engine oil CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1076 of 1938

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove Air cleaner and hoses.

(4) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(5) Remove upper radiator hose and remove radia-

tor fans. Refer to Group 7, Cooling System for proce-

dure.

(6) Remove lower radiator hose.

(7) Disconnect automatic transmission cooler lines

and plug, if equipped.

(8) Disconnect transmission shift linkage.

(9) Disconnect throttle body linkage.

(10) Disconnect engine wiring harness.

(11) Disconnect heater hoses.

(12) Discharge Air Conditioning System. Refer to

Group 24, Air Conditioning for procedure.

(13) Hoist vehicle and remove right inner splash

shield. Remove wheels and tires.

(14) Loosen power steering belt for pump removal.

Refer to Group 7, Cooling System for procedure.

(15) Remove axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(16) Disconnect exhaust pipe from manifold.

(17) Remove front and rear engine mount brackets

from the body.

(18) Remove bending braces and front engine

mount bracket. Remove transmission inspection

cover.

(19) Mark flexplate to torque converter and

remove torque converter bolts.

(20) Install front engine mount bracket.

(21) Lower vehicle.

(22) Remove power steering pump. Set pump

aside.

(23) Remove A/C lines at compressor and cap.

(24) Remove ground straps to body.

(25) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 and Adaptor Special Tool

8130 to be installed under vehicle (Fig. 27).

(26) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

front engine bracket and A/C compressor bracket

(Fig. 27). Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.(27) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(28) Remove engine and transmission mount bolts.

(29) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around the body.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(4) Install axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(5) Install transmission and engine braces and

splash shields.

(6) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(7) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt ten-

sion adjustment.

(8) Install A/C compressor hoses. Refer to Group

24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front and rear engine mounts. Refer to

this section for procedure.

(11) Install inner splash shield. Install wheels and

tires.

(12) Connect automatic transmission cooler lines,

and shift linkage. Refer to Group 21, Transmission

for procedures.

(13) Connect fuel line and heater hoses.

(14) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(15) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(16) Install radiator fans. Install radiator hoses.

Fill cooling system. Refer to Group 7, Cooling System

for filling procedure.

(17) Connect battery.

(18) Install air cleaner and hoses.

(19) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(20) Start engine and run until operating temper-

ature is reached.

(21) Adjust transmission linkage, if necessary.

9 - 26 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1078 of 1938

CYLINDER HEAD COVER

REMOVAL

(1) Remove upper intake manifold. Refer to Group

11, Exhaust System and Intake Manifold.

(2) Remove nuts attaching front and rear intake

manifold supports from cylinder head cover attaching

studs.

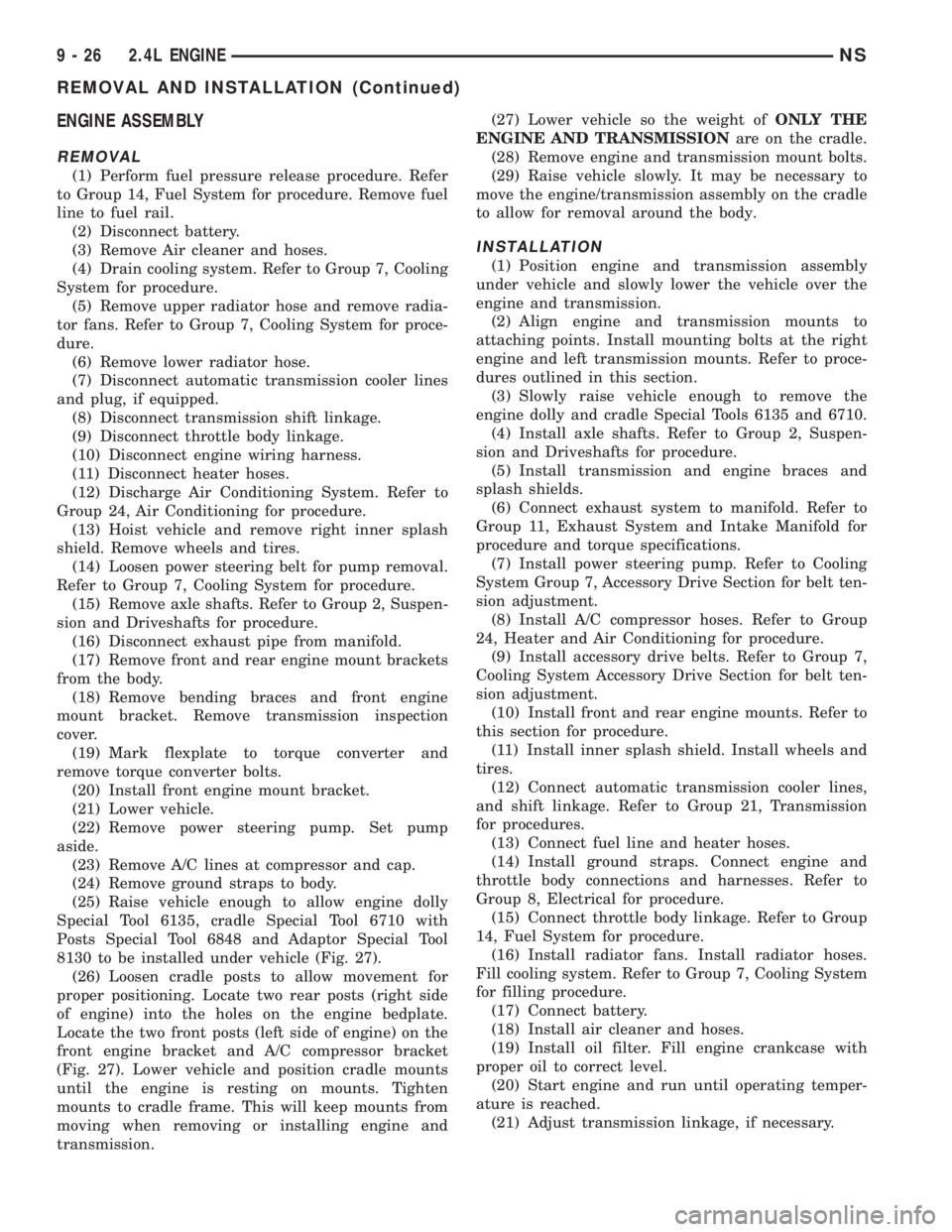

(3) Remove ignition coil pack and plug wires (Fig.

28). Remove ground strap.

(4) Remove the cylinder head cover fasteners.

(5) Remove cylinder head cover from cylinder

head.

