shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1214 of 1938

Valve Margin

Intake.....1.15 ± 1.48 mm (0.0452 ± 0.0582 in.)

Exhaust....1.475 ± 1.805 mm (0.058 ± 0.071 in.)

Valve Length (Overall)

Intake....114.69 ± 115.19 mm (4.515 ± 4.535 in.)

Exhaust . . 109.59 ± 110.09 mm (4.603 ± 4.623 in.)

Valve Stem Tip Height

Intake.......45.01 ± 46.07 mm (1.77 ± 1.81 in.)

Exhaust......43.51 ± 44.57 mm (1.71 ± 1.75 in.)

Stem Diameter

Intake.....5.934 ± 5.952 mm (0.234 ± 0.234 in.)

Exhaust....5.906 ± 5.924 mm (0.233 ± 0.233 in.)

Stem to Guide Clearance

Intake . . . 0.048 ± 0.066 mm (0.0018 ± 0.0025 in.)

Exhaust . 0.0736 ± 0.094 mm (0.0029 ± 0.0037 in.)

Max. Allowable Intake.....0.076 mm (0.003 in.)

Max. Allowable Exhaust....0.101 mm (0.004 in.)

Valve Springs

Free Length (Approx.)......44.4 mm (1.747 in.)

Nominal Force (Valve closed) . 91 N´m @ 39.8 mm

(67 ft. lbs. @ 1.57 in.)

Nominal Force (Valve open) . 239 N´m @ 32.6 mm

(176 lbs. @ 1.28 in.)

Installed Height..........40.18 mm (1.580 in.)

* SERVICE AS AN ASSEMBLY WITH ROCKER

ARM.

** ALL READINGS IN CRANKSHAFT DEGREES,

AT 0.5 mm (0.019 in.) OF VALVE LIFT.

TORQUE CHART 2.0L SOHC

DESCRIPTION...................TORQUE

Camshaft Sensor Pick Up

Bolts...................9.6N´m(85in.lbs.)

Camshaft Sprocket

Bolt....................115N´m(85ft.lbs.)

Connecting Rod Cap

Bolts.........27N´m(20ft.lbs.) Plus 1/4 Turn

CollarÐOil Pan to Transaxle

Step 1: Collar to Oil Pan Bolts . 3 N´m (30 in. lbs.)

Step 2: Collar to Transaxle

Bolts...................108N´m(80ft.lbs.)

Step 3: Collar to Oil Pan

Bolts....................54N´m(40ft.lbs.)

Crankshaft Main Bearing Cap/Bedplate

M8 Bedplate Bolts..........30N´m(22ft.lbs.)

M11 Main Cap Bolts........81N´m(60ft.lbs.)

Crankshaft Damper

Bolt...................142N´m(105 ft. lbs.)

Cylinder Head

Bolts.......Refer To Cylinder Head Installation

Cylinder Head Cover

Bolts...................12N´m(105 in. lbs.)

Engine Mount BracketÐRight

Bolts....................61N´m(45ft.lbs.)DESCRIPTION...................TORQUE

Engine Mounting

Bolts.......Refer to Engine Mount Installation

Exhaust Manifold to Cylinder Head

Bolts...................23N´m(200 in. lbs.)

Exhaust Manifold Heat Shield

Bolts...................12N´m(105 in. lbs.)

Intake Manifold

Bolts...................12N´m(105 in. lbs.)

Oil Filter Adapter

Fastener.................80N´m(60ft.lbs.)

Oil Filter.................20N´m(15ft.lbs.)

Oil Pan

Bolts...................12N´m(105 in. lbs.)

Drain Plug...............27N´m(20ft.lbs.)

Oil Pump Attaching

Bolts...................28N´m(250 in. lbs.)

Oil Pump Cover Fastener . . . 12 N´m (105 in. lbs.)

Oil Pump Pick-up Tube Bolt . 28 N´m (250 in. lbs.)

Oil Pump Relief Valve Cap . . . 41 N´m (30 ft. lbs.)

Rocker Arm Shaft

Bolts...................28N´m(250 in. lbs.)

Spark Plugs...............28N´m(20ft.lbs.)

Thermostat Housing

Bolts...................23N´m(200 in lbs.)

Timing Belt Cover

Bolts M6................12N´m(105 in. lbs.)

Timing Belt Mechanical Tensioner Assembly

Bolts...................28N´m(250 in. lbs.)

Timing Belt Hydraulic Tensioner

Pulley Bolt...............68N´m(50ft.lbs.)

Pivot Bracket Bolt..........31N´m(23ft.lbs.)

Tensioner Bolts............31N´m(23ft.lbs.)

Water Pump Mounting

Bolts...................12N´m(105 in. lbs.)

SPECIAL TOOLS

ENGINE 2.0L SOHC

Puller 1026

9 - 36 ENGINENS/GS

SPECIFICATIONS (Continued)

