Egr CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1874 of 1938

move towards the Cold position. When Pin 13 is High

and Pin 15 is Low the door will move towards the

Heat position. When both Pins are high or when both

Pins are low, the actuator will not move. The Driver

feedback signal is a voltage signal that is supplied by

the actuator to the control. The signal will be about

4.0 volts in the Heat position and 1.0 volt in the Cold

position. As the position of the Driver Actuator

changes, so will the feedback signal. The feedback

signal is necessary for the correct positioning of the

temperature door.

MODE ACTUATOR BACKGROUND

The Mode actuator can move the mode door in two

directions. When the voltage at Pin 18 of the control

module is high, about 11.5 volts, and the voltage at

Pin 12 is low, about 1.5 volts the door will move

towards the Panel position. When Pin 12 is High and

Pin 18 is Low the door will move towards the Defrost

position. When both Pin are high or when both Pins

are low, the actuator will not move. The Mode door

feedback signal is a voltage signal that is supplied by

the actuator to the control. The signal will be about

4.5 volts in the Panel position and 0.5 volts in the

Defrost position. As the position of the Mode actuator

changes, so will the feedback signal. The feedback

signal is necessary for the correct positioning of the

mode door.

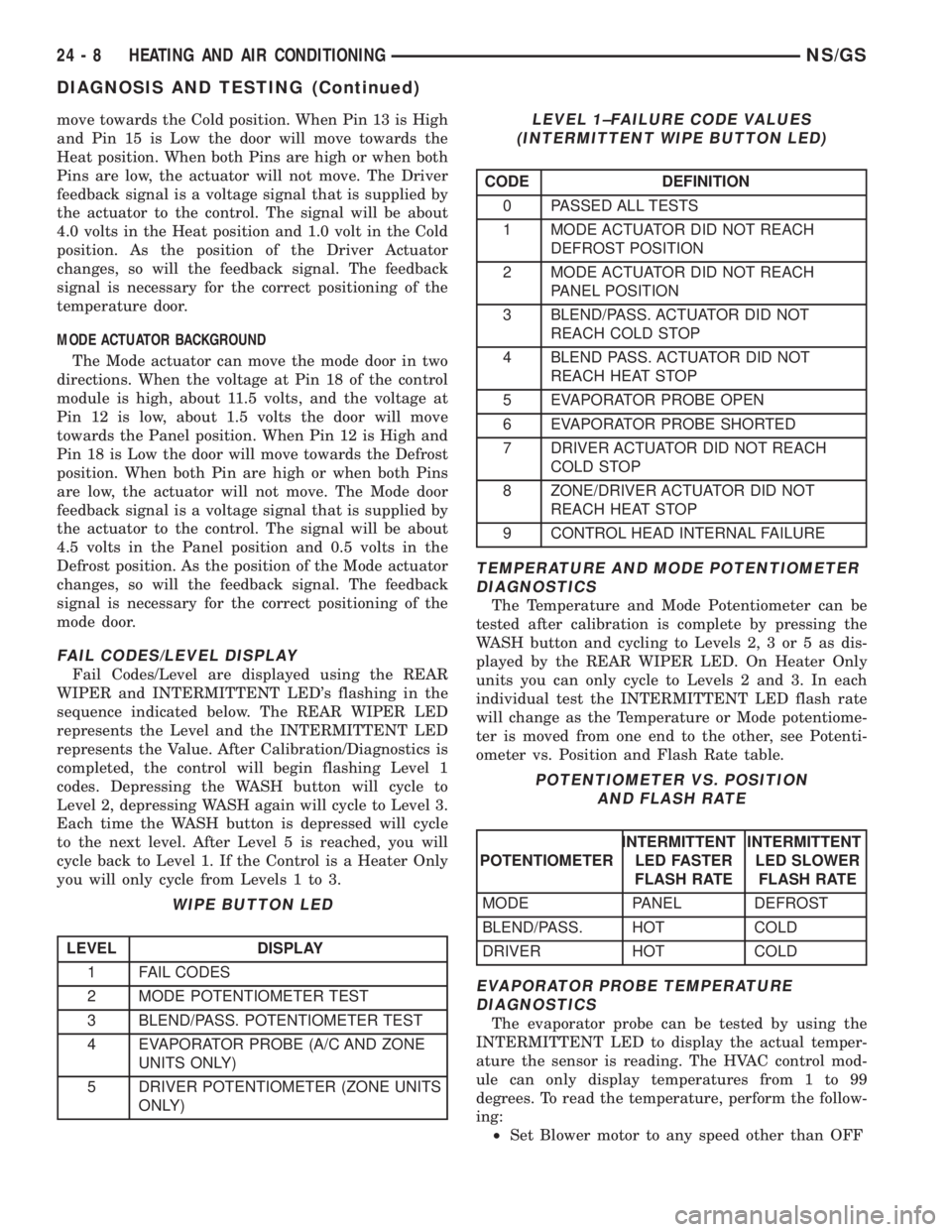

FAIL CODES/LEVEL DISPLAY

Fail Codes/Level are displayed using the REAR

WIPER and INTERMITTENT LED's flashing in the

sequence indicated below. The REAR WIPER LED

represents the Level and the INTERMITTENT LED

represents the Value. After Calibration/Diagnostics is

completed, the control will begin flashing Level 1

codes. Depressing the WASH button will cycle to

Level 2, depressing WASH again will cycle to Level 3.

Each time the WASH button is depressed will cycle

to the next level. After Level 5 is reached, you will

cycle back to Level 1. If the Control is a Heater Only

you will only cycle from Levels 1 to 3.

