compartment and fuel tank before resetting

the system and starting the engine. If there are no

fuel leaks or damage to the vehicle electrical devices

(e.g. headlights) after an accident, reset the system

by following the procedure described below. If you

have any doubt, contact an authorized dealer.

Enhanced Accident Response System

Reset Procedure

If applicable, refer to the “Hybrid Supplement”

for additional information.

In order to reset the Enhanced Accident Response

System functions after an event, the ignition switch

must be changed from ignition START or ON/RUN

to ignition OFF. Carefully check the vehicle for fuel

leaks in the engine compartment and on the

ground near the engine compartment and fuel

tank before resetting the system and starting the

engine.

After an accident, if the vehicle will not start after

performing the reset procedure, the vehicle must

be towed to an authorized dealer to be inspected

and to have the Enhanced Accident Response

System reset.

6

21_RUP_OM_EN_USC_t.book Page 273

Page 308 of 401

306IN CASE OF EMERGENCY

6. Switch the power button ON.

7. Inflate the tire to 60 psi (4.2 Bar)

recommended as per the label on

the wheel or if the vehicle equipped

with the inflatable spare tire

pressure indicated on the Tire and Loading

information label located on the driver-side

door opening.

NOTE:If the tire is overinflated, use the deflation button

to reduce the tire air pressure.

8. After the tire reaches the

recommended pressure, lower the

vehicle with the jack as described in

the Jack Instructions section in this

manual.

9. Remove the speed limit label

sticker from the Portable Air

Compressor and place it on the

center of the steering wheel.

10. Return the Portable Air Compressor to the foam tray and secure it with the strap. Store

the foam tray in the cargo area.

RETURN INFLATABLE SPARE TIRE

To return Inflatable Spare Tire to its storage

location.

1. Return the Jack.

2. Deflate the spare tire. Use the Tire Service Kit or Portable Air Compressor and push the

deflation button to do this step. See the

Portable Air Compressor in this section for

additional information. The inflatable spare

tire will return to its original shape. 3. Install the inflatable spare tire back into its

original stowage location and position facing

outward.

4. Install the foam tray with wrench and funnel installed.

5. Install and tighten the wing nut by hand.

6. Install the Tire Service Kit or Portable Air Compressor (if equipped) and tighten the

strap.

7. Install access panel door.

TIRE SERVICE KIT WITH A SUBWOOFER —

IF EQUIPPED

Your vehicle may be equipped with a Tire Service

Kit. Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not be

removed from the tire. Tire Service Kit can be used

in outside temperatures down to approximately

-4°F (-20°C). This kit will provide a temporary tire

seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of

50 mph (80 km/h).

WARNING!

Do not lift or carry the Portable Air Compressor

by the hose.

Always stow the Portable Air Compressor only

in the provided place.

The metal end fitting from Power Plug may get

hot after use, so it should be handled care -

fully.

Keep the Portable Air Compressor away from

open flames or heat source.

21_RUP_OM_EN_USC_t.book Page 306

Page 312 of 401

310IN CASE OF EMERGENCY

2. The pump will start to inject air into

the tire immediately after the

Sealant Bottle is empty. Continue to

operate the pump and inflate the tire

to the cold tire inflation pressure found on the

tire and loading information label located in

the driver-side door opening. Check the tire

pressure by looking at the Pressure Gauge.

If the tire does not inflate to at least 26 psi

(1.8 Bar) pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire inflates to the recommended pressure

or is at least 26 psi (1.8 Bar) pressure within

15 minutes:

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

1. Push the Power Button to turn the

Tire Service Kit off.

2. Remove the speed limit label from

the Tire Service Kit and place sticker

on the steering wheel. 3. Immediately disconnect the Sealant Hose

from the valve stem, reinstall the cap on the

fitting at the end of the hose, and place the Tire

Service Kit in the vehicle storage location.

Drive Vehicle: Immediately after injecting sealant and

inflating the tire, drive the vehicle 5 miles

(8 km) or 10 minutes to ensure distribution of the Tire Service Kit Sealant

within the tire. Do not exceed 50 mph (80 km/h). After Driving:

Pull over to a safe location and turn on the

vehicle’s Hazard Warning Flashers.

Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hose

to reach the valve stem and keep the Tire

Service Kit flat on the ground. This will provide

the best positioning of the kit when injecting the

sealant into the deflated tire and running the air

pump. Move the vehicle as necessary to place

the valve stem in this position before

proceeding.

Place the transmission in PARK (P) and cycle the

ignition in the OFF position.

Apply the parking brake.

NOTE:If tire has improper inflation follow the steps below

1. Uncoil the Sealant Hose, and then remove the

cap from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on

the ground next to the deflated tire.

3. Remove the cap from the valve stem, and then screw the fitting at the end of the Sealant Hose

onto the valve stem.

WARNING!

The Tire Service Kit is not a permanent flat tire

repair. Have the tire inspected and repaired or

replaced after using the Tire Service Kit. Do not

exceed 50 mph (80 km/h) until the tire is

repaired or replaced. Failure to follow this

warning can result in injuries that are serious or

fatal to you, your passengers, and others around

you. Have the tire checked as soon as possible

at an authorized dealer.