Page 1215 of 1938

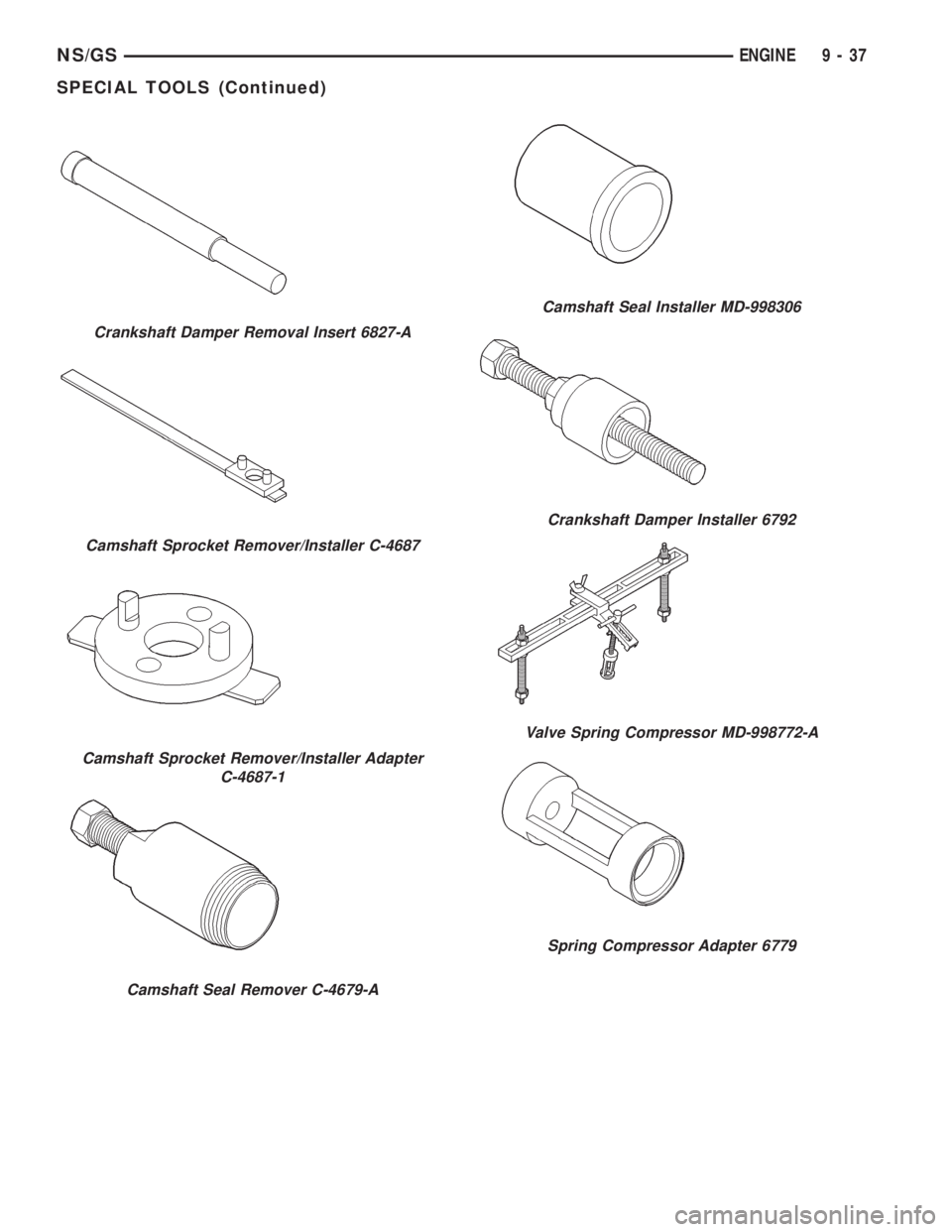

Crankshaft Damper Removal Insert 6827-A

Camshaft Sprocket Remover/Installer C-4687

Camshaft Sprocket Remover/Installer Adapter

C-4687-1

Camshaft Seal Remover C-4679-A

Camshaft Seal Installer MD-998306

Crankshaft Damper Installer 6792

Valve Spring Compressor MD-998772-A

Spring Compressor Adapter 6779

NS/GSENGINE 9 - 37

SPECIAL TOOLS (Continued)

Page 1216 of 1938

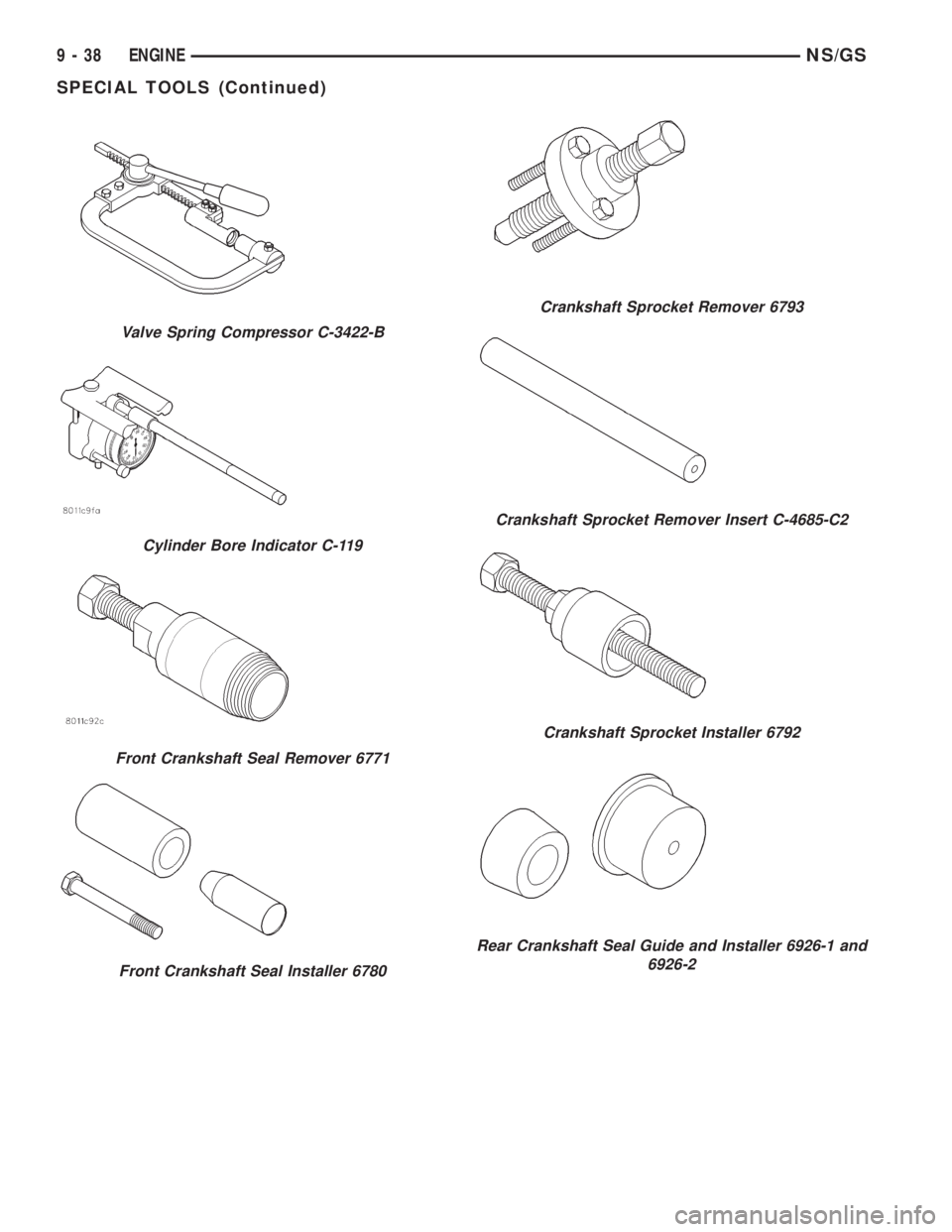

Valve Spring Compressor C-3422-B

Cylinder Bore Indicator C-119

Front Crankshaft Seal Remover 6771

Front Crankshaft Seal Installer 6780

Crankshaft Sprocket Remover 6793

Crankshaft Sprocket Remover Insert C-4685-C2

Crankshaft Sprocket Installer 6792

Rear Crankshaft Seal Guide and Installer 6926-1 and

6926-2

9 - 38 ENGINENS/GS

SPECIAL TOOLS (Continued)

