CHRYSLER PT CRUISER 2004 1.G Owners Manual

Manufacturer: CHRYSLER, Model Year: 2004, Model line: PT CRUISER, Model: CHRYSLER PT CRUISER 2004 1.GPages: 341, PDF Size: 5.06 MB

Page 261 of 341

Air Conditioner

Check the air conditioning system at the start of the

warm weather season.

NOTE:If your air conditioning performance seems

lower than expected, check the front of the A/C con-

denser for an accumulation of dirt or insects. Clean with

a gentle water spray from behind the radiator and

through the condenser as required. Fabric front fascia

protectors may reduce air flow to the condenser, reducing

air conditioning performance.

WARNING!

The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal injury

or damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced repairman.

Refrigerant Recovery And Recycling

The air conditioning system of your vehicle contains

R-134a, a refrigerant that does not deplete the ozone layer

in the upper atmosphere, the manufacturer recommends

that air conditioning service be done by facilities using

refrigerant recycling and recovery equipment that meets

SAE standard J1991.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.9

MAINTAINING YOUR VEHICLE 261

7

Page 262 of 341

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Recommended Fluids, Lubricants, and

Genuine Parts for correct fluid types.

Front Suspension Ball Joints

There are two front suspension lower ball joints that are

permanently lubricated. Inspect these ball joints when-

ever under vehicle service is done. Damaged seals and

their corresponding potentially damaged ball joints must

be replaced.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors,liftgate and hood hinges, should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching compo-

nents to insure proper function. When performing other

underhood services, the hood latch, release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

262 MAINTAINING YOUR VEHICLE

Page 263 of 341

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild non abrasive cleaner or use the washer solvent. This

will remove accumulations of salt, waxes or road film

and help reduce streaking and smearing.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield. Avoid using the wiper blades to

remove frost or ice from the windshield. make sure that

they are not frozen to the glass before turning them on to

avoid damaging the blade. Keep the blade rubber out of

contact with petroleum products such as engine oil,

gasoline, etc.

