engine oil CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1115 of 1938

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to front of engine, locat-

ing probe on nose of crankshaft (Fig. 11).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Crankshaft Specifi-

cation Chart.

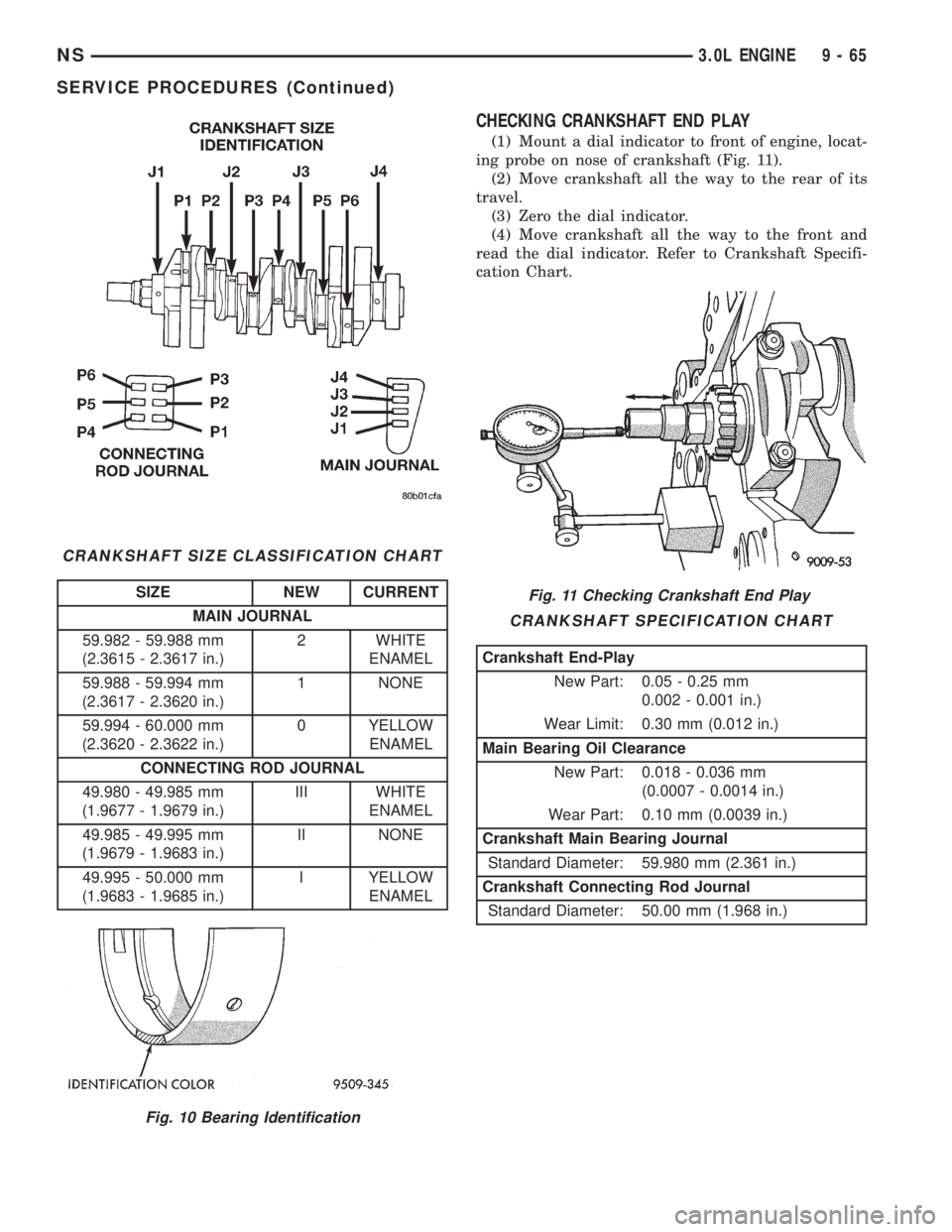

CRANKSHAFT SIZE CLASSIFICATION CHART

SIZE NEW CURRENT

MAIN JOURNAL

59.982 - 59.988 mm

(2.3615 - 2.3617 in.)2 WHITE

ENAMEL

59.988 - 59.994 mm

(2.3617 - 2.3620 in.)1 NONE

59.994 - 60.000 mm

(2.3620 - 2.3622 in.)0 YELLOW

ENAMEL

CONNECTING ROD JOURNAL

49.980 - 49.985 mm

(1.9677 - 1.9679 in.)III WHITE

ENAMEL

49.985 - 49.995 mm

(1.9679 - 1.9683 in.)II NONE

49.995 - 50.000 mm

(1.9683 - 1.9685 in.)I YELLOW

ENAMEL

Fig. 10 Bearing Identification

Fig. 11 Checking Crankshaft End Play

CRANKSHAFT SPECIFICATION CHART

Crankshaft End-Play

New Part: 0.05 - 0.25 mm

0.002 - 0.001 in.)

Wear Limit: 0.30 mm (0.012 in.)

Main Bearing Oil Clearance

New Part: 0.018 - 0.036 mm

(0.0007 - 0.0014 in.)

Wear Part: 0.10 mm (0.0039 in.)

Crankshaft Main Bearing Journal

Standard Diameter: 59.980 mm (2.361 in.)

Crankshaft Connecting Rod Journal

Standard Diameter: 50.00 mm (1.968 in.)

NS3.0L ENGINE 9 - 65

SERVICE PROCEDURES (Continued)

