check engine CHRYSLER TOWN AND COUNTRY 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: TOWN AND COUNTRY, Model: CHRYSLER TOWN AND COUNTRY 2002Pages: 2399, PDF Size: 57.96 MB

Page 1350 of 2399

INSPECTION

Check manifold for:

²Damage and cracks.

²Mounting surface distortion by using a straight-

edge and thickness gauge.

INSTALLATION - UPPER INTAKE MANIFOLD

(1) If the following components were removed from

manifold, install and tighten to specifications:

CAUTION: The special screws used for the compos-

ite manifold attached components must be installed

slowly using hand tools only. This requirement is to

prevent the melting of material that causes stripped

threads. If threads become stripped, an oversize

repair screw is available. For more information and

procedure (Refer to 9 - ENGINE/MANIFOLDS/IN-

TAKE MANIFOLD - STANDARD PROCEDURE - MAN-

IFOLD STRIPPED THREAD REPAIR).²MAP sensor - 1.7 N´m (15 in. lbs.)

²Throttle cable bracket - 5.6 N´m (50 in. lbs.)

(2) Remove covering on lower intake manifold and

clean surfaces.

(3) Inspect manifold gasket condition. Gaskets can

be re-used, if not damaged. To replace, remove gasket

from upper manifold (Fig. 123). Position new gasket

in seal channel and press lightly in-place. Repeat

procedure for each gasket position.

(4) Position upper manifold on lower manifold (Fig.

123). Install and tighten bolts to 12 N´m (105 in. lbs.)

following torque sequence in (Fig. 124).

(5) Connect the MAP sensor electrical connector.

(6) Connect the brake booster and LDP vacuum

hose to intake manifold (Fig. 122).

CAUTION: The special screws used for attaching

the EGR tube and power steering reservoir to the

manifold must be installed slowly using hand tools

only. This requirement is to prevent the melting of

material that causes stripped threads. If threads

become stripped, an oversize repair screw is avail-

able. For more information and procedure (Refer to

9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD - STAN-

DARD PROCEDURE - MANIFOLD STRIPPED

THREAD REPAIR).

(7) Install the power steering reservoir (Fig. 121).

Tighten screws to manifold to 5.6 N´m (50 in. lbs.).

(8) Connect throttle and speed control cables to

throttle body (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/THROTTLE CONTROL CABLE -

INSTALLATION)

(9) Attach make up air hose clip into the hole in

the throttle cable bracket.

(10) Connect the wiring connectors to the throttle

position sensor (TPS) and Automatic Idle Speed (AIS)

motor.

Fig. 123 INTAKE MANIFOLD - UPPER

1 - BOLT

2 - MAP SENSOR

3 - SCREW

4 - MANIFOLD - UPPER

5 - WIRE HARNESS

6 - GASKET (3 PER CYL. BANK)

Fig. 124 UPPER MANIFOLD TIGHTENING

SEQUENCE

RSENGINE 3.3/3.8L9 - 149

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1351 of 2399

(11) Install air cleaner and air inlet hose assembly.

(12) Connect the inlet air temperature (IAT) sen-

sor electrical connector.

(13) Connect battery negative cable.

INTAKE MANIFOLD - LOWER

REMOVAL - LOWER INTAKE MANIFOLD

(1) Perform fuel system pressure release procedure

(before attempting any repairs).(Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE)

(2) Drain the cooling system. (Refer to 7 - COOL-

ING - STANDARD PROCEDURE)

(3) Remove the upper intake manifold. (Refer to 9

- ENGINE/MANIFOLDS/INTAKE MANIFOLD -

REMOVAL)

(4) Remove the fuel line. (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL LINES - STANDARD

PROCEDURE) (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/QUICK CONNECT FITTING - STAN-

DARD PROCEDURE)

(5) Remove ignition coil and bracket (Fig. 125).

(6) Disconnect heater supply hose and engine cool-

ant temperature sensor (Fig. 126).

(7) Disconnect the fuel injector wire harness.

(8) Remove the fuel injectors and rail assembly

(Fig. 125).

(9) Remove radiator upper hose.

(10) Remove the intake manifold bolts.

(11) Remove lower intake manifold (Fig. 127).

WARNING: INTAKE MANIFOLD GASKET IS MADE

OF VERY THIN METAL AND MAY CAUSE PER-

SONAL INJURY, HANDLE WITH CARE.

(12) Remove intake manifold seal retainers screws

(Fig. 127). Remove intake manifold gasket.

(13) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSPECTION) (Refer to 9 - ENGINE/MANIFOLDS/

INTAKE MANIFOLD - CLEANING)

CLEANING

(1) Discard gasket(s).

(2) Clean all sealing surfaces.

INSPECTION

Check for:

²Damage and cracks of each section.

²Clogged water passages in end cross-overs (if

equipped).

²Check for cylinder head mounting surface distor-

tion using a straightedge and thickness gauge. (Refer

to 9 - ENGINE/CYLINDER HEAD - INSPECTION)

INSTALLATION - LOWER INTAKE MANIFOLD

(1) Place a bead (approximately 1/4 in. diameter)

of MopartEngine RTV GEN II onto each of thefour

manifold to cylinder head gasket corners (Fig. 128).