INSTALLATION

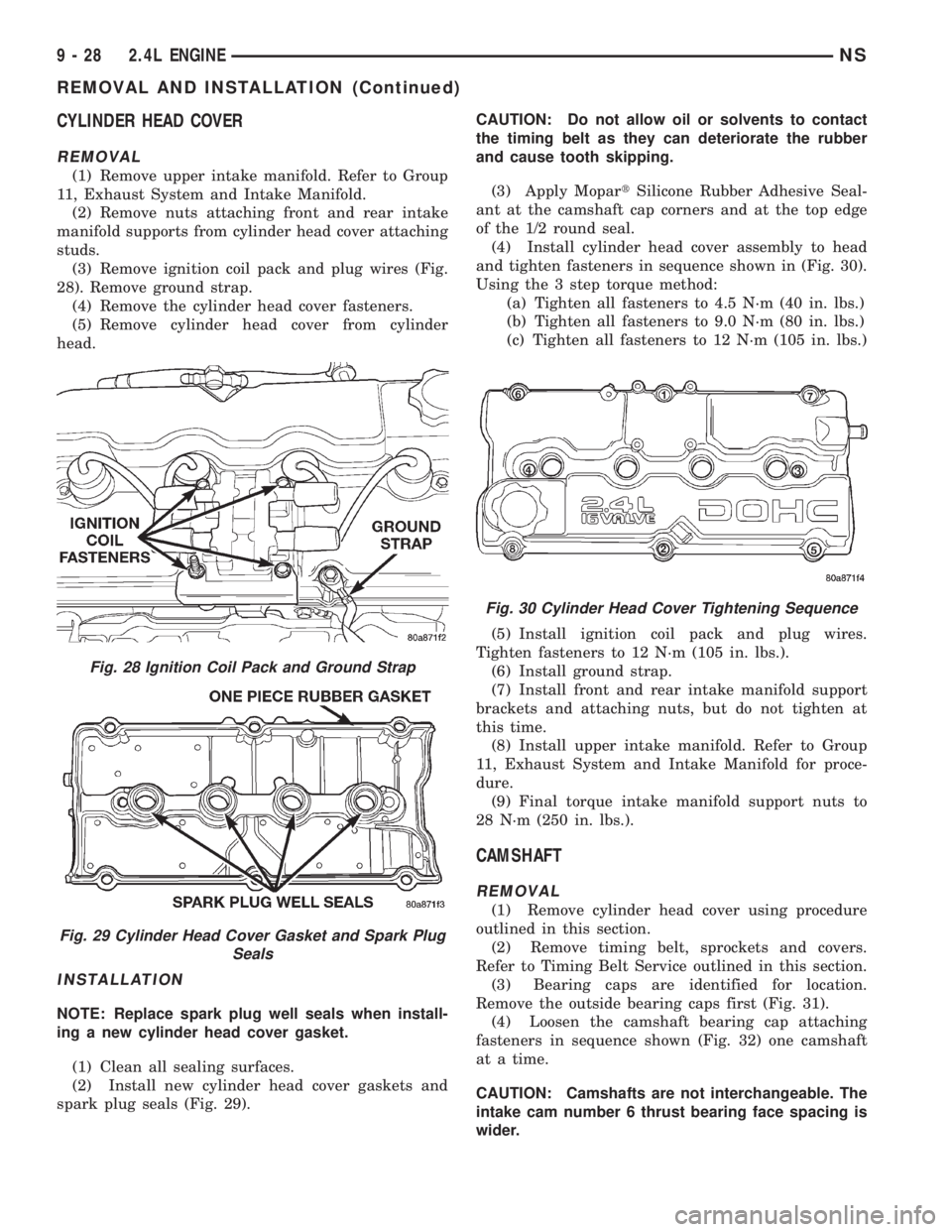

NOTE: Replace spark plug well seals when install-

ing a new cylinder head cover gasket.

(1) Clean all sealing surfaces.

(2) Install new cylinder head cover gaskets and

spark plug seals (Fig. 29).CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

(3) Apply MopartSilicone Rubber Adhesive Seal-

ant at the camshaft cap corners and at the top edge

of the 1/2 round seal.

(4) Install cylinder head cover assembly to head

and tighten fasteners in sequence shown in (Fig. 30).

Using the 3 step torque method:

(a) Tighten all fasteners to 4.5 N´m (40 in. lbs.)

(b) Tighten all fasteners to 9.0 N´m (80 in. lbs.)

(c) Tighten all fasteners to 12 N´m (105 in. lbs.)

(5) Install ignition coil pack and plug wires.

Tighten fasteners to 12 N´m (105 in. lbs.).

(6) Install ground strap.

(7) Install front and rear intake manifold support

brackets and attaching nuts, but do not tighten at

this time.

(8) Install upper intake manifold. Refer to Group

11, Exhaust System and Intake Manifold for proce-

dure.

(9) Final torque intake manifold support nuts to

28 N´m (250 in. lbs.).

CAMSHAFT

REMOVAL

(1) Remove cylinder head cover using procedure

outlined in this section.

(2) Remove timing belt, sprockets and covers.

Refer to Timing Belt Service outlined in this section.

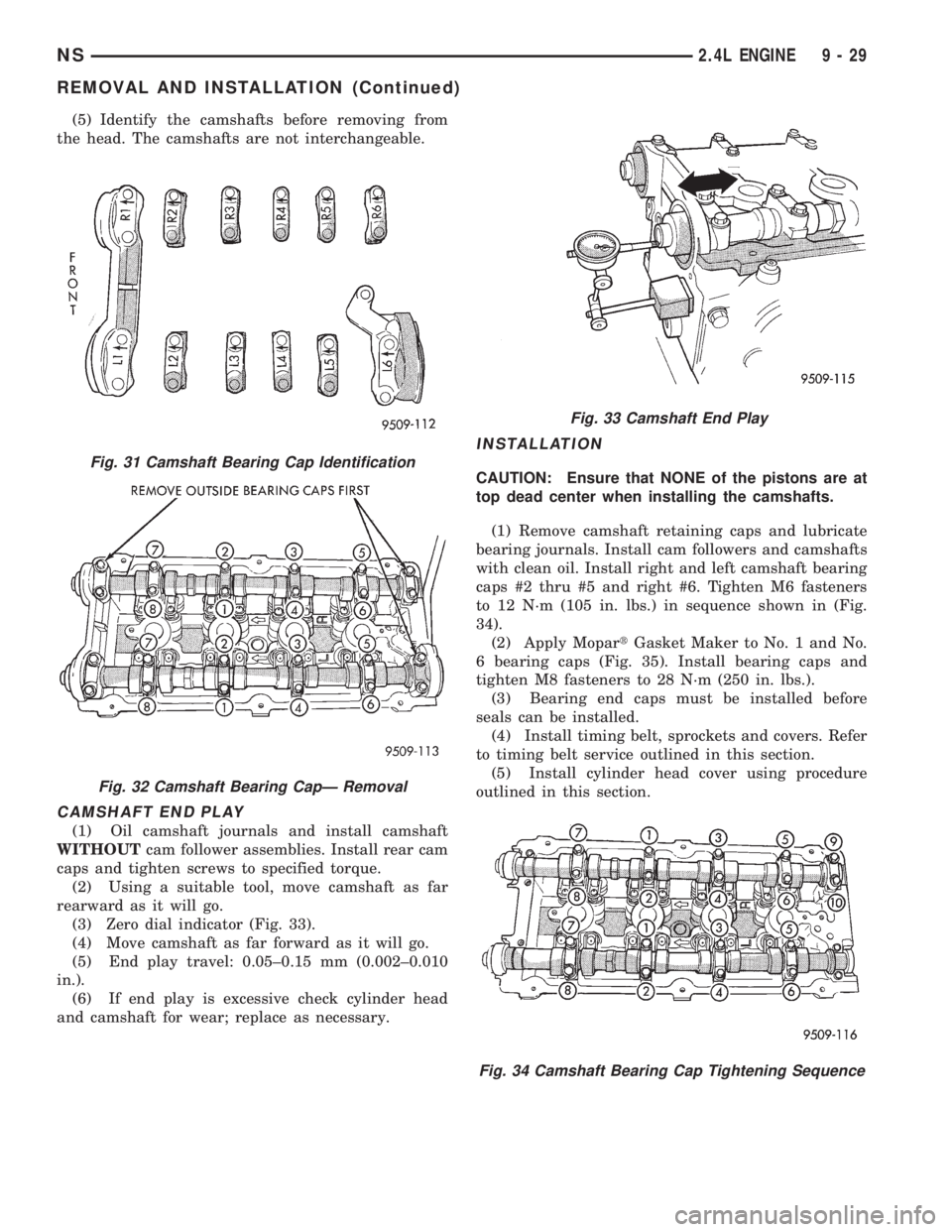

(3) Bearing caps are identified for location.

