Egr CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1936 of 1938

REMOVAL

(1) Disconnect both cables from battery, negative

cable first.

(2) Remove 2 screws holding PDC to bracket,

swing out of way.

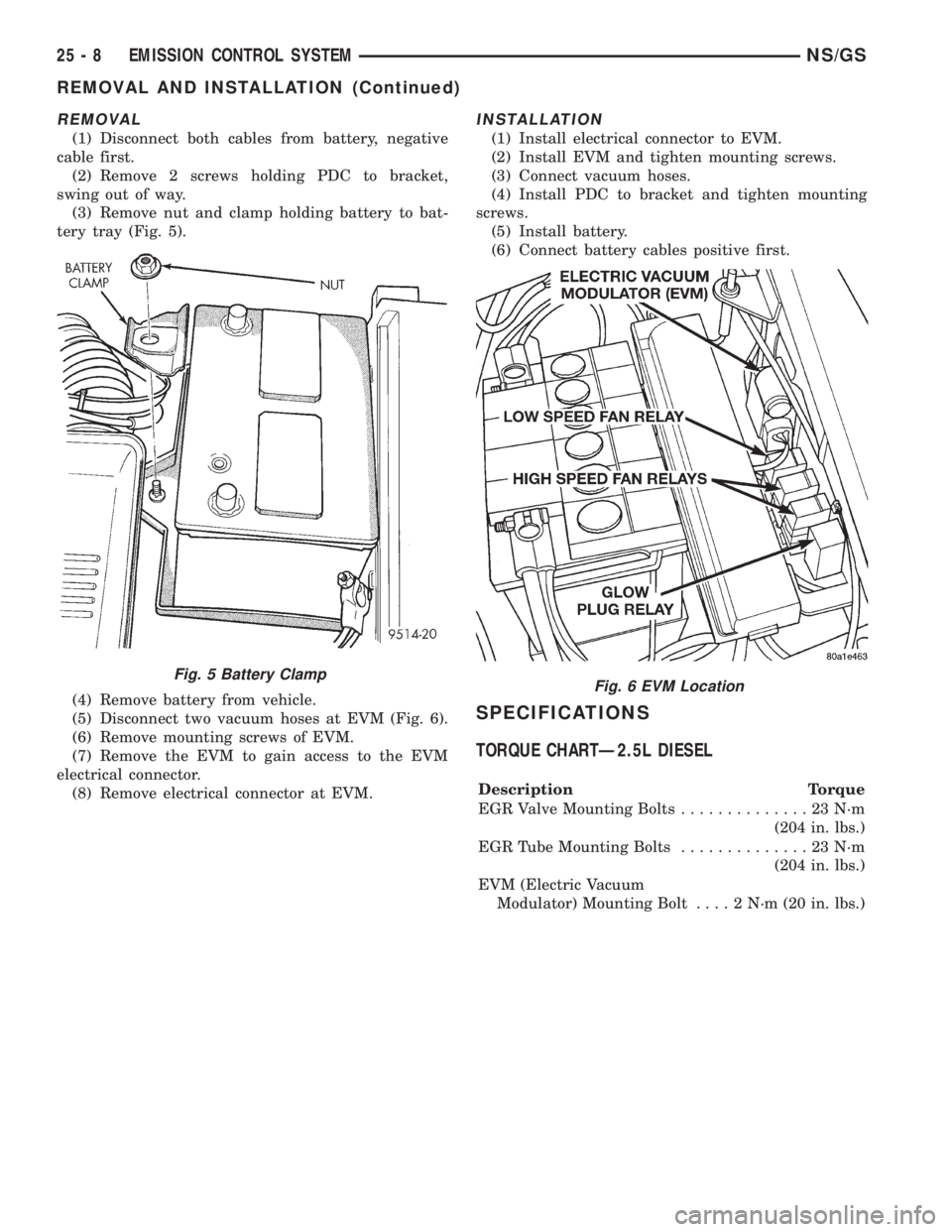

(3) Remove nut and clamp holding battery to bat-

tery tray (Fig. 5).

