warning light CHRYSLER VOYAGER 1996 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 527 of 1938

If motor grunts and does not move, verify that reg-

ulator is not binding.

WIRING VOLTAGE TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to switch.

(1) Remove the master power window switch and

bezel assembly from the driver door. Refer to Group

23, Body for proper procedures.

(2) Disconnect wire connector from back of power

window switch.

(3) Switch ignition ON position.

(4) Connect the clip end of a 12 volt test light to

Pin 13 in door harness connector at the window

switch. Touch the test light probe to Pin 9 and then

to Pin 11.

²If the test light illuminates, the wiring circuit

between the battery and switch is OK.

²If light does not illuminate, check the 40 amp

fuse in the Power Distribution Center or for a broken

wire.

²The power window motors are protected with

Positive Temperature Coefficient (PTC) device that

prevents motor burn out. Check Junction Block.

²Refer to Group 8W, Wiring Diagrams for circuit

information and component locations.

REMOVAL AND INSTALLATION

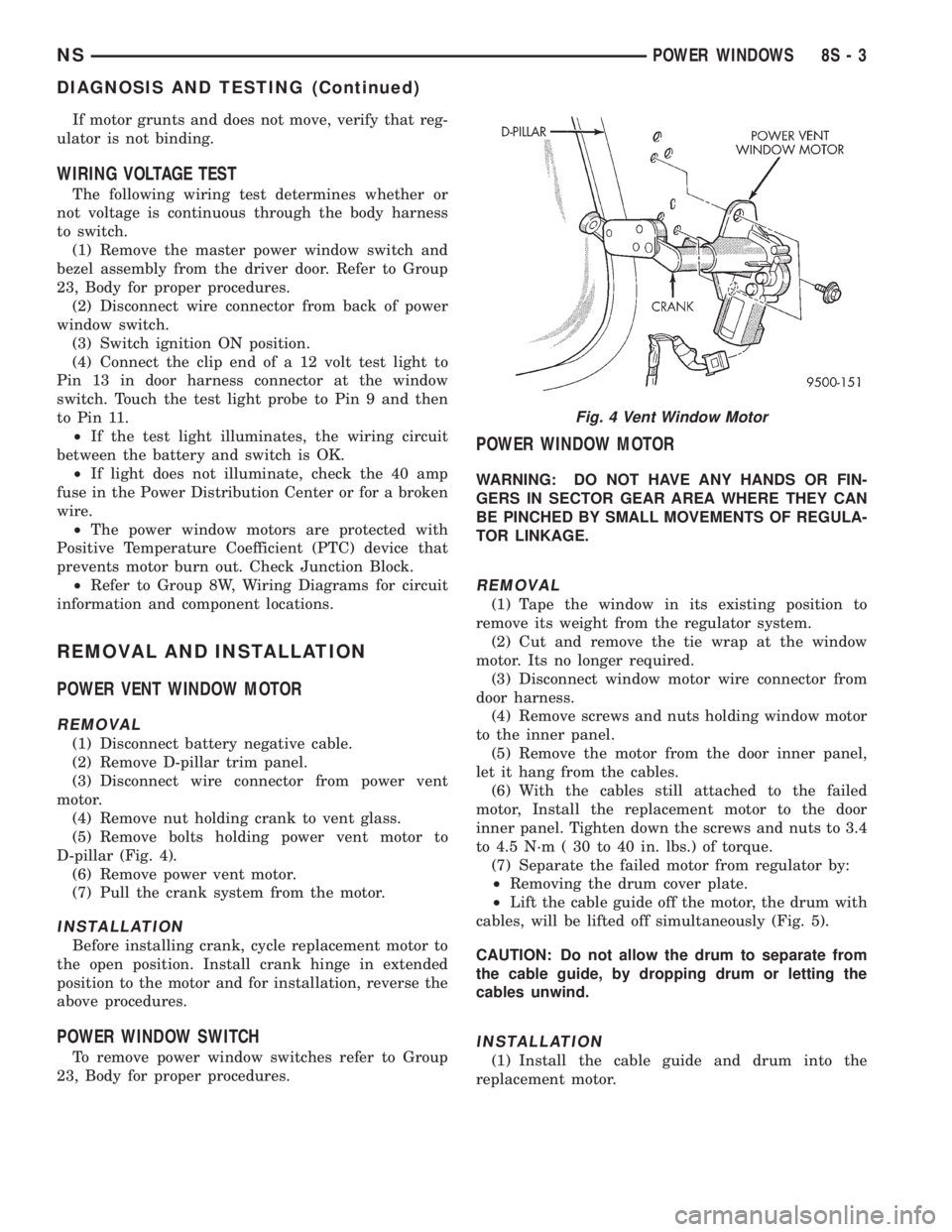

POWER VENT WINDOW MOTOR

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove D-pillar trim panel.

