CHRYSLER SEBRING COUPE 2005 2.G Owners Manual

Manufacturer: CHRYSLER, Model Year: 2005, Model line: SEBRING COUPE, Model: CHRYSLER SEBRING COUPE 2005 2.GPages: 394, PDF Size: 2.47 MB

Page 301 of 394

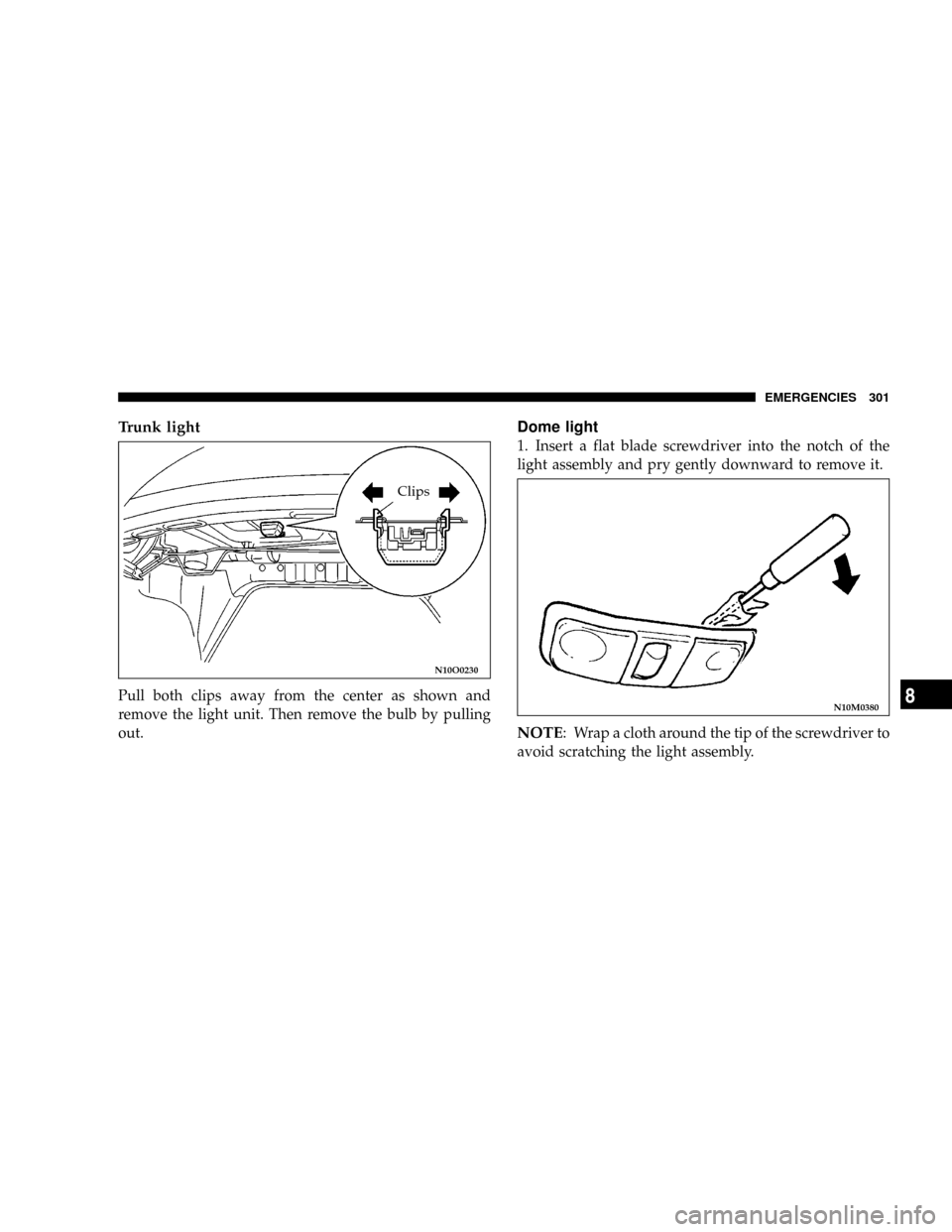

Trunk light

Pull both clips away from the center as shown and

remove the light unit. Then remove the bulb by pulling

out.

