air filter CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1195 of 1938

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

OIL PAN

REMOVAL

(1) Drain engine oil.

(2) Remove transmission inspection cover.

(3) If equipped with air conditioning remove oil fil-

ter and adaptor. Refer to Oil Filter Adapter Removal

and Installation in this section.

(4) Remove oil pan.(5) Clean oil pan and all gasket surfaces.

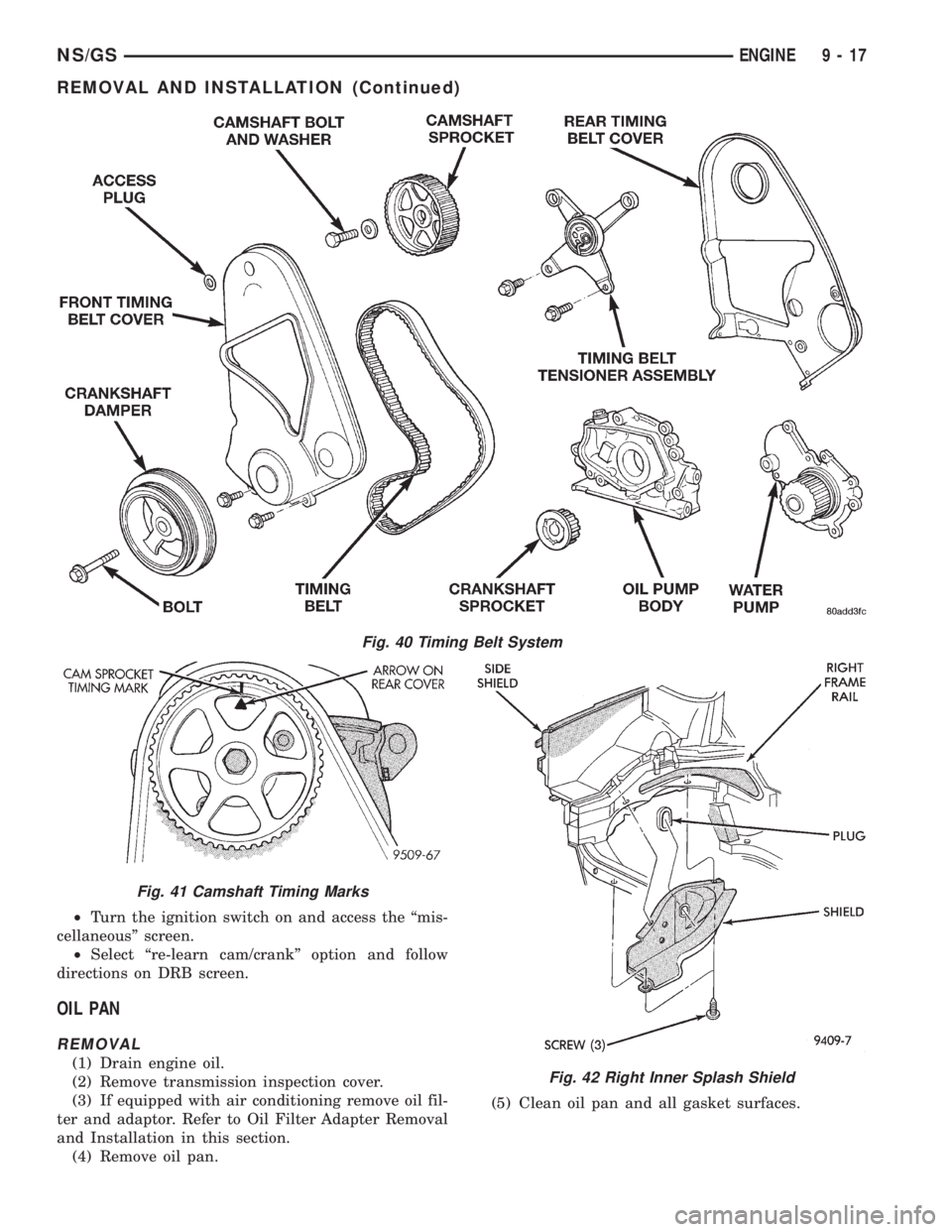

Fig. 40 Timing Belt System

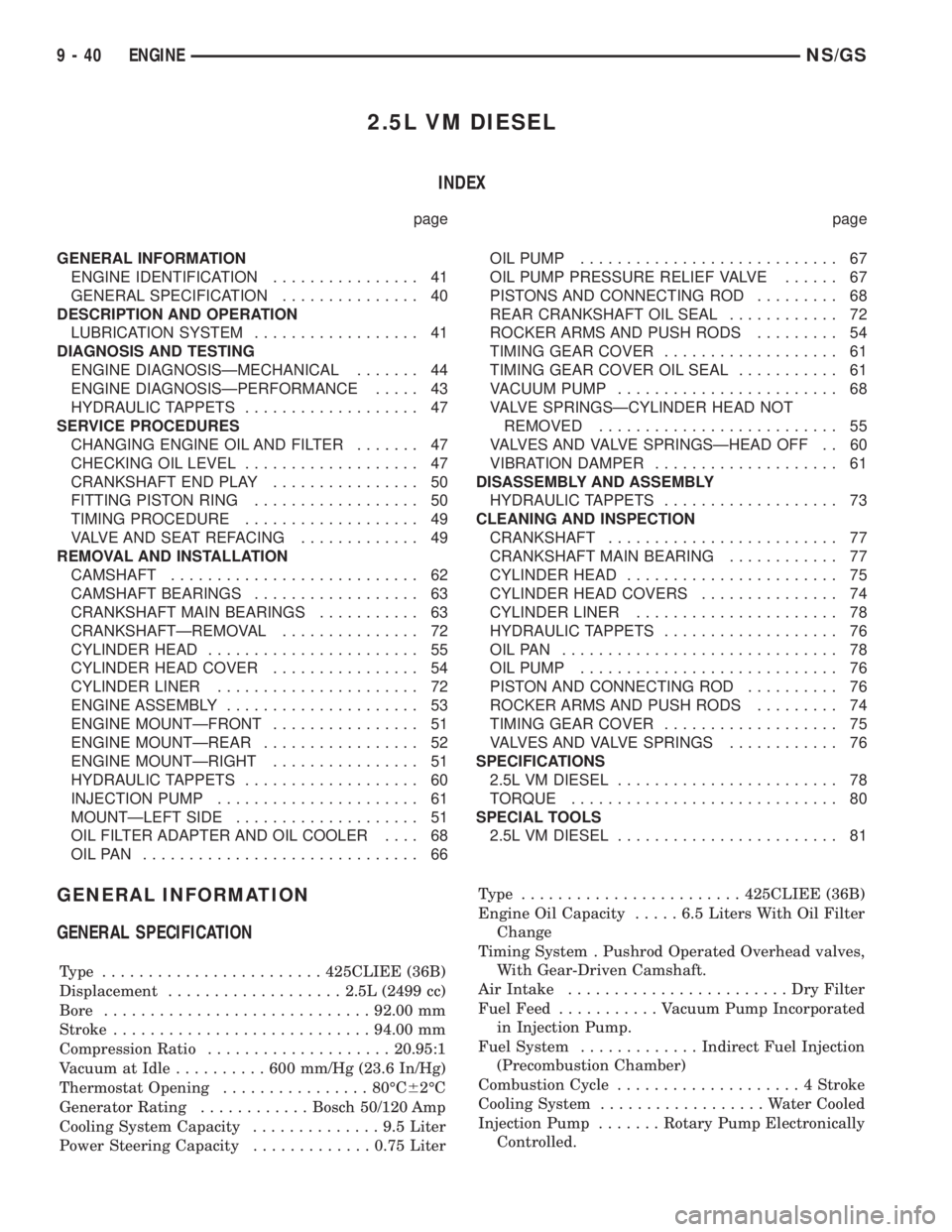

Fig. 41 Camshaft Timing Marks

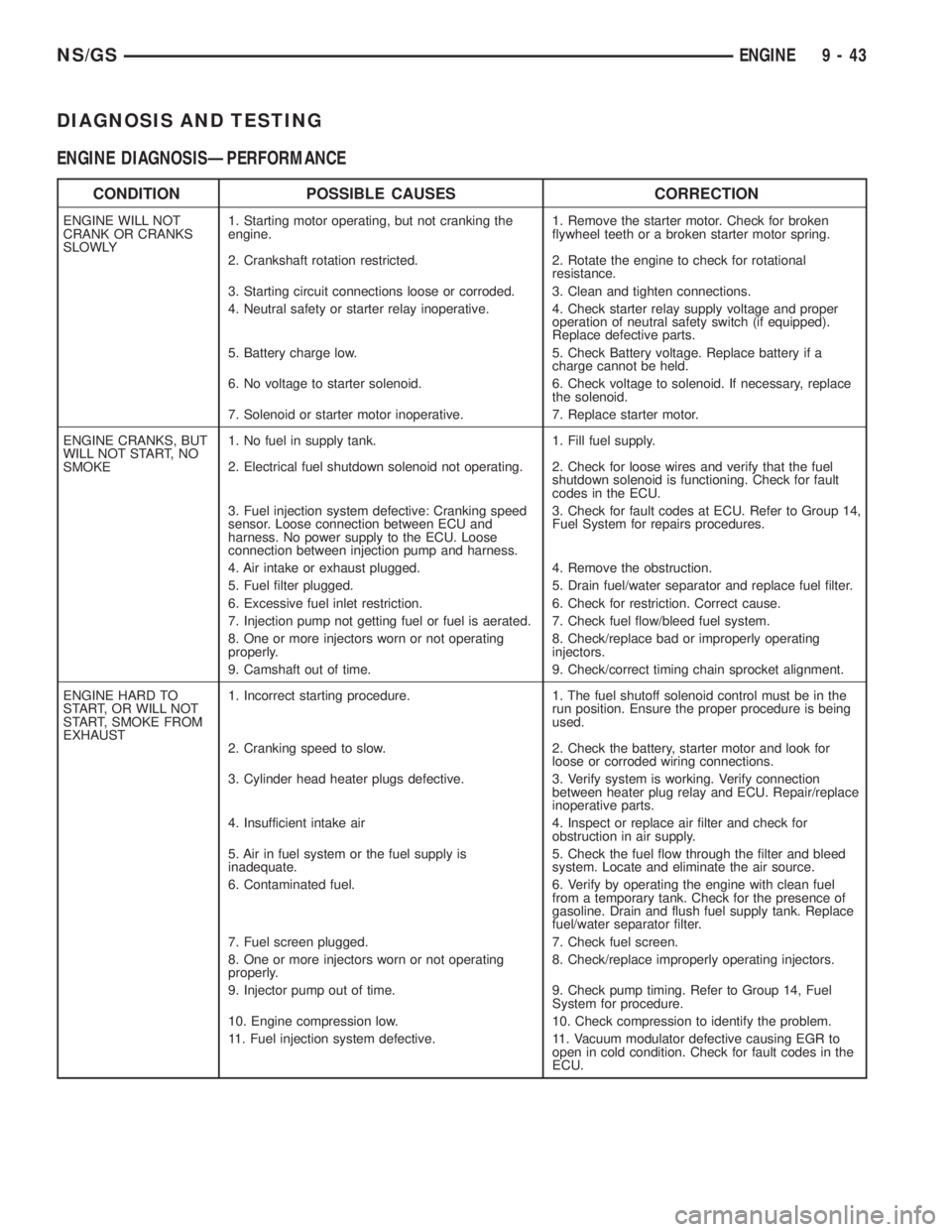

Fig. 42 Right Inner Splash Shield

NS/GSENGINE 9 - 17

REMOVAL AND INSTALLATION (Continued)

