battery replacement CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 575 of 1938

(5) Repair or replace the connector or terminal as

necessary.

(6) When re-assembling the connector, the locking

wedge must be placed in the locked position to pre-

vent terminal push out.

TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector being repaired from

its mating half. Remove connector locking wedge, if

required (Fig. 19).

(3) Remove connector locking wedge, if required

(Fig. 19).

(4) Position the connector locking finger away from

the terminal using the proper pick from special tool

kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 20) (Fig. 21).

(5) Cut the wire 6 inches from the back of the con-

nector.

(6) Remove 1 inch of insulation from the wire on

the harness side.(7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired.

(8) Cut the repair wire to the proper length and

remove 1 inch of insulation.

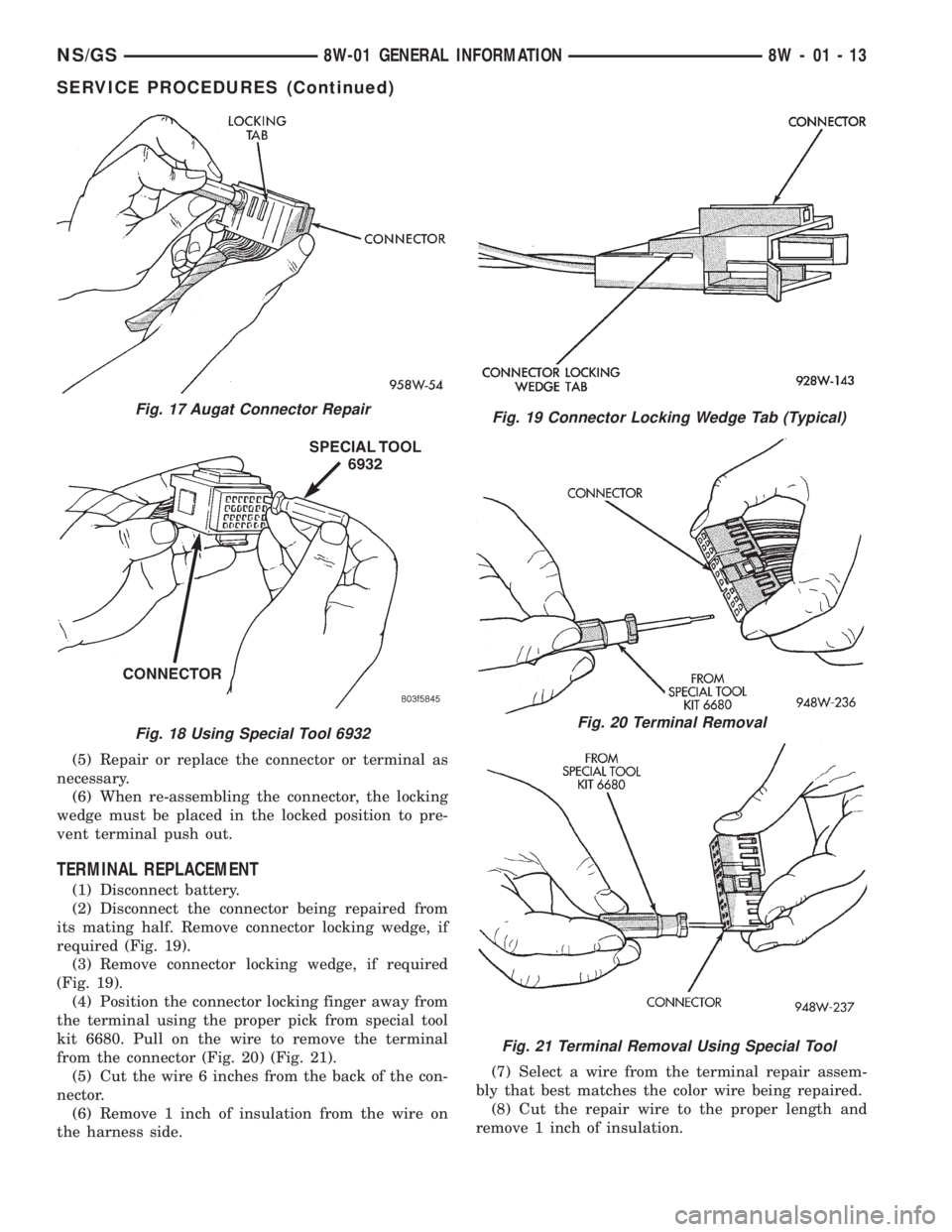

Fig. 17 Augat Connector Repair

Fig. 18 Using Special Tool 6932

Fig. 19 Connector Locking Wedge Tab (Typical)

Fig. 20 Terminal Removal

Fig. 21 Terminal Removal Using Special Tool

NS/GS8W-01 GENERAL INFORMATION 8W - 01 - 13

SERVICE PROCEDURES (Continued)

Page 576 of 1938

(9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires.

(11) Push the two ends of wire together until the

strands of wire are close to the insulation.

(12) Twist the wires together.

(13) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge, if

required, and reconnect the connector to its mating

half/component.

(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(18) Connect battery, and test all affected systems.

DIODE REPLACEMENT

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 22).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8)

Re-connect the battery, and test affected systems.

