shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1200 of 1938

CAUTION: Do not pry up on one side of the bed-

plate. Damage may occur to cylinder block and bed-

plate alignment.(7) Bedplate should be removed evenly from the

cylinder block dowel pins.

(8) Lift out crankshaft from cylinder block. Be sure

not to damage the main bearings or journals when

removing the crankshaft.

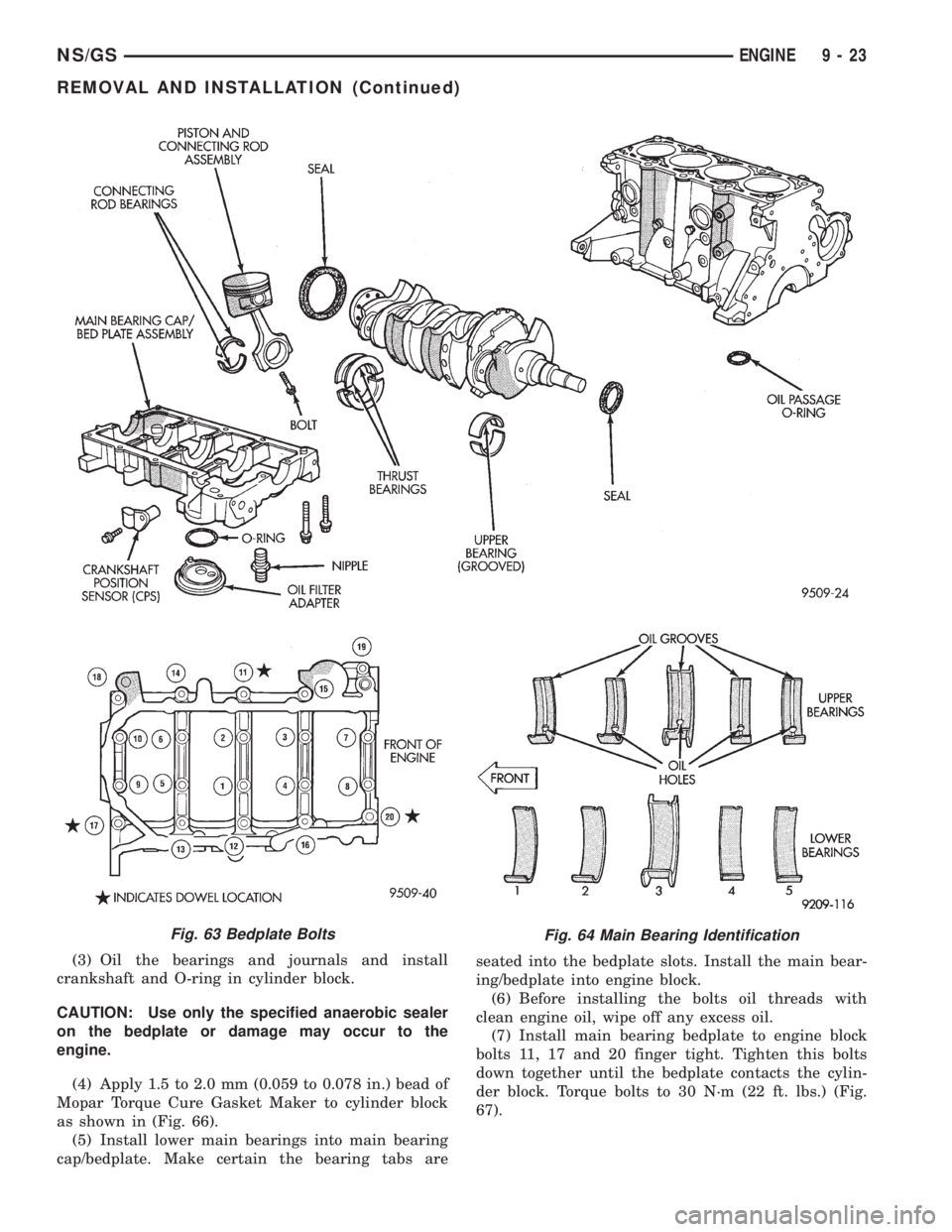

CRANKSHAFT MAIN BEARINGS LOCATION

The crankshaft is supported in five main bearings.

All upper bearing shells in the crankcase have oil

grooves. All lower bearing shells installed in the (bed-

plate) main bearing cap are plain. Crankshaft end

play is controlled by a flanged bearing on the number

three main bearing journal (Fig. 64).

NOTE: The upper and lower main Bearing shells

are Not interchangeable. The lower shells have a

revised tab to prevent improper installation.

CRANKSHAFT MAIN JOURNALS INSPECTION

The crankshaft journals should be checked for

excessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to .025 mm (.001 inch). Journal grinding should

not exceed .305 mm (.012 inch) under the standard

journal diameter. DO NOT grind thrust faces of

Number 3 main bearing. DO NOT nick crank pin or

bearing fillets. After grinding, remove rough edges

from crankshaft oil holes and clean out all passages.

CAUTION: With the nodular cast iron crankshafts

used it is important that the final paper or cloth pol-

ish after any journal regrind be in the same direc-

tion as normal rotation in the engine.

Upper and lower Number 3 bearing halves are

flanged to carry the crankshaft thrust loads and are

NOT interchangeable with any other bearing halves

in the engine (Fig. 64). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersized: 0.016 mm

(.0006 inch), .032 mm (.0012 inch), .250 mm (.010

inch). Never install an undersize bearing that will

reduce clearance below specifications.

