Index CHRYSLER VOYAGER 1996 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1732 of 1938

PAINT

INDEX

page page

GENERAL INFORMATION

AFTERMARKET PAINT REPAIR PRODUCTS.... 3

BASE COAT/CLEAR COAT FINISH............ 2PAINT CODE............................ 2

PAINTED SURFACE TOUCH-UP............. 2

WET SANDING, BUFFING, AND POLISHING.... 2

GENERAL INFORMATION

PAINT CODE

A paint code is provided on the body code plate

located in the engine compartment. Refer to the

Introduction section at the front of this manual for

body code plate description. The paint and trim codes

are also included on the Vehicle Safety Label located

on the driver's door end frame.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two-part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultraviolet light and provides a dura-

ble high-gloss finish.

WET SANDING, BUFFING, AND POLISHING

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light wet sanding, hand buffing, and polishing.

If the finish has been wet sanded in the past, it

cannot be repeated. Wet sanding operation

should be performed by a trained automotive

paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly wet sanded (1500 grit) and pol-

ished with rubbing compound.

(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

23 - 2 BODYNS

Page 1734 of 1938

STATIONARY GLASS

INDEX

page page

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS................... 4

REMOVAL AND INSTALLATION

BODY SIDE/SLIDING DOOR STATIONARY

GLASS............................... 6REAR WINDOW.......................... 7

WINDSHIELD............................ 4

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCHWELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

CHRYSLER DOES NOT RECOMMEND GLASS

ADHESIVE BY BRAND. TECHNICIANS SHOULD

REVIEW PRODUCT LABELS AND TECHNICAL DATA

SHEETS, AND USE ONLY ADHESIVES THAT THEIR

MANUFACTURES WARRANT WILL RESTORE A

VEHICLE TO THE REQUIREMENTS OF FMVSS 212.

TECHNICIANS SHOULD ALSO INSURE THAT PRIM-

ERS AND CLEANERS ARE COMPATIBLE WITH THE

PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.

CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

REMOVAL AND INSTALLATION

WINDSHIELD

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

WINDSHIELD REMOVAL ± EXTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove windshield wiper arms.

(3) Remove cowl cover.

(4) Remove A-pillar trim panels.

(5) Disconnect wire connectors to windshield

defroster grid.

(6) Place protective covers over instrument panel

and hood.

(7) Remove windshield molding (Fig. 1). Using pli-

ers, pull outward on molding at the bottom of A-pil-

lars.

(8) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 2). A power

cutting device can be used if available.

(9) Remove windshield from vehicle.