Page 1218 of 1938

2.5L VM DIESEL

INDEX

page page

GENERAL INFORMATION

ENGINE IDENTIFICATION................ 41

GENERAL SPECIFICATION............... 40

DESCRIPTION AND OPERATION

LUBRICATION SYSTEM.................. 41

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐMECHANICAL....... 44

ENGINE DIAGNOSISÐPERFORMANCE..... 43

HYDRAULIC TAPPETS................... 47

SERVICE PROCEDURES

CHANGING ENGINE OIL AND FILTER....... 47

CHECKING OIL LEVEL................... 47

CRANKSHAFT END PLAY................ 50

FITTING PISTON RING.................. 50

TIMING PROCEDURE................... 49

VALVE AND SEAT REFACING............. 49

REMOVAL AND INSTALLATION

CAMSHAFT........................... 62

CAMSHAFT BEARINGS.................. 63

CRANKSHAFT MAIN BEARINGS........... 63

CRANKSHAFTÐREMOVAL............... 72

CYLINDER HEAD....................... 55

CYLINDER HEAD COVER................ 54

CYLINDER LINER...................... 72

ENGINE ASSEMBLY..................... 53

ENGINE MOUNTÐFRONT................ 51

ENGINE MOUNTÐREAR................. 52

ENGINE MOUNTÐRIGHT................ 51

HYDRAULIC TAPPETS................... 60

INJECTION PUMP...................... 61

MOUNTÐLEFT SIDE.................... 51

OIL FILTER ADAPTER AND OIL COOLER.... 68

OILPAN .............................. 66OIL PUMP............................ 67

OIL PUMP PRESSURE RELIEF VALVE...... 67

PISTONS AND CONNECTING ROD......... 68

REAR CRANKSHAFT OIL SEAL............ 72

ROCKER ARMS AND PUSH RODS......... 54

TIMING GEAR COVER................... 61

TIMING GEAR COVER OIL SEAL........... 61

VACUUM PUMP........................ 68

VALVE SPRINGSÐCYLINDER HEAD NOT

REMOVED.......................... 55

VALVES AND VALVE SPRINGSÐHEAD OFF . . 60

VIBRATION DAMPER.................... 61

DISASSEMBLY AND ASSEMBLY

HYDRAULIC TAPPETS................... 73

CLEANING AND INSPECTION

CRANKSHAFT......................... 77

CRANKSHAFT MAIN BEARING............ 77

CYLINDER HEAD....................... 75

CYLINDER HEAD COVERS............... 74

CYLINDER LINER...................... 78

HYDRAULIC TAPPETS................... 76

OILPAN .............................. 78

OIL PUMP............................ 76

PISTON AND CONNECTING ROD.......... 76

ROCKER ARMS AND PUSH RODS......... 74

TIMING GEAR COVER................... 75

VALVES AND VALVE SPRINGS............ 76

SPECIFICATIONS

2.5L VM DIESEL........................ 78

TORQUE............................. 80

SPECIAL TOOLS

2.5L VM DIESEL........................ 81

GENERAL INFORMATION

GENERAL SPECIFICATION

Type ........................425CLIEE (36B)

Displacement...................2.5L (2499 cc)

Bore.............................92.00 mm

Stroke............................94.00 mm

Compression Ratio....................20.95:1

Vacuum at Idle..........600mm/Hg (23.6 In/Hg)

Thermostat Opening................80ÉC62ÉC

Generator Rating............Bosch 50/120 Amp

Cooling System Capacity..............9.5Liter

Power Steering Capacity.............0.75 LiterType ........................425CLIEE (36B)

Engine Oil Capacity.....6.5Liters With Oil Filter

Change

Timing System . Pushrod Operated Overhead valves,

With Gear-Driven Camshaft.

Air Intake........................DryFilter

Fuel Feed...........Vacuum Pump Incorporated

in Injection Pump.

Fuel System.............Indirect Fuel Injection

(Precombustion Chamber)

Combustion Cycle....................4Stroke

Cooling System..................Water Cooled

Injection Pump.......Rotary Pump Electronically

Controlled.

9 - 40 ENGINENS/GS

Page 1219 of 1938

Type ........................425CLIEE (36B)