21_RUP_OM_EN_USC_t.book Page 310

Page 313 of 401

IN CASE OF EMERGENCY311

4. Uncoil the Power Plug and insert

the plug into the vehicle's 12 Volt

power outlet.

5. Uncoil the Hose and screw the

fitting at the end of the hose onto the

valve stem.

6. Turn the Mode Select Knob and

turn to the Air Mode position.

7. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button to turn on

Tire Service Kit and inflate the tire to

the cold tire inflation pressure found

on the tire and loading information

label located in the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing. 2. Disconnect the Tire Service Kit from the valve

stem, reinstall the cap on the valve stem and

unplug from 12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

5. Remove the Speed Limit sticker from the steering wheel after the tire has been repaired.

6. Replace the Sealant Bottle at an authorized dealer as soon as possible.

NOTE:When having the tire serviced, advise the autho -

rized dealer or service center that the tire has been

sealed using the Tire Service Kit.

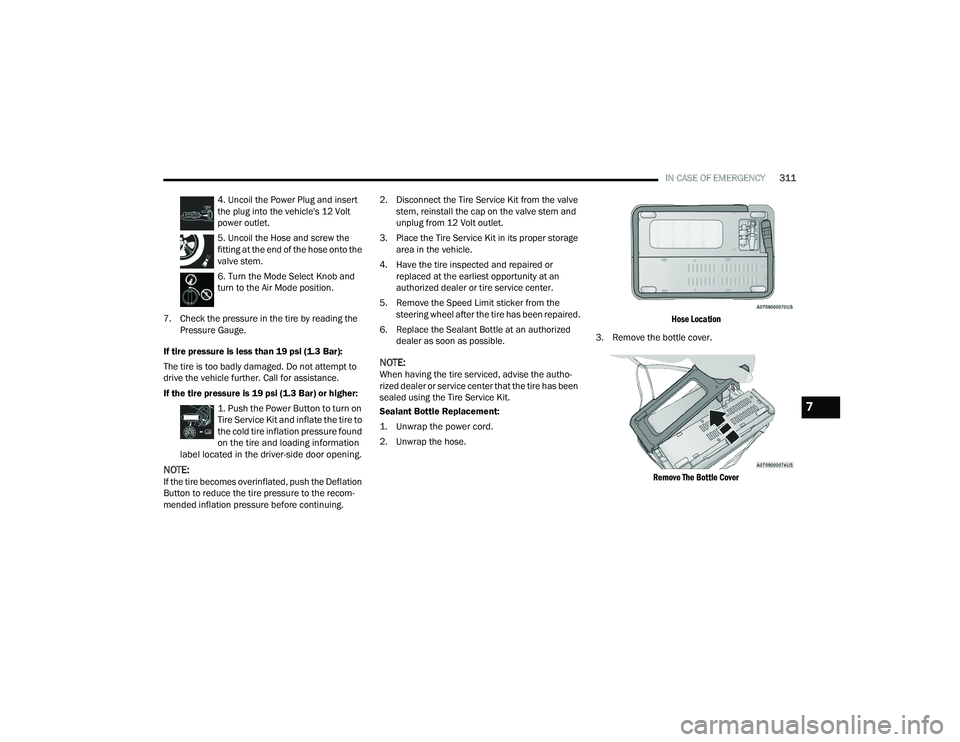

Sealant Bottle Replacement:

1. Unwrap the power cord.

2. Unwrap the hose.

Hose Location

3. Remove the bottle cover.

Remove The Bottle Cover

7

21_RUP_OM_EN_USC_t.book Page 311

Page 318 of 401

316IN CASE OF EMERGENCY

If the tire inflates to the recommended pressure

or is at least 26 psi (1.8 Bar) pressure within

15 minutes:

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

1. Push the Power Button to turn the

Tire Service Kit off.

2. Remove the speed limit label from

the Tire Service Kit and place sticker

on the steering wheel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the

fitting at the end of the hose, and place the Tire

Service Kit in the vehicle storage location.

Drive Vehicle: Immediately after injecting sealant and

inflating the tire, drive the vehicle 5 miles

(8 km) or 10 minutes to ensure distribution of the Tire Service Kit Sealant

within the tire. Do not exceed 50 mph (80 km/h). After Driving:

Pull over to a safe location and turn on the

vehicle’s Hazard Warning Flashers.

Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hose

to reach the valve stem and keep the Tire

Service Kit flat on the ground. This will provide

the best positioning of the kit when injecting the

sealant into the deflated tire and running the air

pump. Move the vehicle as necessary to place

the valve stem in this position before

proceeding.

Place the transmission in PARK (P) and cycle the

ignition in the OFF position.

Apply the parking brake.

NOTE:If tire has improper inflation see the following

steps:

1. Uncoil the Sealant Hose, and then remove the

cap from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on

the ground next to the deflated tire.

3. Remove the cap from the valve stem, and then screw the fitting at the end of the Sealant Hose

onto the valve stem.

4. Uncoil the Power Plug and insert

the plug into the vehicle's 12 Volt

power outlet.

5. Uncoil the Hose and screw the

fitting at the end of the hose onto the

valve stem.

