battery replacement CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 91 of 1938

normal. This may indicate:(1)Abnormal loss of

brake fluid in the master cylinder fluid reservoir

resulting from a leak in the hydraulic system.(2)

Brake shoe linings which have worn to a point

requiring replacement.

As the brake fluid drops below the minimum level,

the brake fluid level sensor closes to ground the

brake warning light circuit. This will turn on the red

brake warning light. At this time, master cylinder

fluid reservoir should be checked and filled to the full

mark with DOT 3 brake fluid.If brake fluid level

has dropped below the add line in the master

cylinder fluid reservoir, the entire brake

hydraulic system should be checked for evi-

dence of a leak.

STOP LAMP SWITCH

The stop lamp switch controls operation of the

vehicles stop lamps. Also, if the vehicle is equippedwith speed control, the stop lamp switch will deacti-

vate speed control when the brake pedal is

depressed.

The stop lamp switch controls operation of the

right and left tail, stop and turn signal lamp and

CHMSL lamp, by supplying battery current to these

lamps.

The stop lamp switch controls the lamp operation

by opening and closing the electrical circuit to the

stop lamps.

HUB/BEARING REAR WHEEL

The rear hub and bearing assembly used on this

vehicle is serviceable only as a complete assembly. No

attempt should be made to disassemble a rear hub

and bearing assembly in an effort to repair it.

The rear hub and bearing assembly is attached to

the rear axle using 4 mounting bolts that are remov-

able from the back of the rear hub/bearing.

DIAGNOSIS AND TESTING

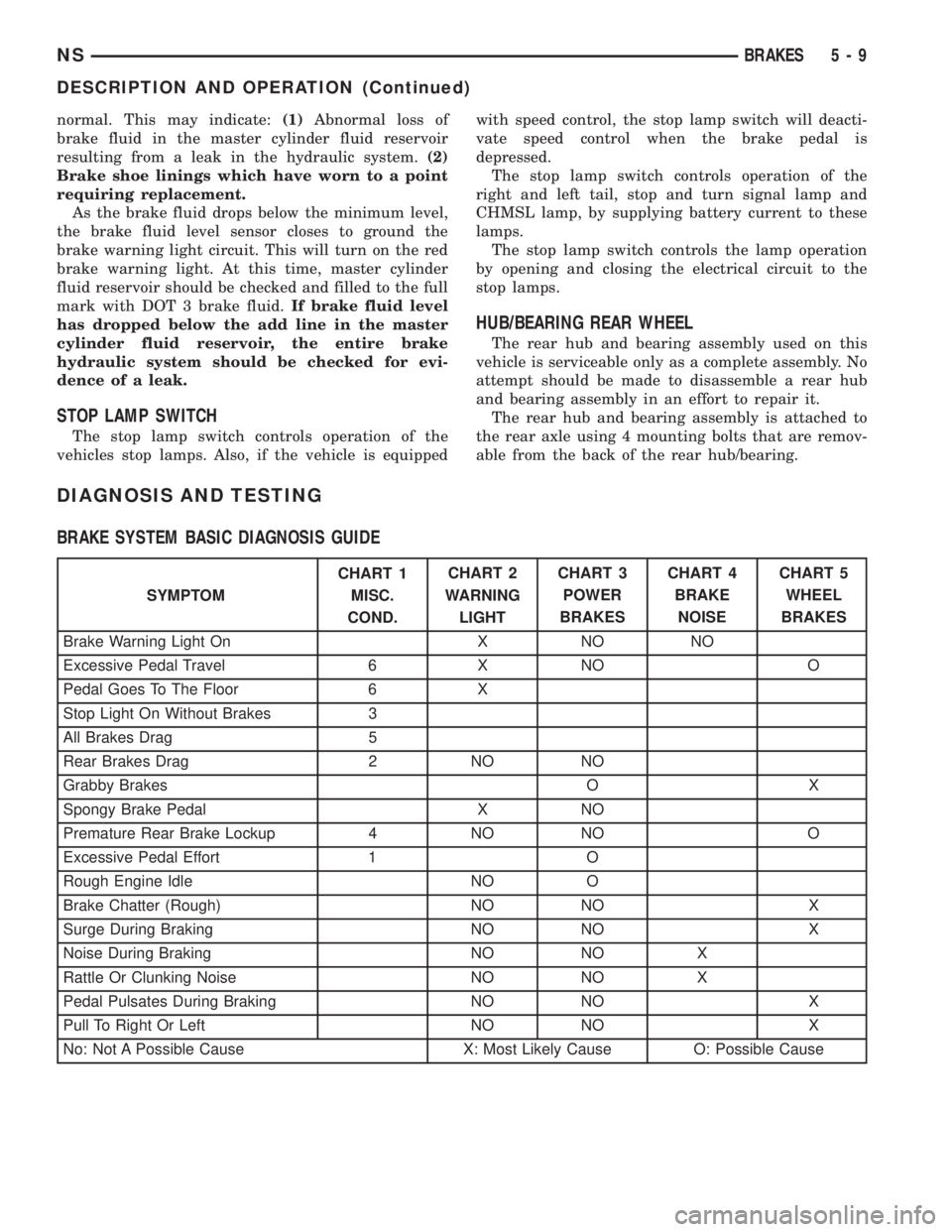

BRAKE SYSTEM BASIC DIAGNOSIS GUIDE

SYMPTOMCHART 1

MISC.

COND.CHART 2

WARNING

LIGHTCHART 3

POWER

BRAKESCHART 4

BRAKE

NOISECHART 5

WHEEL

BRAKES

Brake Warning Light On X NO NO

Excessive Pedal Travel 6 X NO O

Pedal Goes To The Floor 6 X

Stop Light On Without Brakes 3

All Brakes Drag 5

Rear Brakes Drag 2 NO NO

Grabby Brakes O X

Spongy Brake Pedal X NO

Premature Rear Brake Lockup 4 NO NO O

Excessive Pedal Effort 1 O

Rough Engine Idle NO O

Brake Chatter (Rough) NO NO X

Surge During Braking NO NO X

Noise During Braking NO NO X

Rattle Or Clunking Noise NO NO X

Pedal Pulsates During Braking NO NO X

Pull To Right Or Left NO NO X

No: Not A Possible Cause X: Most Likely Cause O: Possible Cause

NSBRAKES 5 - 9

DESCRIPTION AND OPERATION (Continued)

