CHRYSLER VOYAGER 1996 Service Manual

Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1851 of 1938

CAUTION: Do not damage the insulation barrier

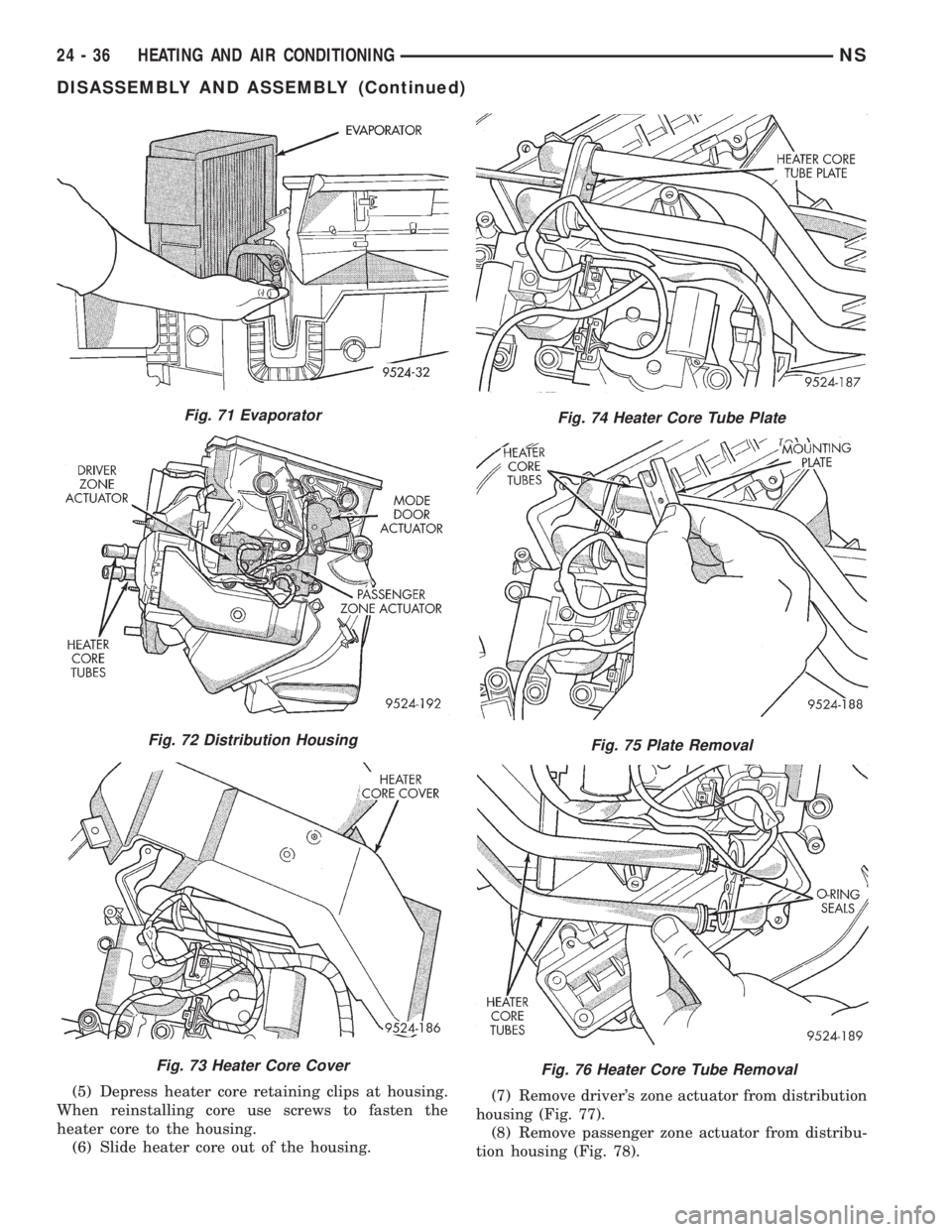

surrounding the evaporator.(9) Carefully pull up on evaporator and remove

from housing (Fig. 71).

(10) If replacing evaporator, drain and measure

amount of oil from old evaporator and add new oil of

the same amount (ND8 PAG) to the new evaporator

before installing. Use SP 10 PAG oil for 2.5L diesel

and 2.0L gasoline engine vehicles.

ASSEMBLYÐEVAPORATOR HOUSING

(1) For reassembly of the evaporator housing,

reverse the above procedures.

(2) Perform the HVAC control Calibration Diagnos-

tic and Cooldown test.

DISASSEMBLYÐDISTRIBUTION HOUSING

(1) Place distribution housing on workbench (Fig.

72).

(2) Remove heater core cover (Fig. 73).

(3) Remove heater core tube plate (Fig. 74) and

(Fig. 75).

(4) Remove heater core tubes (Fig. 76).