Page 1120 of 1938

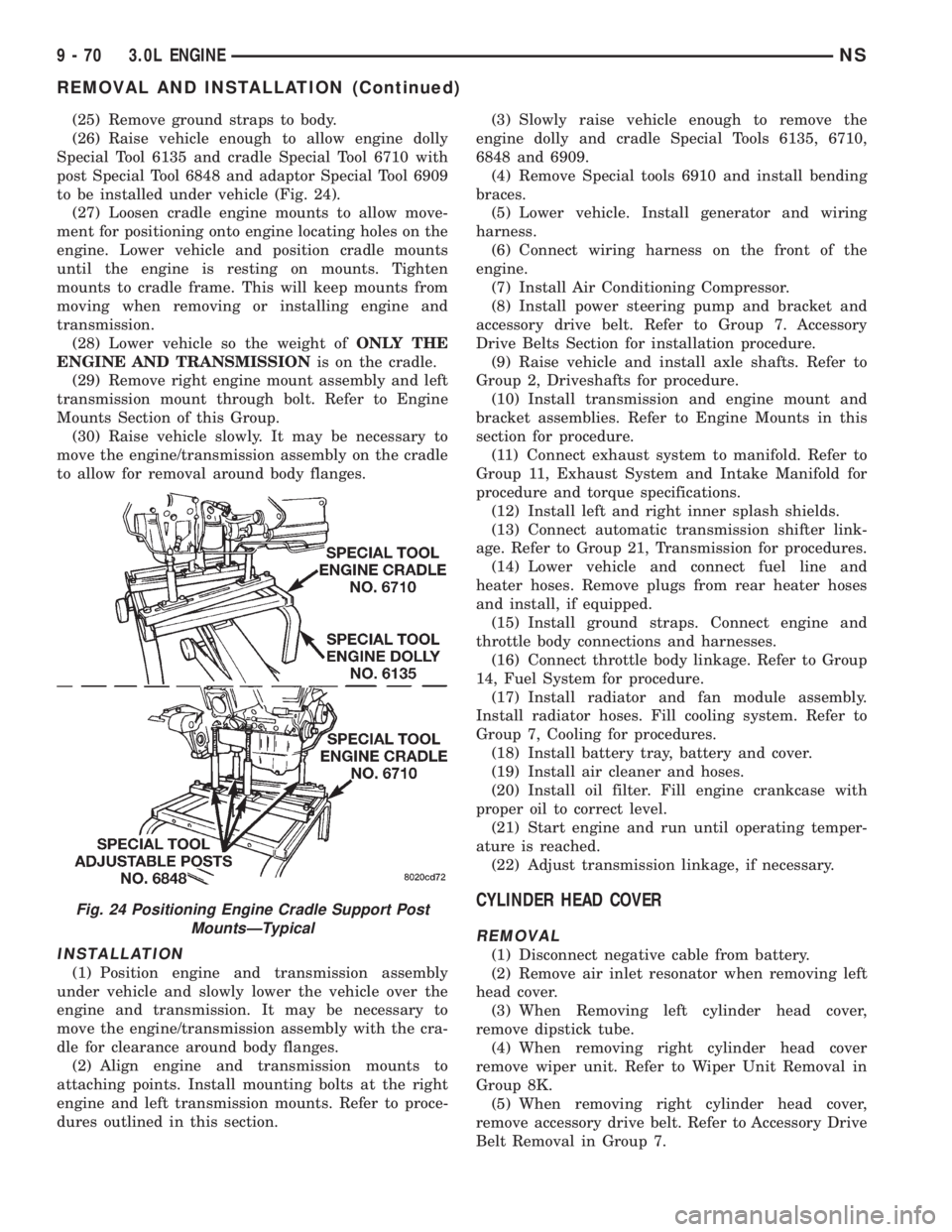

(25) Remove ground straps to body.

(26) Raise vehicle enough to allow engine dolly

Special Tool 6135 and cradle Special Tool 6710 with

post Special Tool 6848 and adaptor Special Tool 6909

to be installed under vehicle (Fig. 24).

(27) Loosen cradle engine mounts to allow move-

ment for positioning onto engine locating holes on the

engine. Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.

(28) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONis on the cradle.

(29) Remove right engine mount assembly and left

transmission mount through bolt. Refer to Engine

Mounts Section of this Group.

(30) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission. It may be necessary to

move the engine/transmission assembly with the cra-

dle for clearance around body flanges.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135, 6710,

6848 and 6909.

(4) Remove Special tools 6910 and install bending

braces.

(5) Lower vehicle. Install generator and wiring

harness.

(6) Connect wiring harness on the front of the

engine.

(7) Install Air Conditioning Compressor.

(8) Install power steering pump and bracket and

accessory drive belt. Refer to Group 7. Accessory

Drive Belts Section for installation procedure.

(9) Raise vehicle and install axle shafts. Refer to

Group 2, Driveshafts for procedure.

(10) Install transmission and engine mount and

bracket assemblies. Refer to Engine Mounts in this

section for procedure.

(11) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(12) Install left and right inner splash shields.

(13) Connect automatic transmission shifter link-

age. Refer to Group 21, Transmission for procedures.

(14) Lower vehicle and connect fuel line and

heater hoses. Remove plugs from rear heater hoses

and install, if equipped.

(15) Install ground straps. Connect engine and

throttle body connections and harnesses.

(16) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(17) Install radiator and fan module assembly.

Install radiator hoses. Fill cooling system. Refer to

Group 7, Cooling for procedures.

(18) Install battery tray, battery and cover.

(19) Install air cleaner and hoses.

(20) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(21) Start engine and run until operating temper-

ature is reached.

(22) Adjust transmission linkage, if necessary.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove air inlet resonator when removing left

head cover.

(3) When Removing left cylinder head cover,

remove dipstick tube.

(4) When removing right cylinder head cover

remove wiper unit. Refer to Wiper Unit Removal in

Group 8K.

(5) When removing right cylinder head cover,

remove accessory drive belt. Refer to Accessory Drive

Belt Removal in Group 7.

