traction control CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 241 of 1938

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

COOLANT PRESSURE BOTTLE............ 1

COOLING SYSTEM Ð 2.0L GASOLINE...... 1

COOLING SYSTEM Ð 2.5L VM DIESEL..... 1

LOW COOLANT LEVEL SENSOR........... 1

RADIATOR............................ 2

DESCRIPTION AND OPERATION

AUTOMATIC BELT TENSIONER............ 6

BELT TENSION......................... 5

COOLANT PERFORMANCE............... 5

PRESSURE/VENT CAP................... 4

THERMOSTAT OPERATION............... 4

THERMOSTAT......................... 6

WATER PUMP......................... 3

SERVICE PROCEDURES

ADDING ADDITIONAL COOLANT........... 7

DRAINING COOLING SYSTEM............. 7

REFILLING COOLING SYSTEM............ 7

REMOVAL AND INSTALLATION

ENGINE THERMOSTATÐ 2.0L GASOLINE . . . 9GENERATOR/POWER STEERING BELT Ð 2.5L

VM DIESEL......................... 10

RADIATOR Ð 2.5L VM DIESEL........... 9

THERMOSTAT Ð 2.5L VM DIESEL......... 9

WATER PUMP BELT Ð 2.5L VM DIESEL . . . 10

WATER PUMP Ð 2.0L GASOLINE......... 7

WATER PUMP Ð 2.5L VM DIESEL........ 8

CLEANING AND INSPECTION

WATER PUMP........................ 10

ADJUSTMENTS

BELT TENSION CHART................. 11

BELT TENSION GAUGE METHOD......... 11

SPECIFICATIONS

COOLING SYSTEM CAPACITY............ 12

TORQUE CHART...................... 12

SPECIAL TOOLS

COOLING............................ 12

GENERAL INFORMATION

COOLING SYSTEM Ð 2.0L GASOLINE

The 2.0L gasoline engine cooling system consists of

an engine cooling module, thermostat, coolant, a

water pump to circulate the coolant. The engine cool-

ing module may consist of a radiator, electric fan

motors, fan, shroud, coolant reserve system, hoses,

clamps, air condition condenser.

²When the Engine is cold: The thermostat is

closed; the cooling system has no flow through the

radiator. The coolant flows through the engine,

heater system and bypass.

²When the Engine is warm: Thermostat is open;

the cooling system has flow through radiator, engine,

heater system and bypass.

COOLING SYSTEM Ð 2.5L VM DIESEL

The cooling system has a radiator, coolant, electric

fan motors, shroud, pressure cap, thermostat, coolant

pressure bottle, hoses, a water pump to circulate the

coolant, to complete the circuit. Coolant flow for the

VM diesel engine is shown in (Fig. 1).

COOLANT PRESSURE BOTTLE

2.5L VM DIESEL

This system works with the pressure cap to use

thermal expansion and contraction of the coolant to

keep the coolant free of trapped air. It provides some

reserve coolant to cover minor leaks and evaporation

or boiling losses. The coolant pressure bottle location

for 2.5L diesel is above the cylinder head cover (Fig.

2).

LOW COOLANT LEVEL SENSOR

The low coolant level sensor checks for low coolant

level in the coolant tank. A signal will be sent from

this sensor to the Body Control Module (BCM). When

the BCM determines low coolant level for 30 contin-

uous seconds, the instrument panel mounted low

coolant level warning lamp will be illuminated. The

sensor is located on the front side of the coolant tank

(Fig. 4). For information, refer to Group 8E, Instru-

ment Panel and Gauges.

If this lamp is illuminated, it indicates the need to

fill the coolant tank and check for leaks.