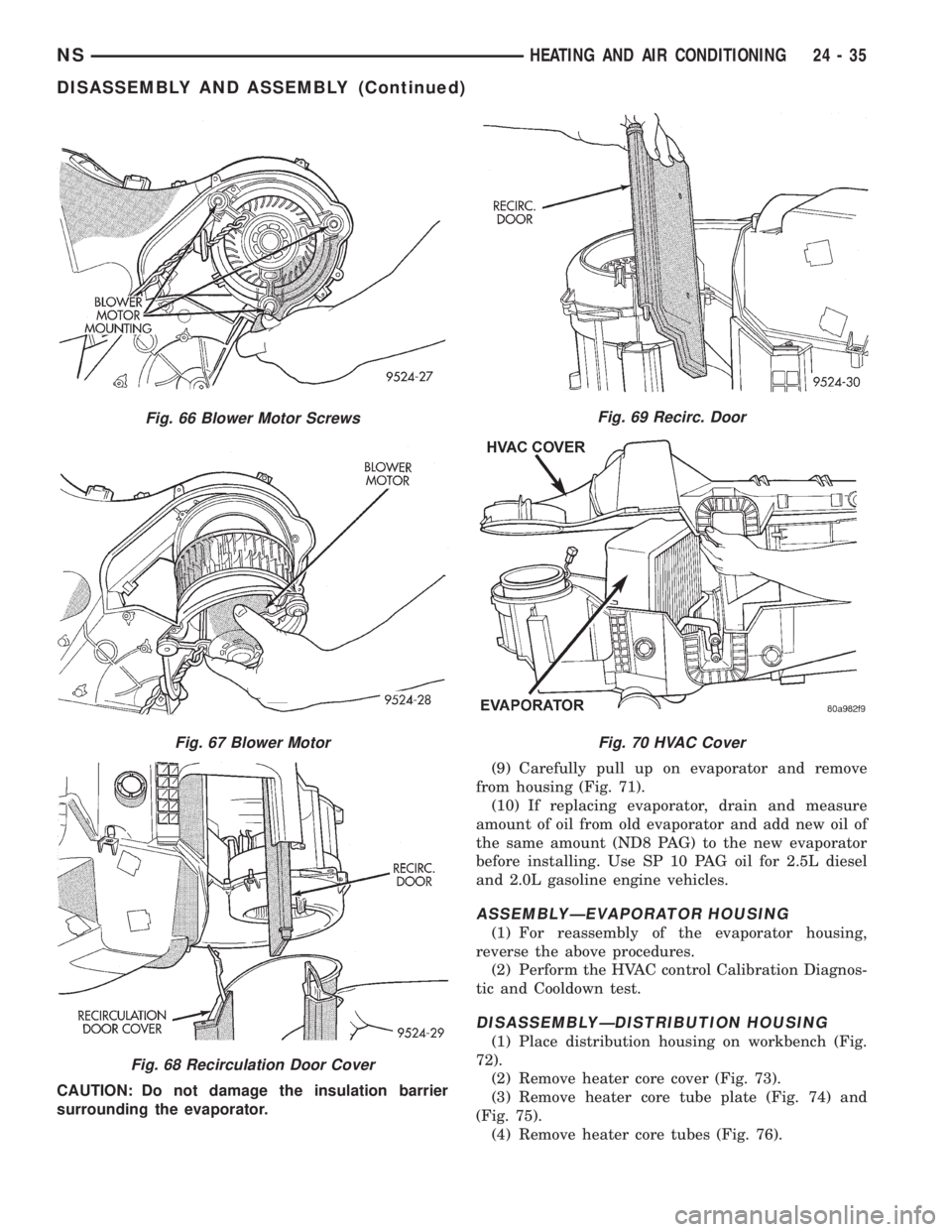

Fig. 66 Blower Motor Screws

Fig. 67 Blower Motor

Fig. 68 Recirculation Door Cover

Fig. 69 Recirc. Door

Fig. 70 HVAC Cover

NSHEATING AND AIR CONDITIONING 24 - 35

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1852 of 1938

(5) Depress heater core retaining clips at housing.

When reinstalling core use screws to fasten the

heater core to the housing.

(6) Slide heater core out of the housing.(7) Remove driver's zone actuator from distribution

housing (Fig. 77).

(8) Remove passenger zone actuator from distribu-

tion housing (Fig. 78).

Fig. 71 Evaporator

Fig. 72 Distribution Housing

Fig. 73 Heater Core Cover

Fig. 74 Heater Core Tube Plate

Fig. 75 Plate Removal

Fig. 76 Heater Core Tube Removal

24 - 36 HEATING AND AIR CONDITIONINGNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1853 of 1938