(2) Carefully install the new intake manifold gas-

ket (Fig. 127). Tighten end seal retainer screws to 12

N´m (105 in. lbs.).

(3) Install lower intake manifold (Fig. 127). Install

the bolts and torque to 1 N´m (10 in. lbs.). Then

torque bolts to 22 N´m (200 in. lbs.) in sequence

shown in (Fig. 129). Then torque again to 22 N´m

(200 in. lbs.). After intake manifold is in place,

inspect to make sure seals are in place.

(4) Install the fuel injectors and rail assembly.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

FUEL RAIL - INSTALLATION)

(5) Connect fuel injector electrical harness.

Fig. 125 FUEL RAIL AND IGNITION COIL &

BRACKET

1 - FUEL RAIL

2 - BOLT - FUEL RAIL

3 - NUT - IGNITION COIL

4 - BOLT - IGNITION COIL

5 - IGNITION COIL

6 - BRACKET - IGNITION COIL

7 - STUD - IGNITION COIL

8 - SEPARATOR - SPARK PLUG CABLE

9 - BRACKET - SPARK PLUG CABLE SEPARATOR

10 - BOLT - SEPARATOR BRACKET

11 - BRACKET - SPARK PLUG CABLE SEPARATOR

9 - 150 ENGINE 3.3/3.8LRS

INTAKE MANIFOLD - UPPER (Continued)

ProCarManuals.com

Page 1354 of 2399

INSPECTION

Inspect exhaust manifolds for damage or cracks

and check distortion of the cylinder head mountingsurface and exhaust crossover mounting surface with

a straightedge and thickness gauge (Fig. 134).

Manifold surface flatness limits should not exceed

1.0 mm (0.039 in.).

INSTALLATION

(1) Position exhaust manifold on cylinder head and

install bolts to center runner (cylinder #3) and initial

tighten to 2.8 N´m (25 in. lbs.) (Fig. 133)

(2) Using a new gasket, attach crossover pipe to

exhaust manifold and tighten bolts to 41 N´m (30 ft.

lbs.) (Fig. 130).

NOTE: Inspect crossover pipe fasteners for damage

from heat and corrosion. The cross-over bolts are

made of a special stainless steel alloy. If replace-

ment is required, OEM bolts are highly recom-

mended.

(3) Install the remaining manifold attaching bolts.

Tighten all bolts to 23 N´m (200 in. lbs.).

(4) Position the power steering pump support strut

and install upper bolt (Fig. 131).

(5) Install heat shield and attaching screws (Fig.

133).

(6) Install and connect upstream oxygen sensor

(Fig. 133).

(7) Raise the vehicle.

(8) Attach catalytic converter pipe to exhaust man-

ifold using new gasket and tighten bolts to 37 N´m

(27 ft. lbs.) (Fig. 132).

(9) Connect downstream oxygen sensor connector.

(10) Tighten the power steering pump support

strut lower bolt (Fig. 131).

(11) Install the belt splash shield and lower the

vehicle.

Fig. 132 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

Fig. 133 EXHAUST MANIFOLD - RIGHT

1 - SCREW - HEAT SHIELD

2 - HEAT SHIELD - UPPER

3 - BOLT - EXHAUST MANIFOLD

4 - HEAT SHIELD - LOWER

5 - EXHAUST MANIFOLD - RIGHT

6 - OXYGEN SENSOR - UPSTREAM

Fig. 134 Check Exhaust Manifold Mounting

1 - STRAIGHT EDGE

2 - CROSSOVER PIPE MOUNTING SURFACE

3 - FEELER GAUGE

RSENGINE 3.3/3.8L9 - 153

EXHAUST MANIFOLD - RIGHT (Continued)

ProCarManuals.com

Page 1355 of 2399

(12) Install the wiper module. (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION)

(13) Connect battery negative cable.