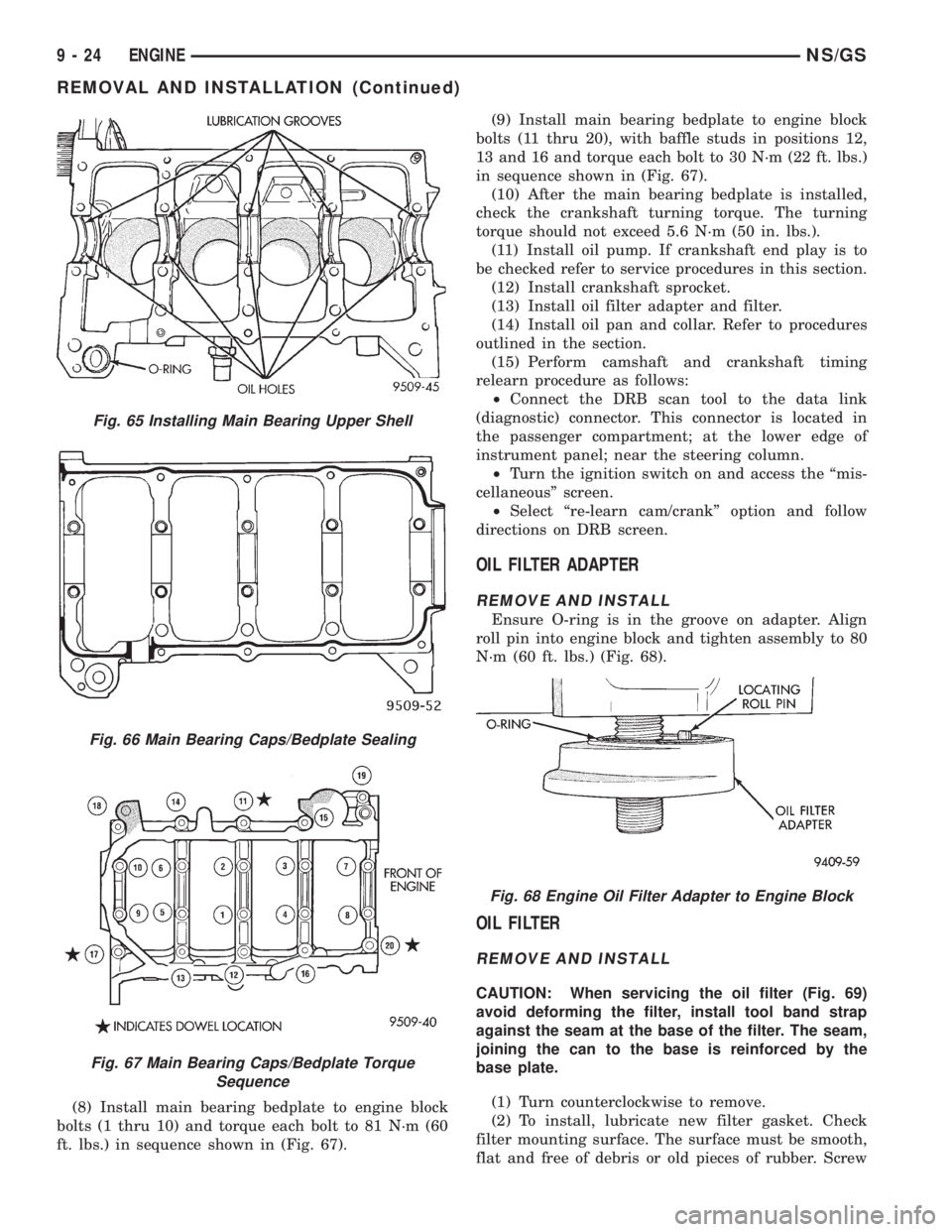

INSTALLATION

(1) Install the main bearing shells with the lubri-

cation groove in the cylinder block. Install O-ring

into recess in the block (Fig. 65).

(2) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block

tab slots.

CAUTION: Do Not get oil on the bedplate mating

surface. It will affect the sealer ability to seal the

bedplate to cylinder block.

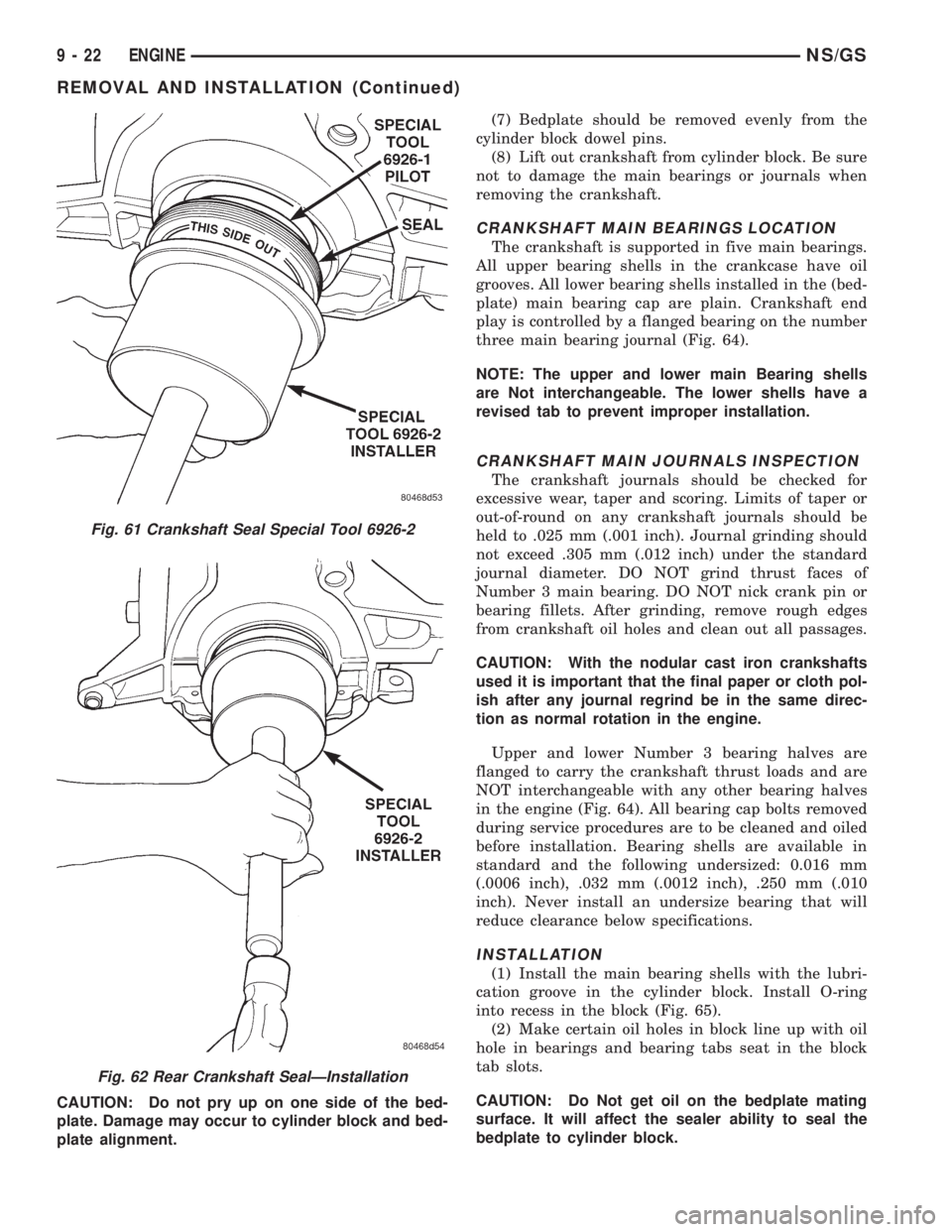

Fig. 61 Crankshaft Seal Special Tool 6926-2

Fig. 62 Rear Crankshaft SealÐInstallation

9 - 22 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1201 of 1938

(3) Oil the bearings and journals and install

crankshaft and O-ring in cylinder block.

CAUTION: Use only the specified anaerobic sealer

on the bedplate or damage may occur to the

engine.

