engine CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 19 of 1938

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to.

Schedule ±A, lists scheduled maintenance to be

performed when the vehicle is used for general trans-

portation.

Schedule ±B, lists maintenance intervals for vehi-

cles that are operated under the conditions listed at

the beginning of the Maintenance Schedule section.

Use the schedule that best describes your driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on Schedule ± B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter on 2.4L engines.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect brake linings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Change automatic transmission fluid.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect tie rod ends and boot seals.

37,500 Miles (60 000 km) or at 30 months

²Change engine oil.

45,000 Miles (72 000 km) or at 36 months

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

²Flush and replace engine coolant at 36 months,

regardless of mileage.

NSLUBRICATION AND MAINTENANCE 0 - 3

Page 20 of 1938

52,500 Miles (84 000 km) or at 42 months

²Change engine oil.

²Flush and replace engine coolant if not done at

36 months.

60,000 Miles (96 000 km) or at 48 months

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Check PCV valve and replace, if necessary.

*

²Inspect serpentine drive belt, replace if neces-

sary.

²Inspect tie rod ends and boot seals.

67,500 Miles (108 000 km) or at 54 months

²Change engine oil.

²Inspect brake linings.

75,000 Miles (120 000 km) or at 60 months

²Change engine oil.

²Replace engine oil filter.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

82,500 Miles (132 000 km) or at 66 months

²Change engine oil.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

90,000 Miles (144 000 km) or at 72 months

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Check PCV valve and replace, if necessary.

Not required if previously changed. *

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Inspect tie rod ends and boot seals.

²Inspect brake linings.

97,500 Miles (156 000 km) or at 78 months

²Change engine oil.

100,000 Miles (160,000 km)

²Replace spark plugs on 3.3L and 3.8L

engines.

²Replace ignition cables on 3.3L and 3.8L

engines.

105,000 Miles (168 000 km) or at 84 months

²Change engine oil.

²Replace engine oil filter.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

112,500 Miles (180 000 km) or at 90 months

²Change engine oil.

²Inspect brake linings.

²Flush and replace engine coolant if it has been

30,000 miles (48 000 km) or 24 months since last

change.

120,000 Miles (192 000 km) or at 96 months

²Change engine oil.

²Replace engine oil filter.

²Replace automatic transmission fluid.

²Replace engine air cleaner element.

²Check and replace PCV valve, if necessary.

*

²Inspect serpentine drive belt. Not required if

replaced at 75,000, 90,000 or 105,000 miles.

²Inspect tie rod ends and boot seals.

* This maintenance is recommended by Chrysler to

the owner but is not required to maintain the war-

ranty on the PCV valve.

** If California vehicle, this maintenance is recom-

mended by Chrysler to the owner but is not required

to maintain the warranty of the timing belt.

SCHEDULE ± B

3,000 Miles (5 000 km)

²Change engine oil.

6,000 Miles (10 000 km)

²Change engine oil.

²Replace engine oil filter.

9,000 Miles (14 000 km)

²Change engine oil.

²Inspect brake linings.

12,000 Miles (19 000 km)

²Change engine oil.

²Replace engine oil filter.

15,000 Miles (24 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.

0 - 4 LUBRICATION AND MAINTENANCENS

GENERAL INFORMATION (Continued)

Page 21 of 1938

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD powertransfer fluid unit.

18,000 Miles (29 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

21,000 Miles (34 000 km)

²Change engine oil.

²Check AWD overrunning clutch and rear carrier

fluid.

24,000 Miles (38 000 km)

²Change engine oil.

²Replace engine oil filter.

27,000 Miles (43 000 km)

²Change engine oil.

²Inspect brake linings.

30,000 Miles (48 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect PCV valve. Replace as necessary. *

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

33,000 Miles (53 000 km)

²Change engine oil.

36,000 Miles (58 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

39,000 Miles (62 000 km)

²Change engine oil.

42,000 Miles (67 000 km)

²Change engine oil.

²Replace engine oil filter.

²Change AWD overrunning clutch and rear car-

rier fluid.