EXHAUST MANIFOLD - LEFT

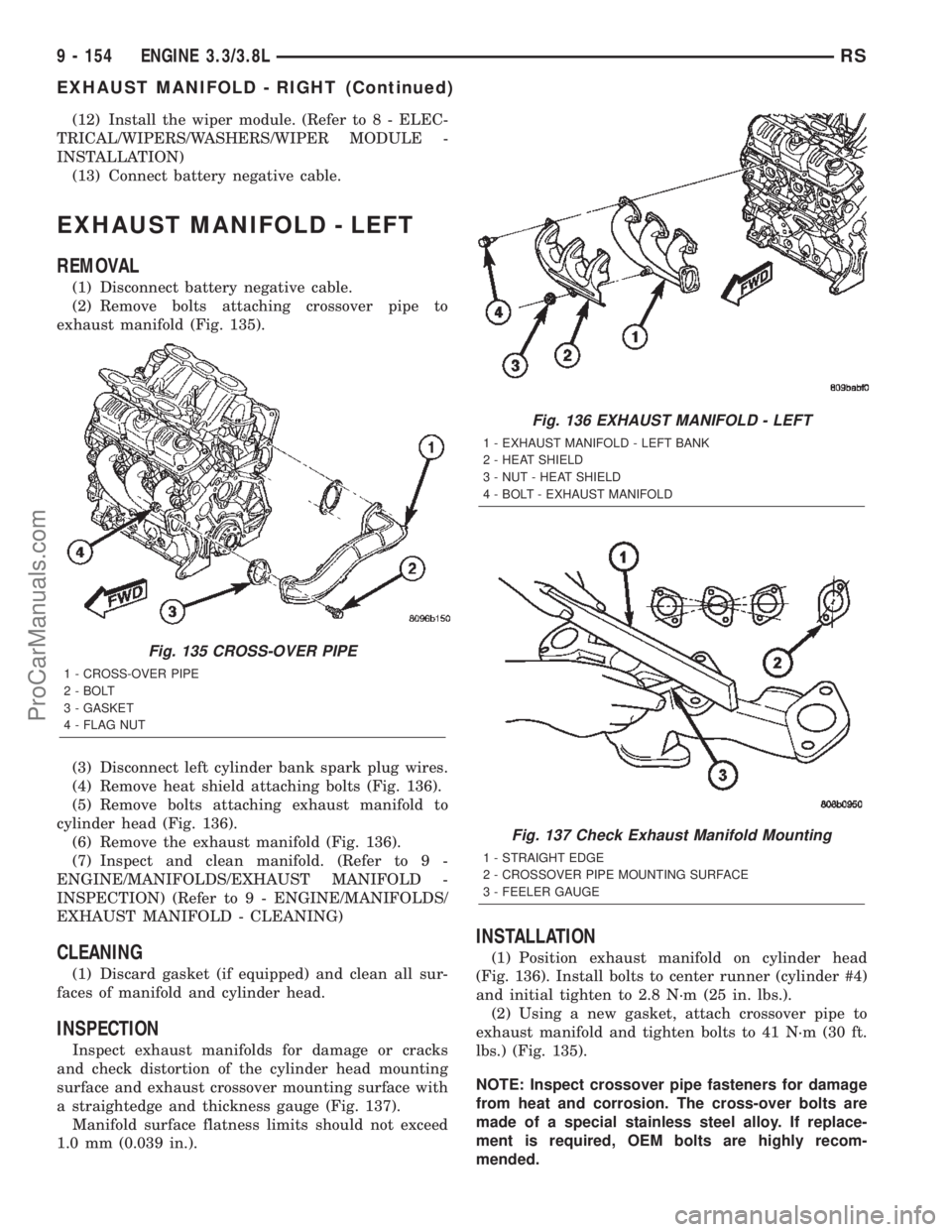

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove bolts attaching crossover pipe to

exhaust manifold (Fig. 135).

(3) Disconnect left cylinder bank spark plug wires.

(4) Remove heat shield attaching bolts (Fig. 136).

(5) Remove bolts attaching exhaust manifold to

cylinder head (Fig. 136).

(6) Remove the exhaust manifold (Fig. 136).

(7) Inspect and clean manifold. (Refer to 9 -

ENGINE/MANIFOLDS/EXHAUST MANIFOLD -

INSPECTION) (Refer to 9 - ENGINE/MANIFOLDS/

EXHAUST MANIFOLD - CLEANING)

CLEANING

(1) Discard gasket (if equipped) and clean all sur-

faces of manifold and cylinder head.

INSPECTION

Inspect exhaust manifolds for damage or cracks

and check distortion of the cylinder head mounting

surface and exhaust crossover mounting surface with

a straightedge and thickness gauge (Fig. 137).

Manifold surface flatness limits should not exceed

1.0 mm (0.039 in.).

INSTALLATION

(1) Position exhaust manifold on cylinder head

(Fig. 136). Install bolts to center runner (cylinder #4)

and initial tighten to 2.8 N´m (25 in. lbs.).

(2) Using a new gasket, attach crossover pipe to

exhaust manifold and tighten bolts to 41 N´m (30 ft.

lbs.) (Fig. 135).

NOTE: Inspect crossover pipe fasteners for damage

from heat and corrosion. The cross-over bolts are

made of a special stainless steel alloy. If replace-

ment is required, OEM bolts are highly recom-

mended.

Fig. 135 CROSS-OVER PIPE

1 - CROSS-OVER PIPE

2 - BOLT

3 - GASKET

4 - FLAG NUT

Fig. 136 EXHAUST MANIFOLD - LEFT

1 - EXHAUST MANIFOLD - LEFT BANK

2 - HEAT SHIELD

3 - NUT - HEAT SHIELD

4 - BOLT - EXHAUST MANIFOLD

Fig. 137 Check Exhaust Manifold Mounting

1 - STRAIGHT EDGE

2 - CROSSOVER PIPE MOUNTING SURFACE

3 - FEELER GAUGE

9 - 154 ENGINE 3.3/3.8LRS

EXHAUST MANIFOLD - RIGHT (Continued)

