height adjustment CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1257 of 1938

DESCRIPTION...........SPECIFICATIONS

Nominal.................63.005±63.020 mm

±0.25....................62.755±62.770 mm

±0.125...................62.880±62.895 mm

Center Bearing Diameter...................

Nominal.................63.050±63.093 mm

±0.25....................62.800±62.843 mm

±0.125...................62.925±62.968 mm

Clearance Between Journal and Bearing:

0.030±0.088 mm..........................

Rear Journal Diameter.....................

Nominal.................79.980±80.000 mm

±0.25....................79.730±79.750 mm

±0.125...................79.855±79.875 mm

Rear Bearing Diameter.....................

Nominal.................80.045±80.070 mm

±0.25....................79.795±79.820 mm

±0.125...................79.920±79.945 mm

Clearance Between Journal and Bearing:

0.045±0.090 mm (Wear Limit: 0.200 mm).......

Connecting Rod Journal....................

Nominal.................53.940±53.955 mm

±0.25....................53.690±53.705 mm

±0.125...................53.815±53.830 mm

Connecting Rod Bearing....................

Nominal.................53.977±54.016 mm

±0.25....................53.727±53.766 mm

±0.125...................53.852±53.891 mm

Clearance Between Journal and Bearing:

0.022±0.076 mm (Wear Limit: 0.200 mm).......

Crankshaft End Play

End Play.....................0.08±0.21 mm

Adjustment.................Thrust Washers

Thrust Washers Available........2.31±2.36 mm

Thrust Washers Available........2.41±2.46 mm

Thrust Washers Available........2.51±2.56 mm

Main Bearing Carriers

Front....................67.025±67.050 mm

Center...................66.670±66.690 mm

Rear....................85.985±86.005 mm

Liners

Internal Diameter..........92.000±92.010 mm

Protrusion....................0.01±0.06 mm

Adjustment.........................Shims

Available Shims:...................0.15 mm

Available Shims:...................0.17 mm

Available Shims:...................0.20 mm

Available Shims:...................0.23 mm

Available Shims:...................0.25 mm

Cylinder Head

Minimum Thickness..........89.95±90.05 mm

Gasket.............................Steel

Gasket thickness:.......1.4260.1 mm 0 Holes

Gasket thickness:.......1.6260.1 mm 1 HolesDESCRIPTION...........SPECIFICATIONS

Gasket thickness:.......1.5260.1 mm 2 Holes

End Plates

Height.....................89.02±90.00 mm

Connecting Rods

Weight (Without the crank

bearing)..................1129±1195 grams

Small End Bearing Internal Diameter

Minimum.......................30.035 mm

Maximum......................30.050 mm

Crankshaft Bearings Standard Internal

Diameter.................53.997±54.016 mm

Pistons

Skirt Diameter............91.935±91.945 mm

(Measured at approximately 15 mm above the

bottom of the skirt)

Piston Clearance.............0.055±0.075 mm

Top of Piston to Cylinder Head....0.80±0.89 mm

Piston Protrusion.....0.53±0.62 mm Fit Gasket

(1.42), 0 Holes

Piston Protrusion.....0.73±0.82 mm Fit Gasket

(1.62), 1 Hole

Piston Protrusion.....0.63±0.72 mm Fit Gasket

(1.52), 2 Holes

Piston Pins

Type .........................Full Floating

Pin Diameter..............29.990±29.996 mm

Clearance..................0.004±0.014 mm

Piston Rings (Clearance in Groove)

Top .......................0.080±0.130 mm

Second.....................0.070±0.102 mm

Oil Control.................0.040±0.072 mm

Piston Rings (Fitted Gap)

Top .........................0.25±0.50 mm

Second......................0.20±0.35 mm

Oil Control...................0.25±0.58 mm

Camshaft

Journal Diameter Front.....53.460±53.480 mm

Bearing Clearance.............0.06±0.13 mm

Journal Diameter Center....53.460±53.480 mm

Bearing Clearance.............0.06±0.13 mm

Journal Diameter Rear......53.460±53.480 mm

Bearing Clearance.............0.06±0.13 mm

Tappets

Outside Diameter..........22.195±22.212 mm

Rocker Gear

Shaft Diameter.............21.979±22.00 mm

Bushing internal diameter . . . 22.020±22.041 mm

Assembly Clearance..........0.020±0.062 mm

Valves (Intake)

Opens........................26ÉB.T.D.C.