Remove the outside bearing caps first (Fig. 31).

(4) Loosen the camshaft bearing cap attaching

fasteners in sequence shown (Fig. 32) one camshaft

at a time.

CAUTION: Camshafts are not interchangeable. The

intake cam number 6 thrust bearing face spacing is

wider.

Fig. 28 Ignition Coil Pack and Ground Strap

Fig. 29 Cylinder Head Cover Gasket and Spark Plug

Seals

Fig. 30 Cylinder Head Cover Tightening Sequence

9 - 28 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1079 of 1938

(5) Identify the camshafts before removing from

the head. The camshafts are not interchangeable.

CAMSHAFT END PLAY

(1) Oil camshaft journals and install camshaft

WITHOUTcam follower assemblies. Install rear cam

caps and tighten screws to specified torque.

(2) Using a suitable tool, move camshaft as far

rearward as it will go.

(3) Zero dial indicator (Fig. 33).

(4) Move camshaft as far forward as it will go.

(5) End play travel: 0.05±0.15 mm (0.002±0.010

in.).

(6) If end play is excessive check cylinder head

and camshaft for wear; replace as necessary.

INSTALLATION

CAUTION: Ensure that NONE of the pistons are at

top dead center when installing the camshafts.

(1) Remove camshaft retaining caps and lubricate

bearing journals. Install cam followers and camshafts

with clean oil. Install right and left camshaft bearing

caps #2 thru #5 and right #6. Tighten M6 fasteners

to 12 N´m (105 in. lbs.) in sequence shown in (Fig.

34).

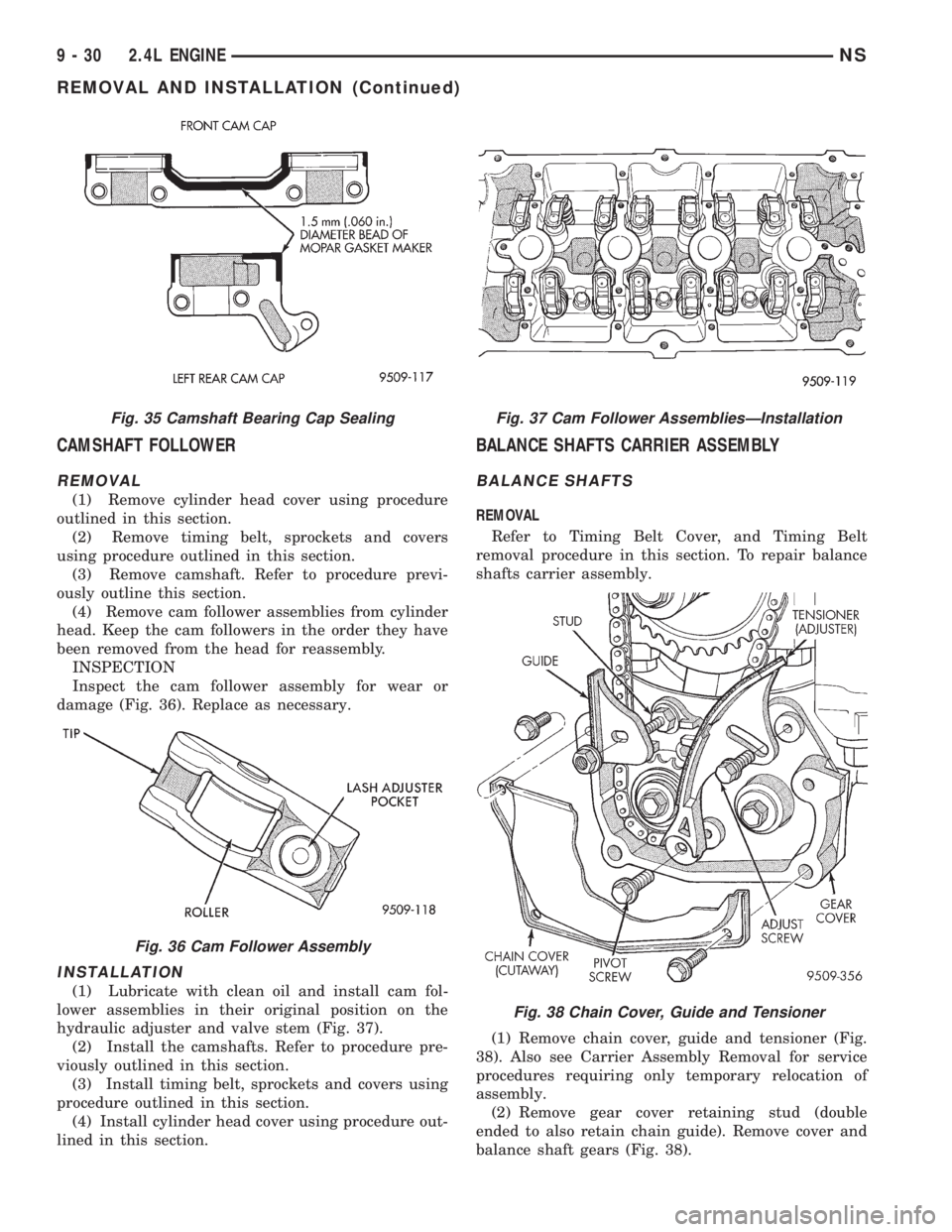

(2) Apply MopartGasket Maker to No. 1 and No.

6 bearing caps (Fig. 35). Install bearing caps and

tighten M8 fasteners to 28 N´m (250 in. lbs.).

(3) Bearing end caps must be installed before

seals can be installed.

(4) Install timing belt, sprockets and covers. Refer

to timing belt service outlined in this section.

(5) Install cylinder head cover using procedure

outlined in this section.Fig. 31 Camshaft Bearing Cap Identification

Fig. 32 Camshaft Bearing CapÐ Removal

Fig. 33 Camshaft End Play

Fig. 34 Camshaft Bearing Cap Tightening Sequence

NS2.4L ENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1080 of 1938

CAMSHAFT FOLLOWER

REMOVAL

(1) Remove cylinder head cover using procedure

outlined in this section.

(2) Remove timing belt, sprockets and covers

using procedure outlined in this section.