Page 140 of 1938

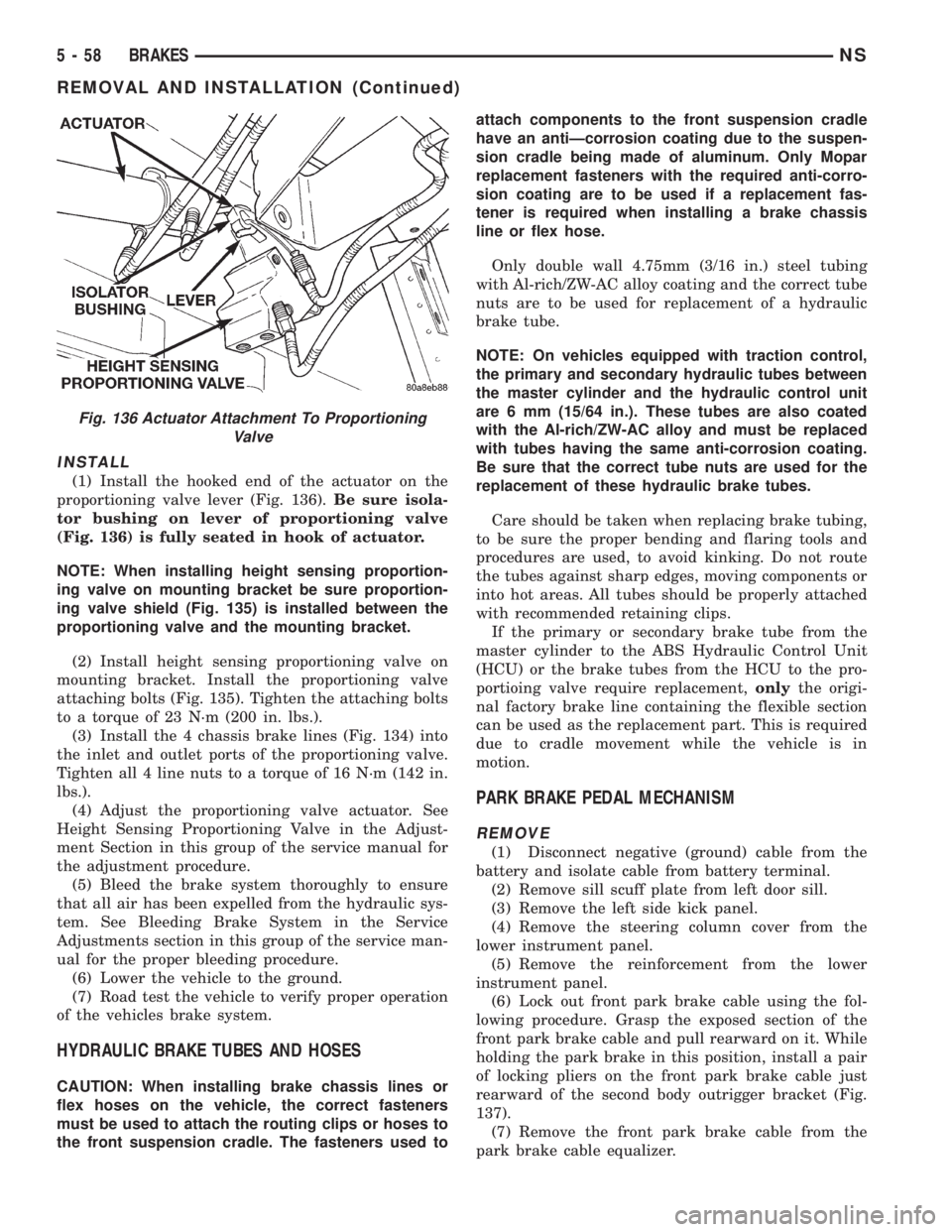

INSTALL

(1) Install the hooked end of the actuator on the

proportioning valve lever (Fig. 136).Be sure isola-

tor bushing on lever of proportioning valve

(Fig. 136) is fully seated in hook of actuator.

NOTE: When installing height sensing proportion-

ing valve on mounting bracket be sure proportion-

ing valve shield (Fig. 135) is installed between the

proportioning valve and the mounting bracket.

(2) Install height sensing proportioning valve on

mounting bracket. Install the proportioning valve

attaching bolts (Fig. 135). Tighten the attaching bolts

to a torque of 23 N´m (200 in. lbs.).

(3) Install the 4 chassis brake lines (Fig. 134) into

the inlet and outlet ports of the proportioning valve.

Tighten all 4 line nuts to a torque of 16 N´m (142 in.

lbs.).

(4) Adjust the proportioning valve actuator. See

Height Sensing Proportioning Valve in the Adjust-

ment Section in this group of the service manual for

the adjustment procedure.

(5) Bleed the brake system thoroughly to ensure

that all air has been expelled from the hydraulic sys-

tem. See Bleeding Brake System in the Service

Adjustments section in this group of the service man-

ual for the proper bleeding procedure.

(6) Lower the vehicle to the ground.

(7) Road test the vehicle to verify proper operation

of the vehicles brake system.

HYDRAULIC BRAKE TUBES AND HOSES

CAUTION: When installing brake chassis lines or

flex hoses on the vehicle, the correct fasteners

must be used to attach the routing clips or hoses to

the front suspension cradle. The fasteners used toattach components to the front suspension cradle

have an antiÐcorrosion coating due to the suspen-

sion cradle being made of aluminum. Only Mopar

replacement fasteners with the required anti-corro-

sion coating are to be used if a replacement fas-

tener is required when installing a brake chassis

line or flex hose.

Only double wall 4.75mm (3/16 in.) steel tubing

with Al-rich/ZW-AC alloy coating and the correct tube

nuts are to be used for replacement of a hydraulic

brake tube.

NOTE: On vehicles equipped with traction control,

the primary and secondary hydraulic tubes between

the master cylinder and the hydraulic control unit

are 6 mm (15/64 in.). These tubes are also coated

with the Al-rich/ZW-AC alloy and must be replaced

with tubes having the same anti-corrosion coating.

Be sure that the correct tube nuts are used for the

replacement of these hydraulic brake tubes.

Care should be taken when replacing brake tubing,

to be sure the proper bending and flaring tools and

procedures are used, to avoid kinking. Do not route

the tubes against sharp edges, moving components or

into hot areas. All tubes should be properly attached

with recommended retaining clips.

If the primary or secondary brake tube from the

master cylinder to the ABS Hydraulic Control Unit

(HCU) or the brake tubes from the HCU to the pro-

portioing valve require replacement,onlythe origi-

nal factory brake line containing the flexible section

can be used as the replacement part. This is required

due to cradle movement while the vehicle is in

motion.

PARK BRAKE PEDAL MECHANISM

REMOVE

(1) Disconnect negative (ground) cable from the

battery and isolate cable from battery terminal.

(2) Remove sill scuff plate from left door sill.

(3) Remove the left side kick panel.

(4) Remove the steering column cover from the

lower instrument panel.

(5) Remove the reinforcement from the lower

instrument panel.

(6) Lock out front park brake cable using the fol-

lowing procedure. Grasp the exposed section of the

front park brake cable and pull rearward on it. While

holding the park brake in this position, install a pair

of locking pliers on the front park brake cable just

rearward of the second body outrigger bracket (Fig.

137).

(7) Remove the front park brake cable from the

park brake cable equalizer.