23 - 4 BODYNS

Page 1739 of 1938

SEATS

INDEX

page page

REMOVAL AND INSTALLATION

ARM REST.............................. 9

BENCH SEAT BACK COVER................ 9

BENCH SEAT BACK HINGE COVERS........ 10

BENCH SEAT BACK HINGE................. 9

BENCH SEAT RISER ± FIRST REAR......... 11

BENCH SEAT RISER ± SECOND REAR....... 11

BENCH SEAT TRACK ± SECOND REAR...... 11

BUCKET SEAT BACK ASSIST STRAP........ 12

BUCKET SEAT BACK..................... 12

BUCKET SEAT CUSHION PAN.............. 12

BUCKET SEAT CUSHION SIDE COVER....... 13

BUCKET SEAT RECLINER ± MANUAL........ 13

BUCKET SEAT RECLINER ± POWER......... 14

BUCKET SEAT RISER ± MANUAL TRACK..... 14

BUCKET SEAT TRACK FRONT COVER ±

POWER.............................. 15BUCKET SEAT TRACK REAR COVER ±

POWER.............................. 15

BUCKET SEAT TRACK ± MANUAL........... 14

BUCKET SEAT TRACK ± POWER........... 14

CHILD RESTRAINT SEAT MODULE.......... 16

HEAD RESTRAINT SLEEVE................ 18

HEAD RESTRAINT ± BENCH SEAT.......... 16

HEAD RESTRAINT ± BUCKET SEAT......... 17

HEATED SEAT HEATING ELEMENT.......... 18

HEATED SEAT MODULE.................. 18

HEATED SEAT SWITCH................... 19

MECHANICAL LUMBAR HANDLE ASSEMBLY . . 19

PLASTIC GROCERY BAG RETAINER......... 19

POWER SEAT SWITCH................... 20

RECLINER HANDLE ± MANUAL............. 20

UNDER SEAT STORAGE BIN GUIDE......... 21

UNDER SEAT STORAGE BIN LOCK/LATCH.... 21

UNDER SEAT STORAGE BIN............... 20

REMOVAL AND INSTALLATION

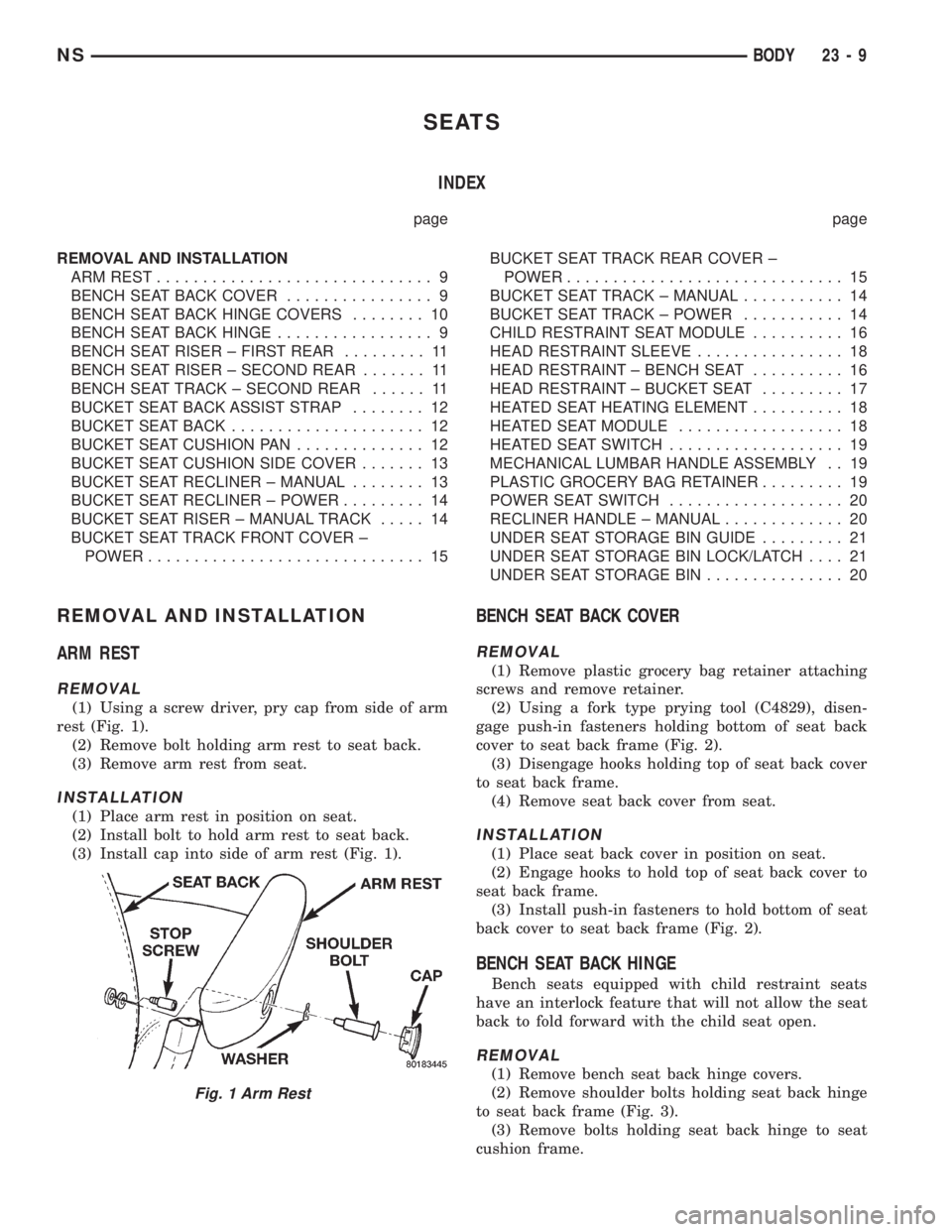

ARM REST

REMOVAL

(1) Using a screw driver, pry cap from side of arm

rest (Fig. 1).

(2) Remove bolt holding arm rest to seat back.

(3) Remove arm rest from seat.

INSTALLATION

(1) Place arm rest in position on seat.

(2) Install bolt to hold arm rest to seat back.

(3) Install cap into side of arm rest (Fig. 1).

BENCH SEAT BACK COVER

REMOVAL

(1) Remove plastic grocery bag retainer attaching

screws and remove retainer.

(2) Using a fork type prying tool (C4829), disen-

gage push-in fasteners holding bottom of seat back

cover to seat back frame (Fig. 2).

(3) Disengage hooks holding top of seat back cover

to seat back frame.

(4) Remove seat back cover from seat.

INSTALLATION

(1) Place seat back cover in position on seat.

(2) Engage hooks to hold top of seat back cover to

seat back frame.

(3) Install push-in fasteners to hold bottom of seat

back cover to seat back frame (Fig. 2).

BENCH SEAT BACK HINGE

Bench seats equipped with child restraint seats

have an interlock feature that will not allow the seat

back to fold forward with the child seat open.

REMOVAL

(1) Remove bench seat back hinge covers.

(2) Remove shoulder bolts holding seat back hinge

to seat back frame (Fig. 3).

(3) Remove bolts holding seat back hinge to seat

cushion frame.