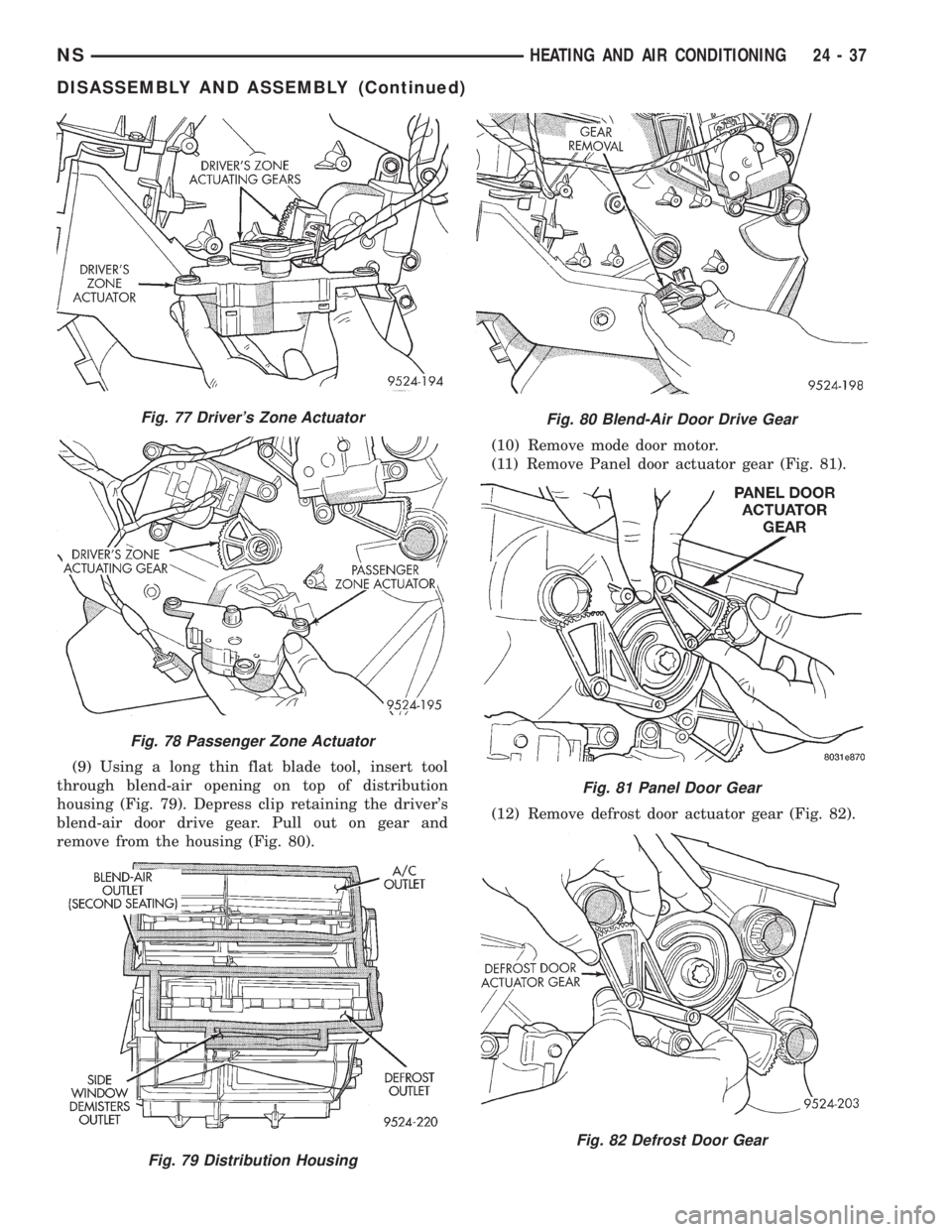

(9) Using a long thin flat blade tool, insert tool

through blend-air opening on top of distribution

housing (Fig. 79). Depress clip retaining the driver's

blend-air door drive gear. Pull out on gear and

remove from the housing (Fig. 80).(10) Remove mode door motor.

(11) Remove Panel door actuator gear (Fig. 81).

(12) Remove defrost door actuator gear (Fig. 82).