45,000 Miles (72 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Inspect brake linings.

²Change AWD power transfer unit fluid.

48,000 Miles (77 000 km)

²Change engine oil.

²Replace engine oil filter.

51,000 Miles (82 000 km)

²Change engine oil.

²Flush and replace engine coolant.

54,000 Miles (86 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

57,000 Miles (91 000 km)

²Change engine oil.

60,000 Miles (96 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect PCV valve, replace if necessary. *

²Inspect serpentine drive belt, replace if neces-

sary.

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

63,000 Miles (101 000 km)

²Change engine oil.

²Change AWD overrunning clutch and rear car-

rier fluid.

²Inspect brake linings.

66,000 Miles (106 000 km)

²Change engine oil.

²Replace engine oil filter.

69,000 Miles (110 000 km)

²Change engine oil.

72,000 Miles (115 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

75,000 Miles (120 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.

NSLUBRICATION AND MAINTENANCE 0 - 5

GENERAL INFORMATION (Continued)

Page 22 of 1938

²Replace spark plugs.

²Replace ignition cables.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Drain and refill automatic transaxle fluid and

replace filter. Adjust band, if so equipped. (See note)

²Change AWD power transfer unit fluid.

78,000 Miles (125 000 km)

²Change engine oil.

²Replace engine oil filter.

81,000 Miles (130 000 km)

²Change engine oil.

²Inspect brake linings.

²Flush and replace engine coolant.

84,000 Miles (134 000 km)

²Change engine oil.

²Replace engine oil filter.

²Change AWD overrunning clutch and rear car-

rier fluid.

87,000 Miles (139 000 km)

²Change engine oil.

90,000 Miles (144 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Check PCV valve and replace if necessary.

Not required if previously changed. *

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped. (See

note)

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

²Inspect brake linings.

93,000 Miles (149 000 km)

²Change engine oil.

96,000 Miles (154 000 km)

²Change engine oil.

²Replace engine oil filter.

99,000 Miles (158 000 km)

²Change engine oil.

²Inspect brake linings.

102,000 Miles (163 000 km)

²Change engine oil.

²Replace engine oil filter.

105,000 Miles (168 000 km)

²Change engine oil.

²Inspect air cleaner element. Replace as

necessary.

²Inspect serpentine drive belt, replace if neces-

sary. This maintenance is not required if belt was

previously replaced.

²Drain and refill automatic transmission fluid

and filter. Adjust bands, if so equipped. (See note)

²Change AWD power transfer unit fluid.

²Change AWD overrunning clutch and rear car-

rier fluid.

108,000 Miles (173 000 km)

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

111,000 Miles (178 000 km)

²Change engine oil.

²Flush and replace engine coolant.

114,000 Miles (182 000 km)

²Change engine oil.

²Replace engine oil filter.

117,000 Miles (187 000 km)

²Change engine oil.

²Inspect brake linings.

120,000 Miles (192 000 km)

²Change engine oil.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect PCV valve. Replace as necessary. *

²Inspect serpentine drive belt. Not required if

replaced at 75,000, 90,000 or 105,000 miles.

²Drain and refill automatic transmission fluid

and replace filter. Adjust bands, if so equipped.

²Change AWD power transfer unit fluid.

²Inspect tie rod ends and boot seals.

* This maintenance is recommended by Chrysler to

the owner but is not required to maintain the war-

ranty on the PCV valve.

** If California vehicle, this maintenance is recom-

mended by Chrysler to the owner but is not required

to maintain the warranty of the timing belt.