Fig. 1 Arm Rest

NSBODY 23 - 9

Page 1752 of 1938

BODY COMPONENT SERVICE

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 23

WIND NOISE........................... 24

SERVICE PROCEDURES

HEAT STAKING......................... 24

REMOVAL AND INSTALLATION

A-PILLAR LOWER EXTENSION TRIM........ 25

A-PILLAR TRIM PANEL................... 25

COWL COVER.......................... 25

COWL TRIM............................ 25

FLOOR CARPET........................ 26

FRONT DOOR APPLIQUE................. 28

FRONT DOOR CHECK STRAP.............. 28

FRONT DOOR FRAME CLOSEOUT MOLDINGS . 29

FRONT DOOR GLASS RUN WEATHER-STRIP . . 30

FRONT DOOR GLASS.................... 29

FRONT DOOR HINGE.................... 30

FRONT DOOR INNER BELT MOLDING....... 31

FRONT DOOR LATCH STRIKER............ 32

FRONT DOOR LATCH.................... 31

FRONT DOOR LOCK CYLINDER............ 32

FRONT DOOR OUTER BELT MOLDING....... 33

FRONT DOOR OUTSIDE HANDLE........... 33

FRONT DOOR REFLECTOR............... 34

FRONT DOOR SILL PLATE................ 34

FRONT DOOR TRIM PANEL................ 34

FRONT DOOR WEATHER-STRIP............ 36

FRONT DOOR WINDOW CRANK............ 36

FRONT DOOR WINDOW REGULATOR....... 36

FRONT DOOR.......................... 27

FRONT SEAT........................... 37

FRONT WHEELHOUSE SPLASH SHIELD..... 37

FUEL FILL DOOR BLOCKER LATCH STRIKER . . 38

FUEL FILL DOOR BLOCKER LATCH......... 38

FUEL FILL DOOR BLOCKER LOCKOUT LINK . . 38

FUEL FILLER HOUSING ± WITH BLOCKER

LATCH .............................. 39

GRILLE............................... 39

HEADLINING........................... 39

HOOD HINGE.......................... 41

HOOD LATCH STRIKER................... 42

HOOD LATCH.......................... 41

HOOD RELEASE CABLE.................. 42

HOOD RELEASE HANDLE................. 42

HOOD................................ 40

JACK STORAGE COVER.................. 43

LEFT D-PILLAR TRIM PANEL............... 43

LEFT QUARTER TRIM PANEL.............. 44

LIFTGATE CHMSL ACCESS PANEL.......... 47

LIFTGATE HINGE........................ 47LIFTGATE LATCH STRIKER................ 47

LIFTGATE LATCH........................ 47

LIFTGATE LOCK CYLINDER............... 48

LIFTGATE OUTSIDE HANDLE.............. 48

LIFTGATE PROP ASSEMBLY............... 49

LIFTGATE SILL PLATE.................... 49

LIFTGATE STABILIZER WEDGE STRIKER..... 49

LIFTGATE STABILIZER WEDGE............. 49

LIFTGATE TRIM PANEL................... 50

LIFTGATE UPPER FRAME MOLDING........ 50

LIFTGATE UPPER FRAME SIDE MOLDINGS . . . 51

LIFTGATE............................. 46

LOWER B-PILLAR TRIM COVER............ 51