(3) Remove camshaft. Refer to procedure previ-

ously outline this section.

(4) Remove cam follower assemblies from cylinder

head. Keep the cam followers in the order they have

been removed from the head for reassembly.

INSPECTION

Inspect the cam follower assembly for wear or

damage (Fig. 36). Replace as necessary.

INSTALLATION

(1) Lubricate with clean oil and install cam fol-

lower assemblies in their original position on the

hydraulic adjuster and valve stem (Fig. 37).

(2) Install the camshafts. Refer to procedure pre-

viously outlined in this section.

(3) Install timing belt, sprockets and covers using

procedure outlined in this section.

(4) Install cylinder head cover using procedure out-

lined in this section.

BALANCE SHAFTS CARRIER ASSEMBLY

BALANCE SHAFTS

REMOVAL

Refer to Timing Belt Cover, and Timing Belt

removal procedure in this section. To repair balance

shafts carrier assembly.

(1) Remove chain cover, guide and tensioner (Fig.

38). Also see Carrier Assembly Removal for service

procedures requiring only temporary relocation of

assembly.

(2) Remove gear cover retaining stud (double

ended to also retain chain guide). Remove cover and

balance shaft gears (Fig. 38).

Fig. 35 Camshaft Bearing Cap Sealing

Fig. 36 Cam Follower Assembly

Fig. 37 Cam Follower AssembliesÐInstallation

Fig. 38 Chain Cover, Guide and Tensioner

9 - 30 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1083 of 1938

NOTE: THE TIMING MARK ON THE SPROCKET,

THE (LOWER) NICKEL PLATED LINK, AND THE

ARROW ON THE SIDE OF THE GEAR COVER

SHOULD LINE UP WHEN THE BALANCE SHAFTS

ARE TIMED CORRECTLY.

(9) If the sprockets are timed correctly install the

balance shaft bolts and tighten to 28 N´m (250 in.

lbs.). A wood block placed between crankcase and

crankshaft counterbalance will prevent crankshaft

and gear rotation.

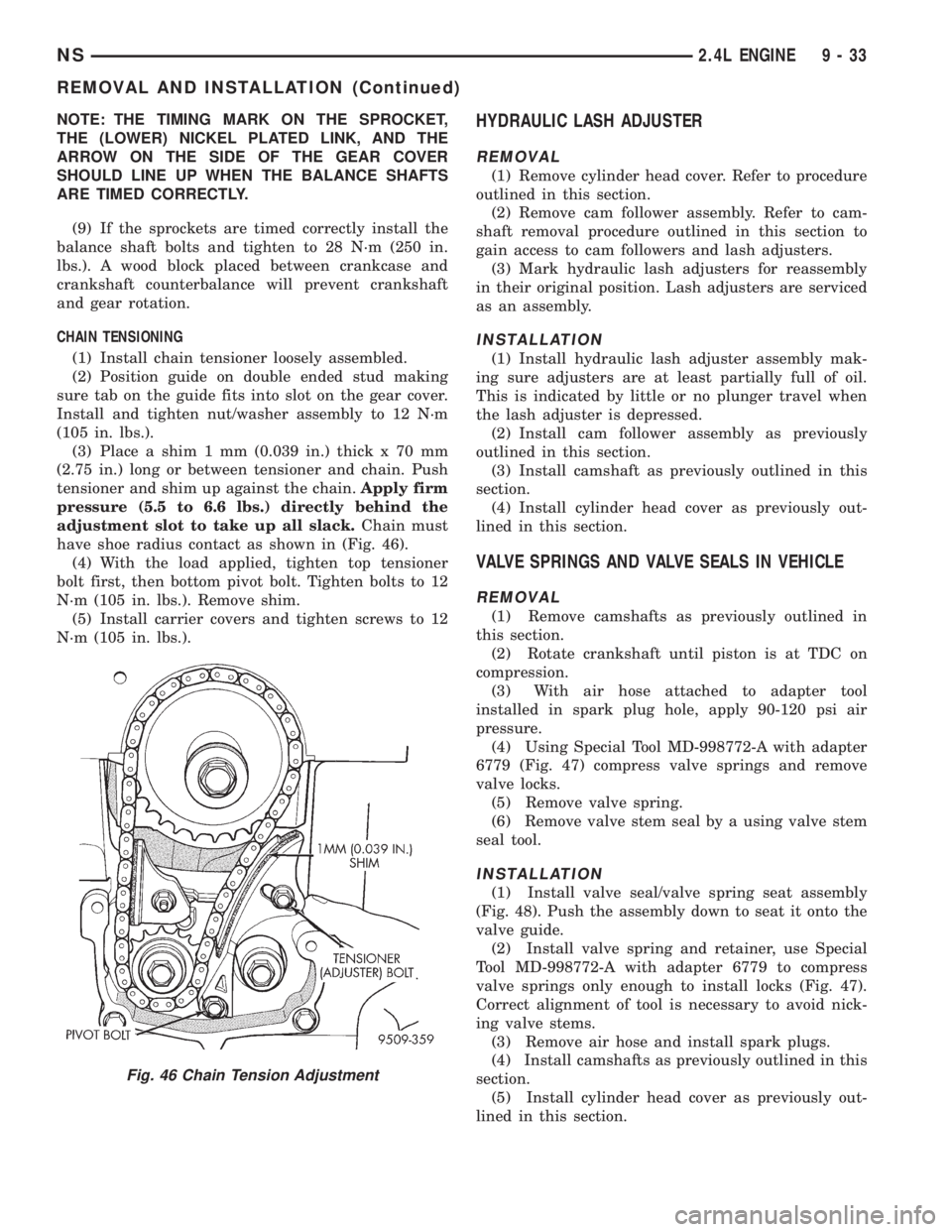

CHAIN TENSIONING

(1) Install chain tensioner loosely assembled.

(2) Position guide on double ended stud making

sure tab on the guide fits into slot on the gear cover.

Install and tighten nut/washer assembly to 12 N´m

(105 in. lbs.).

(3) Place a shim 1 mm (0.039 in.) thick x 70 mm

(2.75 in.) long or between tensioner and chain. Push

tensioner and shim up against the chain.Apply firm

pressure (5.5 to 6.6 lbs.) directly behind the

adjustment slot to take up all slack.Chain must

have shoe radius contact as shown in (Fig. 46).

(4) With the load applied, tighten top tensioner

bolt first, then bottom pivot bolt. Tighten bolts to 12

N´m (105 in. lbs.). Remove shim.

(5) Install carrier covers and tighten screws to 12

N´m (105 in. lbs.).HYDRAULIC LASH ADJUSTER

REMOVAL

(1) Remove cylinder head cover. Refer to procedure

outlined in this section.

(2) Remove cam follower assembly. Refer to cam-

shaft removal procedure outlined in this section to

gain access to cam followers and lash adjusters.

(3) Mark hydraulic lash adjusters for reassembly

in their original position. Lash adjusters are serviced

as an assembly.

INSTALLATION

(1) Install hydraulic lash adjuster assembly mak-

ing sure adjusters are at least partially full of oil.

This is indicated by little or no plunger travel when

the lash adjuster is depressed.

(2) Install cam follower assembly as previously

outlined in this section.

