Index CHRYSLER VOYAGER 1996 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1475 of 1938

TRANSAXLE AND POWER TRANSFER UNIT

CONTENTS

page page

31TH AUTOMATIC TRANSAXLE.............. 1

41TE AUTOMATIC TRANSAXLE............. 71POWER TRANSFER UNIT................. 165

31TH AUTOMATIC TRANSAXLE

INDEX

page page

GENERAL INFORMATION

31TH TRANSAXLE........................ 2

FLUID LEVEL AND CONDITION.............. 2

SELECTION OF LUBRICANT................ 3

SPECIAL ADDITIVES...................... 3

DESCRIPTION AND OPERATION

CLUTCHES, BAND SERVOS, AND

ACCUMULATOR

...................... 3

FLOW CONTROL VALVES.................. 3

GEARSHIFT AND PARKING LOCK CONTROLS . . 4

GOVERNOR............................. 4

HYDRAULIC CONTROL SYSTEM............. 3

PRESSURE REGULATING VALVES........... 3

PRESSURE SUPPLY SYSTEM............... 3

TORQUE CONVERTER CLUTCH SOLENOID

WIRING CONNECTOR................... 4

TORQUE CONVERTER CLUTCH............. 3

DIAGNOSIS AND TESTING

CLUTCH AND SERVO AIR PRESSURE TESTS . 15

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA............ 15

HYDRAULIC PRESSURE TESTS............ 13

ROAD TEST............................. 4

THREE SPEED TRANSAXLE DIAGNOSIS AND

TESTS............................... 4

SERVICE PROCEDURES

ALUMINUM THREAD REPAIR.............. 18

FLUID AND FILTER CHANGE............... 16

FLUID DRAIN AND REFILL................. 18

FLUSHING COOLERS AND TUBES.......... 18

OIL PUMP VOLUME CHECK............... 19

REMOVAL AND INSTALLATION

FRONT PUMP OIL SEAL.................. 21

PARK/NEUTRAL STARTING AND BACK-UP

LAMP SWITCH........................ 19

TRANSAXLE AND TORQUE CONVERTER

REMOVAL............................ 20

VEHICLE SPEED SENSOR PINION GEAR..... 19DISASSEMBLY AND ASSEMBLY

ACCUMULATOR-RECONDITION............ 36

DIFFERENTIAL REPAIR................... 46

FRONT CLUTCH-RECONDITION............ 32

FRONT PLANETARY & ANNULUS GEAR-

RECONDITION........................ 35

KICKDOWN SERVO (CONTROLLED LOAD)-

RECONDITION........................ 37

LOW/REVERSE (REAR)

SERVO-RECONDITION.................. 36

OIL PUMP-RECONDITION................. 31

OUTPUT SHAFT REPAIR.................. 43

PARKING PAWL......................... 42

REAR CLUTCH-RECONDITION............. 33

TRANSAXLE........................... 21

TRANSFER SHAFT REPAIR................ 38

VALVE BODY RECONDITION............... 27

CLEANING AND INSPECTION

VALVE BODY........................... 50

ADJUSTMENTS

BAND ADJUSTMENT..................... 51

BEARING ADJUSTMENT PROCEDURES...... 52

DIFFERENTIAL BEARING................. 53

GEARSHIFT CABLE ADJUSTMENT.......... 51

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS....................... 52

OUTPUT SHAFT BEARING................ 52

THROTTLE PRESSURE LINKAGE

ADJUSTMENT......................... 51

TRANSFER SHAFT BEARING.............. 54

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC SCHEMATIC . . 56

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE............. 64

31TH TORQUE SPECIFICATIONS........... 65

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE............. 66

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 1

Page 1545 of 1938

41TE AUTOMATIC TRANSAXLE

INDEX

page page

GENERAL INFORMATION

41TE FOUR SPEED AUTOMATIC TRANSAXLE . 71

FLUID LEVEL AND CONDITION............. 72

SELECTION OF LUBRICANT............... 72

SPECIAL ADDITIVES..................... 72

DESCRIPTION AND OPERATION

ADAPTIVE CONTROLS................... 73

CLUTCH AND GEAR..................... 72

ELECTRONICS......................... 73

GEARSHIFT AND PARKING LOCK CONTROLS . 74

HYDRAULICS........................... 73

ON-BOARD DIAGNOSTICS................ 74

SENSORS............................. 73

SHIFT POSITION INDICATOR.............. 74

SOLENOIDS............................ 73

TORQUE MANAGEMENT.................. 74

TRANSMISSION CONTROL MODULE........ 74

TRANSMISSION RANGE SENSOR........... 74

DIAGNOSIS AND TESTING

41TE TRANSAXLE GENERAL DIAGNOSIS..... 75

CLUTCH AIR PRESSURE TESTS............ 77

FLUID LEAKAGE-TORQUE CONVERTER

HOUSING AREA....................... 78

HYDRAULIC PRESSURE TESTS............ 75

ROAD TEST............................ 75

SHIFT POSITION INDICATOR.............. 78

SERVICE PROCEDURES

ALUMINUM THREAD REPAIR.............. 81

FLUID AND FILTER CHANGE............... 79

FLUID DRAIN AND REFILL................. 81

FLUSHING COOLERS AND TUBES.......... 81OIL PUMP VOLUME CHECK............... 82

PINION FACTOR PROCEDURE............. 83

TRANSAXLE QUICK LEARN PROCEDURE.... 82

REMOVAL AND INSTALLATION

GEARSHIFT CABLE...................... 83

MANUAL VALVE LEVER (SHIFT LEVER)...... 84

OIL PUMP SEAL......................... 92

SOLENOID ASSEMBLY-REPLACE........... 85

SPEED SENSOR-INPUT................... 86

SPEED SENSOR-OUTPUT................. 86

TRANSAXLE........................... 89

TRANSMISSION CONTROL MODULE........ 87

TRANSMISSION RANGE SENSOR........... 85

VALVE BODY........................... 88

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL REPAIR.................. 139