SPECIAL TOOLS

WIRING/TERMINAL

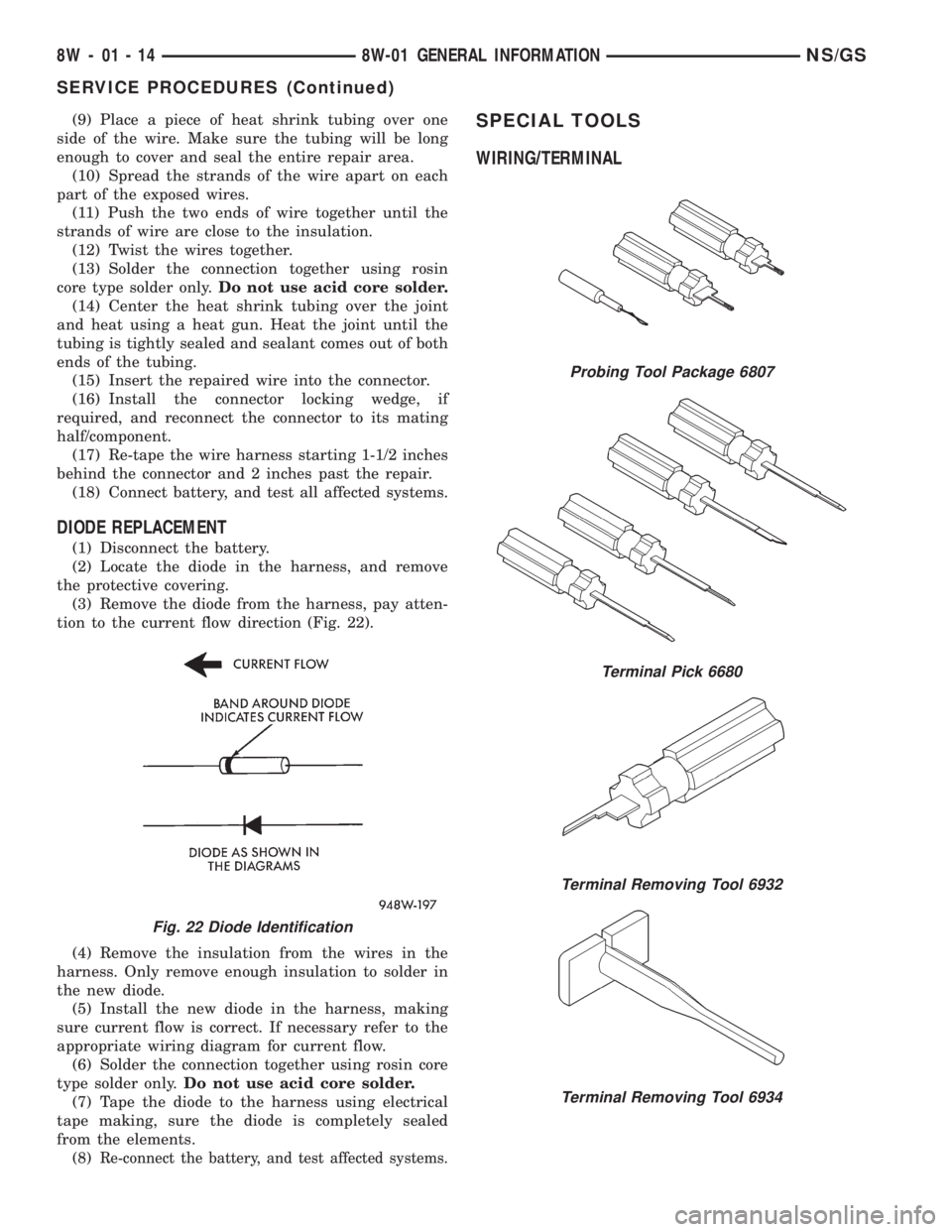

Fig. 22 Diode Identification

Probing Tool Package 6807

Terminal Pick 6680

Terminal Removing Tool 6932

Terminal Removing Tool 6934

8W - 01 - 14 8W-01 GENERAL INFORMATIONNS/GS

SERVICE PROCEDURES (Continued)

Page 1059 of 1938

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

(6) Disconnect the fresh air hose (makeup air) at

the cylinder head cover and plug or cap the nipple on

the cover.

(7) Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil galley cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified. Refer to Rear

Crankshaft Seals, for proper replacement procedures.

NSENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 1119 of 1938

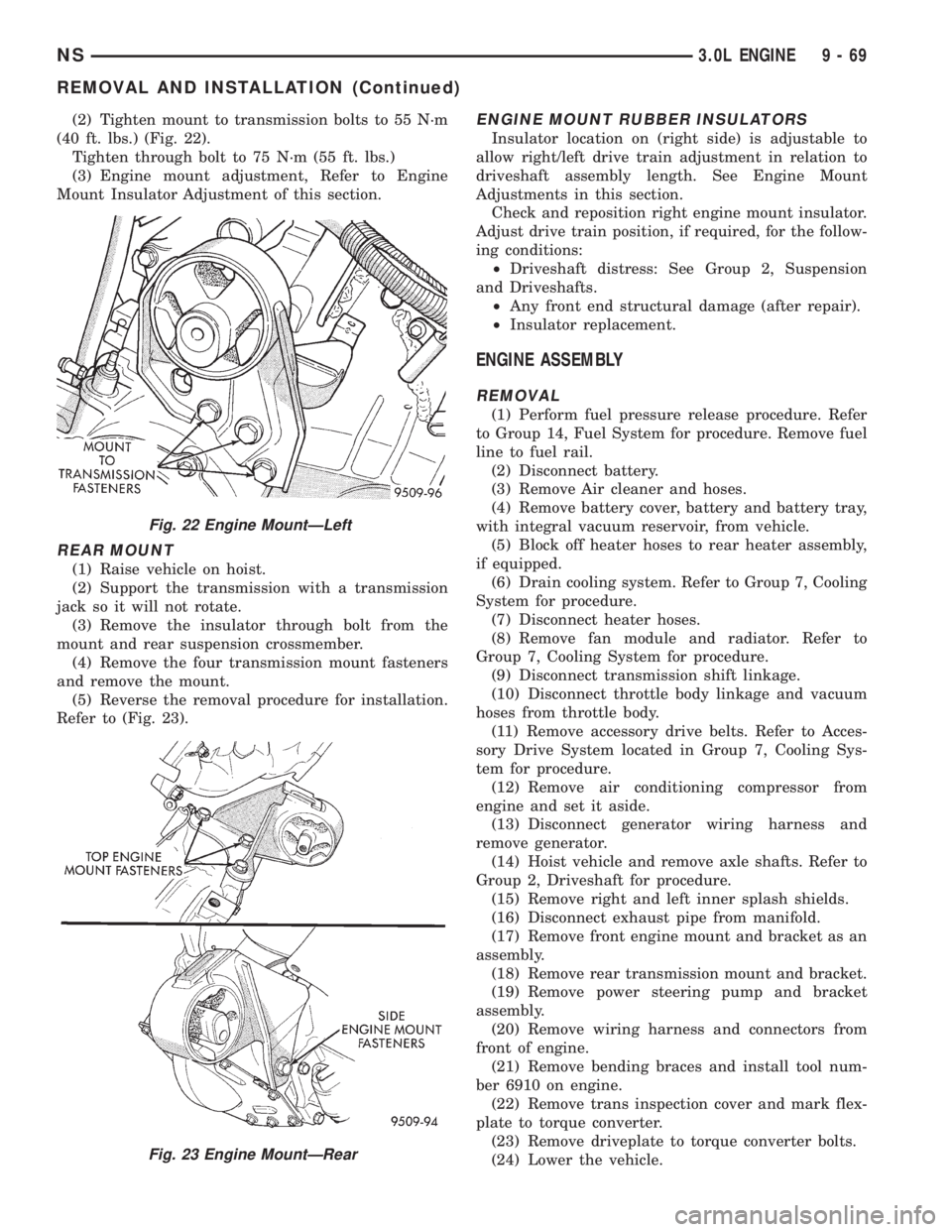

(2) Tighten mount to transmission bolts to 55 N´m

(40 ft. lbs.) (Fig. 22).

Tighten through bolt to 75 N´m (55 ft. lbs.)

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

REAR MOUNT

(1) Raise vehicle on hoist.

(2) Support the transmission with a transmission

jack so it will not rotate.

(3) Remove the insulator through bolt from the

mount and rear suspension crossmember.

(4) Remove the four transmission mount fasteners

and remove the mount.

(5) Reverse the removal procedure for installation.

Refer to (Fig. 23).

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) is adjustable to

allow right/left drive train adjustment in relation to

driveshaft assembly length. See Engine Mount

Adjustments in this section.

Check and reposition right engine mount insulator.

Adjust drive train position, if required, for the follow-

ing conditions:

²Driveshaft distress: See Group 2, Suspension

and Driveshafts.

²Any front end structural damage (after repair).

²Insulator replacement.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove Air cleaner and hoses.

(4) Remove battery cover, battery and battery tray,

with integral vacuum reservoir, from vehicle.

(5) Block off heater hoses to rear heater assembly,

if equipped.

(6) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(7) Disconnect heater hoses.

(8) Remove fan module and radiator. Refer to

Group 7, Cooling System for procedure.

(9) Disconnect transmission shift linkage.

(10) Disconnect throttle body linkage and vacuum

hoses from throttle body.

(11) Remove accessory drive belts. Refer to Acces-

sory Drive System located in Group 7, Cooling Sys-

tem for procedure.

(12) Remove air conditioning compressor from

engine and set it aside.

(13) Disconnect generator wiring harness and

remove generator.

(14) Hoist vehicle and remove axle shafts. Refer to

Group 2, Driveshaft for procedure.

(15) Remove right and left inner splash shields.

(16) Disconnect exhaust pipe from manifold.

(17) Remove front engine mount and bracket as an

assembly.

(18) Remove rear transmission mount and bracket.

(19) Remove power steering pump and bracket

assembly.

(20) Remove wiring harness and connectors from

front of engine.

(21) Remove bending braces and install tool num-

ber 6910 on engine.

(22) Remove trans inspection cover and mark flex-

plate to torque converter.

(23) Remove driveplate to torque converter bolts.

(24) Lower the vehicle.

Fig. 22 Engine MountÐLeft

Fig. 23 Engine MountÐRear

NS3.0L ENGINE 9 - 69

REMOVAL AND INSTALLATION (Continued)

