glove box CHRYSLER VOYAGER 1996 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 393 of 1938

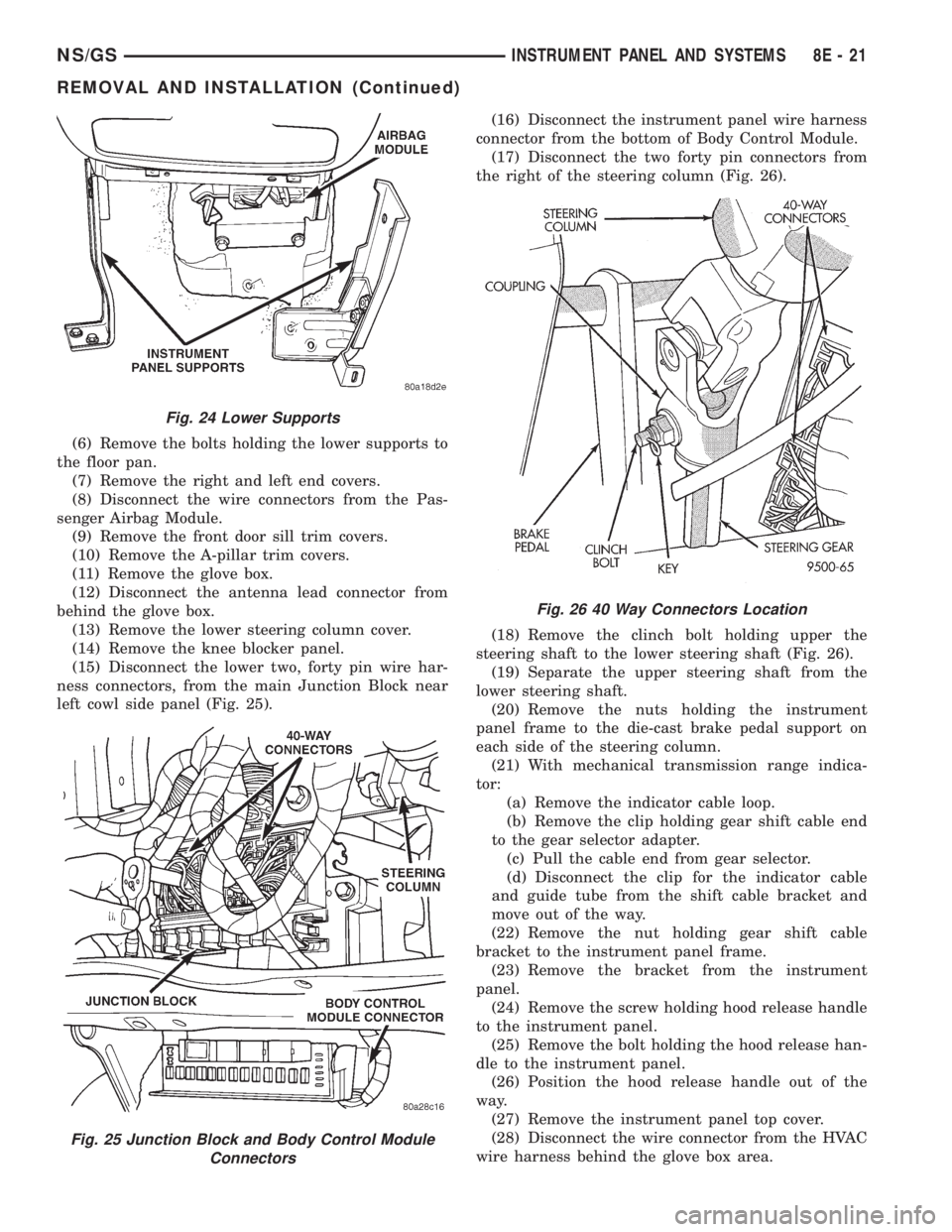

(6) Remove the bolts holding the lower supports to

the floor pan.

(7) Remove the right and left end covers.

(8) Disconnect the wire connectors from the Pas-

senger Airbag Module.

(9) Remove the front door sill trim covers.

(10) Remove the A-pillar trim covers.

(11) Remove the glove box.

(12) Disconnect the antenna lead connector from

behind the glove box.

(13) Remove the lower steering column cover.

(14) Remove the knee blocker panel.

(15) Disconnect the lower two, forty pin wire har-

ness connectors, from the main Junction Block near

left cowl side panel (Fig. 25).(16) Disconnect the instrument panel wire harness

connector from the bottom of Body Control Module.

(17) Disconnect the two forty pin connectors from

the right of the steering column (Fig. 26).

(18) Remove the clinch bolt holding upper the

steering shaft to the lower steering shaft (Fig. 26).

(19) Separate the upper steering shaft from the

lower steering shaft.

(20) Remove the nuts holding the instrument

panel frame to the die-cast brake pedal support on

each side of the steering column.

(21) With mechanical transmission range indica-

tor:

(a) Remove the indicator cable loop.

(b) Remove the clip holding gear shift cable end

to the gear selector adapter.

(c) Pull the cable end from gear selector.

(d) Disconnect the clip for the indicator cable

and guide tube from the shift cable bracket and

move out of the way.

(22) Remove the nut holding gear shift cable

bracket to the instrument panel frame.

(23) Remove the bracket from the instrument

panel.

(24) Remove the screw holding hood release handle

to the instrument panel.

(25) Remove the bolt holding the hood release han-

dle to the instrument panel.

(26) Position the hood release handle out of the

way.

(27) Remove the instrument panel top cover.

(28) Disconnect the wire connector from the HVAC

wire harness behind the glove box area.

Fig. 24 Lower Supports

Fig. 25 Junction Block and Body Control Module

Connectors

Fig. 26 40 Way Connectors Location

NS/GSINSTRUMENT PANEL AND SYSTEMS 8E - 21

REMOVAL AND INSTALLATION (Continued)

Page 398 of 1938

(3) Remove reinforcement.

INSTALLATION

(1) Place reinforcement in position.

(2) Install screws to hold knee blocker reinforce-

ment to instrument panel.

(3) Install lower steering column cover.