Fig. 24 Positioning Engine Cradle Support Post

MountsÐTypical

9 - 70 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1121 of 1938

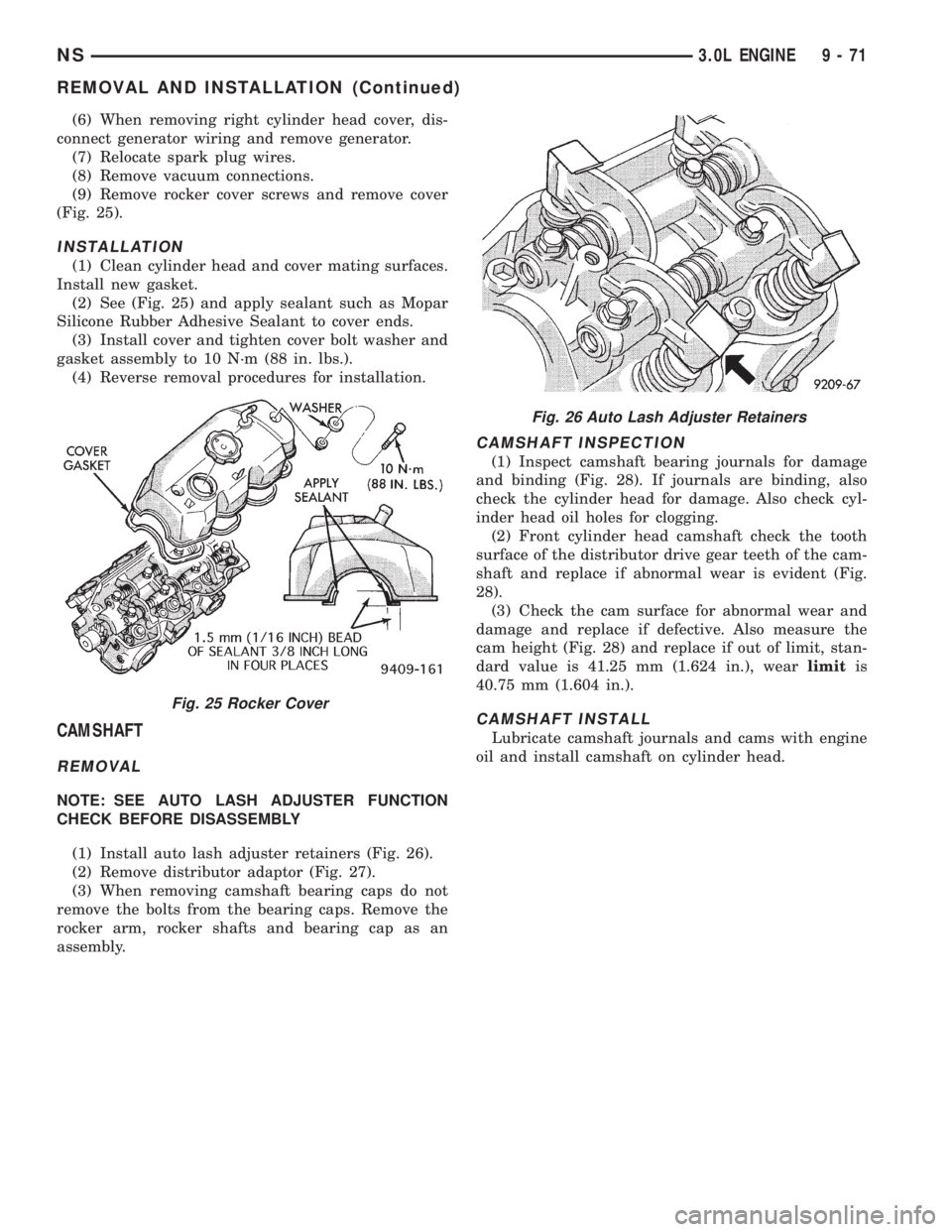

(6) When removing right cylinder head cover, dis-

connect generator wiring and remove generator.

(7) Relocate spark plug wires.

(8) Remove vacuum connections.

(9) Remove rocker cover screws and remove cover

(Fig. 25).

INSTALLATION

(1) Clean cylinder head and cover mating surfaces.

Install new gasket.

(2) See (Fig. 25) and apply sealant such as Mopar

Silicone Rubber Adhesive Sealant to cover ends.

(3) Install cover and tighten cover bolt washer and

gasket assembly to 10 N´m (88 in. lbs.).

(4) Reverse removal procedures for installation.

CAMSHAFT

REMOVAL

NOTE: SEE AUTO LASH ADJUSTER FUNCTION

CHECK BEFORE DISASSEMBLY

(1) Install auto lash adjuster retainers (Fig. 26).

(2) Remove distributor adaptor (Fig. 27).

(3) When removing camshaft bearing caps do not

remove the bolts from the bearing caps. Remove the

rocker arm, rocker shafts and bearing cap as an

assembly.

CAMSHAFT INSPECTION

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 28). If journals are binding, also

check the cylinder head for damage. Also check cyl-

inder head oil holes for clogging.

(2) Front cylinder head camshaft check the tooth

surface of the distributor drive gear teeth of the cam-

shaft and replace if abnormal wear is evident (Fig.

28).

(3) Check the cam surface for abnormal wear and

damage and replace if defective. Also measure the

cam height (Fig. 28) and replace if out of limit, stan-

dard value is 41.25 mm (1.624 in.), wearlimitis

40.75 mm (1.604 in.).

CAMSHAFT INSTALL

Lubricate camshaft journals and cams with engine

oil and install camshaft on cylinder head.

Fig. 25 Rocker Cover

Fig. 26 Auto Lash Adjuster Retainers

NS3.0L ENGINE 9 - 71

REMOVAL AND INSTALLATION (Continued)