Page 1154 of 1938

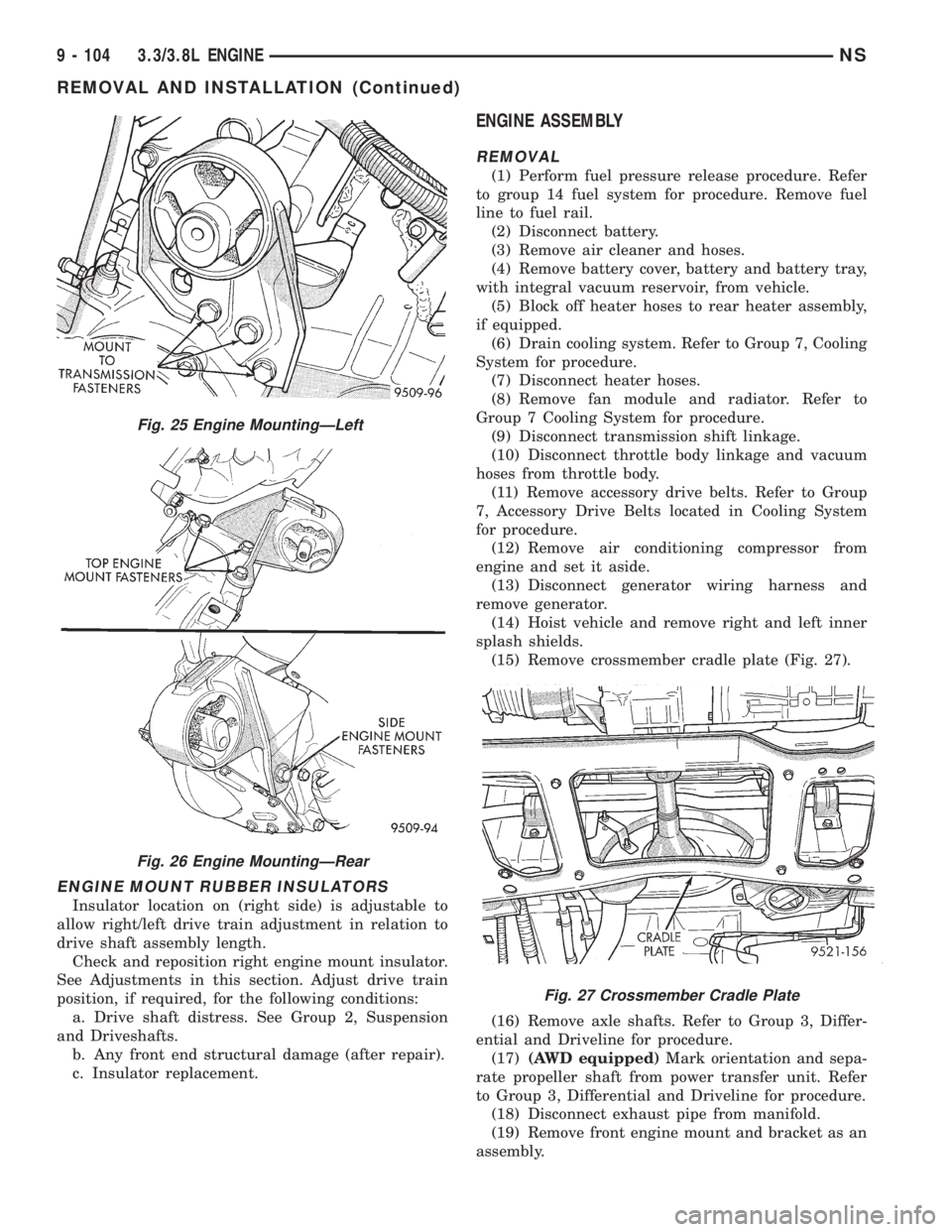

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) is adjustable to

allow right/left drive train adjustment in relation to

drive shaft assembly length.

Check and reposition right engine mount insulator.

See Adjustments in this section. Adjust drive train

position, if required, for the following conditions:

a. Drive shaft distress. See Group 2, Suspension

and Driveshafts.

b. Any front end structural damage (after repair).

c. Insulator replacement.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to group 14 fuel system for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove air cleaner and hoses.

(4) Remove battery cover, battery and battery tray,

with integral vacuum reservoir, from vehicle.

(5) Block off heater hoses to rear heater assembly,

if equipped.

(6) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(7) Disconnect heater hoses.

(8) Remove fan module and radiator. Refer to

Group 7 Cooling System for procedure.

(9) Disconnect transmission shift linkage.

(10) Disconnect throttle body linkage and vacuum

hoses from throttle body.

(11) Remove accessory drive belts. Refer to Group

7, Accessory Drive Belts located in Cooling System

for procedure.

(12) Remove air conditioning compressor from

engine and set it aside.

(13) Disconnect generator wiring harness and

remove generator.

(14) Hoist vehicle and remove right and left inner

splash shields.

(15) Remove crossmember cradle plate (Fig. 27).

(16) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(17)(AWD equipped)Mark orientation and sepa-

rate propeller shaft from power transfer unit. Refer

to Group 3, Differential and Driveline for procedure.

(18) Disconnect exhaust pipe from manifold.

(19) Remove front engine mount and bracket as an

assembly.