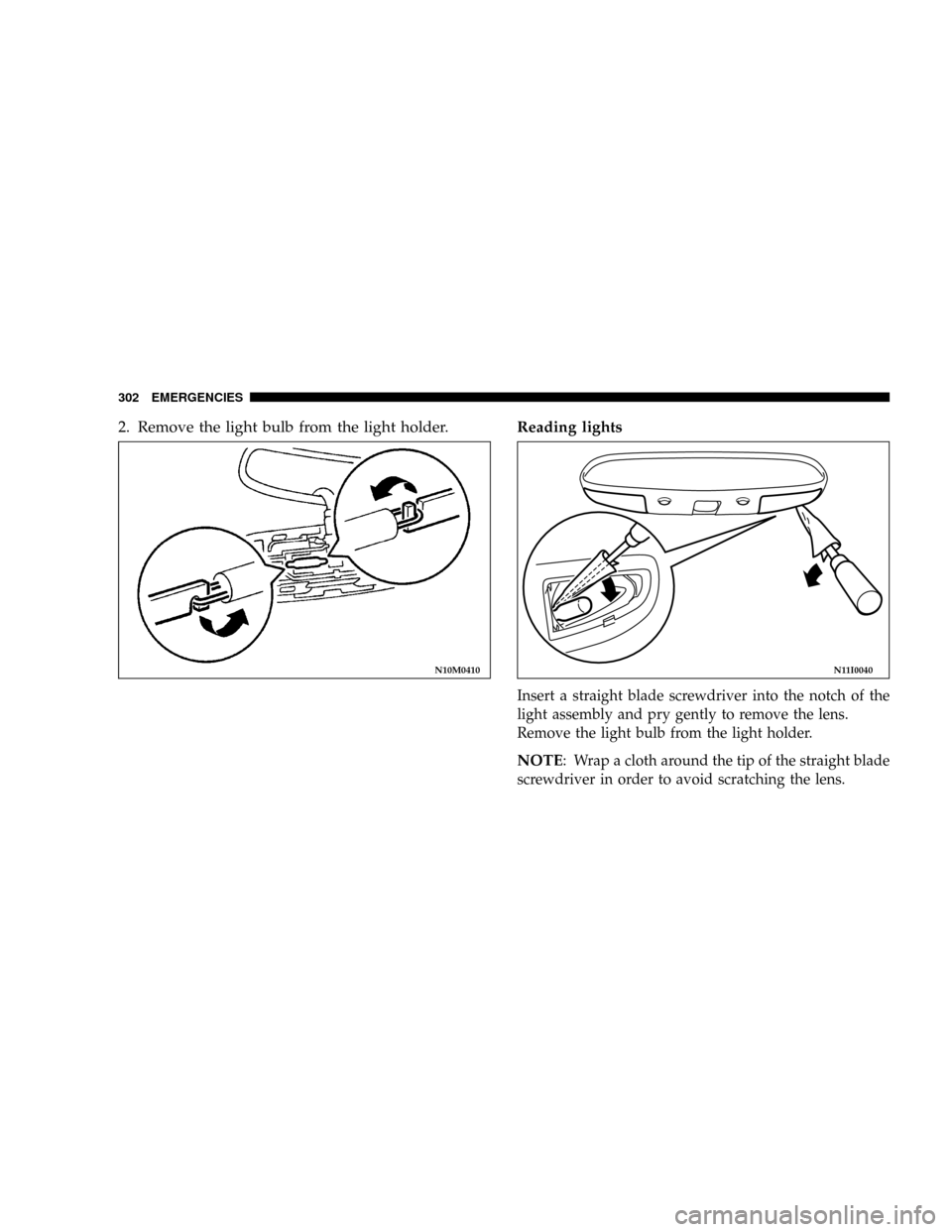

Dome light

1. Insert a flat blade screwdriver into the notch of the

light assembly and pry gently downward to remove it.