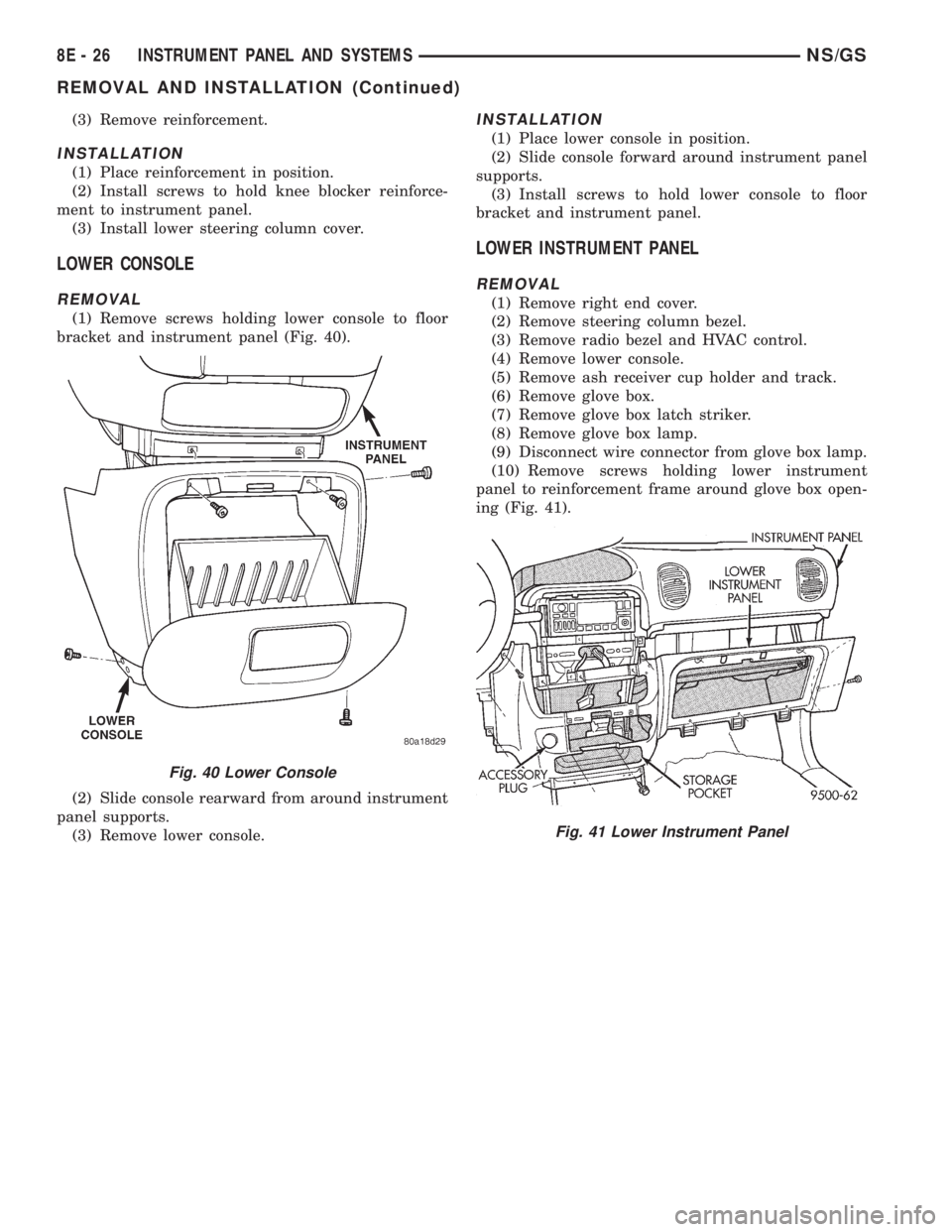

LOWER CONSOLE

REMOVAL

(1) Remove screws holding lower console to floor

bracket and instrument panel (Fig. 40).

(2) Slide console rearward from around instrument

panel supports.

(3) Remove lower console.

INSTALLATION

(1) Place lower console in position.

(2) Slide console forward around instrument panel

supports.

(3) Install screws to hold lower console to floor

bracket and instrument panel.

LOWER INSTRUMENT PANEL

REMOVAL

(1) Remove right end cover.

(2) Remove steering column bezel.

(3) Remove radio bezel and HVAC control.

(4) Remove lower console.

(5) Remove ash receiver cup holder and track.

(6) Remove glove box.

(7) Remove glove box latch striker.

(8) Remove glove box lamp.

(9) Disconnect wire connector from glove box lamp.

(10) Remove screws holding lower instrument

panel to reinforcement frame around glove box open-

ing (Fig. 41).

Fig. 40 Lower Console

Fig. 41 Lower Instrument Panel

8E - 26 INSTRUMENT PANEL AND SYSTEMSNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 404 of 1938

CD/3-band graphic equalizer (RBR sales code), or an

AM/FM/CD/cassette/3-band graphic equalizer (RAZ

sales code).

All factory-installed radio receivers are stereo Elec-

tronically Tuned Radios (ETR) and include an elec-

tronic digital clock function.

All factory-installed radio receivers, except the

RAS model, communicate on the Chrysler Collision

Detection (CCD) data bus network through a sepa-

rate two-way wire harness connector. The CCD data

bus network allows the sharing of sensor informa-

tion. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor

current loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and

allows the addition of many new feature capabilities.

In addition, radios connected to the CCD data bus

have several audio system functions that can be diag-

nosed using a DRB scan tool. Refer to the proper

Diagnostic Procedures manual for more information

on DRB testing of the audio systems.

The radio can only be serviced by an authorized

radio repair station. Refer to the latest Warranty Pol-

icies and Procedures manual for a current listing of

authorized radio repair stations.

For more information on radio features, setting

procedures, and control functions refer to the owner's

manual in the vehicle glove box.

RADIO IGNITION INTERFERENCE

If receiving ignition/engine interference noise on

the radio stations, check and clean all engine and

body ground connections. Tighten properly after

cleaning. Example (Fig. 1), (Fig. 2), (Fig. 3) and (Fig.

4).

Ensure all ground connections are without corro-

sion.