Fig. 136 Actuator Attachment To Proportioning

Valve

5 - 58 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 182 of 1938

If the brake system is to be bled using pressurized

bleeding equipment, refer to Bleeding Brake System

in the Service Adjustments section at the beginning

of this group for proper equipment usage and proce-

dures.

(1) Assemble and install all brake system compo-

nents on the vehicle making sure all hydraulic fluid

lines are installed and properly torqued.

(2) Connect the DRB Diagnostics Tester to the

diagnostics connector. The Teves Mark 20 ABS diag-

nostic connector is located under the instrument

panel to the left of the steering column cover.

(3) Using the DRB, check to make sure the CAB

does not have any fault codes stored. If it does,

remove them using the DRB.

WARNING: WHEN BLEEDING THE BRAKE SYS-

TEM WEAR SAFETY GLASSES. A CLEAR BLEED

TUBE MUST BE ATTACHED TO THE BLEEDER

SCREWS AND SUBMERGED IN A CLEAR CON-

TAINER FILLED PART WAY WITH CLEAN BRAKE

FLUID. DIRECT THE FLOW OF BRAKE FLUID AWAY

FROM THE PAINTED SURFACES OF THE VEHICLE.

BRAKE FLUID AT HIGH PRESSURE MAY COME

OUT OF THE BLEEDER SCREWS WHEN OPENED.

(4) Bleed the base brake system using the stan-

dard pressure or manual bleeding procedure as out-

lined in the Service Adjustments section of this

service manual.

(5) Using the DRB, go to the9Bleed ABS9routine.

Apply the brake pedal firmly and initiate the9Bleed

ABS9cycle one time. Release the brake pedal.

(6) Bleed the base brake system again, as in step

Step 4 above.

(7) Repeat steps Step 5 and Step 6 above until

brake fluid flows clear and is free of any air bubbles.

Check brake fluid level in reservoir periodically to

prevent reservoir from running low on brake fluid.

(8) Test drive the vehicle to be sure brakes are

operating correctly and that brake pedal is solid.

REMOVAL AND INSTALLATION

ABS GENERAL SERVICE PRECAUTIONS

CAUTION: Review this entire section prior to per-

forming any mechanical work on a vehicle equipped

with the ITT Tevis Mark 20 ABS brake system. This

section contains information on precautions per-

taining to potential component damage, vehicle

damage and personal injury which could result

when servicing an ABS equipped vehicle.

CAUTION: Only the recommended jacking or hoist-

ing positions for this vehicle are to be used when-ever it is necessary to lift a vehicle. Failure to raise

a vehicle from the recommended locations could

result in lifting a vehicle by the hydraulic control

unit mounting bracket. Lifting a vehicle by the

hydraulic control unit mounting bracket will result

in damage to the mounting bracket and the hydrau-

lic control unit.

CAUTION: Certain components of the ABS System

are not intended to be serviced individually.

Attempting to remove or disconnect certain system

components may result in improper system opera-

tion. Only those components with approved

removal and installation procedures in this manual

should be serviced.

CAUTION: Brake fluid will damage painted sur-

faces. If brake fluid is spilled on any painted sur-

faces, wash off with water immediately.

CAUTION: When performing any service procedure

on a vehicle equipped with ABS do not apply a 12

volt power source to the ground circuit of the pump

motor in the CAB. Doing this will damage the pump

motor and will require replacement of the HCU.

The following are general cautions which should be

observed when servicing the ABS system and/or

other vehicle systems. Failure to observe these pre-

cautions may result in ABS System component dam-

age.

If welding work is to be performed on the vehicle,

using an electric arc welder, the CAB connector

should be disconnected during the welding operation.

The CAB 25 way connector connector should never

be connected or disconnected with the ignition switch

in the ON position.

Many components of the ABS System are not ser-

viceable and must be replaced as an assembly. Do not

disassemble any component which is not designed to

be serviced.

HYDRAULIC CONTROL UNIT

REMOVE

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. Vehicle is to be raised and sup-

ported on jackstands or on a frame contact type

5 - 100 BRAKESNS

SERVICE PROCEDURES (Continued)

Page 184 of 1938

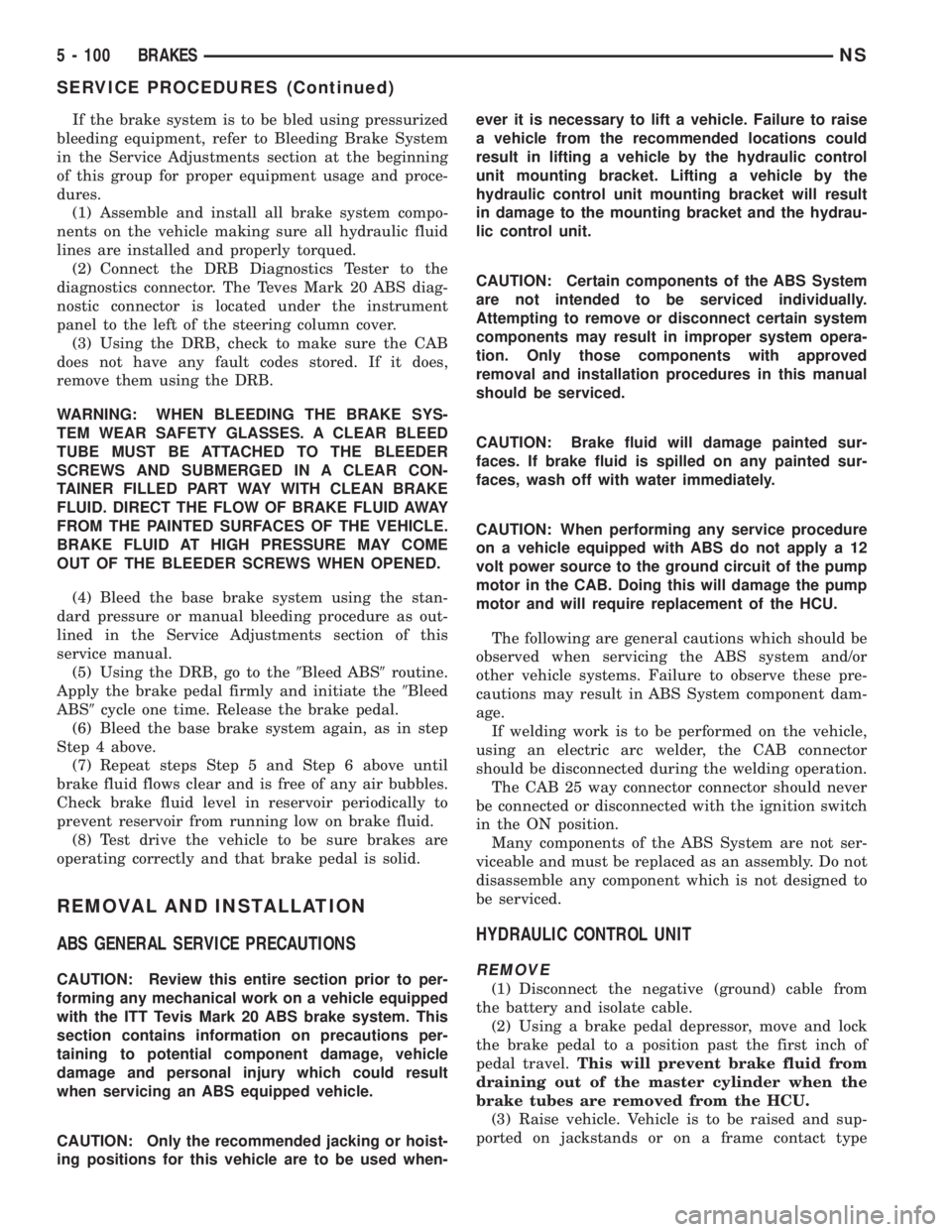

INSTALL

(1) Install the CAB (Fig. 19) on the bottom of the

HCU. Refer to Controller Antilock Brakes (CAB) in

the Removal And Installation Section in this group of

the service manual for the required procedure.