ProCarManuals.com

Page 1361 of 2399

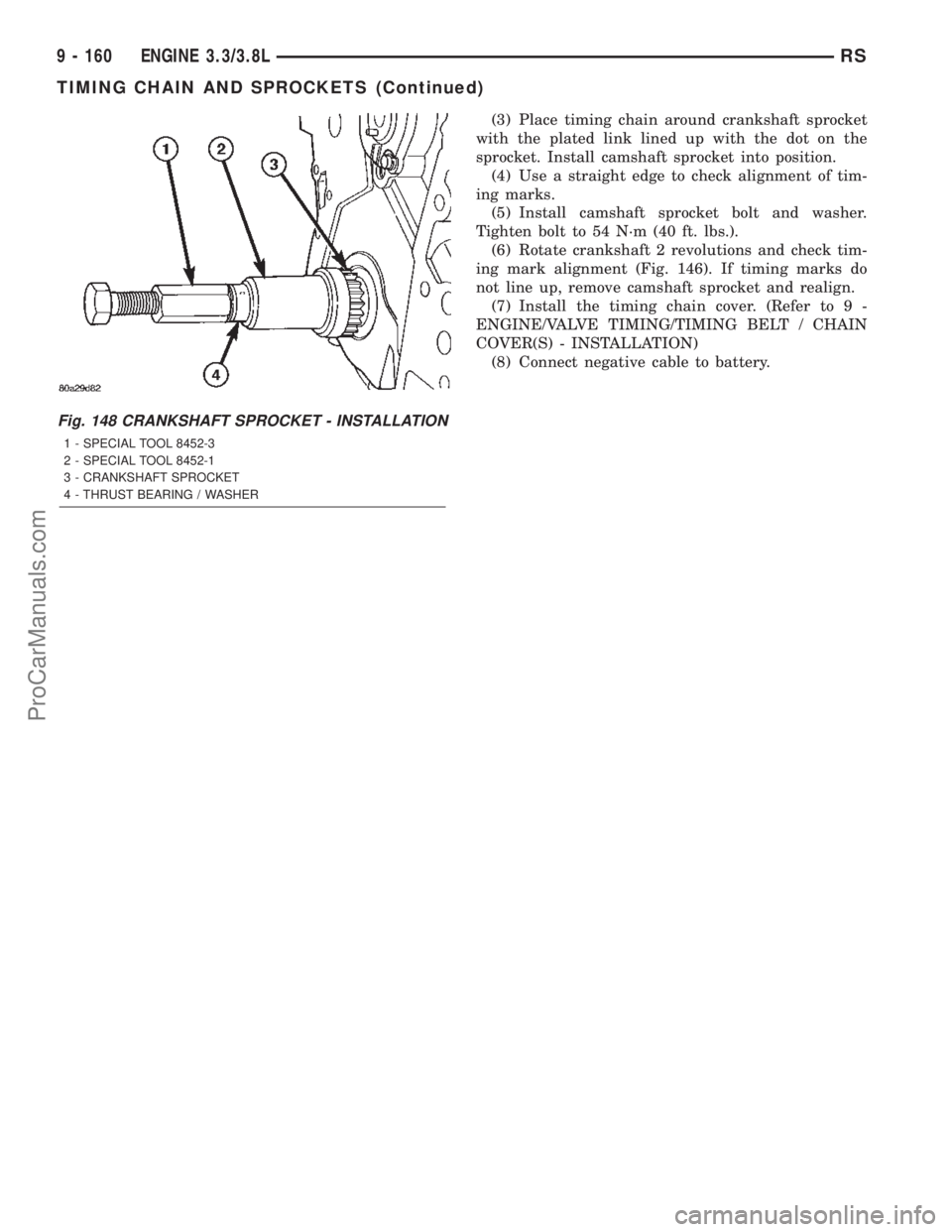

(3) Place timing chain around crankshaft sprocket

with the plated link lined up with the dot on the

sprocket. Install camshaft sprocket into position.

(4) Use a straight edge to check alignment of tim-

ing marks.

(5) Install camshaft sprocket bolt and washer.

Tighten bolt to 54 N´m (40 ft. lbs.).

(6) Rotate crankshaft 2 revolutions and check tim-

ing mark alignment (Fig. 146). If timing marks do

not line up, remove camshaft sprocket and realign.

(7) Install the timing chain cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(8) Connect negative cable to battery.

Fig. 148 CRANKSHAFT SPROCKET - INSTALLATION

1 - SPECIAL TOOL 8452-3

2 - SPECIAL TOOL 8452-1

3 - CRANKSHAFT SPROCKET

4 - THRUST BEARING / WASHER

9 - 160 ENGINE 3.3/3.8LRS

TIMING CHAIN AND SPROCKETS (Continued)

ProCarManuals.com

Page 1362 of 2399

ENGINE

TABLE OF CONTENTS

page page

ENGINE 2.5L TURBO DIESEL

DESCRIPTION

DESCRIPTION - 2.5L COMMON RAIL

DIESEL ENGINE.......................2

DESCRIPTION - ENGINE COVER..........3

REMOVAL

REMOVAL - 2.5L DIESEL ENGINE..........3

REMOVAL - ENGINE COVER.............6

INSTALLATION

INSTALLATION - 2.5L TURBO DIESEL

ENGINE..............................7

INSTALLATION - ENGINE COVER..........7

SPECIFICATIONS

SPECIFICATIONS - 2.5L COMMON RAIL

DIESEL ENGINE.......................8

SPECIFICATIONS - TORQUE............10

SPECIAL TOOLS.......................12

CYLINDER HEAD

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE

SERVICE............................17

STANDARD PROCEDURE - MEASURING

PISTON PROTRUSION.................18

REMOVAL.............................19

CLEANING............................21

INSPECTION..........................21

INSTALLATION.........................21

CAMSHAFT(S)