NOTE: Operating vehicle more than 50% in heavy

traffic during hot weather, above 90ÉF (32ÉC), using

vehicle for police, taxi, limousine type operation or

trailer towing require the more frequent transaxle

service noted in Schedule ± B. Perform these ser-

vices if vehicle is usually operated under these con-

ditions.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

0 - 6 LUBRICATION AND MAINTENANCENS

GENERAL INFORMATION (Continued)

Page 23 of 1938

JUMP STARTING, HOISTING AND TOWING

INDEX

page page

SERVICE PROCEDURES

HOISTING RECOMMENDATIONS............ 9JUMP STARTING PROCEDURE.............. 7

TOWING RECOMMENDATIONS.............. 8

SERVICE PROCEDURES

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, placethe automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

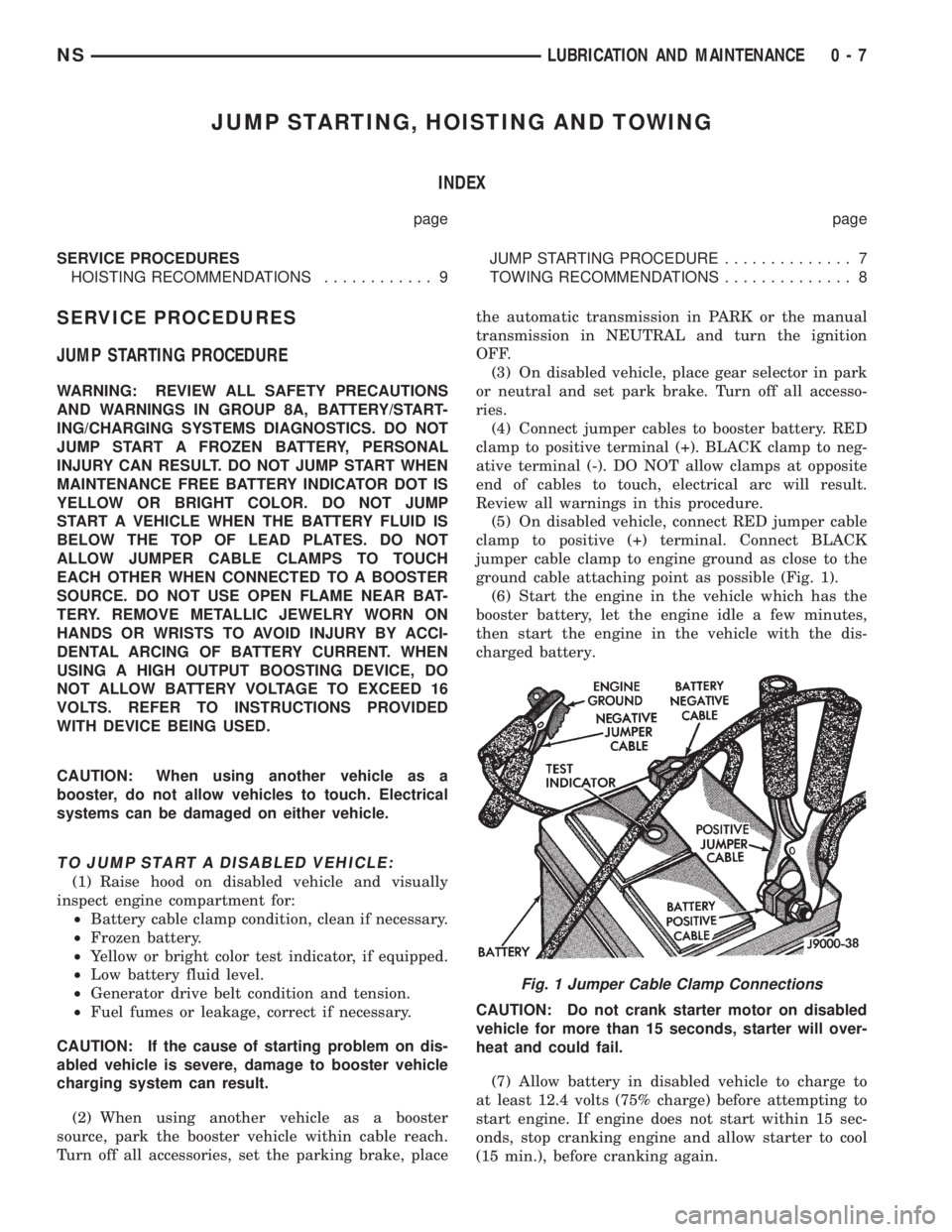

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 1).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

Fig. 1 Jumper Cable Clamp Connections

NSLUBRICATION AND MAINTENANCE 0 - 7

Page 24 of 1938

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING RECOMMENDATIONS

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER, OR BUMPER ENERGY ABSORBER

UNITS.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not attach towing device to front or rear sus-

pension components.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects

from a damaged vehicle before towing.