Page 1123 of 1938

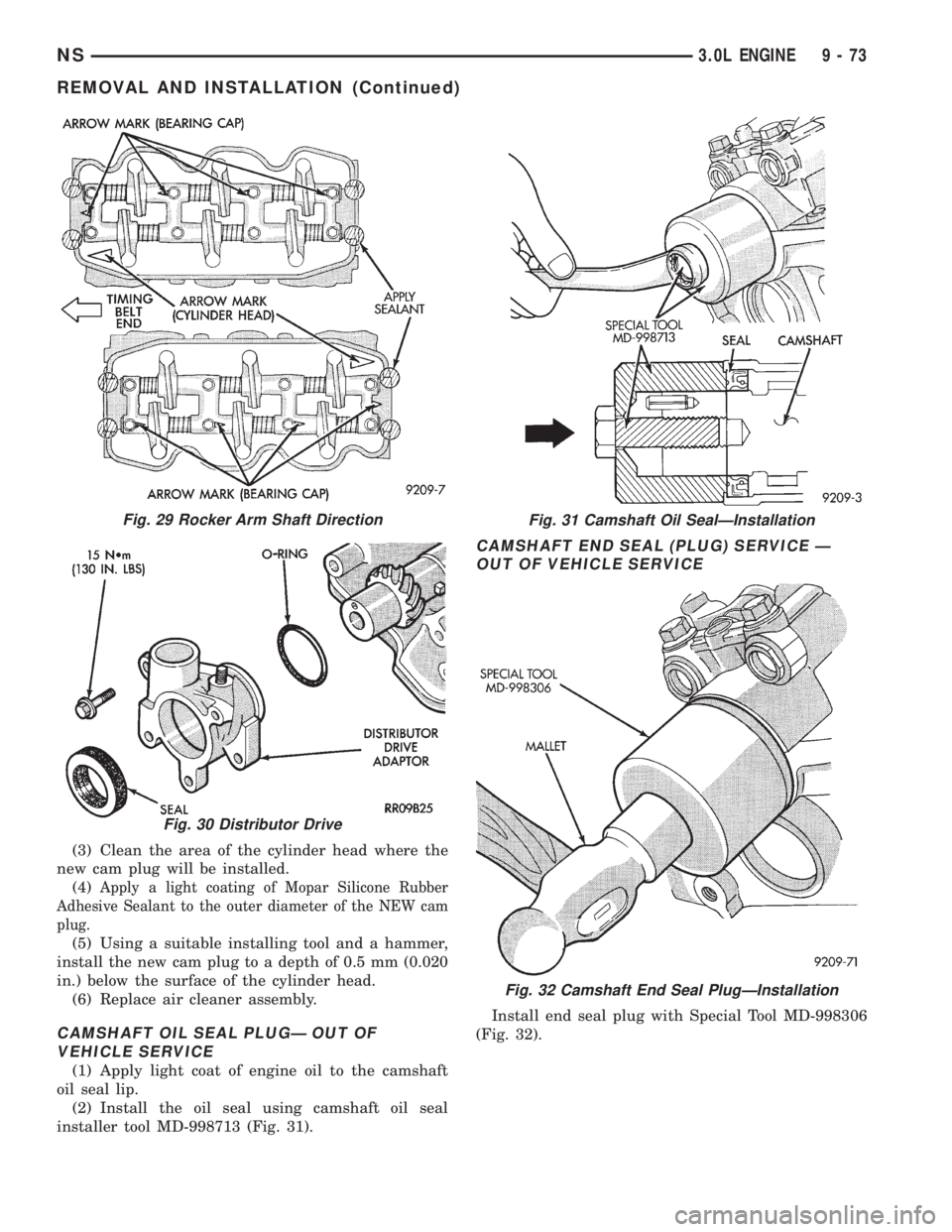

(3) Clean the area of the cylinder head where the

new cam plug will be installed.

(4)

Apply a light coating of Mopar Silicone Rubber

Adhesive Sealant to the outer diameter of the NEW cam

plug.

(5) Using a suitable installing tool and a hammer,

install the new cam plug to a depth of 0.5 mm (0.020

in.) below the surface of the cylinder head.

(6) Replace air cleaner assembly.

CAMSHAFT OIL SEAL PLUGÐ OUT OF

VEHICLE SERVICE

(1) Apply light coat of engine oil to the camshaft

oil seal lip.

(2) Install the oil seal using camshaft oil seal

installer tool MD-998713 (Fig. 31).

CAMSHAFT END SEAL (PLUG) SERVICE Ð

OUT OF VEHICLE SERVICE

Install end seal plug with Special Tool MD-998306

(Fig. 32).

Fig. 29 Rocker Arm Shaft Direction

Fig. 30 Distributor Drive

Fig. 31 Camshaft Oil SealÐInstallation

Fig. 32 Camshaft End Seal PlugÐInstallation

NS3.0L ENGINE 9 - 73

REMOVAL AND INSTALLATION (Continued)

Page 1127 of 1938

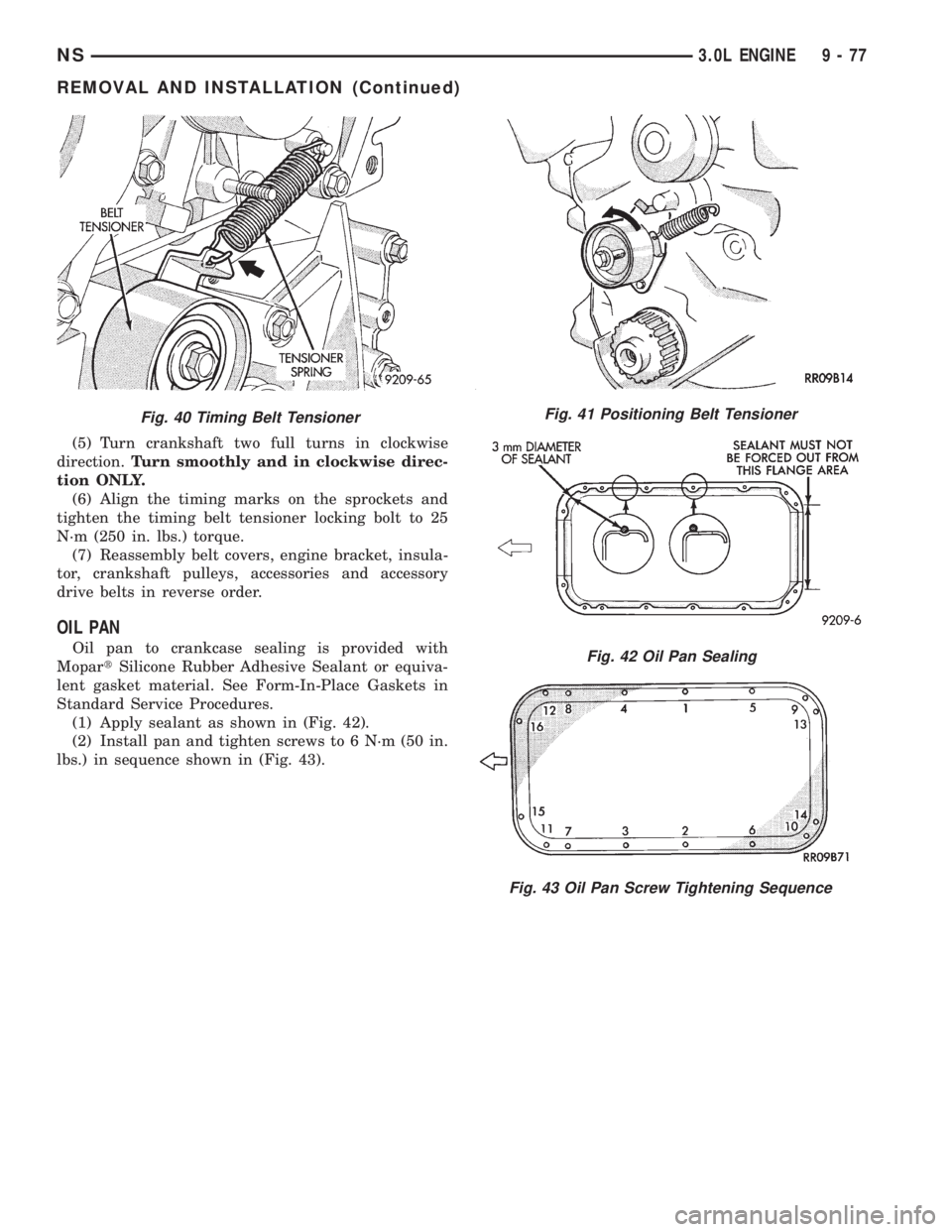

(5) Turn crankshaft two full turns in clockwise

direction.Turn smoothly and in clockwise direc-

tion ONLY.