DESCRIPTION.........................22

OPERATION...........................22

REMOVAL.............................22

INSTALLATION.........................23

CYLINDER HEAD COVER(S)

DESCRIPTION.........................24

REMOVAL.............................24

INSTALLATION.........................25

CAMSHAFT OIL SEAL(S)

REMOVAL.............................27

INSTALLATION.........................27

ROCKER ARMS

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................27

INSTALLATION.........................28

HYDRAULIC LIFTERS

DESCRIPTION.........................29

REMOVAL.............................29

INSPECTION..........................30

INSTALLATION.........................30ENGINE BLOCK

DESCRIPTION.........................30

CRANKSHAFT

DESCRIPTION.........................30

OPERATION...........................30

STANDARD PROCEDURE - CHECKING

CRANKSHAFT END PLAY...............31

REMOVAL.............................31

INSTALLATION.........................32

CYLINDER LINERS

DESCRIPTION.........................33

REMOVAL.............................33

INSPECTION..........................34

INSTALLATION.........................34

INTERNAL VACUUM PUMP

DESCRIPTION.........................35

REMOVAL.............................35

INSTALLATION.........................35

PISTON & CONNECTING ROD

DESCRIPTION.........................36

STANDARD PROCEDURE - PISTON RING

FITTING.............................36

REMOVAL.............................36

INSPECTION..........................38

INSTALLATION.........................39

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................41

INSTALLATION.........................41

VIBRATION DAMPER

REMOVAL.............................42

INSTALLATION.........................42

ENGINE COVER - FRONT

DESCRIPTION.........................43

REMOVAL.............................43

INSTALLATION.........................43

CRANKSHAFT MAIN BEARINGS

REMOVAL.............................44

INSTALLATION.........................45

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................46

INSTALLATION.........................46

OIL PAN

REMOVAL.............................46

INSTALLATION.........................46

OIL PUMP

REMOVAL

REMOVAL...........................47

REMOVAL...........................47

RGENGINE9a-1

ProCarManuals.com

Page 1366 of 2399

(17) Remove battery shield.

(18) Remove charge air cooler outlet hose.

(19) Remove charge air cooler inlet hose (Fig. 6).

(20) Disconnect upper radiator hose at engine (Fig.

7).

(21) Disconnect lower radiator hose at engine (Fig.

7).

(22) Disconnet brake booster vacuum supply hose.

(23) Disconnect heater core return hose at engine.

(24) Disconnect egr solenoid vacuum line at brake

booster check valve.

(25) Disconnect fuel injector, cam sensor, boost

pressure/intake air temp sensor, fuel rail high pres-

sure, and egr solenoid connectors (Fig. 8).

(26) Disconnect generator electrical connectors.

(27) Disconnect coolant temp sensor and glow plug

electrical connectors.

(28) Disconnect injection pump and A/C compres-

sor electrical connectors.

(29) Disconnect starter electrical connectors.

(30) Disconnect ground wires at engine block.

(31) Raise vehicle on hoist.

(32) Disconnect oil temp sensor, oil pressure sen-

sor, engine speed sensor, and vehicle speed sensor

electrical connector (Fig. 9).(33) Remove front wheels.

(34) Remove the suspension cradle assembly (Refer

to 13 - FRAME & BUMPERS/FRAME/ENGINE

CRADLE CROSSMEMBER - REMOVAL).

(35) Remove both axle shaft assemblies (Refer to 3

- DIFFERENTIAL & DRIVELINE/HALF SHAFT -

REMOVAL).

(36) Disconnect the clutch slave cylinder quick dis-

connect line (RHD only)(Refer to 6 - CLUTCH/SLAVE

CYLINDER - REMOVAL).

(37) Disconnect reverse lamp connector.

(38) Disconnect shifter cables at the tranmission

(Refer to 21 - TRANSMISSION/TRANSAXLE/MAN-

UAL/GEAR SHIFT CABLE - REMOVAL).

(39) Disconnect exhaust pipe from the turbo-

charger downpipe and reposition to right side of vehi-

cle.

(40) Disconnect cabin heater coolant line (Refer to

24 - HEATING & AIR CONDITIONING/CABIN

HEATER/HEATER UNIT - REMOVAL).

(41) Remove front engine mount bracket retaining

bolts from lower radiator support

(42) Lower vehicle. Evacuate the A/C system

(Refer to 24 - HEATING & AIR CONDITIONING/

Fig. 6 CHARGE AIR COOLER HOSES

1 - COOLING MODULE

2 - BYPASS HOSE

3 - UPPER RADIATOR HOSE

4 - CHARGE AIR COOLER OULET HOSE

5 - CHARGE AIR COOLER INLET HOSE

6 - LOWER RADIATOR HOSE

7 - CHARGE AIR COOLER

Fig. 7 UPPER AND LOWER RADIATOR HOSES

1 - COOLANT BYPASS HOSE

2 - RADIATOR ASSEMBLY

3 - UPPER RADIATOR HOSE

4 - COOLING FAN

5 - LOWER RADIATOR HOSE

6 - CHARGE AIR COOLER

7 - RADIATOR BRACKET

RGENGINE9a-5

ENGINE 2.5L TURBO DIESEL (Continued)

ProCarManuals.com

Page 1378 of 2399

CYLINDER HEAD

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE SERVICE

This procedure is done with the engine cylinder

head removed from the block.