(3) Disconnect wire connector from power vent

motor.

(4) Remove nut holding crank to vent glass.

(5) Remove bolts holding power vent motor to

D-pillar (Fig. 4).

(6) Remove power vent motor.

(7) Pull the crank system from the motor.

INSTALLATION

Before installing crank, cycle replacement motor to

the open position. Install crank hinge in extended

position to the motor and for installation, reverse the

above procedures.

POWER WINDOW SWITCH

To remove power window switches refer to Group

23, Body for proper procedures.

POWER WINDOW MOTOR

WARNING: DO NOT HAVE ANY HANDS OR FIN-

GERS IN SECTOR GEAR AREA WHERE THEY CAN

BE PINCHED BY SMALL MOVEMENTS OF REGULA-

TOR LINKAGE.

REMOVAL

(1) Tape the window in its existing position to

remove its weight from the regulator system.

(2) Cut and remove the tie wrap at the window

motor. Its no longer required.

(3) Disconnect window motor wire connector from

door harness.

(4) Remove screws and nuts holding window motor

to the inner panel.

(5) Remove the motor from the door inner panel,

let it hang from the cables.

(6) With the cables still attached to the failed

motor, Install the replacement motor to the door

inner panel. Tighten down the screws and nuts to 3.4

to 4.5 N´m ( 30 to 40 in. lbs.) of torque.

(7) Separate the failed motor from regulator by:

²Removing the drum cover plate.

²Lift the cable guide off the motor, the drum with

cables, will be lifted off simultaneously (Fig. 5).

CAUTION: Do not allow the drum to separate from

the cable guide, by dropping drum or letting the

cables unwind.

INSTALLATION

(1) Install the cable guide and drum into the

replacement motor.

Fig. 4 Vent Window Motor

NSPOWER WINDOWS 8S - 3

DIAGNOSIS AND TESTING (Continued)

Page 544 of 1938

(2) Inspect BCM connectors and wires for proper

connection. If OK, replace BCM for tone condition.

DOME LAMP ON CHIME

The dome lamp on chime will warn the driver that

the dome lamps have been left on.

With the ignition is OFF:

²Driver's door OPEN (door ajar switch is closed to

ground)

²Dome lamps are ON (dome lamp switch is closed

to ground),

The chime will sound continuously until driver's

door is closed, dome lamps tuned OFF or until the

battery protection time out of 15 minutes has

expired. Refer Group 8L, Lamps proper procedures.

Chime rate: 168 to 192 chimes per minute.

ENGINE TEMPERATURE CRITICAL CHIME

The engine temperature critical chime will warn

the driver that the vehicle's engine is overheating.

While monitoring the coolant temperature, the Pow-

ertrain Control Module (PCM) will send on the CCD

bus as engine temperature every 1.376 seconds to the

Body Control Module (BCM). The BCM calculates

engine temperature and determines if a warning

should occur. This feature is functional only with the

Ignition Switch in the Run/Start position.

When the engine temperature reaches 122ÉC

(252ÉF) the BCM will chime one tone and the engine

temperature lamp comes ON. The BCM turns OFF

the lamp when the engine temperature reaches

117ÉC (242ÉF). The BCM will chime continuously

when the engine temperature reaches 125ÉC (257ÉF).

The chime will turn OFF after four minutes or when

the temperature reaches 117ÉC (242ÉF), which ever

occurs first.

EXTERIOR LAMPS ON CHIME

The exterior lamp on chime will warn the driver

that the exterior lights have been left on.

With the ignition switch OFF:

²Driver's door is open (door ajar switch is closed

to ground)

²Parking lamps or headlamps ON (parking lamp

switch is closed to ground)

The chime will sound until lights are turned OFF,

driver's door closed or until the battery protection

time out of 3 minutes has expired.