Fig. 77 Driver's Zone Actuator

Fig. 78 Passenger Zone Actuator

Fig. 79 Distribution Housing

Fig. 80 Blend-Air Door Drive Gear

Fig. 81 Panel Door Gear

Fig. 82 Defrost Door Gear

NSHEATING AND AIR CONDITIONING 24 - 37

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1854 of 1938

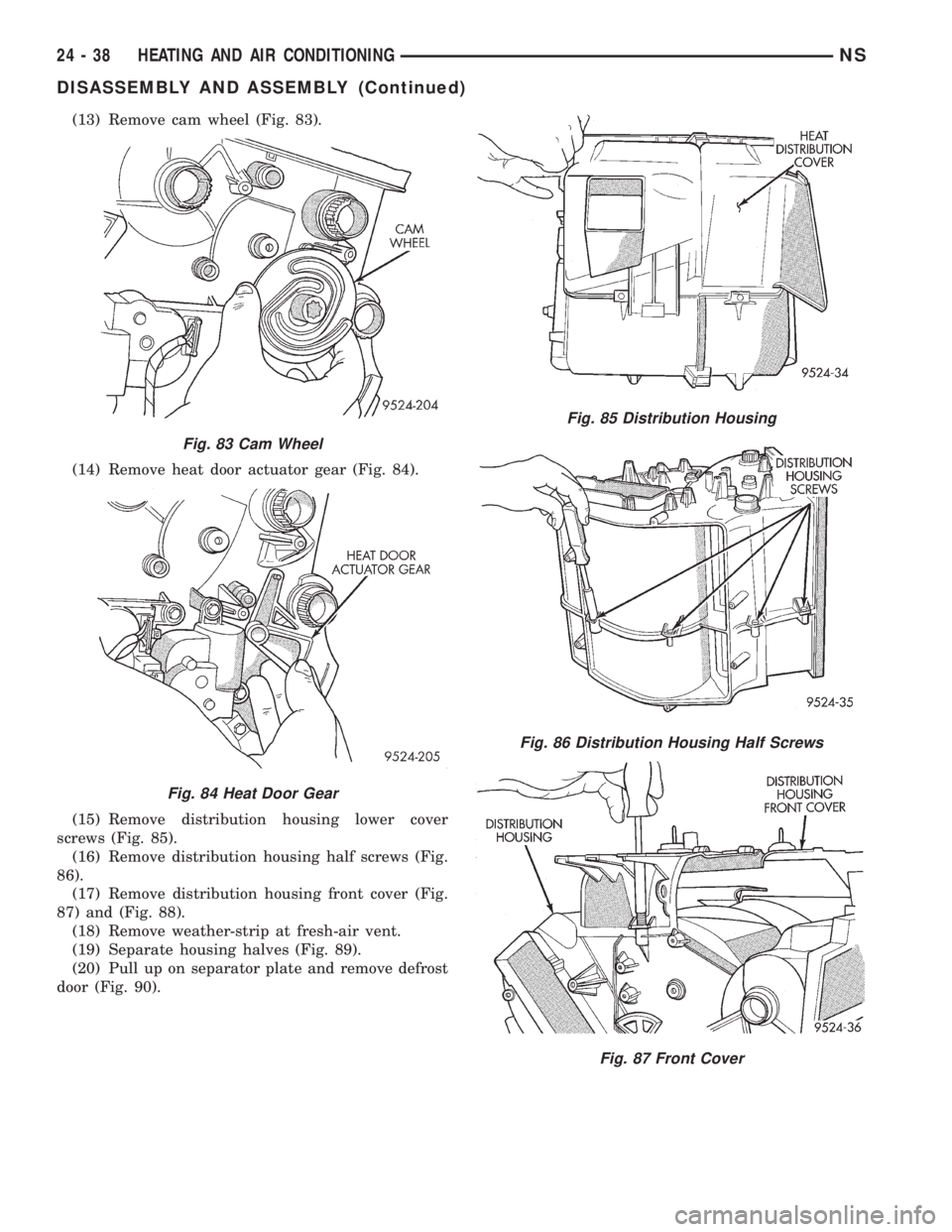

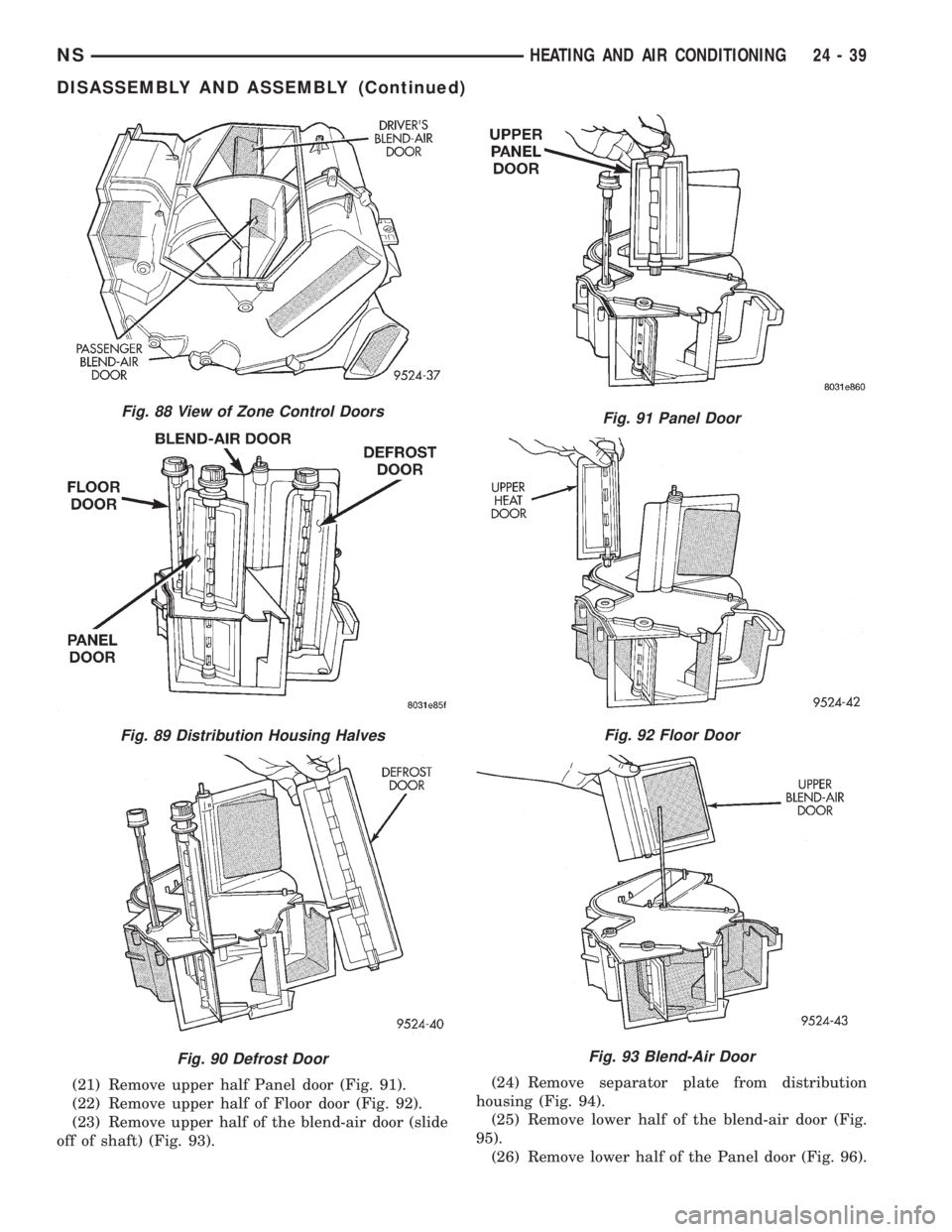

(13) Remove cam wheel (Fig. 83).

(14) Remove heat door actuator gear (Fig. 84).

(15) Remove distribution housing lower cover

screws (Fig. 85).

(16) Remove distribution housing half screws (Fig.

86).

(17) Remove distribution housing front cover (Fig.

87) and (Fig. 88).

(18) Remove weather-strip at fresh-air vent.

(19) Separate housing halves (Fig. 89).

(20) Pull up on separator plate and remove defrost

door (Fig. 90).

Fig. 83 Cam Wheel

Fig. 84 Heat Door Gear

Fig. 85 Distribution Housing

Fig. 86 Distribution Housing Half Screws

Fig. 87 Front Cover

24 - 38 HEATING AND AIR CONDITIONINGNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1855 of 1938

(21) Remove upper half Panel door (Fig. 91).

(22) Remove upper half of Floor door (Fig. 92).