Fig. 25 Engine MountingÐLeft

Fig. 26 Engine MountingÐRear

Fig. 27 Crossmember Cradle Plate

9 - 104 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1156 of 1938

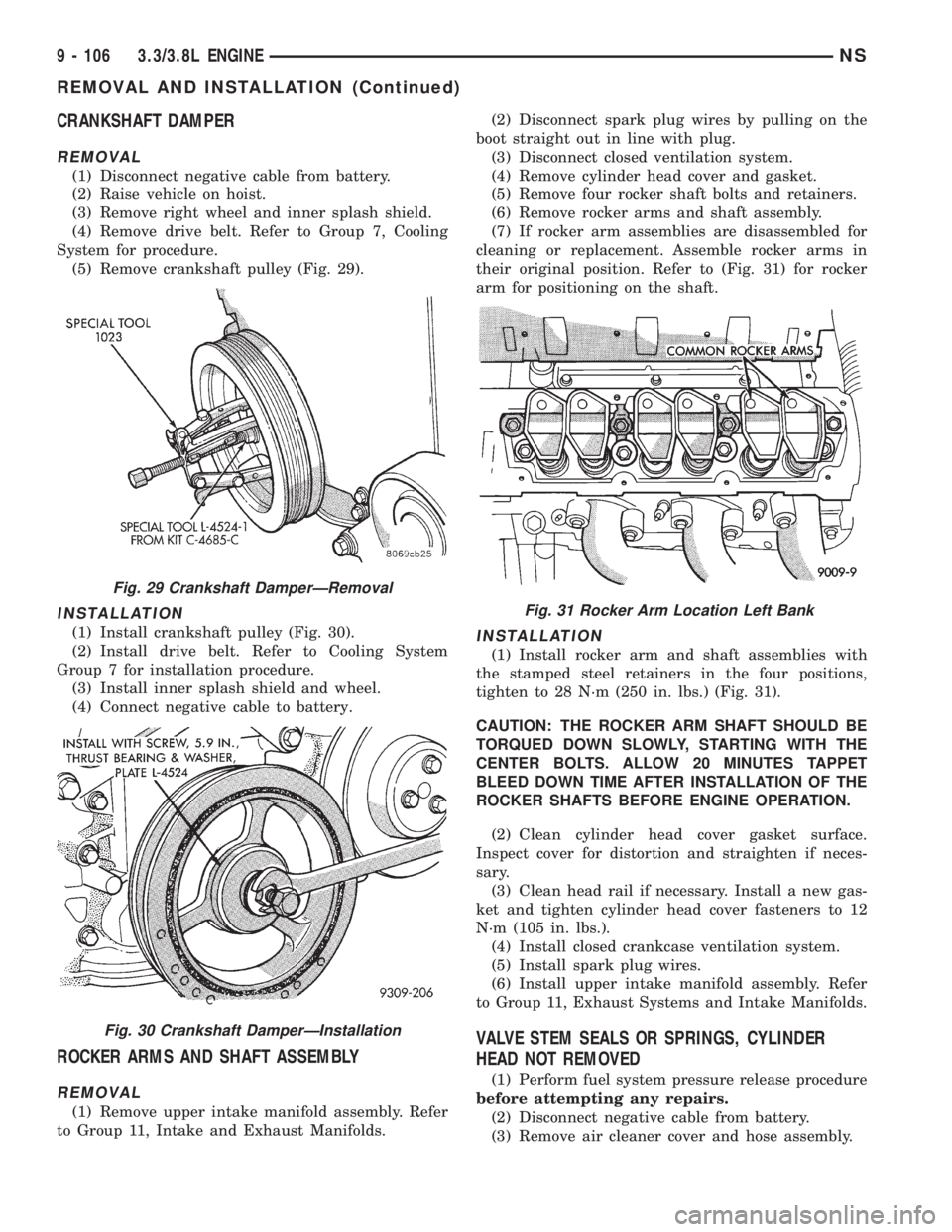

CRANKSHAFT DAMPER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Raise vehicle on hoist.

(3) Remove right wheel and inner splash shield.

(4) Remove drive belt. Refer to Group 7, Cooling

System for procedure.

(5) Remove crankshaft pulley (Fig. 29).

INSTALLATION

(1) Install crankshaft pulley (Fig. 30).

(2) Install drive belt. Refer to Cooling System

Group 7 for installation procedure.

(3) Install inner splash shield and wheel.

(4) Connect negative cable to battery.

ROCKER ARMS AND SHAFT ASSEMBLY

REMOVAL

(1) Remove upper intake manifold assembly. Refer

to Group 11, Intake and Exhaust Manifolds.(2) Disconnect spark plug wires by pulling on the

boot straight out in line with plug.

(3) Disconnect closed ventilation system.

(4) Remove cylinder head cover and gasket.

(5) Remove four rocker shaft bolts and retainers.

(6) Remove rocker arms and shaft assembly.

(7) If rocker arm assemblies are disassembled for

cleaning or replacement. Assemble rocker arms in

their original position. Refer to (Fig. 31) for rocker

arm for positioning on the shaft.

INSTALLATION

(1) Install rocker arm and shaft assemblies with

the stamped steel retainers in the four positions,

tighten to 28 N´m (250 in. lbs.) (Fig. 31).

CAUTION: THE ROCKER ARM SHAFT SHOULD BE

TORQUED DOWN SLOWLY, STARTING WITH THE

CENTER BOLTS. ALLOW 20 MINUTES TAPPET

BLEED DOWN TIME AFTER INSTALLATION OF THE

ROCKER SHAFTS BEFORE ENGINE OPERATION.

(2) Clean cylinder head cover gasket surface.

Inspect cover for distortion and straighten if neces-

sary.

(3) Clean head rail if necessary. Install a new gas-

ket and tighten cylinder head cover fasteners to 12

N´m (105 in. lbs.).

(4) Install closed crankcase ventilation system.

(5) Install spark plug wires.

(6) Install upper intake manifold assembly. Refer

to Group 11, Exhaust Systems and Intake Manifolds.

VALVE STEM SEALS OR SPRINGS, CYLINDER

HEAD NOT REMOVED

(1) Perform fuel system pressure release procedure

before attempting any repairs.

(2) Disconnect negative cable from battery.

(3) Remove air cleaner cover and hose assembly.

Fig. 29 Crankshaft DamperÐRemoval

Fig. 30 Crankshaft DamperÐInstallation

Fig. 31 Rocker Arm Location Left Bank

9 - 106 3.3/3.8L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1237 of 1938