Refer to Group 8L, Lamps, for proper service pro-

cedures. Chime rate: 168 to 192 chimes per minute.

To test the exterior lamps left on function:

²Turn ignition off

²Remove ignition key

²Turn exterior lamps on with driver's door open.

Chime should sound until lamps are turned off or

driver's door is closed.

KEY-IN IGNITION CHIME

The key-in ignition chime will act as a warning to

the driver that the ignition key has been left in the

ignition switch.

With the ignition switch is in OFF position ONLY:

²Driver's door is open/ajar (door ajar switch is

closed to ground)

²Key is in the ignition switch (key-in ignition

switch is closed to ground)

The chime will sound until one of the above condi-

tions is removed. Chime rate: 168 to 192 chimes per

minute.

To test the key-in ignition function, insert key into

the ignition and open driver's door. Do not turn igni-

tion ON. Chime should sound until key is removed

from ignition or driver's door is closed.

LOW OIL PRESSURE CHIME OPERATION

The low oil pressure chime will warn the driver

that the engine oil pressure is low. The oil pressure

switch, will close to ground during a low oil pressure

condition. The oil pressure lamp will illuminate in

the message center. The body control module will

monitor the oil pressure switch and signal a low oil

pressure condition. A continuous four minute warn-

ing chime will sound and the oil pressure lamp will

come ON when the following conditions are met:

²Ignition on and engine not cranking

²Engine running at 420 to 480 rpm for 10 sec-

onds

²Oil pressure switch closed to ground for (1 sec-

ond minimum, 2 seconds maximum)

Chime rate: 168 to 192 chimes per minute.

SEAT BELT CHIME

The seat belt chime will sound for 4 to 8 seconds,

when the ignition is turned on and the driver's seat

belt is not buckled (seat belt switch is closed to

ground). This is a reminder to the driver to buckle

the seat belt. The seat belt lamp is controlled by the

mechanical instrument cluster. The cluster will also

illuminate the seat belt warning lamp for 6 seconds.

Buckling the driver's seat belt before the time out

has expired will cause the chime to stop immediately.

Chime rate: 38 to 62 chimes per minute.

To test the seat belt warning system, the ignition

switch must be in the OFF position for 1 minute

before starting the test. Turn the ignition switch to

the on position with the driver's seat belt not buck-

led. The seat belt warning lamp should light and the

chime should sound 4 to 8 seconds.

SEAT BELT LAMP

The seat belt lamp in the instrument cluster sig-

nals the vehicle passengers to fasten their seat belts.

The seat belt lamp is illuminated directly by the

8U - 2 CHIME WARNING/REMINDER SYSTEMNS

DIAGNOSIS AND TESTING (Continued)

Page 548 of 1938

FASTEN SEAT BELT LAMP OR TONE

CONTINUES FOR MORE THAN 10 SECONDS

AFTER SEAT BELTS ARE FASTENED AND

DRIVER'S DOOR IS CLOSED.

(1) Check left door ajar switch for no ground when

switch is depressed.

(a) If continuity replace door ajar switch.

(b) If NO continuity replace BCM for tone condi-

tion, or replace mechanical instrument panel for

lamp condition.

(c) Replace BCM for tone condition.

(d) Replace mechanical instrument cluster for

lamp condition.

NO TONE WHEN PARK OR HEADLAMPS ARE

ON AND DRIVER'S DOOR IS OPEN.

(1) Check left door ajar switch for good ground

when driver's door is open. Repair as necessary.

(2) Inspect BCM connectors and wires for proper

connection. If OK, replace BCM for tone condition.

DOME LAMP ON CHIME

The dome lamp on chime will warn the driver that

the dome lamps have been left on.

With the ignition is OFF:

²Driver's door OPEN (door ajar switch is closed to

ground)

²Dome lamps are ON (dome lamp switch is closed

to ground),

The chime will sound continuously until driver's

door is closed, dome lamps tuned OFF or until the

battery protection time out of 15 minutes has

expired. Refer Group 8L, Lamps proper procedures.

Chime rate: 168 to 192 chimes per minute.

ENGINE TEMPERATURE CRITICAL CHIME

The engine temperature critical chime will warn

the driver that the vehicle's engine is overheating.