(2) Install the HCU on the mounting bracket (Fig.

23). Install the 3 bolts (Fig. 23) attaching the HCU to

the mounting bracket. Tighten the 3 mounting bolts

to a torque of 11 N´m (97 in. lbs.).

CAUTION: The HCU mounting bracket to front sus-

pension cradle mounting bolts have a unique corro-

sion protection coating and a special aluminum

washer. For this reason, only the original, or origi-

nal equipment Mopar replacement bolts can be

used to mount the HCU bracket to the front suspen-

sion crossmember.

(3) Install the HCU and its mounting bracket as

an assembly on the front suspension crossmember.

Install the 3 bolts attaching the HCU bracket to the

crossmember (Fig. 22). Tighten the 3 mounting bolts

to a torque of 28 N´m (250 in. lbs.).

CAUTION: Because of the flexible section in the

primary and secondary brake tubes, and the brake

tubes between the HCU and the proportioning

valve, the brake tubes must be held in proper ori-

entation when tightened and torqued. These tubes

must not contact each other or other vehicle com-

ponents when installed. Also, after the brake tubes

are installed on the HCU, ensure all spacer clips are

reinstalled on the brake tubes.

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation. Refer to (Fig. 21) for the correct chassis

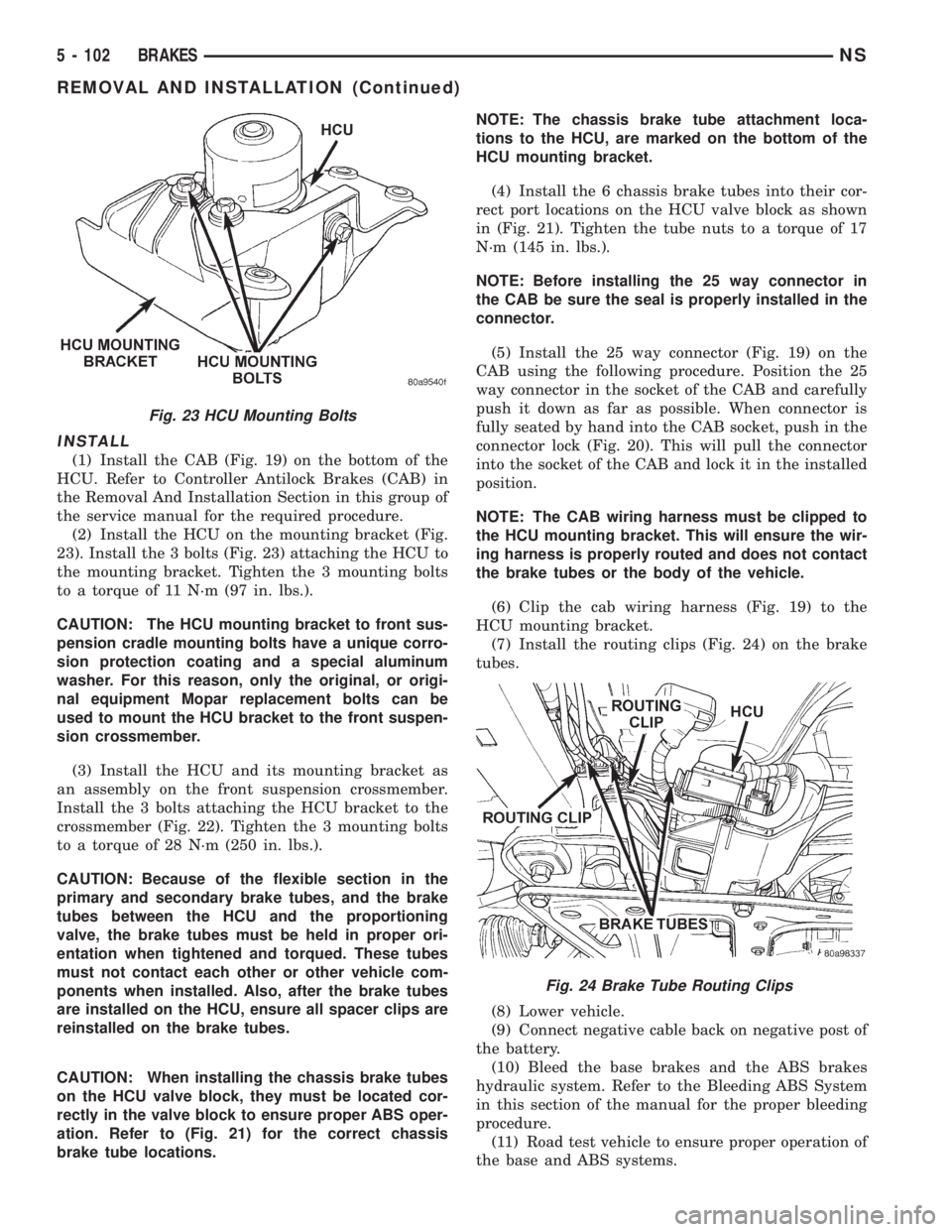

brake tube locations.NOTE: The chassis brake tube attachment loca-

tions to the HCU, are marked on the bottom of the

HCU mounting bracket.

(4) Install the 6 chassis brake tubes into their cor-

rect port locations on the HCU valve block as shown

in (Fig. 21). Tighten the tube nuts to a torque of 17

N´m (145 in. lbs.).

NOTE: Before installing the 25 way connector in

the CAB be sure the seal is properly installed in the

connector.

(5) Install the 25 way connector (Fig. 19) on the

CAB using the following procedure. Position the 25

way connector in the socket of the CAB and carefully

push it down as far as possible. When connector is

fully seated by hand into the CAB socket, push in the

connector lock (Fig. 20). This will pull the connector

into the socket of the CAB and lock it in the installed

position.

NOTE: The CAB wiring harness must be clipped to

the HCU mounting bracket. This will ensure the wir-

ing harness is properly routed and does not contact

the brake tubes or the body of the vehicle.

(6) Clip the cab wiring harness (Fig. 19) to the

HCU mounting bracket.