INPUT CLUTCHES-RECONDITION.......... 110

TRANSAXLE ASSEMBLE................. 122

TRANSAXLE DISASSEMBLE............... 95

VALVE BODY RECONDITION............... 92

CLEANING AND INSPECTION

CLEANING VALVE BODY................. 144

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT......... 144

SCHEMATICS AND DIAGRAMS

41TE TRANSAXLE HYDRAULIC SCHEMATICS . 145

SPECIFICATIONS

41TE AUTOMATIC TRANSAXLE............ 158

41TE TORQUE SPECIFICATIONS.......... 158

SPECIAL TOOLS

41TE AUTOMATIC TRANSAXLE............ 159

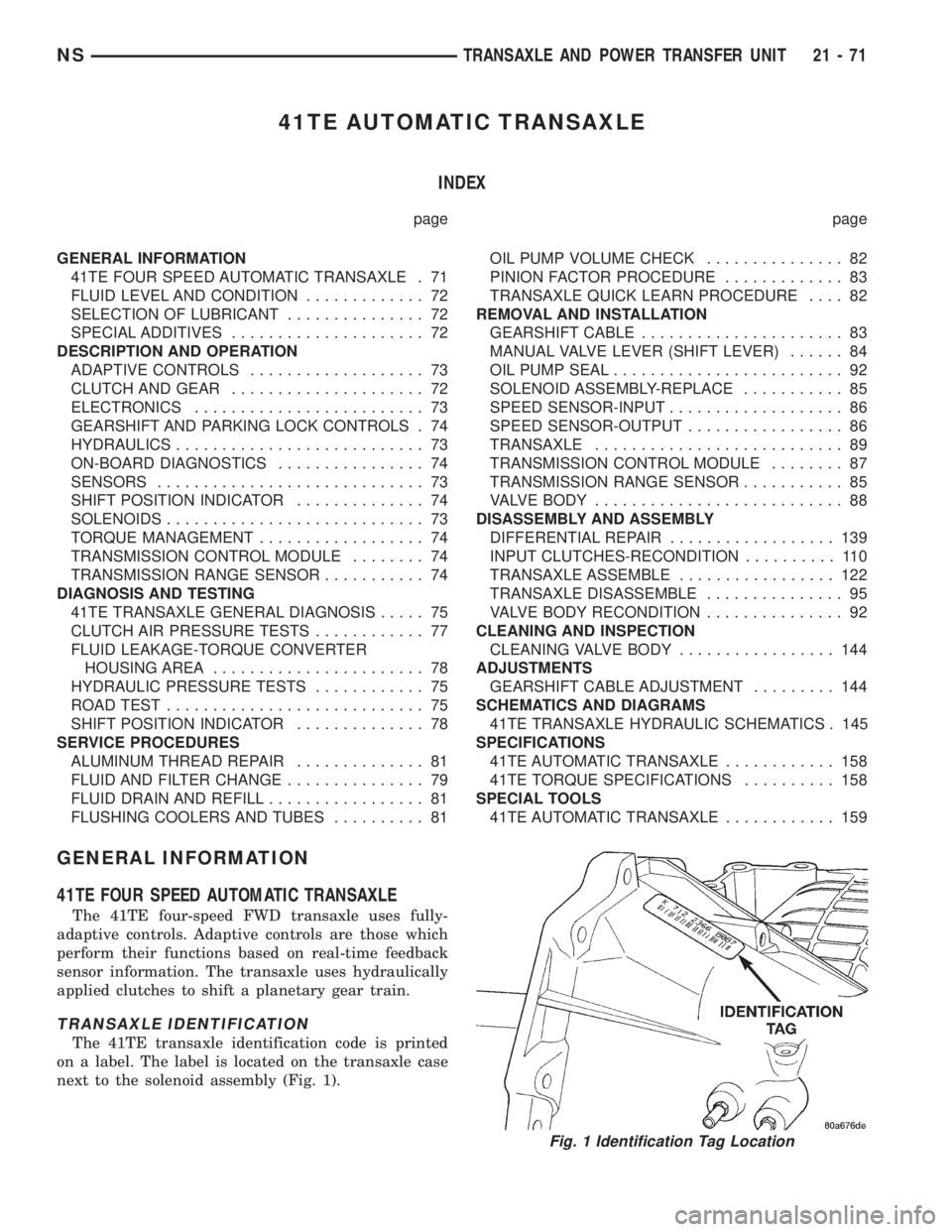

GENERAL INFORMATION

41TE FOUR SPEED AUTOMATIC TRANSAXLE

The 41TE four-speed FWD transaxle uses fully-

adaptive controls. Adaptive controls are those which

perform their functions based on real-time feedback

sensor information. The transaxle uses hydraulically

applied clutches to shift a planetary gear train.

TRANSAXLE IDENTIFICATION

The 41TE transaxle identification code is printed

on a label. The label is located on the transaxle case

next to the solenoid assembly (Fig. 1).

