transmission CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1053 of 1938

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system as out-

lined in Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.

HONING CYLINDER BORES

(1) Used carefully, the cylinder bore resizing hone

C-823 equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round as well as removing light

scuffing, scoring or scratches. Usually a few strokes

will clean up a bore and maintain the required lim-

its.

(2) Deglazing of the cylinder walls may be done

using a cylinder surfacing hone, Tool C-3501,

equipped with 280 grit stones, if the cylinder bore is

straight and round. 20-60 strokes depending on the

bore condition, will be sufficient to provide a satisfac-

tory surface. Inspect cylinder walls after each 20

strokes, using a light honing oil.Do not use engine

or transmission oil, mineral spirits or kerosene.

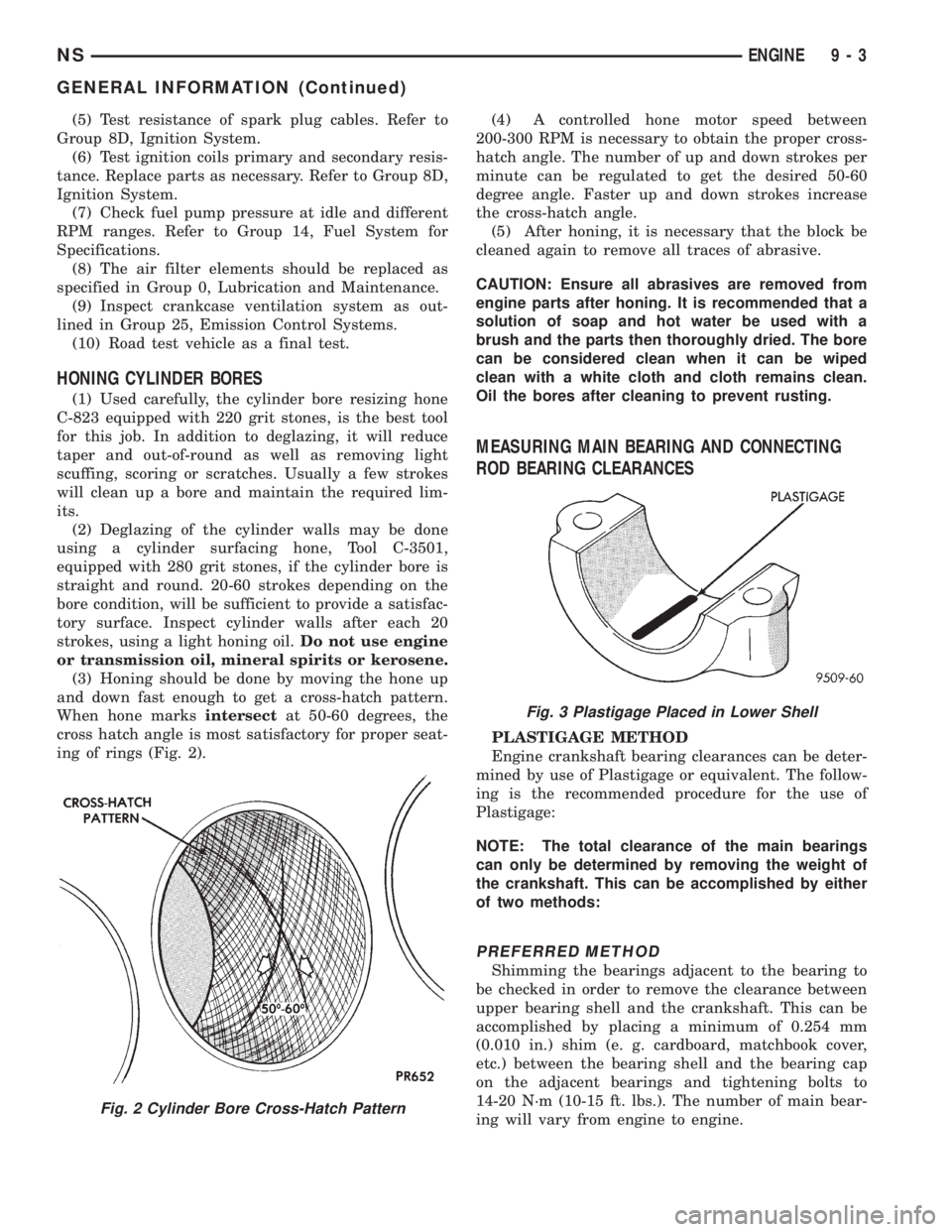

(3) Honing should be done by moving the hone up

and down fast enough to get a cross-hatch pattern.

When hone marksintersectat 50-60 degrees, the

cross hatch angle is most satisfactory for proper seat-

ing of rings (Fig. 2).(4) A controlled hone motor speed between

200-300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50-60

degree angle. Faster up and down strokes increase

the cross-hatch angle.

(5) After honing, it is necessary that the block be

cleaned again to remove all traces of abrasive.

CAUTION: Ensure all abrasives are removed from

engine parts after honing. It is recommended that a

solution of soap and hot water be used with a

brush and the parts then thoroughly dried. The bore

can be considered clean when it can be wiped

clean with a white cloth and cloth remains clean.

Oil the bores after cleaning to prevent rusting.