(7) Install the routing clips (Fig. 24) on the brake

tubes.

(8) Lower vehicle.

(9) Connect negative cable back on negative post of

the battery.

(10) Bleed the base brakes and the ABS brakes

hydraulic system. Refer to the Bleeding ABS System

in this section of the manual for the proper bleeding

procedure.

(11) Road test vehicle to ensure proper operation of

the base and ABS systems.

Fig. 23 HCU Mounting Bolts

Fig. 24 Brake Tube Routing Clips

5 - 102 BRAKESNS

REMOVAL AND INSTALLATION (Continued)

Page 288 of 1938

GENERATOR

The generator is belt-driven by the engine. It is

serviced only as a complete assembly. If the genera-

tor fails for any reason, the entire assembly must be

replaced.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator, battery, and ground terminals.

Noise emitting from the generator may be caused

by:

²Worn, loose or defective bearings

²Loose or defective drive pulley

²Incorrect, worn, damaged or misadjusted drive

belt

²Loose mounting bolts

²Misaligned drive pulley

²Defective stator or diode

BATTERY TEMPERATURE SENSOR

The temperature sensor, in the PCM, is used to

determine the battery temperature. This temperature

data, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

System voltage will be higher at colder temperatures

and is gradually reduced at warmer temperatures.

ELECTRONIC VOLTAGE REGULATOR

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

Operation:The amount of DC current produced

by the generator is controlled by EVR circuitry con-

tained within the PCM. This circuitry is connected in

series with the generators second rotor field terminal

and its ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage and bat-

tery temperature (refer to Battery Temperature Sen-

sor for more information). It then compensates and

regulates generator current output accordingly. Also

refer to Charging System Operation for additional

information.

DIAGNOSIS AND TESTING

CHARGING SYSTEM

When the ignition switch is turned to the ON posi-

tion, battery potential will register on the voltmeter.

During engine cranking a lower voltage will appear

on the meter. With the engine running, a voltage

reading higher than the first reading (ignition in ON)

should register.

The following are possible symptoms of a charging

system fault:

²The voltmeter does not operate properly

²An undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²Accessories being left on with the engine not

running

²A faulty or improperly adjusted switch that

allows a lamp to stay on. See Ignition-Off Draw Test

in Group 8A, Battery for more information.

The following procedures may be used to correct a

problem diagnosed as a charging system fault.

INSPECTION

(1) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(2) Inspect all fuses in the fuseblock module and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(3) Inspect the electrolyte level in the battery.

Replace battery if electrolyte level is low.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications.

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications in Group 7, Cooling Sys-

tem.

(6) Inspect automatic belt tensioner (if equipped).

Refer to Group 7, Cooling System for information.

(7) Inspect connections at generator field, battery

output, and ground terminals. Also check ground con-

nection at engine. They should all be clean and tight.

Repair as required.

8C - 2 CHARGING SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 425 of 1938

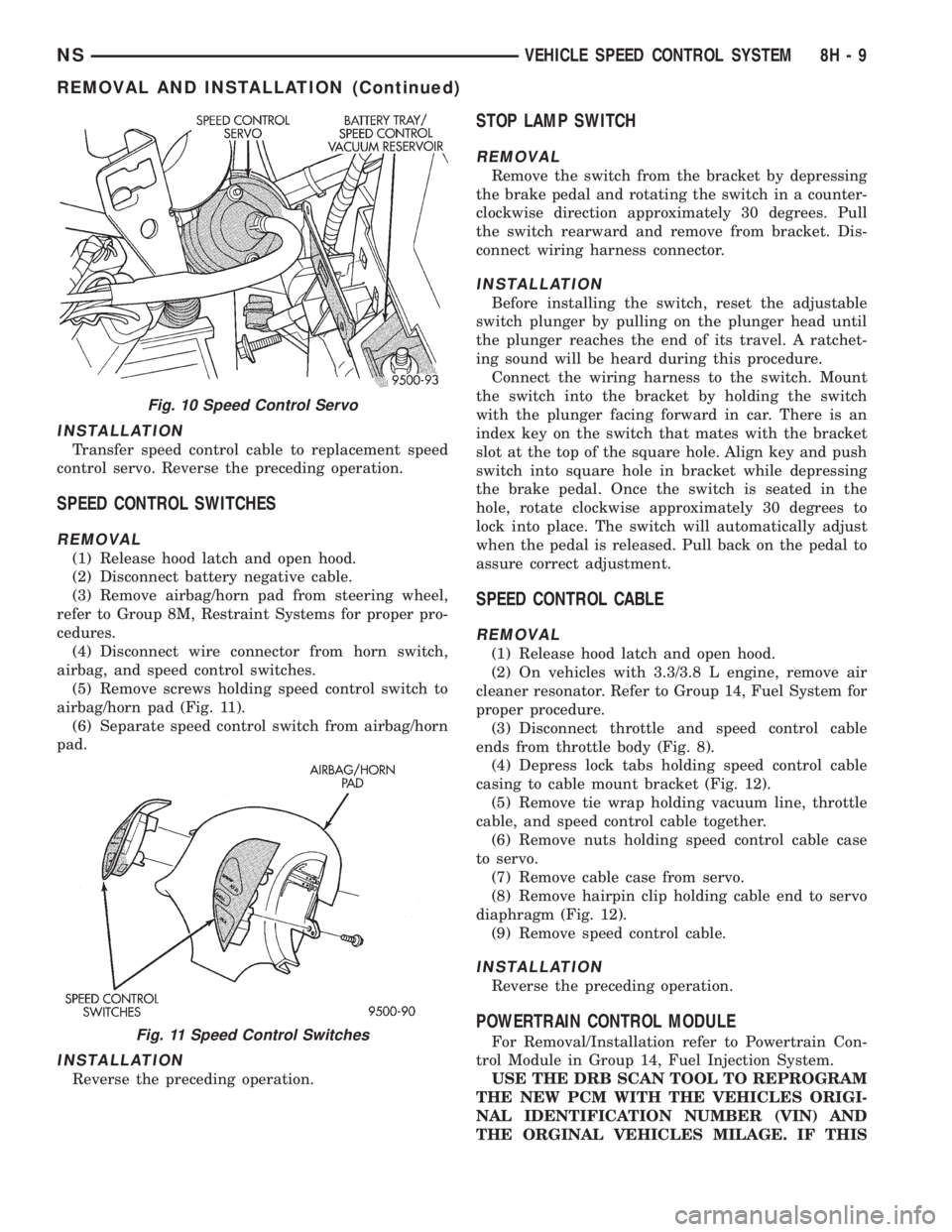

INSTALLATION

Transfer speed control cable to replacement speed

control servo. Reverse the preceding operation.