Page 1218 of 1938

2.5L VM DIESEL

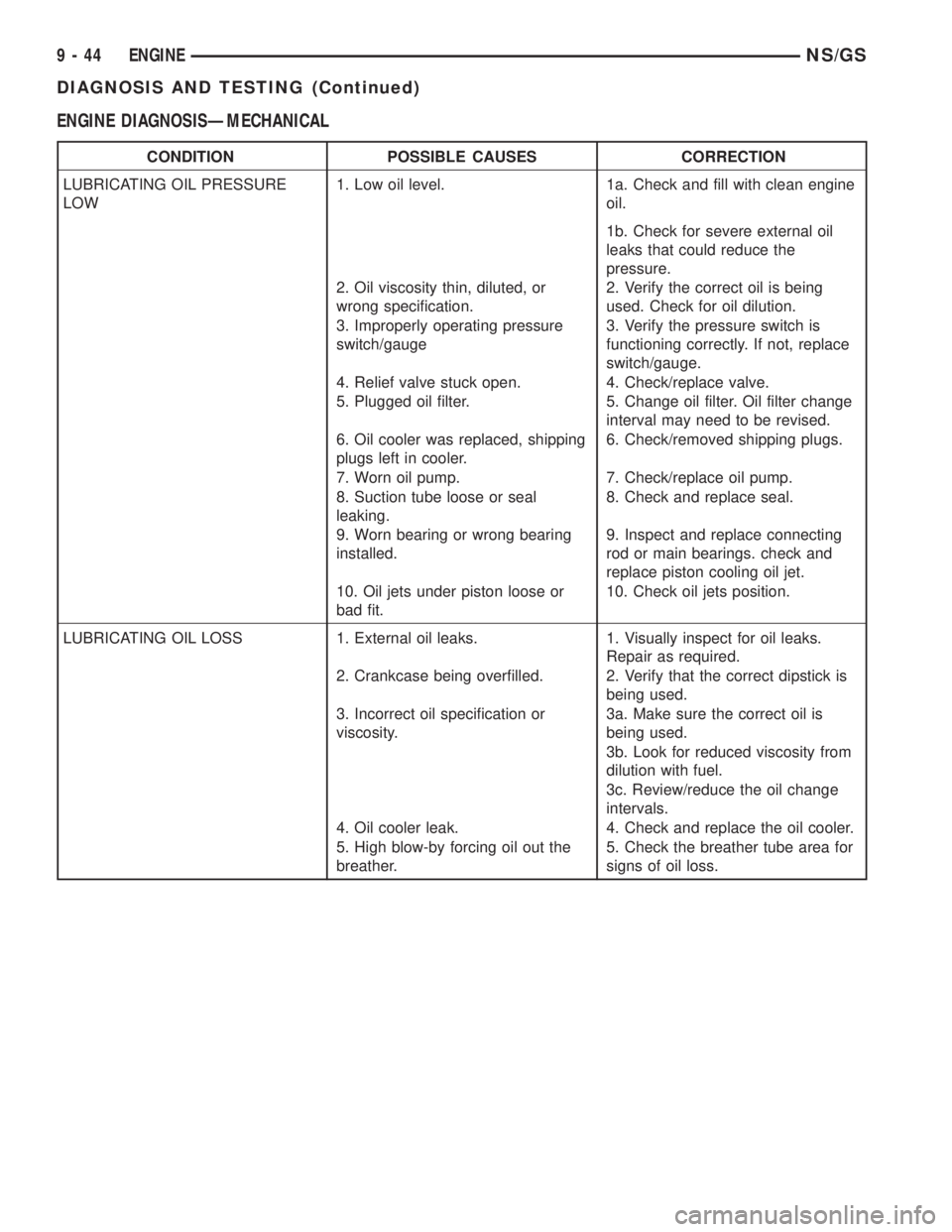

INDEX

page page

GENERAL INFORMATION

ENGINE IDENTIFICATION................ 41

GENERAL SPECIFICATION............... 40

DESCRIPTION AND OPERATION

LUBRICATION SYSTEM.................. 41

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐMECHANICAL....... 44

ENGINE DIAGNOSISÐPERFORMANCE..... 43

HYDRAULIC TAPPETS................... 47

SERVICE PROCEDURES

CHANGING ENGINE OIL AND FILTER....... 47

CHECKING OIL LEVEL................... 47

CRANKSHAFT END PLAY................ 50

FITTING PISTON RING.................. 50

TIMING PROCEDURE................... 49

VALVE AND SEAT REFACING............. 49

REMOVAL AND INSTALLATION

CAMSHAFT........................... 62

CAMSHAFT BEARINGS.................. 63

CRANKSHAFT MAIN BEARINGS........... 63

CRANKSHAFTÐREMOVAL............... 72

CYLINDER HEAD....................... 55

CYLINDER HEAD COVER................ 54

CYLINDER LINER...................... 72

ENGINE ASSEMBLY..................... 53

ENGINE MOUNTÐFRONT................ 51

ENGINE MOUNTÐREAR................. 52

ENGINE MOUNTÐRIGHT................ 51

HYDRAULIC TAPPETS................... 60

INJECTION PUMP...................... 61

MOUNTÐLEFT SIDE.................... 51

OIL FILTER ADAPTER AND OIL COOLER.... 68

OILPAN .............................. 66OIL PUMP............................ 67

OIL PUMP PRESSURE RELIEF VALVE...... 67

PISTONS AND CONNECTING ROD......... 68

REAR CRANKSHAFT OIL SEAL............ 72

ROCKER ARMS AND PUSH RODS......... 54

TIMING GEAR COVER................... 61

TIMING GEAR COVER OIL SEAL........... 61

VACUUM PUMP........................ 68

VALVE SPRINGSÐCYLINDER HEAD NOT

REMOVED.......................... 55

VALVES AND VALVE SPRINGSÐHEAD OFF . . 60

VIBRATION DAMPER.................... 61

DISASSEMBLY AND ASSEMBLY

HYDRAULIC TAPPETS................... 73

CLEANING AND INSPECTION

CRANKSHAFT......................... 77

CRANKSHAFT MAIN BEARING............ 77

CYLINDER HEAD....................... 75

CYLINDER HEAD COVERS............... 74

CYLINDER LINER...................... 78

HYDRAULIC TAPPETS................... 76

OILPAN .............................. 78

OIL PUMP............................ 76

PISTON AND CONNECTING ROD.......... 76

ROCKER ARMS AND PUSH RODS......... 74

TIMING GEAR COVER................... 75

VALVES AND VALVE SPRINGS............ 76

SPECIFICATIONS

2.5L VM DIESEL........................ 78

TORQUE............................. 80

SPECIAL TOOLS

2.5L VM DIESEL........................ 81

GENERAL INFORMATION

GENERAL SPECIFICATION

Type ........................425CLIEE (36B)

Displacement...................2.5L (2499 cc)

Bore.............................92.00 mm

Stroke............................94.00 mm

Compression Ratio....................20.95:1

Vacuum at Idle..........600mm/Hg (23.6 In/Hg)

Thermostat Opening................80ÉC62ÉC

Generator Rating............Bosch 50/120 Amp

Cooling System Capacity..............9.5Liter

Power Steering Capacity.............0.75 LiterType ........................425CLIEE (36B)

Engine Oil Capacity.....6.5Liters With Oil Filter

Change

Timing System . Pushrod Operated Overhead valves,

With Gear-Driven Camshaft.

Air Intake........................DryFilter

Fuel Feed...........Vacuum Pump Incorporated

in Injection Pump.

Fuel System.............Indirect Fuel Injection

(Precombustion Chamber)

Combustion Cycle....................4Stroke

Cooling System..................Water Cooled

Injection Pump.......Rotary Pump Electronically

Controlled.

9 - 40 ENGINENS/GS

Page 1221 of 1938

DIAGNOSIS AND TESTING

ENGINE DIAGNOSISÐPERFORMANCE

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WILL NOT

CRANK OR CRANKS

SLOWLY1. Starting motor operating, but not cranking the

engine.1. Remove the starter motor. Check for broken

flywheel teeth or a broken starter motor spring.

2. Crankshaft rotation restricted. 2. Rotate the engine to check for rotational

resistance.

3. Starting circuit connections loose or corroded. 3. Clean and tighten connections.

4. Neutral safety or starter relay inoperative. 4. Check starter relay supply voltage and proper

operation of neutral safety switch (if equipped).

Replace defective parts.

5. Battery charge low. 5. Check Battery voltage. Replace battery if a

charge cannot be held.

6. No voltage to starter solenoid. 6. Check voltage to solenoid. If necessary, replace

the solenoid.

7. Solenoid or starter motor inoperative. 7. Replace starter motor.

ENGINE CRANKS, BUT

WILL NOT START, NO

SMOKE1. No fuel in supply tank. 1. Fill fuel supply.

2. Electrical fuel shutdown solenoid not operating. 2. Check for loose wires and verify that the fuel

shutdown solenoid is functioning. Check for fault

codes in the ECU.

3. Fuel injection system defective: Cranking speed

sensor. Loose connection between ECU and

harness. No power supply to the ECU. Loose

connection between injection pump and harness.3. Check for fault codes at ECU. Refer to Group 14,

Fuel System for repairs procedures.

4. Air intake or exhaust plugged. 4. Remove the obstruction.

5. Fuel filter plugged. 5. Drain fuel/water separator and replace fuel filter.

6. Excessive fuel inlet restriction. 6. Check for restriction. Correct cause.

7. Injection pump not getting fuel or fuel is aerated. 7. Check fuel flow/bleed fuel system.

8. One or more injectors worn or not operating

properly.8. Check/replace bad or improperly operating

injectors.

9. Camshaft out of time. 9. Check/correct timing chain sprocket alignment.

ENGINE HARD TO

START, OR WILL NOT

START, SMOKE FROM

EXHAUST1. Incorrect starting procedure. 1. The fuel shutoff solenoid control must be in the

run position. Ensure the proper procedure is being

used.

2. Cranking speed to slow. 2. Check the battery, starter motor and look for

loose or corroded wiring connections.

3. Cylinder head heater plugs defective. 3. Verify system is working. Verify connection

between heater plug relay and ECU. Repair/replace

inoperative parts.

4. Insufficient intake air 4. Inspect or replace air filter and check for

obstruction in air supply.

5. Air in fuel system or the fuel supply is

inadequate.5. Check the fuel flow through the filter and bleed

system. Locate and eliminate the air source.

6. Contaminated fuel. 6. Verify by operating the engine with clean fuel

from a temporary tank. Check for the presence of

gasoline. Drain and flush fuel supply tank. Replace

fuel/water separator filter.

7. Fuel screen plugged. 7. Check fuel screen.

8. One or more injectors worn or not operating

properly.8. Check/replace improperly operating injectors.

9. Injector pump out of time. 9. Check pump timing. Refer to Group 14, Fuel

System for procedure.

10. Engine compression low. 10. Check compression to identify the problem.

11. Fuel injection system defective. 11. Vacuum modulator defective causing EGR to

open in cold condition. Check for fault codes in the

ECU.

NS/GSENGINE 9 - 43

Page 1222 of 1938

ENGINE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING OIL PRESSURE

LOW1. Low oil level. 1a. Check and fill with clean engine

oil.