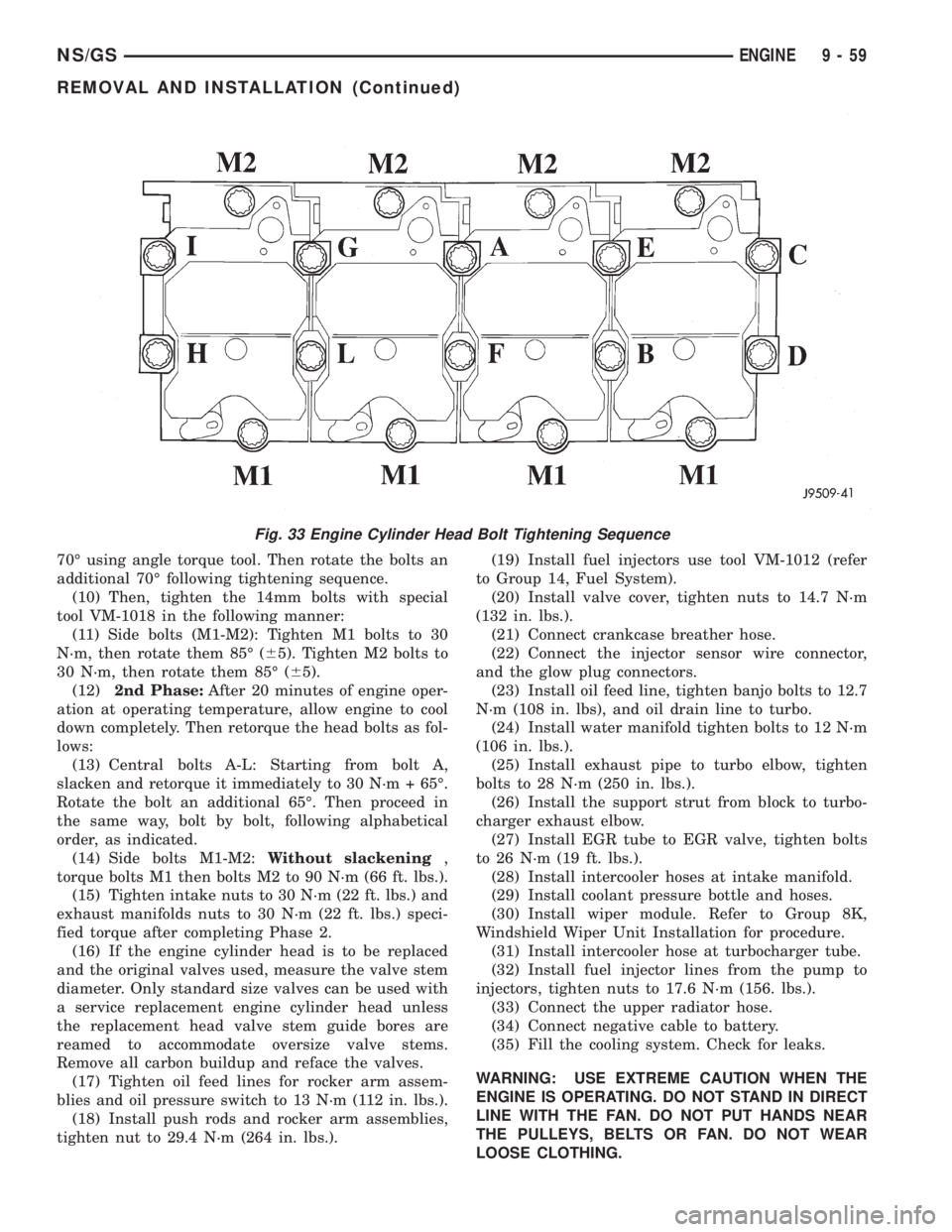

70É using angle torque tool. Then rotate the bolts an

additional 70É following tightening sequence.

(10) Then, tighten the 14mm bolts with special

tool VM-1018 in the following manner:

(11) Side bolts (M1-M2): Tighten M1 bolts to 30

N´m, then rotate them 85É (65). Tighten M2 bolts to

30 N´m, then rotate them 85É (65).

(12)2nd Phase:After 20 minutes of engine oper-

ation at operating temperature, allow engine to cool

down completely. Then retorque the head bolts as fol-

lows:

(13) Central bolts A-L: Starting from bolt A,

slacken and retorque it immediately to 30 N´m + 65É.

Rotate the bolt an additional 65É. Then proceed in

the same way, bolt by bolt, following alphabetical

order, as indicated.

(14) Side bolts M1-M2:Without slackening,

torque bolts M1 then bolts M2 to 90 N´m (66 ft. lbs.).

(15) Tighten intake nuts to 30 N´m (22 ft. lbs.) and

exhaust manifolds nuts to 30 N´m (22 ft. lbs.) speci-

fied torque after completing Phase 2.

(16) If the engine cylinder head is to be replaced

and the original valves used, measure the valve stem

diameter. Only standard size valves can be used with

a service replacement engine cylinder head unless

the replacement head valve stem guide bores are

reamed to accommodate oversize valve stems.

Remove all carbon buildup and reface the valves.

(17) Tighten oil feed lines for rocker arm assem-

blies and oil pressure switch to 13 N´m (112 in. lbs.).

(18) Install push rods and rocker arm assemblies,

tighten nut to 29.4 N´m (264 in. lbs.).(19) Install fuel injectors use tool VM-1012 (refer

to Group 14, Fuel System).

(20) Install valve cover, tighten nuts to 14.7 N´m

(132 in. lbs.).

(21) Connect crankcase breather hose.

(22) Connect the injector sensor wire connector,

and the glow plug connectors.

(23) Install oil feed line, tighten banjo bolts to 12.7

N´m (108 in. lbs), and oil drain line to turbo.

(24) Install water manifold tighten bolts to 12 N´m

(106 in. lbs.).

(25) Install exhaust pipe to turbo elbow, tighten

bolts to 28 N´m (250 in. lbs.).

(26) Install the support strut from block to turbo-

charger exhaust elbow.

(27) Install EGR tube to EGR valve, tighten bolts

to 26 N´m (19 ft. lbs.).

(28) Install intercooler hoses at intake manifold.

(29) Install coolant pressure bottle and hoses.

(30) Install wiper module. Refer to Group 8K,

Windshield Wiper Unit Installation for procedure.

(31) Install intercooler hose at turbocharger tube.

(32) Install fuel injector lines from the pump to

injectors, tighten nuts to 17.6 N´m (156. lbs.).

(33) Connect the upper radiator hose.

(34) Connect negative cable to battery.

(35) Fill the cooling system. Check for leaks.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

Fig. 33 Engine Cylinder Head Bolt Tightening Sequence

NS/GSENGINE 9 - 59

REMOVAL AND INSTALLATION (Continued)