(6) Align the timing marks on the sprockets and

tighten the timing belt tensioner locking bolt to 25

N´m (250 in. lbs.) torque.

(7) Reassembly belt covers, engine bracket, insula-

tor, crankshaft pulleys, accessories and accessory

drive belts in reverse order.

OIL PAN

Oil pan to crankcase sealing is provided with

MopartSilicone Rubber Adhesive Sealant or equiva-

lent gasket material. See Form-In-Place Gaskets in

Standard Service Procedures.

(1) Apply sealant as shown in (Fig. 42).

(2) Install pan and tighten screws to 6 N´m (50 in.

lbs.) in sequence shown in (Fig. 43).

Fig. 41 Positioning Belt Tensioner

Fig. 42 Oil Pan Sealing

Fig. 43 Oil Pan Screw Tightening Sequence

Fig. 40 Timing Belt Tensioner

NS3.0L ENGINE 9 - 77

REMOVAL AND INSTALLATION (Continued)

Page 1129 of 1938

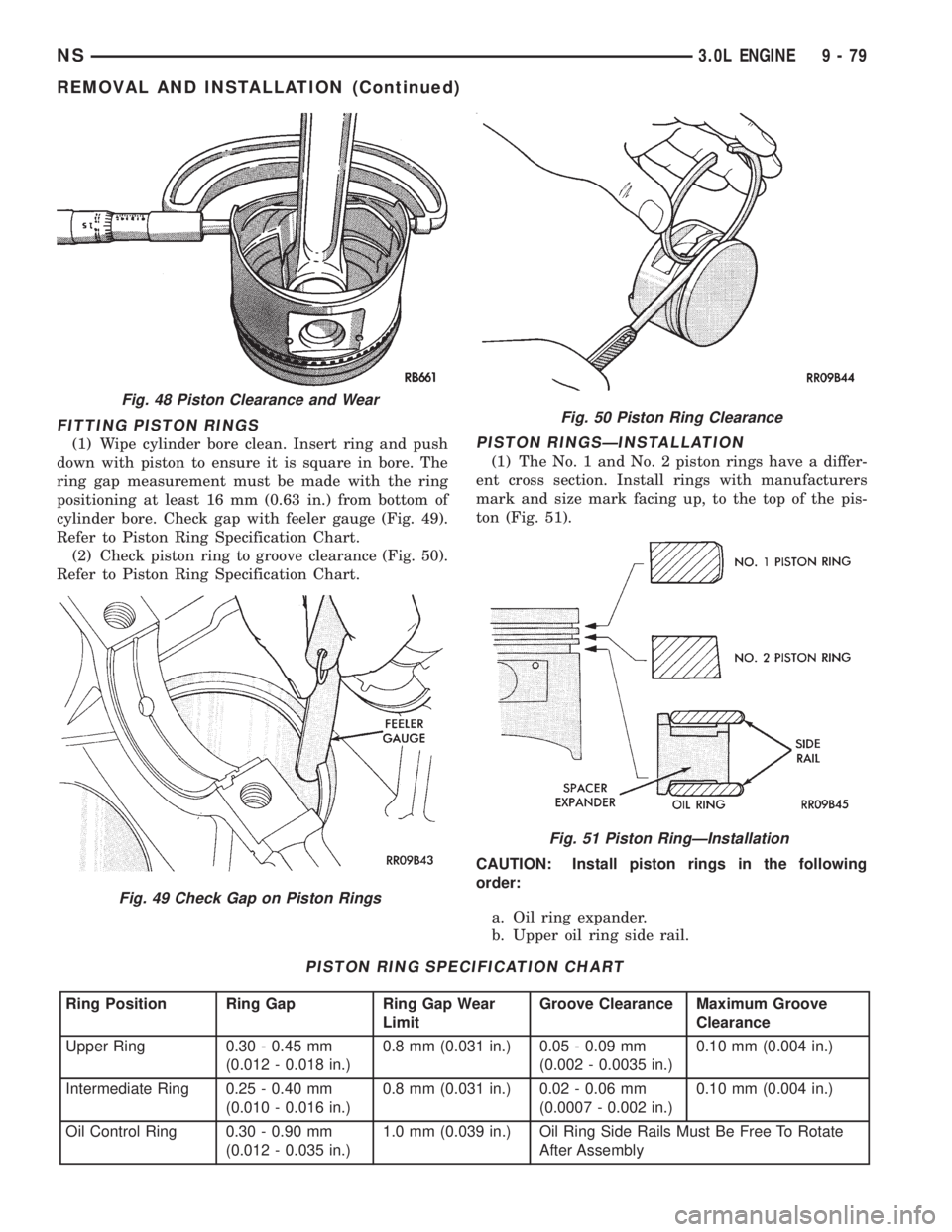

FITTING PISTON RINGS

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 16 mm (0.63 in.) from bottom of

cylinder bore. Check gap with feeler gauge (Fig. 49).

Refer to Piston Ring Specification Chart.

(2) Check piston ring to groove clearance (Fig. 50).

Refer to Piston Ring Specification Chart.PISTON RINGSÐINSTALLATION

(1) The No. 1 and No. 2 piston rings have a differ-

ent cross section. Install rings with manufacturers

mark and size mark facing up, to the top of the pis-

ton (Fig. 51).

CAUTION: Install piston rings in the following

order:

a. Oil ring expander.

b. Upper oil ring side rail.

PISTON RING SPECIFICATION CHART

Ring Position Ring Gap Ring Gap Wear

LimitGroove Clearance Maximum Groove

Clearance

Upper Ring 0.30 - 0.45 mm

(0.012 - 0.018 in.)0.8 mm (0.031 in.) 0.05 - 0.09 mm

(0.002 - 0.0035 in.)0.10 mm (0.004 in.)

Intermediate Ring 0.25 - 0.40 mm

(0.010 - 0.016 in.)0.8 mm (0.031 in.) 0.02 - 0.06 mm

(0.0007 - 0.002 in.)0.10 mm (0.004 in.)