NS/GSCOOLING SYSTEM 7 - 1

Page 337 of 1938

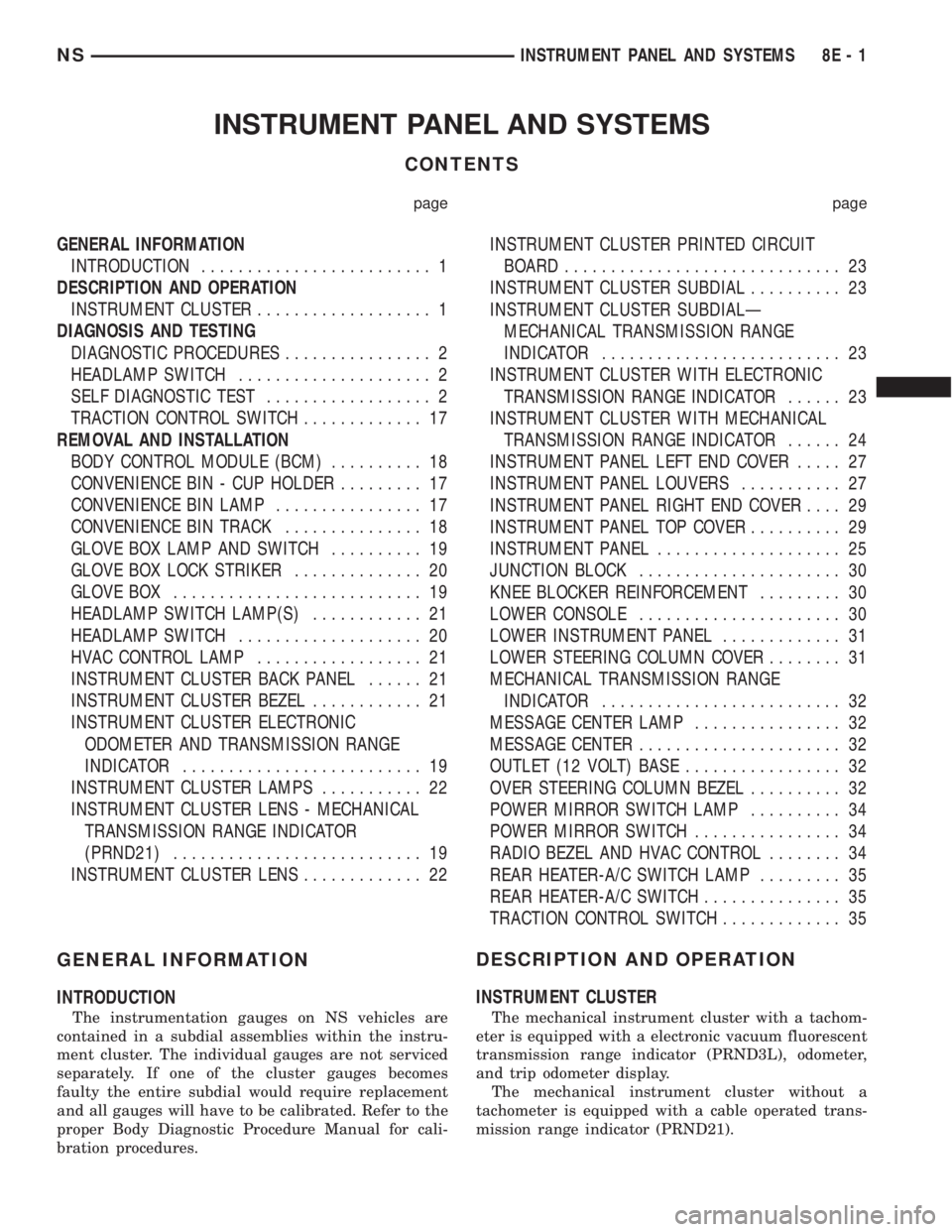

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

INSTRUMENT CLUSTER................... 1

DIAGNOSIS AND TESTING

DIAGNOSTIC PROCEDURES................ 2

HEADLAMP SWITCH..................... 2

SELF DIAGNOSTIC TEST.................. 2

TRACTION CONTROL SWITCH............. 17

REMOVAL AND INSTALLATION

BODY CONTROL MODULE (BCM).......... 18

CONVENIENCE BIN - CUP HOLDER......... 17

CONVENIENCE BIN LAMP................ 17

CONVENIENCE BIN TRACK............... 18

GLOVE BOX LAMP AND SWITCH.......... 19

GLOVE BOX LOCK STRIKER.............. 20

GLOVE BOX........................... 19

HEADLAMP SWITCH LAMP(S)............ 21

HEADLAMP SWITCH.................... 20

HVAC CONTROL LAMP.................. 21

INSTRUMENT CLUSTER BACK PANEL...... 21

INSTRUMENT CLUSTER BEZEL............ 21

INSTRUMENT CLUSTER ELECTRONIC

ODOMETER AND TRANSMISSION RANGE

INDICATOR.......................... 19

INSTRUMENT CLUSTER LAMPS........... 22

INSTRUMENT CLUSTER LENS - MECHANICAL

TRANSMISSION RANGE INDICATOR

(PRND21)........................... 19

INSTRUMENT CLUSTER LENS............. 22INSTRUMENT CLUSTER PRINTED CIRCUIT

BOARD.............................. 23

INSTRUMENT CLUSTER SUBDIAL.......... 23

INSTRUMENT CLUSTER SUBDIALÐ

MECHANICAL TRANSMISSION RANGE

INDICATOR.......................... 23

INSTRUMENT CLUSTER WITH ELECTRONIC

TRANSMISSION RANGE INDICATOR...... 23

INSTRUMENT CLUSTER WITH MECHANICAL

TRANSMISSION RANGE INDICATOR...... 24

INSTRUMENT PANEL LEFT END COVER..... 27

INSTRUMENT PANEL LOUVERS........... 27

INSTRUMENT PANEL RIGHT END COVER.... 29

INSTRUMENT PANEL TOP COVER.......... 29

INSTRUMENT PANEL.................... 25

JUNCTION BLOCK...................... 30

KNEE BLOCKER REINFORCEMENT......... 30

LOWER CONSOLE...................... 30

LOWER INSTRUMENT PANEL............. 31

LOWER STEERING COLUMN COVER........ 31

MECHANICAL TRANSMISSION RANGE

INDICATOR.......................... 32

MESSAGE CENTER LAMP................ 32

MESSAGE CENTER...................... 32

OUTLET (12 VOLT) BASE................. 32

OVER STEERING COLUMN BEZEL.......... 32

POWER MIRROR SWITCH LAMP.......... 34

POWER MIRROR SWITCH................ 34

RADIO BEZEL AND HVAC CONTROL........ 34

REAR HEATER-A/C SWITCH LAMP......... 35

REAR HEATER-A/C SWITCH............... 35

TRACTION CONTROL SWITCH............. 35

GENERAL INFORMATION

INTRODUCTION

The instrumentation gauges on NS vehicles are

contained in a subdial assemblies within the instru-

ment cluster. The individual gauges are not serviced

separately. If one of the cluster gauges becomes

faulty the entire subdial would require replacement

and all gauges will have to be calibrated. Refer to the

proper Body Diagnostic Procedure Manual for cali-

bration procedures.

DESCRIPTION AND OPERATION

INSTRUMENT CLUSTER

The mechanical instrument cluster with a tachom-

eter is equipped with a electronic vacuum fluorescent

transmission range indicator (PRND3L), odometer,

and trip odometer display.

The mechanical instrument cluster without a

tachometer is equipped with a cable operated trans-

mission range indicator (PRND21).

NSINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 353 of 1938

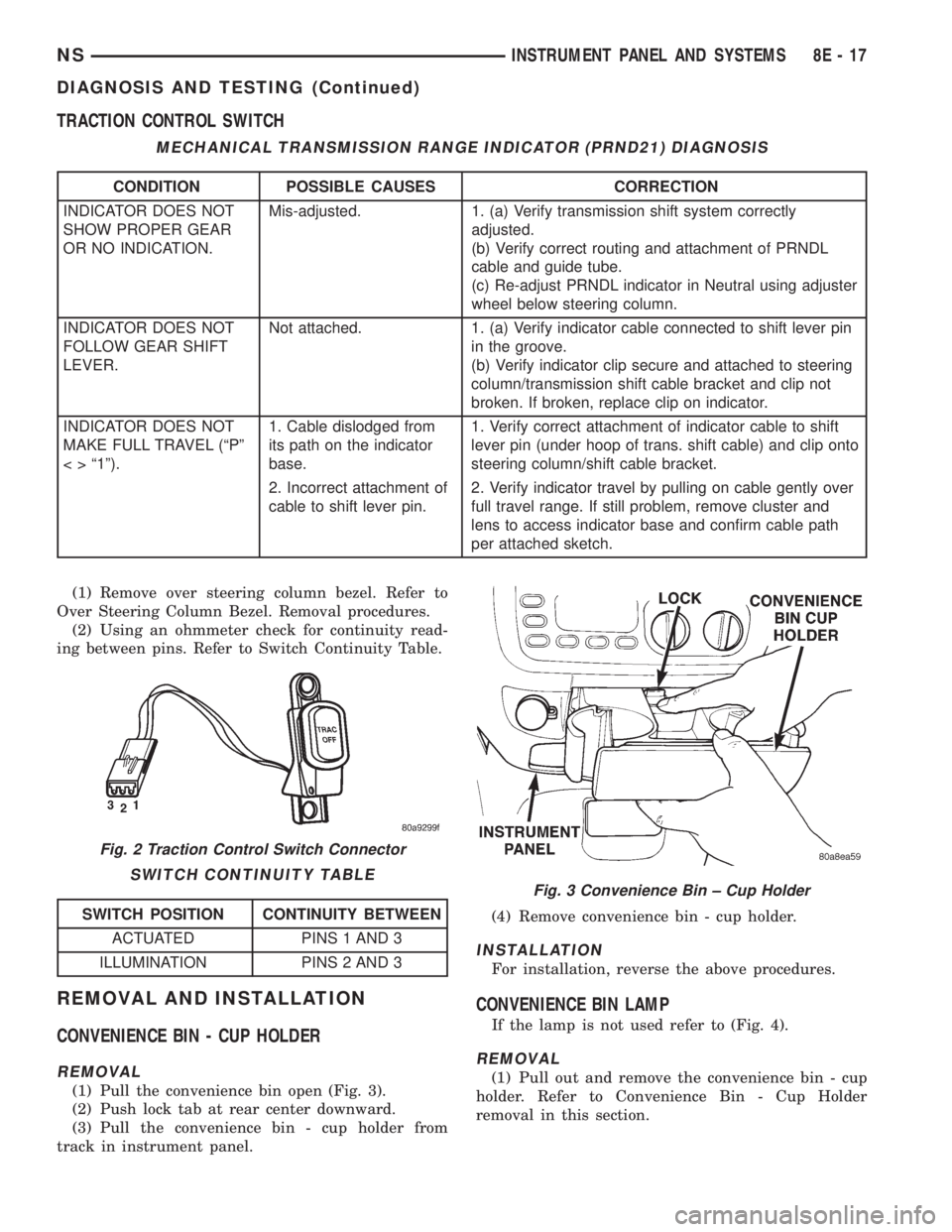

TRACTION CONTROL SWITCH

(1) Remove over steering column bezel. Refer to

Over Steering Column Bezel. Removal procedures.

(2) Using an ohmmeter check for continuity read-

ing between pins. Refer to Switch Continuity Table.

REMOVAL AND INSTALLATION

CONVENIENCE BIN - CUP HOLDER

REMOVAL

(1) Pull the convenience bin open (Fig. 3).

(2) Push lock tab at rear center downward.

(3) Pull the convenience bin - cup holder from

track in instrument panel.(4) Remove convenience bin - cup holder.

INSTALLATION

For installation, reverse the above procedures.

CONVENIENCE BIN LAMP

If the lamp is not used refer to (Fig. 4).

REMOVAL

(1) Pull out and remove the convenience bin - cup

holder. Refer to Convenience Bin - Cup Holder

removal in this section.

MECHANICAL TRANSMISSION RANGE INDICATOR (PRND21) DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INDICATOR DOES NOT

SHOW PROPER GEAR

OR NO INDICATION.Mis-adjusted. 1. (a) Verify transmission shift system correctly

adjusted.

(b) Verify correct routing and attachment of PRNDL

cable and guide tube.

(c) Re-adjust PRNDL indicator in Neutral using adjuster

wheel below steering column.

INDICATOR DOES NOT

FOLLOW GEAR SHIFT

LEVER.Not attached. 1. (a) Verify indicator cable connected to shift lever pin

in the groove.

(b) Verify indicator clip secure and attached to steering

column/transmission shift cable bracket and clip not

broken. If broken, replace clip on indicator.

INDICATOR DOES NOT

MAKE FULL TRAVEL (ªPº

< > ª1º).1. Cable dislodged from

its path on the indicator

base.1. Verify correct attachment of indicator cable to shift

lever pin (under hoop of trans. shift cable) and clip onto

steering column/shift cable bracket.

2. Incorrect attachment of

cable to shift lever pin.2. Verify indicator travel by pulling on cable gently over

full travel range. If still problem, remove cluster and

lens to access indicator base and confirm cable path

per attached sketch.

Fig. 2 Traction Control Switch Connector

SWITCH CONTINUITY TABLE

SWITCH POSITION CONTINUITY BETWEEN

ACTUATED PINS 1 AND 3

ILLUMINATION PINS 2 AND 3

Fig. 3 Convenience Bin ± Cup Holder

NSINSTRUMENT PANEL AND SYSTEMS 8E - 17

DIAGNOSIS AND TESTING (Continued)