(4) Remove battery from vehicle.

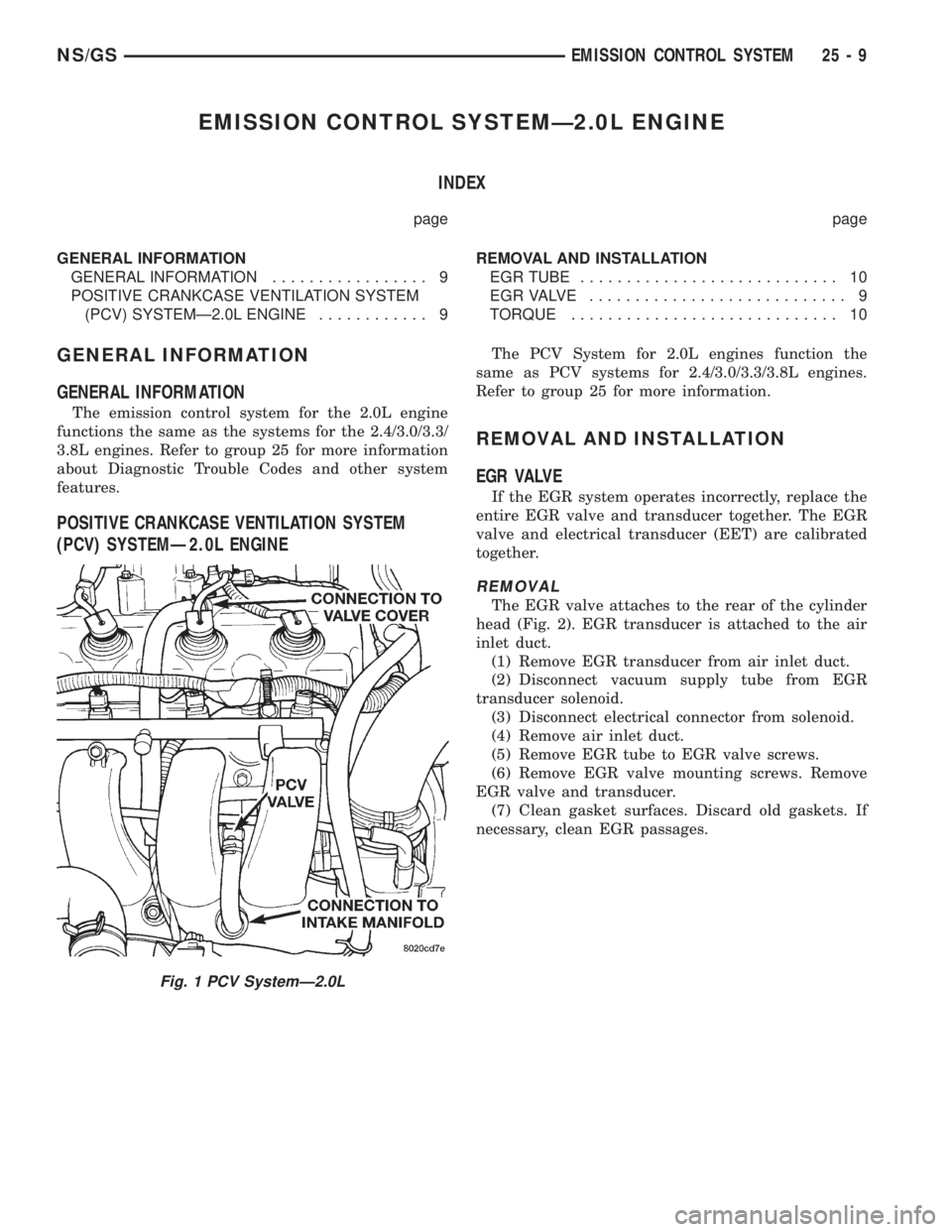

(5) Disconnect two vacuum hoses at EVM (Fig. 6).

(6) Remove mounting screws of EVM.

(7) Remove the EVM to gain access to the EVM

electrical connector.

(8) Remove electrical connector at EVM.