MEASURING MAIN BEARING AND CONNECTING

ROD BEARING CLEARANCES

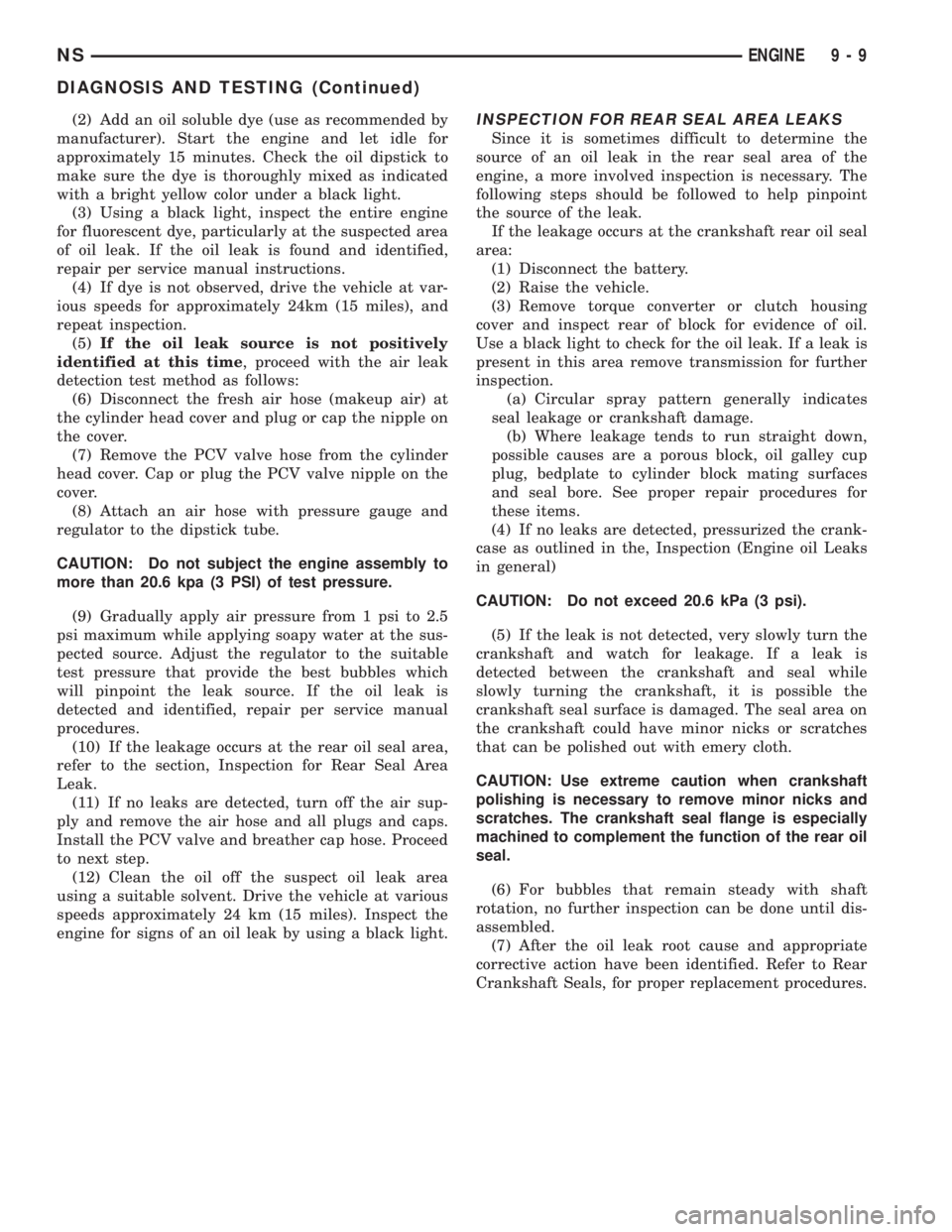

PLASTIGAGE METHOD

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

NOTE: The total clearance of the main bearings

can only be determined by removing the weight of

the crankshaft. This can be accomplished by either

of two methods:

PREFERRED METHOD

Shimming the bearings adjacent to the bearing to

be checked in order to remove the clearance between

upper bearing shell and the crankshaft. This can be

accomplished by placing a minimum of 0.254 mm

(0.010 in.) shim (e. g. cardboard, matchbook cover,

etc.) between the bearing shell and the bearing cap

on the adjacent bearings and tightening bolts to

14-20 N´m (10-15 ft. lbs.). The number of main bear-

ing will vary from engine to engine.

Fig. 2 Cylinder Bore Cross-Hatch Pattern

Fig. 3 Plastigage Placed in Lower Shell

NSENGINE 9 - 3

GENERAL INFORMATION (Continued)

Page 1059 of 1938

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.

(5)If the oil leak source is not positively

identified at this time, proceed with the air leak

detection test method as follows:

(6) Disconnect the fresh air hose (makeup air) at

the cylinder head cover and plug or cap the nipple on

the cover.

(7) Remove the PCV valve hose from the cylinder

head cover. Cap or plug the PCV valve nipple on the

cover.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.

(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil galley cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified. Refer to Rear

Crankshaft Seals, for proper replacement procedures.

NSENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 1076 of 1938

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove Air cleaner and hoses.

(4) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(5) Remove upper radiator hose and remove radia-

tor fans. Refer to Group 7, Cooling System for proce-

dure.

(6) Remove lower radiator hose.

(7) Disconnect automatic transmission cooler lines

and plug, if equipped.

(8) Disconnect transmission shift linkage.

(9) Disconnect throttle body linkage.

(10) Disconnect engine wiring harness.

(11) Disconnect heater hoses.

(12) Discharge Air Conditioning System. Refer to

Group 24, Air Conditioning for procedure.

(13) Hoist vehicle and remove right inner splash

shield. Remove wheels and tires.

(14) Loosen power steering belt for pump removal.

Refer to Group 7, Cooling System for procedure.

(15) Remove axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(16) Disconnect exhaust pipe from manifold.

(17) Remove front and rear engine mount brackets

from the body.

(18) Remove bending braces and front engine

mount bracket. Remove transmission inspection

cover.

(19) Mark flexplate to torque converter and

remove torque converter bolts.

(20) Install front engine mount bracket.

(21) Lower vehicle.

(22) Remove power steering pump. Set pump

aside.

(23) Remove A/C lines at compressor and cap.

(24) Remove ground straps to body.

(25) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 and Adaptor Special Tool

8130 to be installed under vehicle (Fig. 27).

(26) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

front engine bracket and A/C compressor bracket

(Fig. 27). Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.(27) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(28) Remove engine and transmission mount bolts.

(29) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around the body.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(4) Install axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(5) Install transmission and engine braces and

splash shields.

(6) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(7) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt ten-

sion adjustment.

(8) Install A/C compressor hoses. Refer to Group

24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front and rear engine mounts. Refer to

this section for procedure.

(11) Install inner splash shield. Install wheels and

tires.

(12) Connect automatic transmission cooler lines,

and shift linkage. Refer to Group 21, Transmission

for procedures.

(13) Connect fuel line and heater hoses.

(14) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(15) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(16) Install radiator fans. Install radiator hoses.

Fill cooling system. Refer to Group 7, Cooling System

for filling procedure.

(17) Connect battery.

(18) Install air cleaner and hoses.

(19) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(20) Start engine and run until operating temper-

ature is reached.

(21) Adjust transmission linkage, if necessary.

9 - 26 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1104 of 1938

CYLINDER BLOCK

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are installed, refer to Engine

Core Plugs outlined in this section.

(3) Examine block and cylinder bores for cracks or

fractures.