Refer to state and local rules and regulations

before towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

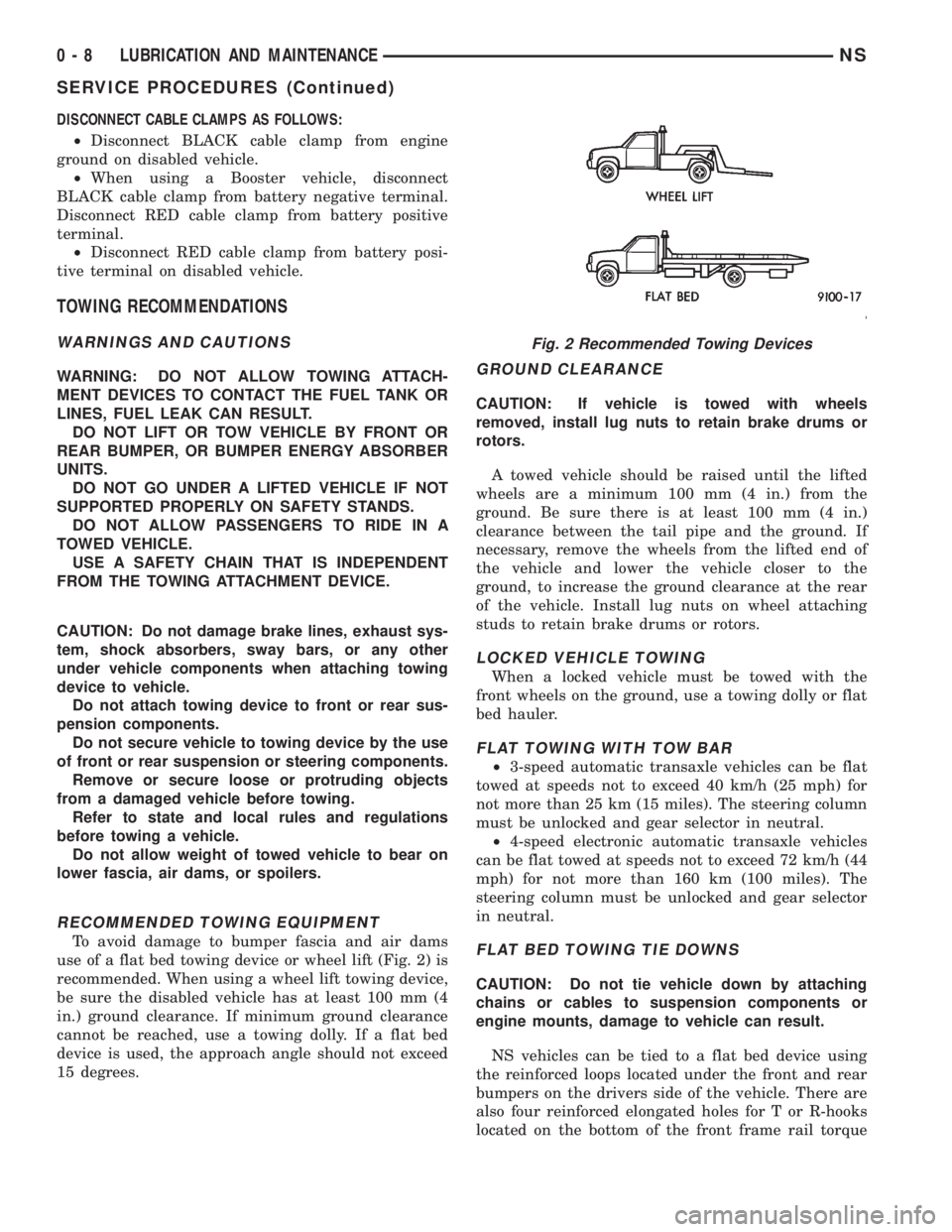

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use of a flat bed towing device or wheel lift (Fig. 2) is

recommended. When using a wheel lift towing device,

be sure the disabled vehicle has at least 100 mm (4

in.) ground clearance. If minimum ground clearance

cannot be reached, use a towing dolly. If a flat bed

device is used, the approach angle should not exceed

15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels

removed, install lug nuts to retain brake drums or

rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the lifted end of

the vehicle and lower the vehicle closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