Lubrication . Pressure Lubrication by Rotary Pump,

Full-Flow Filtration

Engine Rotation....Clockwise Viewed From Front

Cover

ENGINE IDENTIFICATION

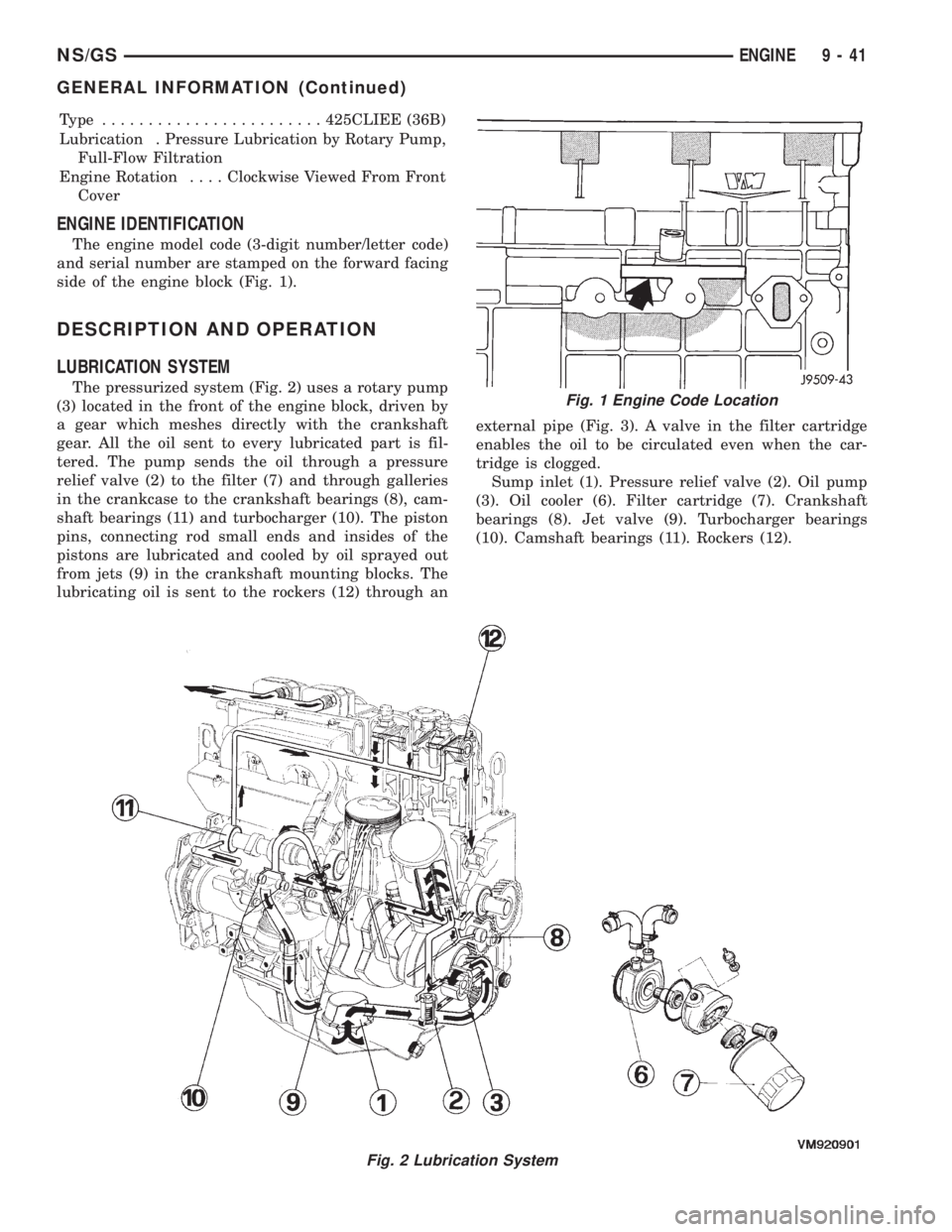

The engine model code (3-digit number/letter code)

and serial number are stamped on the forward facing

side of the engine block (Fig. 1).

DESCRIPTION AND OPERATION

LUBRICATION SYSTEM

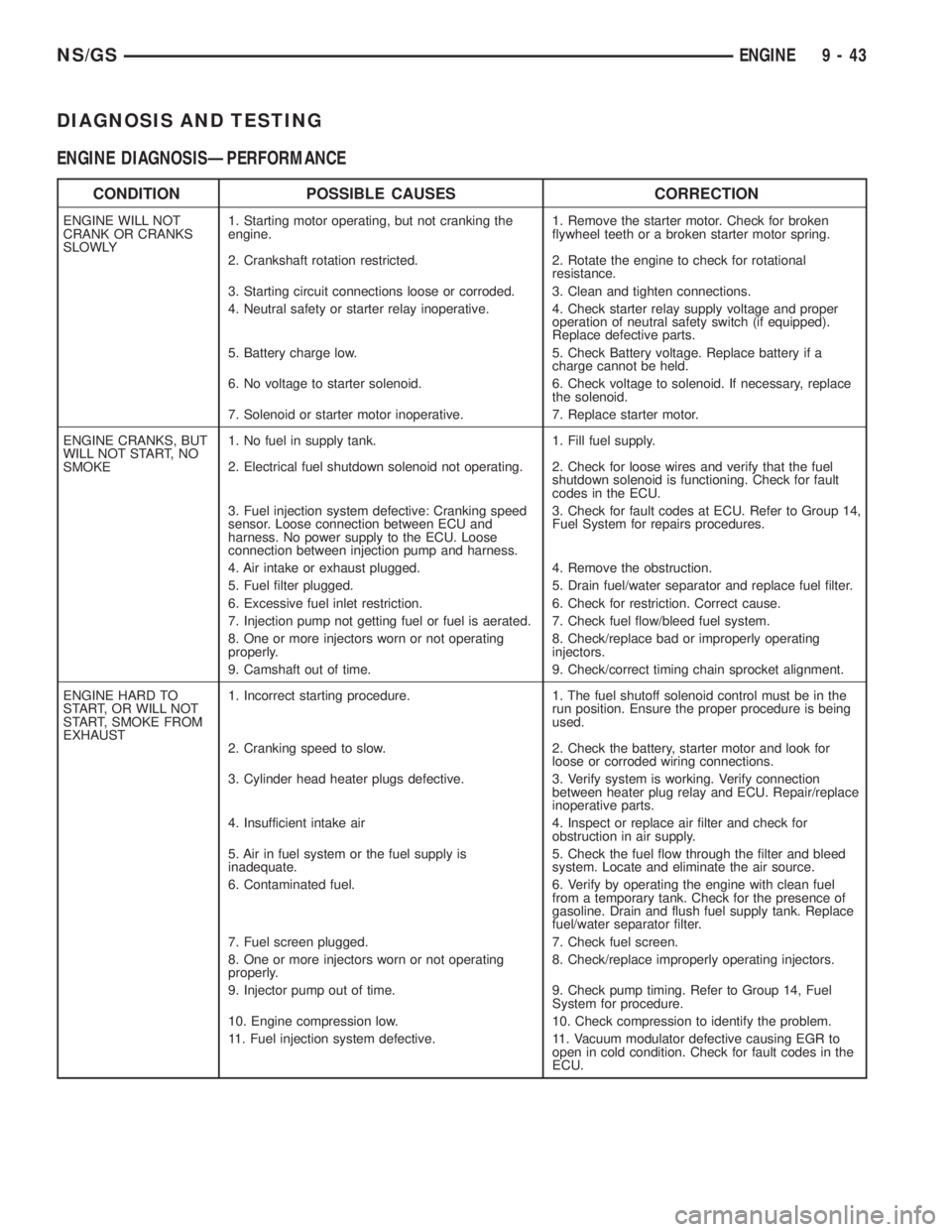

The pressurized system (Fig. 2) uses a rotary pump

(3) located in the front of the engine block, driven by

a gear which meshes directly with the crankshaft

gear. All the oil sent to every lubricated part is fil-

tered. The pump sends the oil through a pressure

relief valve (2) to the filter (7) and through galleries

in the crankcase to the crankshaft bearings (8), cam-

shaft bearings (11) and turbocharger (10). The piston

pins, connecting rod small ends and insides of the

pistons are lubricated and cooled by oil sprayed out

from jets (9) in the crankshaft mounting blocks. The

lubricating oil is sent to the rockers (12) through anexternal pipe (Fig. 3). A valve in the filter cartridge

enables the oil to be circulated even when the car-

tridge is clogged.

Sump inlet (1). Pressure relief valve (2). Oil pump

(3). Oil cooler (6). Filter cartridge (7). Crankshaft

bearings (8). Jet valve (9). Turbocharger bearings

(10). Camshaft bearings (11). Rockers (12).