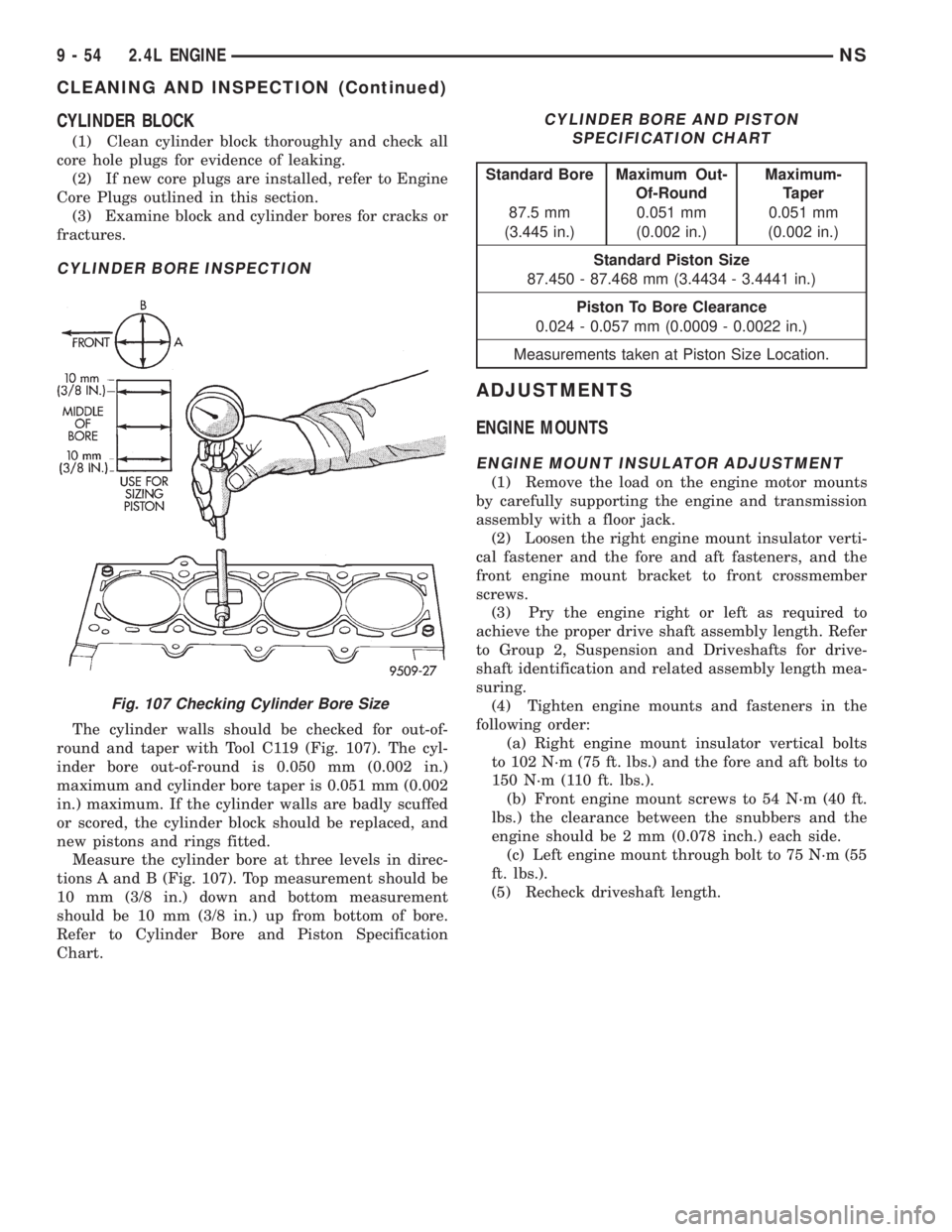

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C119 (Fig. 107). The cyl-

inder bore out-of-round is 0.050 mm (0.002 in.)

maximum and cylinder bore taper is 0.051 mm (0.002

in.) maximum. If the cylinder walls are badly scuffed

or scored, the cylinder block should be replaced, and

new pistons and rings fitted.

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 107). Top measurement should be

10 mm (3/8 in.) down and bottom measurement

should be 10 mm (3/8 in.) up from bottom of bore.

Refer to Cylinder Bore and Piston Specification

Chart.

ADJUSTMENTS

ENGINE MOUNTS

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

(2) Loosen the right engine mount insulator verti-

cal fastener and the fore and aft fasteners, and the

front engine mount bracket to front crossmember

screws.

(3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. Refer

to Group 2, Suspension and Driveshafts for drive-

shaft identification and related assembly length mea-

suring.

(4) Tighten engine mounts and fasteners in the

following order:

(a) Right engine mount insulator vertical bolts

to 102 N´m (75 ft. lbs.) and the fore and aft bolts to

150 N´m (110 ft. lbs.).

(b) Front engine mount screws to 54 N´m (40 ft.

lbs.) the clearance between the snubbers and the

engine should be 2 mm (0.078 inch.) each side.

(c) Left engine mount through bolt to 75 N´m (55

ft. lbs.).

(5) Recheck driveshaft length.

Fig. 107 Checking Cylinder Bore Size

CYLINDER BORE AND PISTON

SPECIFICATION CHART

Standard Bore Maximum Out-

Of-RoundMaximum-

Taper

87.5 mm 0.051 mm 0.051 mm

(3.445 in.) (0.002 in.) (0.002 in.)

Standard Piston Size

87.450 - 87.468 mm (3.4434 - 3.4441 in.)

Piston To Bore Clearance

0.024 - 0.057 mm (0.0009 - 0.0022 in.)

Measurements taken at Piston Size Location.

9 - 54 2.4L ENGINENS

CLEANING AND INSPECTION (Continued)