Closes........................58ÉA.B.D.C.

Valves (Exhaust)

Opens........................64ÉB.B.D.C.

Closes........................38ÉA.T.D.C.

NS/GSENGINE 9 - 79

SPECIFICATIONS (Continued)

Page 1753 of 1938

SHOULDER BELT HEIGHT ADJUSTER KNOB . . 64

SHOULDER BELT HEIGHT ADJUSTER±BOR

C-PILLAR............................ 64

SIDE VIEW MIRROR..................... 64

SLIDING DOOR CENTER HINGE............ 66

SLIDING DOOR CENTER STOP TRIM COVER . . 66

SLIDING DOOR CENTER STRIKER ASSEMBLY . 67

SLIDING DOOR HOLD OPEN LATCH STRIKER . 67

SLIDING DOOR HOLD OPEN LATCH......... 67

SLIDING DOOR INSIDE LATCH HANDLE

BELLCRANK.......................... 68

SLIDING DOOR INSIDE LATCH HANDLE...... 68

SLIDING DOOR INSIDE LATCH RELEASE

MECHANISM.......................... 69

SLIDING DOOR LATCH STRIKER........... 69

SLIDING DOOR LATCH/LOCK CONTROL..... 70

SLIDING DOOR LOWER ROLLER ARM

BRACKET............................ 71

SLIDING DOOR LOWER ROLLER ARM....... 71SLIDING DOOR OUTSIDE LATCH RELEASE

HANDLE............................. 72

SLIDING DOOR REAR LATCH.............. 73

SLIDING DOOR SILL PLATE............... 73

SLIDING DOOR STABILIZER SOCKET........ 74

SLIDING DOOR STABILIZER............... 73

SLIDING DOOR STOP BUMPER............ 74

SLIDING DOOR TRIM PANEL............... 74

SLIDING DOOR UPPER ROLLER............ 75

SLIDING DOOR WEATHER-STRIP........... 75

SLIDING DOOR......................... 64

STICK-ON BODY SIDE MOLDING........... 75

SUN VISOR SUPPORT................... 78

SUN VISOR............................ 76

UPPER B-PILLAR TRIM COVER............. 78

UPPER C-PILLAR TRIM................... 80

ADJUSTMENTS

SLIDING DOOR ADJUSTMENTS............ 80

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK

TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-

cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

NSBODY 23 - 23

Page 1810 of 1938

UPPER C-PILLAR TRIM

REMOVAL

(1) Remove quarter trim bolster.

(2) Remove seat belt turning loop from height

adjuster.

(3) Remove screw holding C-pillar trim panel to

C-pillar on right side of SWB vehicle.

(4) Disengage hidden clips holding trim to upper

C-pillar.

(5) Remove upper C-pillar trim from vehicle.

INSTALLATION

(1) Place upper C-pillar trim in position on vehicle.

(2) Engage hidden clips to hold trim to upper

C-pillar.

(3) Install screw to hold C-pillar trim panel to

C-pillar on right side of SWB vehicle.

(4) Install seat belt turning loop onto height

adjuster. Tighten all seat belt bolts to 39 N´m (29 in.

lbs.) torque.

(5) Install quarter trim bolster.

ADJUSTMENTS

SLIDING DOOR ADJUSTMENTS

PRELIMINARY CHECKS

(1) Close sliding door, visually checking C-post

striker alignment entry into latch. Striker at this

point must not affect alignment.(2) On vehicles with left sliding doors, check the

fuel door blocker striker entry into latch. Striker at

this point must not affect alignment.

(3) Check C-post and B-post for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

61 mm.

(4) C

heck door for height using character lines as a

reference. Also check roof contour as a controlling factor.