(4) Apply 1.5 to 2.0 mm (0.059 to 0.078 in.) bead of

Mopar Torque Cure Gasket Maker to cylinder block

as shown in (Fig. 66).

(5) Install lower main bearings into main bearing

cap/bedplate. Make certain the bearing tabs areseated into the bedplate slots. Install the main bear-

ing/bedplate into engine block.

(6) Before installing the bolts oil threads with

clean engine oil, wipe off any excess oil.

(7) Install main bearing bedplate to engine block

bolts 11, 17 and 20 finger tight. Tighten this bolts

down together until the bedplate contacts the cylin-

der block. Torque bolts to 30 N´m (22 ft. lbs.) (Fig.

67).

Fig. 63 Bedplate BoltsFig. 64 Main Bearing Identification

NS/GSENGINE 9 - 23

REMOVAL AND INSTALLATION (Continued)

Page 1202 of 1938

(8) Install main bearing bedplate to engine block

bolts (1 thru 10) and torque each bolt to 81 N´m (60

ft. lbs.) in sequence shown in (Fig. 67).(9) Install main bearing bedplate to engine block

bolts (11 thru 20), with baffle studs in positions 12,

13 and 16 and torque each bolt to 30 N´m (22 ft. lbs.)

in sequence shown in (Fig. 67).

(10) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(11) Install oil pump. If crankshaft end play is to

be checked refer to service procedures in this section.

(12) Install crankshaft sprocket.

(13) Install oil filter adapter and filter.

(14) Install oil pan and collar. Refer to procedures

outlined in the section.

(15) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

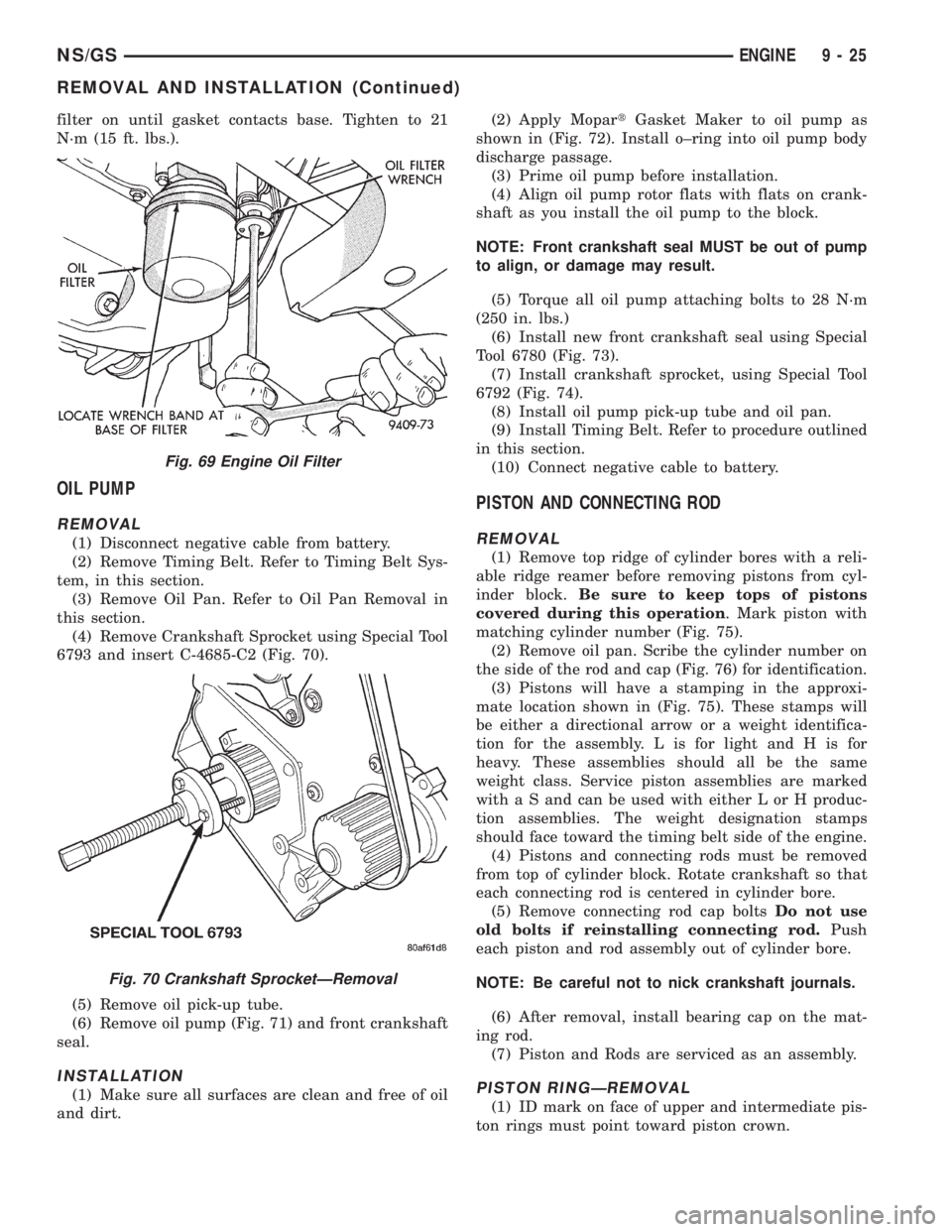

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 68).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 69)

avoid deforming the filter, install tool band strap

against the seam at the base of the filter. The seam,

joining the can to the base is reinforced by the

base plate.

(1) Turn counterclockwise to remove.

(2) To install, lubricate new filter gasket. Check

filter mounting surface. The surface must be smooth,

flat and free of debris or old pieces of rubber. Screw

Fig. 65 Installing Main Bearing Upper Shell

Fig. 66 Main Bearing Caps/Bedplate Sealing

Fig. 67 Main Bearing Caps/Bedplate Torque

Sequence

Fig. 68 Engine Oil Filter Adapter to Engine Block

9 - 24 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1203 of 1938

filter on until gasket contacts base. Tighten to 21

N´m (15 ft. lbs.).