TEMPERATURE AND MODE POTENTIOMETER

DIAGNOSTICS

The Temperature and Mode Potentiometer can be

tested after calibration is complete by pressing the

WASH button and cycling to Levels 2, 3 or 5 as dis-

played by the REAR WIPER LED. On Heater Only

units you can only cycle to Levels 2 and 3. In each

individual test the INTERMITTENT LED flash rate

will change as the Temperature or Mode potentiome-

ter is moved from one end to the other, see Potenti-

ometer vs. Position and Flash Rate table.

EVAPORATOR PROBE TEMPERATURE

DIAGNOSTICS

The evaporator probe can be tested by using the

INTERMITTENT LED to display the actual temper-

ature the sensor is reading. The HVAC control mod-

ule can only display temperatures from 1 to 99

degrees. To read the temperature, perform the follow-

ing:

²Set Blower motor to any speed other than OFF

WIPE BUTTON LED

LEVEL DISPLAY

1 FAIL CODES

2 MODE POTENTIOMETER TEST

3 BLEND/PASS. POTENTIOMETER TEST

4 EVAPORATOR PROBE (A/C AND ZONE

UNITS ONLY)

5 DRIVER POTENTIOMETER (ZONE UNITS

ONLY)

LEVEL 1±FAILURE CODE VALUES

(INTERMITTENT WIPE BUTTON LED)

CODE DEFINITION

0 PASSED ALL TESTS

1 MODE ACTUATOR DID NOT REACH

DEFROST POSITION

2 MODE ACTUATOR DID NOT REACH

PANEL POSITION

3 BLEND/PASS. ACTUATOR DID NOT

REACH COLD STOP

4 BLEND PASS. ACTUATOR DID NOT

REACH HEAT STOP

5 EVAPORATOR PROBE OPEN

6 EVAPORATOR PROBE SHORTED

7 DRIVER ACTUATOR DID NOT REACH

COLD STOP

8 ZONE/DRIVER ACTUATOR DID NOT

REACH HEAT STOP

9 CONTROL HEAD INTERNAL FAILURE

POTENTIOMETER VS. POSITION

AND FLASH RATE

POTENTIOMETERINTERMITTENT

LED FASTER

FLASH RATEINTERMITTENT

LED SLOWER

FLASH RATE

MODE PANEL DEFROST

BLEND/PASS. HOT COLD

DRIVER HOT COLD

24 - 8 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1885 of 1938

SYSTEM LEAK CHECKING

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. SOME MIXTURES OF AIR/R-134a HAVE BEEN

SHOWN TO BE COMBUSTIBLE AT ELEVATED

PRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR

EXPLOSION CAUSING INJURY OR PROPERTY

DAMAGE.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing this

test A/C liquid line pressure is less than 207 kPa (30

psi) proceed to Empty Refrigerant System Leak Test.

If liquid line pressure is greater than 207 kPa (30

psi) proceed to low refrigerant level leak test. If the

refrigerant system is empty or low in refrigerant

charge, a leak at any line fitting or component seal is

likely. A review of the fittings, lines and components

for oily residue is an indication of the leak location.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

symptoms.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

EMPTY REFRIGERANT SYSTEM LEAK TEST

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (about 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-

tem will not maintain vacuum level, proceed with

this procedure.

(2) Prepare a .284 Kg. (10 oz.) refrigerant charge

to be injected into the system.

(3) Connect and dispense .284 Kg. (10 oz.) of

refrigerant into the evacuated refrigerant system.

(4) Proceed to step two of Low Refrigerant Level

Leak Test.

LOW REFRIGERANT LEVEL LEAK TEST

(1) Determine if there is any (R-134a) refrigerant

in the system. Use the scan tool (DRB) under the

menu Systems Sensors±A/C Pressure test or pressuregauge liquid line temperature partial charge check.

See system charge level check or fill for procedure.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set in 100 percent outside air

²Full Panel Mode

²Blower motor ON HIGH

²A/C in the ON position

²Front Windows Open.

²Rear Air Off (If Equipped)

CAUTION: A leak detector designed for R-12 refrig-

erant will not detect leaks in a R-134a refrigerant

system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the recirculating air door opening

or a heat duct.

If a thorough leak check has been completed with-

out indication of a leak, proceed to System Charge

Level-Check or Fill.

REMOVAL AND INSTALLATION

A/C PRESSURE TRANSDUCER

REMOVAL

(1) Disconnect the wire connector at the pressure

transducer.

(2) Using an open end wrench, remove the trans-

ducer from the liquid line (Fig. 11).

INSTALLATION

(1) Replace transducer O-ring.

(2) For installation, reverse the above procedures.

A/C SERVICE PORTS

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

The High Side service port is serviceable, the Low

Side is not serviceable.

NS/GSHEATING AND AIR CONDITIONING 24 - 19

SERVICE PROCEDURES (Continued)

Page 1905 of 1938

EMISSION CONTROL SYSTEMS

CONTENTS

page page

EVAPORATIVE EMISSION CONTROLS........ 13

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM.............................. 18ON-BOARD DIAGNOSTICS.................. 1

ON-BOARD DIAGNOSTICS

INDEX

page page

GENERAL INFORMATION

SYSTEM DESCRIPTION................... 1

DESCRIPTION AND OPERATION

CIRCUIT ACTUATION TEST MODE........... 3

COMPONENT MONITORS................. 10

DIAGNOSTIC TROUBLE CODES............. 3

HIGH AND LOW LIMITS................... 11LOAD VALUE........................... 12

MALFUNCTION INDICATOR LAMP (MIL)....... 1

MONITORED SYSTEMS.................... 8

NON-MONITORED CIRCUITS............... 11

STATE DISPLAY TEST MODE............... 2

TRIP DEFINITION........................ 10

GENERAL INFORMATION

SYSTEM DESCRIPTION

The Powertrain Control Module (PCM) monitors

many different circuits in the fuel injection, ignition,

emission and engine systems. If the PCM senses a

problem with a monitored circuit often enough to

indicate an actual problem, it stores a Diagnostic

Trouble Code (DTC) in the PCM's memory. If the

code applies to a non-emissions related component or

system, and the problem is repaired or ceases to

exist, the PCM cancels the code after 40 warmup

cycles. Diagnostic trouble codes that affect vehicle

emissions illuminate the Malfunction Indicator Lamp

(MIL). Refer to Malfunction Indicator Lamp in this

section.