Page 1118 of 1938

REMOVAL AND INSTALLATION

ENGINE MOUNTS

RIGHT SIDE MOUNT

REMOVAL

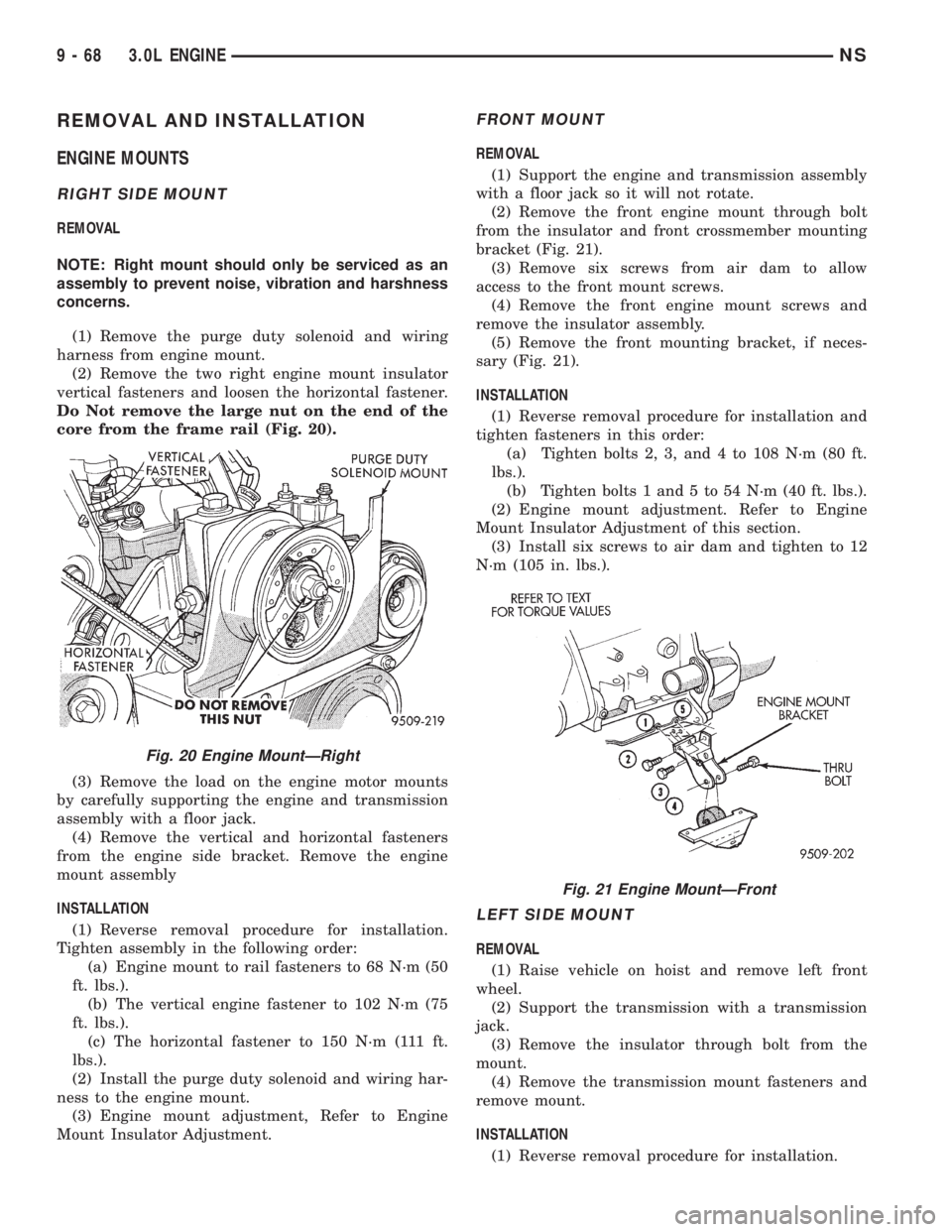

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount.

(2) Remove the two right engine mount insulator

vertical fasteners and loosen the horizontal fastener.

Do Not remove the large nut on the end of the

core from the frame rail (Fig. 20).

(3) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

(4) Remove the vertical and horizontal fasteners

from the engine side bracket. Remove the engine

mount assembly

INSTALLATION

(1) Reverse removal procedure for installation.

Tighten assembly in the following order:

(a) Engine mount to rail fasteners to 68 N´m (50

ft. lbs.).

(b) The vertical engine fastener to 102 N´m (75

ft. lbs.).

(c) The horizontal fastener to 150 N´m (111 ft.

lbs.).

(2) Install the purge duty solenoid and wiring har-

ness to the engine mount.

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment.

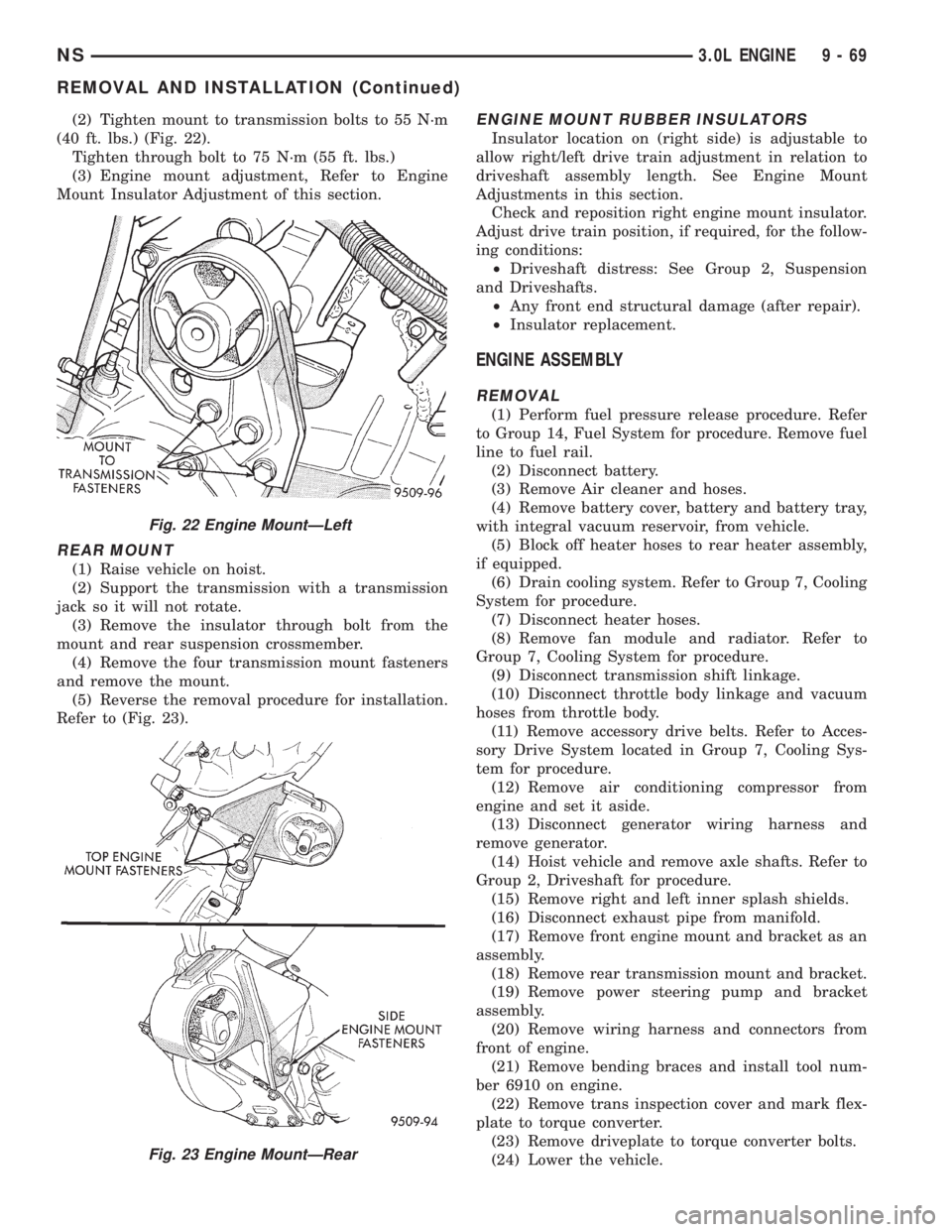

FRONT MOUNT

REMOVAL

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 21).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly.