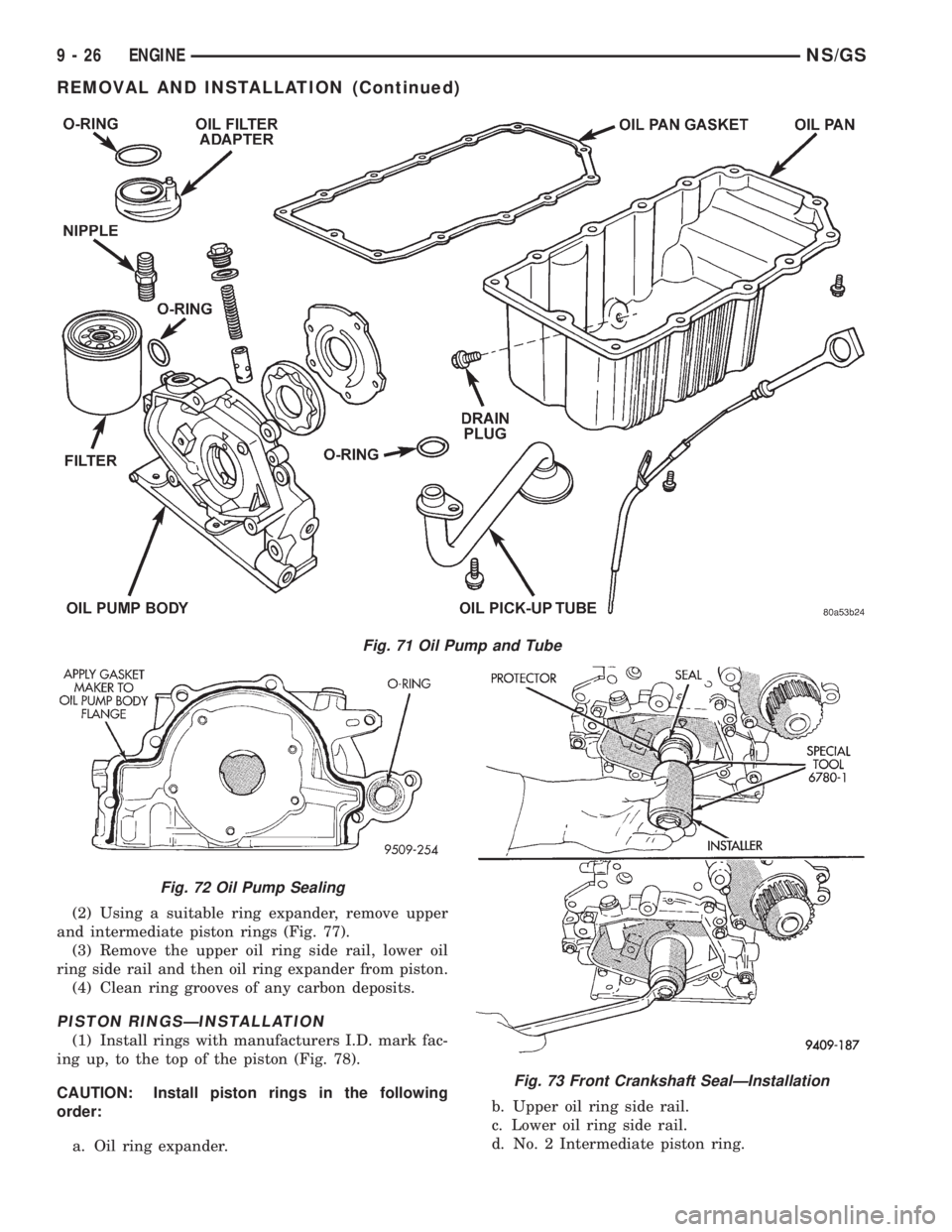

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove Timing Belt. Refer to Timing Belt Sys-

tem, in this section.

(3) Remove Oil Pan. Refer to Oil Pan Removal in

this section.

(4) Remove Crankshaft Sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 70).

(5) Remove oil pick-up tube.

(6) Remove oil pump (Fig. 71) and front crankshaft

seal.

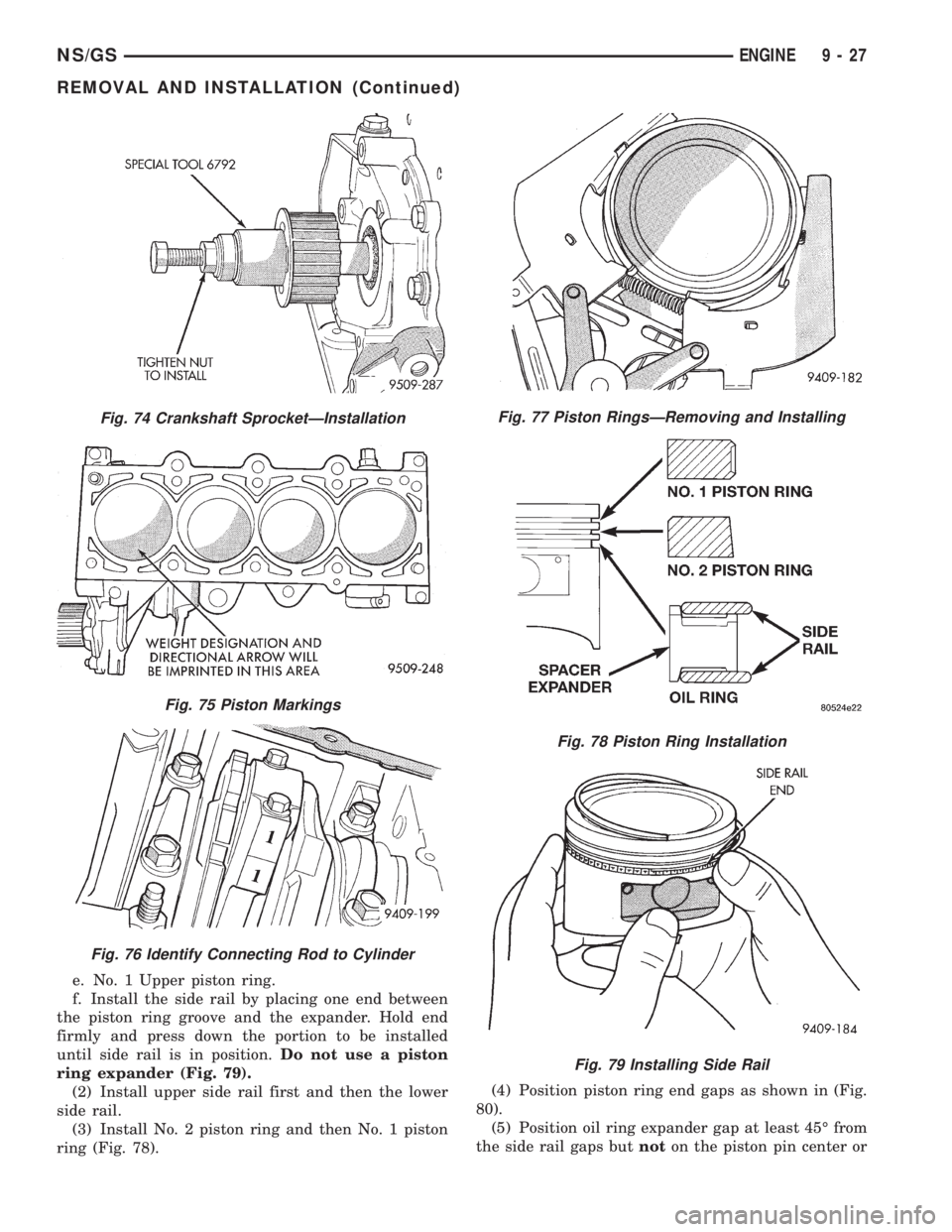

INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 72). Install o±ring into oil pump body

discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.)