Page 369 of 1938

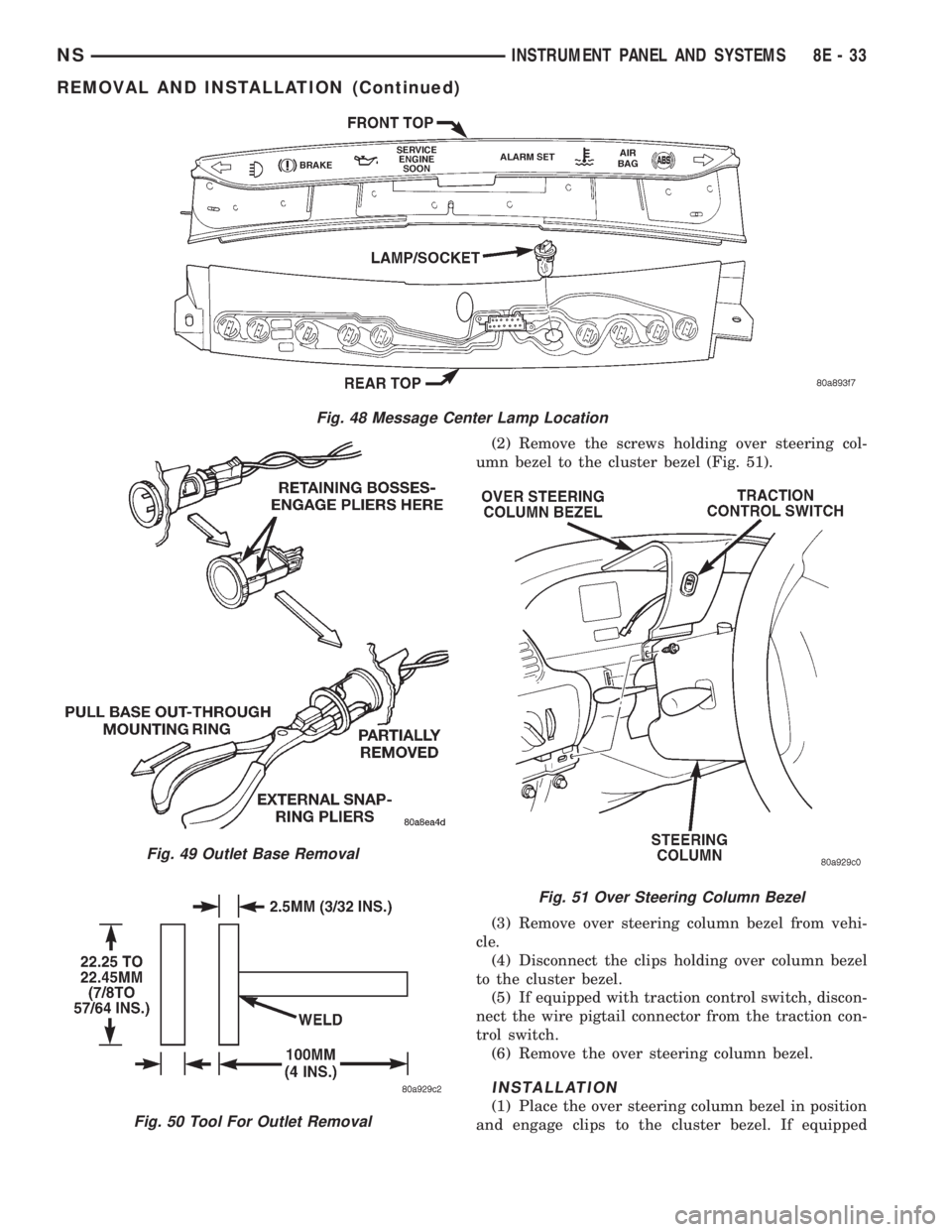

(2) Remove the screws holding over steering col-

umn bezel to the cluster bezel (Fig. 51).

(3) Remove over steering column bezel from vehi-

cle.

(4) Disconnect the clips holding over column bezel

to the cluster bezel.

(5) If equipped with traction control switch, discon-

nect the wire pigtail connector from the traction con-

trol switch.

(6) Remove the over steering column bezel.

INSTALLATION

(1) Place the over steering column bezel in position

and engage clips to the cluster bezel. If equipped

Fig. 48 Message Center Lamp Location

Fig. 49 Outlet Base Removal

Fig. 50 Tool For Outlet Removal

Fig. 51 Over Steering Column Bezel

NSINSTRUMENT PANEL AND SYSTEMS 8E - 33

REMOVAL AND INSTALLATION (Continued)

Page 370 of 1938

with traction control switch connect the wire pigtail

before engaging clips.

(2) Install the screws to hold the over steering col-

umn bezel to the cluster bezel.

(3) Install the lower column cover.