(5) Remove the front mounting bracket, if neces-

sary (Fig. 21).

INSTALLATION

(1) Reverse removal procedure for installation and

tighten fasteners in this order:

(a) Tighten bolts 2, 3, and 4 to 108 N´m (80 ft.

lbs.).

(b) Tighten bolts 1 and 5 to 54 N´m (40 ft. lbs.).

(2) Engine mount adjustment. Refer to Engine

Mount Insulator Adjustment of this section.

(3) Install six screws to air dam and tighten to 12

N´m (105 in. lbs.).

LEFT SIDE MOUNT

REMOVAL

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Support the transmission with a transmission

jack.

(3) Remove the insulator through bolt from the

mount.

(4) Remove the transmission mount fasteners and

remove mount.

INSTALLATION

(1) Reverse removal procedure for installation.

Fig. 20 Engine MountÐRight

Fig. 21 Engine MountÐFront

9 - 68 3.0L ENGINENS

Page 1119 of 1938

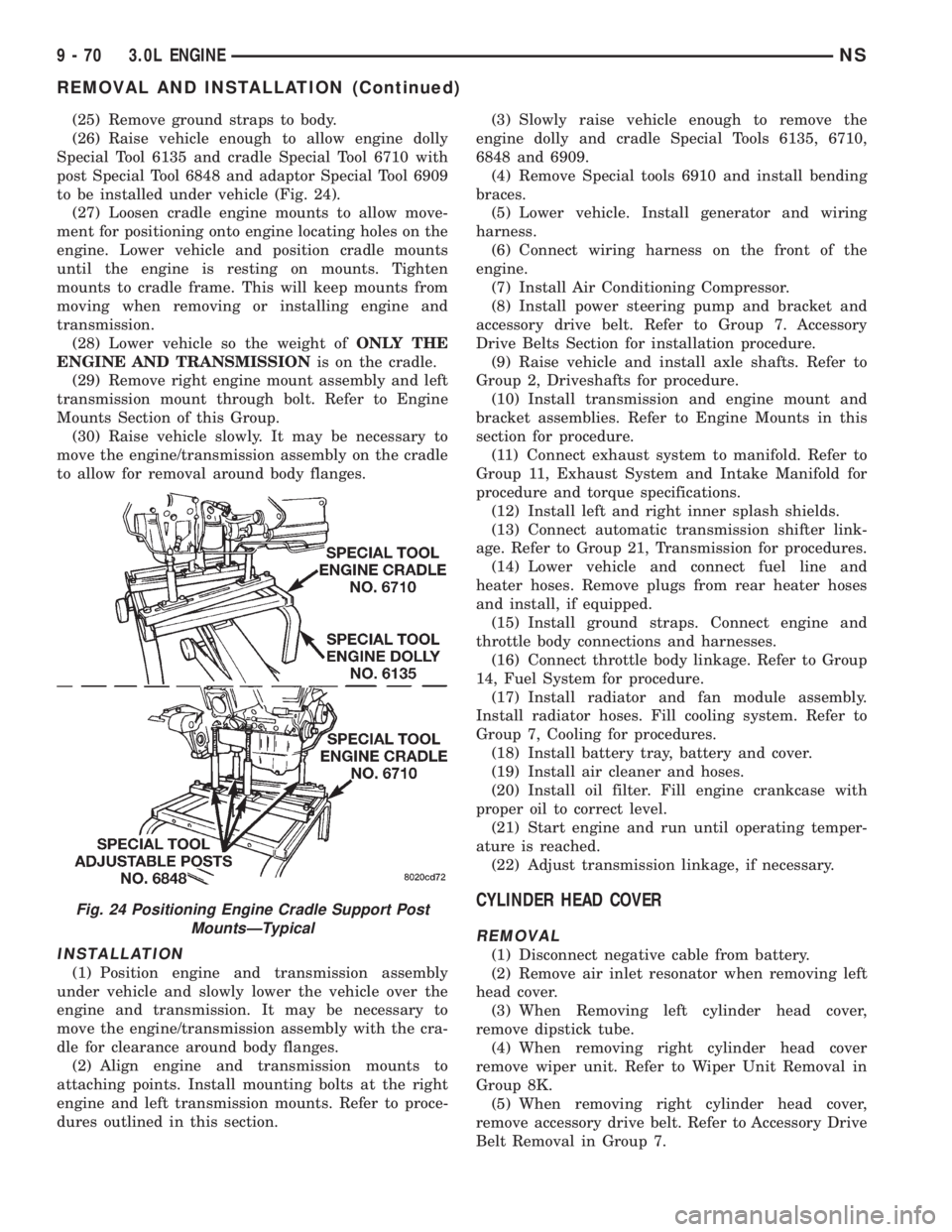

(2) Tighten mount to transmission bolts to 55 N´m

(40 ft. lbs.) (Fig. 22).

Tighten through bolt to 75 N´m (55 ft. lbs.)

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

REAR MOUNT

(1) Raise vehicle on hoist.

(2) Support the transmission with a transmission

jack so it will not rotate.

(3) Remove the insulator through bolt from the

mount and rear suspension crossmember.

(4) Remove the four transmission mount fasteners

and remove the mount.

(5) Reverse the removal procedure for installation.

Refer to (Fig. 23).

ENGINE MOUNT RUBBER INSULATORS

Insulator location on (right side) is adjustable to

allow right/left drive train adjustment in relation to

driveshaft assembly length. See Engine Mount

Adjustments in this section.

Check and reposition right engine mount insulator.

Adjust drive train position, if required, for the follow-

ing conditions:

²Driveshaft distress: See Group 2, Suspension

and Driveshafts.

²Any front end structural damage (after repair).

²Insulator replacement.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove Air cleaner and hoses.

(4) Remove battery cover, battery and battery tray,

with integral vacuum reservoir, from vehicle.

(5) Block off heater hoses to rear heater assembly,

if equipped.

(6) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(7) Disconnect heater hoses.

(8) Remove fan module and radiator. Refer to

Group 7, Cooling System for procedure.

(9) Disconnect transmission shift linkage.

(10) Disconnect throttle body linkage and vacuum

hoses from throttle body.

(11) Remove accessory drive belts. Refer to Acces-

sory Drive System located in Group 7, Cooling Sys-

tem for procedure.

(12) Remove air conditioning compressor from

engine and set it aside.

(13) Disconnect generator wiring harness and

remove generator.

(14) Hoist vehicle and remove axle shafts. Refer to

Group 2, Driveshaft for procedure.

(15) Remove right and left inner splash shields.

(16) Disconnect exhaust pipe from manifold.

(17) Remove front engine mount and bracket as an

assembly.

(18) Remove rear transmission mount and bracket.

(19) Remove power steering pump and bracket

assembly.