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 73).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 74).

(8) Install oil pump pick-up tube and oil pan.

(9) Install Timing Belt. Refer to procedure outlined

in this section.

(10) Connect negative cable to battery.

PISTON AND CONNECTING ROD

REMOVAL

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 75).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 76) for identification.

(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 75). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

(6) After removal, install bearing cap on the mat-

ing rod.

(7) Piston and Rods are serviced as an assembly.

PISTON RINGÐREMOVAL

(1) ID mark on face of upper and intermediate pis-

ton rings must point toward piston crown.

Fig. 69 Engine Oil Filter

Fig. 70 Crankshaft SprocketÐRemoval

NS/GSENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1204 of 1938

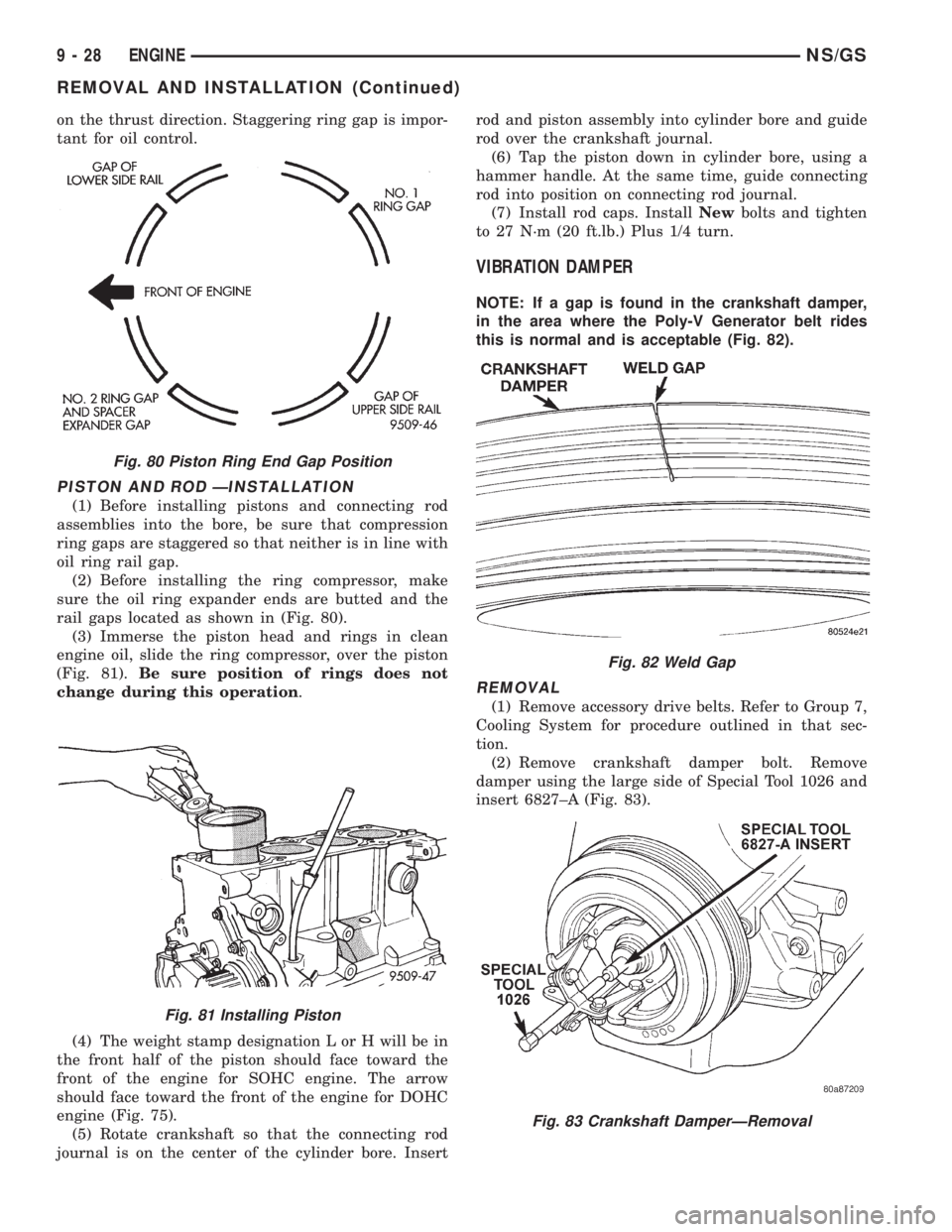

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 77).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Clean ring grooves of any carbon deposits.

PISTON RINGSÐINSTALLATION

(1) Install rings with manufacturers I.D. mark fac-

ing up, to the top of the piston (Fig. 78).

CAUTION: Install piston rings in the following

order:

a. Oil ring expander.b. Upper oil ring side rail.

c. Lower oil ring side rail.

d. No. 2 Intermediate piston ring.

Fig. 71 Oil Pump and Tube

Fig. 72 Oil Pump Sealing

Fig. 73 Front Crankshaft SealÐInstallation

9 - 26 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1205 of 1938

e. No. 1 Upper piston ring.

f. Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed

until side rail is in position.Do not use a piston

ring expander (Fig. 79).

(2) Install upper side rail first and then the lower

side rail.

(3) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 78).(4) Position piston ring end gaps as shown in (Fig.

80).

(5) Position oil ring expander gap at least 45É from

the side rail gaps butnoton the piston pin center or

Fig. 74 Crankshaft SprocketÐInstallation

Fig. 75 Piston Markings

Fig. 76 Identify Connecting Rod to Cylinder

Fig. 77 Piston RingsÐRemoving and Installing

Fig. 78 Piston Ring Installation

Fig. 79 Installing Side Rail

NS/GSENGINE 9 - 27

REMOVAL AND INSTALLATION (Continued)

Page 1206 of 1938

on the thrust direction. Staggering ring gap is impor-

tant for oil control.