Fig. 1 Identification Tag Location

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 71

Page 1639 of 1938

POWER TRANSFER UNIT

INDEX

page page

GENERAL INFORMATION

POWER TRANSFER UNIT................ 165

DIAGNOSIS AND TESTING

FLUID LEAK DIAGNOSIS................. 167

SEAL IDENTIFICATION................... 165

REMOVAL AND INSTALLATION

DIFFERENTIAL CARRIER SEAL............ 170

END COVER BALL BEARING.............. 178

END COVER SEAL...................... 169

HALF SHAFT INNER SEAL................ 175

INPUT SHAFT COVER SEAL.............. 174

INPUT SHAFT END SEAL................. 177INPUT SHAFT SEAL..................... 169

OUTER HALF SHAFT SEAL............... 177

POWER TRANSFER UNIT (P.T.U.).......... 167

POWER TRANSFER UNIT OUTPUT SEAL.... 171

REAR COVER O-RING................... 171

ADJUSTMENTS

OUTPUT FLANGE SHIM SELECTION........ 180

SPECIFICATIONS

TORQUE............................. 180

SPECIAL TOOLS

SDP POWER TRANSFER UNIT............ 181

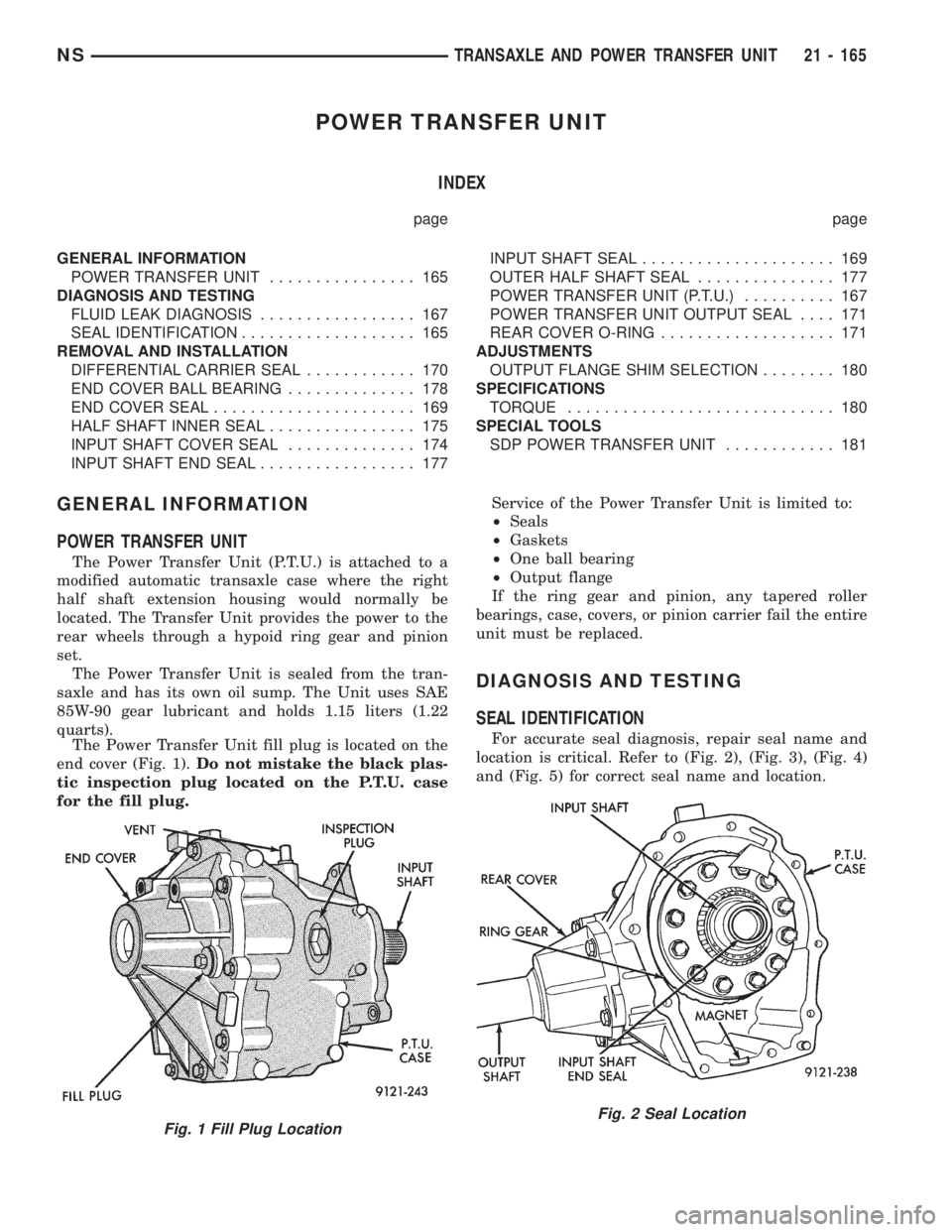

GENERAL INFORMATION

POWER TRANSFER UNIT

The Power Transfer Unit (P.T.U.) is attached to a

modified automatic transaxle case where the right

half shaft extension housing would normally be

located. The Transfer Unit provides the power to the

rear wheels through a hypoid ring gear and pinion

set.

The Power Transfer Unit is sealed from the tran-

saxle and has its own oil sump. The Unit uses SAE

85W-90 gear lubricant and holds 1.15 liters (1.22

quarts).

The Power Transfer Unit fill plug is located on the

end cover (Fig. 1).Do not mistake the black plas-

tic inspection plug located on the P.T.U. case

for the fill plug.Service of the Power Transfer Unit is limited to:

²Seals

²Gaskets

²One ball bearing

²Output flange

If the ring gear and pinion, any tapered roller

bearings, case, covers, or pinion carrier fail the entire

unit must be replaced.