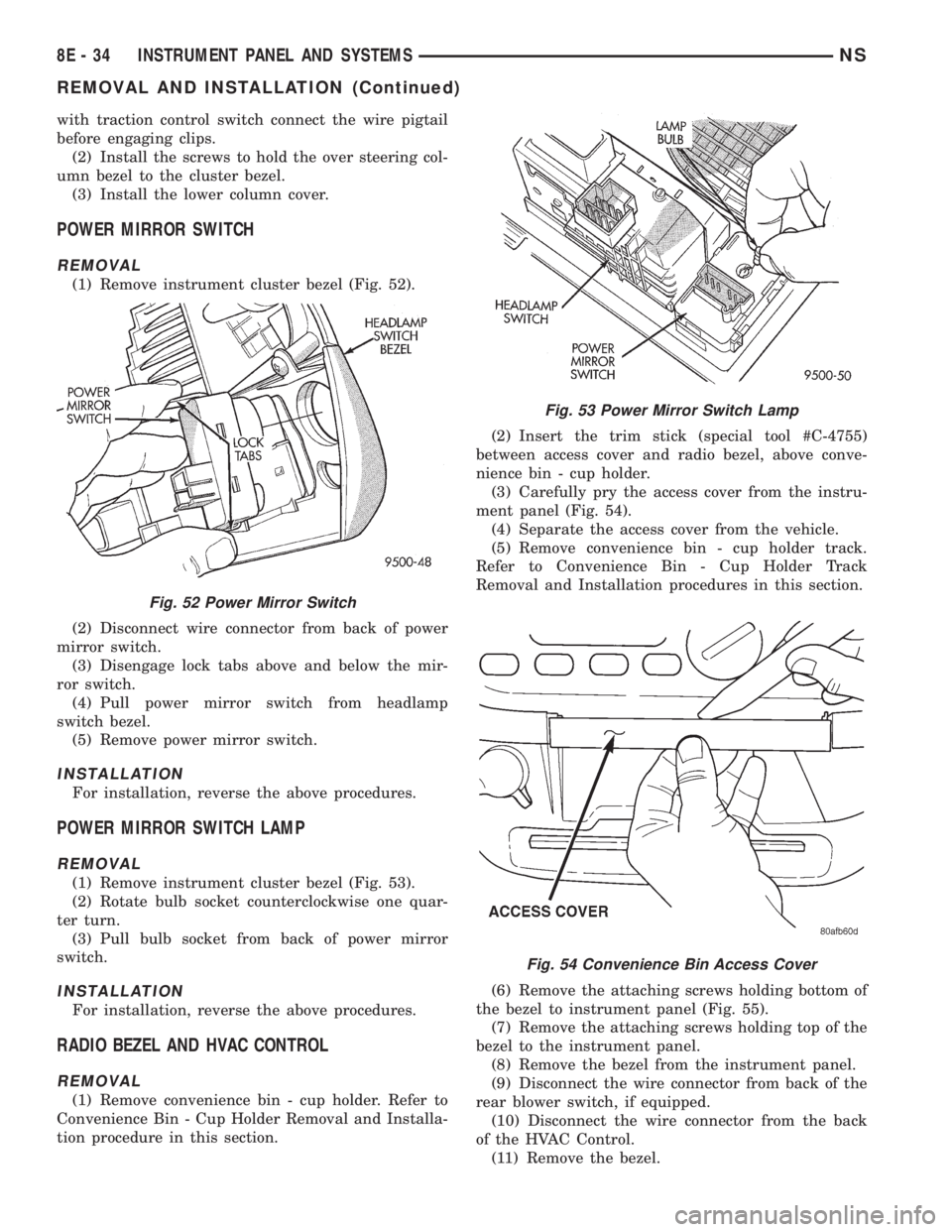

POWER MIRROR SWITCH

REMOVAL

(1) Remove instrument cluster bezel (Fig. 52).

(2) Disconnect wire connector from back of power

mirror switch.

(3) Disengage lock tabs above and below the mir-

ror switch.

(4) Pull power mirror switch from headlamp

switch bezel.

(5) Remove power mirror switch.

INSTALLATION

For installation, reverse the above procedures.

POWER MIRROR SWITCH LAMP

REMOVAL

(1) Remove instrument cluster bezel (Fig. 53).

(2) Rotate bulb socket counterclockwise one quar-

ter turn.

(3) Pull bulb socket from back of power mirror

switch.

INSTALLATION

For installation, reverse the above procedures.

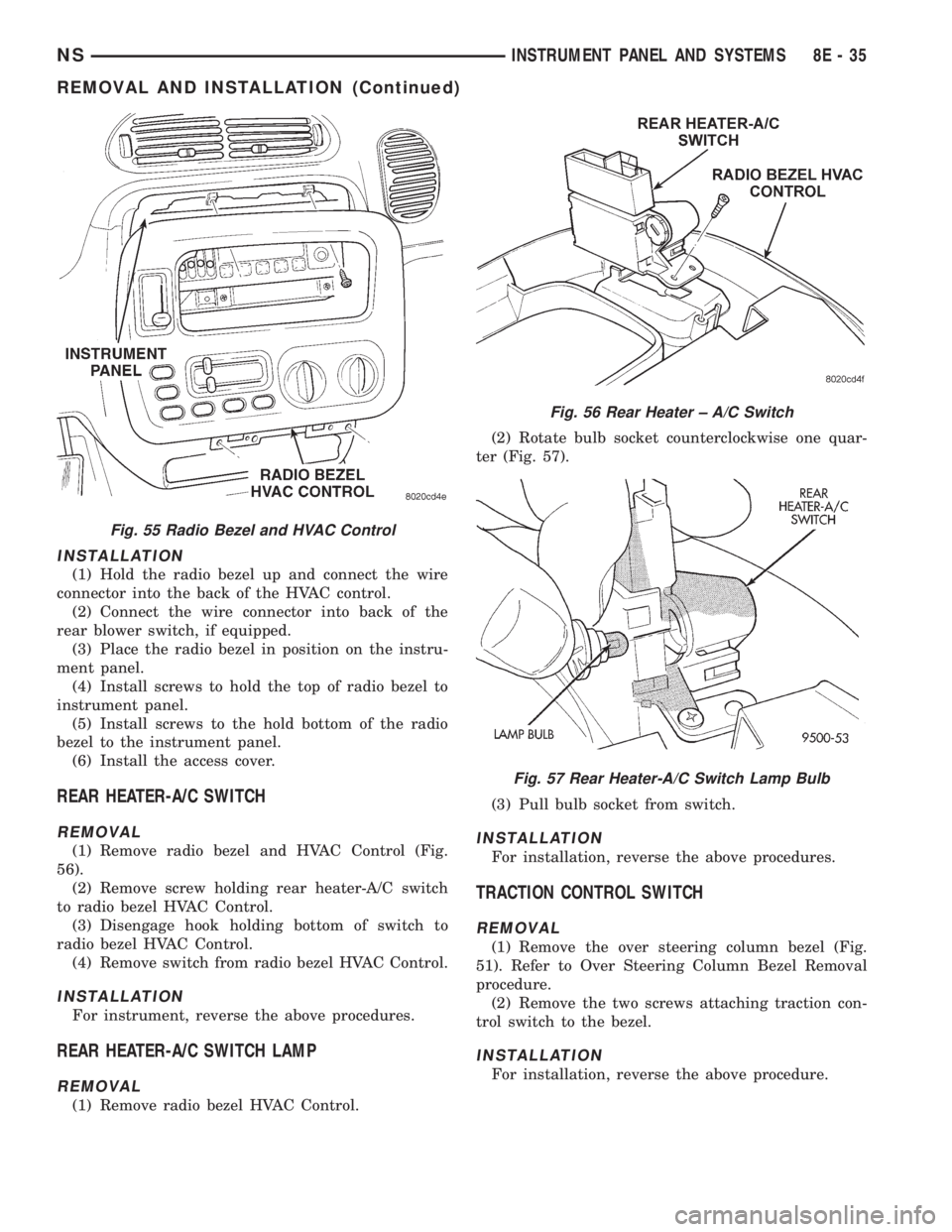

RADIO BEZEL AND HVAC CONTROL

REMOVAL

(1) Remove convenience bin - cup holder. Refer to

Convenience Bin - Cup Holder Removal and Installa-

tion procedure in this section.(2) Insert the trim stick (special tool #C-4755)

between access cover and radio bezel, above conve-

nience bin - cup holder.

(3) Carefully pry the access cover from the instru-

ment panel (Fig. 54).

(4) Separate the access cover from the vehicle.

(5) Remove convenience bin - cup holder track.

Refer to Convenience Bin - Cup Holder Track

Removal and Installation procedures in this section.

(6) Remove the attaching screws holding bottom of

the bezel to instrument panel (Fig. 55).

(7) Remove the attaching screws holding top of the

bezel to the instrument panel.

(8) Remove the bezel from the instrument panel.

(9) Disconnect the wire connector from back of the

rear blower switch, if equipped.

(10) Disconnect the wire connector from the back

of the HVAC Control.