(23) Remove upper half of the blend-air door (slide

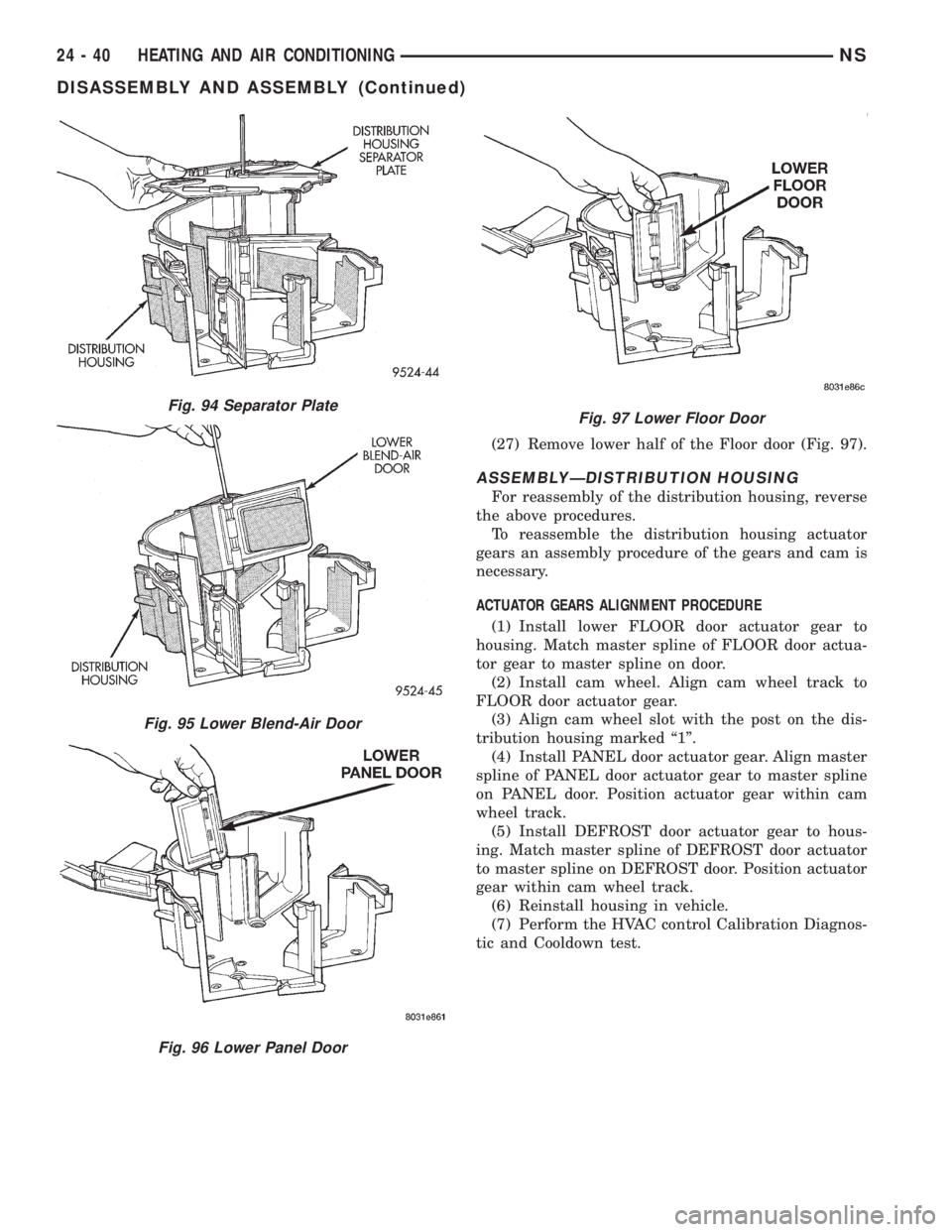

off of shaft) (Fig. 93).(24) Remove separator plate from distribution

housing (Fig. 94).

(25) Remove lower half of the blend-air door (Fig.

95).

(26) Remove lower half of the Panel door (Fig. 96).

Fig. 88 View of Zone Control Doors

Fig. 89 Distribution Housing Halves

Fig. 90 Defrost Door

Fig. 91 Panel Door

Fig. 92 Floor Door

Fig. 93 Blend-Air Door

NSHEATING AND AIR CONDITIONING 24 - 39

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1856 of 1938

(27) Remove lower half of the Floor door (Fig. 97).

ASSEMBLYÐDISTRIBUTION HOUSING

For reassembly of the distribution housing, reverse

the above procedures.

To reassemble the distribution housing actuator

gears an assembly procedure of the gears and cam is

necessary.

ACTUATOR GEARS ALIGNMENT PROCEDURE

(1) Install lower FLOOR door actuator gear to

housing. Match master spline of FLOOR door actua-

tor gear to master spline on door.

(2) Install cam wheel. Align cam wheel track to

FLOOR door actuator gear.

(3) Align cam wheel slot with the post on the dis-

tribution housing marked ª1º.

(4) Install PANEL door actuator gear. Align master

spline of PANEL door actuator gear to master spline

on PANEL door. Position actuator gear within cam

wheel track.

(5) Install DEFROST door actuator gear to hous-

ing. Match master spline of DEFROST door actuator

to master spline on DEFROST door. Position actuator

gear within cam wheel track.

(6) Reinstall housing in vehicle.

(7) Perform the HVAC control Calibration Diagnos-

tic and Cooldown test.

Fig. 97 Lower Floor DoorFig. 94 Separator Plate

Fig. 95 Lower Blend-Air Door

Fig. 96 Lower Panel Door

24 - 40 HEATING AND AIR CONDITIONINGNS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1857 of 1938

REAR HEATING AND AIR CONDITIONING SYSTEM

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 41

DESCRIPTION AND OPERATION

REAR BLOWER RESISTOR BLOCK.......... 41

REAR HEATER AND A/C LINES............. 41

SYSTEM OPERATION.................... 41

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES............... 43

REMOVAL AND INSTALLATION

AIR DISTRIBUTION DUCT-A/C.............. 43

AIR DISTRIBUTION DUCT-HEATER.......... 43

EVAPORATOR AND EXPANSION VALVE...... 44MODE DOOR ACTUATOR................. 49

MODE DOOR........................... 49

REAR AIR CONDITIONING LINES........... 45

REAR HEATER A/C AIR OUTLETS........... 45

REAR HEATER A/C BLOWER MOTOR........ 46

REAR HEATER A/C UNIT.................. 46

REAR HEATER CORE.................... 48

REAR HEATER LINES.................... 49

REAR HEATER-A/C AUXILIARY CONDENSER . . 45

REAR HEATER-A/C CONTROL ILLUMINATION

BULB............................... 46

GENERAL INFORMATION

INTRODUCTION

For proper operation of the rear heating A/C sys-

tem, refer to Owner's Manual supplied with the vehi-

cle.