Fig. 2 Lubrication System

Fig. 1 Engine Code Location

NS/GSENGINE 9 - 41

GENERAL INFORMATION (Continued)

Page 1221 of 1938

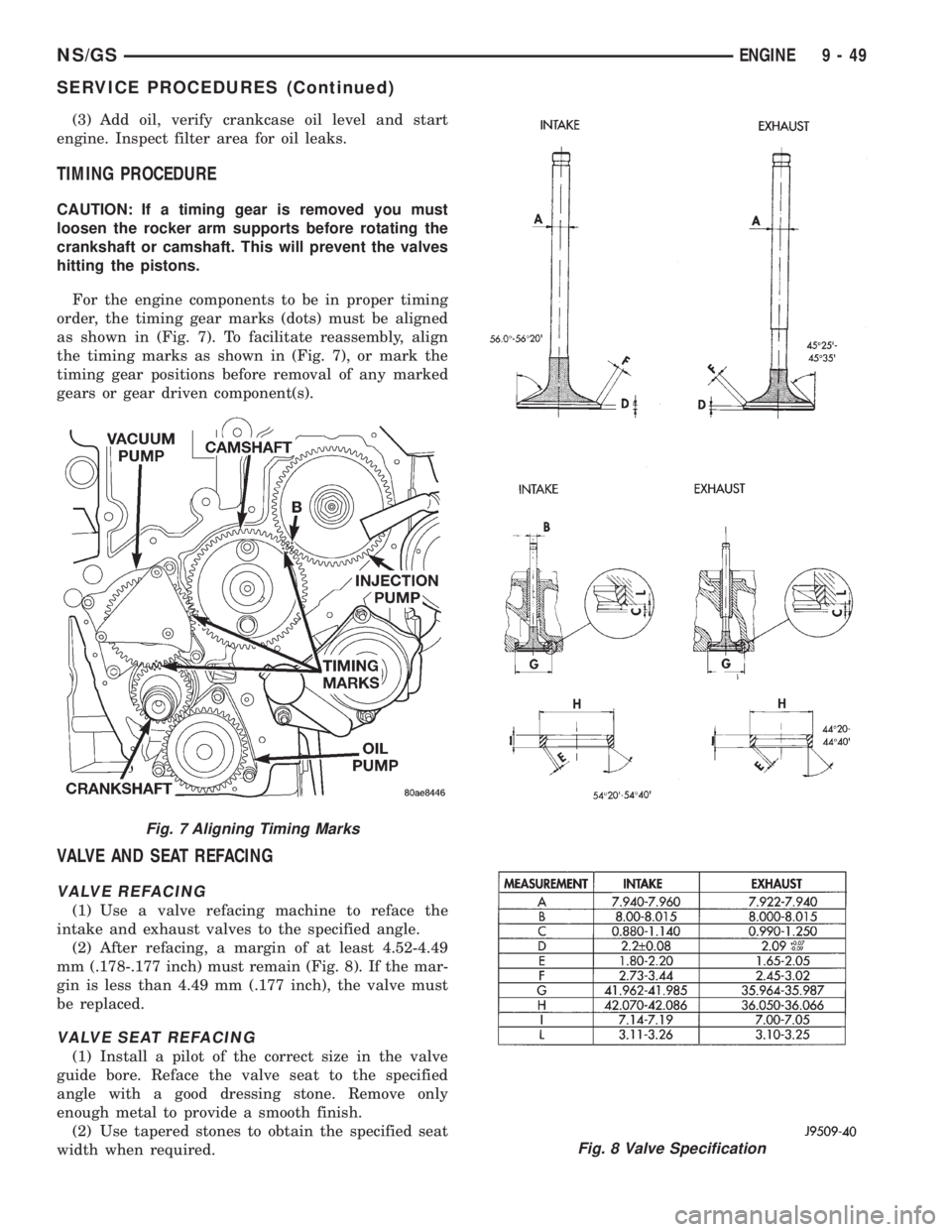

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐPERFORMANCE

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT

CRANK OR CRANKS

SLOWLY1. Starting motor operating, but not cranking the

engine.1. Remove the starter motor. Check for broken

flywheel teeth or a broken starter motor spring.

2. Crankshaft rotation restricted. 2. Rotate the engine to check for rotational

resistance.

3. Starting circuit connections loose or corroded. 3. Clean and tighten connections.

4. Neutral safety or starter relay inoperative. 4. Check starter relay supply voltage and proper

operation of neutral safety switch (if equipped).

Replace defective parts.

5. Battery charge low. 5. Check Battery voltage. Replace battery if a

charge cannot be held.

6. No voltage to starter solenoid. 6. Check voltage to solenoid. If necessary, replace

the solenoid.

7. Solenoid or starter motor inoperative. 7. Replace starter motor.

ENGINE CRANKS, BUT

WILL NOT START, NO

SMOKE1. No fuel in supply tank. 1. Fill fuel supply.

2. Electrical fuel shutdown solenoid not operating. 2. Check for loose wires and verify that the fuel

shutdown solenoid is functioning. Check for fault

codes in the ECU.

3. Fuel injection system defective: Cranking speed

sensor. Loose connection between ECU and

harness. No power supply to the ECU. Loose

connection between injection pump and harness.3. Check for fault codes at ECU. Refer to Group 14,

Fuel System for repairs procedures.

4. Air intake or exhaust plugged. 4. Remove the obstruction.

5. Fuel filter plugged. 5. Drain fuel/water separator and replace fuel filter.

6. Excessive fuel inlet restriction. 6. Check for restriction. Correct cause.

7. Injection pump not getting fuel or fuel is aerated. 7. Check fuel flow/bleed fuel system.

8. One or more injectors worn or not operating

properly.8. Check/replace bad or improperly operating

injectors.

9. Camshaft out of time. 9. Check/correct timing chain sprocket alignment.

ENGINE HARD TO

START, OR WILL NOT

START, SMOKE FROM

EXHAUST1. Incorrect starting procedure. 1. The fuel shutoff solenoid control must be in the

run position. Ensure the proper procedure is being

used.

2. Cranking speed to slow. 2. Check the battery, starter motor and look for

loose or corroded wiring connections.

3. Cylinder head heater plugs defective. 3. Verify system is working. Verify connection

between heater plug relay and ECU. Repair/replace

inoperative parts.

4. Insufficient intake air 4. Inspect or replace air filter and check for

obstruction in air supply.

5. Air in fuel system or the fuel supply is

inadequate.5. Check the fuel flow through the filter and bleed

system. Locate and eliminate the air source.

6. Contaminated fuel. 6. Verify by operating the engine with clean fuel

from a temporary tank. Check for the presence of

gasoline. Drain and flush fuel supply tank. Replace

fuel/water separator filter.

7. Fuel screen plugged. 7. Check fuel screen.

8. One or more injectors worn or not operating

properly.8. Check/replace improperly operating injectors.

9. Injector pump out of time. 9. Check pump timing. Refer to Group 14, Fuel

System for procedure.

10. Engine compression low. 10. Check compression to identify the problem.

11. Fuel injection system defective. 11. Vacuum modulator defective causing EGR to

open in cold condition. Check for fault codes in the

ECU.

NS/GSENGINE 9 - 43

Page 1227 of 1938

(3) Add oil, verify crankcase oil level and start

engine. Inspect filter area for oil leaks.