DIAGNOSIS AND TESTING

SEAL IDENTIFICATION

For accurate seal diagnosis, repair seal name and

location is critical. Refer to (Fig. 2), (Fig. 3), (Fig. 4)

and (Fig. 5) for correct seal name and location.

Fig. 1 Fill Plug LocationFig. 2 Seal Location

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 165

Page 1645 of 1938

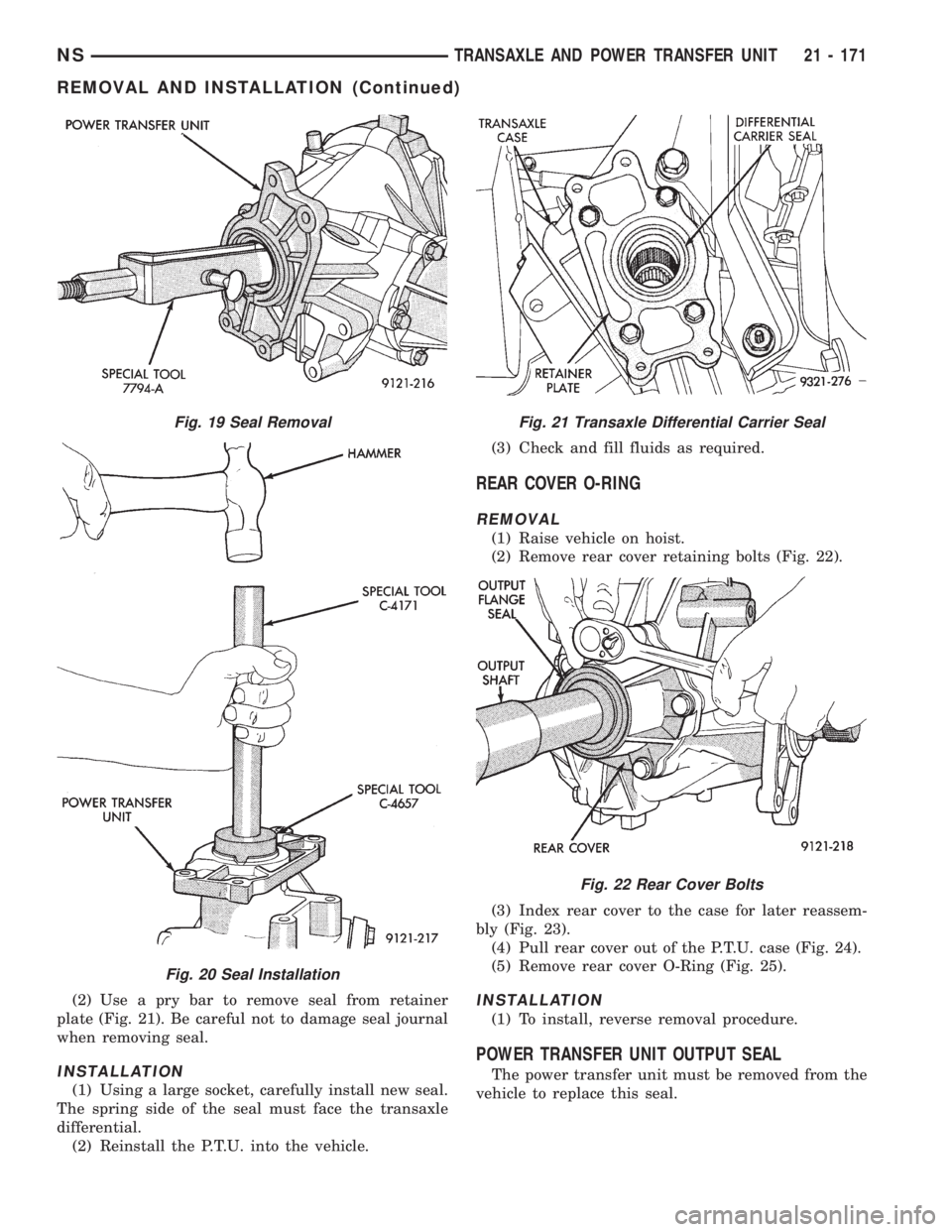

(2) Use a pry bar to remove seal from retainer

plate (Fig. 21). Be careful not to damage seal journal

when removing seal.

INSTALLATION

(1) Using a large socket, carefully install new seal.

The spring side of the seal must face the transaxle

differential.

(2) Reinstall the P.T.U. into the vehicle.(3) Check and fill fluids as required.