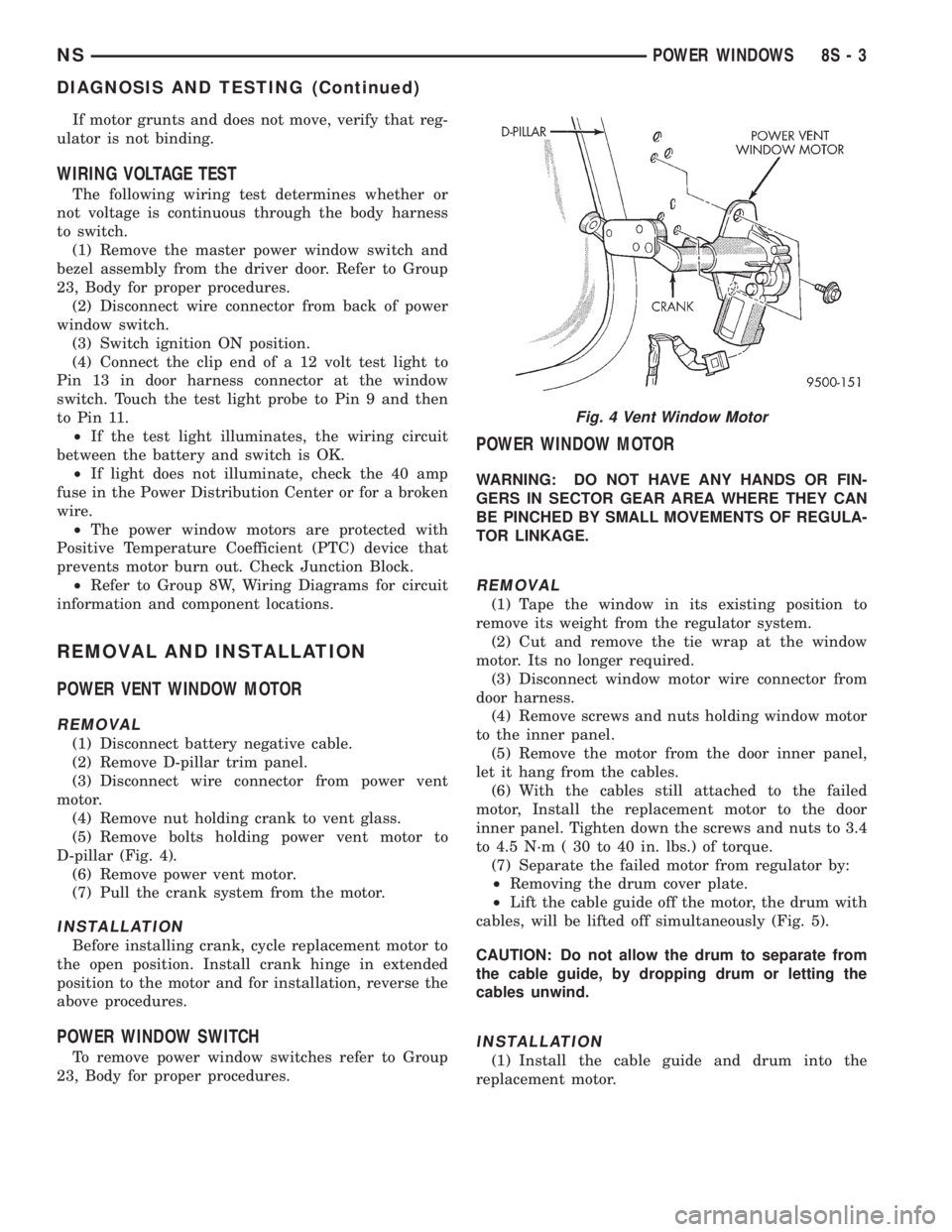

SPEED CONTROL SWITCHES

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect battery negative cable.

(3) Remove airbag/horn pad from steering wheel,

refer to Group 8M, Restraint Systems for proper pro-

cedures.

(4) Disconnect wire connector from horn switch,

airbag, and speed control switches.

(5) Remove screws holding speed control switch to

airbag/horn pad (Fig. 11).

(6) Separate speed control switch from airbag/horn

pad.

INSTALLATION

Reverse the preceding operation.

STOP LAMP SWITCH

REMOVAL

Remove the switch from the bracket by depressing

the brake pedal and rotating the switch in a counter-

clockwise direction approximately 30 degrees. Pull

the switch rearward and remove from bracket. Dis-

connect wiring harness connector.

INSTALLATION

Before installing the switch, reset the adjustable

switch plunger by pulling on the plunger head until

the plunger reaches the end of its travel. A ratchet-

ing sound will be heard during this procedure.

Connect the wiring harness to the switch. Mount

the switch into the bracket by holding the switch

with the plunger facing forward in car. There is an

index key on the switch that mates with the bracket

slot at the top of the square hole. Align key and push

switch into square hole in bracket while depressing

the brake pedal. Once the switch is seated in the

hole, rotate clockwise approximately 30 degrees to

lock into place. The switch will automatically adjust

when the pedal is released. Pull back on the pedal to

assure correct adjustment.

SPEED CONTROL CABLE

REMOVAL

(1) Release hood latch and open hood.

(2) On vehicles with 3.3/3.8 L engine, remove air

cleaner resonator. Refer to Group 14, Fuel System for

proper procedure.

(3) Disconnect throttle and speed control cable

ends from throttle body (Fig. 8).

(4) Depress lock tabs holding speed control cable

casing to cable mount bracket (Fig. 12).

(5) Remove tie wrap holding vacuum line, throttle

cable, and speed control cable together.

(6) Remove nuts holding speed control cable case

to servo.

(7) Remove cable case from servo.

(8) Remove hairpin clip holding cable end to servo

diaphragm (Fig. 12).

(9) Remove speed control cable.

INSTALLATION

Reverse the preceding operation.

POWERTRAIN CONTROL MODULE

For Removal/Installation refer to Powertrain Con-

trol Module in Group 14, Fuel Injection System.

USE THE DRB SCAN TOOL TO REPROGRAM

THE NEW PCM WITH THE VEHICLES ORIGI-

NAL IDENTIFICATION NUMBER (VIN) AND

THE ORGINAL VEHICLES MILAGE. IF THIS

Fig. 10 Speed Control Servo

Fig. 11 Speed Control Switches

NSVEHICLE SPEED CONTROL SYSTEM 8H - 9

REMOVAL AND INSTALLATION (Continued)

Page 497 of 1938

RESTRAINT SYSTEM

CONTENTS

page page

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS............ 1

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)......... 1

CLOCKSPRING.......................... 2

DRIVER AND PASSENGER

AIRBAG MODULES..................... 2

DIAGNOSIS AND TESTING

AIRBAG SYSTEM TEST................... 2

SERVICE PROCEDURES

CLEANUP PROCEDURE................... 3HANDLING AIRBAG MODULE.............. 3

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE............... 3

CLOCKSPRING.......................... 5

DRIVER AIRBAG MODULE................. 5

PASSENGER AIRBAG..................... 6

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE..... 7

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR TWO MINUTES BEFORE REMOVING AIRBAG

COMPONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIR-

BAG FACE DOWN ON A SOLID SURFACE, THE AIR-

BAG WILL PROPEL INTO THE AIR IF

ACCIDENTALLY DEPLOYED AND COULD RESULT

IN PERSONAL INJURY. WHEN CARRYING OR HAN-

DLING AN UNDEPLOYED AIRBAG MODULE, THE

TRIM SIDE OF THE AIRBAG SHOULD BE POINTING

AWAY FROM THE BODY TO MINIMIZE POSSIBILITY

OF INJURY IF ACCIDENTAL DEPLOYMENT

OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES,

AND LONG SLEEVED CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDERRESIDUE EMITTED FROM A DEPLOYED AIRBAG

CAN CAUSE SKIN IRRITATION. FLUSH AFFECTED

AREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT AND PERSONAL INJURY CAN

RESULT.