DISASSEMBLY

(1) Remove the engine cylinder head from the cyl-

inder block. Refer to cylinder head removal and

installation in this section.

(2) Use Valve Spring Compressor Tool and com-

press each valve spring.

(3) Remove the valve locks, retainers, and springs.

(4) Use an Arkansas smooth stone or a jewelers

file to remove any burrs on the top of the valve stem,

especially around the groove for the locks.

(5) Remove the valves, and place them in a rack in

the same order as removed.

VALVE CLEANING

(1) Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

(2) Clean all grime and gasket material from the

engine cylinder head machined gasket surface.

INSPECTION

(1) Inspect for cracks in the combustion chambers

and valve ports.

(2) Inspect for cracks on the exhaust seat.

(3) Inspect for cracks in the gasket surface at each

coolant passage.

(4) Inspect valves for burned, cracked or warped

heads.

(5) Inspect for scuffed or bent valve stems.

(6) Replace valves displaying any damage.

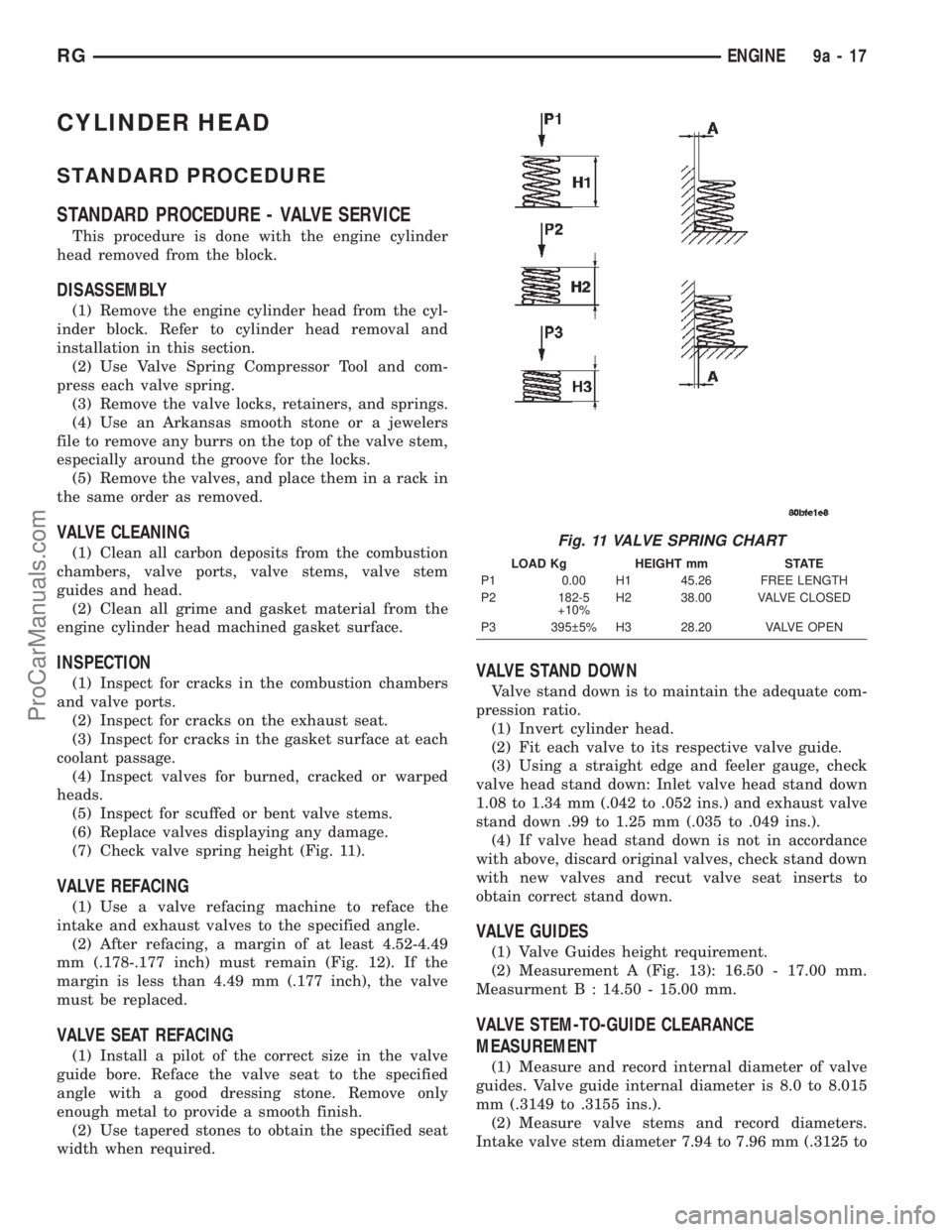

(7) Check valve spring height (Fig. 11).