Certain criteria must be met before the PCM

stores a DTC in memory. The criteria may be a spe-

cific range of engine RPM, engine temperature,

and/or input voltage to the PCM.

The PCM might not store a DTC for a monitored

circuit even though a malfunction has occurred. This

may happen because one of the DTC criteria for the

circuit has not been met.For example, assume the

diagnostic trouble code criteria requires the PCM to

monitor the circuit only when the engine operates

between 750 and 2000 RPM. Suppose the sensor'soutput circuit shorts to ground when engine operates

above 2400 RPM (resulting in 0 volt input to the

PCM). Because the condition happens at an engine

speed above the maximum threshold (2000 rpm), the

PCM will not store a DTC.

There are several operating conditions for which

the PCM monitors and sets DTC's. Refer to Moni-

tored Systems, Components, and Non-Monitored Cir-

cuits in this section.

NOTE: Various diagnostic procedures may actually

cause a diagnostic monitor to set a DTC. For

instance, pulling a spark plug wire to perform a

spark test may set the misfire code. When a repair

is completed and verified, use the DRB scan tool to

erase all DTC's and extinguish the MIL.

Technicians can display stored DTC's by using the

DRB scan tool. Refer to Diagnostic Trouble Codes in

this section. For DTC information, refer to charts in

this section.

DESCRIPTION AND OPERATION

MALFUNCTION INDICATOR LAMP (MIL)

As a functional test, the Malfunction Indicator

Lamp (MIL) illuminates at key-on before engine

NSEMISSION CONTROL SYSTEMS 25 - 1

Page 1906 of 1938

cranking. Whenever the Powertrain Control Module

(PCM) sets a Diagnostic Trouble Code (DTC) that

affects vehicle emissions, it illuminates the MIL. If a

problem is detected, the PCM sends a message over

the CCD Bus to the instrument cluster to illuminate

the lamp. The PCM illuminates the MIL only for

DTC's that affect vehicle emissions. The MIL stays

on continuously when the PCM has entered a

Limp-In mode or identified a failed emission compo-

nent or system. The MIL remains on until the DTC

is erased. Refer to the Diagnostic Trouble Code

charts in this group for emission related codes.

Also, the MIL either flashes or illuminates contin-

uously when the PCM detects active engine misfire.

Refer to Misfire Monitoring in this section.

Additionally, the PCM may reset (turn off) the MIL

when one of the following occur:

²PCM does not detect the malfunction for 3 con-

secutive trips (except misfire and fuel system moni-

tors).

²PCM does not detect a malfunction while per-

forming three successive engine misfire or fuel sys-

tem tests. The PCM performs these tests while the

engine is operating within6375 RPM of and within

10 % of the load of the operating condition at which

the malfunction was first detected.