1b. Check for severe external oil

leaks that could reduce the

pressure.

2. Oil viscosity thin, diluted, or

wrong specification.2. Verify the correct oil is being

used. Check for oil dilution.

3. Improperly operating pressure

switch/gauge3. Verify the pressure switch is

functioning correctly. If not, replace

switch/gauge.

4. Relief valve stuck open. 4. Check/replace valve.

5. Plugged oil filter. 5. Change oil filter. Oil filter change

interval may need to be revised.

6. Oil cooler was replaced, shipping

plugs left in cooler.6. Check/removed shipping plugs.

7. Worn oil pump. 7. Check/replace oil pump.

8. Suction tube loose or seal

leaking.8. Check and replace seal.

9. Worn bearing or wrong bearing

installed.9. Inspect and replace connecting

rod or main bearings. check and

replace piston cooling oil jet.

10. Oil jets under piston loose or

bad fit.10. Check oil jets position.

LUBRICATING OIL LOSS 1. External oil leaks. 1. Visually inspect for oil leaks.

Repair as required.

2. Crankcase being overfilled. 2. Verify that the correct dipstick is

being used.

3. Incorrect oil specification or

viscosity.3a. Make sure the correct oil is

being used.

3b. Look for reduced viscosity from

dilution with fuel.

3c. Review/reduce the oil change

intervals.

4. Oil cooler leak. 4. Check and replace the oil cooler.

5. High blow-by forcing oil out the

breather.5. Check the breather tube area for

signs of oil loss.

9 - 44 ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1225 of 1938

HYDRAULIC TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending unit. The pressure should be

between 3.5 bars to 5.0 bars at 4000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these 2 condi-

tions could be responsible for noisy tappets.

OIL LEVEL HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.

OIL LEVEL LOW

Low oil level may allow oil pump to take in air.

When air is fed to the tappets, they lose length which

allows valves to seat noisily. Any leaks on intake side

of oil pump through which air can be drawn will cre-

ate the same tappet action. Check the lubrication

system from the intake strainer to the pump cover,

including the relief valve retainer cap. When tappet

noise is due to aeration, it may be intermittent or

constant, and usually more than 1 tappet will be

noisy. When oil level and leaks have been corrected,

operate the engine at fast idle. Run engine for a suf-

ficient time to allow all of the air inside the tappets

to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak down around the unit plunger or by the

plunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click iscaused by a tappet check valve not seating or by for-

eign particles becoming wedged between the plunger

and the tappet body. This will cause the plunger to

stick in the down position. This heavy click will be

accompanied by excessive clearance between the

valve stem and rocker arm as valve closes. In either

case, tappet assembly should be removed for inspec-

tion and cleaning.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. In general, if more than one tappet

seems to be noisy, its probably not the tappets.

SERVICE PROCEDURES

CHECKING OIL LEVEL

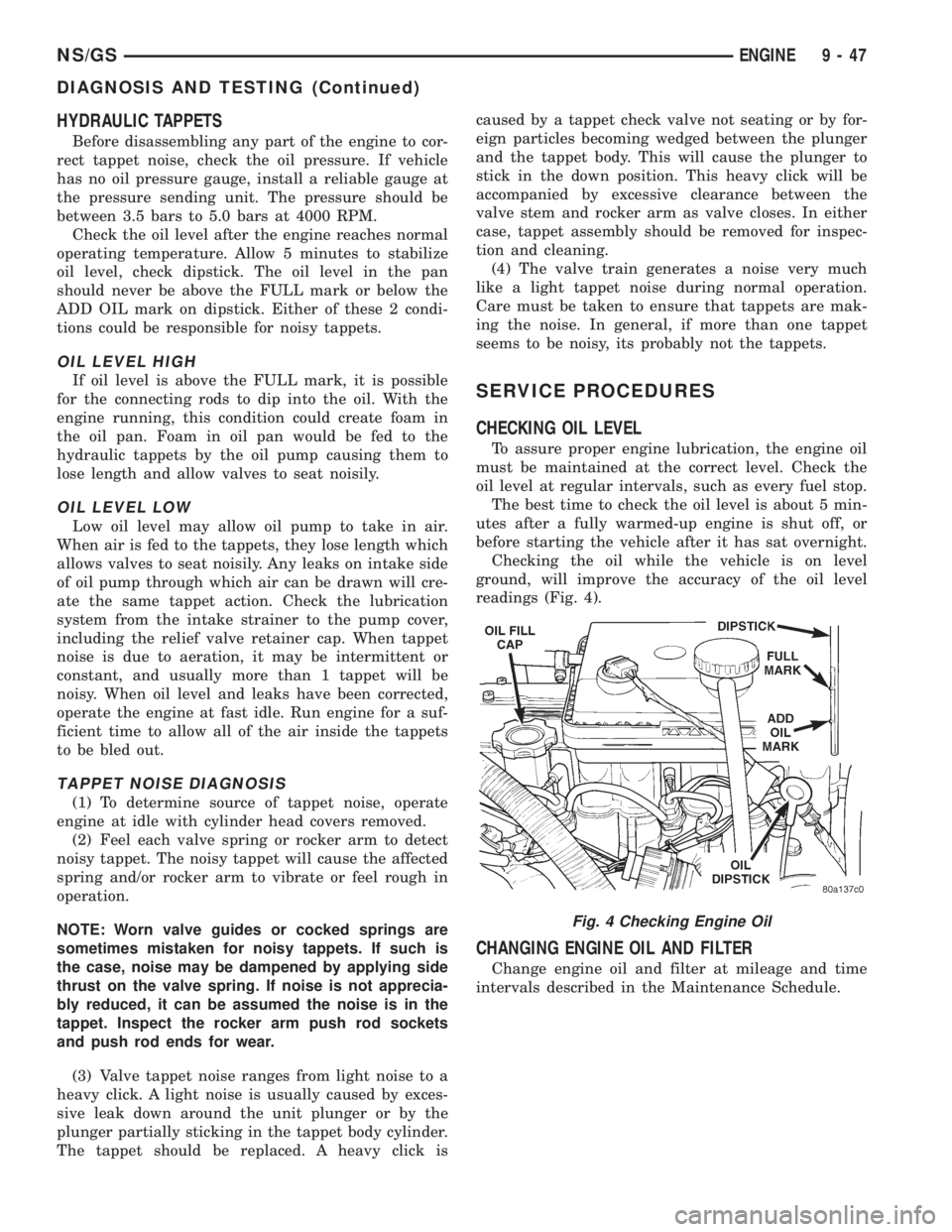

To assure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the

oil level at regular intervals, such as every fuel stop.

The best time to check the oil level is about 5 min-

utes after a fully warmed-up engine is shut off, or

before starting the vehicle after it has sat overnight.

Checking the oil while the vehicle is on level

ground, will improve the accuracy of the oil level

readings (Fig. 4).

CHANGING ENGINE OIL AND FILTER

Change engine oil and filter at mileage and time

intervals described in the Maintenance Schedule.