LUGGAGE RACK CROSSBAR.............. 51

LUGGAGE RACK RISER COVER............ 52

LUGGAGE RACK SIDE RAIL............... 52

OVERHEAD GRAB-HANDLES.............. 52

QUARTER GLASS....................... 52

QUARTER TRIM BOLSTER................ 53

RADIATOR CLOSURE PANEL CROSSMEMBER . 53

RAIL LAMP MODULE..................... 54

REAR HEADER TRIM..................... 55

REAR HVAC LOUVER AND BEZEL.......... 55

RIGHT D-PILLAR TRIM PANEL.............. 55

RIGHT QUARTER TRIM PANEL............. 56

ROOF APERTURE (RAP) MOLDING.......... 57

SEAT BELT BUCKLE FIRST REAR QUAD

BUCKET............................. 58

SEAT BELT BUCKLE FIRST REAR ± TWO

PASSENGER BENCH................... 58

SEAT BELT BUCKLE SECOND REAR ± THREE

PASSENGER BENCH................... 59

SEAT BELT BUCKLE ± FRONT INBOARD..... 57

SEAT BELT FIRST REAR ANCHOR BRACKET ±

LWB ................................ 59

SEAT BELT FIRST REAR OUTBOARD ± LWB

FOUR DOOR.......................... 60

SEAT BELT FIRST REAR OUTBOARD ± SWB

FOUR DOOR.......................... 60

SEAT BELT LEFT FIRST REAR OUTBOARD ±

LWB THREE DOOR..................... 61

SEAT BELT LEFT FIRST REAR OUTBOARD ±

SWB THREE DOOR.................... 61

SEAT BELT SECOND REAR OUTBOARD ±

SWB ................................ 61

SEAT BELT SECOND RIGHT REAR OUTBOARD

±LWB ............................... 62

SEAT BELT ± OUTBOARD FRONT........... 59

SECOND RIGHT REAR OUTBOARD SEAT BELT

± LWB W/REAR HVAC................... 62

23 - 22 BODYNS

Page 1813 of 1938

BODY

CONTENTS

page page

BODY COMPONENT SERVICE............... 3 SEATS .................................. 1

SEATS

INDEX

page page

REMOVAL AND INSTALLATION

BENCH SEAT BACK COVER................ 2

HEAD RESTRAINT ESCUTCHEON........... 1HEAD RESTRAINT SLEEVE................. 2

HEAD RESTRAINT........................ 1

REMOVAL AND INSTALLATION

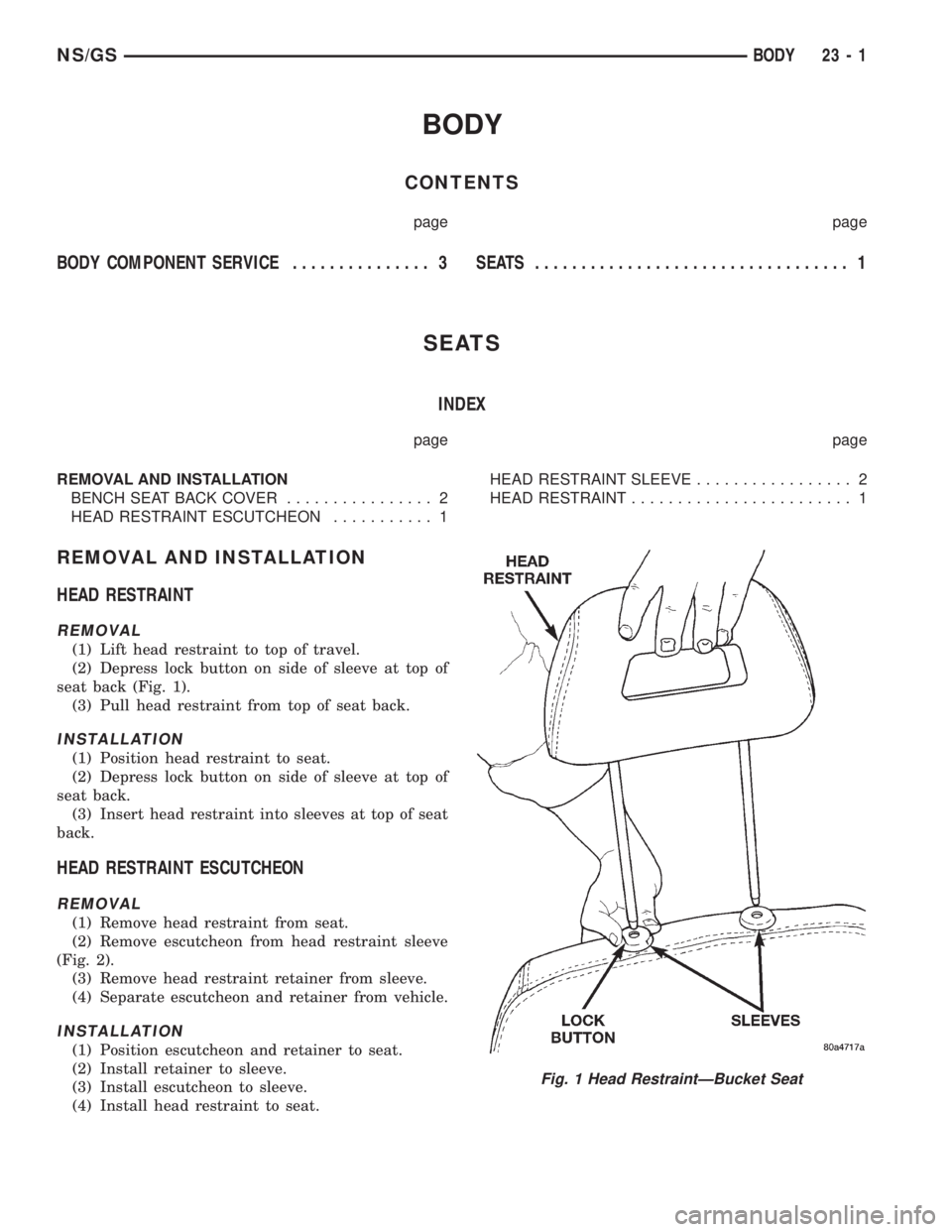

HEAD RESTRAINT

REMOVAL

(1) Lift head restraint to top of travel.

(2) Depress lock button on side of sleeve at top of

seat back (Fig. 1).

(3) Pull head restraint from top of seat back.

INSTALLATION

(1) Position head restraint to seat.

(2) Depress lock button on side of sleeve at top of

seat back.

(3) Insert head restraint into sleeves at top of seat

back.

HEAD RESTRAINT ESCUTCHEON

REMOVAL

(1) Remove head restraint from seat.

(2) Remove escutcheon from head restraint sleeve

(Fig. 2).

(3) Remove head restraint retainer from sleeve.

(4) Separate escutcheon and retainer from vehicle.

INSTALLATION

(1) Position escutcheon and retainer to seat.

(2) Install retainer to sleeve.

(3) Install escutcheon to sleeve.

(4) Install head restraint to seat.