(20) Remove wiring harness and connectors from

front of engine.

(21) Remove bending braces and install tool num-

ber 6910 on engine.

(22) Remove trans inspection cover and mark flex-

plate to torque converter.

(23) Remove driveplate to torque converter bolts.

(24) Lower the vehicle.

Fig. 22 Engine MountÐLeft

Fig. 23 Engine MountÐRear

NS3.0L ENGINE 9 - 69

REMOVAL AND INSTALLATION (Continued)

Page 1120 of 1938

(25) Remove ground straps to body.

(26) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 24).

(27) Loosen cradle engine mounts to allow move-

ment for positioning onto engine locating holes on the

engine. Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.

(28) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(29) Remove right engine mount assembly and left

transmission mount through bolt. Refer to Engine

Mounts Section of this Group.

(30) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission. It may be necessary to

move the engine/transmission assembly with the cra-

dle for clearance around body flanges.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909.

(4) Remove Special tools 6910 and install bending

braces.

(5) Lower vehicle. Install generator and wiring

harness.

(6) Connect wiring harness on the front of the

engine.

(7) Install Air Conditioning Compressor.

(8) Install power steering pump and bracket and

accessory drive belt. Refer to Group 7. Accessory

Drive Belts Section for installation procedure.

(9) Raise vehicle and install axle shafts. Refer to

Group 2, Driveshafts for procedure.

(10) Install transmission and engine mount and

bracket assemblies. Refer to Engine Mounts in this

section for procedure.

(11) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(12) Install left and right inner splash shields.

(13) Connect automatic transmission shifter link-

age. Refer to Group 21, Transmission for procedures.

(14) Lower vehicle and connect fuel line and

heater hoses. Remove plugs from rear heater hoses

and install, if equipped.

(15) Install ground straps. Connect engine and

throttle body connections and harnesses.

(16) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(17) Install radiator and fan module assembly.

Install radiator hoses. Fill cooling system. Refer to

Group 7, Cooling for procedures.

(18) Install battery tray, battery and cover.

(19) Install air cleaner and hoses.

(20) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(21) Start engine and run until operating temper-

ature is reached.

(22) Adjust transmission linkage, if necessary.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove air inlet resonator when removing left

head cover.

(3) When Removing left cylinder head cover,

remove dipstick tube.

(4) When removing right cylinder head cover

remove wiper unit. Refer to Wiper Unit Removal in

Group 8K.

(5) When removing right cylinder head cover,

remove accessory drive belt. Refer to Accessory Drive

Belt Removal in Group 7.

Fig. 24 Positioning Engine Cradle Support Post

MountsÐTypical

9 - 70 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1138 of 1938

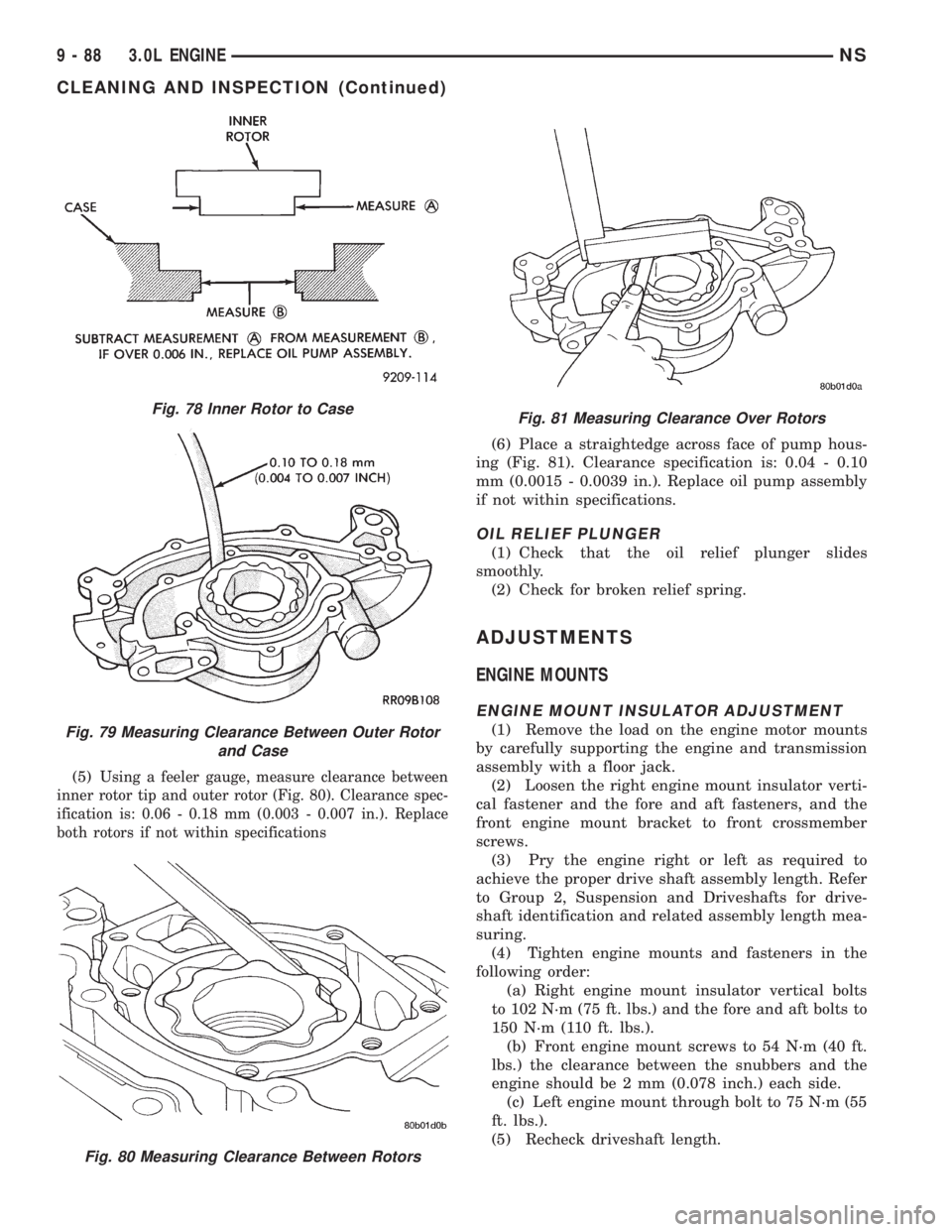

(5)Using a feeler gauge, measure clearance between

inner rotor tip and outer rotor (Fig. 80). Clearance spec-

ification is: 0.06 - 0.18 mm (0.003 - 0.007 in.). Replace

both rotors if not within specifications

(6) Place a straightedge across face of pump hous-

ing (Fig. 81). Clearance specification is: 0.04 - 0.10

mm (0.0015 - 0.0039 in.). Replace oil pump assembly

if not within specifications.