REAR COVER O-RING

REMOVAL

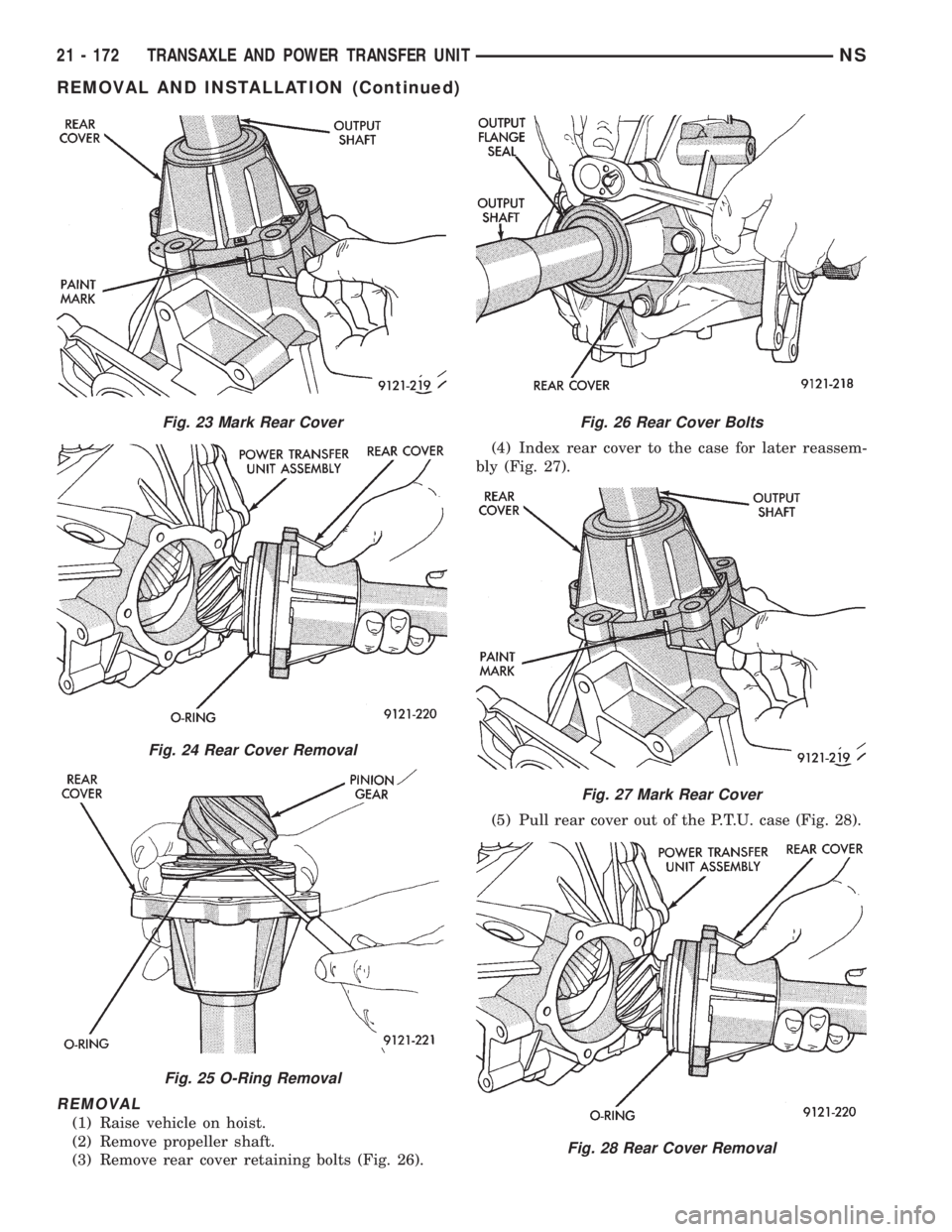

(1) Raise vehicle on hoist.

(2) Remove rear cover retaining bolts (Fig. 22).

(3) Index rear cover to the case for later reassem-

bly (Fig. 23).

(4) Pull rear cover out of the P.T.U. case (Fig. 24).

(5) Remove rear cover O-Ring (Fig. 25).

INSTALLATION

(1) To install, reverse removal procedure.

POWER TRANSFER UNIT OUTPUT SEAL

The power transfer unit must be removed from the

vehicle to replace this seal.

Fig. 19 Seal Removal

Fig. 20 Seal Installation

Fig. 21 Transaxle Differential Carrier Seal

Fig. 22 Rear Cover Bolts

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 171

REMOVAL AND INSTALLATION (Continued)

Page 1646 of 1938

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove propeller shaft.

(3) Remove rear cover retaining bolts (Fig. 26).(4) Index rear cover to the case for later reassem-

bly (Fig. 27).

(5) Pull rear cover out of the P.T.U. case (Fig. 28).