(3) Install camshaft as previously outlined in this

section.

(4) Install cylinder head cover as previously out-

lined in this section.

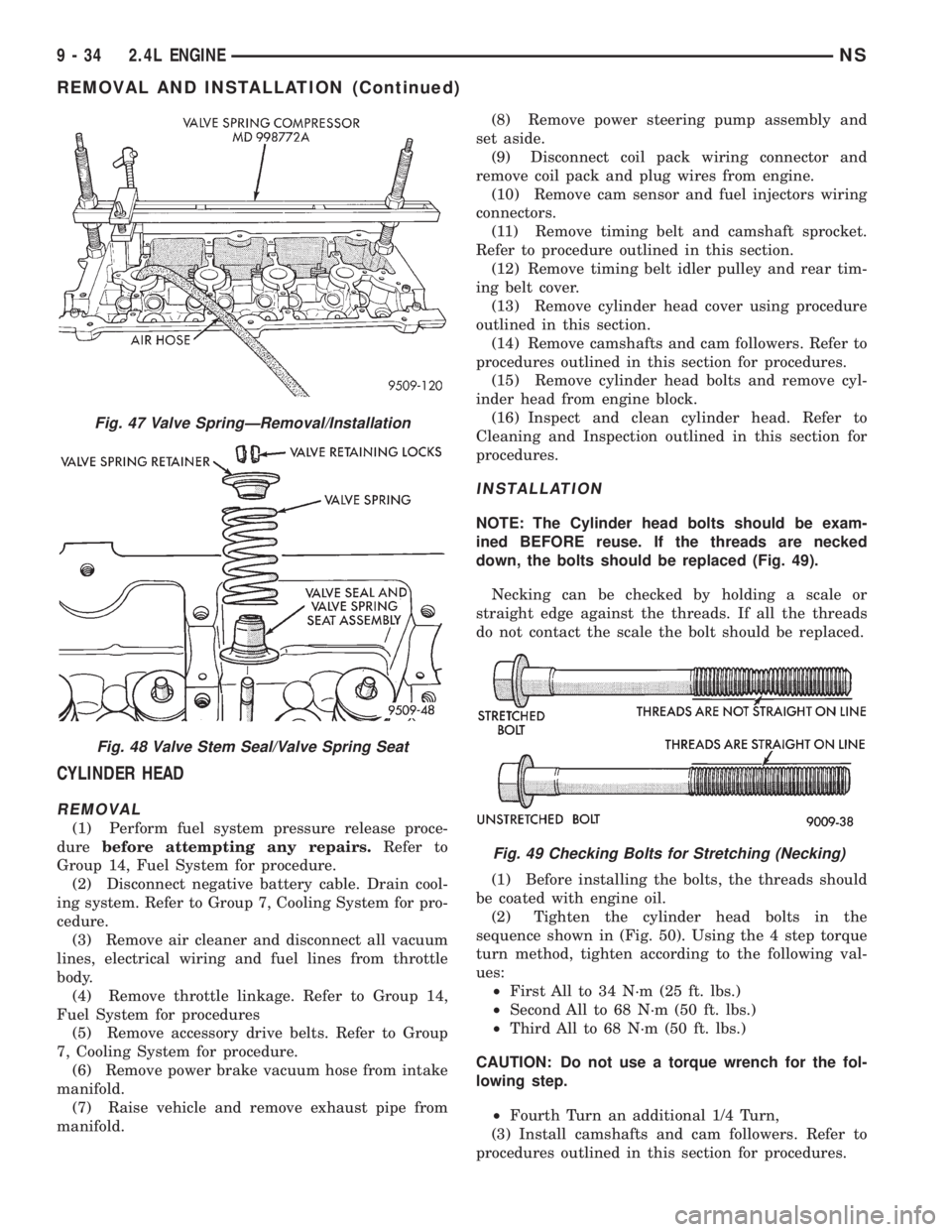

VALVE SPRINGS AND VALVE SEALS IN VEHICLE

REMOVAL

(1) Remove camshafts as previously outlined in

this section.

(2) Rotate crankshaft until piston is at TDC on

compression.

(3) With air hose attached to adapter tool

installed in spark plug hole, apply 90-120 psi air

pressure.

(4) Using Special Tool MD-998772-A with adapter

6779 (Fig. 47) compress valve springs and remove

valve locks.

(5) Remove valve spring.

(6) Remove valve stem seal by a using valve stem

seal tool.

INSTALLATION

(1) Install valve seal/valve spring seat assembly

(Fig. 48). Push the assembly down to seat it onto the

valve guide.

(2) Install valve spring and retainer, use Special

Tool MD-998772-A with adapter 6779 to compress

valve springs only enough to install locks (Fig. 47).

Correct alignment of tool is necessary to avoid nick-

ing valve stems.

(3) Remove air hose and install spark plugs.

(4) Install camshafts as previously outlined in this

section.

(5) Install cylinder head cover as previously out-

lined in this section.

Fig. 46 Chain Tension Adjustment

NS2.4L ENGINE 9 - 33

REMOVAL AND INSTALLATION (Continued)

Page 1084 of 1938

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release proce-

durebefore attempting any repairs.Refer to

Group 14, Fuel System for procedure.

(2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Group 7, Cooling System for pro-

cedure.

(3) Remove air cleaner and disconnect all vacuum

lines, electrical wiring and fuel lines from throttle

body.

(4) Remove throttle linkage. Refer to Group 14,

Fuel System for procedures

(5) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(6) Remove power brake vacuum hose from intake

manifold.

(7) Raise vehicle and remove exhaust pipe from

manifold.(8) Remove power steering pump assembly and

set aside.

(9) Disconnect coil pack wiring connector and

remove coil pack and plug wires from engine.

(10) Remove cam sensor and fuel injectors wiring

connectors.

(11) Remove timing belt and camshaft sprocket.

Refer to procedure outlined in this section.

(12) Remove timing belt idler pulley and rear tim-

ing belt cover.

(13) Remove cylinder head cover using procedure

outlined in this section.

(14) Remove camshafts and cam followers. Refer to

procedures outlined in this section for procedures.

(15) Remove cylinder head bolts and remove cyl-

inder head from engine block.

(16) Inspect and clean cylinder head. Refer to

Cleaning and Inspection outlined in this section for

procedures.

INSTALLATION

NOTE: The Cylinder head bolts should be exam-

ined BEFORE reuse. If the threads are necked

down, the bolts should be replaced (Fig. 49).

Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt should be replaced.

(1) Before installing the bolts, the threads should

be coated with engine oil.