OIL RELIEF PLUNGER

(1) Check that the oil relief plunger slides

smoothly.

(2) Check for broken relief spring.

ADJUSTMENTS

ENGINE MOUNTS

ENGINE MOUNT INSULATOR ADJUSTMENT

(1) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

(2) Loosen the right engine mount insulator verti-

cal fastener and the fore and aft fasteners, and the

front engine mount bracket to front crossmember

screws.

(3) Pry the engine right or left as required to

achieve the proper drive shaft assembly length. Refer

to Group 2, Suspension and Driveshafts for drive-

shaft identification and related assembly length mea-

suring.

(4) Tighten engine mounts and fasteners in the

following order:

(a) Right engine mount insulator vertical bolts

to 102 N´m (75 ft. lbs.) and the fore and aft bolts to

150 N´m (110 ft. lbs.).

(b) Front engine mount screws to 54 N´m (40 ft.

lbs.) the clearance between the snubbers and the

engine should be 2 mm (0.078 inch.) each side.

(c) Left engine mount through bolt to 75 N´m (55

ft. lbs.).

(5) Recheck driveshaft length.

Fig. 78 Inner Rotor to Case

Fig. 79 Measuring Clearance Between Outer Rotor

and Case

Fig. 80 Measuring Clearance Between Rotors

Fig. 81 Measuring Clearance Over Rotors

9 - 88 3.0L ENGINENS

CLEANING AND INSPECTION (Continued)

Page 1152 of 1938

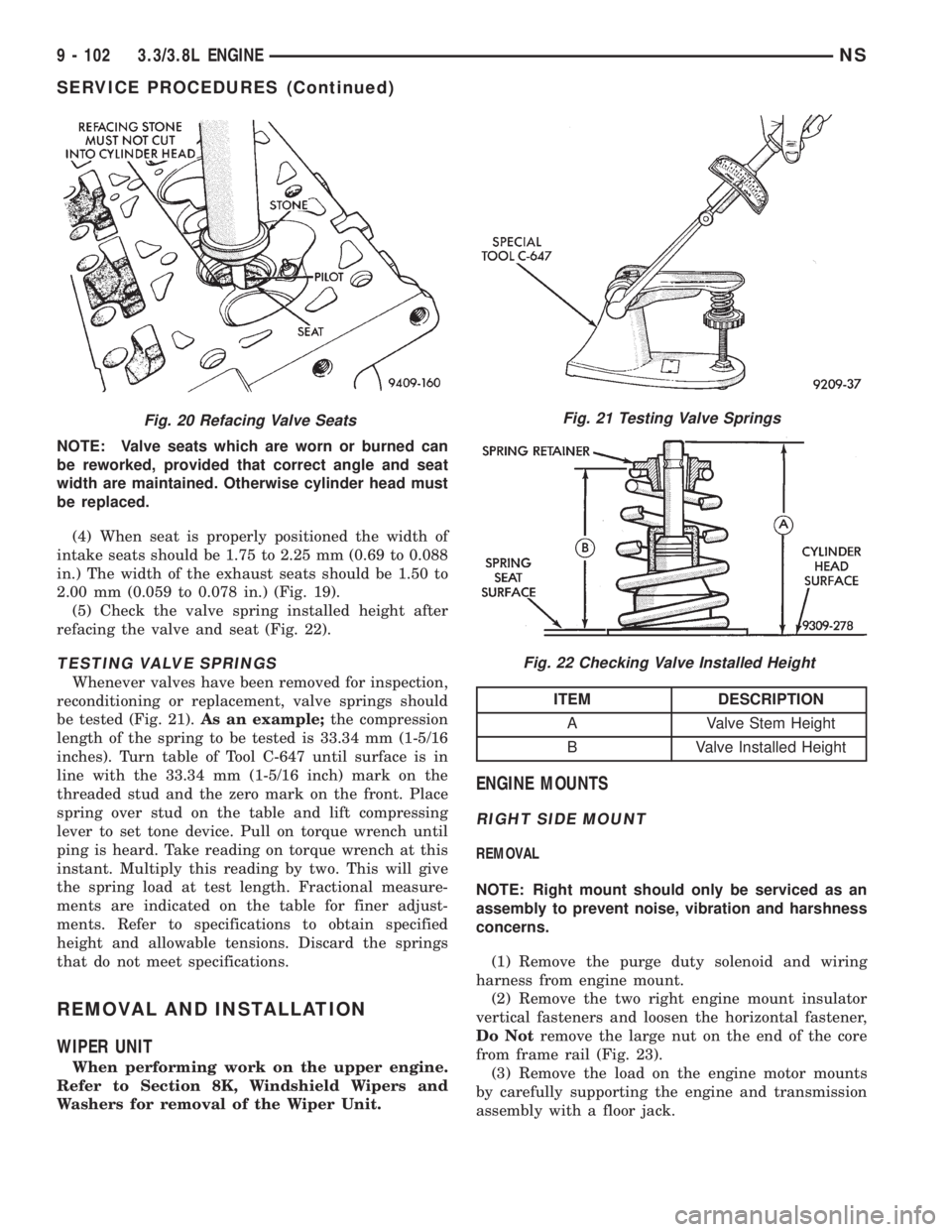

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

(4) When seat is properly positioned the width of

intake seats should be 1.75 to 2.25 mm (0.69 to 0.088

in.) The width of the exhaust seats should be 1.50 to

2.00 mm (0.059 to 0.078 in.) (Fig. 19).

(5) Check the valve spring installed height after

refacing the valve and seat (Fig. 22).

TESTING VALVE SPRINGS

Whenever valves have been removed for inspection,

reconditioning or replacement, valve springs should

be tested (Fig. 21).As an example;the compression

length of the spring to be tested is 33.34 mm (1-5/16

inches). Turn table of Tool C-647 until surface is in

line with the 33.34 mm (1-5/16 inch) mark on the

threaded stud and the zero mark on the front. Place

spring over stud on the table and lift compressing

lever to set tone device. Pull on torque wrench until

ping is heard. Take reading on torque wrench at this

instant. Multiply this reading by two. This will give

the spring load at test length. Fractional measure-

ments are indicated on the table for finer adjust-

ments. Refer to specifications to obtain specified

height and allowable tensions. Discard the springs

that do not meet specifications.

REMOVAL AND INSTALLATION

WIPER UNIT

When performing work on the upper engine.

Refer to Section 8K, Windshield Wipers and

Washers for removal of the Wiper Unit.