CHOKEÐINFINITY SPEAKERS

If the audio system is lacking bass response, check

for continuity across the choke connector. If no conti-

nuity Replace choke. The choke is located on the

Fig. 1 Motor Mount to Frame Rail Ground

Fig. 2 2.4L Engine Block Ground

Fig. 3 3.0L Engine Block Ground

Fig. 4 3.3/3.8L Engine Block Ground

8F - 2 AUDIO SYSTEMSNS

DESCRIPTION AND OPERATION (Continued)

Page 405 of 1938

bracket behind the junction block/body control mod-

ule (Fig. 5).

REMOTE RADIO SWITCHES

A remote radio control switch option is available on

LXI models sold in North America with the AM/FM/

cassette/5-band graphic equalizer with CD changer

control feature (RBN sales code), or the AM/FM/CD/

cassette/3-band graphic equalizer (RAZ sales code)

radio receivers. Two rocker-type switches are

mounted on the back (instrument panel side) of the

steering wheel spokes. The switch on the left spoke is

the seek switch and has seek up, seek down, and pre-

set station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions (Fig. 6).

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the propermessages on the Chrysler Collision Detection (CCD)

data bus network to the radio receiver. For diagnosis

of the BCM or the CCD data bus, the use of a DRB

scan tool and the proper Diagnostic Procedures man-

ual are recommended. For more information on the

operation of the remote radio switch controls, refer to

the owner's manual in the vehicle glove box.

NAME BRAND SPEAKER RELAY

Relay is located in the junction block. To test relay

refer to the Audio Diagnostic Test Procedures or use

a known good relay.

DIAGNOSIS AND TESTING

ANTENNA

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to coaxial shield test.

The ohmmeter test lead connections for each test

are shown in Antenna Tests (Fig. 7).

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate a coaxial cable problem; from the

coaxial cable connection under the right end of the

instrument panel near the right cowl side panel to

the antenna base, and then from the coaxial cable

connection to the radio chassis connection.

TEST 1

Test 1 determines if the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable connector

from the radio chassis and isolate.

(2) Connect one ohmmeter test lead to the tip of

the antenna mast. Connect the other test lead to the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

Fig. 5 Choke Location

Fig. 6 Remote Radio Switch Operational View

NSAUDIO SYSTEMS 8F - 3

DESCRIPTION AND OPERATION (Continued)

Page 409 of 1938

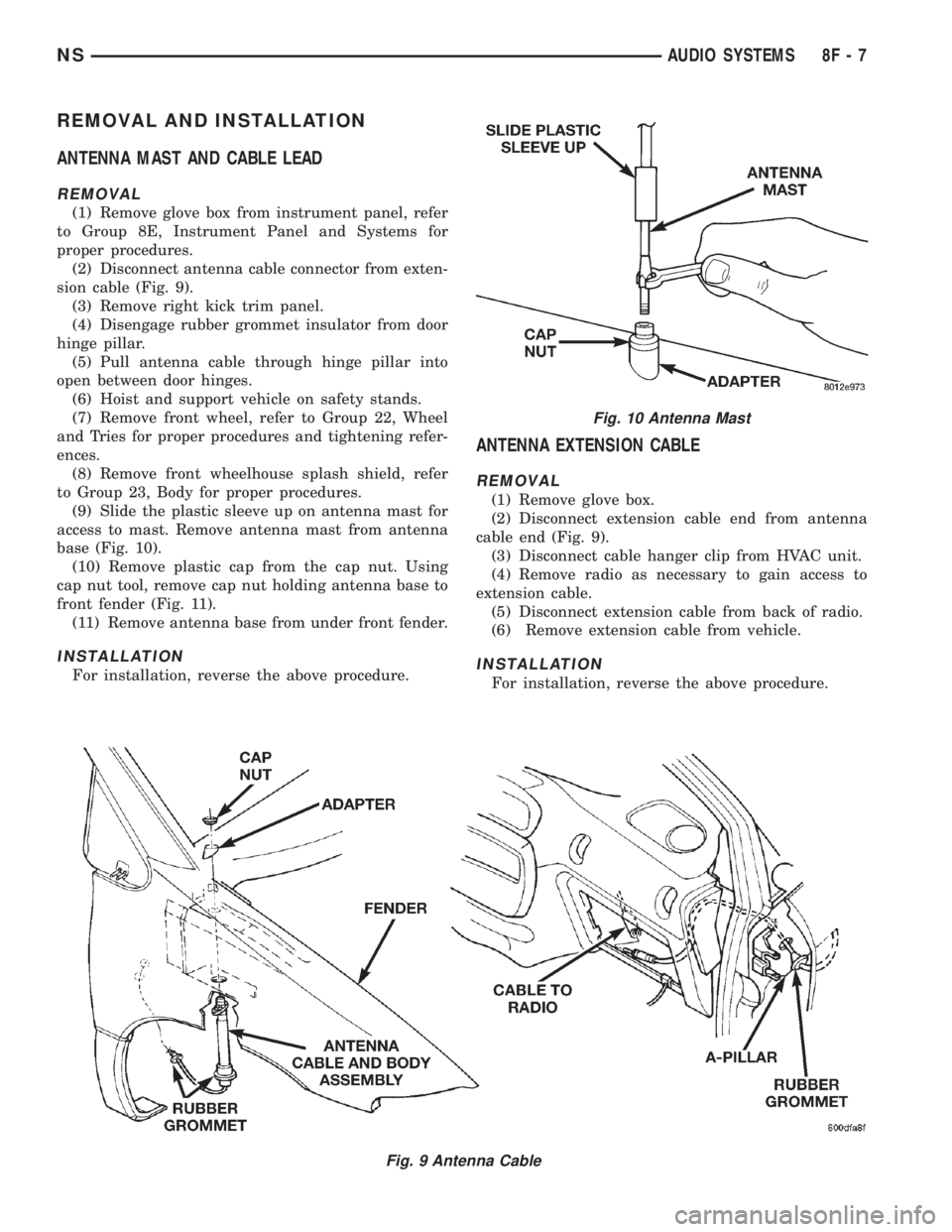

REMOVAL AND INSTALLATION

ANTENNA MAST AND CABLE LEAD

REMOVAL

(1) Remove glove box from instrument panel, refer

to Group 8E, Instrument Panel and Systems for

proper procedures.