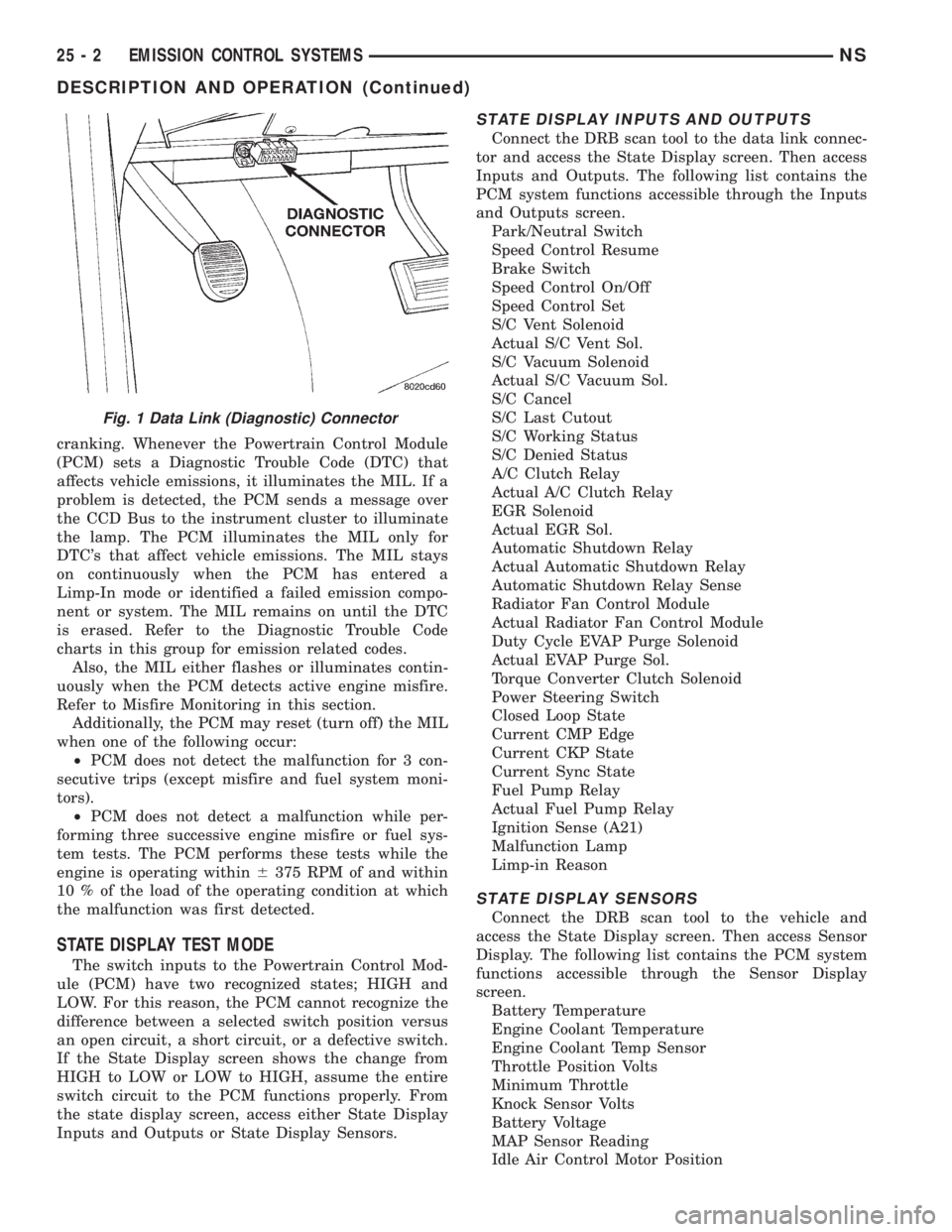

STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. From

the state display screen, access either State Display

Inputs and Outputs or State Display Sensors.

STATE DISPLAY INPUTS AND OUTPUTS

Connect the DRB scan tool to the data link connec-

tor and access the State Display screen. Then access

Inputs and Outputs. The following list contains the

PCM system functions accessible through the Inputs

and Outputs screen.

Park/Neutral Switch

Speed Control Resume

Brake Switch

Speed Control On/Off

Speed Control Set

S/C Vent Solenoid

Actual S/C Vent Sol.

S/C Vacuum Solenoid

Actual S/C Vacuum Sol.

S/C Cancel

S/C Last Cutout

S/C Working Status

S/C Denied Status

A/C Clutch Relay

Actual A/C Clutch Relay

EGR Solenoid

Actual EGR Sol.

Automatic Shutdown Relay

Actual Automatic Shutdown Relay

Automatic Shutdown Relay Sense

Radiator Fan Control Module

Actual Radiator Fan Control Module

Duty Cycle EVAP Purge Solenoid

Actual EVAP Purge Sol.

Torque Converter Clutch Solenoid

Power Steering Switch

Closed Loop State

Current CMP Edge

Current CKP State

Current Sync State

Fuel Pump Relay

Actual Fuel Pump Relay

Ignition Sense (A21)

Malfunction Lamp

Limp-in Reason

STATE DISPLAY SENSORS

Connect the DRB scan tool to the vehicle and

access the State Display screen. Then access Sensor

Display. The following list contains the PCM system

functions accessible through the Sensor Display

screen.

Battery Temperature

Engine Coolant Temperature

Engine Coolant Temp Sensor

Throttle Position Volts

Minimum Throttle

Knock Sensor Volts

Battery Voltage

MAP Sensor Reading

Idle Air Control Motor Position

Fig. 1 Data Link (Diagnostic) Connector

25 - 2 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1907 of 1938

Adaptive Fuel Factor

Barometric Pressure

Engine Speed

Module Spark Advance

Speed Control Target

Intake Air Temp Degrees

Intake Air Temp Volts

Charging System Goal

Theft Alarm Status

Map Sensor Voltage

Vehicle Speed

Throttle Opening (percentage)

TPS Calculated

Cam Timing Position

Target Idle

Time From Start To Run

Run Time At Stall

Injector Pulse-width

Upstream O2S Volts

Downstream O2S Volts

Closed Loop Timer

Short Term Adaptive

Current Adaptive Cell

Adaptive Memory Cell 0

Adaptive Memory Cell 1

Adaptive Memory Cell 2

Adaptive Memory Cell 3

Adaptive Memory Cell 4

Adaptive Memory Cell 5

Adaptive Memory Cell 6

Adaptive Memory Cell 7

Adaptive Memory Cell 8

Adaptive Memory Cell 9

Adaptive Memory Cell 10

Adaptive Memory Cell 11

Adaptive Memory Cell 12

Adaptive Memory Cell 13

Adaptive Memory Cell 14

Adaptive Memory Cell 15

Purge Free Idle Cell

Purge Free Cell 2 (corresponds to memory cell 2)

Purge Free Cell 3 (corresponds to memory cell 5)

Target IAC Steps

Retard Cylinder (1)

Retard Cylinder (2)

Retard Cylinder (3)

Retard Cylinder (4)

Retard Cylinder (5)