While monitoring the coolant temperature, the Pow-

ertrain Control Module (PCM) will send on the CCD

bus as engine temperature every 1.376 seconds to the

Body Control Module (BCM). The BCM calculates

engine temperature and determines if a warning

should occur. This feature is functional only with the

Ignition Switch in the Run/Start position. On the

Diesel vehicles, the coolant temperature sensor is

read directly by the BCM.

When the engine temperature reaches 122ÉC

(252ÉF) or the diesel engine 112ÉC (234ÉF), the BCM

will chime one tone and the engine temperature lamp

comes ON. The BCM turns OFF the lamp when the

engine temperature reaches 117ÉC (242ÉF) or the die-

sel engine 108ÉC (226ÉF). The BCM will chime con-

tinuously when the engine temperature reaches

125ÉC (257ÉF) or diesel engine 116ÉC (241ÉF). The

chime will turn OFF after four minutes or when thetemperature reaches 117ÉC (242ÉF) or diesel engine

108ÉC (226ÉF), which ever occurs first.

EXTERIOR LAMPS ON CHIME

The exterior lamp on chime will warn the driver

that the exterior lights have been left on.

With the ignition switch OFF:

²Driver's door is open (door ajar switch is closed

to ground)

²Parking lamps or headlamps ON (parking lamp

switch is closed to ground)

The chime will sound until lights are turned OFF,

driver's door closed or until the battery protection

time out of 3 minutes has expired.

Refer to Group 8L, Lamps, for proper service pro-

cedures. Chime rate: 168 to 192 chimes per minute.

To test the exterior lamps left on function:

²Turn ignition off

²Remove ignition key

²Turn exterior lamps on with driver's door open.

Chime should sound until lamps are turned off or

driver's door is closed.

KEY-IN IGNITION CHIME

The key-in ignition chime will act as a warning to

the driver that the ignition key has been left in the

ignition switch.

With the ignition switch is in OFF position ONLY:

²Driver's door is open/ajar (door ajar switch is

closed to ground)

²Key is in the ignition switch (key-in ignition

switch is closed to ground)

The chime will sound until one of the above condi-

tions is removed. Chime rate: 168 to 192 chimes per

minute.

To test the key-in ignition function, insert key into

the ignition and open driver's door. Do not turn igni-

tion ON. Chime should sound until key is removed

from ignition or driver's door is closed.

LOW OIL PRESSURE CHIME OPERATION

The low oil pressure chime will warn the driver

that the engine oil pressure is low. The oil pressure

switch, will close to ground during a low oil pressure

condition. The oil pressure lamp will illuminate in

the message center. The body control module will

monitor the oil pressure switch and signal a low oil

pressure condition. A continuous four minute warn-

ing chime will sound and the oil pressure lamp will

come ON when the following conditions are met:

²Ignition on and engine not cranking

²Engine running at 420 to 480 rpm for 10 sec-

onds

²Oil pressure switch closed to ground for (1 sec-

ond minimum, 2 seconds maximum)

Chime rate: 168 to 192 chimes per minute.

8U - 2 CHIME WARNING/REMINDER SYSTEMNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 549 of 1938

SEAT BELT CHIME

The seat belt chime will sound for 4 to 8 seconds,

when the ignition is turned on and the driver's seat

belt is not buckled (seat belt switch is closed to

ground). This is a reminder to the driver to buckle

the seat belt. The seat belt lamp is controlled by the

mechanical instrument cluster. The cluster will also

illuminate the seat belt warning lamp for 6 seconds.

Buckling the driver's seat belt before the time out

has expired will cause the chime to stop immediately.

Chime rate: 38 to 62 chimes per minute.

To test the seat belt warning system, the ignition

switch must be in the OFF position for 1 minute

before starting the test. Turn the ignition switch to

the on position with the driver's seat belt not buck-

led. The seat belt warning lamp should light and the

chime should sound 4 to 8 seconds.

SEAT BELT LAMP

The seat belt lamp in the instrument cluster sig-

nals the vehicle passengers to fasten their seat belts.

The seat belt lamp is illuminated directly by the

instrument cluster for 6 seconds after the instrument

cluster receives the message from the Body Control

Module. The seat belt lamp is therefore illuminated

for 6 seconds whenever the ignition switch is moved

to run/start position.