DESCRIPTION AND OPERATION

REAR BLOWER RESISTOR BLOCK

The rear blower motor resistor is not serviceable

separately. The resistor is integral to the blower

motor. If resistor is faulty, it is necessary to replace

the complete blower motor.

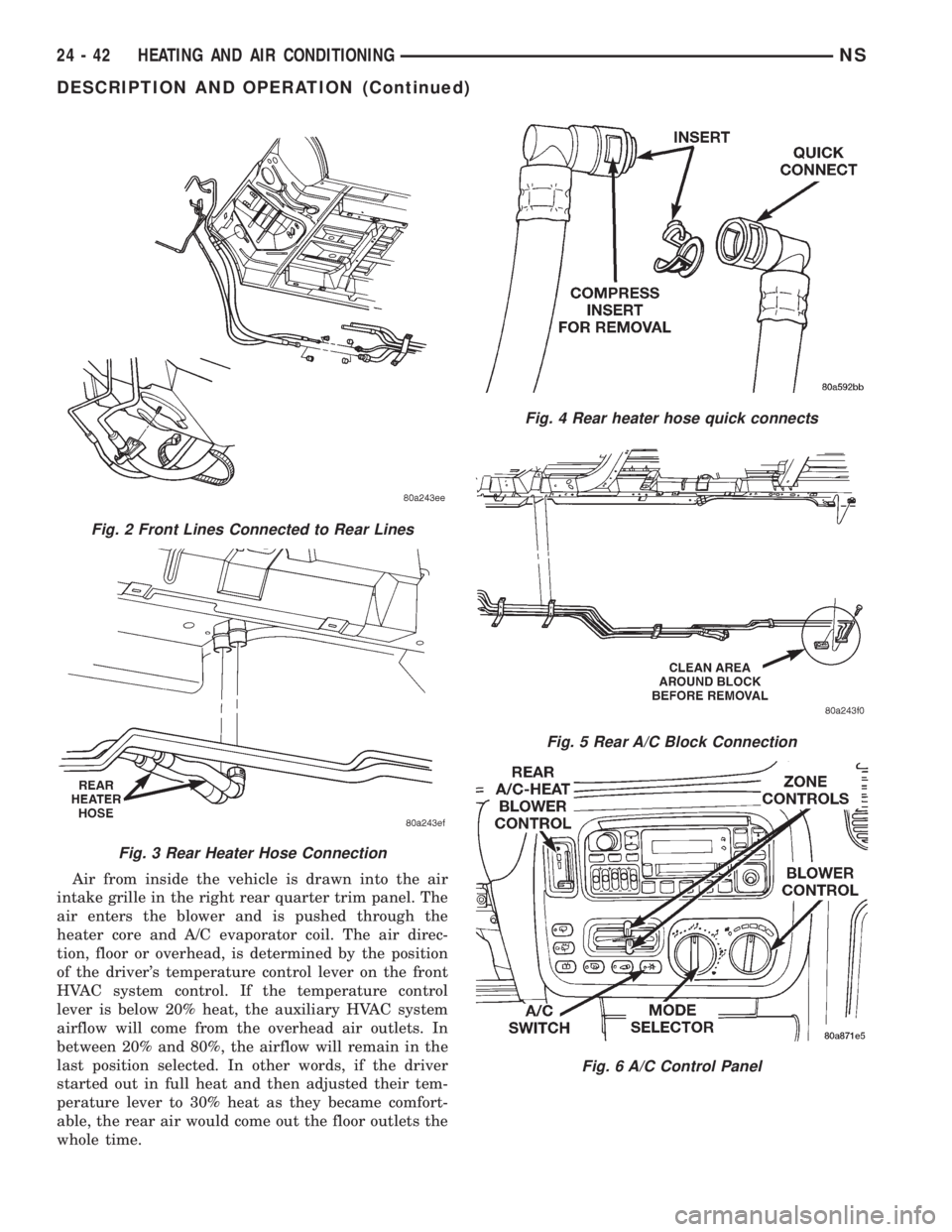

REAR HEATER AND A/C LINES

The rear heater and A/C lines are all serviced as

individual pieces. When disconnecting any line orblock ensure that the area around it is clean of any

contaminations that can get in to the system (Fig. 1),

(Fig. 2), (Fig. 4), (Fig. 3) and (Fig. 5).

SYSTEM OPERATION

The auxiliary rear heating-air/conditioning unit is

located in the right rear quarter panel. The rear

heater A/C control operates in conjunction with the

front heater A/C control. A four position two speed

blower (override) switch is located on the front

Heater A/C control panel (Fig. 6). The operator can

use the rear heater A/C blower switch to operate the

blower, regardless of the rear control setting. In the

OFF position, the rear control will not function. In

the ON (RR) position, the rear control will function

normally providing three speeds (Fig. 7). The mode

setting is controlled by the front A/C control panel.