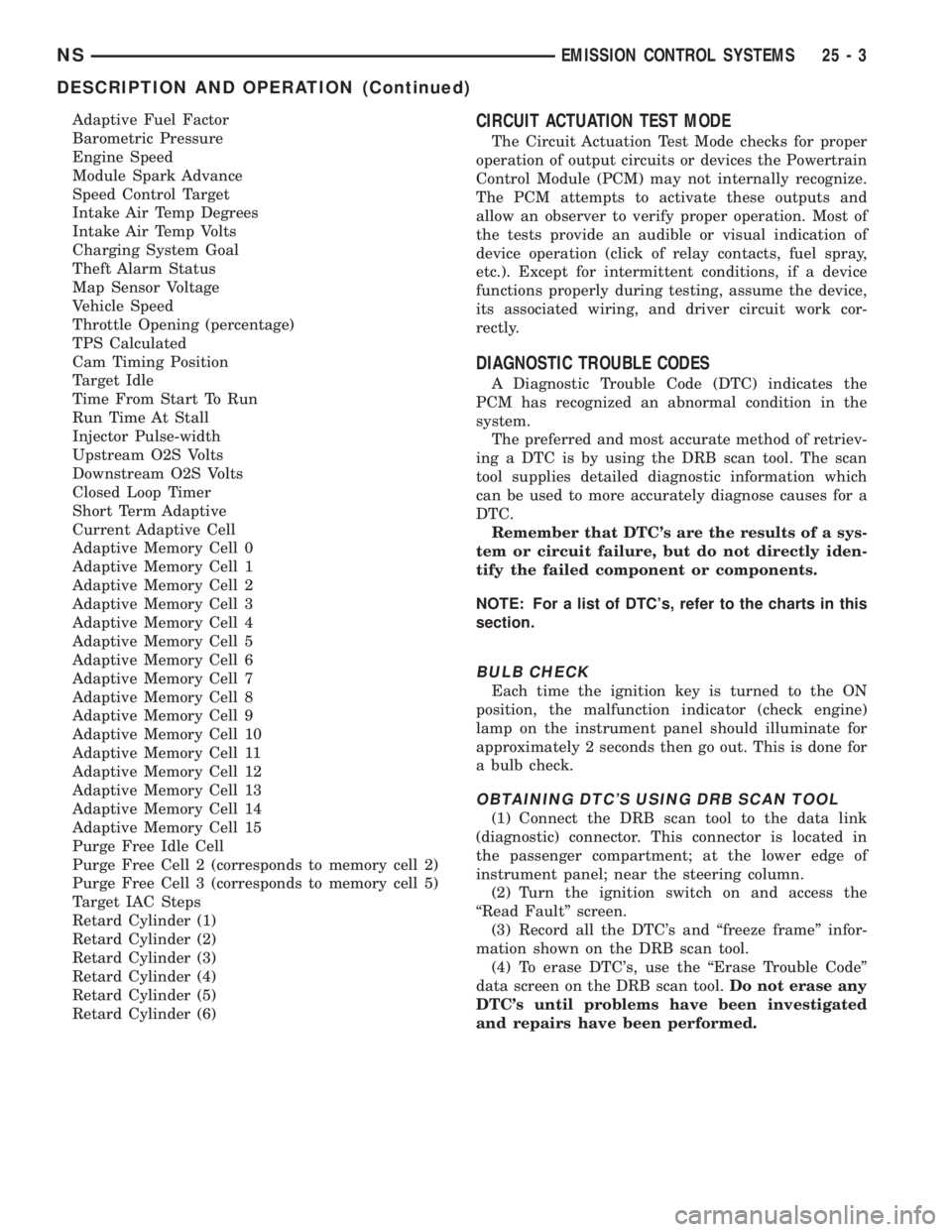

Retard Cylinder (6)CIRCUIT ACTUATION TEST MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly.

DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.

The preferred and most accurate method of retriev-

ing a DTC is by using the DRB scan tool. The scan

tool supplies detailed diagnostic information which

can be used to more accurately diagnose causes for a

DTC.

Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

NSEMISSION CONTROL SYSTEMS 25 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1908 of 1938

DIAGNOSTIC TROUBLE CODE DESCRIPTIONS

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC

TROUBLE CODE

01 P0340 No Cam Signal at PCM No camshaft signal detected during engine

cranking.

02 P0601 Internal Controller Failure PCM Internal fault condition detected.

05 Charging System Voltage Too Low Battery voltage sense input below target charging

during engine operation. Also, no significant

change detected in battery voltage during active

test of generator output circuit.

06 Charging System Voltage Too High Battery voltage sense input above target charging

voltage during engine operation.

0A* Auto Shutdown Relay Control

CircuitAn open or shorted condition detected in the auto

shutdown relay circuit.

0B Generator Field Not Switching

ProperlyAn open or shorted condition detected in the

generator field control circuit.

0C P0743 Torque Converter Clutch Soleniod/

Trans Relay CircuitsAn open or shorted condition detected in the

torque converter part throttle unlock solenoid

control circuit (3 speed auto RH trans. only).

0E P1491 Rad Fan Control Relay Circuit An open or shorted condition detected in the low

speed radiator fan relay control circuit.

0F* Speed Control Solenoid Circuits An open or shorted condition detected in the

Speed Control vacuum or vent solenoid circuits.

10* A/C Clutch Relay Circuit An open or shorted condition detected in the A/C

clutch relay circuit.

11 P0403 EGR Solenoid Circuit An open or shorted condition detected in the EGR

transducer solenoid circuit.

12 P0443 EVAP Purge Solenoid Circuit An open or shorted condition detected in the duty

cycle purge solenoid circuit.

13 P0203 Injector #3 Control Circuit Injector #3 output driver does not respond properly

to the control signal.

14 P0202 Injector #2 Control Circuit Injector #2 output driver does not respond properly

to the control signal.

15 P0201 Injector #1 Control Circuit Injector #1 output driver does not respond properly

to the control signal.

19 P0505 Idle Air Control Motor Circuits A shorted or open condition detected in one or

more of the idle air control motor circuits.

1A P0122 Throttle Position Sensor Voltage

LowThrottle position sensor input below the minimum

acceptable voltage

1B P0123 Throttle Position Sensor Voltage

HighThrottle position sensor input above the maximum

acceptable voltage.

1E P0117 ECT Sensor Voltage Too Low Engine coolant temperature sensor input below

minimum acceptable voltage.

1F P0118 ECT Sensor Voltage Too High Engine coolant temperature sensor input above

maximum acceptable voltage.