INSTALLATION

(1) Install electrical connector to EVM.

(2) Install EVM and tighten mounting screws.

(3) Connect vacuum hoses.

(4) Install PDC to bracket and tighten mounting

screws.

(5) Install battery.

(6) Connect battery cables positive first.

SPECIFICATIONS

TORQUE CHARTÐ2.5L DIESEL

Description Torque

EGR Valve Mounting Bolts..............23N´m

(204 in. lbs.)

EGR Tube Mounting Bolts..............23N´m

(204 in. lbs.)

EVM (Electric Vacuum

Modulator) Mounting Bolt. . . . 2 N´m (20 in. lbs.)

Fig. 5 Battery ClampFig. 6 EVM Location

25 - 8 EMISSION CONTROL SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1937 of 1938

EMISSION CONTROL SYSTEMÐ2.0L ENGINE

INDEX

page page

GENERAL INFORMATION

GENERAL INFORMATION................. 9

POSITIVE CRANKCASE VENTILATION SYSTEM

(PCV) SYSTEMÐ2.0L ENGINE............ 9REMOVAL AND INSTALLATION

EGR TUBE............................ 10

EGRVALVE ............................ 9

TORQUE............................. 10

GENERAL INFORMATION

GENERAL INFORMATION

The emission control system for the 2.0L engine

functions the same as the systems for the 2.4/3.0/3.3/

3.8L engines. Refer to group 25 for more information

about Diagnostic Trouble Codes and other system

features.