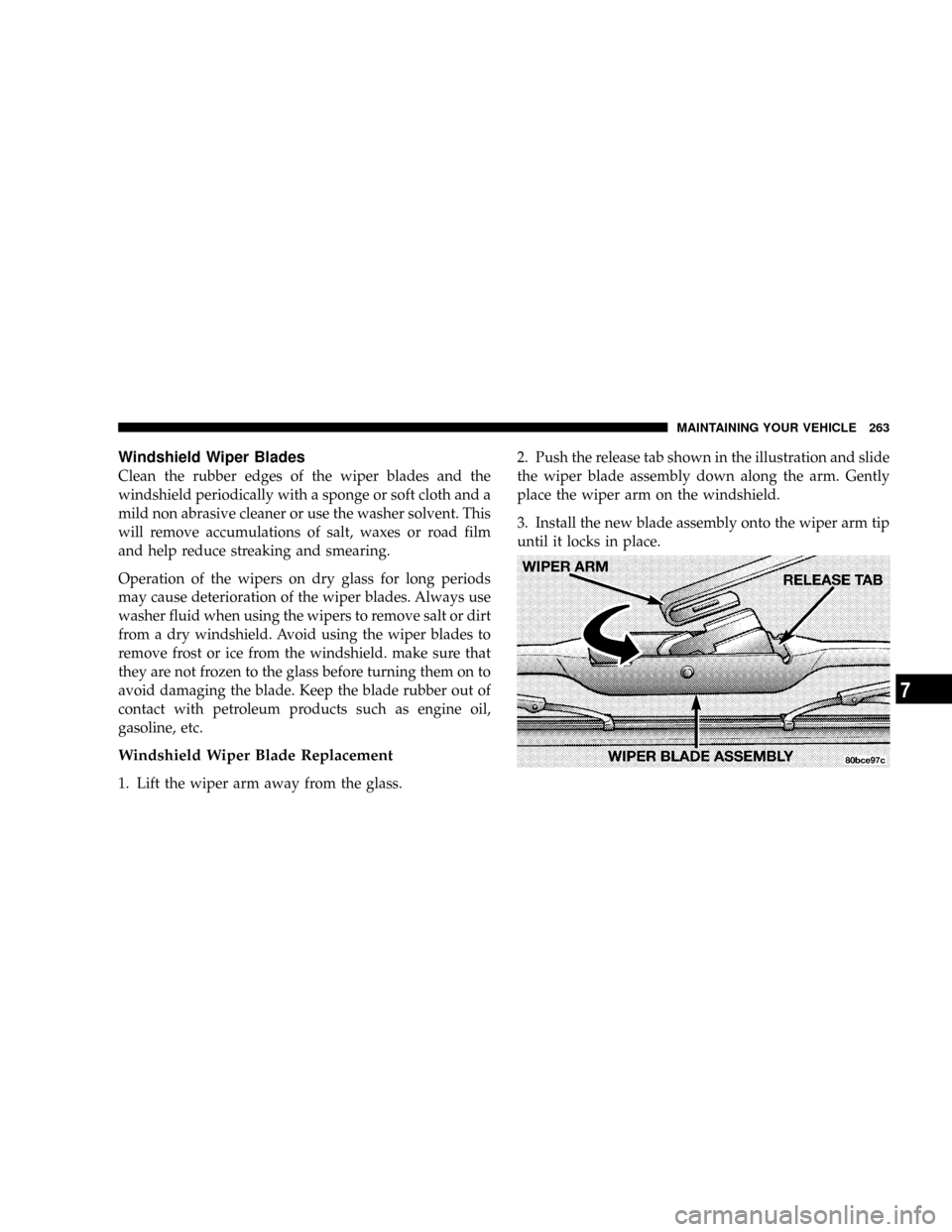

Windshield Wiper Blade Replacement

1. Lift the wiper arm away from the glass.2. Push the release tab shown in the illustration and slide

the wiper blade assembly down along the arm. Gently

place the wiper arm on the windshield.

3. Install the new blade assembly onto the wiper arm tip

until it locks in place.

MAINTAINING YOUR VEHICLE 263

7

Page 264 of 341

Windshield Washer Reservoir

The washer fluid reservoir is located in the rear of the

engine compartment on the passenger side and should be

checked for fluid level at regular intervals. Fill the

reservoir with windshield washer solvent (not radiator

antifreeze).

Exhaust System

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system,

or if exhaust fumes can be detected inside the vehicle, or

when the underside or rear of the vehicle is damaged;

have a competent technician inspect the complete ex-

haust system and adjacent body areas for broken, dam-

aged, deteriorated, or mispositioned parts. Open seams

or loose connections could permit exhaust fumes to seep

into the passenger compartment. In addition, inspect the

exhaust system each time the vehicle is raised for an oil

change or lubrication. Replace as required.

264 MAINTAINING YOUR VEHICLE

Page 265 of 341

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide which is colorless and odorless. Breathing

it can make you unconscious and can eventually

poison you. Follow the above precautions to keep

your exhaust system as safe as possible.

Cooling System

WARNING!

²When working near the radiator cooling fan, dis-

connect the fan motor lead or turn the ignition

switch to the OFF position. The fan is temperature

controlled and can start at any time the ignition

switch is in the ON position.

²You or others can be badly burned by hot coolant

or steam from your radiator. If you see or hear

steam coming from under the hood, don't open

the hood until the radiator has had time to cool.

Never try to open a cooling system pressure cap

when the radiator is hot.

MAINTAINING YOUR VEHICLE 265

7

Page 266 of 341

Coolant Checks

Check coolant protection every 12 months (before the

onset of freezing weather, where applicable). If coolant is

dirty or rusty in appearance, the system should be

drained, flushed and refilled with fresh coolant.

Check the front of the radiator for an accumulation of

bugs, leaves, etc. Clean the radiator by gently spraying

water from a garden hose at the back of the core.

Check the coolant recovery bottle tubing for brittle rubber,

cracking, tears, cuts and tightness of the connection at the

bottle and radiator. Inspect the entire system for leaks.

With the engine at normal operating temperature (but

not running), check the cooling system pressure cap for

proper vacuum sealing by draining a small amount of

coolant from the radiator drain cock. If the cap is sealing

properly, the coolant will begin to drain from the coolant

recovery bottle. Do not remove the cap when the cooling

system is hot.

Cooling System Ð Drain, Flush And Refill

At the intervals shown on the Maintenance Schedules,

the system should be drained, flushed and refilled.

If the solution is dirty and contains a considerable

amount of sediment, clean and flush with a reliable

cooling system cleaner. Follow with a thorough rinsing to

remove all deposits and chemicals. Discard old antifreeze

solution.

Engine Coolant Disposal

Used ethylene glycol based engine coolant is a regulated

substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. To prevent ingestion by animals or children

do not store ethylene glycol based engine coolant in open

containers or allow it to remain in puddles on the

ground. If ingested by a child, contact a physician

immediately. Clean up any ground spills immediately.