Fig. 4 Checking Engine Oil

NS/GSENGINE 9 - 47

DIAGNOSIS AND TESTING (Continued)

Page 1330 of 1938

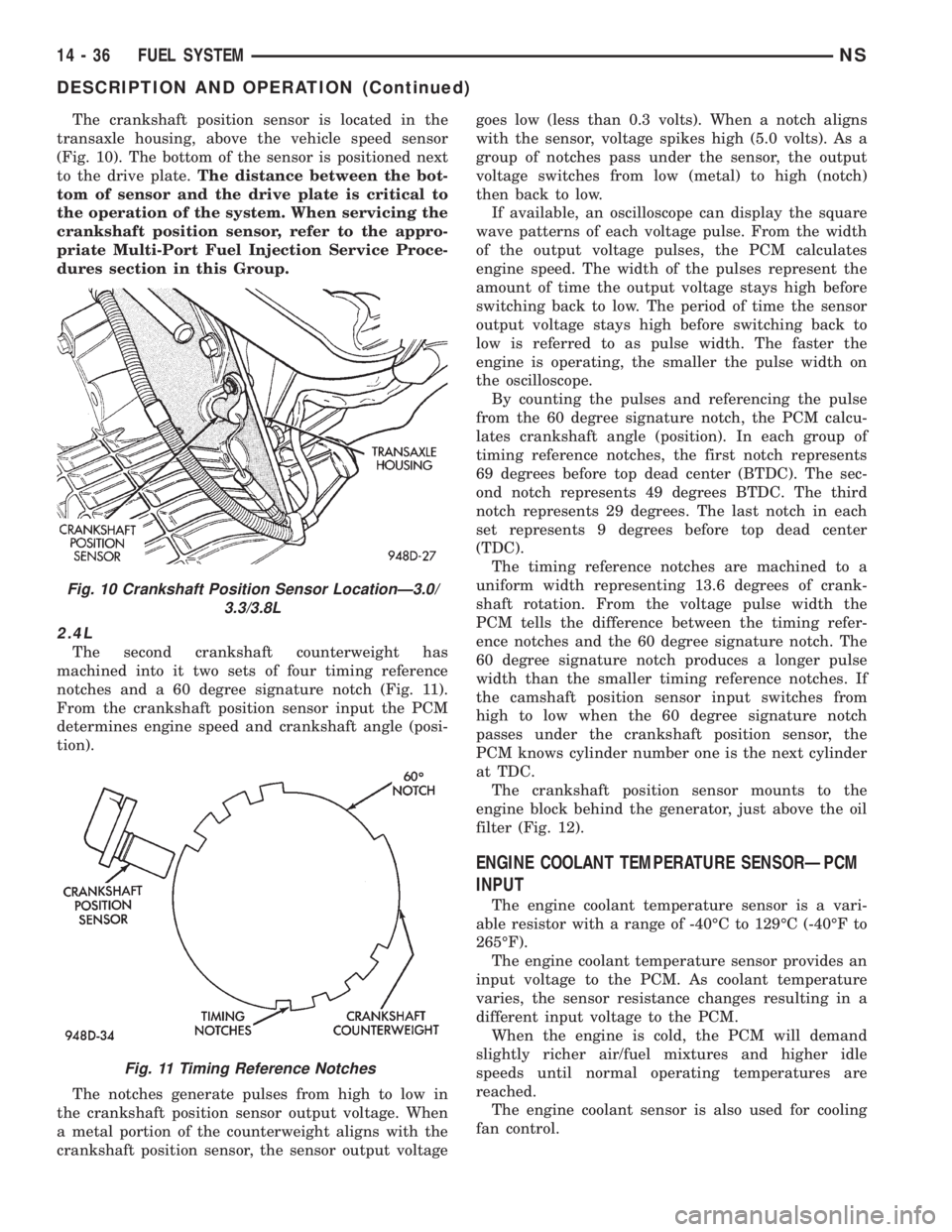

The crankshaft position sensor is located in the

transaxle housing, above the vehicle speed sensor

(Fig. 10). The bottom of the sensor is positioned next

to the drive plate.The distance between the bot-

tom of sensor and the drive plate is critical to

the operation of the system. When servicing the

crankshaft position sensor, refer to the appro-

priate Multi-Port Fuel Injection Service Proce-

dures section in this Group.

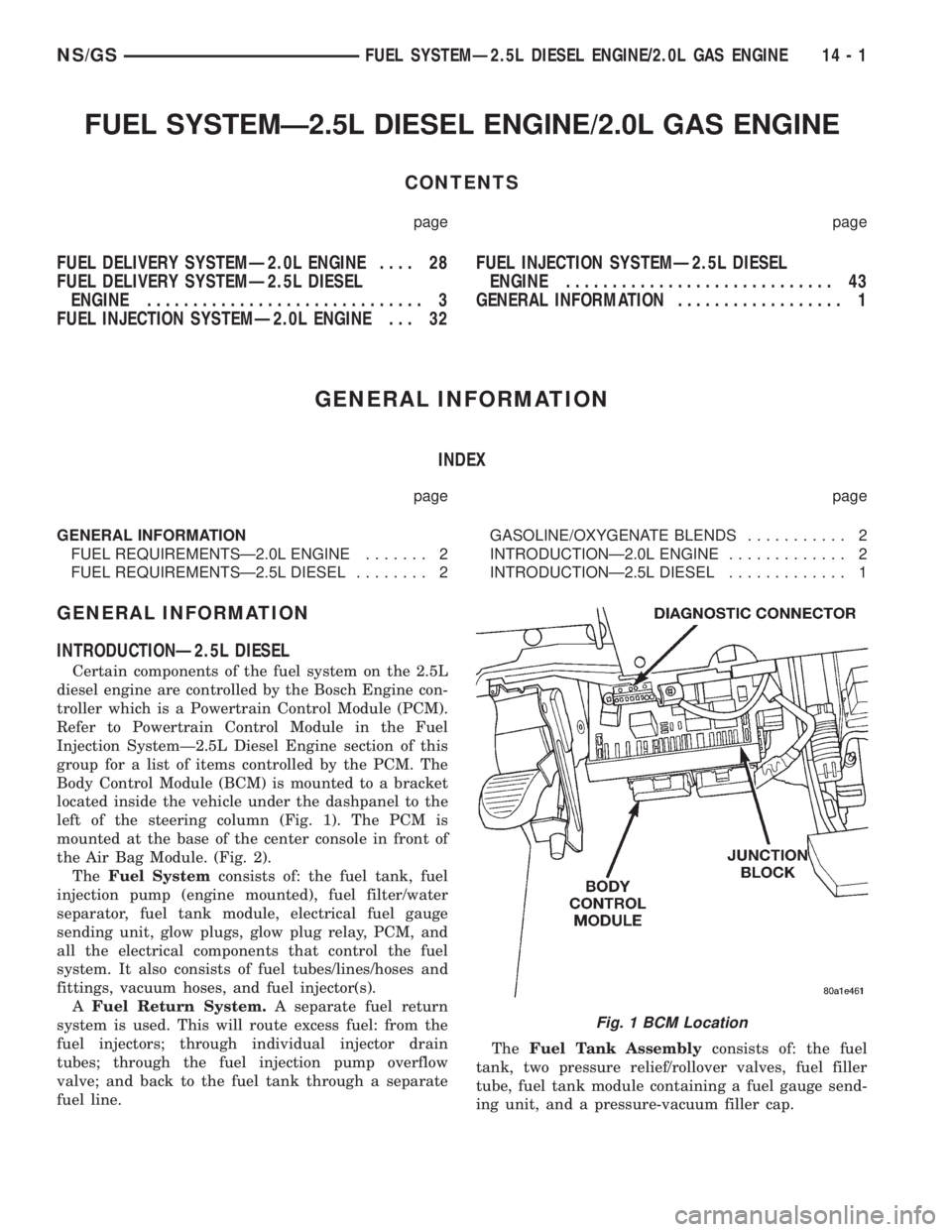

2.4L

The second crankshaft counterweight has

machined into it two sets of four timing reference

notches and a 60 degree signature notch (Fig. 11).