25 - 4 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1909 of 1938

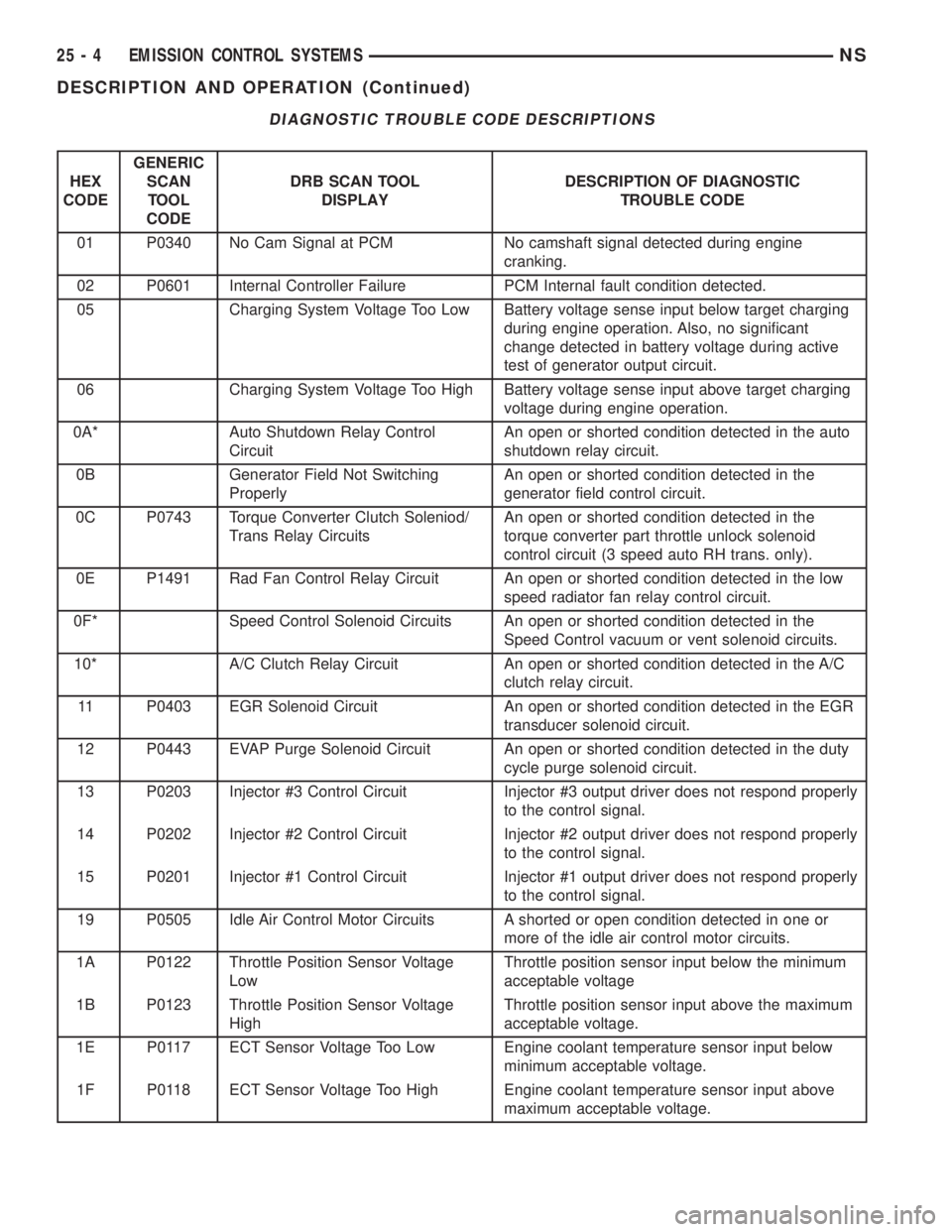

HEX

CODEGENERIC

SCAN

TOOL

CODEDRB SCAN TOOL

DISPLAYDESCRIPTION OF DIAGNOSTIC

TROUBLE CODE

20 P0134 Right Rear (or just) Upstream O2S

Stays at CenterNeither rich or lean condition detected from the

oxygen sensor.

21* Engine Is Cold Too Long Engine did not reach operating temperature within

acceptable limits.

23 P0500 No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during

road load conditions.

24 P0107 MAP Sensor Voltage Too Low MAP sensor input below minimum acceptable

voltage.

25 P0108 MAP Sensor Voltage Too High MAP sensor input above maximum acceptable

voltage.

27 P1297 No Change in MAP From Start to

RunNo difference recognized between the engine MAP

reading and the barometric (atmospheric) pressure

reading from start-up.

28* No Crank Reference Signal at PCM No crank reference signal detected during engine

cranking.

29 P0353 Ignition Coil #3 Primary Circuit Peak primary circuit current not achieved with

maximum dwell time.

2A P0352 Ignition Coil #2 Primary Circuit Peak primary circuit current not achieved with

maximum dwell time.

2B P0351 Ignition Coil #1 Primary Circuit Peak primary circuit current not achieved with

maximum dwell time.

2C* No ASD Relay Output Voltage at

PCMAn Open condition Detected In The ASD Relay

Output Circuit.

2E P0401 EGR System Failure Required change in air/fuel ratio not detected

during diagnostic test.

30* P1697 PCM Failure SRI Miles Not Stored Unsuccessful attempt to update EMR mileage in

the PCM EEPROM.

31 P1698 PCM Failure EEPROM Write

DeniedUnsuccessful attempt to write to an EEPROM

location by the PCM.

39 P0112 Intake Air Temp Sensor Voltage

LowIntake air temperature sensor input below the

maximum acceptable voltage.

3A P0113 Intake Air Temp Sensor Voltage

HighIntake air temperature sensor input above the

minimum acceptable voltage.

3C P0106 Barometric Pressure Out Of Range MAP sensor has a baro reading below an

acceptable value.

3D P0204 Injector #4 Control Circuit Injector #4 output driver does not respond properly

to the control signal.

3E P0132 Right Rear (or just) Upstream O2S

Shorted to VoltageOxygen sensor input voltage maintained above the

normal operating range.

