CHRYSLER SEBRING COUPE 2005 2.G Owners Manual

Manufacturer: CHRYSLER, Model Year: 2005, Model line: SEBRING COUPE, Model: CHRYSLER SEBRING COUPE 2005 2.GPages: 394, PDF Size: 2.47 MB

Page 321 of 394

BATTERY

The condition of the battery is very important for quick

starting and to keep the vehicle's electrical system work-

ing properly. Check the battery regularly.

If battery performance is suspect, have the battery and

charging system tested by an authorized Mitsubishi

dealer.

NOTE

(1) After replacing the battery, the electronic control

system data for the automatic transaxle, etc., will be

erased. As a result, shifting may be rough.

Shifting will become smoother after several changes

in speed.

(2) Memory data for settings made by the user may be

erased when the battery is replaced. If this happens,

establish the settings again using the relevant proce-

dures.

Checking battery electrolyte level

Use the following procedure to check the battery electro-

lyte level.Open the lid on the battery cover (if so equipped).

NOTE:Be sure to close the battery cover after checking

the battery fluid level and after replacing the battery.

MAINTENANCE 321

9

Page 322 of 394

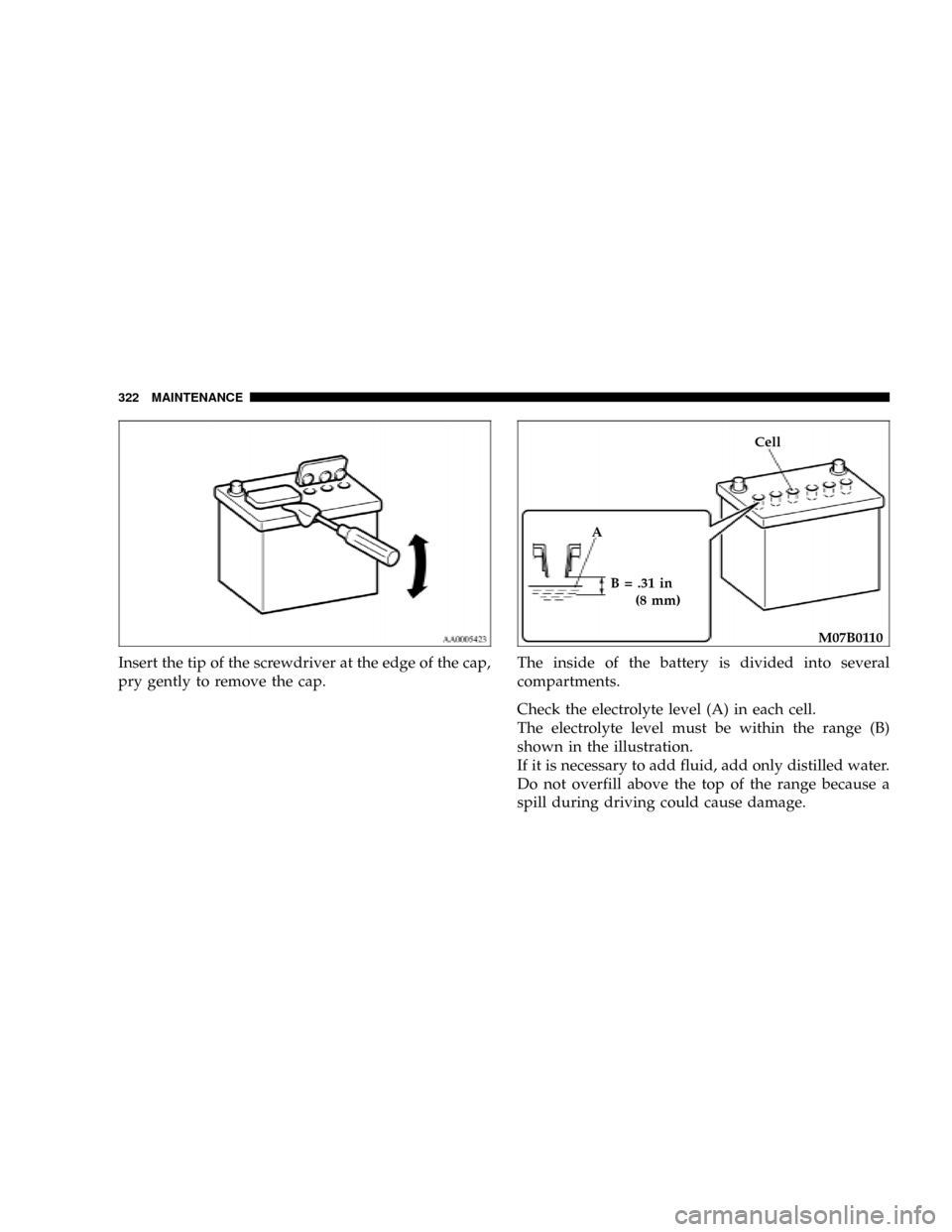

Insert the tip of the screwdriver at the edge of the cap,

pry gently to remove the cap.The inside of the battery is divided into several

compartments.

Check the electrolyte level (A) in each cell.

The electrolyte level must be within the range (B)

shown in the illustration.

If it is necessary to add fluid, add only distilled water.

Do not overfill above the top of the range because a

spill during driving could cause damage.

Cell

A

B = .31 in

(8 mm)

M07B0110

322 MAINTENANCE

Page 323 of 394

WARNING!

²If the battery goes flat, be sure to check the battery

electrolyte level before connecting booster cables.

²After checking the battery electrolyte level, make

sure the caps are fitted securely.

²If any of the caps has a loose fit, replace the

battery.

During cold weather

The capacity of the battery is reduced at low tempera-

tures. This is the result of its chemical and physical

properties and this is why a very cold battery, particu-

larly one that is not fully charged, will only deliver a

fraction of the starter current that is normally available.

It is recommended that you have the battery checked by

an authorized dealer before the start of cold weather and,

if necessary, have it charged or replaced. This not only

ensures reliable starting, but prolongs battery life.

Disconnection and connection

To disconnect the battery cable, stop the engine, discon-

nect the negative terminal first, then the positive termi-

nal. To reconnect the battery, first connect the positive

terminal and then the negative terminal, before starting