From the crankshaft position sensor input the PCM

determines engine speed and crankshaft angle (posi-

tion).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltagegoes low (less than 0.3 volts). When a notch aligns

with the sensor, voltage spikes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulse. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined to a

uniform width representing 13.6 degrees of crank-

shaft rotation. From the voltage pulse width the

PCM tells the difference between the timing refer-

ence notches and the 60 degree signature notch. The

60 degree signature notch produces a longer pulse

width than the smaller timing reference notches. If

the camshaft position sensor input switches from

high to low when the 60 degree signature notch

passes under the crankshaft position sensor, the

PCM knows cylinder number one is the next cylinder

at TDC.

The crankshaft position sensor mounts to the

engine block behind the generator, just above the oil

filter (Fig. 12).

ENGINE COOLANT TEMPERATURE SENSORÐPCM

INPUT

The engine coolant temperature sensor is a vari-

able resistor with a range of -40ÉC to 129ÉC (-40ÉF to

265ÉF).

The engine coolant temperature sensor provides an

input voltage to the PCM. As coolant temperature

varies, the sensor resistance changes resulting in a

different input voltage to the PCM.

When the engine is cold, the PCM will demand

slightly richer air/fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

The engine coolant sensor is also used for cooling

fan control.

Fig. 10 Crankshaft Position Sensor LocationÐ3.0/

3.3/3.8L

Fig. 11 Timing Reference Notches

14 - 36 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1369 of 1938

FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE

CONTENTS

page page

FUEL DELIVERY SYSTEMÐ2.0L ENGINE.... 28

FUEL DELIVERY SYSTEMÐ2.5L DIESEL

ENGINE.............................. 3

FUEL INJECTION SYSTEMÐ2.0L ENGINE . . . 32FUEL INJECTION SYSTEMÐ2.5L DIESEL

ENGINE............................. 43

GENERAL INFORMATION.................. 1

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

FUEL REQUIREMENTSÐ2.0L ENGINE....... 2

FUEL REQUIREMENTSÐ2.5L DIESEL........ 2GASOLINE/OXYGENATE BLENDS........... 2

INTRODUCTIONÐ2.0L ENGINE............. 2

INTRODUCTIONÐ2.5L DIESEL............. 1

GENERAL INFORMATION

INTRODUCTIONÐ2.5L DIESEL

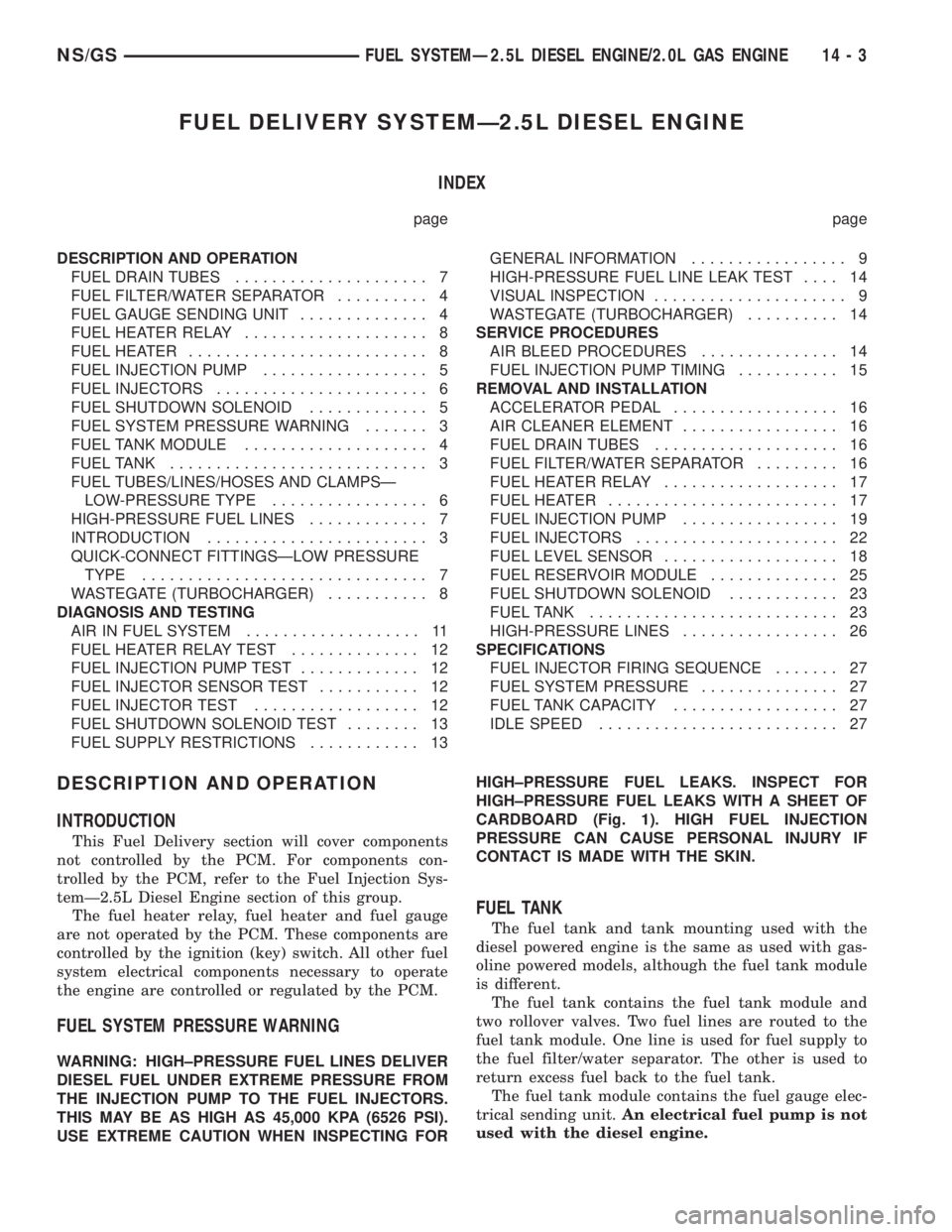

Certain components of the fuel system on the 2.5L

diesel engine are controlled by the Bosch Engine con-

troller which is a Powertrain Control Module (PCM).

Refer to Powertrain Control Module in the Fuel

Injection SystemÐ2.5L Diesel Engine section of this

group for a list of items controlled by the PCM. The

Body Control Module (BCM) is mounted to a bracket

located inside the vehicle under the dashpanel to the

left of the steering column (Fig. 1). The PCM is

mounted at the base of the center console in front of

the Air Bag Module. (Fig. 2).

TheFuel Systemconsists of: the fuel tank, fuel

injection pump (engine mounted), fuel filter/water

separator, fuel tank module, electrical fuel gauge

sending unit, glow plugs, glow plug relay, PCM, and

all the electrical components that control the fuel

system. It also consists of fuel tubes/lines/hoses and

fittings, vacuum hoses, and fuel injector(s).

AFuel Return System.A separate fuel return

system is used. This will route excess fuel: from the

fuel injectors; through individual injector drain

tubes; through the fuel injection pump overflow

valve; and back to the fuel tank through a separate

fuel line.TheFuel Tank Assemblyconsists of: the fuel

tank, two pressure relief/rollover valves, fuel filler

tube, fuel tank module containing a fuel gauge send-

ing unit, and a pressure-vacuum filler cap.