44 P0600 PCM Failure SPI Communications PCM Internal fault condition detected.

45 P0205 Injector #5 Control Circuit Injector #5 output driver does not respond properly

to the control signal.

46 P0206 Injector #6 Control Circuit Injector #6 output driver does not respond properly

to the control signal.

NSEMISSION CONTROL SYSTEMS 25 - 5

DESCRIPTION AND OPERATION (Continued)

Page 1912 of 1938

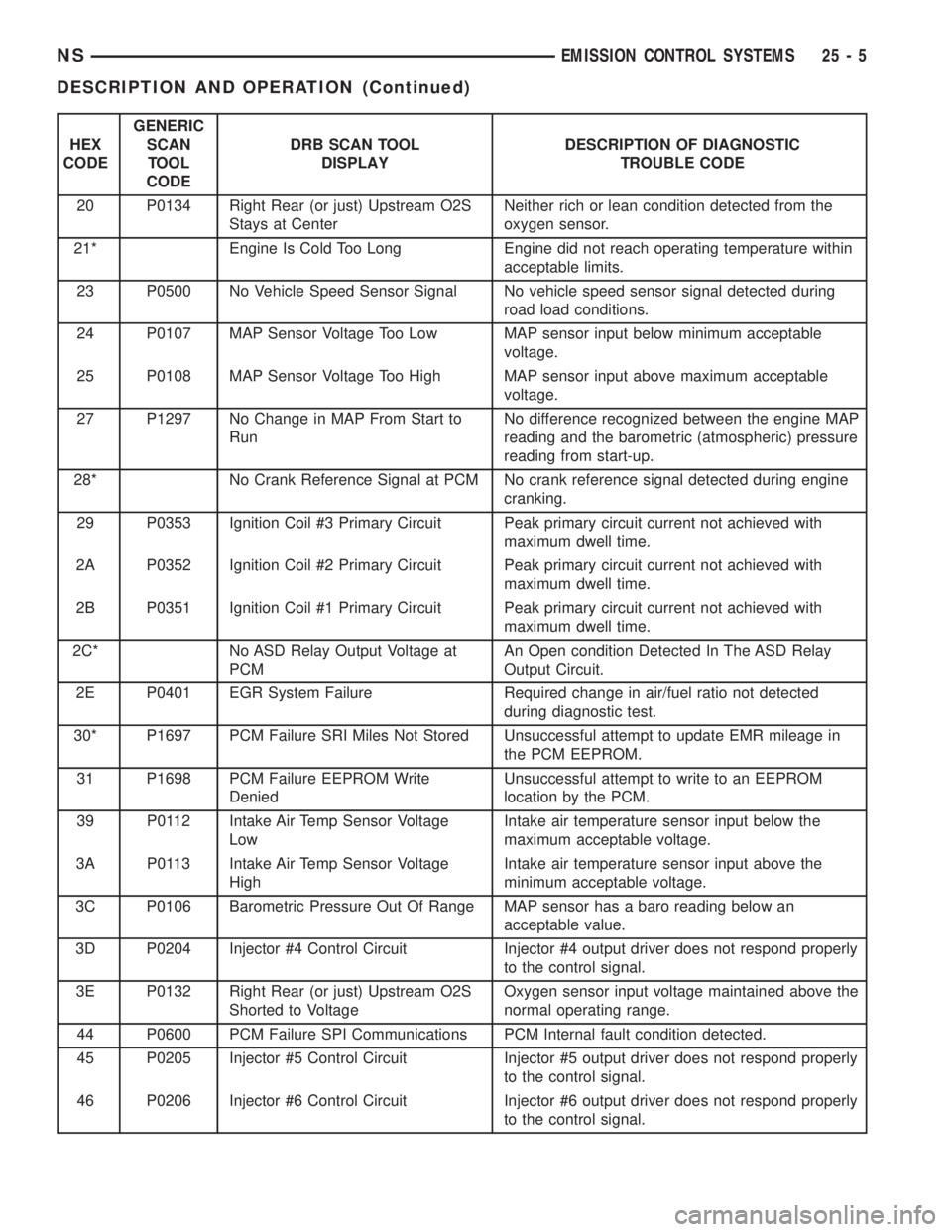

MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the system monitors:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

HEX 66, and 7AÐOXYGEN SENSOR (O2S)

MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572É to 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 air fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrous oxide (NOx) from

the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate

²Reduced output voltage

²Dynamic shift

²Shorted or open circuitsResponse rate is the time required for the sensor to

switch from lean to rich once it is exposed to a richer

than optimum A/F mixture or vice versa. As the sen-

sor starts malfunctioning, it could take longer to

detect the changes in the oxygen content of the

exhaust gas.

The output voltage of the O2S ranges from 0 to 1

volt. A good sensor can easily generate any output

voltage in this range as it is exposed to different con-

centrations of oxygen. To detect a shift in the A/F

mixture (lean or rich), the output voltage has to

change beyond a threshold value. A malfunctioning

sensor could have difficulty changing beyond the

threshold value.

HEX 67, 69, 7C, and 7DÐOXYGEN SENSOR

HEATER MONITOR

If there is an oxygen sensor (O2S) DTC as well as

a O2S heater DTC, the O2S fault MUST be repaired

first. After the O2S fault is repaired, verify that the

heater circuit is operating correctly.

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperature 300É to 350ÉC (572 Éto 662ÉF), the

sensor generates a voltage that is inversely propor-

tional to the amount of oxygen in the exhaust. The

information obtained by the sensor is used to calcu-

late the fuel injector pulse width. This maintains a

14.7 to 1 Air Fuel (A/F) ratio. At this mixture ratio,

the catalyst works best to remove hydrocarbons (HC),

carbon monoxide (CO) and nitrogen oxide (NOx) from

the exhaust.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The O2S circuit is monitored for a drop in voltage.