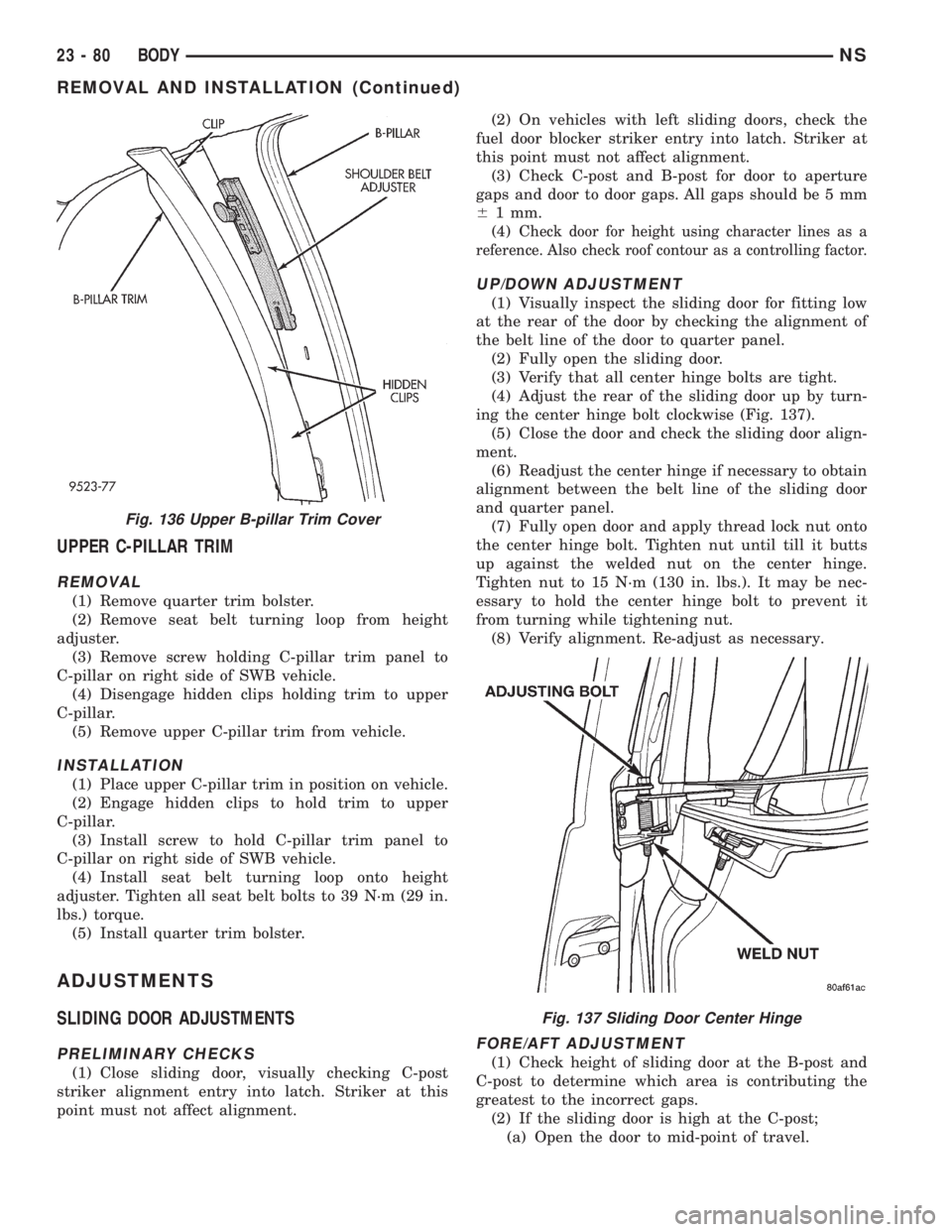

UP/DOWN ADJUSTMENT

(1) Visually inspect the sliding door for fitting low

at the rear of the door by checking the alignment of

the belt line of the door to quarter panel.

(2) Fully open the sliding door.

(3) Verify that all center hinge bolts are tight.

(4) Adjust the rear of the sliding door up by turn-

ing the center hinge bolt clockwise (Fig. 137).

(5) Close the door and check the sliding door align-

ment.

(6) Readjust the center hinge if necessary to obtain

alignment between the belt line of the sliding door

and quarter panel.

(7) Fully open door and apply thread lock nut onto

the center hinge bolt. Tighten nut until till it butts

up against the welded nut on the center hinge.

Tighten nut to 15 N´m (130 in. lbs.). It may be nec-

essary to hold the center hinge bolt to prevent it

from turning while tightening nut.

(8) Verify alignment. Re-adjust as necessary.

FORE/AFT ADJUSTMENT

(1) Check height of sliding door at the B-post and

C-post to determine which area is contributing the

greatest to the incorrect gaps.

(2) If the sliding door is high at the C-post;

(a) Open the door to mid-point of travel.

Fig. 136 Upper B-pillar Trim Cover

Fig. 137 Sliding Door Center Hinge

23 - 80 BODYNS

REMOVAL AND INSTALLATION (Continued)