Fig. 1 Head RestraintÐBucket Seat

NS/GSBODY 23 - 1

Page 1815 of 1938

BODY COMPONENT SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

GEARSHIFT CONSOLE.................... 3LIFTGATE CHMSL ACCESS PANEL........... 3

REMOVAL AND INSTALLATION

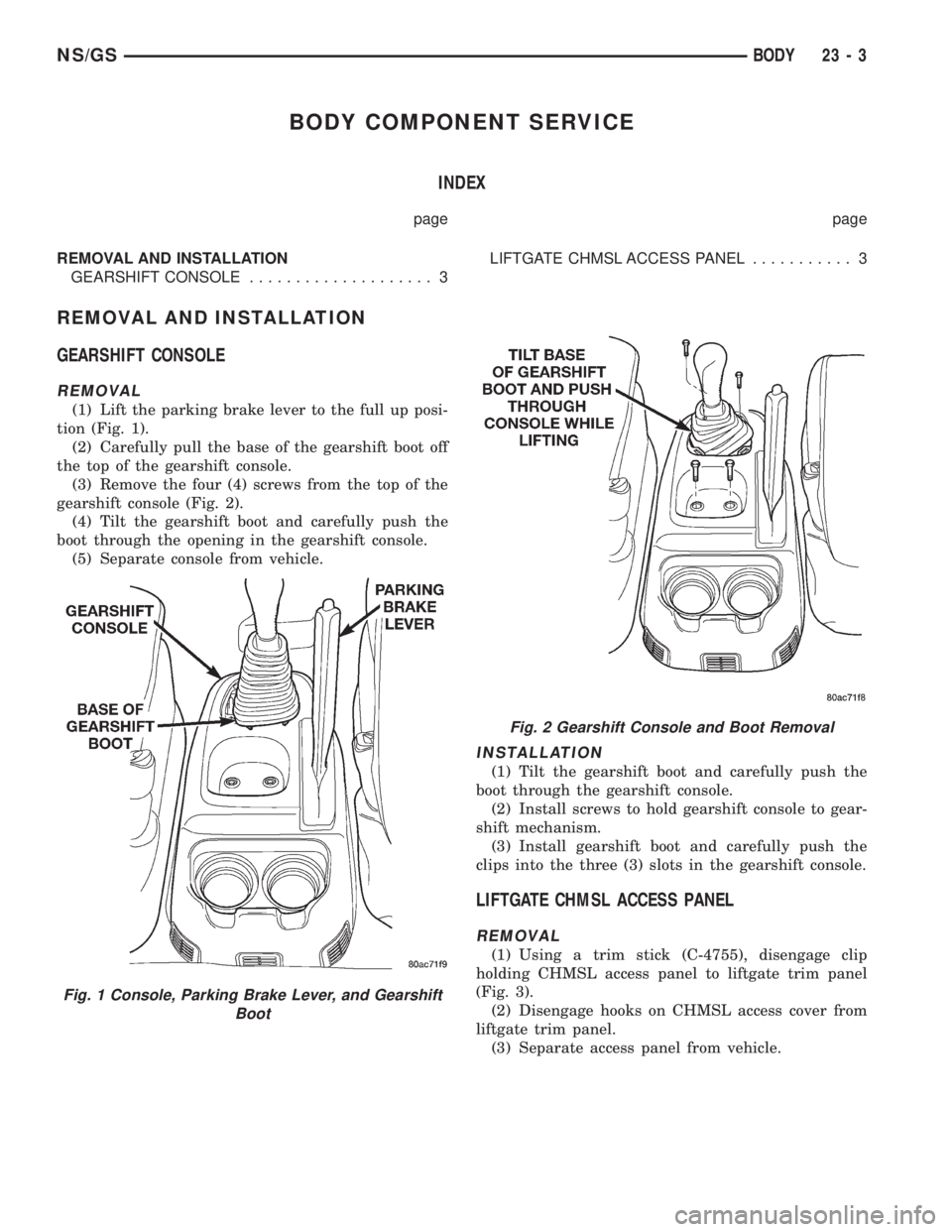

GEARSHIFT CONSOLE

REMOVAL

(1) Lift the parking brake lever to the full up posi-

tion (Fig. 1).

(2) Carefully pull the base of the gearshift boot off

the top of the gearshift console.

(3) Remove the four (4) screws from the top of the

gearshift console (Fig. 2).

(4) Tilt the gearshift boot and carefully push the

boot through the opening in the gearshift console.

(5) Separate console from vehicle.

INSTALLATION

(1) Tilt the gearshift boot and carefully push the

boot through the gearshift console.

(2) Install screws to hold gearshift console to gear-

shift mechanism.

(3) Install gearshift boot and carefully push the

clips into the three (3) slots in the gearshift console.

LIFTGATE CHMSL ACCESS PANEL

REMOVAL

(1) Using a trim stick (C-4755), disengage clip

holding CHMSL access panel to liftgate trim panel

(Fig. 3).

(2) Disengage hooks on CHMSL access cover from

liftgate trim panel.

(3) Separate access panel from vehicle.

Fig. 1 Console, Parking Brake Lever, and Gearshift

Boot

Fig. 2 Gearshift Console and Boot Removal

NS/GSBODY 23 - 3

Page 1817 of 1938

HEATING AND AIR CONDITIONING

CONTENTS

page page

FRONT HEATING AND AIR CONDITIONING

SYSTEM............................... 1REAR HEATING AND AIR CONDITIONING

SYSTEM.............................. 41

FRONT HEATING AND AIR CONDITIONING SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 2