(2) Disconnect antenna cable connector from exten-

sion cable (Fig. 9).

(3) Remove right kick trim panel.

(4) Disengage rubber grommet insulator from door

hinge pillar.

(5) Pull antenna cable through hinge pillar into

open between door hinges.

(6) Hoist and support vehicle on safety stands.

(7) Remove front wheel, refer to Group 22, Wheel

and Tries for proper procedures and tightening refer-

ences.

(8) Remove front wheelhouse splash shield, refer

to Group 23, Body for proper procedures.

(9) Slide the plastic sleeve up on antenna mast for

access to mast. Remove antenna mast from antenna

base (Fig. 10).

(10) Remove plastic cap from the cap nut. Using

cap nut tool, remove cap nut holding antenna base to

front fender (Fig. 11).

(11) Remove antenna base from under front fender.

INSTALLATION

For installation, reverse the above procedure.

ANTENNA EXTENSION CABLE

REMOVAL

(1) Remove glove box.

(2) Disconnect extension cable end from antenna

cable end (Fig. 9).

(3) Disconnect cable hanger clip from HVAC unit.

(4) Remove radio as necessary to gain access to

extension cable.

(5) Disconnect extension cable from back of radio.

(6) Remove extension cable from vehicle.

INSTALLATION

For installation, reverse the above procedure.

Fig. 9 Antenna Cable

Fig. 10 Antenna Mast

NSAUDIO SYSTEMS 8F - 7

Page 470 of 1938

INTERIOR LAMPS

INDEX

page page

REMOVAL AND INSTALLATION

CONVENIENCE BIN LAMP................. 20

DOME LAMP BULB...................... 21

DOME LAMP........................... 21

FRONT DOOR COURTESY LAMP BULB...... 22

FRONT DOOR COURTESY LAMP........... 21

GLOVE BOX LAMP AND SWITCH........... 19

GLOVE BOX LAMP BULB.................. 19

HEADER READING/COURTESY LAMP BULB . . . 19HEADER READING/COURTESY LAMP....... 18

IGNITION HALO LAMP BULB............... 19

INSTRUMENT PANEL LAMPS AND SWITCHES . 20

LIFTGATE COURTESY LAMP BULB.......... 24

LIFTGATE COURTESY LAMP............... 23

OVERHEAD CONSOLE READING/COURTESY

LAMP BULB.......................... 18

RAIL LAMP MODULE BULB................ 23

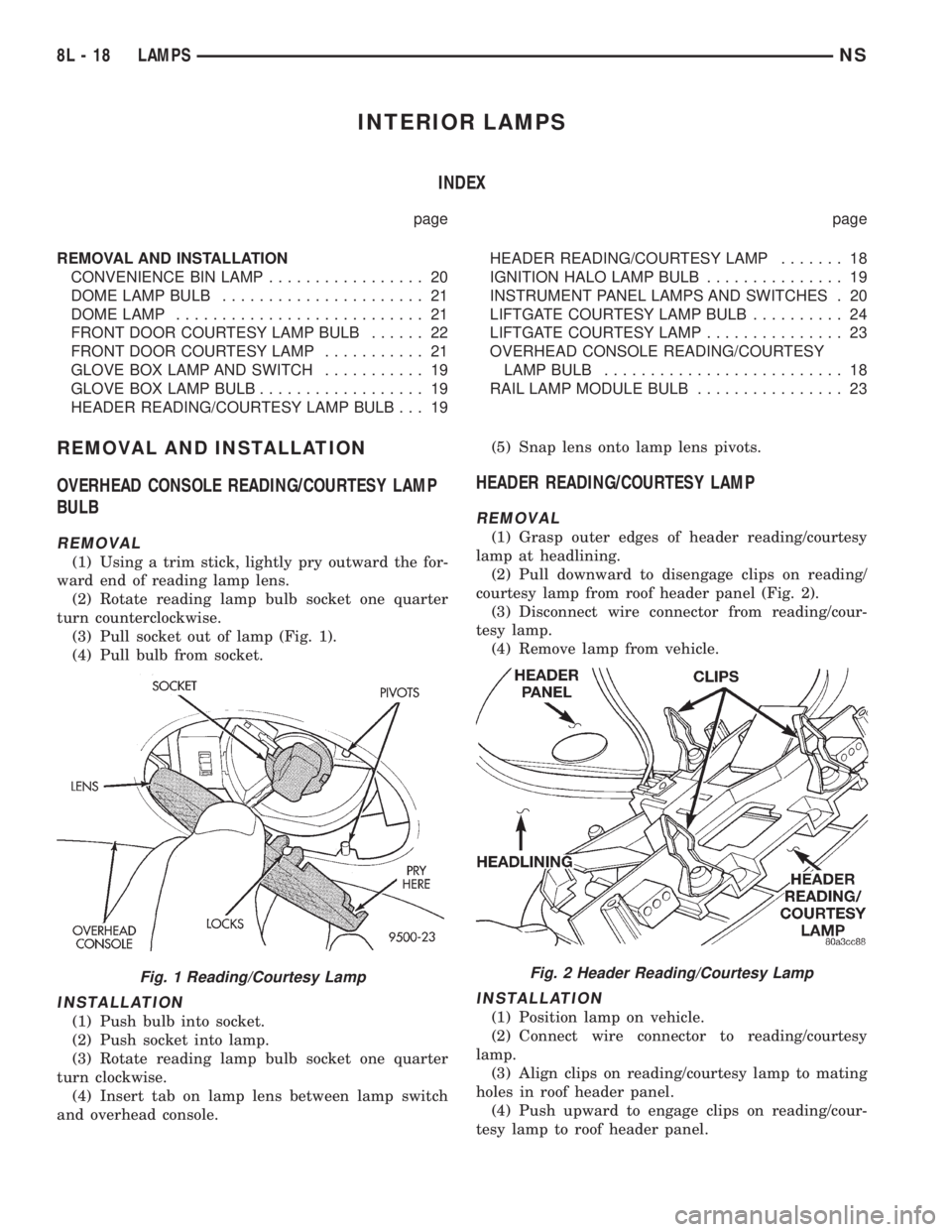

REMOVAL AND INSTALLATION

OVERHEAD CONSOLE READING/COURTESY LAMP

BULB

REMOVAL

(1) Using a trim stick, lightly pry outward the for-

ward end of reading lamp lens.