(11) Remove the bezel.

Fig. 52 Power Mirror Switch

Fig. 53 Power Mirror Switch Lamp

Fig. 54 Convenience Bin Access Cover

8E - 34 INSTRUMENT PANEL AND SYSTEMSNS

REMOVAL AND INSTALLATION (Continued)

Page 371 of 1938

INSTALLATION

(1) Hold the radio bezel up and connect the wire

connector into the back of the HVAC control.

(2) Connect the wire connector into back of the

rear blower switch, if equipped.

(3) Place the radio bezel in position on the instru-

ment panel.

(4) Install screws to hold the top of radio bezel to

instrument panel.

(5) Install screws to the hold bottom of the radio

bezel to the instrument panel.

(6) Install the access cover.

REAR HEATER-A/C SWITCH

REMOVAL

(1) Remove radio bezel and HVAC Control (Fig.

56).

(2) Remove screw holding rear heater-A/C switch

to radio bezel HVAC Control.

(3) Disengage hook holding bottom of switch to

radio bezel HVAC Control.

(4) Remove switch from radio bezel HVAC Control.

INSTALLATION

For instrument, reverse the above procedures.

REAR HEATER-A/C SWITCH LAMP

REMOVAL

(1) Remove radio bezel HVAC Control.(2) Rotate bulb socket counterclockwise one quar-

ter (Fig. 57).

(3) Pull bulb socket from switch.

INSTALLATION

For installation, reverse the above procedures.

TRACTION CONTROL SWITCH

REMOVAL

(1) Remove the over steering column bezel (Fig.

51). Refer to Over Steering Column Bezel Removal

procedure.

(2) Remove the two screws attaching traction con-

trol switch to the bezel.

INSTALLATION

For installation, reverse the above procedure.

Fig. 55 Radio Bezel and HVAC Control

Fig. 56 Rear Heater ± A/C Switch

Fig. 57 Rear Heater-A/C Switch Lamp Bulb

NSINSTRUMENT PANEL AND SYSTEMS 8E - 35

REMOVAL AND INSTALLATION (Continued)

Page 400 of 1938

INSTALLATION

(1) Place message center in position on top cover.

(2) Install screws to hold message center to instru-

ment panel top cover.

(3) Connect wire connector into back of message

center.

(4) Install instrument panel top cover.

(5) Install A-pillar trim.

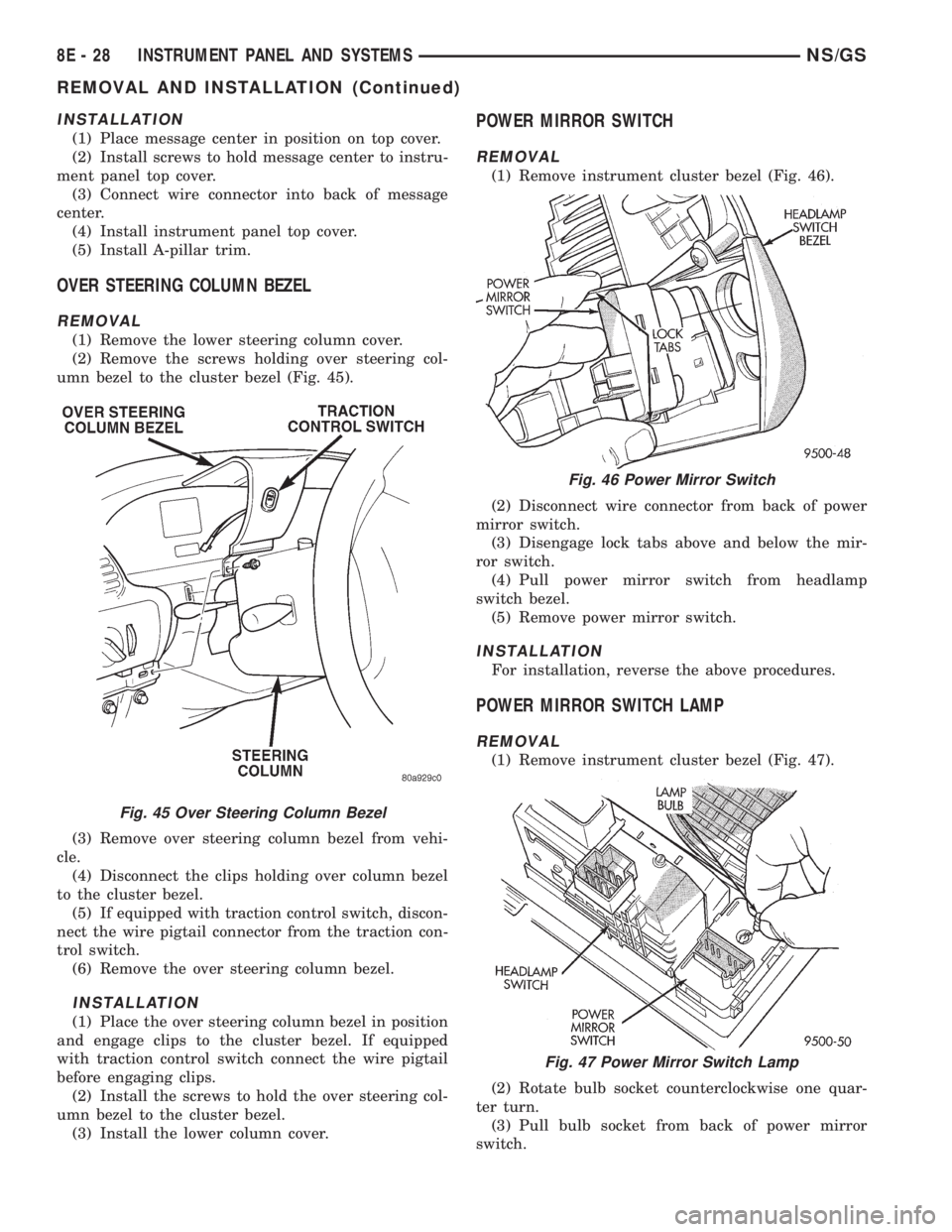

OVER STEERING COLUMN BEZEL

REMOVAL

(1) Remove the lower steering column cover.

(2) Remove the screws holding over steering col-

umn bezel to the cluster bezel (Fig. 45).