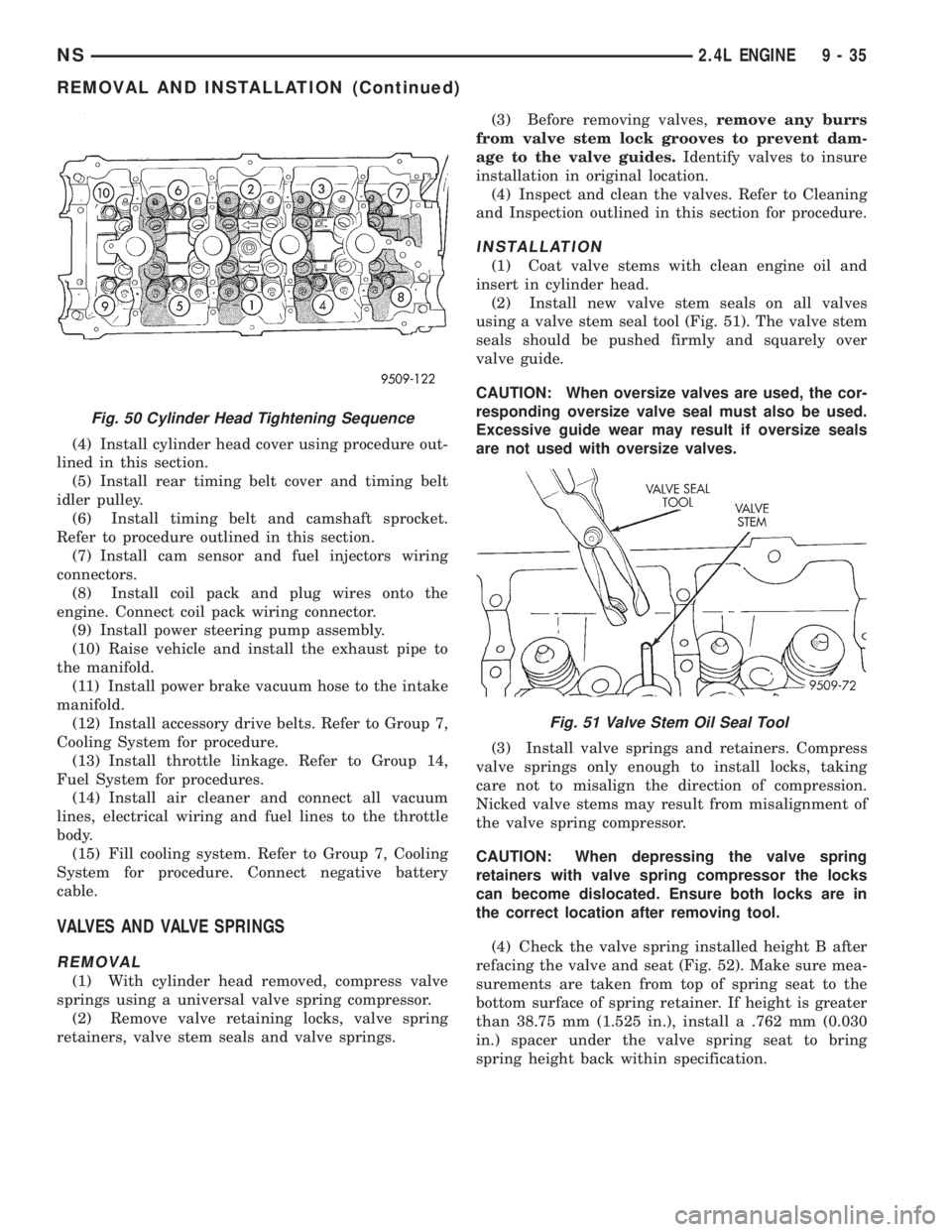

(2) Tighten the cylinder head bolts in the

sequence shown in (Fig. 50). Using the 4 step torque

turn method, tighten according to the following val-

ues:

²First All to 34 N´m (25 ft. lbs.)

²Second All to 68 N´m (50 ft. lbs.)

²Third All to 68 N´m (50 ft. lbs.)

CAUTION: Do not use a torque wrench for the fol-

lowing step.

²Fourth Turn an additional 1/4 Turn,

(3) Install camshafts and cam followers. Refer to

procedures outlined in this section for procedures.

Fig. 47 Valve SpringÐRemoval/Installation

Fig. 48 Valve Stem Seal/Valve Spring Seat

Fig. 49 Checking Bolts for Stretching (Necking)

9 - 34 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1085 of 1938

(4) Install cylinder head cover using procedure out-

lined in this section.

(5) Install rear timing belt cover and timing belt

idler pulley.

(6) Install timing belt and camshaft sprocket.

Refer to procedure outlined in this section.

(7) Install cam sensor and fuel injectors wiring

connectors.

(8) Install coil pack and plug wires onto the

engine. Connect coil pack wiring connector.

(9) Install power steering pump assembly.

(10) Raise vehicle and install the exhaust pipe to

the manifold.

(11) Install power brake vacuum hose to the intake

manifold.

(12) Install accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(13) Install throttle linkage. Refer to Group 14,

Fuel System for procedures.

(14) Install air cleaner and connect all vacuum

lines, electrical wiring and fuel lines to the throttle

body.

(15) Fill cooling system. Refer to Group 7, Cooling

System for procedure. Connect negative battery

cable.

VALVES AND VALVE SPRINGS

REMOVAL

(1) With cylinder head removed, compress valve

springs using a universal valve spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

(4) Inspect and clean the valves. Refer to Cleaning

and Inspection outlined in this section for procedure.

INSTALLATION

(1) Coat valve stems with clean engine oil and

insert in cylinder head.

(2) Install new valve stem seals on all valves

using a valve stem seal tool (Fig. 51). The valve stem

seals should be pushed firmly and squarely over

valve guide.

CAUTION: When oversize valves are used, the cor-

responding oversize valve seal must also be used.

Excessive guide wear may result if oversize seals

are not used with oversize valves.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Ensure both locks are in

the correct location after removing tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 52). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 38.75 mm (1.525 in.), install a .762 mm (0.030

in.) spacer under the valve spring seat to bring

spring height back within specification.

Fig. 50 Cylinder Head Tightening Sequence

Fig. 51 Valve Stem Oil Seal Tool

NS2.4L ENGINE 9 - 35

REMOVAL AND INSTALLATION (Continued)