ENGINE MOUNTS

RIGHT SIDE MOUNT

REMOVAL

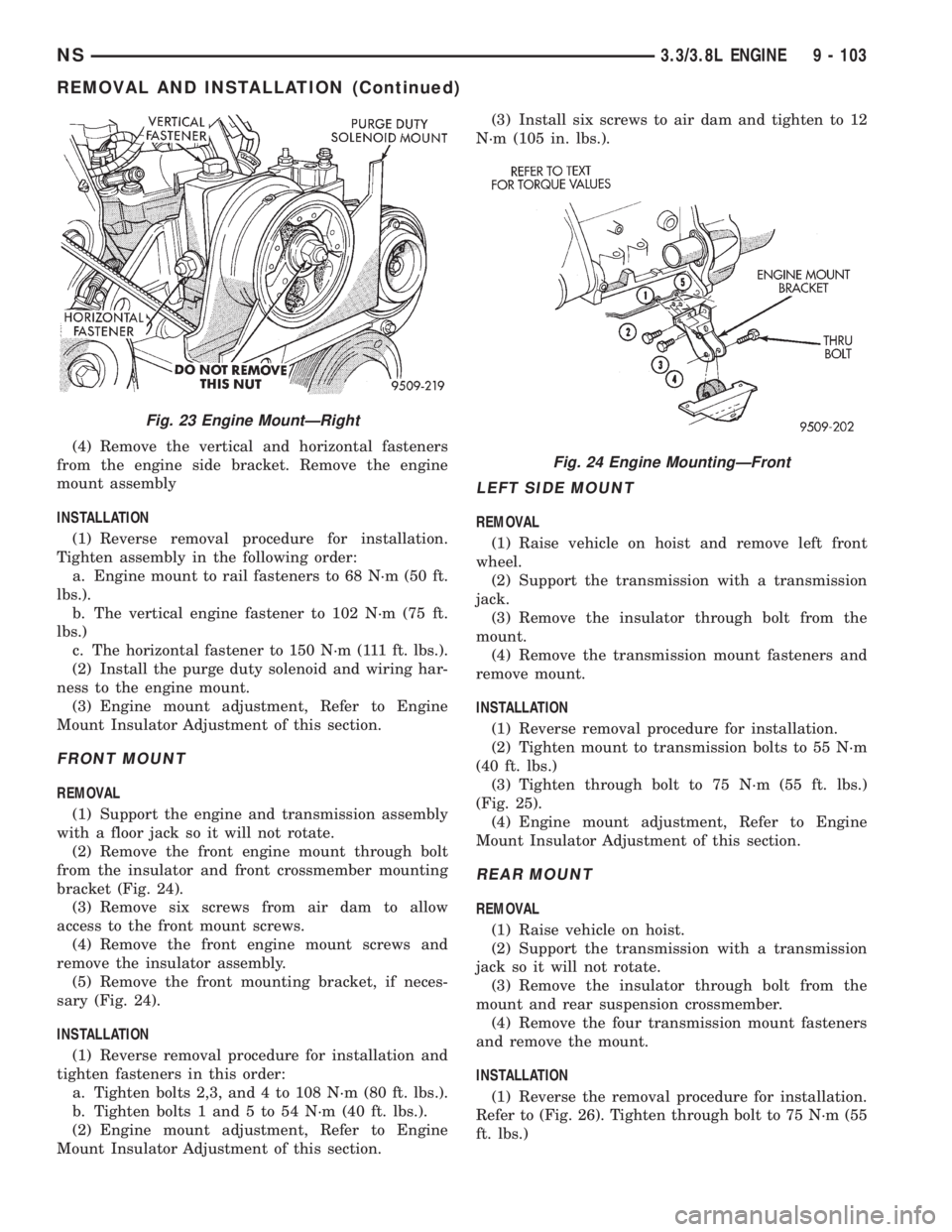

NOTE: Right mount should only be serviced as an

assembly to prevent noise, vibration and harshness

concerns.

(1) Remove the purge duty solenoid and wiring

harness from engine mount.

(2) Remove the two right engine mount insulator

vertical fasteners and loosen the horizontal fastener,

Do Notremove the large nut on the end of the core

from frame rail (Fig. 23).

(3) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

Fig. 20 Refacing Valve SeatsFig. 21 Testing Valve Springs

Fig. 22 Checking Valve Installed Height

ITEM DESCRIPTION

A Valve Stem Height

B Valve Installed Height

9 - 102 3.3/3.8L ENGINENS

SERVICE PROCEDURES (Continued)

Page 1153 of 1938

(4) Remove the vertical and horizontal fasteners

from the engine side bracket. Remove the engine

mount assembly

INSTALLATION

(1) Reverse removal procedure for installation.

Tighten assembly in the following order:

a. Engine mount to rail fasteners to 68 N´m (50 ft.

lbs.).

b. The vertical engine fastener to 102 N´m (75 ft.

lbs.)

c. The horizontal fastener to 150 N´m (111 ft. lbs.).

(2) Install the purge duty solenoid and wiring har-

ness to the engine mount.

(3) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

FRONT MOUNT

REMOVAL

(1) Support the engine and transmission assembly

with a floor jack so it will not rotate.

(2) Remove the front engine mount through bolt

from the insulator and front crossmember mounting

bracket (Fig. 24).

(3) Remove six screws from air dam to allow

access to the front mount screws.

(4) Remove the front engine mount screws and

remove the insulator assembly.

(5) Remove the front mounting bracket, if neces-

sary (Fig. 24).

INSTALLATION

(1) Reverse removal procedure for installation and

tighten fasteners in this order:

a. Tighten bolts 2,3, and 4 to 108 N´m (80 ft. lbs.).

b. Tighten bolts 1 and 5 to 54 N´m (40 ft. lbs.).

(2) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.(3) Install six screws to air dam and tighten to 12

N´m (105 in. lbs.).

LEFT SIDE MOUNT

REMOVAL

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Support the transmission with a transmission

jack.

(3) Remove the insulator through bolt from the

mount.

(4) Remove the transmission mount fasteners and

remove mount.

INSTALLATION

(1) Reverse removal procedure for installation.

(2) Tighten mount to transmission bolts to 55 N´m

(40 ft. lbs.)

(3) Tighten through bolt to 75 N´m (55 ft. lbs.)

(Fig. 25).

(4) Engine mount adjustment, Refer to Engine

Mount Insulator Adjustment of this section.

REAR MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Support the transmission with a transmission

jack so it will not rotate.

(3) Remove the insulator through bolt from the

mount and rear suspension crossmember.

(4) Remove the four transmission mount fasteners

and remove the mount.

INSTALLATION

(1) Reverse the removal procedure for installation.

Refer to (Fig. 26). Tighten through bolt to 75 N´m (55

ft. lbs.)

Fig. 23 Engine MountÐRight

Fig. 24 Engine MountingÐFront

NS3.3/3.8L ENGINE 9 - 103

REMOVAL AND INSTALLATION (Continued)