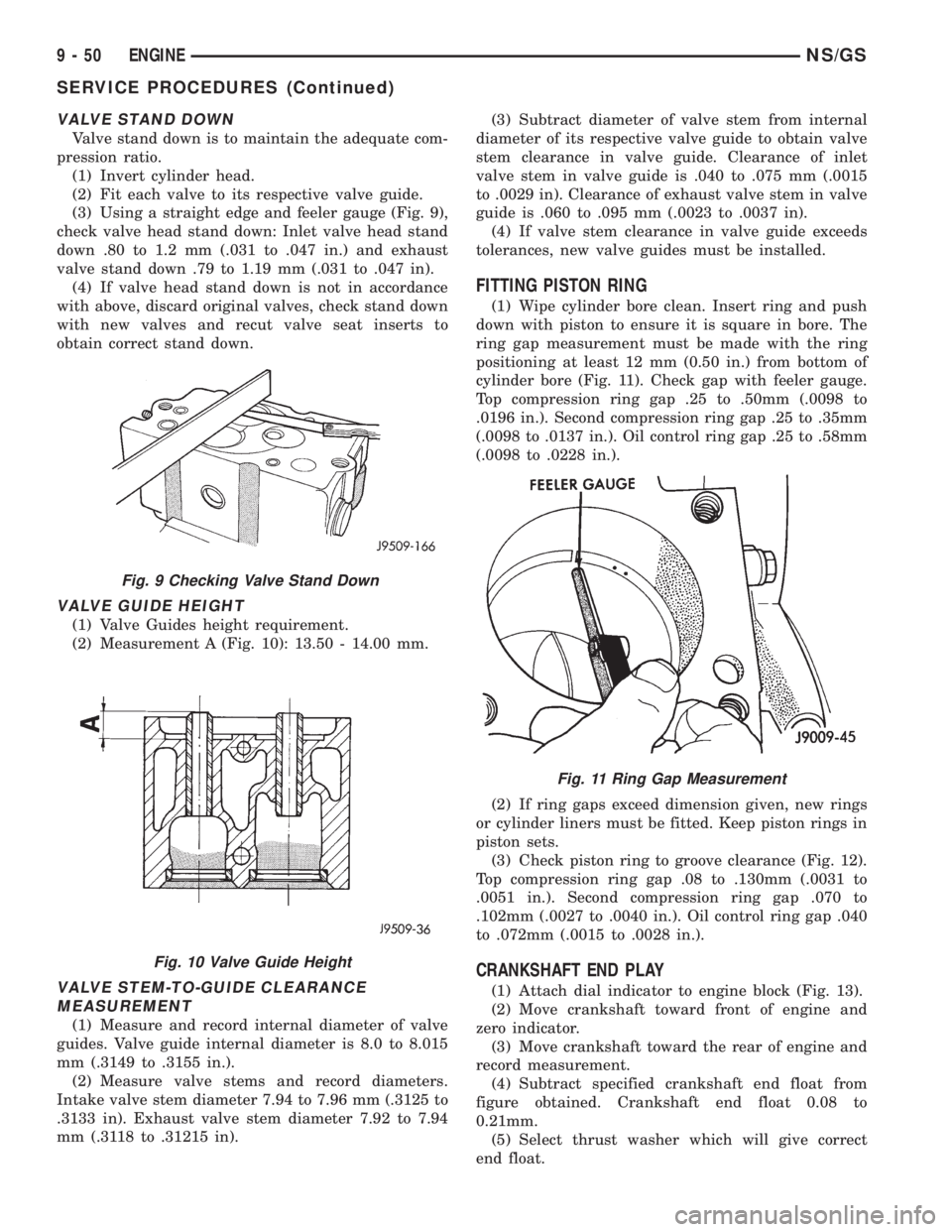

TIMING PROCEDURE

CAUTION: If a timing gear is removed you must

loosen the rocker arm supports before rotating the

crankshaft or camshaft. This will prevent the valves

hitting the pistons.

For the engine components to be in proper timing

order, the timing gear marks (dots) must be aligned

as shown in (Fig. 7). To facilitate reassembly, align

the timing marks as shown in (Fig. 7), or mark the

timing gear positions before removal of any marked

gears or gear driven component(s).

VALVE AND SEAT REFACING

VALVE REFACING

(1) Use a valve refacing machine to reface the

intake and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 4.52-4.49

mm (.178-.177 inch) must remain (Fig. 8). If the mar-

gin is less than 4.49 mm (.177 inch), the valve must

be replaced.

VALVE SEAT REFACING

(1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified

angle with a good dressing stone. Remove only

enough metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

Fig. 7 Aligning Timing Marks

Fig. 8 Valve Specification

NS/GSENGINE 9 - 49

SERVICE PROCEDURES (Continued)

Page 1228 of 1938

VALVE STAND DOWN

Valve stand down is to maintain the adequate com-

pression ratio.

(1) Invert cylinder head.

(2) Fit each valve to its respective valve guide.

(3) Using a straight edge and feeler gauge (Fig. 9),

check valve head stand down: Inlet valve head stand

down .80 to 1.2 mm (.031 to .047 in.) and exhaust

valve stand down .79 to 1.19 mm (.031 to .047 in).

(4) If valve head stand down is not in accordance

with above, discard original valves, check stand down

with new valves and recut valve seat inserts to

obtain correct stand down.

VALVE GUIDE HEIGHT

(1) Valve Guides height requirement.

(2) Measurement A (Fig. 10): 13.50 - 14.00 mm.

VALVE STEM-TO-GUIDE CLEARANCE

MEASUREMENT

(1) Measure and record internal diameter of valve

guides. Valve guide internal diameter is 8.0 to 8.015

mm (.3149 to .3155 in.).

(2) Measure valve stems and record diameters.

Intake valve stem diameter 7.94 to 7.96 mm (.3125 to

.3133 in). Exhaust valve stem diameter 7.92 to 7.94

mm (.3118 to .31215 in).(3) Subtract diameter of valve stem from internal

diameter of its respective valve guide to obtain valve

stem clearance in valve guide. Clearance of inlet

valve stem in valve guide is .040 to .075 mm (.0015

to .0029 in). Clearance of exhaust valve stem in valve

guide is .060 to .095 mm (.0023 to .0037 in).

(4) If valve stem clearance in valve guide exceeds

tolerances, new valve guides must be installed.

FITTING PISTON RING

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 in.) from bottom of

cylinder bore (Fig. 11). Check gap with feeler gauge.

Top compression ring gap .25 to .50mm (.0098 to

.0196 in.). Second compression ring gap .25 to .35mm

(.0098 to .0137 in.). Oil control ring gap .25 to .58mm

(.0098 to .0228 in.).

(2) If ring gaps exceed dimension given, new rings

or cylinder liners must be fitted. Keep piston rings in

piston sets.