(3) Remove over steering column bezel from vehi-

cle.

(4) Disconnect the clips holding over column bezel

to the cluster bezel.

(5) If equipped with traction control switch, discon-

nect the wire pigtail connector from the traction con-

trol switch.

(6) Remove the over steering column bezel.

INSTALLATION

(1) Place the over steering column bezel in position

and engage clips to the cluster bezel. If equipped

with traction control switch connect the wire pigtail

before engaging clips.

(2) Install the screws to hold the over steering col-

umn bezel to the cluster bezel.

(3) Install the lower column cover.

POWER MIRROR SWITCH

REMOVAL

(1) Remove instrument cluster bezel (Fig. 46).

(2) Disconnect wire connector from back of power

mirror switch.

(3) Disengage lock tabs above and below the mir-

ror switch.

(4) Pull power mirror switch from headlamp

switch bezel.

(5) Remove power mirror switch.

INSTALLATION

For installation, reverse the above procedures.

POWER MIRROR SWITCH LAMP

REMOVAL

(1) Remove instrument cluster bezel (Fig. 47).

(2) Rotate bulb socket counterclockwise one quar-

ter turn.

(3) Pull bulb socket from back of power mirror

switch.

Fig. 45 Over Steering Column Bezel

Fig. 46 Power Mirror Switch

Fig. 47 Power Mirror Switch Lamp

8E - 28 INSTRUMENT PANEL AND SYSTEMSNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 579 of 1938

Component Page

Seat Belt Indicator Lamp.................8W-40

Seat Belt Switch........................8W-40

Sentry Key Immobilizer Module............8W-39

Service Engine Soon Lamp.............8W-30, 46

Sliding Door Contacts....................8W-61

Sliding Door Lock Motors.................8W-61

Speed Control Switches...............8W-30, 33

Speedometer...........................8W-40

Stop Lamp Switch...................8W-33, 51

Stop/Turn Signal Relays..................8W-54

Tachometer............................8W-40

Tail/Stop Lamp.........................8W-51

Tail/Turn Signal Lamp................8W-51, 52

Throttle Position Sensor..................8W-30

Traction Control Switch..................8W-35

Trailer Tow Connector...................8W-54

Transmission Control Module..............8W-31

Transmission Control Relay............8W-10, 31

Transmission Control Solenoids............8W-31

Transmission Range Sensor...............8W-31

Trip Odometer.........................8W-40Component Page

Turbine Speed Sensor....................8W-31

Turbo Boost Pressure Sensor..............8W-30

Turn Indicators......................8W-46, 52

Turn Signal/Hazard Switch............8W-46, 52

Underdrive Solenoid.....................8W-31

Universal Garage Door Opener............8W-49

Vacuum Solenoid.......................8W-33

Vehicle Speed Control Servo...............8W-33

Vehicle Speed Sensor....................8W-30

Vent Motors...........................8W-60

Vent Solenoids.........................8W-33

Visor/Vanity Mirror Lamps................8W-44

Voltage Regulator.......................8W-20

Volts Indicator Lamp....................8W-40

VTSS Lamp........................8W-39, 46

Washer Module.........................8W-53

Wheel Speed Sensors....................8W-35

Wiper High/Low Relay...................8W-53

Wiper Module..........................8W-53

Wiper On Relay........................8W-53

NS/GS8W - 02 COMPONENT INDEX 8W - 02 - 3

Page 617 of 1938

8W-12 JUNCTION BLOCK

Component PageA/C Compressor Clutch Relay..............8W-12-13

A/C Heater Control.................8W-12-9, 12, 23

Airbag Control Module...................8W-12-13

Ash Receiver Lamp...................8W-12-19, 23

Automatic Day/Night Mirror................8W-12-9

Back-Up Switch........................8W-12-12

Body Control Module........8W-12-8, 9, 14, 15, 17, 18,

19, 20, 22, 23, 24, 26

Brake Pressure Switch...................8W-12-17

Cigar/Accessory Relay....................8W-12-16

Clutch Interlock Switch..................8W-12-16

Clutch Interlock Switch Jumper............8W-12-16

Combination Flasher/DRL Module . . .8W-12-12, 17, 18, 19

Controller Anti-Lock Brake................8W-12-12

Courtesy Lamp Relay....................8W-12-22

CS01...............................8W-12-22

CS02...............................8W-12-21

CS04................................8W-12-9

CS1................................8W-12-22

Data Link Connector....................8W-12-20

Door Lock Relay.....................8W-12-15, 19

Door Unlock Relay...................8W-12-14, 19

Driver Door Courtesy Lamp...............8W-12-22

Driver Door Lock Motor................8W-12-14, 15

Driver Door Lock Switch..................8W-12-23

Driver Door Unlock Relay..............8W-12-14, 19

Driver Heated Seat Switch................8W-12-12

Driver Power Mirror..................8W-12-10, 26

Driver Power Window Switch............8W-12-16, 23

EGR Solenoid.........................8W-12-13

Electric Wiper De-Icer...................8W-12-11

Engine Starter Motor Relay...............8W-12-16

ES07...............................8W-12-13

ES29...............................8W-12-13

Evap Leak Detection Pump................8W-12-13

Fog Lamp Relay.......................8W-12-25

Front Blower Motor Relay.................8W-12-12

Front Cigar Lighter/Power Outlet...........8W-12-23

Front Reading Lamps/Switch..............8W-12-21

Front Washer Motor................8W-12-16, 23, 24

Front Wiper Switch................8W-12-16, 23, 24

Fuel Heater Relay......................8W-12-13

Fuel Pump Relay.......................8W-12-13

Fuse 1 (JB)............................8W-12-8

Fuse 2 (JB).........................8W-12-9, 20

Fuse 2 (PDC)..........................8W-12-13

Fuse 3 (JB)............................8W-12-8

Fuse 4 (JB)............................8W-12-8

Fuse 5 (JB).........................8W-12-8, 24

Fuse 6 (JB)............................8W-12-9

Fuse 6 (PDC)..........................8W-12-25

Fuse 7 (JB)...........................8W-12-10

Fuse 8 (JB)...........................8W-12-11

Fuse 9 (JB)...........................8W-12-11

Fuse 10 (JB)..........................8W-12-16

Fuse 11 (JB)..........................8W-12-11

Fuse 12 (JB)..........................8W-12-12

Fuse 18 (PDC).........................8W-12-26

Fuse 22 (PDC).......................8W-12-8, 24

G300..........................8W-12-11, 19, 26

Glove Box Lamp.......................8W-12-21

Headlamp Dimmer Switch..............8W-12-18, 25

Headlamp Switch.............8W-12-8, 19, 22, 23, 25

Headlamp Washer......................8W-12-24

Horn Relay...........................8W-12-17

HS2................................8W-12-12

HS4................................8W-12-12Component PageIgnition Switch...................8W-12-17, 19, 20