the vehicle.

MAINTENANCE 323

9

Page 324 of 394

WARNING!

²Never disconnect the battery while the engine is

running; doing so could damage the vehicle's

electrical components.

²Never short-circuit the battery; doing so could

cause it to overheat and be damaged.

²Keep sparks, cigarettes and flames away from the

battery because the battery may produce an explo-

sion.

²Electrolyte (battery acid) is corrosive diluted sul-

furic acid. If electrolyte comes in contact with,

your hands, eyes, clothes, or the coated surface of

your vehicle, thoroughly flush the area with wa-

ter. If electrolyte gets in your eyes, flush them

with water immediately and get prompt medical

attention.

WARNING!

²Ventilate the area when charging or using the

battery in an enclosed space.

²Always wear protective clothing and goggles

when working with the battery, or have a skilled

technician do it.

²If the battery is to be quick-charged, first discon-

nect the battery cables from the vehicle.

²In order to prevent a short circuit, be sure to

disconnect the negative(-) terminal first, and re-

connect it last.

²If the electrolyte level is very low, have the battery

checked at an authorized dealer.

²Battery posts, terminals and related accessories

contain lead and lead compounds. Wash hands

after handling.

324 MAINTENANCE

Page 325 of 394

NOTE

1. Check each battery terminal for corrosion. If necessary,

neutralize corrosion by washing with a solution of bak-

ing soda and water. Apply grease to posts and clamps

after cleaning or tightening.

2. Before cleaning the battery, tighten all filler port caps

to prevent foreign matter from entering the battery.

3. Check to see if the battery is securely installed and

cannot be moved. Also check each terminal for tightness.

4. When the vehicle is to be left unused for a long period

of time, remove the battery and store it in a place where

the battery fluid will not freeze. The battery should be

stored only in a fully charged condition.

AUTOMATIC TRANSAXLE

The automatic transaxle should be maintained and ser-

viced by an authorized dealer to obtain the best perfor-

mance and maximize life. It is important that the trans-

axle fluid be maintained at the level prescribed.

M05A0530

Good

MAINTENANCE 325

9

Page 326 of 394

To check the fluid level

The fluid level should be checked when the engine

temperature gauge indicates a normal warmed up con-

dition and the fluid in the transaxle is heated to its

normal operating temperature. Operation with an im-

proper fluid level will greatly reduce the life of the

transaxle and the fluid.

Procedure for checking the fluid level

1. With the parking brake engaged and the engine idling,

select each gear momentarily, ending with the selector

lever in the ªNº (NEUTRAL) position.