266 MAINTAINING YOUR VEHICLE

Page 267 of 341

Selection Of Coolant

Use only the manufacturers recommended coolant, refer

to Recommended Fluids, Lubricants and Genuine Parts

for correct coolant type.

CAUTION!

Failure to use the proper antifreeze could cause

radiator plugging and engine overheating. Do not

mix antifreeze brands or use plain water alone or

alcohol based antifreeze products. Do not use addi-

tional rust inhibitors or antirust products, as they

may not be compatible with the radiator coolant and

may plug the radiator.

Adding Coolant

When adding coolant, a minimum solution of 50% eth-

ylene glycol antifreeze coolant in water should be used.Use higher concentrations (not to exceed 70%) if tempera-

tures below234ÉF (237ÉC) are anticipated.

Use only high purity water such as distilled or deionized

water when mixing the water/antifreeze solution. The

use of lower quality water will reduce the amount of

corrosion protection in the engine cooling system.

Please note that it is the owner's responsibility to main-

tain the proper level of protection against freezing ac-

cording to the temperatures occurring in the area where

the vehicle is operated.

NOTE:Mixing coolant types will decrease the life of the

engine coolant and will require more frequent coolant

changes.

Cooling System Pressure Cap

The cap must be fully tightened to prevent loss of

coolant, and to insure that coolant will return to the

radiator from the coolant recovery bottle.

MAINTAINING YOUR VEHICLE 267

7

Page 268 of 341

The cap should be inspected and cleaned if there is any

accumulation of foreign material on the sealing surfaces.

WARNING!

The warning words ªDO NOT OPEN HOTº on the

cooling system pressure cap are a safety precaution.

Never add coolant when the engine is overheated.

Do not loosen or remove the cap to cool an over-

heated engine. Heat causes pressure to build up in

the cooling system. To prevent scalding or injury, do

not remove the pressure cap while the system is hot

or under pressure.

Coolant Level

The coolant recovery bottle provides a quick visual

method for determining that the coolant level is ad-

equate. With the engine idling, and warm to normaloperating temperature, the level of the coolant in the

bottle should be between the ªFULLº and ªADDº marks.

The radiator normally remains completely full, so there is

no need to remove the radiator cap unless checking for

coolant freeze point or replacing coolant. Advise your

service attendant of this. As long as the engine operating

temperature is satisfactory, the coolant recovery bottle

need only be checked once a month.

When additional coolant is needed to maintain the

proper level, it should be added to the coolant recovery

bottle. Do not overfill.

Points To Remember

NOTE:When the vehicle is stopped after a few kilome-

ters (a few miles) of operation, you may observe vapor

coming from the front of the engine compartment. This is

normally a result of moisture from rain, snow, or high

268 MAINTAINING YOUR VEHICLE

Page 269 of 341

humidity accumulation on the radiator and being vapor-

ized when the thermostat opens, allowing hot water to

enter the radiator.

If an examination of your engine compartment shows no

evidence of radiator or hose leaks, the vehicle may be

safely driven. The vapor will soon dissipate.

²Do not overfill the coolant recovery bottle.

²Check coolant freeze point in the system.

²If frequent coolant additions are required, the cooling

system should be pressure tested for leaks.

²Maintain coolant concentration at 50% ethylene glycol

antifreeze (minimum) in water for proper corrosion

protection of your engine which contains aluminum

components.

²Make sure that the radiator and coolant recovery

bottle hoses are not kinked or obstructed.

²Keep the front of the radiator clean. If your vehicle has

air conditioning, keep the front of the condenser clean,

also.

²Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor gas

mileage, and increased emissions.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber

Pay particular attention to the hoses nearest to high heat

sources such as the exhaust manifold. Inspect hose rout-

ing to be sure hoses do not touch any heat source or

moving component that may cause heat damage or

mechanical wear.

MAINTAINING YOUR VEHICLE 269

7

Page 270 of 341

Insure nylon tubing in these areas has not melted or

collapsed

Inspect all hose connections such as clamps and cou-

plings to make sure the are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of degradation that could cause failure.

Fuel System Connections

Electronic Fuel Injection high pressure fuel systems are

designed with tubes and special connects, connections

and clamps which have unique material characteristics to

provide adequate sealing and resist attack by deterio-

rated gasoline.

You are urged to use only the manufactures-specified

tubes, connections and clamps, or their equivalent in

material and specification, in any fuel system servicing.

Brake System

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect the surface of the hoses and nylon tubing for

evidence of heat and mechanical damage. Hard and

270 MAINTAINING YOUR VEHICLE