Page 1088 of 1938

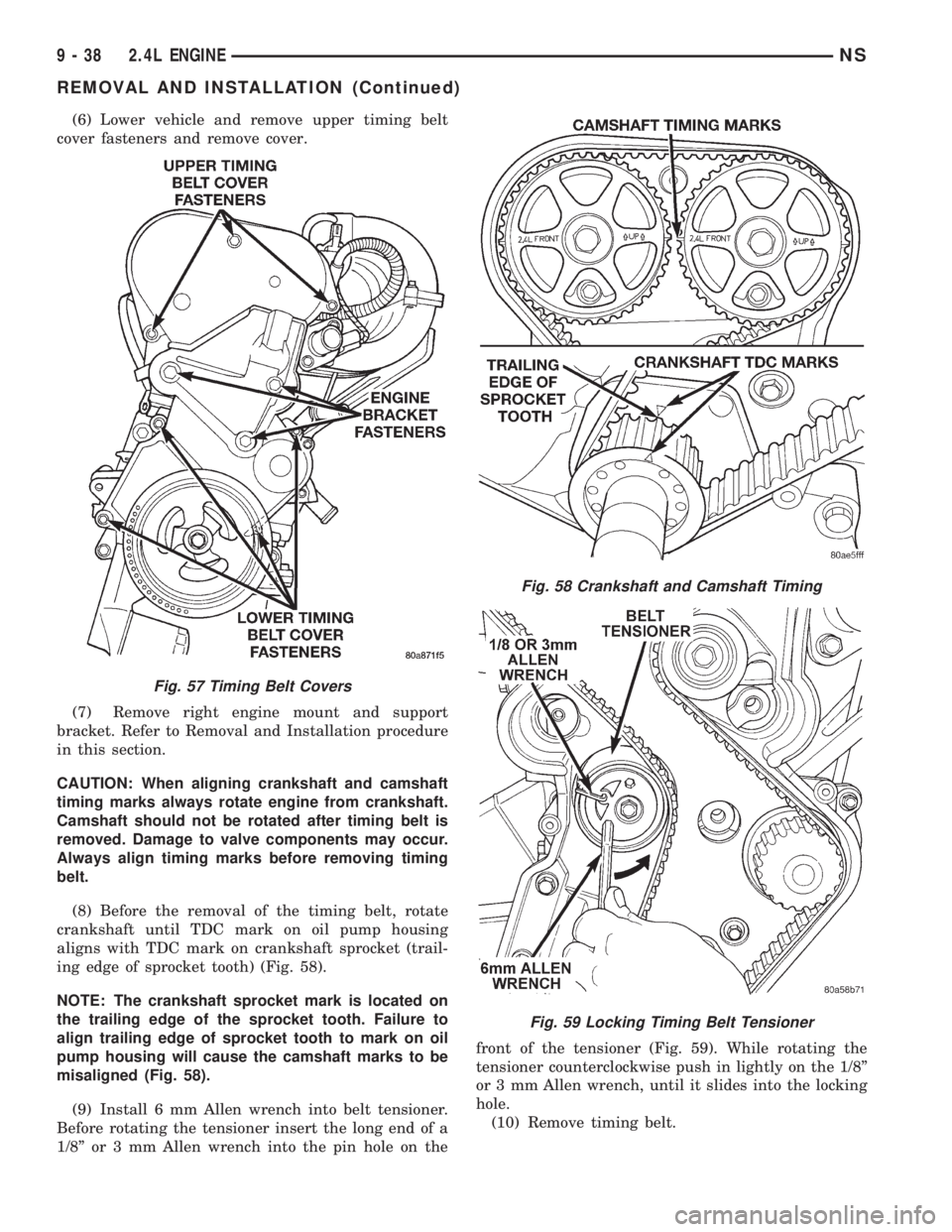

(6) Lower vehicle and remove upper timing belt

cover fasteners and remove cover.

(7) Remove right engine mount and support

bracket. Refer to Removal and Installation procedure

in this section.

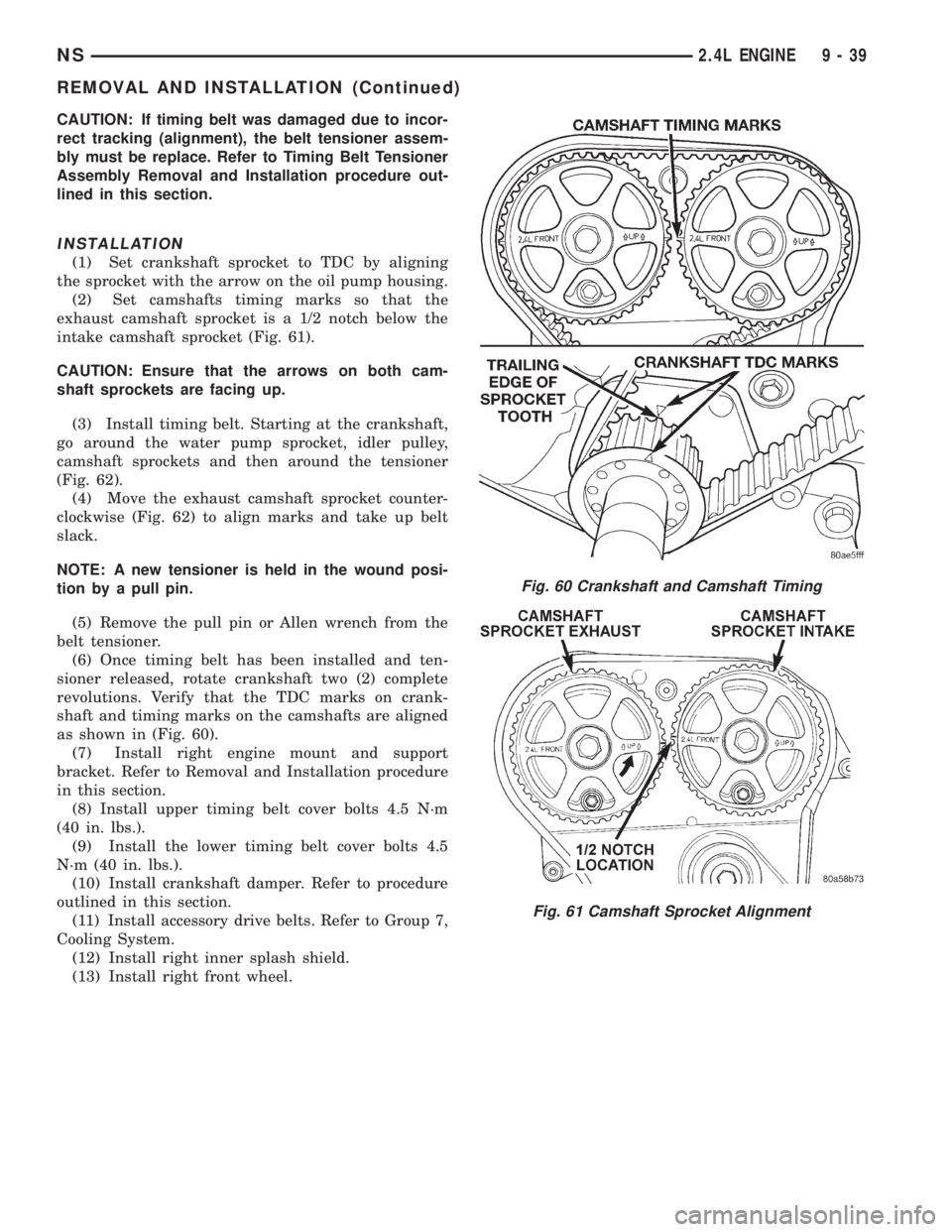

CAUTION: When aligning crankshaft and camshaft

timing marks always rotate engine from crankshaft.

Camshaft should not be rotated after timing belt is

removed. Damage to valve components may occur.

Always align timing marks before removing timing

belt.

(8) Before the removal of the timing belt, rotate

crankshaft until TDC mark on oil pump housing

aligns with TDC mark on crankshaft sprocket (trail-

ing edge of sprocket tooth) (Fig. 58).

NOTE: The crankshaft sprocket mark is located on

the trailing edge of the sprocket tooth. Failure to

align trailing edge of sprocket tooth to mark on oil

pump housing will cause the camshaft marks to be

misaligned (Fig. 58).

(9) Install 6 mm Allen wrench into belt tensioner.

Before rotating the tensioner insert the long end of a

1/8º or 3 mm Allen wrench into the pin hole on thefront of the tensioner (Fig. 59). While rotating the

tensioner counterclockwise push in lightly on the 1/8º

or 3 mm Allen wrench, until it slides into the locking

hole.