Oil Control Ring 0.30 - 0.90 mm

(0.012 - 0.035 in.)1.0 mm (0.039 in.) Oil Ring Side Rails Must Be Free To Rotate

After Assembly

Fig. 48 Piston Clearance and Wear

Fig. 49 Check Gap on Piston Rings

Fig. 50 Piston Ring Clearance

Fig. 51 Piston RingÐInstallation

NS3.0L ENGINE 9 - 79

REMOVAL AND INSTALLATION (Continued)

Page 1130 of 1938

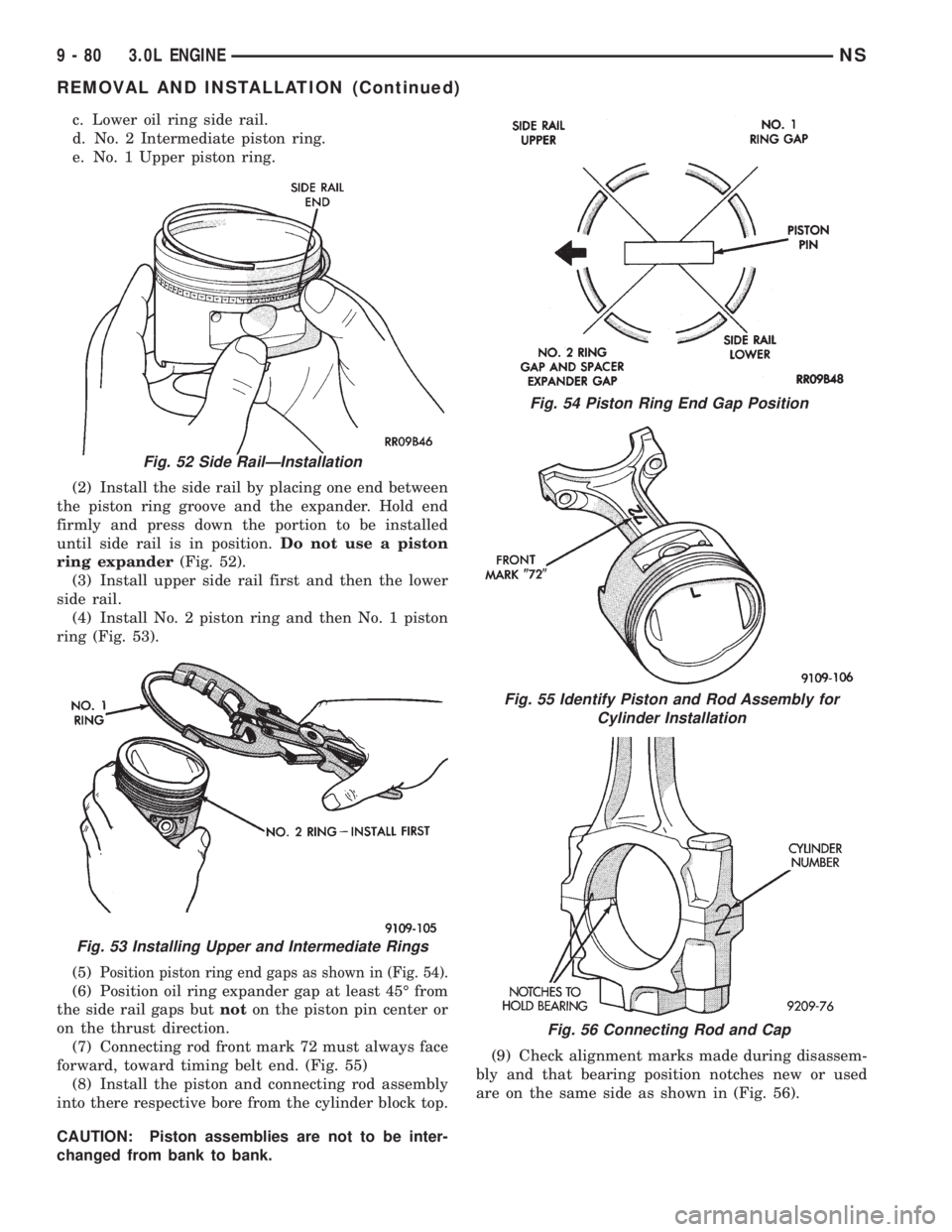

c. Lower oil ring side rail.

d. No. 2 Intermediate piston ring.

e. No. 1 Upper piston ring.

(2) Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed

until side rail is in position.Do not use a piston

ring expander(Fig. 52).

(3) Install upper side rail first and then the lower

side rail.

(4) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 53).

(5)

Position piston ring end gaps as shown in (Fig. 54).

(6) Position oil ring expander gap at least 45É from

the side rail gaps butnoton the piston pin center or

on the thrust direction.

(7) Connecting rod front mark 72 must always face

forward, toward timing belt end. (Fig. 55)

(8) Install the piston and connecting rod assembly

into there respective bore from the cylinder block top.

CAUTION: Piston assemblies are not to be inter-

changed from bank to bank.(9) Check alignment marks made during disassem-

bly and that bearing position notches new or used

are on the same side as shown in (Fig. 56).