THE FACTORY INSTALLED FASTENERS,

SCREWS AND BOLTS USED TO FASTEN AIRBAG

COMPONENTS HAVE A SPECIAL COATING AND

ARE SPECIFICALLY DESIGNED FOR THE AIRBAG

SYSTEM. DO NOT USE SUBSTITUTE FASTENERS,

USE ONLY ORIGINAL EQUIPMENT FASTENERS

LISTED IN THE PARTS CATALOG WHEN FASTENER

REPLACEMENT IS REQUIRED.

NOTE: Airbags should be stored in a cool dry loca-

tion away from excessive heat and static electrical

activity with the fabric airbag facing UP, or a prema-

ture deployment can result.

If the Driver/Passenger Airbag Module is defective

and not deployed, refer to Chrysler Corporation cur-

rent return list for proper handling procedures.

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)

The Airbag Control Module (ACM) contains the

impact sensor and energy reserve capacitor. The

NSRESTRAINT SYSTEM 8M - 1

Page 527 of 1938

If motor grunts and does not move, verify that reg-

ulator is not binding.

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the master power window switch and

bezel assembly from the driver door. Refer to Group

23, Body for proper procedures.

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 13 in door harness connector at the window

switch. Touch the test light probe to Pin 9 and then

to Pin 11.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If light does not illuminate, check the 40 amp

fuse in the Power Distribution Center or for a broken

wire.

²The power window motors are protected with

Positive Temperature Coefficient (PTC) device that

prevents motor burn out. Check Junction Block.

²Refer to Group 8W, Wiring Diagrams for circuit

information and component locations.

REMOVAL AND INSTALLATION

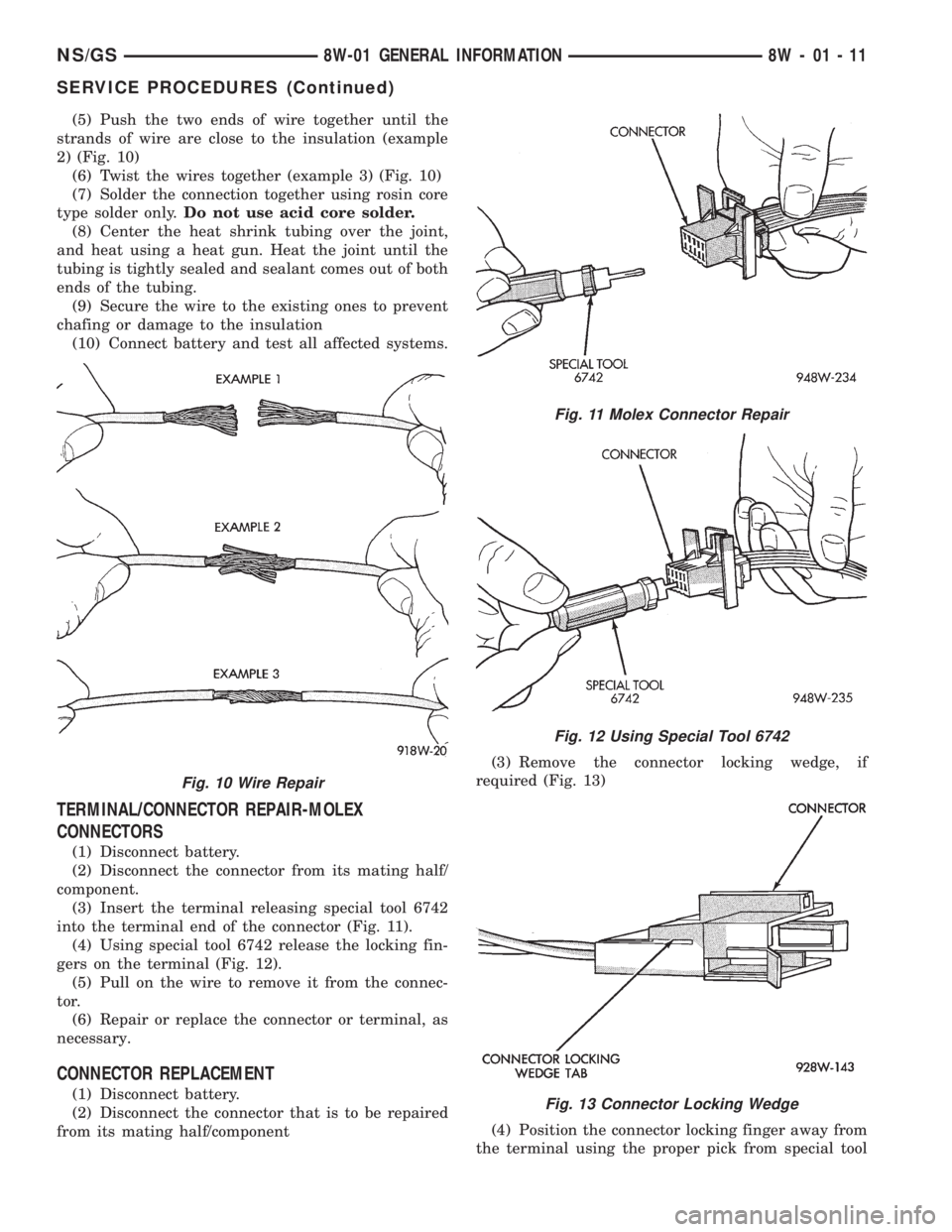

POWER VENT WINDOW MOTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove D-pillar trim panel.

(3) Disconnect wire connector from power vent

motor.

(4) Remove nut holding crank to vent glass.

(5) Remove bolts holding power vent motor to

D-pillar (Fig. 4).

(6) Remove power vent motor.

(7) Pull the crank system from the motor.

INSTALLATION

Before installing crank, cycle replacement motor to

the open position. Install crank hinge in extended

position to the motor and for installation, reverse the

above procedures.

POWER WINDOW SWITCH

To remove power window switches refer to Group

23, Body for proper procedures.

POWER WINDOW MOTOR

WARNING: DO NOT HAVE ANY HANDS OR FIN-

GERS IN SECTOR GEAR AREA WHERE THEY CAN

BE PINCHED BY SMALL MOVEMENTS OF REGULA-

TOR LINKAGE.