NOTE: Wrap a cloth around the tip of the screwdriver to

avoid scratching the light assembly.

N10O0230

Clips

N10M0380

EMERGENCIES 301

8

Page 302 of 394

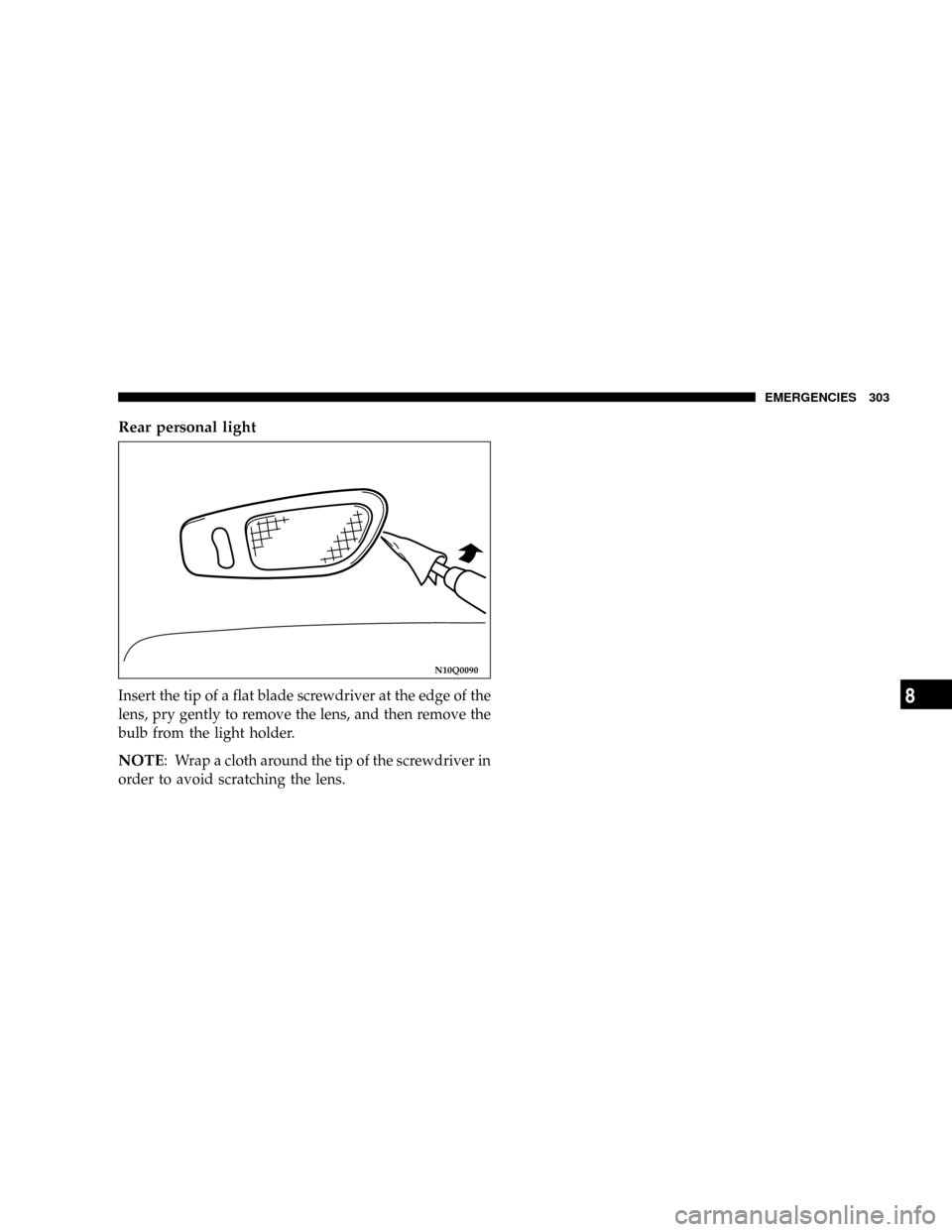

2. Remove the light bulb from the light holder.Reading lights

Insert a straight blade screwdriver into the notch of the

light assembly and pry gently to remove the lens.

Remove the light bulb from the light holder.

NOTE: Wrap a cloth around the tip of the straight blade

screwdriver in order to avoid scratching the lens.