Fig. 23 Mark Rear Cover

Fig. 24 Rear Cover Removal

Fig. 25 O-Ring Removal

Fig. 26 Rear Cover Bolts

Fig. 27 Mark Rear Cover

Fig. 28 Rear Cover Removal

21 - 172 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1647 of 1938

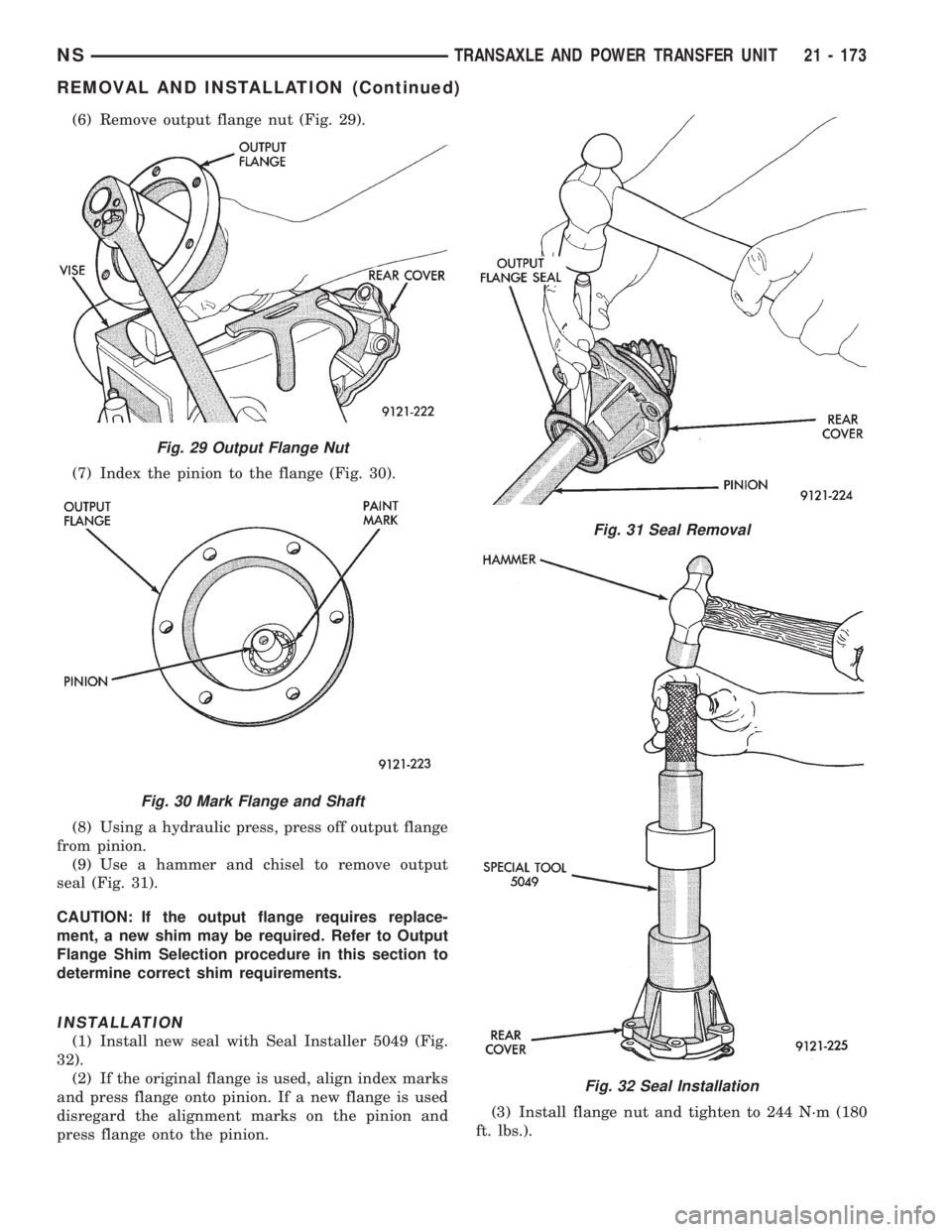

(6) Remove output flange nut (Fig. 29).

(7) Index the pinion to the flange (Fig. 30).

(8) Using a hydraulic press, press off output flange

from pinion.

(9) Use a hammer and chisel to remove output

seal (Fig. 31).

CAUTION: If the output flange requires replace-

ment, a new shim may be required. Refer to Output

Flange Shim Selection procedure in this section to

determine correct shim requirements.

INSTALLATION

(1) Install new seal with Seal Installer 5049 (Fig.

32).

(2) If the original flange is used, align index marks

and press flange onto pinion. If a new flange is used

disregard the alignment marks on the pinion and

press flange onto the pinion.(3) Install flange nut and tighten to 244 N´m (180

ft. lbs.).

Fig. 29 Output Flange Nut

Fig. 30 Mark Flange and Shaft

Fig. 31 Seal Removal

Fig. 32 Seal Installation

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 173

REMOVAL AND INSTALLATION (Continued)