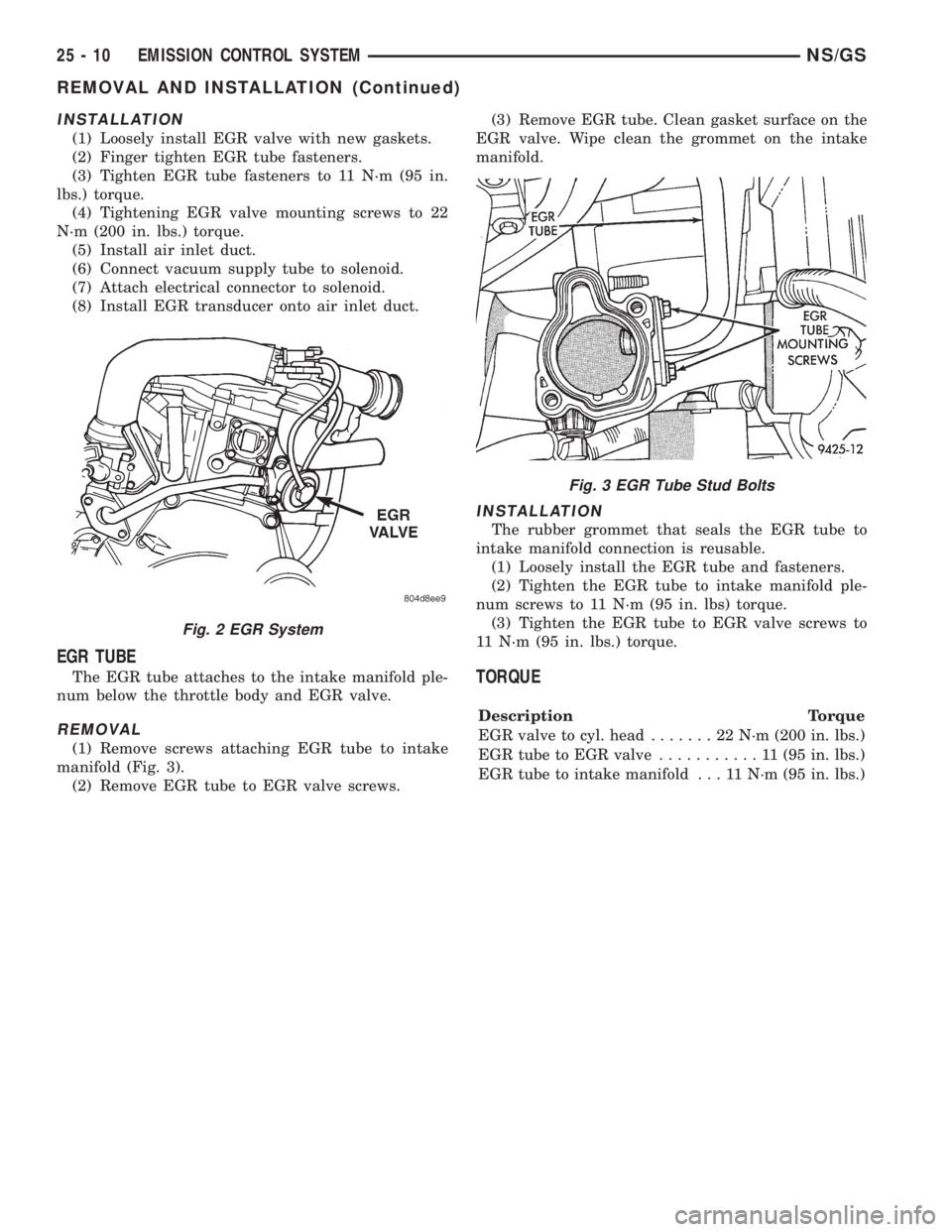

POSITIVE CRANKCASE VENTILATION SYSTEM

(PCV) SYSTEMÐ2.0L ENGINE

The PCV System for 2.0L engines function the

same as PCV systems for 2.4/3.0/3.3/3.8L engines.

Refer to group 25 for more information.

REMOVAL AND INSTALLATION

EGR VALVE

If the EGR system operates incorrectly, replace the

entire EGR valve and transducer together. The EGR

valve and electrical transducer (EET) are calibrated

together.

REMOVAL

The EGR valve attaches to the rear of the cylinder

head (Fig. 2). EGR transducer is attached to the air

inlet duct.

(1) Remove EGR transducer from air inlet duct.

(2) Disconnect vacuum supply tube from EGR

transducer solenoid.

(3) Disconnect electrical connector from solenoid.

(4) Remove air inlet duct.

(5) Remove EGR tube to EGR valve screws.

(6) Remove EGR valve mounting screws. Remove

EGR valve and transducer.

(7) Clean gasket surfaces. Discard old gaskets. If

necessary, clean EGR passages.

Fig. 1 PCV SystemÐ2.0L

NS/GSEMISSION CONTROL SYSTEM 25 - 9

Page 1938 of 1938

INSTALLATION

(1) Loosely install EGR valve with new gaskets.

(2) Finger tighten EGR tube fasteners.

(3) Tighten EGR tube fasteners to 11 N´m (95 in.

lbs.) torque.

(4) Tightening EGR valve mounting screws to 22

N´m (200 in. lbs.) torque.

(5) Install air inlet duct.

(6) Connect vacuum supply tube to solenoid.

(7) Attach electrical connector to solenoid.

(8) Install EGR transducer onto air inlet duct.

EGR TUBE

The EGR tube attaches to the intake manifold ple-

num below the throttle body and EGR valve.

REMOVAL

(1) Remove screws attaching EGR tube to intake

manifold (Fig. 3).

(2) Remove EGR tube to EGR valve screws.(3) Remove EGR tube. Clean gasket surface on the

EGR valve. Wipe clean the grommet on the intake

manifold.

INSTALLATION

The rubber grommet that seals the EGR tube to

intake manifold connection is reusable.

(1) Loosely install the EGR tube and fasteners.

(2) Tighten the EGR tube to intake manifold ple-

num screws to 11 N´m (95 in. lbs) torque.

(3) Tighten the EGR tube to EGR valve screws to

11 N´m (95 in. lbs.) torque.

TORQUE

Description Torque

EGR valve to cyl. head.......22N´m(200 in. lbs.)

EGR tube to EGR valve...........11(95in.lbs.)

EGR tube to intake manifold . . . 11 N´m (95 in. lbs.)

Fig. 2 EGR System

Fig. 3 EGR Tube Stud Bolts

25 - 10 EMISSION CONTROL SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)