N10M0410N11I0040

302 EMERGENCIES

Page 303 of 394

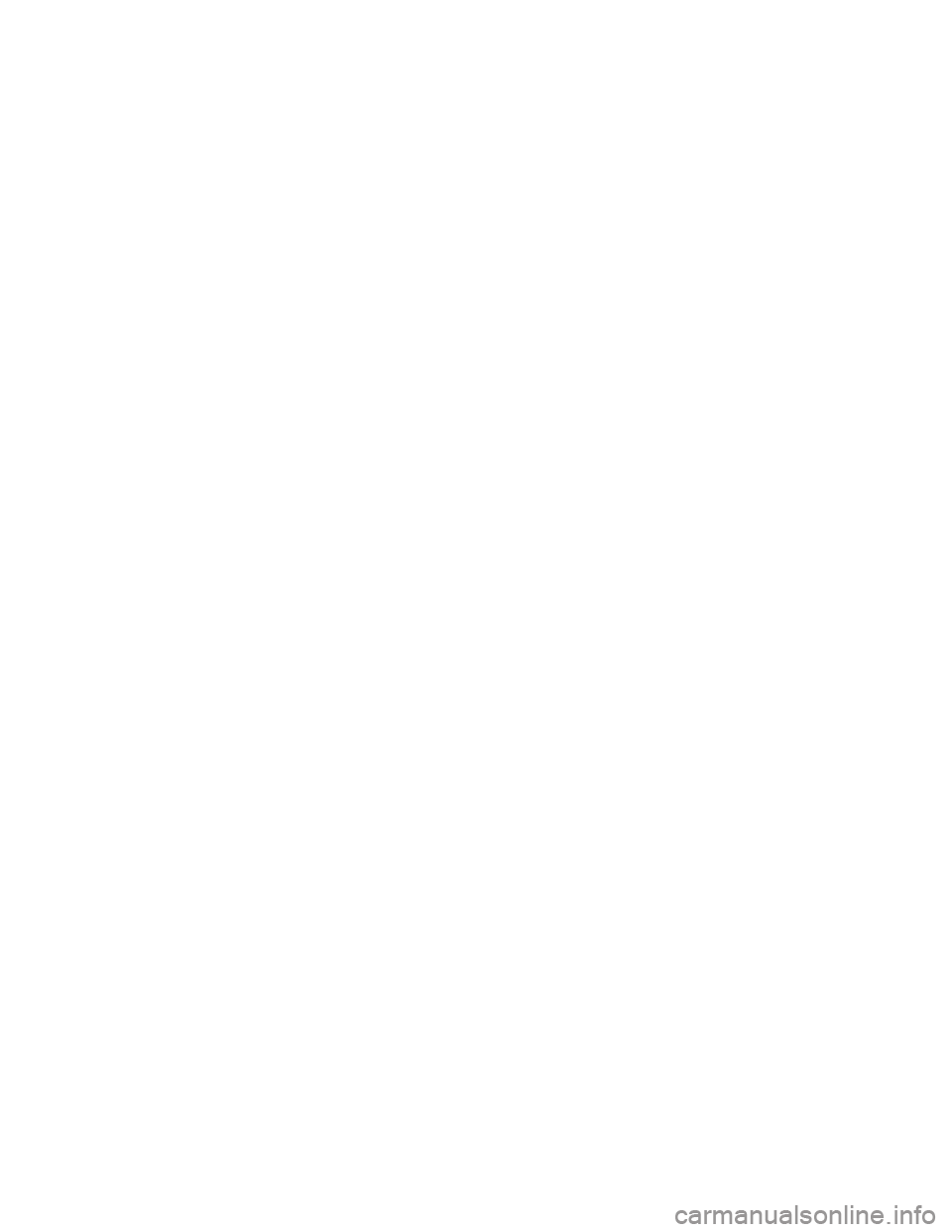

Rear personal light

Insert the tip of a flat blade screwdriver at the edge of the

lens, pry gently to remove the lens, and then remove the

bulb from the light holder.

NOTE: Wrap a cloth around the tip of the screwdriver in

order to avoid scratching the lens.

N10Q0090

EMERGENCIES 303

8

Page 304 of 394

Page 305 of 394

MAINTENANCE

CONTENTS

mView of engine compartment..............307

mService precautions.....................308

mEmission-control system maintenance.......309

mEmissions Testing......................310

mOnboard Diagnostic System (OBD II)........310

mReplacement Parts......................311

NFuel system (tank, filler tube, connections,

and fuel tank filler cap).................311

NFuel hoses...........................311

NAir cleaner filter......................312

NEvaporative emission control system

(except evaporative emission canister).......312

NSpark plugs..........................313

NIgnition cables........................313NDistributor cap and rotor................313

mGeneral maintenance....................314

NEngine oil and oil filter..................314

mEngine coolant.........................318

NTo check the coolant level................318

NTo add coolant........................318

mBrake fluid...........................319

mClutch fluid (manual transaxle)............320

NTo check the clutch fluid.................320

NTo replace the fluid....................320

mBattery..............................321

NDuring cold weather...................323

9

Page 306 of 394

NDisconnection and connection.............323

mAutomatic transaxle.....................325

NTo check the fluid level..................326

NProcedure for checking the fluid level.......326

mManual transaxle.......................327

mDisc brake pads, rear drum brake linings

and rear wheel cylinders.................327

mBrake hoses...........................327

mBall joint, steering linkage seal and drive

shaft boots...........................327

mSupplemental Restraint System (SRS)........327

mHood lock release mechanism and safety

catch

................................328

mExhaust system........................328

mWindshield wiper blades.................329

NWindshield washers....................329

mParking brake.........................330

mDrive belt (for generator, water pump, power

steering pump)