(1) While ignition is off, the seat belt lamp will not

be illuminated.

(2) The ignition power feed status will be updated

every 250 milliseconds or on change.

(3) This lamp will be checked by the instrument

cluster for 6 seconds with every run/start cycle of the

ignition switch.

TURN SIGNAL ON CHIME

The turn signal on chime will warn the driver that

the turn signals have been left on. When the Body

Control Module receives a turn signal input for 1.6

km (1.0 miles), vehicle speed is greater than 24 km/h

(15 mph), the chime will sound continuously until the

turn signal is turned OFF. If vehicle speed drops

below 24 km/h (15 mph) prior to the warning being

activated, the accumulated distance traveled will be

reset. The turn signal chime is not activated whenthe emergency flashers are turned on. This feature

can also be disabled in EEPROM. Chime rate: 38 to

62 chimes per minute.

For the turn signal warning system to operate:

²Must have input from either the right or left

turn signal lamps. Creates a voltage change between

0 and battery voltage.

²The vehicle speed sensor sends a message to the

Powertrain Control Module that vehicle has exceeded

24 km/h (15 mph) for 1.6 km (1.0 miles).

²When the above two conditions are met, the

chime will sound. The chime will stop when no fur-

ther voltage change is detected.

²If hazard warning signals are pulsing, no chime

will sound.

²If speed drops below 24 km/h (15 mph) before

the warning is issued, the warning will not be issued

and the distance counter will be reset.

²If turn signal lamps are not working properly,

the chime will not sound.

²When using the scan tool, refer to the proper

Body Diagnostic Manual for the procedure.

WARNING LAMP ANNOUNCEMENT CHIME

The warning lamp announcement chime will warn

the driver to scan the instrument cluster to observe

which warning lamp is illuminated. Whenever the

volts, low fuel, low washer fluid, coolant level (gas/

diesel), low coolant level, engine temperature high

(diesel only), door ajar or gate ajar lamps are first

illuminated, the chime will sound one tone. The door/

liftgate ajar warning lamp announcement chime

sounds only if the vehicle speed is above 2 m.p.h.

Two seconds after ignition switch is turned ON or

until the seat belt warning chime ends, all warning

announcement chimes will be consolidated into one

warning announcement. This will occur 2 seconds

after the seat belt warning chime ends. If a warning

announcement should occur while another warning

chime in progress (turn signal, low oil pressure or

high speed warnings), no additional chimes will

sound after the chime in progress ends. All associ-

ated lamps will be illuminated, and the active chime

will be the warning announcement.

NS/GSCHIME WARNING/REMINDER SYSTEM 8U - 3

DIAGNOSIS AND TESTING (Continued)