Page 1653 of 1938

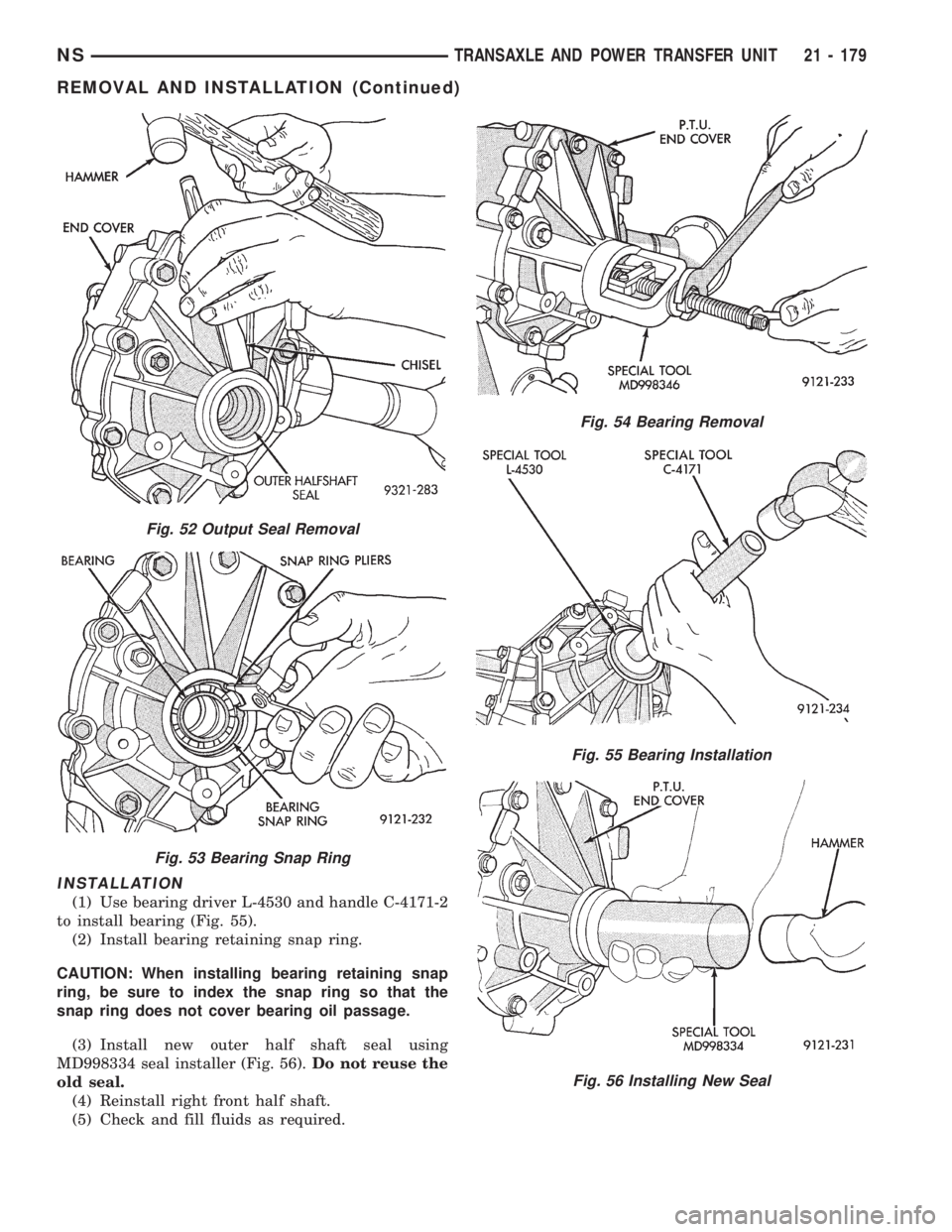

INSTALLATION

(1) Use bearing driver L-4530 and handle C-4171-2

to install bearing (Fig. 55).

(2) Install bearing retaining snap ring.

CAUTION: When installing bearing retaining snap

ring, be sure to index the snap ring so that the

snap ring does not cover bearing oil passage.

(3) Install new outer half shaft seal using

MD998334 seal installer (Fig. 56).Do not reuse the

old seal.

(4) Reinstall right front half shaft.

(5) Check and fill fluids as required.

Fig. 52 Output Seal Removal

Fig. 53 Bearing Snap Ring

Fig. 54 Bearing Removal

Fig. 55 Bearing Installation

Fig. 56 Installing New Seal

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 179

REMOVAL AND INSTALLATION (Continued)

Page 1719 of 1938

TIRES AND WHEELS

CONTENTS

page page

TIRES.................................. 1WHEELS................................ 9

TIRES

INDEX

page page

DESCRIPTION AND OPERATION

RADIAL-PLY TIRES....................... 2

REPLACEMENT TIRES.................... 3

SPARE TIRE (TEMPORARY)................ 2

TIRE INFLATION PRESSURES.............. 2

TIRE INFORMATION...................... 1

TIRE PRESSURE FOR HIGH-SPEED DRIVING . . 3

DIAGNOSIS AND TESTING

LEAD CORRECTION CHART................ 4

PRESSURE GAUGES..................... 3

TIRE NOISE OR VIBRATION................ 4TIRE WEAR PATTERNS.................... 4

TREAD WEAR INDICATORS................ 3

SERVICE PROCEDURES

REPAIRING TIRE LEAKS................... 6

TIRE AND WHEEL MATCH MOUNTING........ 6

TIRE AND WHEEL ROTATION (NON-

DIRECTIONAL THREAD PATTERN).......... 6

CLEANING AND INSPECTION

CLEANING TIRES........................ 7

SPECIFICATIONS

TIRE SPECIFICATIONS.................... 8

DESCRIPTION AND OPERATION

TIRE INFORMATION

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain, in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe application of brakes

²High-speed driving

²Taking turns at excessive speeds

²Striking curbs and other obstacles

Radial ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation. This will

help to achieve a greater tread-life potential.

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 1).

Performance tires will have a speed rating letter

after the aspect ratio number. The speed rating is not

always printed on the tire sidewall. The letterSindi-

cates that the tire is speed rated up to 112 mph.

²Qup to 100 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manu-

facturer for the specific speed rating)