Page 1266 of 1938

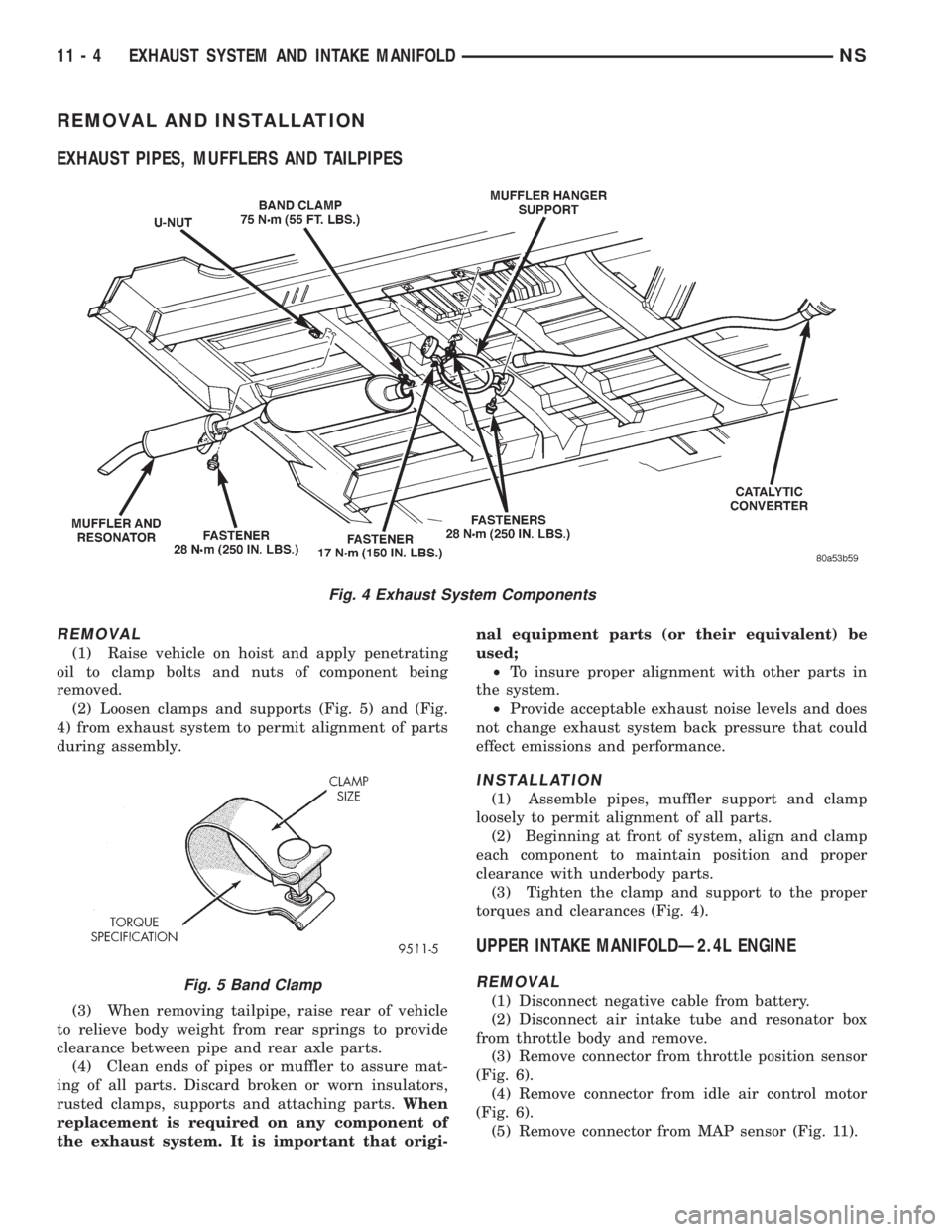

REMOVAL AND INSTALLATION

EXHAUST PIPES, MUFFLERS AND TAILPIPES

REMOVAL

(1) Raise vehicle on hoist and apply penetrating

oil to clamp bolts and nuts of component being

removed.

(2) Loosen clamps and supports (Fig. 5) and (Fig.

4) from exhaust system to permit alignment of parts

during assembly.

(3) When removing tailpipe, raise rear of vehicle

to relieve body weight from rear springs to provide

clearance between pipe and rear axle parts.

(4) Clean ends of pipes or muffler to assure mat-

ing of all parts. Discard broken or worn insulators,

rusted clamps, supports and attaching parts.When

replacement is required on any component of

the exhaust system. It is important that origi-nal equipment parts (or their equivalent) be

used;

²To insure proper alignment with other parts in

the system.

²Provide acceptable exhaust noise levels and does

not change exhaust system back pressure that could

effect emissions and performance.

INSTALLATION

(1) Assemble pipes, muffler support and clamp

loosely to permit alignment of all parts.

(2) Beginning at front of system, align and clamp

each component to maintain position and proper

clearance with underbody parts.

(3) Tighten the clamp and support to the proper

torques and clearances (Fig. 4).

UPPER INTAKE MANIFOLDÐ2.4L ENGINE

REMOVAL

(1) Disconnect negative cable from battery.

(2) Disconnect air intake tube and resonator box

from throttle body and remove.

(3) Remove connector from throttle position sensor

(Fig. 6).

(4) Remove connector from idle air control motor

(Fig. 6).

(5) Remove connector from MAP sensor (Fig. 11).

Fig. 4 Exhaust System Components

Fig. 5 Band Clamp

11 - 4 EXHAUST SYSTEM AND INTAKE MANIFOLDNS

Page 1283 of 1938

FRAME

INDEX

page page

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER MOUNT BUSHINGS . . . 5

FRONT CROSSMEMBER................... 3SPECIFICATIONS

FRAME AND BODY OPENING DIMENSIONS.... 5

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER

The front suspension crossmember must be

installed in the design location to achieve proper

front end suspension alignment. If the crossmember

is removed without applying reference marks on the

frame rails, align the crossmember according to the

dimensions provided in this group.

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through a MoparTParts supplier.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(3) Remove knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to airbag clock spring can result.