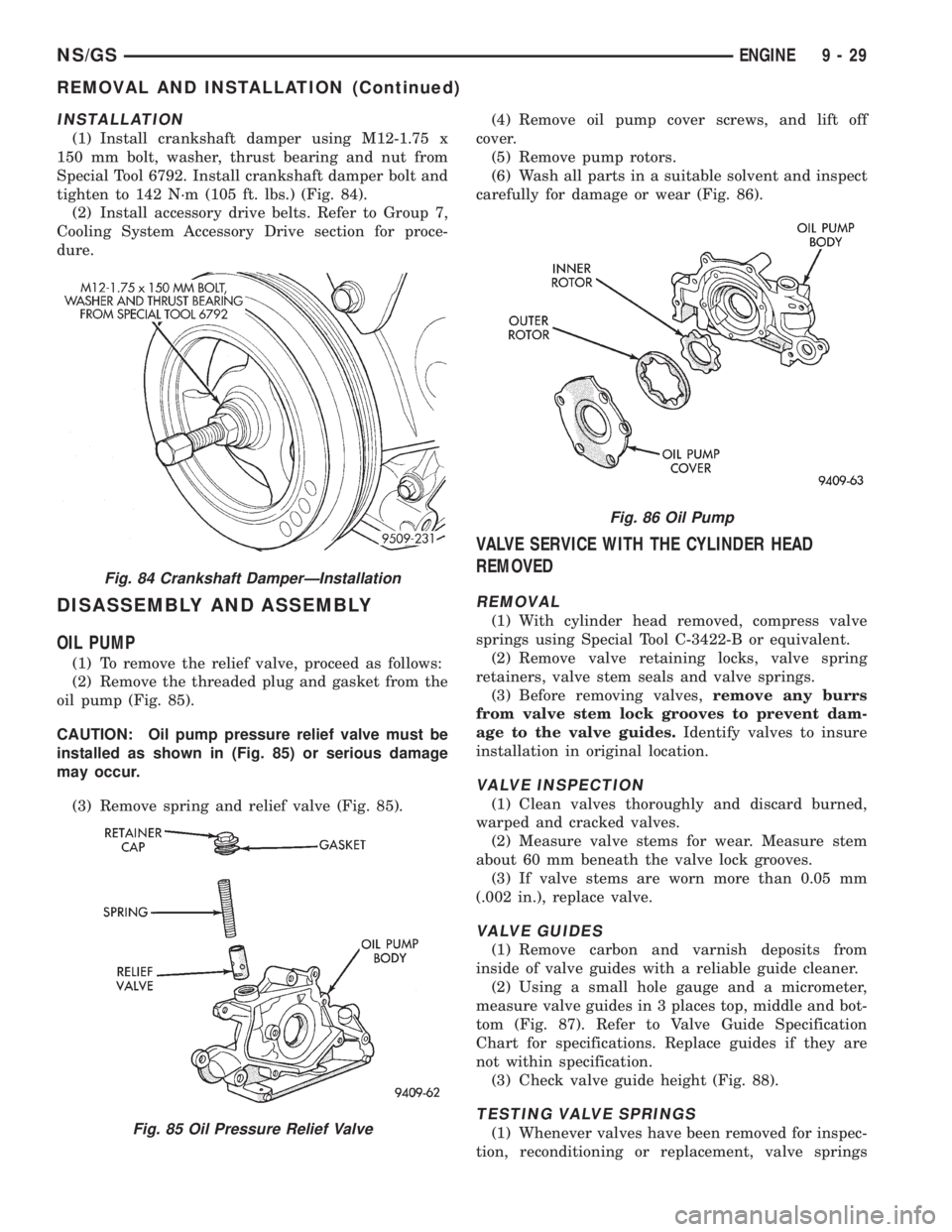

PISTON AND ROD ÐINSTALLATION

(1) Before installing pistons and connecting rod

assemblies into the bore, be sure that compression

ring gaps are staggered so that neither is in line with

oil ring rail gap.

(2) Before installing the ring compressor, make

sure the oil ring expander ends are butted and the

rail gaps located as shown in (Fig. 80).

(3) Immerse the piston head and rings in clean

engine oil, slide the ring compressor, over the piston

(Fig. 81).Be sure position of rings does not

change during this operation.

(4) The weight stamp designation L or H will be in

the front half of the piston should face toward the

front of the engine for SOHC engine. The arrow

should face toward the front of the engine for DOHC

engine (Fig. 75).

(5) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insertrod and piston assembly into cylinder bore and guide

rod over the crankshaft journal.

(6) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(7) Install rod caps. InstallNewbolts and tighten

to 27 N´m (20 ft.lb.) Plus 1/4 turn.

VIBRATION DAMPER

NOTE: If a gap is found in the crankshaft damper,

in the area where the Poly-V Generator belt rides

this is normal and is acceptable (Fig. 82).

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure outlined in that sec-

tion.

(2) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827±A (Fig. 83).

Fig. 80 Piston Ring End Gap Position

Fig. 81 Installing Piston

Fig. 82 Weld Gap

Fig. 83 Crankshaft DamperÐRemoval

9 - 28 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1207 of 1938

INSTALLATION

(1) Install crankshaft damper using M12-1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (105 ft. lbs.) (Fig. 84).

(2) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive section for proce-

dure.

DISASSEMBLY AND ASSEMBLY

OIL PUMP

(1) To remove the relief valve, proceed as follows:

(2) Remove the threaded plug and gasket from the

oil pump (Fig. 85).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 85) or serious damage

may occur.

(3) Remove spring and relief valve (Fig. 85).(4) Remove oil pump cover screws, and lift off

cover.

(5) Remove pump rotors.

(6) Wash all parts in a suitable solvent and inspect

carefully for damage or wear (Fig. 86).

VALVE SERVICE WITH THE CYLINDER HEAD

REMOVED

REMOVAL

(1) With cylinder head removed, compress valve

springs using Special Tool C-3422-B or equivalent.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

age to the valve guides.Identify valves to insure

installation in original location.

VALVE INSPECTION

(1) Clean valves thoroughly and discard burned,

warped and cracked valves.

(2) Measure valve stems for wear. Measure stem

about 60 mm beneath the valve lock grooves.

(3) If valve stems are worn more than 0.05 mm

(.002 in.), replace valve.

VALVE GUIDES

(1) Remove carbon and varnish deposits from

inside of valve guides with a reliable guide cleaner.

(2) Using a small hole gauge and a micrometer,

measure valve guides in 3 places top, middle and bot-

tom (Fig. 87). Refer to Valve Guide Specification

Chart for specifications. Replace guides if they are

not within specification.

(3) Check valve guide height (Fig. 88).