VALVE REFACING

(1) Use a valve refacing machine to reface the

intake and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 4.52-4.49

mm (.178-.177 inch) must remain (Fig. 12). If the

margin is less than 4.49 mm (.177 inch), the valve

must be replaced.

VALVE SEAT REFACING

(1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified

angle with a good dressing stone. Remove only

enough metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

VALVE STAND DOWN

Valve stand down is to maintain the adequate com-

pression ratio.

(1) Invert cylinder head.

(2) Fit each valve to its respective valve guide.

(3) Using a straight edge and feeler gauge, check

valve head stand down: Inlet valve head stand down

1.08 to 1.34 mm (.042 to .052 ins.) and exhaust valve

stand down .99 to 1.25 mm (.035 to .049 ins.).

(4) If valve head stand down is not in accordance

with above, discard original valves, check stand down

with new valves and recut valve seat inserts to

obtain correct stand down.

VALVE GUIDES

(1) Valve Guides height requirement.

(2) Measurement A (Fig. 13): 16.50 - 17.00 mm.

Measurment B : 14.50 - 15.00 mm.

VALVE STEM-TO-GUIDE CLEARANCE

MEASUREMENT

(1) Measure and record internal diameter of valve

guides. Valve guide internal diameter is 8.0 to 8.015

mm (.3149 to .3155 ins.).

(2) Measure valve stems and record diameters.

Intake valve stem diameter 7.94 to 7.96 mm (.3125 to

Fig. 11 VALVE SPRING CHART

LOAD Kg HEIGHT mm STATE

P1 0.00 H1 45.26 FREE LENGTH

P2 182-5

+10%H2 38.00 VALVE CLOSED

P3 395 5% H3 28.20 VALVE OPEN

RGENGINE9a-17

ProCarManuals.com

Page 1382 of 2399

(23) Remove cylinder head assembly from engine

block (Fig. 18).

CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and

exhaust manifold and engine cylinder head mating

surfaces. Remove all gasket material and carbon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons.

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces.

The minimum cylinder head thickness is 89.95mm

(3.541 in.).

INSTALLATION

CAUTION: Piston protrusion must be measured to

determine cylinder head gasket thickness if one or

more cylinder liners have been replaced (Refer to 9

- ENGINE/CYLINDER HEAD - STANDARD PROCE-

DURE).

NOTE: If cylinder liner(s) have not been removed,

the same thickness head gasket that was removed

can be used.

(1) Clean and inspect gasket mating surfaces.

(2) Position correct head gasket on engine block.

(3) Place cylinder head on engine block (Fig. 18).

CAUTION: New cylinder head bolts must be used.

(4) Tighten cylinder head bolts following procedure

below.

Cylinder Head Bolt Torquing Procedure

(1) Lubricate cylinder head bolts with engine oil.

(2) Torque bolts to 30N´m in numerical starting

with bolt #1 (Fig. 19).

(3) Tighten all bolts an additional 75É, starting

with bolt #4 then 5-6-7-8-9-10-1-2-3 (Fig. 19).

(4) Tighten all bolts an additional 50É in numerical

order starting with bolt #11 then 12-13-14-15-16-

17-18 (Fig. 19).

(5) Without loosening any bolts tighten all bolts an

additional 75É in the following seguence: 4-5-6-7-8-9-

10-1-2-3-11-12-13-14-15-16-17-18.

Fig. 18 CYLINDER HEAD ASSEMBLY

1 - VALVE SPRING

2 - CYLINDER HEAD BOLT

3 - GLOW PLUG

4 - COOLANT TEMPERATURE SENSOR

5 - CYLINDER HEAD ALIGNMENT DOWEL

6 - CYLINDER BLOCK

7 - CYLINDER LINER

8 - ENGINE BLOCK DECK

9 - CYLINDER HEAD GASKET

10 - CYLINDER HEAD

11 - ROCKER ARM AND LIFTER ASSEMBLY

Fig. 19 CYLINDER HEAD TORQUE SEQUENCE

RGENGINE9a-21

CYLINDER HEAD (Continued)

ProCarManuals.com

Page 1384 of 2399

CAUTION: Before removing the cylinder head cover/

intake manifold or timing belt the engine must put

at 90É after TDC. Failure to do so could result in

valve and/or piston damage during reassembly.

(Refer to 9 - ENGINE/VALVE TIMING - STANDARD

PROCEDURE)

(10) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(11) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(12) Remove timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(13) Remove cylinder head cover/intake manifold

(Refer to 9 - ENGINE/CYLINDER HEAD/CYLIN-

DER HEAD COVER(S) - REMOVAL).

(14) With cylinder head cover/intake manifold on

work bench, remove plugs at rear of cylinder head

cover/intake manifold.