Fig. 52 Side RailÐInstallation

Fig. 53 Installing Upper and Intermediate Rings

Fig. 54 Piston Ring End Gap Position

Fig. 55 Identify Piston and Rod Assembly for

Cylinder Installation

Fig. 56 Connecting Rod and Cap

9 - 80 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1131 of 1938

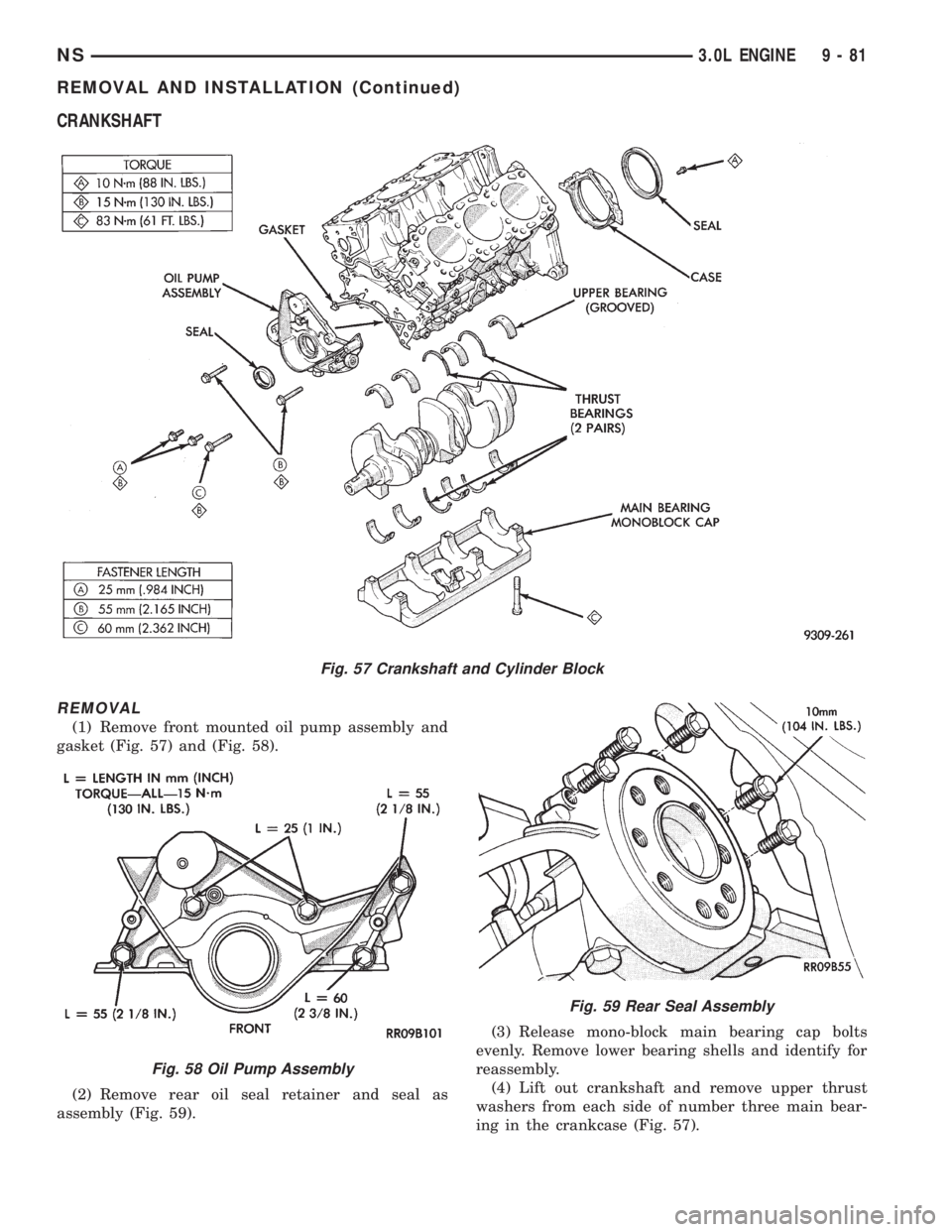

CRANKSHAFT

REMOVAL

(1) Remove front mounted oil pump assembly and

gasket (Fig. 57) and (Fig. 58).

(2) Remove rear oil seal retainer and seal as

assembly (Fig. 59).(3) Release mono-block main bearing cap bolts

evenly. Remove lower bearing shells and identify for

reassembly.

(4) Lift out crankshaft and remove upper thrust

washers from each side of number three main bear-

ing in the crankcase (Fig. 57).

Fig. 57 Crankshaft and Cylinder Block

Fig. 58 Oil Pump Assembly

Fig. 59 Rear Seal Assembly

NS3.0L ENGINE 9 - 81

REMOVAL AND INSTALLATION (Continued)

Page 1132 of 1938

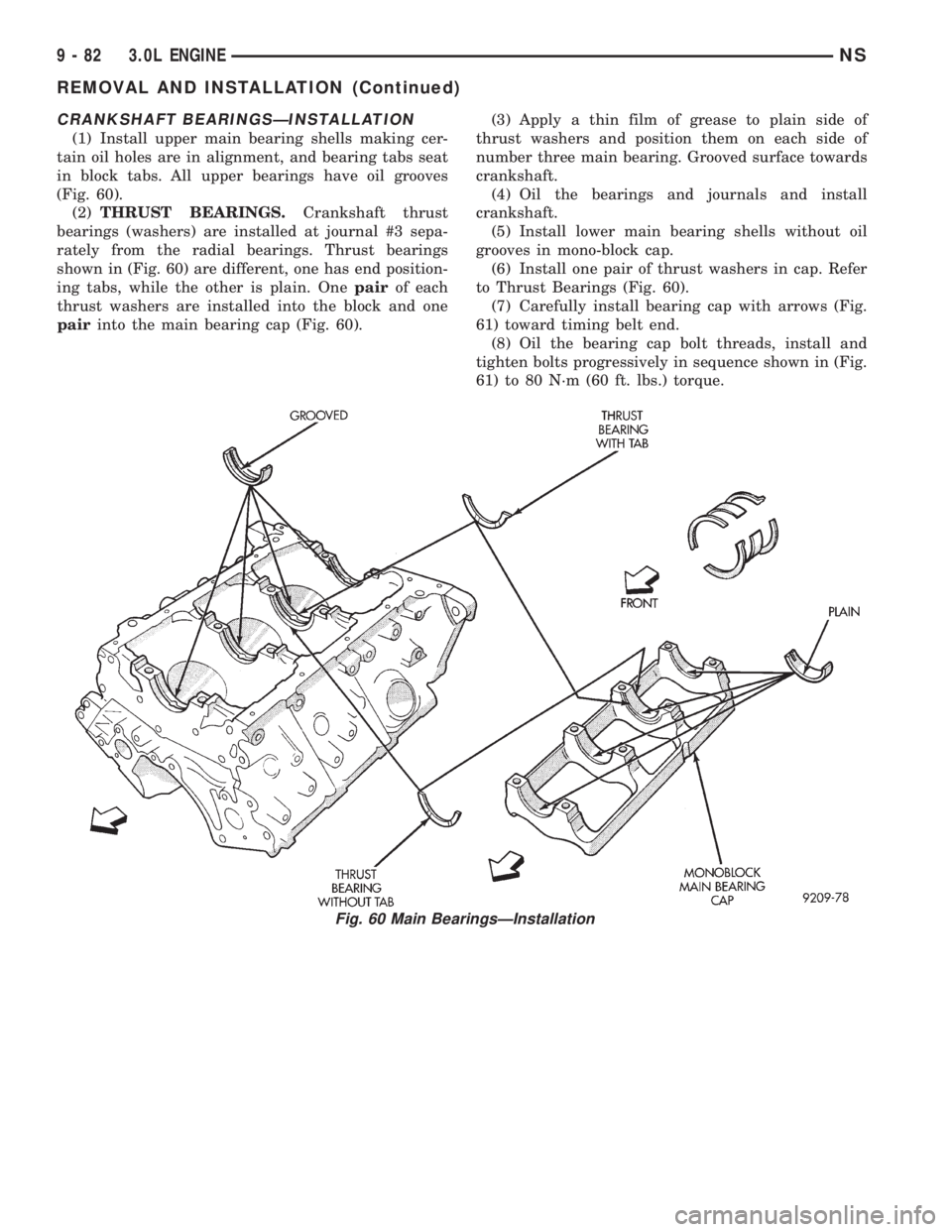

CRANKSHAFT BEARINGSÐINSTALLATION

(1) Install upper main bearing shells making cer-

tain oil holes are in alignment, and bearing tabs seat

in block tabs. All upper bearings have oil grooves

(Fig. 60).