Page 577 of 1938

8W-02 COMPONENT INDEX

Component Page

2-4 Pressure Switch.....................8W-31

2-4 Solenoid...........................8W-31

A/C Compressor Clutch..................8W-42

A/C Compressor Clutch Relay...........8W-10, 42

A/C Heater Control.....................8W-42

A/C On Indicator.......................8W-42

A/C Pressure Transducer..............8W-30, 42

A/C Switch............................8W-42

A/C Zone Door Actuator..................8W-42

ABS Warning Lamp..................8W-35, 46

Accelerator Pedal Position Sensor..........8W-30

Airbag Control Module...................8W-43

Airbag Indicator Lamp...................8W-43

Airbag Warning Lamp...................8W-46

All Wheel Drive Solenoid.................8W-31

Ambient Air Temperature Sensor...........8W-49

Ash Receiver Lamp.....................8W-44

Automatic Day/Night Mirror..............8W-44

Automatic Shut Down Relay............8W-10, 30

Splice Information......................8W-70

Back-Up Lamp.........................8W-51

Back-Up Switch.....................8W-44, 51

Battery...............................8W-20

Blend Door Actuator.....................8W-42

Body Control Module....................8W-45

Brake Pressure Switch...................8W-46

Brake Warning Lamp....................8W-46

Camshaft Position Sensor................8W-30

Center Dome Lamp.....................8W-44

Center High Mounted Stop Lamp..........8W-51

Cigar/Accessory Relay...................8W-41

Clockspring.......8W-10, 15, 30, 33, 39, 40, 41, 43

Cluster Illumination Lamps...............8W-40

Clutch Interlock Switch...............8W-12, 21

Clutch Interlock Switch Jumper......8W-12, 21, 31

Clutch Switch.......................8W-30, 33

Combination Flasher/DRL Module. . . .8W-50, 51, 52

Combination Relays.....................8W-54

Compass/Mini-Trip Computer..............8W-49

Control Sleeve Sensor....................8W-30

Controller Anti-Lock Brake...............8W-35

Courtesy Lamp Relay...........8W-10, 12, 44, 50

Crank Case Heater......................8W-30

Crankshaft Position Sensor...............8W-30

Cruise Indicator Lamp...................8W-40

Data Link Connector....................8W-30

Diesel Power Relay...................8W-10, 30

Dome Lamp Switch.....................8W-50

Door Ajar Indicator Lamp................8W-40

Door Ajar Switches................8W-39, 40, 44

Door Lock Relay........................8W-61

Speakers..............................8W-47Component Page

Door Unlock Relay......................8W-61

Oxygen Sensors........................8W-30

Door Ajar Switches.............8W-39, 40, 44, 45

Door Arm/Disarm Switches.............8W-39, 61

Door Courtesy Lamps....................8W-44

Door Lock Motors.......................8W-61

Door Lock Switches.....................8W-61

Door Unlock Relays.....................8W-61

Heated Seat Backs......................8W-63

Heated Seat Cushions...................8W-63

Heated Seat Modules....................8W-63

Heated Seat Switches....................8W-63

Power Mirrors.........................8W-62

Power Seat Switches....................8W-63

Power Window Switches..................8W-60

Seat Motors...........................8W-63

Window Motors........................8W-60

Radiator Fans.........................8W-42

Dump Solenoid.........................8W-33

EGR Solenoid..........................8W-30

Electric Wiper De-Icer...................8W-48

Electronic PRNDL Indicator...............8W-40

Engine Coolant Temperature Gauge.........8W-40

Engine Coolant Temperature Lamp.........8W-46

Engine Coolant Temperature Sensor........8W-30

Engine Oil Pressure Switch...............8W-46

Engine Speed Sensor....................8W-30

Engine Starter Motor....................8W-21

Engine Starter Motor Relay............8W-10, 21

Evap Leak Detection Pump...............8W-30

Evap/Purge Solenoid....................8W-30

Evaporator Temperature Sensor............8W-42

Express Down Module...................8W-60

Flexible Fuel Sensor.....................8W-30

Fog Lamps............................8W-50

Fog Lamp Relay........................8W-50

Front Blower Motor.....................8W-42

Front Blower Motor Relay.............8W-10, 42

Front Blower Motor Resistor Block.........8W-42

Front Cigar Lighter/Power Outlet..........8W-41

Front Reading Lamp Defeat Switch.........8W-44

Front Reading Lamps/Switch..............8W-44

Front Washer Motor.....................8W-53

Front Wiper Switch.....................8W-53

Fuel Gauge............................8W-40

Fuel Heater...........................8W-30

Fuel Heater Relay...................8W-10, 30

Fuel Injectors..........................8W-30

Fuel Pump Module......................8W-30

Fuel Pump Relay....................8W-10, 30

Fuel Quantity Actuator..................8W-30

Fuel Shutdown Solenoid..................8W-30

NS/GS8W - 02 COMPONENT INDEX 8W - 02 - 1

Page 578 of 1938

Component Page

Fuel Tank Module...................8W-30, 45