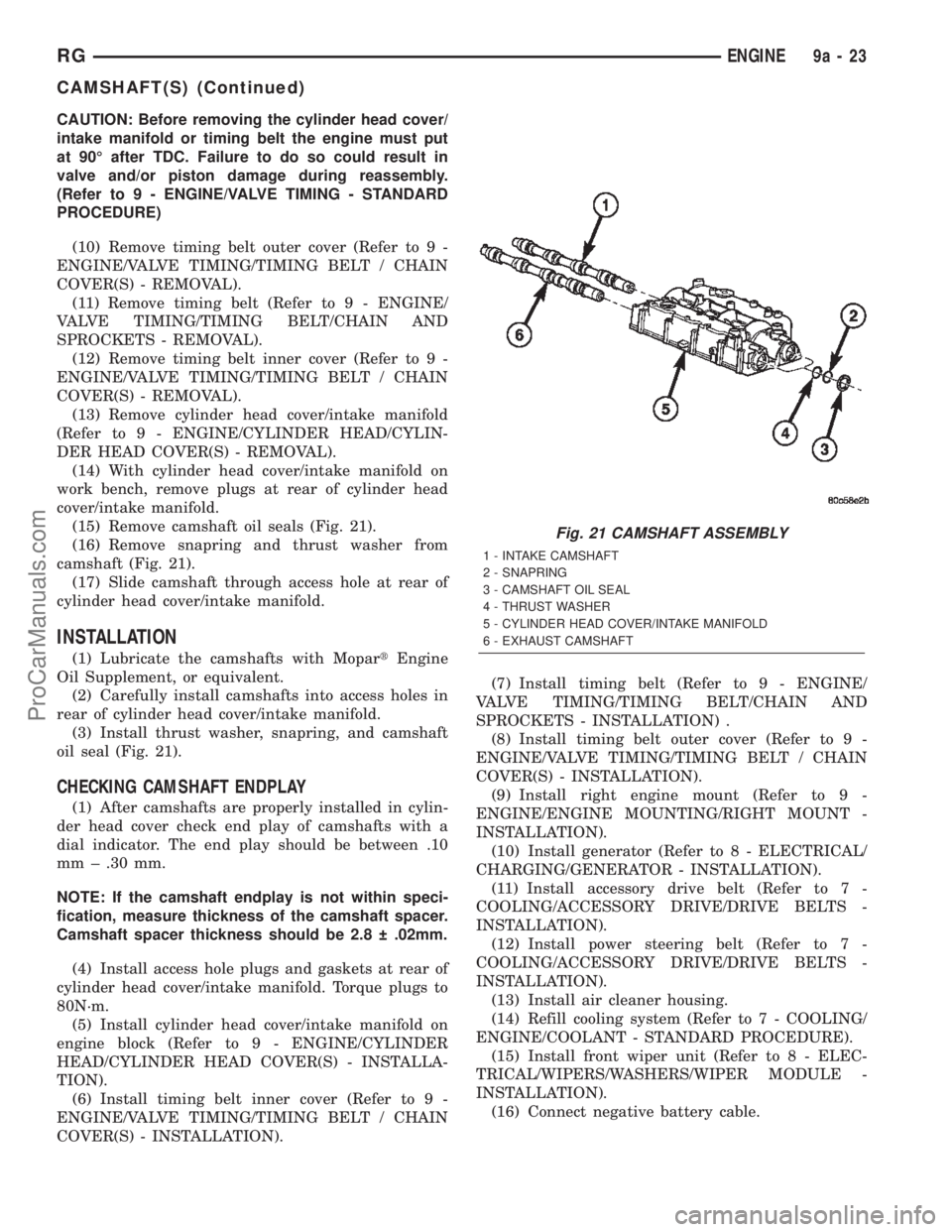

(15) Remove camshaft oil seals (Fig. 21).

(16) Remove snapring and thrust washer from

camshaft (Fig. 21).

(17) Slide camshaft through access hole at rear of

cylinder head cover/intake manifold.

INSTALLATION

(1) Lubricate the camshafts with MopartEngine

Oil Supplement, or equivalent.

(2) Carefully install camshafts into access holes in

rear of cylinder head cover/intake manifold.

(3) Install thrust washer, snapring, and camshaft

oil seal (Fig. 21).

CHECKING CAMSHAFT ENDPLAY

(1) After camshafts are properly installed in cylin-

der head cover check end play of camshafts with a

dial indicator. The end play should be between .10

mm ± .30 mm.

NOTE: If the camshaft endplay is not within speci-

fication, measure thickness of the camshaft spacer.

Camshaft spacer thickness should be 2.8 .02mm.

(4) Install access hole plugs and gaskets at rear of

cylinder head cover/intake manifold. Torque plugs to

80N´m.

(5) Install cylinder head cover/intake manifold on

engine block (Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

(6) Install timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).(7) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(8) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(9) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(10) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(11) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(12) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install air cleaner housing.

(14) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(15) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(16) Connect negative battery cable.

Fig. 21 CAMSHAFT ASSEMBLY

1 - INTAKE CAMSHAFT

2 - SNAPRING

3 - CAMSHAFT OIL SEAL

4 - THRUST WASHER

5 - CYLINDER HEAD COVER/INTAKE MANIFOLD

6 - EXHAUST CAMSHAFT

RGENGINE9a-23

CAMSHAFT(S) (Continued)

ProCarManuals.com