An All Season type tire will have eitherM+S,M

&SorM±S(indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

This vehicle was designed to allow the use of a

specified type of snow chain on the tires. Only com-

pact snow chains or other traction aidsmeeting SAE

type ªClass Sº specifications may be used.Any style

NSTIRES AND WHEELS 22 - 1

Page 1727 of 1938

WHEELS

INDEX

page page

DESCRIPTION AND OPERATION

WHEEL INFORMATION.................... 9

DIAGNOSIS AND TESTING

TIRE AND WHEEL RUNOUT............... 10

WHEEL INSPECTION...................... 9SERVICE PROCEDURES

TIRE AND WHEEL BALANCE............... 11

WHEEL INSTALLATION................... 11

SPECIFICATIONS

WHEEL SPECIFICATIONS................. 12

DESCRIPTION AND OPERATION

WHEEL INFORMATION

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

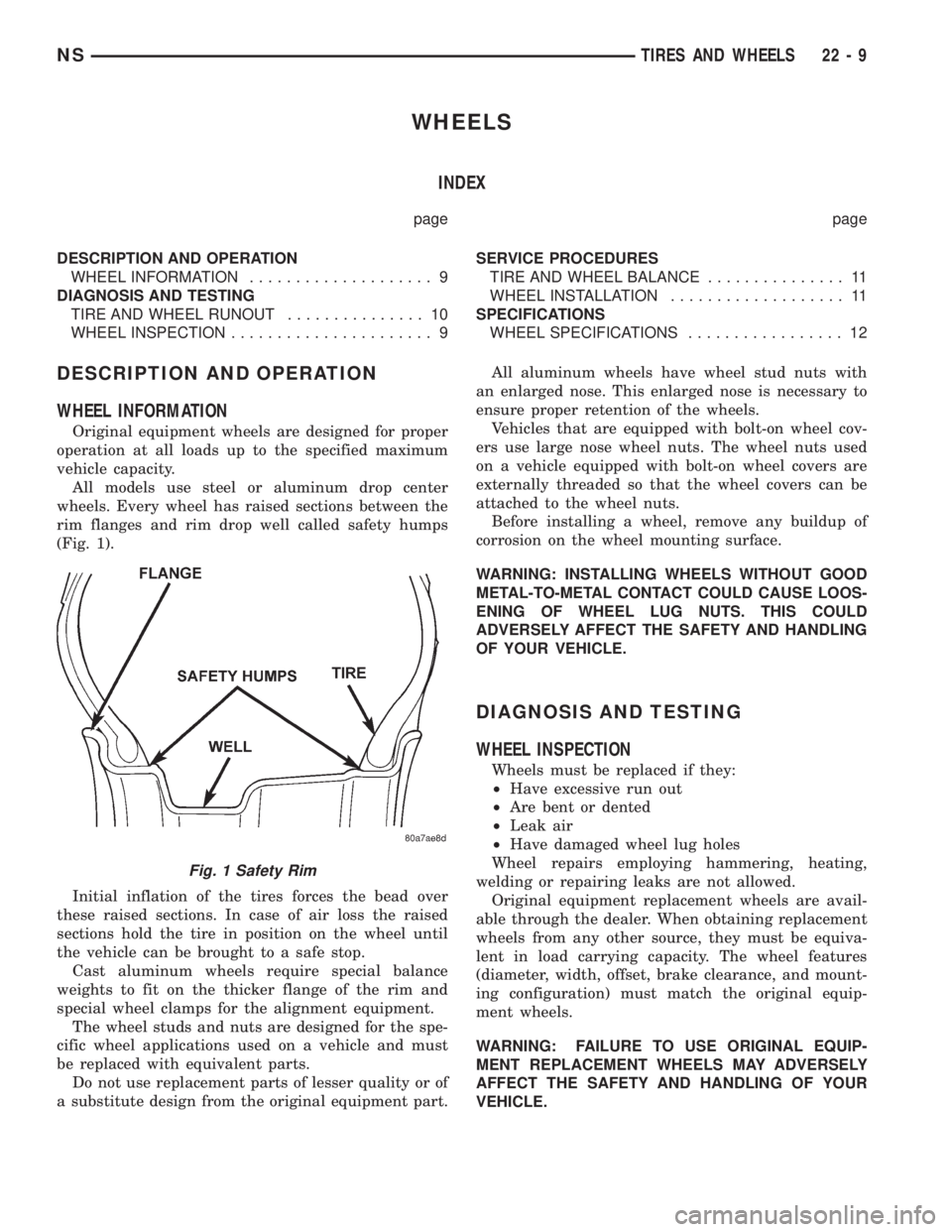

All models use steel or aluminum drop center

wheels. Every wheel has raised sections between the

rim flanges and rim drop well called safety humps

(Fig. 1).

Initial inflation of the tires forces the bead over

these raised sections. In case of air loss the raised

sections hold the tire in position on the wheel until

the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the thicker flange of the rim and

special wheel clamps for the alignment equipment.

The wheel studs and nuts are designed for the spe-

cific wheel applications used on a vehicle and must

be replaced with equivalent parts.

Do not use replacement parts of lesser quality or of

a substitute design from the original equipment part.All aluminum wheels have wheel stud nuts with

an enlarged nose. This enlarged nose is necessary to

ensure proper retention of the wheels.

Vehicles that are equipped with bolt-on wheel cov-

ers use large nose wheel nuts. The wheel nuts used

on a vehicle equipped with bolt-on wheel covers are

externally threaded so that the wheel covers can be

attached to the wheel nuts.

Before installing a wheel, remove any buildup of

corrosion on the wheel mounting surface.

WARNING: INSTALLING WHEELS WITHOUT GOOD

METAL-TO-METAL CONTACT COULD CAUSE LOOS-

ENING OF WHEEL LUG NUTS. THIS COULD

ADVERSELY AFFECT THE SAFETY AND HANDLING

OF YOUR VEHICLE.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Wheels must be replaced if they:

²Have excessive run out

²Are bent or dented

²Leak air

²Have damaged wheel lug holes

Wheel repairs employing hammering, heating,

welding or repairing leaks are not allowed.

Original equipment replacement wheels are avail-

able through the dealer. When obtaining replacement

wheels from any other source, they must be equiva-

lent in load carrying capacity. The wheel features

(diameter, width, offset, brake clearance, and mount-

ing configuration) must match the original equip-

ment wheels.

WARNING: FAILURE TO USE ORIGINAL EQUIP-

MENT REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF YOUR

VEHICLE.

Fig. 1 Safety Rim

NSTIRES AND WHEELS 22 - 9

Page 1731 of 1938

BODY

CONTENTS

page page

BODY COMPONENT SERVICE.............. 22

GENERAL SERVICE INFORMATION........... 1

PAINT.................................. 2SEATS .................................. 9

STATIONARY GLASS....................... 4

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

NSBODY 23 - 1