Fig. 1 BCM Location

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 1

Page 1371 of 1938

FUEL DELIVERY SYSTEMÐ2.5L DIESEL ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

FUEL DRAIN TUBES..................... 7

FUEL FILTER/WATER SEPARATOR.......... 4

FUEL GAUGE SENDING UNIT.............. 4

FUEL HEATER RELAY.................... 8

FUEL HEATER.......................... 8

FUEL INJECTION PUMP.................. 5

FUEL INJECTORS....................... 6

FUEL SHUTDOWN SOLENOID............. 5

FUEL SYSTEM PRESSURE WARNING....... 3

FUEL TANK MODULE.................... 4

FUEL TANK............................ 3

FUEL TUBES/LINES/HOSES AND CLAMPSÐ

LOW-PRESSURE TYPE................. 6

HIGH-PRESSURE FUEL LINES............. 7

INTRODUCTION........................ 3

QUICK-CONNECT FITTINGSÐLOW PRESSURE

TYPE............................... 7

WASTEGATE (TURBOCHARGER)........... 8

DIAGNOSIS AND TESTING

AIR IN FUEL SYSTEM................... 11

FUEL HEATER RELAY TEST.............. 12

FUEL INJECTION PUMP TEST............. 12

FUEL INJECTOR SENSOR TEST........... 12

FUEL INJECTOR TEST.................. 12

FUEL SHUTDOWN SOLENOID TEST........ 13

FUEL SUPPLY RESTRICTIONS............ 13GENERAL INFORMATION................. 9

HIGH-PRESSURE FUEL LINE LEAK TEST.... 14

VISUAL INSPECTION..................... 9

WASTEGATE (TURBOCHARGER).......... 14

SERVICE PROCEDURES

AIR BLEED PROCEDURES............... 14

FUEL INJECTION PUMP TIMING........... 15

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL.................. 16

AIR CLEANER ELEMENT................. 16

FUEL DRAIN TUBES.................... 16

FUEL FILTER/WATER SEPARATOR......... 16

FUEL HEATER RELAY................... 17

FUEL HEATER......................... 17

FUEL INJECTION PUMP................. 19

FUEL INJECTORS...................... 22

FUEL LEVEL SENSOR................... 18

FUEL RESERVOIR MODULE.............. 25

FUEL SHUTDOWN SOLENOID............ 23

FUEL TANK........................... 23

HIGH-PRESSURE LINES................. 26

SPECIFICATIONS

FUEL INJECTOR FIRING SEQUENCE....... 27

FUEL SYSTEM PRESSURE............... 27

FUEL TANK CAPACITY.................. 27

IDLE SPEED.......................... 27

DESCRIPTION AND OPERATION

INTRODUCTION

This Fuel Delivery section will cover components

not controlled by the PCM. For components con-

trolled by the PCM, refer to the Fuel Injection Sys-

temÐ2.5L Diesel Engine section of this group.

The fuel heater relay, fuel heater and fuel gauge

are not operated by the PCM. These components are

controlled by the ignition (key) switch. All other fuel

system electrical components necessary to operate

the engine are controlled or regulated by the PCM.

FUEL SYSTEM PRESSURE WARNING

WARNING: HIGH±PRESSURE FUEL LINES DELIVER

DIESEL FUEL UNDER EXTREME PRESSURE FROM

THE INJECTION PUMP TO THE FUEL INJECTORS.

THIS MAY BE AS HIGH AS 45,000 KPA (6526 PSI).

USE EXTREME CAUTION WHEN INSPECTING FORHIGH±PRESSURE FUEL LEAKS. INSPECT FOR

HIGH±PRESSURE FUEL LEAKS WITH A SHEET OF

CARDBOARD (Fig. 1). HIGH FUEL INJECTION

PRESSURE CAN CAUSE PERSONAL INJURY IF

CONTACT IS MADE WITH THE SKIN.

FUEL TANK

The fuel tank and tank mounting used with the

diesel powered engine is the same as used with gas-

oline powered models, although the fuel tank module

is different.

The fuel tank contains the fuel tank module and

two rollover valves. Two fuel lines are routed to the

fuel tank module. One line is used for fuel supply to

the fuel filter/water separator. The other is used to

return excess fuel back to the fuel tank.

The fuel tank module contains the fuel gauge elec-

trical sending unit.An electrical fuel pump is not

used with the diesel engine.

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 3

Page 1378 of 1938

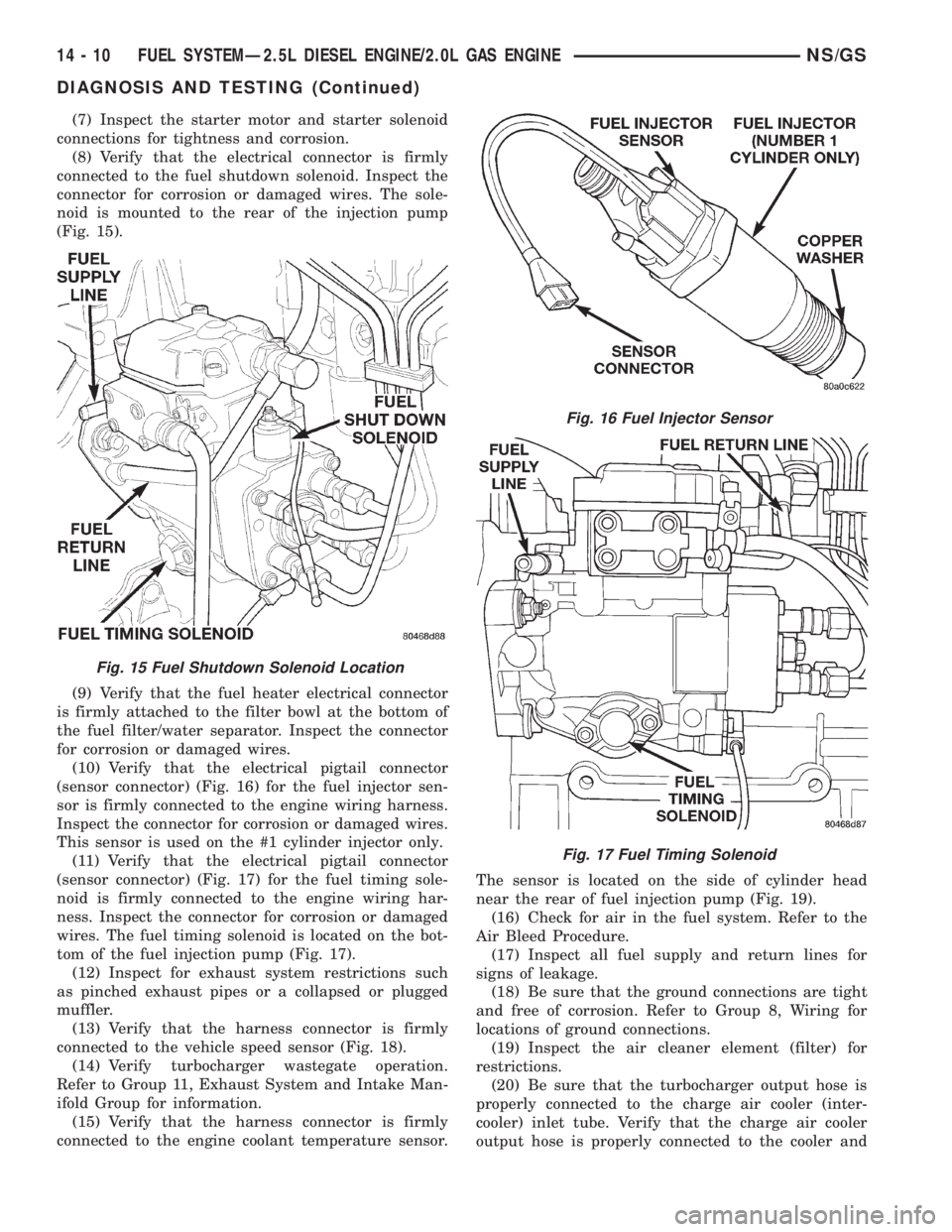

(7) Inspect the starter motor and starter solenoid

connections for tightness and corrosion.

(8) Verify that the electrical connector is firmly

connected to the fuel shutdown solenoid. Inspect the

connector for corrosion or damaged wires. The sole-

noid is mounted to the rear of the injection pump

(Fig. 15).