Fig. 1 Rear Heater and A/C Lines

NSHEATING AND AIR CONDITIONING 24 - 41

Page 1858 of 1938

Air from inside the vehicle is drawn into the air

intake grille in the right rear quarter trim panel. The

air enters the blower and is pushed through the

heater core and A/C evaporator coil. The air direc-

tion, floor or overhead, is determined by the position

of the driver's temperature control lever on the front

HVAC system control. If the temperature control

lever is below 20% heat, the auxiliary HVAC system

airflow will come from the overhead air outlets. In

between 20% and 80%, the airflow will remain in the

last position selected. In other words, if the driver

started out in full heat and then adjusted their tem-

perature lever to 30% heat as they became comfort-

able, the rear air would come out the floor outlets the

whole time.

Fig. 2 Front Lines Connected to Rear Lines

Fig. 3 Rear Heater Hose Connection

Fig. 4 Rear heater hose quick connects

Fig. 5 Rear A/C Block Connection

Fig. 6 A/C Control Panel

24 - 42 HEATING AND AIR CONDITIONINGNS

DESCRIPTION AND OPERATION (Continued)

Page 1859 of 1938

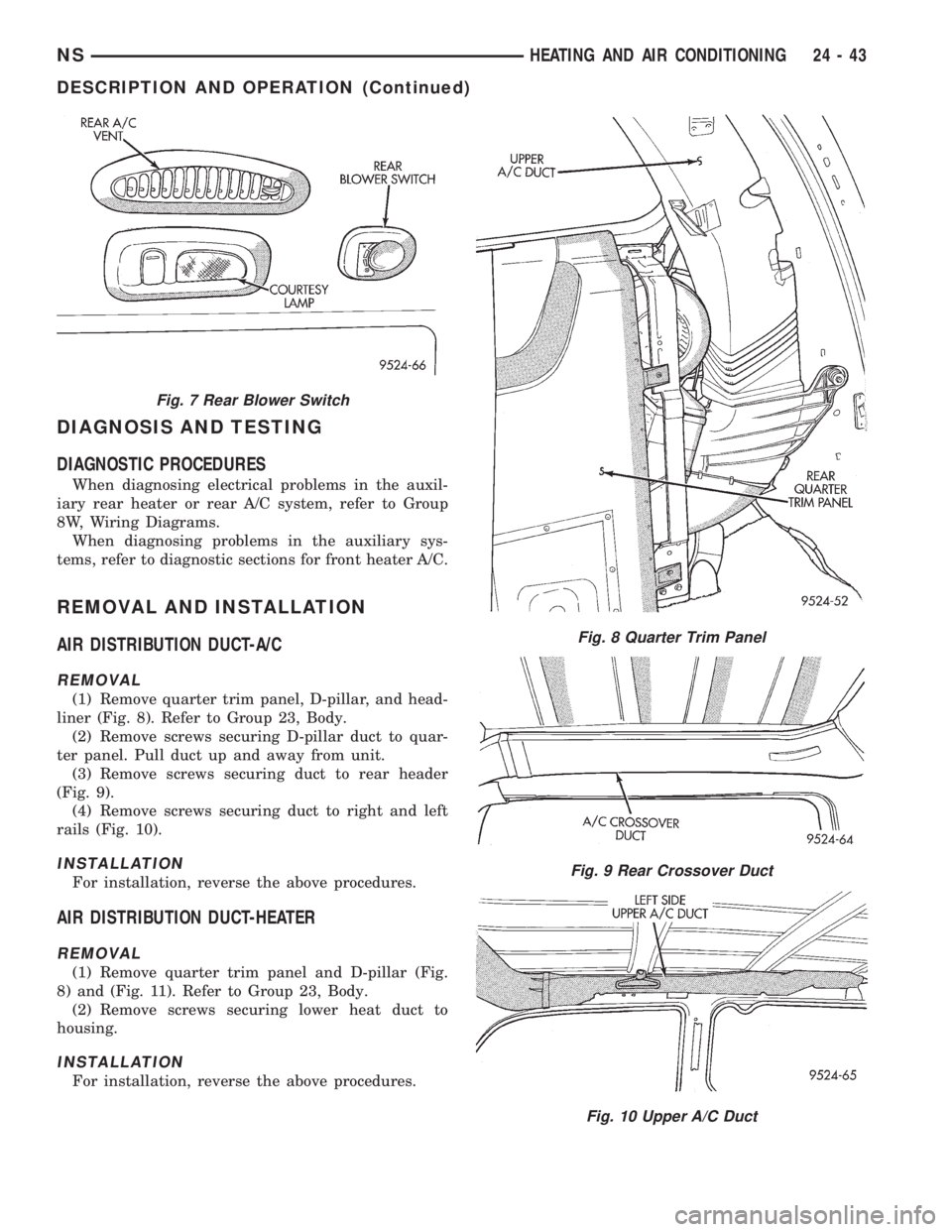

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES

When diagnosing electrical problems in the auxil-

iary rear heater or rear A/C system, refer to Group

8W, Wiring Diagrams.

When diagnosing problems in the auxiliary sys-

tems, refer to diagnostic sections for front heater A/C.

REMOVAL AND INSTALLATION

AIR DISTRIBUTION DUCT-A/C

REMOVAL

(1) Remove quarter trim panel, D-pillar, and head-

liner (Fig. 8). Refer to Group 23, Body.

(2) Remove screws securing D-pillar duct to quar-

ter panel. Pull duct up and away from unit.

(3) Remove screws securing duct to rear header

(Fig. 9).

(4) Remove screws securing duct to right and left

rails (Fig. 10).

INSTALLATION

For installation, reverse the above procedures.

AIR DISTRIBUTION DUCT-HEATER

REMOVAL

(1) Remove quarter trim panel and D-pillar (Fig.

8) and (Fig. 11). Refer to Group 23, Body.

(2) Remove screws securing lower heat duct to

housing.

INSTALLATION

For installation, reverse the above procedures.