(2) Rotate reading lamp bulb socket one quarter

turn counterclockwise.

(3) Pull socket out of lamp (Fig. 1).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Push socket into lamp.

(3) Rotate reading lamp bulb socket one quarter

turn clockwise.

(4) Insert tab on lamp lens between lamp switch

and overhead console.(5) Snap lens onto lamp lens pivots.

HEADER READING/COURTESY LAMP

REMOVAL

(1) Grasp outer edges of header reading/courtesy

lamp at headlining.

(2) Pull downward to disengage clips on reading/

courtesy lamp from roof header panel (Fig. 2).

(3) Disconnect wire connector from reading/cour-

tesy lamp.

(4) Remove lamp from vehicle.

INSTALLATION

(1) Position lamp on vehicle.

(2) Connect wire connector to reading/courtesy

lamp.

(3) Align clips on reading/courtesy lamp to mating

holes in roof header panel.

(4) Push upward to engage clips on reading/cour-

tesy lamp to roof header panel.

Fig. 1 Reading/Courtesy LampFig. 2 Header Reading/Courtesy Lamp

8L - 18 LAMPSNS

Page 471 of 1938

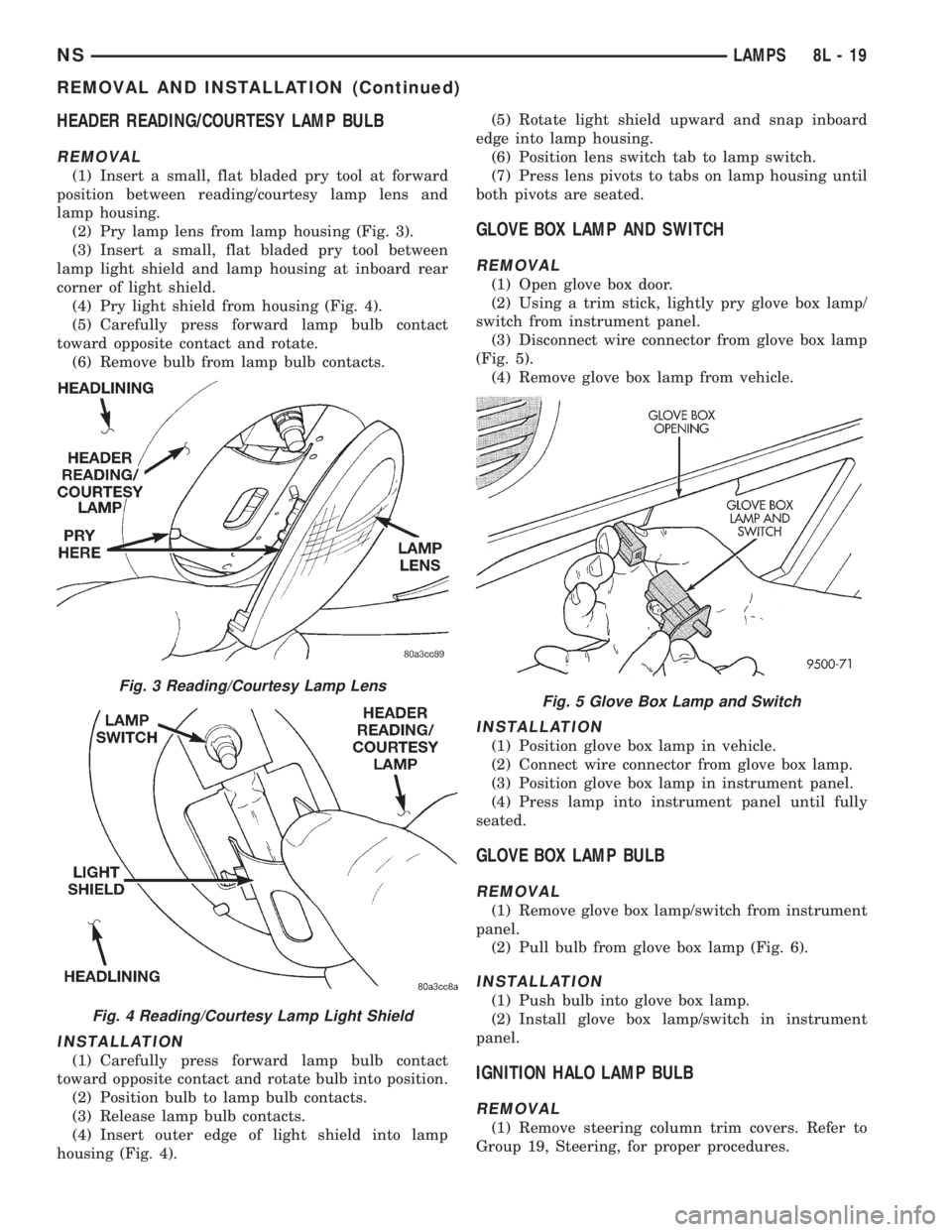

HEADER READING/COURTESY LAMP BULB

REMOVAL

(1) Insert a small, flat bladed pry tool at forward

position between reading/courtesy lamp lens and

lamp housing.

(2) Pry lamp lens from lamp housing (Fig. 3).

(3) Insert a small, flat bladed pry tool between

lamp light shield and lamp housing at inboard rear

corner of light shield.

(4) Pry light shield from housing (Fig. 4).

(5) Carefully press forward lamp bulb contact

toward opposite contact and rotate.

(6) Remove bulb from lamp bulb contacts.

INSTALLATION

(1) Carefully press forward lamp bulb contact

toward opposite contact and rotate bulb into position.

(2) Position bulb to lamp bulb contacts.

(3) Release lamp bulb contacts.

(4) Insert outer edge of light shield into lamp

housing (Fig. 4).(5) Rotate light shield upward and snap inboard

edge into lamp housing.

(6) Position lens switch tab to lamp switch.

(7) Press lens pivots to tabs on lamp housing until

both pivots are seated.