SAFETY PRECAUTIONS AND WARNINGS...... 2

DESCRIPTION AND OPERATION

A/C PRESSURE TRANSDUCER.............. 2

A/C SERVICE PORTS..................... 2

AIR DISTRIBUTION DUCTS................. 2

COMPRESSOR HIGH-PRESSURE RELIEF

VALVE................................ 3

CONDENSATE DRAIN..................... 3

ENGINE COOLING SYSTEM REQUIREMENTS . . 3

EVAPORATOR PROBE..................... 3

HANDLING TUBING AND FITTINGS........... 3

HVAC CONTROL MODULE................. 4

REAR BLOWER SPEED SWITCH............ 3

SIDE DOOR HEATER A/C OUTLETS.......... 4

SIDE WINDOW DEMISTER................. 4

SYSTEM AIRFLOW....................... 4

SYSTEM OIL LEVEL...................... 5

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST................ 12

A/C PRESSURE TRANSDUCER............. 12

ACTUATOR CALIBRATION/DIAGNOSTICS AND

COOLDOWN TEST...................... 6

BLOWER MOTOR AND WHEEL ASSEMBLY.... 13

COMPRESSOR CLUTCH/COIL.............. 13

COMPRESSOR NOISE DIAGNOSIS.......... 13

EXPANSION VALVE...................... 13

HEATER PERFORMANCE TEST............ 15

HVAC CONTROL DIAGNOSTIC CONDITIONS . . . 9

SYSTEM CHARGE LEVEL TEST............ 16SERVICE PROCEDURES

CHARGING REFRIGERANT SYSTEM........ 17

EVACUATING REFRIGERANT SYSTEM....... 18

R-134a REFRIGERANT................... 16

STICKING HVAC CONTROL MODULE PUSH

BUTTONS............................ 19

SYSTEM LEAK CHECKING................ 19

THERMOCOUPLE PROBE................. 19

REMOVAL AND INSTALLATION

A/C PRESSURE TRANSDUCER............. 20

A/C SERVICE PORTS.................... 20

BLEND-AIR DOOR ACTUATOR............. 20

BLOWER MOTOR AND WHEEL ASSEMBLY.... 21

BLOWER MOTOR RESISTOR BLOCK........ 21

BLOWER MOTOR WHEEL................. 22

COMPRESSOR CLUTCH/COIL.............. 23

COMPRESSOR......................... 23

CONDENSER ASSEMBLY................. 25

DISCHARGE LINE....................... 26

EVAPORATOR PROBE.................... 27

EXPANSION VALVE...................... 28

FILTER-DRIER ASSEMBLY................. 28

HEATER A/C UNIT HOUSING............... 29

HEATER CORE......................... 30

HEATER HOSES........................ 31

LIQUID LINE........................... 32

MODE DOOR ACTUATOR................. 32

RECIRC DOOR ACTUATOR................ 34

SIDE WINDOW DEMISTER DUCTS.......... 33

SUCTION LINE.......................... 33

DISASSEMBLY AND ASSEMBLY

HEATER A/C UNIT RECONDITION........... 34

NSHEATING AND AIR CONDITIONING 24 - 1

Page 1857 of 1938

REAR HEATING AND AIR CONDITIONING SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 41

DESCRIPTION AND OPERATION

REAR BLOWER RESISTOR BLOCK.......... 41

REAR HEATER AND A/C LINES............. 41

SYSTEM OPERATION.................... 41

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES............... 43

REMOVAL AND INSTALLATION

AIR DISTRIBUTION DUCT-A/C.............. 43

AIR DISTRIBUTION DUCT-HEATER.......... 43

EVAPORATOR AND EXPANSION VALVE...... 44MODE DOOR ACTUATOR................. 49

MODE DOOR........................... 49

REAR AIR CONDITIONING LINES........... 45

REAR HEATER A/C AIR OUTLETS........... 45

REAR HEATER A/C BLOWER MOTOR........ 46

REAR HEATER A/C UNIT.................. 46

REAR HEATER CORE.................... 48

REAR HEATER LINES.................... 49

REAR HEATER-A/C AUXILIARY CONDENSER . . 45

REAR HEATER-A/C CONTROL ILLUMINATION

BULB............................... 46

GENERAL INFORMATION

INTRODUCTION

For proper operation of the rear heating A/C sys-

tem, refer to Owner's Manual supplied with the vehi-

cle.

DESCRIPTION AND OPERATION

REAR BLOWER RESISTOR BLOCK

The rear blower motor resistor is not serviceable

separately. The resistor is integral to the blower

motor. If resistor is faulty, it is necessary to replace

the complete blower motor.