2. The fluid level should be at the HOT mark, but never

above the HOT mark when the engine is at its normal

warmed up condition. Add or drain as necessary to bring

the fluid to this prescribed level.

3. Make certain that the dipstick cap is reseated properly

to prevent dirt and water from entering the transaxle.

WARNING!

Transaxle fluid is extremely flammable and poison-

ous. Do not spill fluid when adding or draining.

To add or change the fluid

Use only recommended Mopar ATF+4 automatic trans-

mission fluid to ensure optimum transaxle performance.

M05A0460

Drain plug

326 MAINTENANCE

Page 327 of 394

Special additives

DaimlerChrysler does not recommend the addition of

any fluid additives to the transaxle.

MANUAL TRANSAXLE

Add oil to maintain the proper level. Refill or change oil

according to the scheduled maintenance table.

Lubricant Gear Oil Classification GL-4

Viscosity range SAE75W-90 or 75W-85W

DISC BRAKE PADS, REAR DRUM BRAKE

LININGS AND REAR WHEEL CYLINDERS

Proper brakes are essential to safe operation of your

vehicle. Check brake pads and rear brake linings for

wear, and check rear wheel cylinders for leakage.

For proper braking performance, replace brake pads with

original equipment type pads.

BRAKE HOSES

Brake hoses and tubing should be checked for:

1. Severe surface cracking, scuffing or worn spots. If the

casing of the hose is exposed by cracks or abrasions in therubber hose cover, the hose should be replaced. Deterio-

ration of the hose could cause brake failure.

2. Faulty installation may cause twisting, or wheel, tire

or chassis interference.

BALL JOINT, STEERING LINKAGE SEAL AND

DRIVE SHAFT BOOTS

Check the following parts for damage and grease leak-

age:

1. Ball joint boots of the front suspension and steering

linkage

2. Bellows on both ends of the drive shaft

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

The entire SRS system must be inspected by an autho-

rized dealer 10 years after the vehicle manufacture date

shown on the certification label. [See ªSRS servicingº on

page 100.]

MAINTENANCE 327

9

Page 328 of 394

HOOD LOCK RELEASE MECHANISM AND

SAFETY CATCH

The hood lock release mechanism and hood safety catch

should be inspected, cleaned, and lubricated as required

to maintain ease of operation and to provide protection

against rust and wear. Apply Multipurpose Grease NLGI

Grade 2 sparingly to all sliding contact areas of the hood

latch and release lever. Work lubricant into the hood lock

mechanism until all frictional surfaces are covered.

Also, apply a film of the same lubricant to the pivot

contact areas of the safety catch.

EXHAUST SYSTEM

WARNING!

Carbon monoxide gas found in the vehicle's exhaust

is poisonous. Inhalation of exhaust fumes can cause

unconsciousness or death.

The best protection against carbon monoxide entry into

the vehicle interior is a properly maintained engine

exhaust system.Whenever a change is noticed in the sound of the exhaust

system; when exhaust fumes can be detected inside the

vehicle; or when the underside or rear of the vehicle is

damaged, have a competent technician inspect the com-

plete exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts.

In addition inspect the exhaust system each time the

vehicle is raised for lubrication or oil change. Replace as

required.

Open seams or loose connections could permit danger-

ous exhaust fumes to seep into the trunk and passenger

compartments.

Do this service when performing underbody service.

Check for any of the following conditions:

1. Check for holes or exhaust gas leakage caused by

corrosion or damage.

2. Check the joints and connections for looseness or

exhaust gas leakage.

3. Check the rubber hangers and brackets for damage.

328 MAINTENANCE

Page 329 of 394

WINDSHIELD WIPER BLADES

Check the wiper blades occasionally. Periodic cleaning of

the wiper blades is suggested to remove the accumula-

tion of salt and road film. The wiper blade arms and glass

areas should be cleaned with a sponge or cloth and a

mild detergent or non-abrasive cleaner.

If the blades continue to streak or smear, they should be

replaced.

NOTE: Do not operate wipers for long periods on dry

glass; this accelerates deterioration of the rubber and

could scratch the glass.