(9) Verify that the fuel heater electrical connector

is firmly attached to the filter bowl at the bottom of

the fuel filter/water separator. Inspect the connector

for corrosion or damaged wires.

(10) Verify that the electrical pigtail connector

(sensor connector) (Fig. 16) for the fuel injector sen-

sor is firmly connected to the engine wiring harness.

Inspect the connector for corrosion or damaged wires.

This sensor is used on the #1 cylinder injector only.

(11) Verify that the electrical pigtail connector

(sensor connector) (Fig. 17) for the fuel timing sole-

noid is firmly connected to the engine wiring har-

ness. Inspect the connector for corrosion or damaged

wires. The fuel timing solenoid is located on the bot-

tom of the fuel injection pump (Fig. 17).

(12) Inspect for exhaust system restrictions such

as pinched exhaust pipes or a collapsed or plugged

muffler.

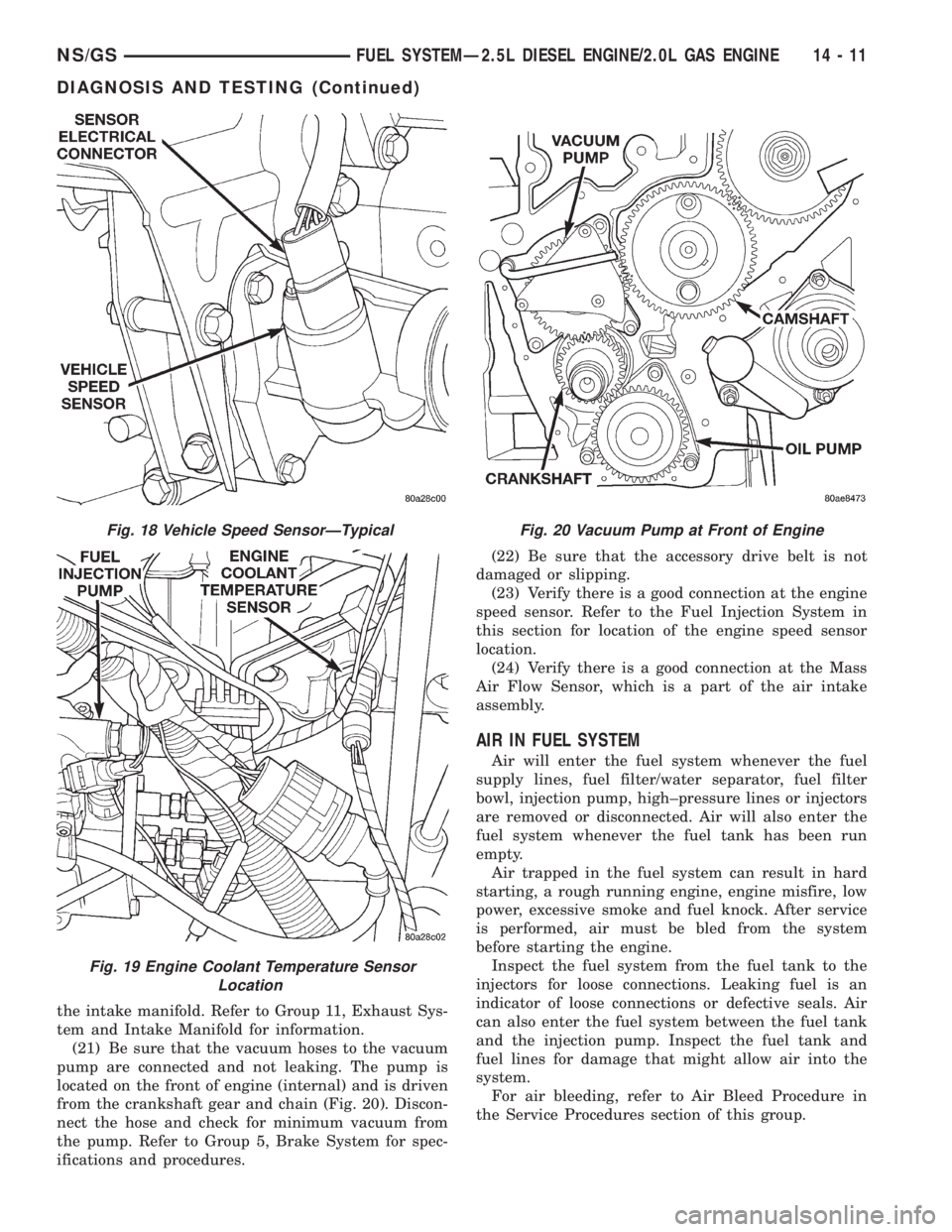

(13) Verify that the harness connector is firmly

connected to the vehicle speed sensor (Fig. 18).

(14) Verify turbocharger wastegate operation.

Refer to Group 11, Exhaust System and Intake Man-

ifold Group for information.

(15) Verify that the harness connector is firmly

connected to the engine coolant temperature sensor.The sensor is located on the side of cylinder head

near the rear of fuel injection pump (Fig. 19).

(16) Check for air in the fuel system. Refer to the

Air Bleed Procedure.

(17) Inspect all fuel supply and return lines for

signs of leakage.

(18) Be sure that the ground connections are tight

and free of corrosion. Refer to Group 8, Wiring for

locations of ground connections.

(19) Inspect the air cleaner element (filter) for

restrictions.

(20) Be sure that the turbocharger output hose is

properly connected to the charge air cooler (inter-

cooler) inlet tube. Verify that the charge air cooler

output hose is properly connected to the cooler and

Fig. 15 Fuel Shutdown Solenoid Location

Fig. 16 Fuel Injector Sensor

Fig. 17 Fuel Timing Solenoid

14 - 10 FUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINENS/GS

DIAGNOSIS AND TESTING (Continued)

Page 1379 of 1938

the intake manifold. Refer to Group 11, Exhaust Sys-

tem and Intake Manifold for information.

(21) Be sure that the vacuum hoses to the vacuum

pump are connected and not leaking. The pump is

located on the front of engine (internal) and is driven

from the crankshaft gear and chain (Fig. 20). Discon-

nect the hose and check for minimum vacuum from

the pump. Refer to Group 5, Brake System for spec-

ifications and procedures.(22) Be sure that the accessory drive belt is not

damaged or slipping.

(23) Verify there is a good connection at the engine

speed sensor. Refer to the Fuel Injection System in

this section for location of the engine speed sensor

location.

(24) Verify there is a good connection at the Mass

Air Flow Sensor, which is a part of the air intake

assembly.

AIR IN FUEL SYSTEM

Air will enter the fuel system whenever the fuel

supply lines, fuel filter/water separator, fuel filter

bowl, injection pump, high±pressure lines or injectors

are removed or disconnected. Air will also enter the

fuel system whenever the fuel tank has been run

empty.

Air trapped in the fuel system can result in hard

starting, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock. After service

is performed, air must be bled from the system

before starting the engine.

Inspect the fuel system from the fuel tank to the

injectors for loose connections. Leaking fuel is an

indicator of loose connections or defective seals. Air

can also enter the fuel system between the fuel tank

and the injection pump. Inspect the fuel tank and

fuel lines for damage that might allow air into the

system.

For air bleeding, refer to Air Bleed Procedure in

the Service Procedures section of this group.

Fig. 18 Vehicle Speed SensorÐTypical

Fig. 19 Engine Coolant Temperature Sensor

Location

Fig. 20 Vacuum Pump at Front of Engine

NS/GSFUEL SYSTEMÐ2.5L DIESEL ENGINE/2.0L GAS ENGINE 14 - 11

DIAGNOSIS AND TESTING (Continued)