Fig. 7 Rear Blower Switch

Fig. 8 Quarter Trim Panel

Fig. 9 Rear Crossover Duct

Fig. 10 Upper A/C Duct

NSHEATING AND AIR CONDITIONING 24 - 43

DESCRIPTION AND OPERATION (Continued)

Page 1860 of 1938

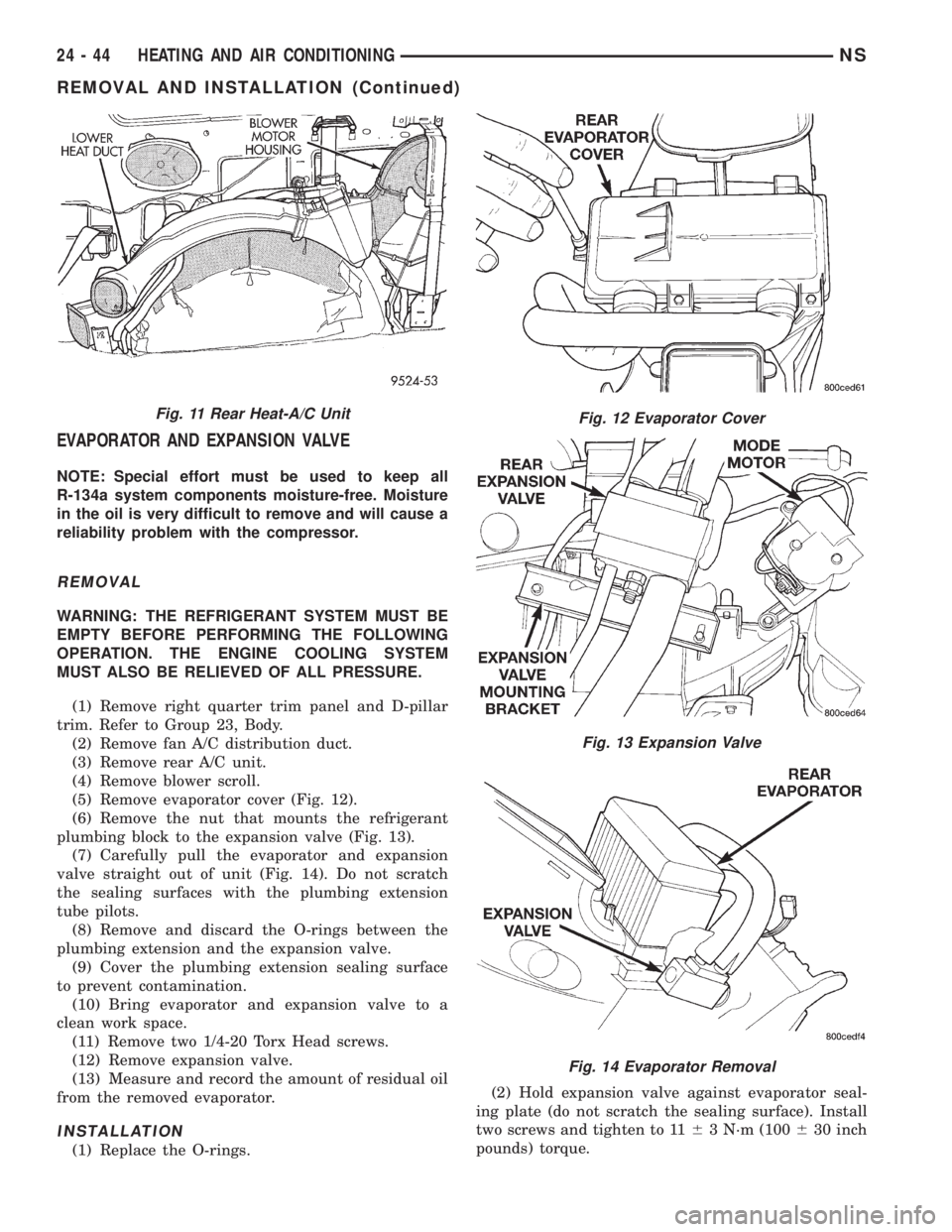

EVAPORATOR AND EXPANSION VALVE

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

REMOVAL

WARNING: THE REFRIGERANT SYSTEM MUST BE

EMPTY BEFORE PERFORMING THE FOLLOWING

OPERATION. THE ENGINE COOLING SYSTEM

MUST ALSO BE RELIEVED OF ALL PRESSURE.

(1) Remove right quarter trim panel and D-pillar

trim. Refer to Group 23, Body.

(2) Remove fan A/C distribution duct.

(3) Remove rear A/C unit.

(4) Remove blower scroll.

(5) Remove evaporator cover (Fig. 12).

(6) Remove the nut that mounts the refrigerant

plumbing block to the expansion valve (Fig. 13).

(7) Carefully pull the evaporator and expansion

valve straight out of unit (Fig. 14). Do not scratch

the sealing surfaces with the plumbing extension

tube pilots.

(8) Remove and discard the O-rings between the

plumbing extension and the expansion valve.

(9) Cover the plumbing extension sealing surface

to prevent contamination.

(10) Bring evaporator and expansion valve to a

clean work space.

(11) Remove two 1/4-20 Torx Head screws.

(12) Remove expansion valve.

(13) Measure and record the amount of residual oil

from the removed evaporator.

INSTALLATION

(1) Replace the O-rings.(2) Hold expansion valve against evaporator seal-

ing plate (do not scratch the sealing surface). Install

two screws and tighten to 1163 N´m (100630 inch

pounds) torque.

Fig. 11 Rear Heat-A/C UnitFig. 12 Evaporator Cover

Fig. 13 Expansion Valve

Fig. 14 Evaporator Removal

24 - 44 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)