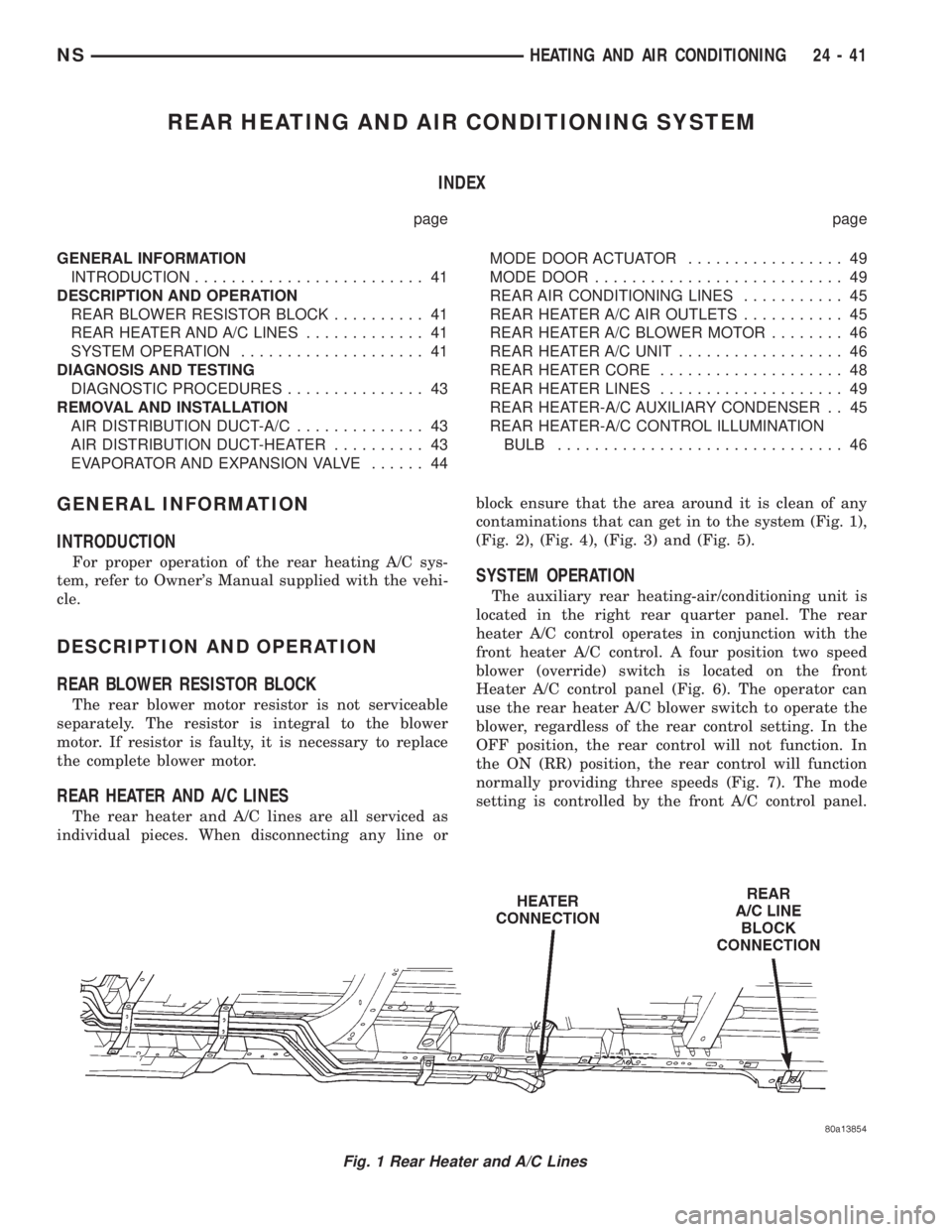

REAR HEATER AND A/C LINES

The rear heater and A/C lines are all serviced as

individual pieces. When disconnecting any line orblock ensure that the area around it is clean of any

contaminations that can get in to the system (Fig. 1),

(Fig. 2), (Fig. 4), (Fig. 3) and (Fig. 5).

SYSTEM OPERATION

The auxiliary rear heating-air/conditioning unit is

located in the right rear quarter panel. The rear

heater A/C control operates in conjunction with the

front heater A/C control. A four position two speed

blower (override) switch is located on the front

Heater A/C control panel (Fig. 6). The operator can

use the rear heater A/C blower switch to operate the

blower, regardless of the rear control setting. In the

OFF position, the rear control will not function. In

the ON (RR) position, the rear control will function

normally providing three speeds (Fig. 7). The mode

setting is controlled by the front A/C control panel.

Fig. 1 Rear Heater and A/C Lines

NSHEATING AND AIR CONDITIONING 24 - 41

Page 1905 of 1938

EMISSION CONTROL SYSTEMS

CONTENTS

page page

EVAPORATIVE EMISSION CONTROLS........ 13

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM.............................. 18ON-BOARD DIAGNOSTICS.................. 1

ON-BOARD DIAGNOSTICS

INDEX

page page

GENERAL INFORMATION

SYSTEM DESCRIPTION................... 1

DESCRIPTION AND OPERATION

CIRCUIT ACTUATION TEST MODE........... 3

COMPONENT MONITORS................. 10

DIAGNOSTIC TROUBLE CODES............. 3

HIGH AND LOW LIMITS................... 11LOAD VALUE........................... 12

MALFUNCTION INDICATOR LAMP (MIL)....... 1

MONITORED SYSTEMS.................... 8

NON-MONITORED CIRCUITS............... 11

STATE DISPLAY TEST MODE............... 2

TRIP DEFINITION........................ 10

GENERAL INFORMATION

SYSTEM DESCRIPTION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor'soutput circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the DRB scan tool to

erase all DTC's and extinguish the MIL.

Technicians can display stored DTC's by using the

DRB scan tool. Refer to Diagnostic Trouble Codes in

this section. For DTC information, refer to charts in

this section.

DESCRIPTION AND OPERATION

MALFUNCTION INDICATOR LAMP (MIL)

As a functional test, the Malfunction Indicator

Lamp (MIL) illuminates at key-on before engine

NSEMISSION CONTROL SYSTEMS 25 - 1

Page 1917 of 1938

EVAPORATIVE EMISSION CONTROLS

INDEX

page page

DESCRIPTION AND OPERATION

CRANKCASE VENT FILTER................ 16

EVAPORATION CONTROL SYSTEM......... 13

EVAPORATIVE (EVAP) CANISTER........... 13

LEAK DETECTION PUMP................. 14

POSITIVE CRANKCASE VENTILATION (PCV)