........................331

mTiming belt...........................332

mTi re s................................332

NTire inflation pressures..................336

NRadial ply tires.......................337

N

Tire pressure for sustained high-speed driving...338

NReplacing tire and wheels................338

NTire maintenance......................338

NCargo loads..........................343

NTread wear indicators...................343

NTire rotation.........................344

NTire chains...........................345

NSnow tires...........................345

mRegular Maintenance Schedule.............346

mSevere Maintenance Schedule..............354

306 MAINTENANCE

Page 307 of 394

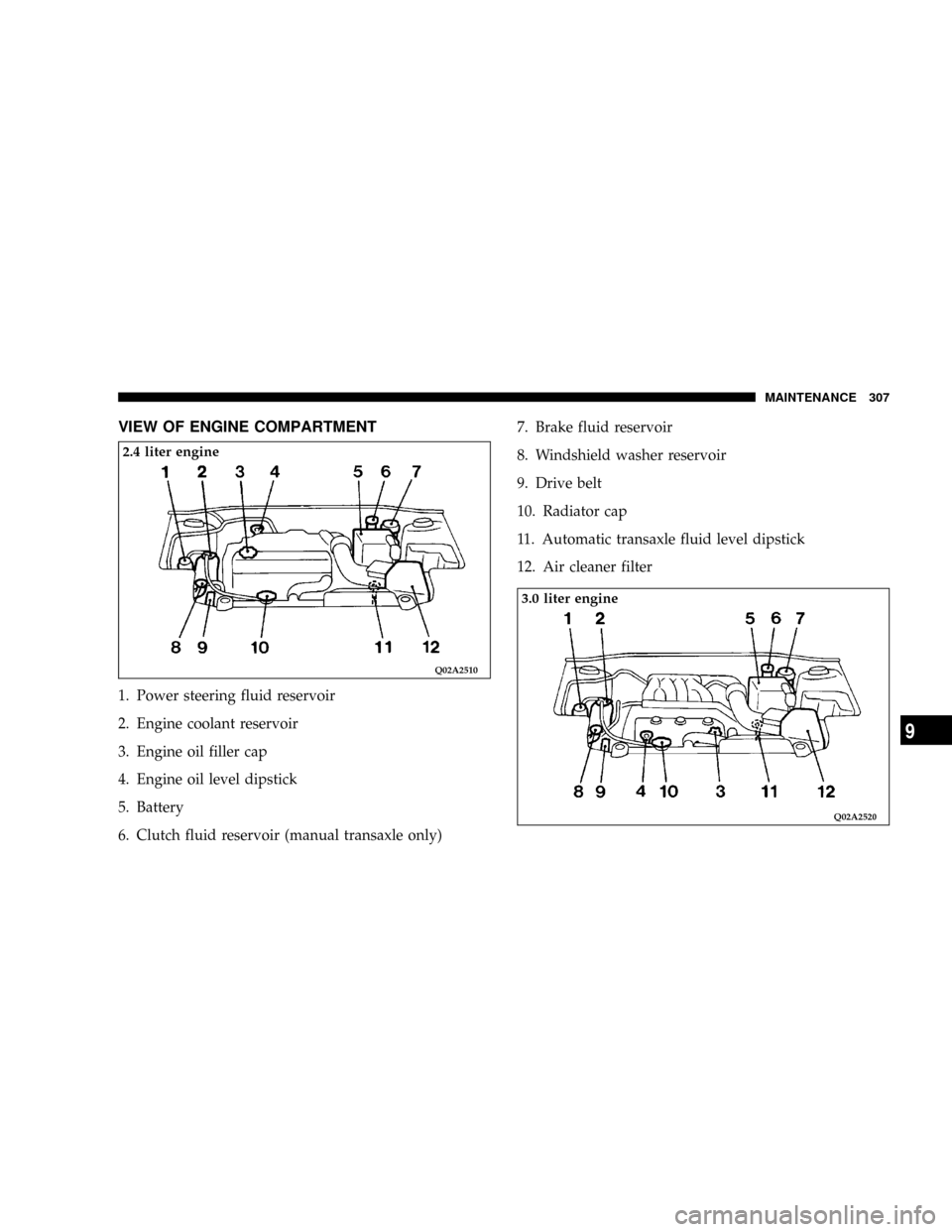

VIEW OF ENGINE COMPARTMENT

1. Power steering fluid reservoir

2. Engine coolant reservoir

3. Engine oil filler cap

4. Engine oil level dipstick

5. Battery

6. Clutch fluid reservoir (manual transaxle only)7. Brake fluid reservoir

8. Windshield washer reservoir

9. Drive belt

10. Radiator cap

11. Automatic transaxle fluid level dipstick

12. Air cleaner filter

Q02A2510

2.4 liter engine

Q02A2520

3.0 liter engine

MAINTENANCE 307

9

Page 308 of 394

NOTE: The Scheduled Maintenance Charts are located

in the rear of this maintenance section. Always refer to

the schedules for proper service intervals.

SERVICE PRECAUTIONS

Adequate care of your vehicle at regular intervals serves

to preserve the value and appearance as long as possible.