GLOVE BOX LAMP AND SWITCH

REMOVAL

(1) Open glove box door.

(2) Using a trim stick, lightly pry glove box lamp/

switch from instrument panel.

(3) Disconnect wire connector from glove box lamp

(Fig. 5).

(4) Remove glove box lamp from vehicle.

INSTALLATION

(1) Position glove box lamp in vehicle.

(2) Connect wire connector from glove box lamp.

(3) Position glove box lamp in instrument panel.

(4) Press lamp into instrument panel until fully

seated.

GLOVE BOX LAMP BULB

REMOVAL

(1) Remove glove box lamp/switch from instrument

panel.

(2) Pull bulb from glove box lamp (Fig. 6).

INSTALLATION

(1) Push bulb into glove box lamp.

(2) Install glove box lamp/switch in instrument

panel.

IGNITION HALO LAMP BULB

REMOVAL

(1) Remove steering column trim covers. Refer to

Group 19, Steering, for proper procedures.

Fig. 3 Reading/Courtesy Lamp Lens

Fig. 4 Reading/Courtesy Lamp Light Shield

Fig. 5 Glove Box Lamp and Switch

NSLAMPS 8L - 19

REMOVAL AND INSTALLATION (Continued)

Page 472 of 1938

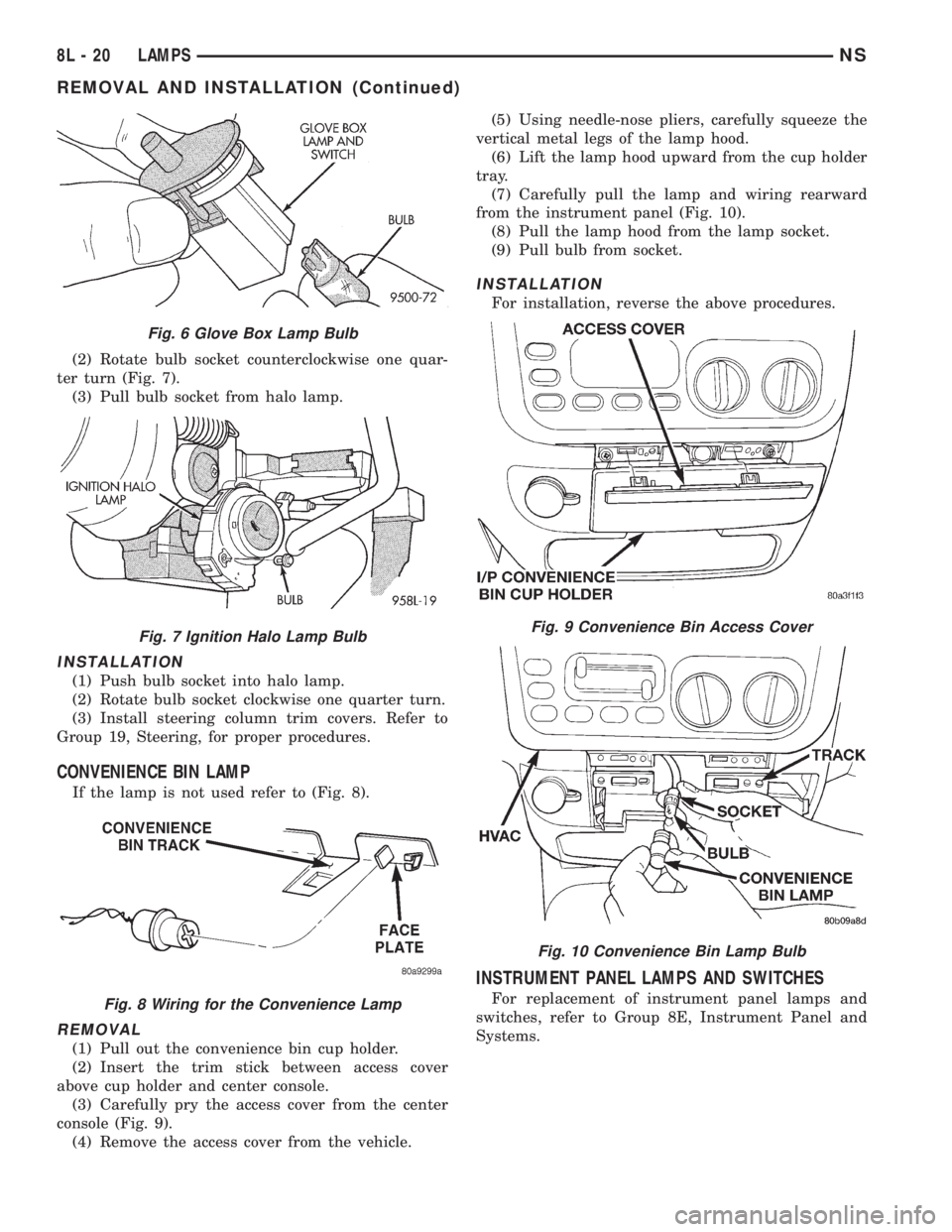

(2) Rotate bulb socket counterclockwise one quar-

ter turn (Fig. 7).

(3) Pull bulb socket from halo lamp.

INSTALLATION

(1) Push bulb socket into halo lamp.

(2) Rotate bulb socket clockwise one quarter turn.

(3) Install steering column trim covers. Refer to

Group 19, Steering, for proper procedures.

CONVENIENCE BIN LAMP

If the lamp is not used refer to (Fig. 8).

REMOVAL

(1) Pull out the convenience bin cup holder.

(2) Insert the trim stick between access cover

above cup holder and center console.

(3) Carefully pry the access cover from the center

console (Fig. 9).

(4) Remove the access cover from the vehicle.(5) Using needle-nose pliers, carefully squeeze the

vertical metal legs of the lamp hood.

(6) Lift the lamp hood upward from the cup holder

tray.

(7) Carefully pull the lamp and wiring rearward

from the instrument panel (Fig. 10).

(8) Pull the lamp hood from the lamp socket.

(9) Pull bulb from socket.

INSTALLATION

For installation, reverse the above procedures.