SYSTEMS............................ 15

PRESSURE-VACUUM FILLER CAP.......... 14

PROPORTIONAL PURGE SOLENOID......... 13ROLLOVER VALVE....................... 13

VEHICLE EMISSION CONTROL INFORMATION

LABEL............................... 16

DIAGNOSIS AND TESTING

LEAK DETECTION PUMP................. 16

PCV VALVE TEST....................... 16

REMOVAL AND INSTALLATION

LEAK DETECTION PUMP REPLACEMENT.... 16

ROLLOVER VALVES..................... 17

DESCRIPTION AND OPERATION

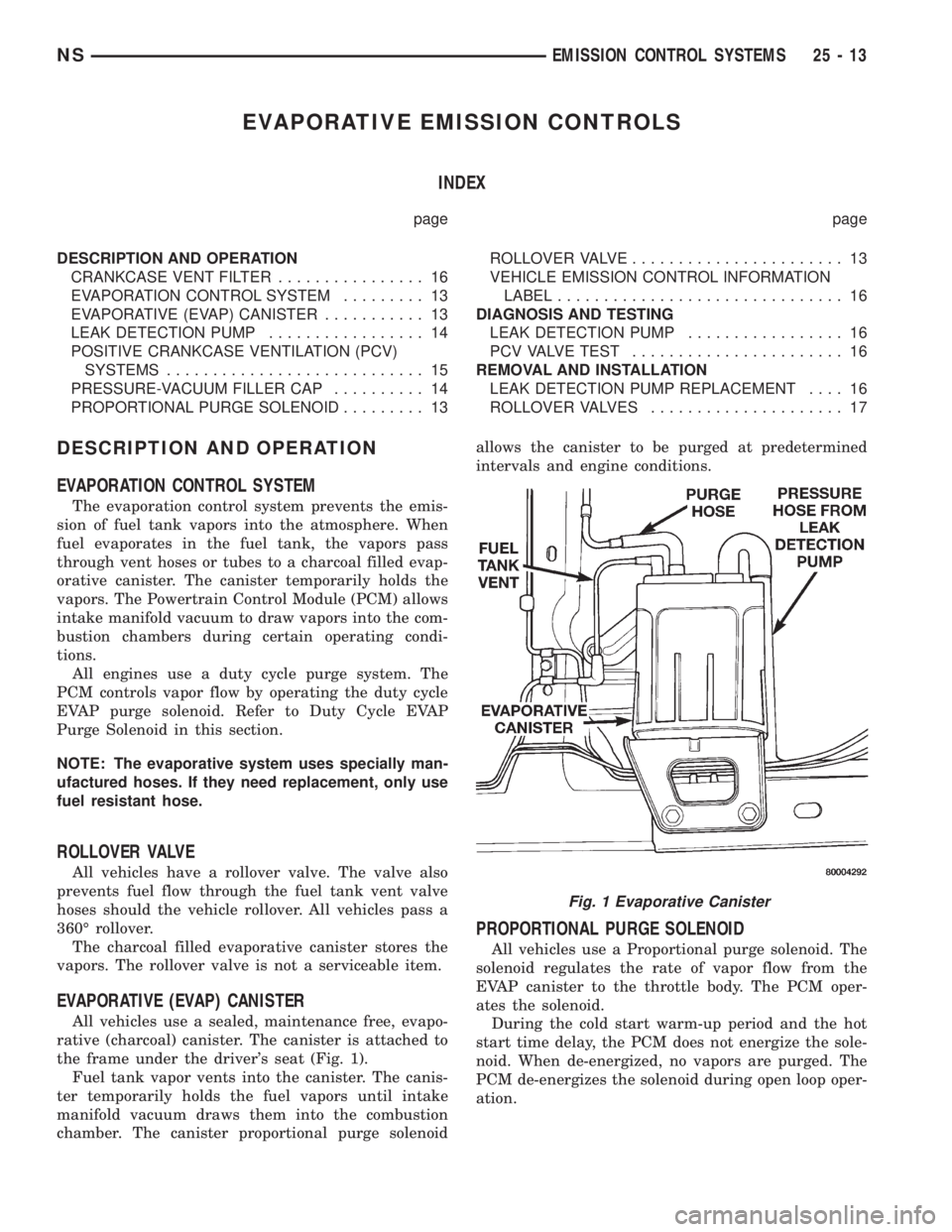

EVAPORATION CONTROL SYSTEM

The evaporation control system prevents the emis-

sion of fuel tank vapors into the atmosphere. When

fuel evaporates in the fuel tank, the vapors pass

through vent hoses or tubes to a charcoal filled evap-

orative canister. The canister temporarily holds the

vapors. The Powertrain Control Module (PCM) allows

intake manifold vacuum to draw vapors into the com-

bustion chambers during certain operating condi-

tions.

All engines use a duty cycle purge system. The

PCM controls vapor flow by operating the duty cycle

EVAP purge solenoid. Refer to Duty Cycle EVAP

Purge Solenoid in this section.

NOTE: The evaporative system uses specially man-

ufactured hoses. If they need replacement, only use

fuel resistant hose.

ROLLOVER VALVE

All vehicles have a rollover valve. The valve also

prevents fuel flow through the fuel tank vent valve

hoses should the vehicle rollover. All vehicles pass a

360É rollover.

The charcoal filled evaporative canister stores the

vapors. The rollover valve is not a serviceable item.

EVAPORATIVE (EVAP) CANISTER

All vehicles use a sealed, maintenance free, evapo-

rative (charcoal) canister. The canister is attached to

the frame under the driver's seat (Fig. 1).

Fuel tank vapor vents into the canister. The canis-

ter temporarily holds the fuel vapors until intake

manifold vacuum draws them into the combustion

chamber. The canister proportional purge solenoidallows the canister to be purged at predetermined

intervals and engine conditions.

PROPORTIONAL PURGE SOLENOID

All vehicles use a Proportional purge solenoid. The

solenoid regulates the rate of vapor flow from the

EVAP canister to the throttle body. The PCM oper-

ates the solenoid.

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged. The

PCM de-energizes the solenoid during open loop oper-

ation.

Fig. 1 Evaporative Canister

NSEMISSION CONTROL SYSTEMS 25 - 13