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

Fig. 84 Crankshaft DamperÐInstallation

Fig. 85 Oil Pressure Relief Valve

Fig. 86 Oil Pump

NS/GSENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1210 of 1938

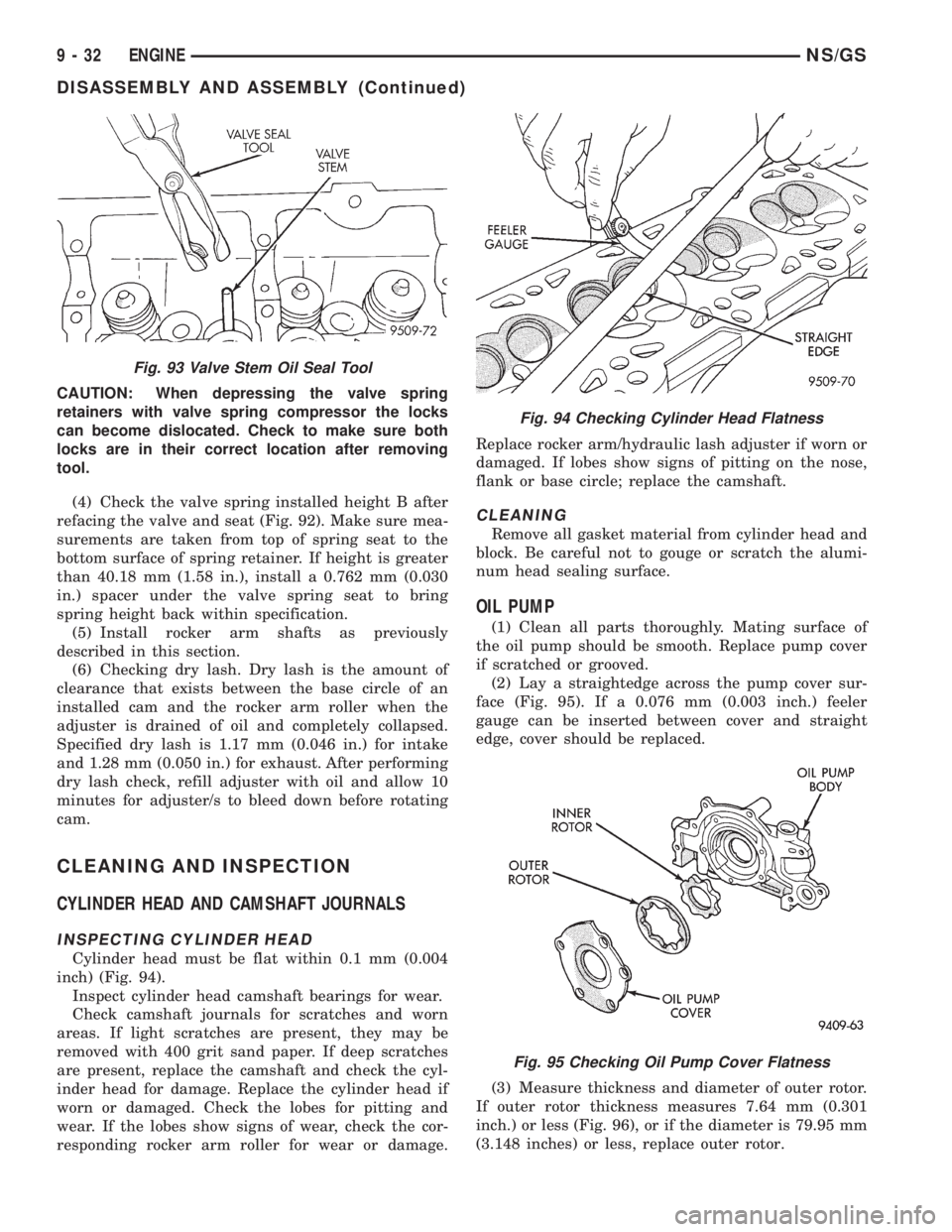

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 92). Make sure mea-

surements are taken from top of spring seat to the

bottom surface of spring retainer. If height is greater

than 40.18 mm (1.58 in.), install a 0.762 mm (0.030

in.) spacer under the valve spring seat to bring

spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster/s to bleed down before rotating

cam.

CLEANING AND INSPECTION

CYLINDER HEAD AND CAMSHAFT JOURNALS

INSPECTING CYLINDER HEAD

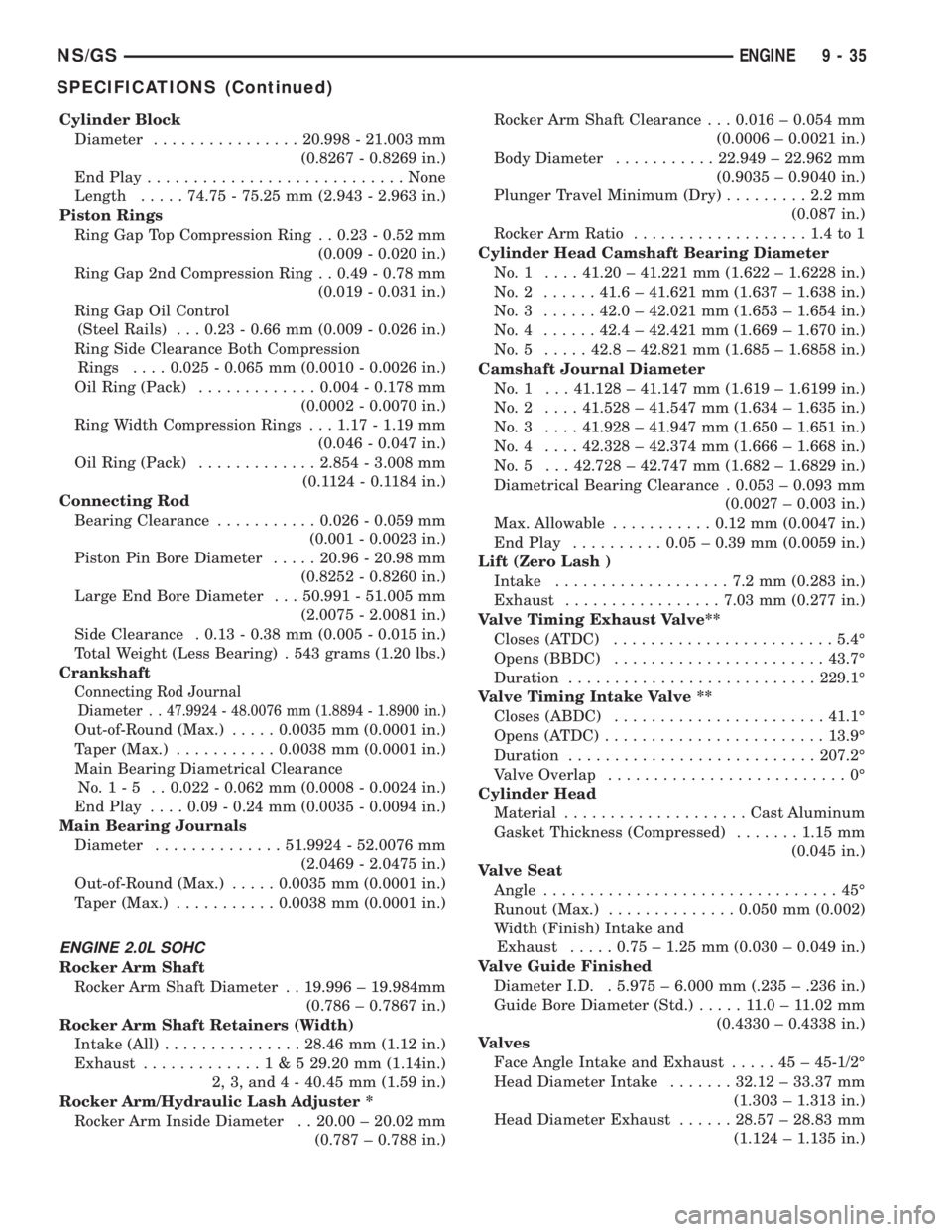

Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 94).