Instrument Cluster..............8W-12-9, 19, 20, 23

Junction Block......8W-12-2, 8, 9, 10, 11, 12, 13, 14, 15,

16, 17, 18, 19, 20, 21, 22, 23, 24, 25, 26

Key-In Halo Lamp.................8W-12-19, 22, 26

Left Combination Relay..................8W-12-18

Left Fog Lamp.......................8W-12-8, 25

Left Front Park/Turn Signal Lamp.........8W-12-8, 18

Left Liftgate Flood Lamp.................8W-12-22

Left Low Headlamp.....................8W-12-25

Left Rear Lamp Assembly...............8W-12-8, 18

Left Rear Sliding Door Contact...........8W-12-14, 15

Left Repeater Lamp.....................8W-12-18

Left Stop/Turn Signal Relay...............8W-12-18

License Lamp..........................8W-12-8

Liftgate Lock Motor..................8W-12-14, 15

Low Beam Relay.......................8W-12-25

Message Center..............8W-12-9, 17, 18, 19, 20

Name Brand Speaker Relay.............8W-12-11, 19

Overhead Console.......................8W-12-9

Park Brake Switch......................8W-12-17

Park Lamp Relay.....................8W-12-8, 24

Passenger Door Courtesy Lamp.............8W-12-22

Passenger Door Lock Motor.............8W-12-14, 15

Passenger Door Lock Switch...............8W-12-23

Passenger Heated Seat Switch..............8W-12-12

Passenger Power Mirror...............8W-12-10, 26

Passenger Power Window Switch.........8W-12-16, 23

Power Distribution Center.........8W-8,12-12, 13, 16,

17, 24, 25, 26

Power Folding Mirror Switch............8W-12-19, 26

Power Mirror Fold Relay..................8W-12-26

Power Mirror Switch...............8W-12-19, 21, 23

Power Mirror Unfold Relay................8W-12-26

Powertrain Control Module................8W-12-13

PTC 1 (JB)...........................8W-12-13

PTC 3 (JB)......................8W-12-14, 15, 24

PTC 7 (JB).........................8W-12-16, 24

PTC 8 (JB)...........................8W-12-16

PTC 9 (JB)...........................8W-12-16

Radio..........................8W-12-11, 20, 23

Radio Choke..........................8W-12-11

Rear A/C Heater Unit....................8W-12-11

Rear Blower Front Control Switch...........8W-12-23

Rear Blower Rear Control Switch...........8W-12-23

Rear Washer Motor.....................8W-12-16

Rear Window Defogger...................8W-12-10

Rear Window Defogger Relay............8W-12-10, 12

Rear Wiper Motor.......................8W-12-9

Remote Keyless Entry Module..............8W-12-20

Right Combination Relay.................8W-12-18

Right Fog Lamp......................8W-12-8, 25

Right Front Park/Turn Signal Lamp........8W-12-8, 18

Right Liftgate Flood Lamp................8W-12-22

Right Rear Lamp Assembly..............8W-12-8, 18

Right Rear Sliding Door Contact..........8W-12-14, 15

Right Repeater Lamp....................8W-12-18

Right Stop/Turn Signal Relay..............8W-12-18

Sentry Key Immobilizer Module..........8W-12-13, 21

Stop Lamp Switch......................8W-12-19

Traction Control Switch................8W-12-19, 23

Trailer Tow Connector....................8W-12-8

Transmission Control Module.............8W-12-9, 16

Transmission Range Sensor................8W-12-12

Turn Signal/Hazard Switch................8W-12-17

Universal Garage Door Opener.............8W-12-23

Washer Module.................8W-12-8, 15, 16, 23

NS/GS8W - 12 JUNCTION BLOCK 8W - 12 - 1

Page 635 of 1938

HEADLAMP

SWITCH C1

62C2

C42921C4

C21410C2

36C4

BK20Z1

1

HALO KEY-IN

LAMP

C435

SWITCH POWER

MIRROR

SWITCH TRACTION

CONTROL

BK20Z1

BK20Z1

1

11

28C4

C2SWITCH

13

CLUSTER INSTRUMENT

2

IGNITION

Z1

20

BKZ1

20

BK

BK18Z1BK20Z1

RECEIVER ASH

LAMP

1

MESSAGE

CENTER

3

C422

BK14Z1

C22

SPEAKER BRAND

NAME

RELAY

85MODULE

11

COMBINATION

FLASHER/

DRL

MODULE CONTROL

BODY

3 RELAY UNLOCK

87A

DOOR DRIVER

DOOR

UNLOCK

RELAY

87A 87A

RELAY LOCK

DOOR

JUNCTION

BLOCK

8

(RKE)

Z1

18

BK

Z1

20

BK

Z2

20

BK/LGZ2

20

BK/LG

*3 *4FROM

SWITCHLAMPSTOP

Z1

20

BK

2-EXPORT) (BUILT-UP

SWITCH

MIRROR

FOLDING

POWER

Z1

20

BK

* RHD

(RHD)(GAS)

30

3030

86

G300

4

8787

87

(8W-50-9)

(8W-50-10)(8W-50-13)(8W-44-3) (8W-62-2)

(8W-62-4)

(8W-62-5)

(8W-35-2) (8W-10-14) (8W-40-4)

(8W-44-7) (8W-46-4)

(8W-47-4)(8W-45-2) (8W-61-3)

(8W-61-4)

(8W-61-7)

(8W-61-8) (8W-61-3)

(8W-61-4)

(8W-61-7)

(8W-61-8)(8W-12-2)

(8W-61-7)

(8W-61-8)(8W-33-3)(8W-62-8)

(8W-15-6)

NS/GS8W-12 JUNCTION BLOCK 8W - 12 - 19

GS001219J988W-3