REMOVAL

(1) Tape the window in its existing position to

remove its weight from the regulator system.

(2) Cut and remove the tie wrap at the window

motor. Its no longer required.

(3) Disconnect window motor wire connector from

door harness.

(4) Remove screws and nuts holding window motor

to the inner panel.

(5) Remove the motor from the door inner panel,

let it hang from the cables.

(6) With the cables still attached to the failed

motor, Install the replacement motor to the door

inner panel. Tighten down the screws and nuts to 3.4

to 4.5 N´m ( 30 to 40 in. lbs.) of torque.

(7) Separate the failed motor from regulator by:

²Removing the drum cover plate.

²Lift the cable guide off the motor, the drum with

cables, will be lifted off simultaneously (Fig. 5).

CAUTION: Do not allow the drum to separate from

the cable guide, by dropping drum or letting the

cables unwind.

INSTALLATION

(1) Install the cable guide and drum into the

replacement motor.

Fig. 4 Vent Window Motor

NSPOWER WINDOWS 8S - 3

DIAGNOSIS AND TESTING (Continued)

Page 573 of 1938

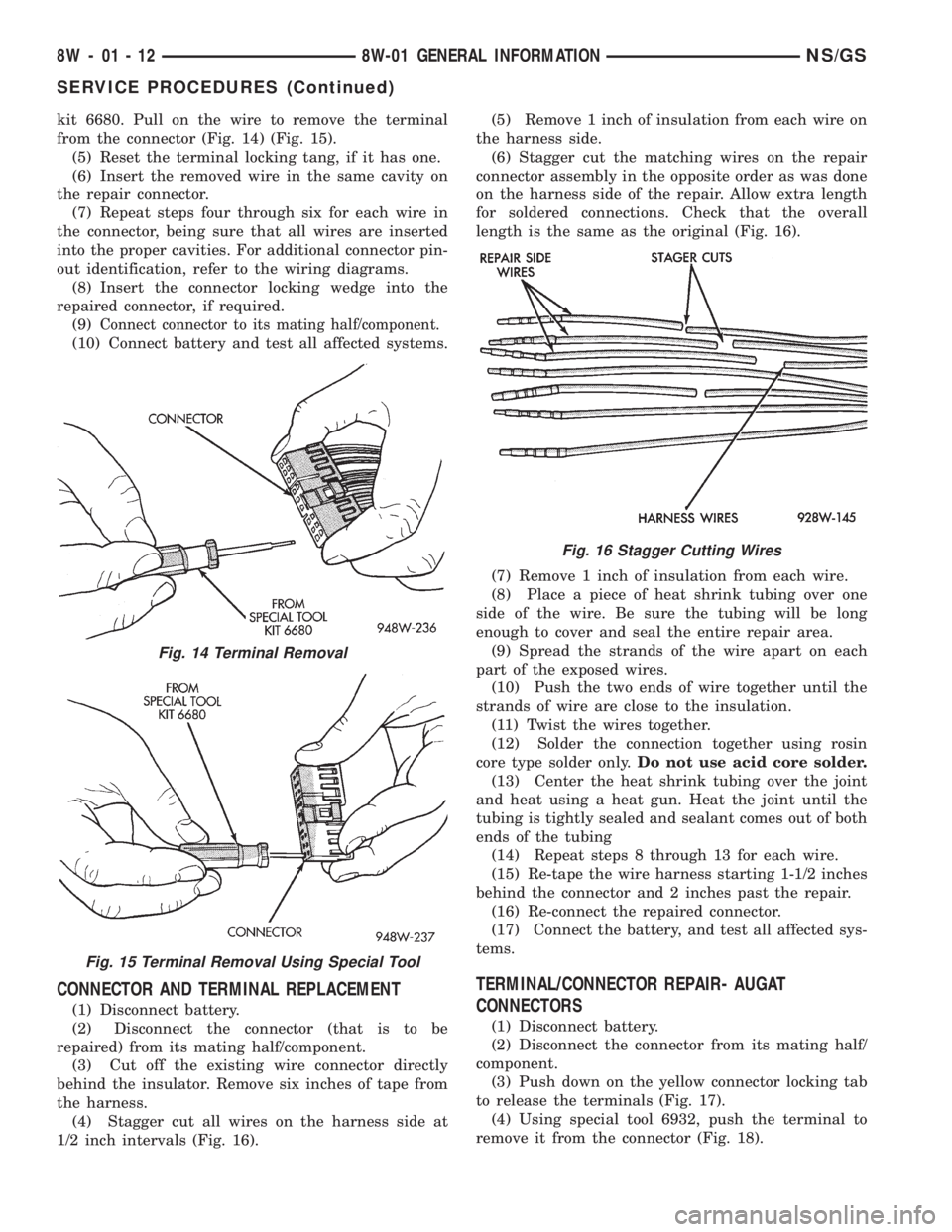

(5) Push the two ends of wire together until the

strands of wire are close to the insulation (example

2) (Fig. 10)

(6) Twist the wires together (example 3) (Fig. 10)

(7) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(8) Center the heat shrink tubing over the joint,

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation

(10) Connect battery and test all affected systems.

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

(3) Insert the terminal releasing special tool 6742

into the terminal end of the connector (Fig. 11).

(4) Using special tool 6742 release the locking fin-

gers on the terminal (Fig. 12).

(5) Pull on the wire to remove it from the connec-

tor.

(6) Repair or replace the connector or terminal, as

necessary.

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half/component(3) Remove the connector locking wedge, if

required (Fig. 13)

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

Fig. 10 Wire Repair

Fig. 11 Molex Connector Repair

Fig. 12 Using Special Tool 6742

Fig. 13 Connector Locking Wedge

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 11

SERVICE PROCEDURES (Continued)

Page 574 of 1938

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 14) (Fig. 15).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the

repaired connector, if required.

(9)

Connect connector to its mating half/component.

(10) Connect battery and test all affected systems.

CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be

repaired) from its mating half/component.

(3) Cut off the existing wire connector directly

behind the insulator. Remove six inches of tape from

the harness.

(4) Stagger cut all wires on the harness side at

1/2 inch intervals (Fig. 16).(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 16).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Be sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires.

(10) Push the two ends of wire together until the

strands of wire are close to the insulation.

(11) Twist the wires together.

(12) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

(17) Connect the battery, and test all affected sys-

tems.

TERMINAL/CONNECTOR REPAIR- AUGAT

CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

(3) Push down on the yellow connector locking tab

to release the terminals (Fig. 17).

(4) Using special tool 6932, push the terminal to

remove it from the connector (Fig. 18).

Fig. 14 Terminal Removal

Fig. 15 Terminal Removal Using Special Tool

Fig. 16 Stagger Cutting Wires

8W - 01 - 12 8W-01 GENERAL INFORMATIONNS/GS

SERVICE PROCEDURES (Continued)