The sensor output is used to test the heater by iso-

lating the effect of the heater element on the O2S

output voltage from the other effects.

HEX 2EÐEGR MONITOR

The Powertrain Control Module (PCM) performs

an on-board diagnostic check of the EGR system.

The EGR system consists of two main components:

a vacuum solenoid and a vacuum operated valve with

a back pressure transducer. The EGR monitor is used

to test whether the EGR system is operating within

specifications. The diagnostic check activates only

during selected engine/driving conditions. When the

25 - 8 EMISSION CONTROL SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 1913 of 1938

conditions are met, the EGR is turned off (solenoid

energized) and the O2S compensation control is mon-

itored. Turning off the EGR shifts the air fuel (A/F)

ratio in the lean direction. The O2S data should indi-

cate an increase in the O2 concentration in the com-

bustion chamber when the exhaust gases are no

longer recirculated. While this test does not directly

measure the operation of the EGR system, it can be

inferred from the shift in the O2S data whether the

EGR system is operating correctly. Because the O2S

is being used, the O2S test must pass its test before

the EGR test.

HEX 6A,6B, 6C, 6D, 6E, AE, and AFÐMISFIRE

MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

HEX 76, 77, 78, and 79ÐFUEL SYSTEM

MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide. The catalyst works best

when the air fuel (A/F) ratio is at or near the opti-

mum of 14.7 to 1.

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S output. The programmed memory

acts as a self calibration tool that the engine control-

ler uses to compensate for variations in engine spec-

ifications, sensor tolerances and engine fatigue over

the life span of the engine. By monitoring the actual

air-fuel ratio with the O2S (short term) and multiply-

ing that with the program long-term (adaptive) mem-

ory and comparing that to the limit, it can be

determined whether it will pass an emissions test. If

a malfunction occurs such that the PCM cannot

maintain the optimum A/F ratio, then the MIL will

be illuminated.

HEX 70, and B4ÐCATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2Ss strategy is based on the fact that as a cat-

alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

PCM calculates the A/F mixture from the output of

the O2S. A low voltage indicates high oxygen content

(lean mixture). A high voltage indicates a low content

of oxygen (rich mixture).

When the upstream O2S detects a lean condition,

there is an abundance of oxygen in the exhaust gas.

A functioning converter would store this oxygen so it

can use it for the oxidation of HC and CO. As the

converter absorbs the oxygen, there will be a lack of

oxygen downstream of the converter. The output of

the downstraem O2S will indicate limited activity in

this condition.

As the converter loses the ability to store oxygen,

the condition can be detected from the behavior of

the downstream O2S. When the efficiency drops, no

chemical reaction takes place. This means the con-

centration of oxygen will be the same downstream as

upstream. The output voltage of the downstream

O2S copies the voltage of the upstream sensor. The

only difference is a time lag (seen by the PCM)

between the switching of the O2S's.

To monitor the system, the number of lean-to-rich

switches of upstream and downstream O2S's is

counted. The ratio of downstream switches to

upstream switches is used to determine whether the

catalyst is operating properly. An effective catalyst

will have fewer downstream switches than it has

upstream switches i.e., a ratio closer to zero. For a

totally ineffective catalyst, this ratio will be one-to-

one, indicating that no oxidation occurs in the device.

The system must be monitored so that when cata-

lyst efficiency deteriorates and exhaust emissions

increase to over the legal limit, the MIL (check

engine lamp) will be illuminated.

HEX A0, A1, B7, and B8ÐLEAK DETECTION

PUMP MONITOR

The leak detection assembly incorporates two pri-

mary functions: it must detect a leak in the evapora-

tive system and seal the evaporative system so the

leak detection test can be run.

NSEMISSION CONTROL SYSTEMS 25 - 9

DESCRIPTION AND OPERATION (Continued)

Page 1915 of 1938

components now have input (rationality) and output

(functionality) checks. Previously, a component like

the Throttle Position sensor (TPS) was checked by

the PCM for an open or shorted circuit. If one of

these conditions occurred, a DTC was set. Now there

is a check to ensure that the component is working.

This is done by watching for a TPS indication of a

greater or lesser throttle opening than MAP and

engine rpm indicate. In the case of the TPS, if engine

vacuum is high and engine rpm is 1600 or greater

and the TPS indicates a large throttle opening, a

DTC will be set. The same applies to low vacuum

and 1600 rpm.

Any component that has an associated limp in will

set a fault after 1 trip with the malfunction present.

Refer to the Diagnostic Trouble Codes Description

Charts in this section and the appropriate Power-

train Diagnostic Procedure Manual for diagnostic

procedures.

NON-MONITORED CIRCUITS

The PCM does not monitor all circuits, systems

and conditions that could have malfunctions causing

driveability problems. However, problems with these

systems may cause the PCM to store diagnostic trou-

ble codes for other systems or components. For exam-

ple, a fuel pressure problem will not register a fault

directly, but could cause a rich/lean condition or mis-

fire. This could cause the PCM to store an oxygen

sensor or misfire diagnostic trouble code.

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor or fuel system diag-

nostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables.

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR or Fuel

system fault or O2S.

FUEL INJECTOR MECHANICAL

MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCM

to store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times, also

during diagnostic.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

HIGH AND LOW LIMITS

The PCM compares input signal voltages from each

input device with established high and low limits for

the device. If the input voltage is not within limits

and other criteria are met, the PCM stores a diagnos-

tic trouble code in memory. Other diagnostic trouble

code criteria might include engine RPM limits or

input voltages from other sensors or switches that

must be present before verifying a diagnostic trouble

code condition.

NSEMISSION CONTROL SYSTEMS 25 - 11

DESCRIPTION AND OPERATION (Continued)