6. Turn the Mode Select Knob and

turn to the Air Mode position.

7. Check the pressure in the tire by reading the Pressure Gauge.

WARNING!

The Tire Service Kit is not a permanent flat tire

repair. Have the tire inspected and repaired or

replaced after using the Tire Service Kit. Do not

exceed 50 mph (80 km/h) until the tire is

repaired or replaced. Failure to follow this

warning can result in injuries that are serious or

fatal to you, your passengers, and others around

you. Have the tire checked as soon as possible

at an authorized dealer.

21_RUP_OM_EN_USC_t.book Page 316

Page 319 of 401

IN CASE OF EMERGENCY317

If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button to turn on

Tire Service Kit and inflate the tire to

the cold tire inflation pressure found

on the tire and loading information

label located in the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and

unplug from 12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center. 5. Remove the Speed Limit sticker from the

steering wheel after the tire has been repaired.

6. Replace the Sealant Bottle at an authorized dealer as soon as possible.

NOTE:When having the tire serviced, advise the autho -

rized dealer or service center that the tire has been

sealed using the Tire Service Kit.

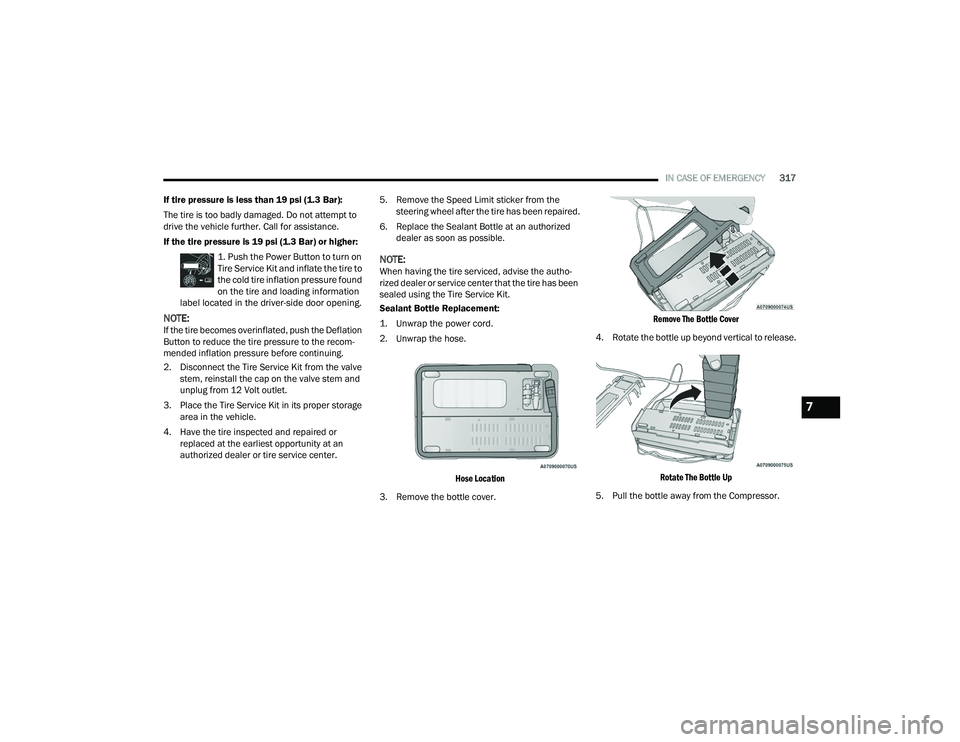

Sealant Bottle Replacement:

1. Unwrap the power cord.

2. Unwrap the hose.

Hose Location

3. Remove the bottle cover.

Remove The Bottle Cover

4. Rotate the bottle up beyond vertical to release.

Rotate The Bottle Up

5. Pull the bottle away from the Compressor.

7

21_RUP_OM_EN_USC_t.book Page 317

Page 348 of 401

346SERVICING AND MAINTENANCE

Fluid Level Check

The fluid level is preset at the factory and does not

require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service tools.

If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an improper

fluid level can cause severe transmission damage.

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not required.

However, change the fluid and filter if the fluid

becomes contaminated (with water, etc.), or if the

transmission is disassembled for any reason.

Selection Of Lubricant

It is important to use the proper transmission fluid

to ensure optimum transmission performance and

life. Use only the manufacturer specified

transmission fluid Úpage 383. It is important to

maintain the transmission fluid at the correct level

using the recommended fluid.

NOTE:No chemical flushes should be used in any trans -

mission; only the approved lubricant should be

used.

FUSES

General Information

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An authorized

dealer has the proper tools to adjust the fluid

level accurately.

CAUTION!

Using a transmission fluid other than the

manufacturer recommended fluid may cause

deterioration in transmission shift quality and/or

torque converter shudder Ú page 383.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

Never replace a blown fuse with metal wires or

any other material. Do not place a fuse inside

a circuit breaker cavity or vice versa. Failure to

use proper fuses may result in serious

personal injury, fire and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems (engine system, transmission

system) or steering system blows, contact an

authorized dealer.

21_RUP_OM_EN_USC_t.book Page 346