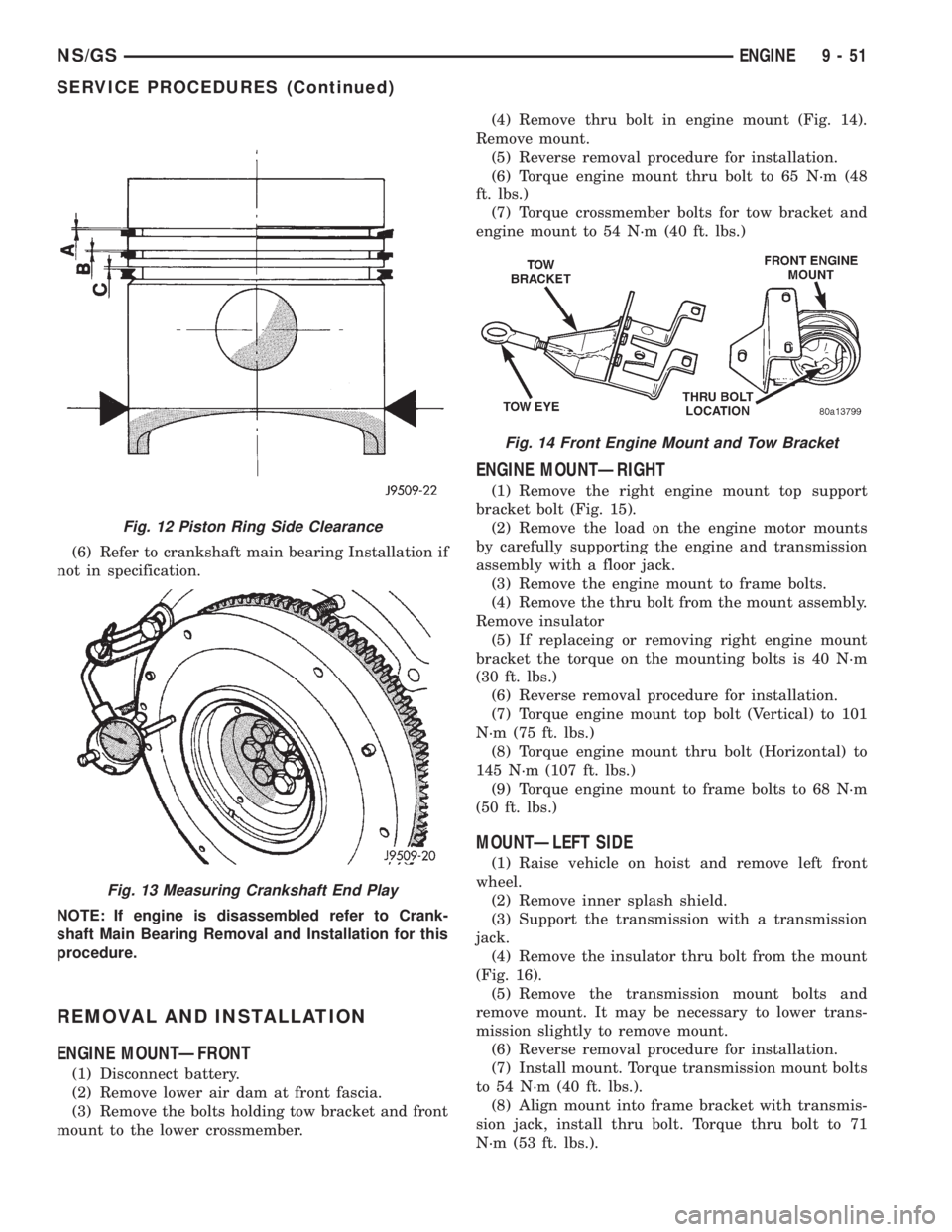

(3) Check piston ring to groove clearance (Fig. 12).

Top compression ring gap .08 to .130mm (.0031 to

.0051 in.). Second compression ring gap .070 to

.102mm (.0027 to .0040 in.). Oil control ring gap .040

to .072mm (.0015 to .0028 in.).

CRANKSHAFT END PLAY

(1) Attach dial indicator to engine block (Fig. 13).

(2) Move crankshaft toward front of engine and

zero indicator.

(3) Move crankshaft toward the rear of engine and

record measurement.

(4) Subtract specified crankshaft end float from

figure obtained. Crankshaft end float 0.08 to

0.21mm.

(5) Select thrust washer which will give correct

end float.

Fig. 9 Checking Valve Stand Down

Fig. 10 Valve Guide Height

Fig. 11 Ring Gap Measurement

9 - 50 ENGINENS/GS

SERVICE PROCEDURES (Continued)

Page 1229 of 1938

(6) Refer to crankshaft main bearing Installation if

not in specification.

NOTE: If engine is disassembled refer to Crank-

shaft Main Bearing Removal and Installation for this

procedure.

REMOVAL AND INSTALLATION

ENGINE MOUNTÐFRONT

(1) Disconnect battery.

(2) Remove lower air dam at front fascia.

(3) Remove the bolts holding tow bracket and front

mount to the lower crossmember.(4) Remove thru bolt in engine mount (Fig. 14).

Remove mount.

(5) Reverse removal procedure for installation.

(6) Torque engine mount thru bolt to 65 N´m (48

ft. lbs.)

(7) Torque crossmember bolts for tow bracket and

engine mount to 54 N´m (40 ft. lbs.)

ENGINE MOUNTÐRIGHT

(1) Remove the right engine mount top support

bracket bolt (Fig. 15).

(2) Remove the load on the engine motor mounts

by carefully supporting the engine and transmission

assembly with a floor jack.

(3) Remove the engine mount to frame bolts.

(4) Remove the thru bolt from the mount assembly.

Remove insulator

(5) If replaceing or removing right engine mount

bracket the torque on the mounting bolts is 40 N´m

(30 ft. lbs.)

(6) Reverse removal procedure for installation.

(7) Torque engine mount top bolt (Vertical) to 101

N´m (75 ft. lbs.)

(8) Torque engine mount thru bolt (Horizontal) to

145 N´m (107 ft. lbs.)

(9) Torque engine mount to frame bolts to 68 N´m

(50 ft. lbs.)

MOUNTÐLEFT SIDE

(1) Raise vehicle on hoist and remove left front

wheel.

(2) Remove inner splash shield.

(3) Support the transmission with a transmission

jack.

(4) Remove the insulator thru bolt from the mount

(Fig. 16).

(5) Remove the transmission mount bolts and

remove mount. It may be necessary to lower trans-

mission slightly to remove mount.

(6) Reverse removal procedure for installation.

(7) Install mount. Torque transmission mount bolts

to 54 N´m (40 ft. lbs.).

(8) Align mount into frame bracket with transmis-

sion jack, install thru bolt. Torque thru bolt to 71

N´m (53 ft. lbs.).

Fig. 12 Piston Ring Side Clearance

Fig. 13 Measuring Crankshaft End Play

Fig. 14 Front Engine Mount and Tow Bracket

NS/GSENGINE 9 - 51

SERVICE PROCEDURES (Continued)

Page 1232 of 1938

(28) Remove radiator support bolts.It is neces-

sary to loosen the receiver/dryer to gain access

to the radiator bolts.