INSTRUMENT PANEL LAMPS AND SWITCHES

For replacement of instrument panel lamps and

switches, refer to Group 8E, Instrument Panel and

Systems.

Fig. 6 Glove Box Lamp Bulb

Fig. 7 Ignition Halo Lamp Bulb

Fig. 8 Wiring for the Convenience Lamp

Fig. 9 Convenience Bin Access Cover

Fig. 10 Convenience Bin Lamp Bulb

8L - 20 LAMPSNS

REMOVAL AND INSTALLATION (Continued)

Page 477 of 1938

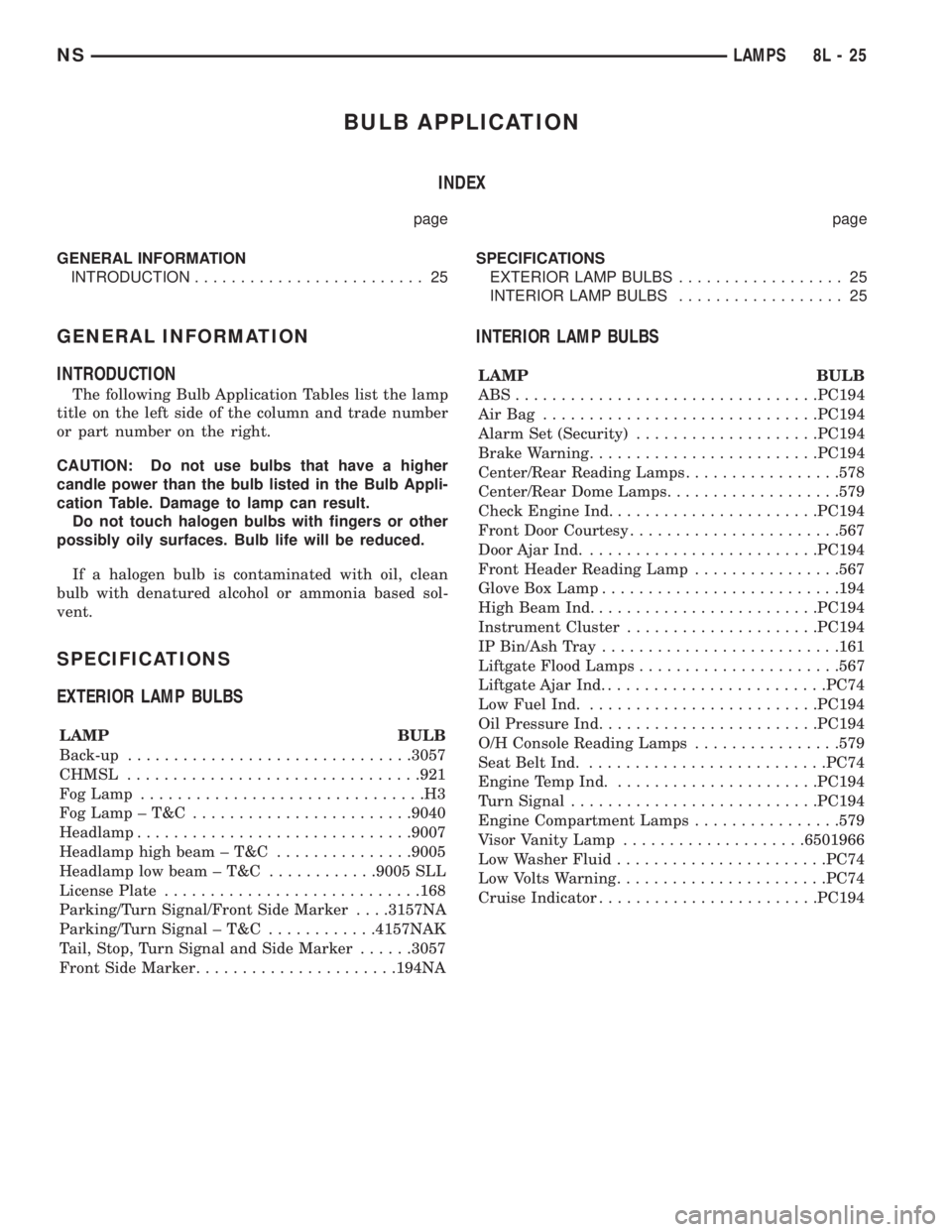

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 25SPECIFICATIONS

EXTERIOR LAMP BULBS.................. 25

INTERIOR LAMP BULBS.................. 25

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMP BULBS

LAMP BULB

Back-up...............................3057

CHMSL................................921

Fog Lamp...............................H3

FogLamp±T&C ........................9040

Headlamp..............................9007

Headlamp high beam ± T&C...............9005

Headlamp low beam ± T&C............9005 SLL

License Plate............................168

Parking/Turn Signal/Front Side Marker. . . .3157NA

Parking/Turn Signal ± T&C............4157NAK

Tail, Stop, Turn Signal and Side Marker......3057

Front Side Marker......................194NA

INTERIOR LAMP BULBS

LAMP BULB

ABS.................................PC194

AirBag ..............................PC194

Alarm Set (Security)....................PC194

Brake Warning.........................PC194

Center/Rear Reading Lamps.................578

Center/Rear Dome Lamps...................579

Check Engine Ind.......................PC194

Front Door Courtesy.......................567

Door Ajar Ind..........................PC194

Front Header Reading Lamp................567

Glove Box Lamp..........................194

High Beam Ind.........................PC194

Instrument Cluster.....................PC194

IP Bin/Ash Tray..........................161

Liftgate Flood Lamps......................567

Liftgate Ajar Ind.........................PC74

Low Fuel Ind..........................PC194

Oil Pressure Ind........................PC194

O/H Console Reading Lamps................579

Seat Belt Ind...........................PC74

Engine Temp Ind.......................PC194

Turn Signal...........................PC194

Engine Compartment Lamps................579

Visor Vanity Lamp....................6501966

Low Washer Fluid.......................PC74

Low Volts Warning.......................PC74

Cruise Indicator........................PC194

NSLAMPS 8L - 25

Page 495 of 1938

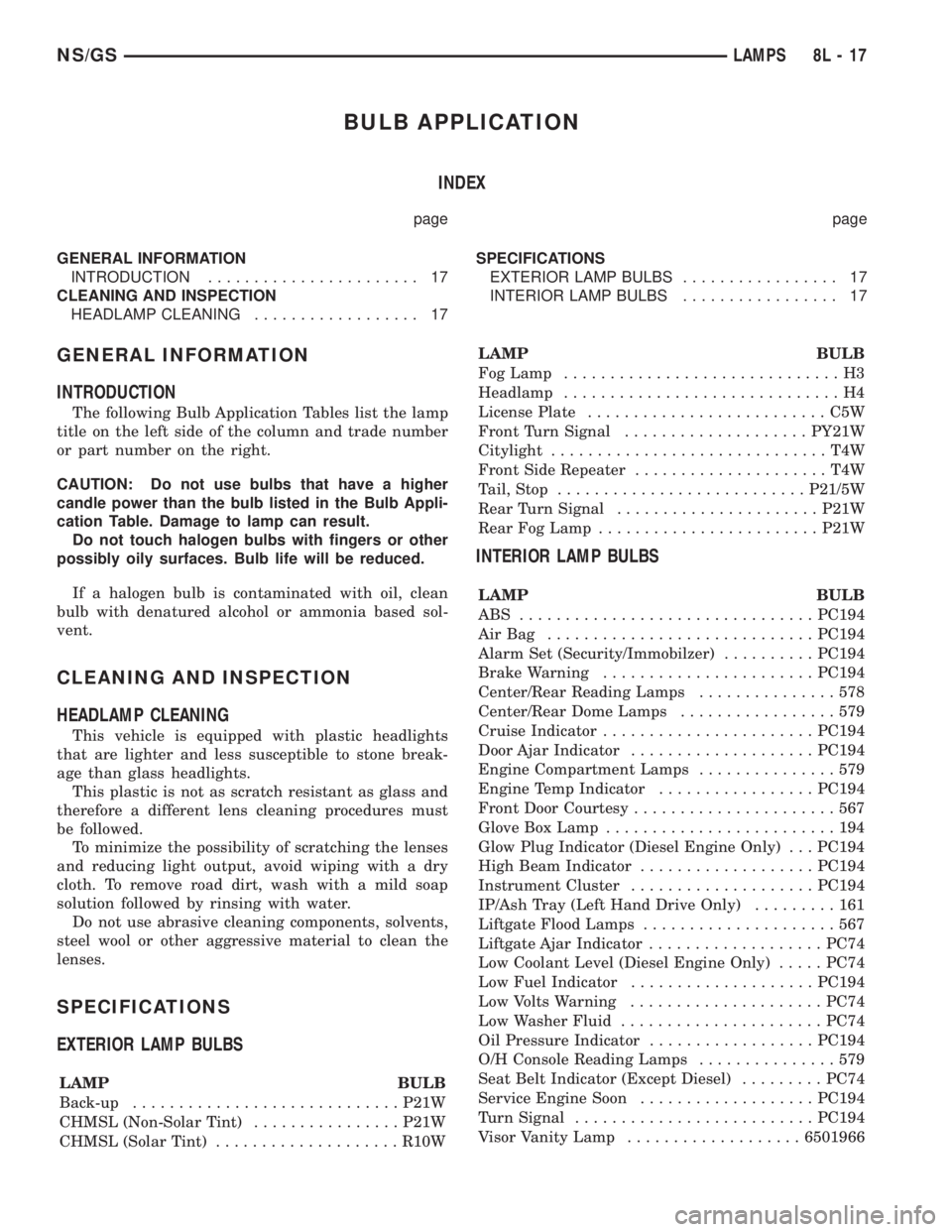

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION....................... 17

CLEANING AND INSPECTION