(2)THRUST BEARINGS.Crankshaft thrust

bearings (washers) are installed at journal #3 sepa-

rately from the radial bearings. Thrust bearings

shown in (Fig. 60) are different, one has end position-

ing tabs, while the other is plain. Onepairof each

thrust washers are installed into the block and one

pairinto the main bearing cap (Fig. 60).(3) Apply a thin film of grease to plain side of

thrust washers and position them on each side of

number three main bearing. Grooved surface towards

crankshaft.

(4) Oil the bearings and journals and install

crankshaft.

(5) Install lower main bearing shells without oil

grooves in mono-block cap.

(6) Install one pair of thrust washers in cap. Refer

to Thrust Bearings (Fig. 60).

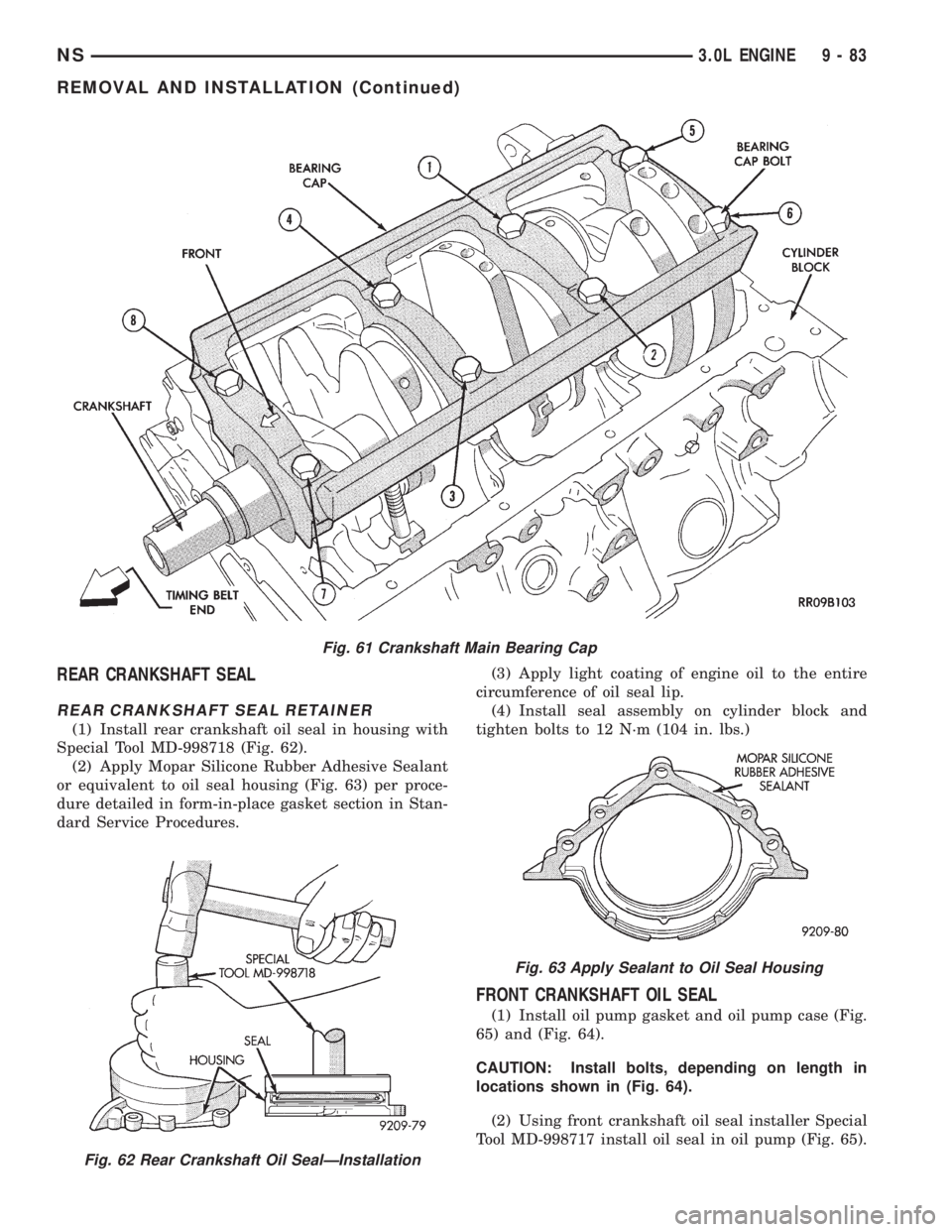

(7) Carefully install bearing cap with arrows (Fig.

61) toward timing belt end.

(8) Oil the bearing cap bolt threads, install and

tighten bolts progressively in sequence shown in (Fig.

61) to 80 N´m (60 ft. lbs.) torque.

Fig. 60 Main BearingsÐInstallation

9 - 82 3.0L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1133 of 1938

REAR CRANKSHAFT SEAL

REAR CRANKSHAFT SEAL RETAINER

(1) Install rear crankshaft oil seal in housing with

Special Tool MD-998718 (Fig. 62).

(2) Apply Mopar Silicone Rubber Adhesive Sealant

or equivalent to oil seal housing (Fig. 63) per proce-

dure detailed in form-in-place gasket section in Stan-

dard Service Procedures.(3) Apply light coating of engine oil to the entire

circumference of oil seal lip.

(4) Install seal assembly on cylinder block and

tighten bolts to 12 N´m (104 in. lbs.)

FRONT CRANKSHAFT OIL SEAL

(1) Install oil pump gasket and oil pump case (Fig.

65) and (Fig. 64).

CAUTION: Install bolts, depending on length in

locations shown in (Fig. 64).

(2) Using front crankshaft oil seal installer Special

Tool MD-998717 install oil seal in oil pump (Fig. 65).

Fig. 62 Rear Crankshaft Oil SealÐInstallation

Fig. 61 Crankshaft Main Bearing Cap

Fig. 63 Apply Sealant to Oil Seal Housing

NS3.0L ENGINE 9 - 83

REMOVAL AND INSTALLATION (Continued)