(29) Remove radiator and fans as an assembly.

(30) Remove accessory drive belt generator/power

steering. Refer to Group 7, for procedure.

(31) Remove both power steering lines at pump,

and cap both lines.

NOTE: It is not necessary to discharge A/C system

for engine removal.

(32) Remove A/C compressor. Secure compressor

away from engine for clearance during engine

removal.

(33) Remove Generator and adjusting bracket.

NOTE: Do not remove the mounting base from the

generator. It is aligned at the factory and cannot be

realigned in the field.

(34) Hoist vehicle.

(35) Remove exhaust pipe at turbo outlet.

(36) Remove connections at starter.

(37) Remove power steering high pressure line

bracket at rear of oil pan.

(38) Remove both driveshafts from transaxle. Refer

to Group 2, Suspension and Driveshafts.

(39) Disconnect clutch cable at transaxle.

(40) Remove reinforcement plate on lower cross-

member.

(41) Remove front and rear engine mounts. Refer

to procedure outlined in this section.

(42) Drain engine oil and remove oil filter if neces-

sary.

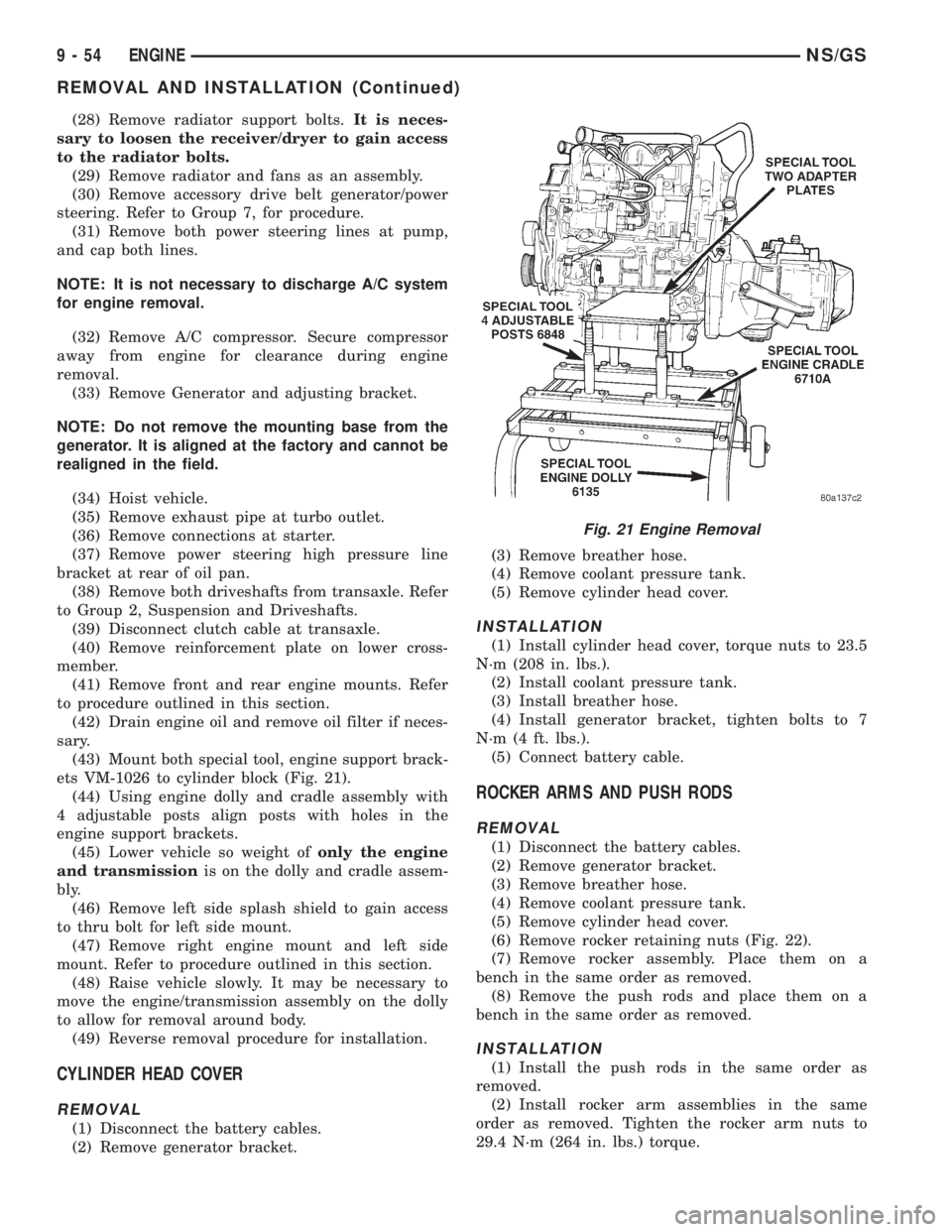

(43) Mount both special tool, engine support brack-

ets VM-1026 to cylinder block (Fig. 21).

(44) Using engine dolly and cradle assembly with

4 adjustable posts align posts with holes in the

engine support brackets.

(45) Lower vehicle so weight ofonly the engine

and transmissionis on the dolly and cradle assem-

bly.

(46) Remove left side splash shield to gain access

to thru bolt for left side mount.

(47) Remove right engine mount and left side

mount. Refer to procedure outlined in this section.

(48) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the dolly

to allow for removal around body.

(49) Reverse removal procedure for installation.

CYLINDER HEAD COVER

REMOVAL

(1) Disconnect the battery cables.

(2) Remove generator bracket.(3) Remove breather hose.

(4) Remove coolant pressure tank.

(5) Remove cylinder head cover.

INSTALLATION

(1) Install cylinder head cover, torque nuts to 23.5

N´m (208 in. lbs.).

(2) Install coolant pressure tank.

(3) Install breather hose.

(4) Install generator bracket, tighten bolts to 7

N´m (4 ft. lbs.).

(5) Connect battery cable.

ROCKER ARMS AND PUSH RODS

REMOVAL

(1) Disconnect the battery cables.

(2) Remove generator bracket.

(3) Remove breather hose.

(4) Remove coolant pressure tank.

(5) Remove cylinder head cover.

(6) Remove rocker retaining nuts (Fig. 22).

(7) Remove rocker assembly. Place them on a

bench in the same order as removed.

(8) Remove the push rods and place them on a

bench in the same order as removed.

INSTALLATION

(1) Install the push rods in the same order as

removed.

(2) Install rocker arm assemblies in the same

order as removed. Tighten the rocker arm nuts to

29.4 N´m (264 in. lbs.) torque.

Fig. 21 Engine Removal

9 - 54 ENGINENS/GS

REMOVAL AND INSTALLATION (Continued)