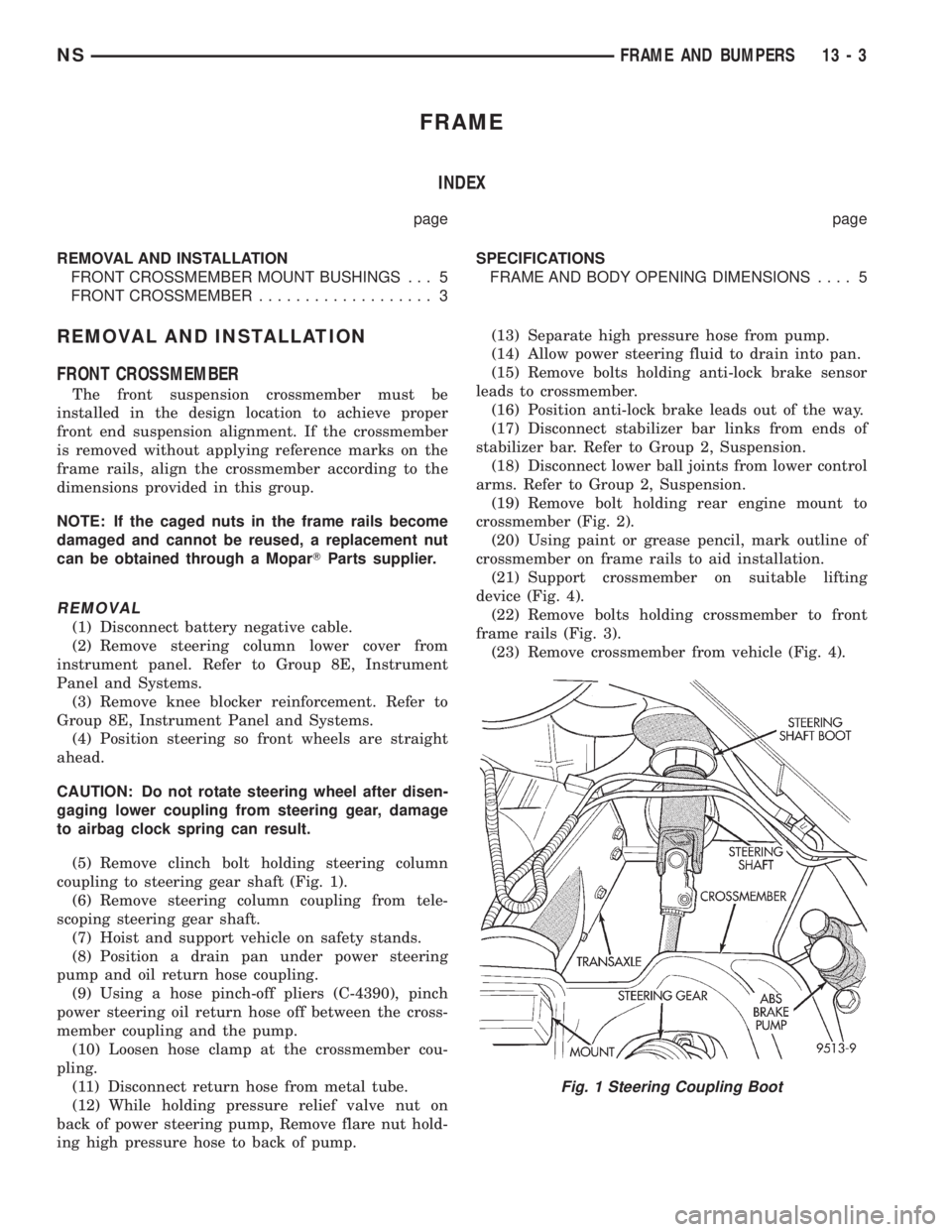

(5) Remove clinch bolt holding steering column

coupling to steering gear shaft (Fig. 1).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.

(7) Hoist and support vehicle on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the crossmember cou-

pling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut hold-

ing high pressure hose to back of pump.(13) Separate high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts holding anti-lock brake sensor

leads to crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar. Refer to Group 2, Suspension.

(18) Disconnect lower ball joints from lower control

arms. Refer to Group 2, Suspension.

(19) Remove bolt holding rear engine mount to

crossmember (Fig. 2).

(20) Using paint or grease pencil, mark outline of

crossmember on frame rails to aid installation.

(21) Support crossmember on suitable lifting

device (Fig. 4).

(22) Remove bolts holding crossmember to front

frame rails (Fig. 3).

(23) Remove crossmember from vehicle (Fig. 4).

Fig. 1 Steering Coupling Boot

NSFRAME AND BUMPERS 13 - 3

Page 1285 of 1938

(7) Connect lower ball joints to lower control arms.

Refer to Group 2, Suspension.

(8) Connect stabilizer bar links to ends of stabi-

lizer bar. Refer to Group 2, Suspension.

(9) Install bolts to hold anti-lock brake sensor

leads to crossmember.

(10) Install high pressure hose to pump.

(11) Connect return hose to metal tube.

(12) Tighten hose clamp at the crossmember cou-

pling.

(13) Remove pinch-off pliers.

(14) Position steering so front wheels are straight

ahead.

(15) Install steering column coupling to telescoping

steering gear shaft.

(16) Install clinch bolt to hold steering column cou-

pling to steering gear shaft.

(17) Install knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(18) Install steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(19) Connect battery negative cable.

FRONT CROSSMEMBER MOUNT BUSHINGS

REMOVAL

(1) Using paint or grease pencil, mark outline of

crossmember on frame rails.

(2) Loosen bolts holding crossmember to frame

rails.

(3) Remove bolt on bushing that requires replace-

ment.

(4) Allow crossmember to drop down enough to

gain clearance for bushing removal.

(5) Remove bushing from vehicle.

INSTALLATION

(1) Apply rubber lube or soap to replacement bush-

ing.(2) Insert lower half of bushing into square hole in

crossmember.

(3) Place upper half of bushing on top of cross-

member aligned to receive square tube protruding

upward from lower bushing half.

(4) Squeeze bushing halves together to ensure they

are properly mated.

(5) Lift crossmember upward to close gap between

the bushing and frame.

(6) Verify that lower bushing is fully seated into

crossmember and upper bushing.

(7) Install bolt to hold bushing and crossmember

to frame rail hand tight.

(8) Align crossmember to reference marks on

frame rails.

(9) Tighten crossmember to frame rails attaching

bolts to 163 N´m (120 ft. lbs.) torque.

SPECIFICATIONS

FRAME AND BODY OPENING DIMENSIONS

Frame dimensions are listed in metric scale. All

dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location.

VEHICLE PREPARATION

Position the vehicle on a frame alignment rack,

refer to instructions provided with equipment being

used. Adjust the vehicle PLP heights to the specified

dimension above the work surface (datum line). Ver-

tical dimensions can be taken from the datum line to

the locations indicated were applicable. Refer to (Fig.

5), (Fig. 6), (Fig. 7), (Fig. 8), (Fig. 9), (Fig. 10) and

(Fig. 11) for proper dimensions.

NSFRAME AND BUMPERS 13 - 5

REMOVAL AND INSTALLATION (Continued)