HEADLAMP CLEANING.................. 17SPECIFICATIONS

EXTERIOR LAMP BULBS................. 17

INTERIOR LAMP BULBS................. 17

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

CLEANING AND INSPECTION

HEADLAMP CLEANING

This vehicle is equipped with plastic headlights

that are lighter and less susceptible to stone break-

age than glass headlights.

This plastic is not as scratch resistant as glass and

therefore a different lens cleaning procedures must

be followed.

To minimize the possibility of scratching the lenses

and reducing light output, avoid wiping with a dry

cloth. To remove road dirt, wash with a mild soap

solution followed by rinsing with water.

Do not use abrasive cleaning components, solvents,

steel wool or other aggressive material to clean the

lenses.

SPECIFICATIONS

EXTERIOR LAMP BULBS

LAMP BULB

Back-up.............................P21W

CHMSL (Non-Solar Tint)................P21W

CHMSL (Solar Tint)....................R10WLAMP BULB

Fog Lamp..............................H3

Headlamp..............................H4

License Plate..........................C5W

Front Turn Signal....................PY21W

Citylight..............................T4W

Front Side Repeater.....................T4W

Tail, Stop...........................P21/5W

Rear Turn Signal......................P21W

Rear Fog Lamp........................P21W

INTERIOR LAMP BULBS

LAMP BULB

ABS ................................PC194

AirBag .............................PC194

Alarm Set (Security/Immobilzer)..........PC194

Brake Warning.......................PC194

Center/Rear Reading Lamps...............578

Center/Rear Dome Lamps.................579

Cruise Indicator.......................PC194

Door Ajar Indicator....................PC194

Engine Compartment Lamps...............579

Engine Temp Indicator.................PC194

Front Door Courtesy......................567

Glove Box Lamp.........................194

Glow Plug Indicator (Diesel Engine Only) . . . PC194

High Beam Indicator...................PC194

Instrument Cluster....................PC194

IP/Ash Tray (Left Hand Drive Only).........161

Liftgate Flood Lamps.....................567

Liftgate Ajar Indicator...................PC74

Low Coolant Level (Diesel Engine Only).....PC74

Low Fuel Indicator....................PC194

Low Volts Warning.....................PC74

Low Washer Fluid......................PC74

Oil Pressure Indicator..................PC194

O/H Console Reading Lamps...............579

Seat Belt Indicator (Except Diesel).........PC74

Service Engine Soon...................PC194

Turn Signal..........................PC194

Visor Vanity Lamp...................6501966

NS/GSLAMPS 8L - 17