(10) Remove timing belt.

Fig. 57 Timing Belt Covers

Fig. 58 Crankshaft and Camshaft Timing

Fig. 59 Locking Timing Belt Tensioner

9 - 38 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1089 of 1938

CAUTION: If timing belt was damaged due to incor-

rect tracking (alignment), the belt tensioner assem-

bly must be replace. Refer to Timing Belt Tensioner

Assembly Removal and Installation procedure out-

lined in this section.

INSTALLATION

(1) Set crankshaft sprocket to TDC by aligning

the sprocket with the arrow on the oil pump housing.

(2) Set camshafts timing marks so that the

exhaust camshaft sprocket is a 1/2 notch below the

intake camshaft sprocket (Fig. 61).

CAUTION: Ensure that the arrows on both cam-

shaft sprockets are facing up.

(3) Install timing belt. Starting at the crankshaft,

go around the water pump sprocket, idler pulley,

camshaft sprockets and then around the tensioner

(Fig. 62).

(4) Move the exhaust camshaft sprocket counter-

clockwise (Fig. 62) to align marks and take up belt

slack.

NOTE: A new tensioner is held in the wound posi-

tion by a pull pin.

(5) Remove the pull pin or Allen wrench from the

belt tensioner.

(6) Once timing belt has been installed and ten-

sioner released, rotate crankshaft two (2) complete

revolutions. Verify that the TDC marks on crank-

shaft and timing marks on the camshafts are aligned

as shown in (Fig. 60).

(7) Install right engine mount and support

bracket. Refer to Removal and Installation procedure

in this section.

(8) Install upper timing belt cover bolts 4.5 N´m

(40 in. lbs.).

(9) Install the lower timing belt cover bolts 4.5

N´m (40 in. lbs.).

(10) Install crankshaft damper. Refer to procedure

outlined in this section.

(11) Install accessory drive belts. Refer to Group 7,

Cooling System.

(12) Install right inner splash shield.

(13) Install right front wheel.

Fig. 60 Crankshaft and Camshaft Timing

Fig. 61 Camshaft Sprocket Alignment

NS2.4L ENGINE 9 - 39

REMOVAL AND INSTALLATION (Continued)

Page 1091 of 1938

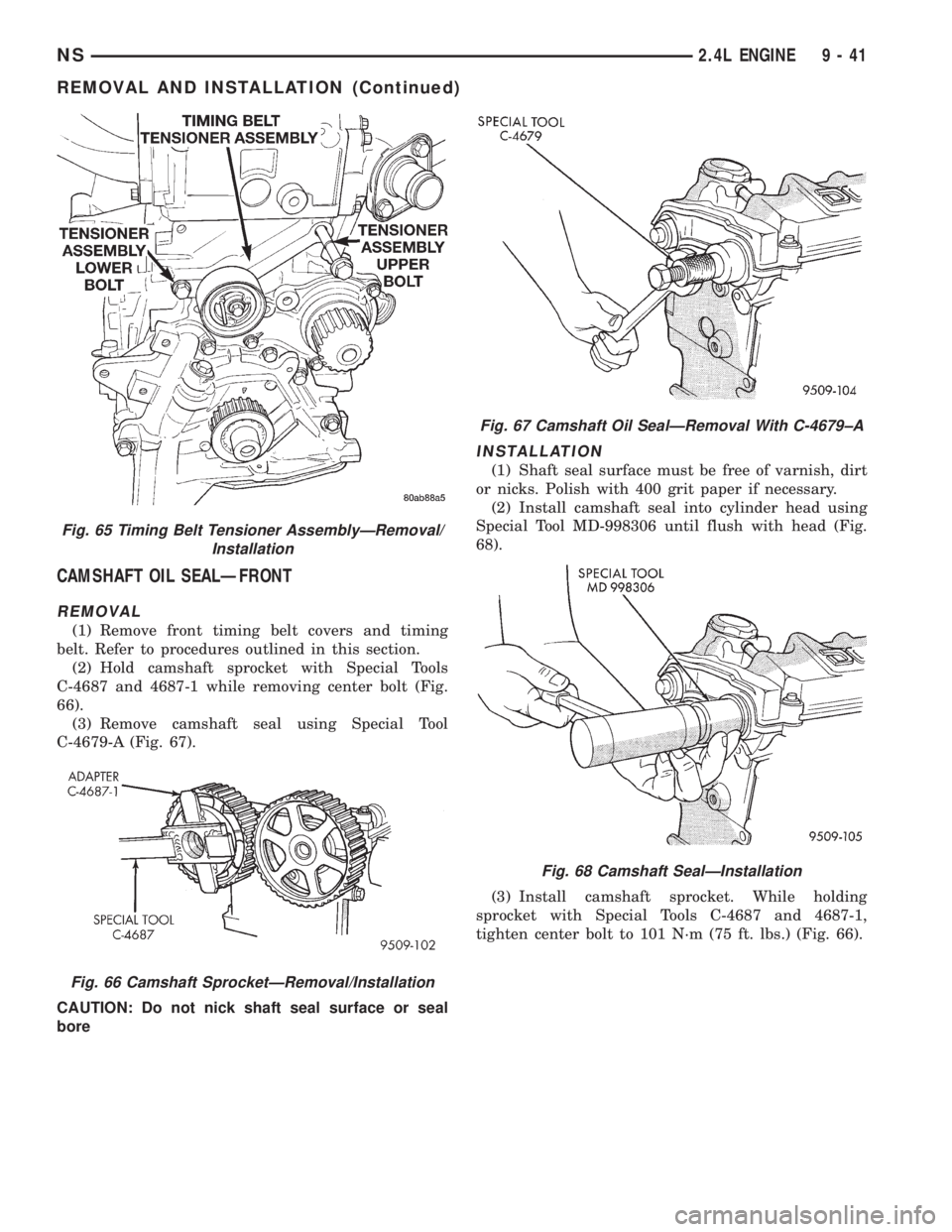

CAMSHAFT OIL SEALÐFRONT

REMOVAL

(1) Remove front timing belt covers and timing

belt. Refer to procedures outlined in this section.

(2) Hold camshaft sprocket with Special Tools

C-4687 and 4687-1 while removing center bolt (Fig.

66).

(3) Remove camshaft seal using Special Tool

C-4679-A (Fig. 67).

CAUTION: Do not nick shaft seal surface or seal

bore

INSTALLATION

(1) Shaft seal surface must be free of varnish, dirt

or nicks. Polish with 400 grit paper if necessary.

(2) Install camshaft seal into cylinder head using

Special Tool MD-998306 until flush with head (Fig.

68).

(3) Install camshaft sprocket. While holding

sprocket with Special Tools C-4687 and 4687-1,

tighten center bolt to 101 N´m (75 ft. lbs.) (Fig. 66).

Fig. 65 Timing Belt Tensioner AssemblyÐRemoval/

Installation

Fig. 66 Camshaft SprocketÐRemoval/Installation

Fig. 67 Camshaft Oil SealÐRemoval With C-4679±A

Fig. 68 Camshaft SealÐInstallation

NS2.4L ENGINE 9 - 41

REMOVAL AND INSTALLATION (Continued)