²4-speed electronic automatic transaxle vehicles

can be flat towed at speeds not to exceed 72 km/h (44

mph) for not more than 160 km (100 miles). The

steering column must be unlocked and gear selector

in neutral.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

NS vehicles can be tied to a flat bed device using

the reinforced loops located under the front and rear

bumpers on the drivers side of the vehicle. There are

also four reinforced elongated holes for T or R-hooks

located on the bottom of the front frame rail torque

Fig. 2 Recommended Towing Devices

0 - 8 LUBRICATION AND MAINTENANCENS

SERVICE PROCEDURES (Continued)

Page 25 of 1938

boxes behind the front wheels and forward of the

rear wheels inboard of the rocker panel weld seam.

TOWINGÐFRONT WHEEL LIFT

Chrysler Corporation recommends that a vehicle be

towed with the front end lifted, whenever possible. A

90 cm (36 in.) length of 4x4 wood beam can be placed

between the wheel lift device and the bottom of the

fascia to prevent damage to vehicle during the lifting

operation. The beam can removed after lifting the

front of the vehicle.

TOWINGÐREAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

²4-speed electronic automatic transaxle vehicles

can be flat towed at speeds not to exceed 72 km/h (44

mph) for not more than 160 km (100 miles). The

steering column must be unlocked and gear selector

in neutral.