Some maintenance items can be performed by the owner,

while others should be done only by an authorized

dealer.

This section describes only those items which can be

performed by the owner. In the event a malfunction or

other problem is discovered, have it corrected by an

authorized dealer.

This section contains information on inspection mainte-

nance procedures that you can do yourself, if you so

desire. Follow the instructions and precautions for each

of the various procedures.

WARNING!

²When checking or servicing the inside of the

engine compartment, be sure the engine is

stopped and has had a chance to cool down.

²If it is necessary to do work in the engine com-

partment with the engine running, be especially

careful that your clothing, hair, etc. does not

become caught by the fan, drive belts, or other

moving parts.

308 MAINTENANCE

Page 309 of 394

WARNING!

²The fan may turn on automatically even if the

engine is not running; turn the ignition key to the

ªLOCKº position and remove the key to ensure

safety while you work in the engine compartment.

²Do not smoke, or allow open flames around fuel

or the battery. The fumes are flammable.

²Be extremely cautious when working around the

battery. It contains poisonous and corrosive sulfu-

ric acid.

²Do not get under your vehicle with just the car's

jack supporting it.

Always use properly rated automotive jack

stands.

²Improper handling of components and materials

used in the vehicle can endanger your personal

safety. Consult an authorized dealer if you have

questions.

EMISSION-CONTROL SYSTEM MAINTENANCE

Your vehicle is equipped with an emission-control sys-

tem which satisfies all requirements of the U.S. Environ-

mental Protection Agency. The emission-control system

consists of:

(1) a positive crankcase ventilation system

(2) an evaporative emission-control system

(3) an exhaust emission- control system.

The9Scheduled9maintenance services listed must be

performed at the times or mileages specified to assure the

continued proper functioning of the emission-control

system. These, and all other ªGeneralº maintenance

services included in this manual, should be performed to

provide the best vehicle performance and reliability.

More frequent maintenance may be needed for vehicles

driven under severe operating conditions such as dusty

areas and frequent start and stop driving.

In order to assure the proper function of the emission-

control system, it is recommended that you have your

vehicle inspected and maintained by an authorized

dealer in accordance with the schedule in this manual.

Inspection and service should also be performed any

time a malfunction is suspected.

MAINTENANCE 309

9

Page 310 of 394

EMISSIONS TESTING

In some localities, it may be or will become a legal

requirement to ensure that all emissions components and

systems are functioning properly as a part of the test

procedure. The test center accomplishes this by checking

the On Board Diagnostic System system (OBD) with an

electronic scan tool. If your vehicle has recently been

serviced, the OBD system may have been reset to a9not

ready9condition because the OBD system has not had

sufficient time since the servicing to reconfirm that

emissions components are operating properly. In most

cases, a reasonable mix and amount of normal city and

highway driving and at least one overnight-off period

will be required to prepare your vehicle for this check;

however your DaimlerChrysler Motors Corporation

dealer has the equipment and procedures required to

make certain that the OBD system of your vehicle is

ready for the required testing.

ONBOARD DIAGNOSTIC SYSTEM (OBD II)

To meet new government regulations and promote

cleaner air, your vehicle is equipped with a sophisticated

onboard diagnostic system called OBD II. This systemmonitors the performance of the emissions, engine, and

automatic transaxle control systems. When these systems

are operating properly, your vehicle will provide excel-

lent performance and fuel economy, as well as engine

emissions well within current government regulations.

If any of these systems require service, the

OBD II system will turn on the Malfunction

Indicator Light. It will also store diagnostic

codes and other information to assist your

service technician in making repairs. Al-

though your vehicle will usually be driveable and not

need towing, see your dealer for service as soon as

possible.

CAUTION!

Prolonged driving with the light on could cause

further damage to the emission control system. It

could also affect fuel economy and driveability. The

vehicle must be serviced before any state emissions

tests can be performed.

310 MAINTENANCE