Inspect cylinder head camshaft bearings for wear.

Check camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head if

worn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 95). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 96), or if the diameter is 79.95 mm

(3.148 inches) or less, replace outer rotor.

Fig. 93 Valve Stem Oil Seal Tool

Fig. 94 Checking Cylinder Head Flatness

Fig. 95 Checking Oil Pump Cover Flatness

9 - 32 ENGINENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1213 of 1938

Cylinder Block

Diameter................20.998 - 21.003 mm

(0.8267 - 0.8269 in.)

End Play............................None

Length.....74.75 - 75.25 mm (2.943 - 2.963 in.)

Piston Rings

Ring Gap Top Compression Ring . . 0.23 - 0.52 mm

(0.009 - 0.020 in.)

Ring Gap 2nd Compression Ring . . 0.49 - 0.78 mm

(0.019 - 0.031 in.)

Ring Gap Oil Control

(Steel Rails) . . . 0.23 - 0.66 mm (0.009 - 0.026 in.)

Ring Side Clearance Both Compression

Rings....0.025 - 0.065 mm (0.0010 - 0.0026 in.)

Oil Ring (Pack).............0.004 - 0.178 mm

(0.0002 - 0.0070 in.)

Ring Width Compression Rings . . . 1.17 - 1.19 mm

(0.046 - 0.047 in.)

Oil Ring (Pack).............2.854 - 3.008 mm

(0.1124 - 0.1184 in.)

Connecting Rod

Bearing Clearance...........0.026 - 0.059 mm

(0.001 - 0.0023 in.)

Piston Pin Bore Diameter.....20.96 - 20.98 mm

(0.8252 - 0.8260 in.)

Large End Bore Diameter . . . 50.991 - 51.005 mm

(2.0075 - 2.0081 in.)

Side Clearance . 0.13 - 0.38 mm (0.005 - 0.015 in.)

Total Weight (Less Bearing) . 543 grams (1.20 lbs.)

Crankshaft

Connecting Rod Journal

Diameter . .

47.9924 - 48.0076 mm (1.8894 - 1.8900 in.)

Out-of-Round (Max.).....0.0035 mm (0.0001 in.)

Taper (Max.)...........0.0038 mm (0.0001 in.)

Main Bearing Diametrical Clearance

No.1-5 ..0.022 - 0.062 mm (0.0008 - 0.0024 in.)

End Play....0.09 - 0.24 mm (0.0035 - 0.0094 in.)

Main Bearing Journals

Diameter..............51.9924 - 52.0076 mm

(2.0469 - 2.0475 in.)

Out-of-Round (Max.).....0.0035 mm (0.0001 in.)

Taper (Max.)...........0.0038 mm (0.0001 in.)

ENGINE 2.0L SOHC

Rocker Arm Shaft

Rocker Arm Shaft Diameter . . 19.996 ± 19.984mm

(0.786 ± 0.7867 in.)

Rocker Arm Shaft Retainers (Width)

Intake (All)...............28.46 mm (1.12 in.)

Exhaust.............1&529.20 mm (1.14in.)

2, 3, and 4 - 40.45 mm (1.59 in.)

Rocker Arm/Hydraulic Lash Adjuster *

Rocker Arm Inside Diameter . . 20.00 ± 20.02 mm

(0.787 ± 0.788 in.)Rocker Arm Shaft Clearance . . . 0.016 ± 0.054 mm

(0.0006 ± 0.0021 in.)

Body Diameter...........22.949 ± 22.962 mm

(0.9035 ± 0.9040 in.)

Plunger Travel Minimum (Dry).........2.2mm

(0.087 in.)

Rocker Arm Ratio...................1.4to1

Cylinder Head Camshaft Bearing Diameter

No.1 ....41.20 ± 41.221 mm (1.622 ± 1.6228 in.)

No.2 ......41.6 ± 41.621 mm (1.637 ± 1.638 in.)

No.3 ......42.0 ± 42.021 mm (1.653 ± 1.654 in.)

No.4 ......42.4 ± 42.421 mm (1.669 ± 1.670 in.)

No.5 .....42.8 ± 42.821 mm (1.685 ± 1.6858 in.)

Camshaft Journal Diameter

No. 1 . . . 41.128 ± 41.147 mm (1.619 ± 1.6199 in.)

No.2 ....41.528 ± 41.547 mm (1.634 ± 1.635 in.)

No.3 ....41.928 ± 41.947 mm (1.650 ± 1.651 in.)

No.4 ....42.328 ± 42.374 mm (1.666 ± 1.668 in.)

No. 5 . . . 42.728 ± 42.747 mm (1.682 ± 1.6829 in.)

Diametrical Bearing Clearance . 0.053 ± 0.093 mm

(0.0027 ± 0.003 in.)

Max. Allowable...........0.12 mm (0.0047 in.)

End Play..........0.05 ± 0.39 mm (0.0059 in.)

Lift (Zero Lash )

Intake...................7.2mm(0.283 in.)

Exhaust.................7.03 mm (0.277 in.)

Valve Timing Exhaust Valve**

Closes (ATDC)........................5.4É

Opens (BBDC).......................43.7É

Duration...........................229.1É

Valve Timing Intake Valve **

Closes (ABDC).......................41.1É

Opens (ATDC)........................13.9É

Duration...........................207.2É

Valve Overlap..........................0É

Cylinder Head

Material....................Cast Aluminum

Gasket Thickness (Compressed).......1.15 mm

(0.045 in.)

Valve Seat

Angle................................45É

Runout (Max.)..............0.050 mm (0.002)

Width (Finish) Intake and

Exhaust.....0.75 ± 1.25 mm (0.030 ± 0.049 in.)

Valve Guide Finished

Diameter I.D. . 5.975 ± 6.000 mm (.235 ± .236 in.)

Guide Bore Diameter (Std.).....11.0±11.02 mm

(0.4330 ± 0.4338 in.)

Valves

Face Angle Intake and Exhaust.....45±45-1/2É

Head Diameter Intake.......32.12 ± 33.37 mm

(1.303 ± 1.313 in.)

Head Diameter Exhaust......28.57 ± 28.83 mm

(1.124 ± 1.135 in.)

NS/GSENGINE 9 - 35

SPECIFICATIONS (Continued)