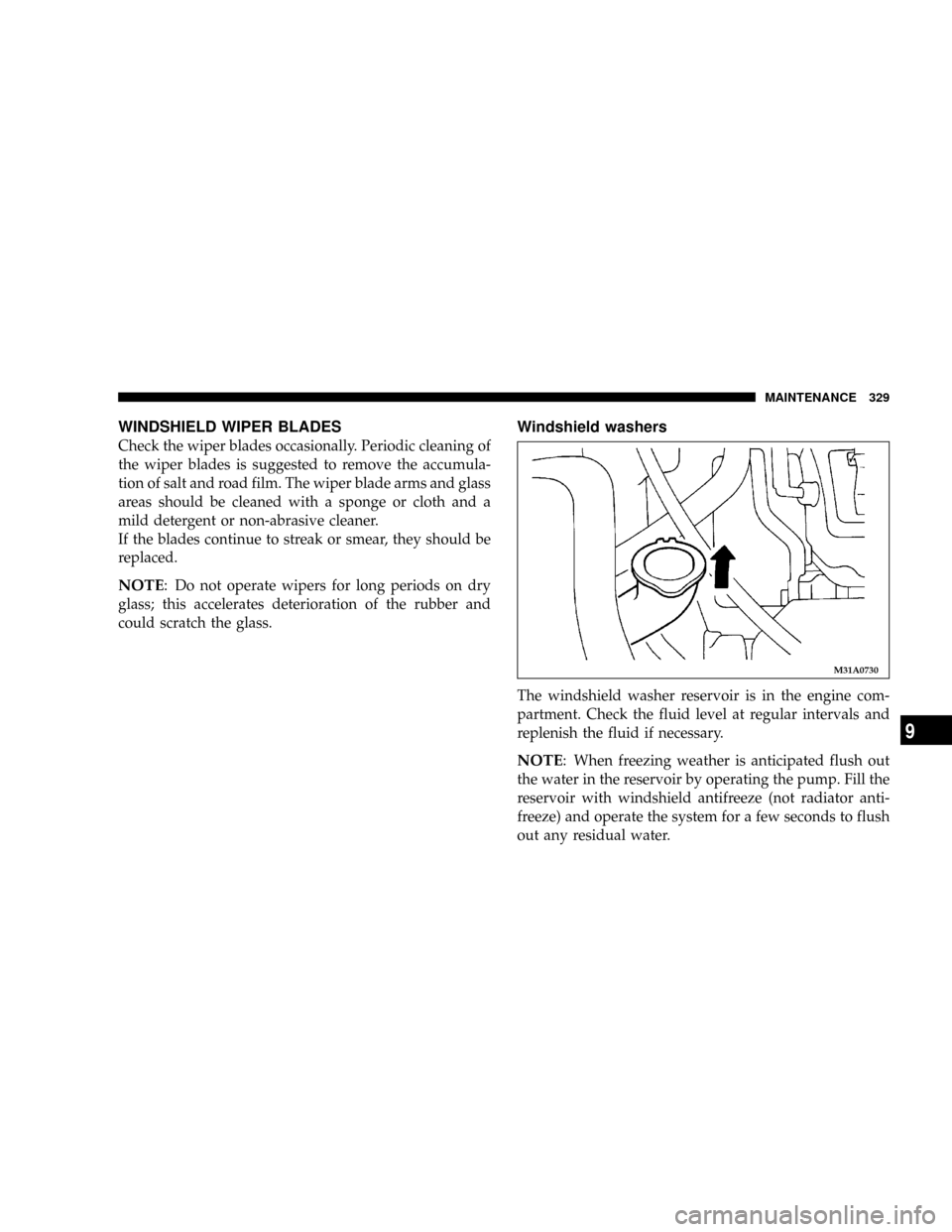

Windshield washers

The windshield washer reservoir is in the engine com-

partment. Check the fluid level at regular intervals and

replenish the fluid if necessary.

NOTE: When freezing weather is anticipated flush out

the water in the reservoir by operating the pump. Fill the

reservoir with windshield antifreeze (not radiator anti-

freeze) and operate the system for a few seconds to flush

out any residual water.

M31A0730

MAINTENANCE 329

9

Page 330 of 394

PARKING BRAKE

Check the parking brake lever travel occasionally. To

check, pull the lever slowly and count the number of

clicks of the ratchet.

For vehicles with rear drum brakes:

You should feel the parking brake take hold between 5 to

7 clicks.For vehicles with rear disc brakes:

You should feel the parking brake take hold between 3 to

5 clicks. Also check to see if the lever is properly engaged

with the ratchet, when pulled.

I27A0100

330 MAINTENANCE