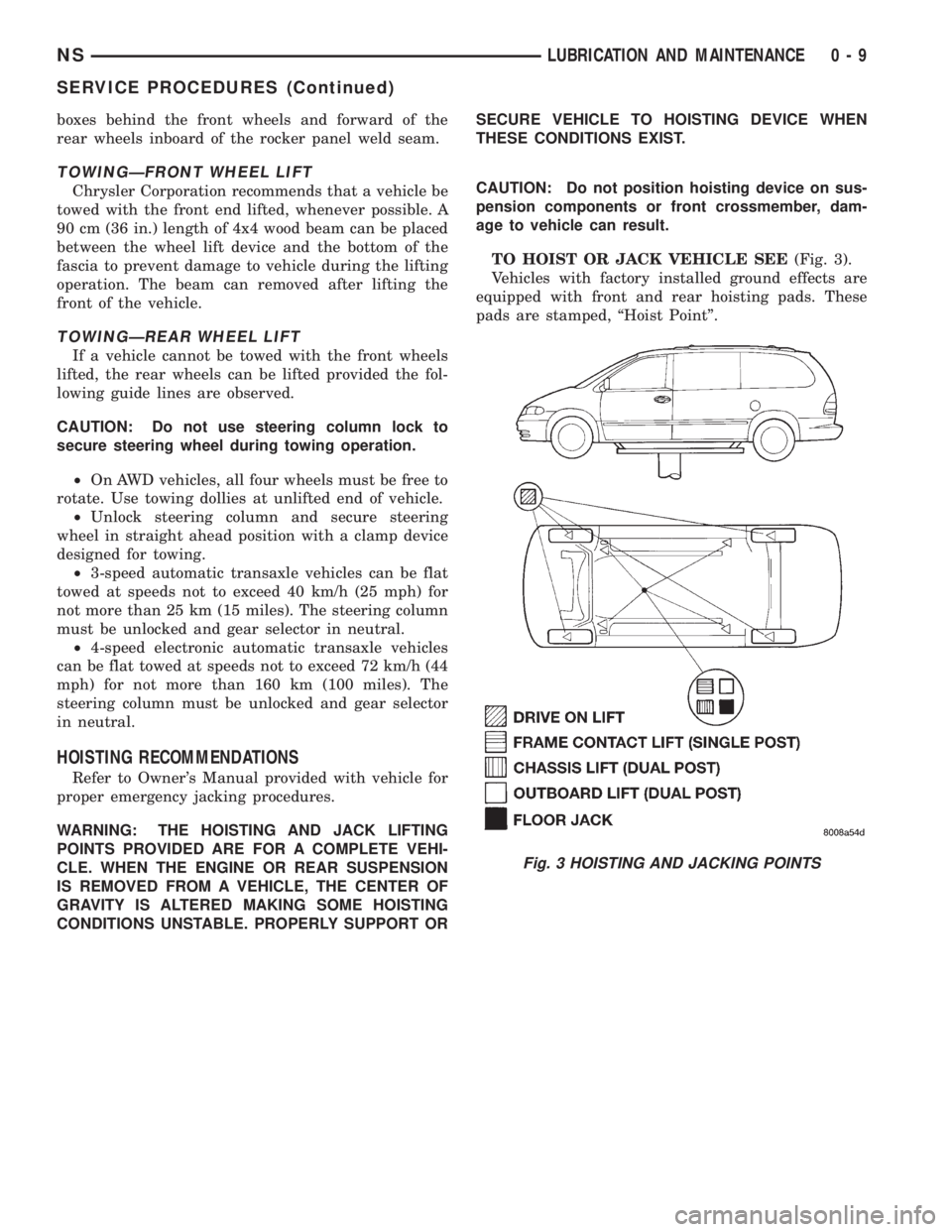

HOISTING RECOMMENDATIONS

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT ORSECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on sus-

pension components or front crossmember, dam-

age to vehicle can result.

TO HOIST OR JACK VEHICLE SEE(Fig. 3).

Vehicles with factory installed ground effects are

equipped with front and rear hoisting pads. These

pads are stamped, ªHoist Pointº.

Fig. 3 HOISTING AND JACKING POINTS

NSLUBRICATION AND MAINTENANCE 0 - 9

SERVICE PROCEDURES (Continued)

Page 27 of 1938

LUBRICATION AND MAINTENANCE

CONTENTS

page page

GENERAL INFORMATION.................. 1

JUMP STARTING, HOISTING AND TOWING . . . 5MAINTENANCE SCHEDULES............... 2

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

ENGINE OIL Ð GASOLINE ENGINES........ 1

ENGINE OILÐDIESEL ENGINES............ 1FLUID CAPACITIES...................... 1

MANUAL TRANSMISSION FLUID

(A-558 and A-598 Models)................ 1

GENERAL INFORMATION

ENGINE OIL Ð GASOLINE ENGINES

Use only oils conforming to API (American Petro-

leum Institute) Quality SJ and Energy Conserving II,

or SH and Energy Conserving II, or ACEA A1±96.

SAE VISCOSITY GRADE

To assure of properly formulated engine oils, it is

recommended that SAE Grade 5W-30 engine oils that

meet Chrysler material standard MS-6395, be used.

SAE Grade 10W-30 oils are also acceptable when the

temperatures do not fall below 0ÉC. In areas where

these grades are not generally available, higher SAE

grades may be used.

Lubricants which have both an SAE grade number

and the proper API service classification shown on

the container should be used.

ENGINE OILÐDIESEL ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationSG/CDorCCMC PD2.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is recom-

mended that SAE Grade 15W-40 engine oils that meet

Chrysler material standard MS-6395, be used. European

Grade 10W-40 oils are also acceptable.

Oils of the SAE 5W-30 or 10W-30 grade number

are preferred when minimum temperatures consis-

tently fall below -12ÉC.

MANUAL TRANSMISSION FLUID (A-558 and A-598

Models)

Use only SAE 10W-40 engine oils carrying the

European CCMC-G5 classification to fill the A-598

5±speed manual transmission.

FLUID CAPACITIES

Fuel Tank.............................76L

2.0L Gasoline Engine Oil with Filter........4.3L

2.5L VM Diesel Engine Oil With Filter......6.5L

2.0L Gasoline Engine Cooling System*.......6.0L

2.5L VM Diesel Engine Cooling System*....10.0 L

TransmissionÐ5-Speed Manual............2.2L

* Includes heater and coolant recovery tank filled

to Max level. Add 2.76L if equipped with Rear

Heater.

NS/GSLUBRICATION AND MAINTENANCE 0 - 1

Page 28 of 1938

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

MAINTENANCE SCHEDULE............... 2

MAINTENANCE SCHEDULEÐ

DIESEL ENGINE....................... 2SCHEDULEÐA (DIESEL).................. 2

SCHEDULEÐB (DIESEL).................. 3

UNSCHEDULED INSPECTION.............. 2

GENERAL INFORMATION

MAINTENANCE SCHEDULE

Refer to the 1998 GS Service Manual for Gasoline

Engine and non-engine related Maintenance Sched-

ules.

MAINTENANCE SCHEDULEÐDIESEL ENGINE

The following are engine related Maintenance

items which are unique to Diesel engine-equipped

vehicles. Refer to the 1998 GS Service Manual for

Gasoline Engine and non-engine related Maintenance

Schedules.

The service intervals are based on odometer read-

ings in kilometers. There are two maintenance sched-

ules that show proper service intervals. Use the

schedule that best describes the conditions the vehi-

cle is operated under.Schedule-Alists all the sched-

uled maintenance to be performed under normal

operating conditions.Schedule-Bis the schedule for

vehicles that are operated under one or more of the

following conditions:

²Day and night temperatures are below freezing.

²Stop and go driving.

²Long periods of engine idling.

²Driving in dusty conditions.

²Short trips of less than 5 miles.

²Operation at sustained high speeds during hot

weather above 32ÉC (90ÉF).

²Taxi, police or delivery service.

²Trailer towing.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on ScheduleÐA (7,500 miles) or every other

interval shown on ScheduleÐ B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter.

SCHEDULEÐA (DIESEL)

1 000 KM

²Change engine oil.

²Change engine oil filter.

²Check all fluid levels.

²Check correct torque, intake manifold mounting

nuts.

²Check correct torque, exhaust manifold mount-

ing nuts.

²Check correct torque, turbocharger mounting

nuts.

²Check correct torque, water manifold bolts.

10 000 KM

²Change engine oil.

²Change engine oil filter.

20 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

0 - 2 LUBRICATION AND MAINTENANCENS/GS

Page 29 of 1938

²Check drive belt tension.

²Check glow plug operation.

30 000 KM

²Change engine oil.

²Change engine oil filter.

40 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Replace fuel filter/water separator element.**

50 000 KM

²Change engine oil.

²Change engine oil filter.

60 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check glow plug operation.

²Replace drive belt.

²Check engine smoke.

²Replace engine coolant.

70 000 KM

²Change engine oil.

²Change engine oil filter.

80 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Replace fuel filter/water separator element.**

90 000 KM

²Change engine oil.

²Change engine oil filter.

100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

EVERY 40 000 KM AFTER 80 000 KM

²Replace fuel filter/water separator element.**

**The fuel filter/water separator element should be

replaced once a year if the vehicle is driven less than

40 000 km annually or if power loss from fuel star-

vation is detected.

EVERY 10 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

EVERY 20 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

SCHEDULEÐB (DIESEL)

500 KM

²Check correct torque, intake manifold mounting

nuts.

²Check correct torque, exhaust manifold mount-

ing nuts.

²Check correct torque, turbocharger mounting

nuts.

²Check correct torque, water manifold bolts.

1 000 KM

²Change engine oil.

²Change engine oil filter.

²Check all fluid levels.

5 000 KM

²Change engine oil.

²Change engine oil filter.

10 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

15 000 KM

²Change engine oil.

²Change engine oil filter.

20 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

25 000 KM

²Change engine oil.

²Change engine oil filter.

30 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

NS/GSLUBRICATION AND MAINTENANCE 0 - 3

GENERAL INFORMATION (Continued)