Fuel Temperature Sensor.................8W-30

Fuel Timing Solenoid....................8W-30

Fuses (JB)............................8W-12

Fuses (PDC)...........................8W-10

Fusible Link.....................8W-20, 21, 63

Fusible Link A0........................8W-30

Fusible Link A11.......................8W-10

Fusible Link A54.......................8W-10

Grounds..............................8W-15

Generator.............................8W-20

Glove Box Lamp........................8W-44

Glow Plug Lamp.....................8W-30, 46

Glow Plugs............................8W-30

Glow Plug Relay........................8W-30

Headlamps............................8W-50

Headlamp Dimmer Switch..........8W-10, 46, 50

Headlamp Leveling Motors...............8W-50

Headlamp Switch.......................8W-50

Headlamp Washer......................8W-53

High Beam Indicator....................8W-46

High Beam Relay....................8W-10, 50

Headlamps............................8W-50

Horns................................8W-41

Hood Ajar Switch....................8W-39, 44

Horn Relay.........................8W-39, 41

Horn Switch.....................8W-10, 39, 41

HVAC Control.........................8W-42

Idle Air Control Motor...................8W-30

Ignition Coil Pack.......................8W-30

Ignition Switch.........................8W-10

Instrument Cluster.....................8W-40

Intake Air Temperature Sensor............8W-30

Intake Air Temperature/Manifold Absolute

Pressure Sensor.....................8W-30

Interior Lamps On Switch................8W-44

Junction Block.........................8W-12

Key-In Halo Lamp......................8W-44

Knock Sensor..........................8W-30

Lamp Assemblies.......................8W-51

License Lamp..........................8W-51

Liftgate Ajar Indicator Lamp..............8W-40

Liftgate Ajar Switch...............8W-39, 40, 44

Liftgate Arm/Disarm Switch............8W-39, 61

Liftgate Flood Lamps....................8W-44

Liftgate Lock Motor.....................8W-61

Low Beam Relay.....................8W-10, 50

Low Coolant Level Switch................8W-45

Low Fuel Warning Indicator Lamp..........8W-40

Low Oil Pressure Lamp..................8W-46

Low Washer Fluid Level Indicator Lamp.....8W-40

Low Washer Fluid Switch.................8W-53

Low/Reverse Pressure Switch..............8W-31

Low/Reverse Solenoid....................8W-31Component Page

Manifold Absolute Pressure Sensor.........8W-30

Memory Power Seat Switch...............8W-63

Seat Sensors...........................8W-63

Memory Seat/Mirror Module...........8W-62, 63

Memory Set Switch..................8W-62, 63

Message Center........................8W-46

Mid Reading Lamps.....................8W-44

Mode Door Actuator.....................8W-42

Name Brand Speaker Relay...............8W-47

Needle Movement Sensor.................8W-30

Odometer.............................8W-40

Output Shaft Speed Sensor...............8W-31

Overdrive Pressure Switch................8W-31

Overdrive Solenoid......................8W-31

Overhead Console.......................8W-49

Park Brake Switch...................8W-46, 50

Park Lamp Relay.........8W-10, 12, 44, 50, 51, 54

Park/Turn Signal Lamps.................8W-50

Airbag Squibs..........................8W-43

Power Distribution Center................8W-10

Power Folding Mirror Switch..............8W-62

Power Mirror Fold Relay.................8W-62

Power Mirror Switch....................8W-62

Power Mirror Unfold Relay...............8W-62

Power Seat Circuit Breaker............8W-62, 63

Powertrain Control Module...............8W-30

PTCs (JB).............................8W-12

Radiator Fan Disconnect.................8W-42

Radiator Fan Relays.....................8W-42

Radio................................8W-47

Radio Choke...........................8W-47

Reading Lamps........................8W-44

Rear A/C Heater Unit....................8W-42

Rear Blower Control Switches.............8W-42

Rear Cigar Lighter/Power Outlet...........8W-41

Rear Defogger On Indicator...............8W-42

Rear Dome Lamp.......................8W-44

Rear Fog Lamp.........................8W-51

Rear Fog Lamp Indicator.................8W-51

Rear Washer Motor.....................8W-53

Rear Washer Switch..................8W-42, 53

Rear Window Defogger...................8W-48

Rear Window Defogger Relay..............8W-48

Rear Window Defogger Switch..........8W-42, 48

Rear Wiper Delay On Indicator.........8W-42, 53

Rear Wiper Delay Switch..............8W-42, 53

Rear Wiper Motor.......................8W-53

Rear Wiper On Indicator..............8W-42, 53

Rear Wiper On Switch................8W-42, 53

Recirculate Mode Indicator................8W-42

Recirculate Mode Switch.................8W-42

Recirculation Door Actuator...............8W-42

Remote Keyless Entry Module.............8W-61

Repeater Lamps.....................8W-51, 52

8W - 02 - 2 8W - 02 COMPONENT INDEXNS/GS

Page 813 of 1938

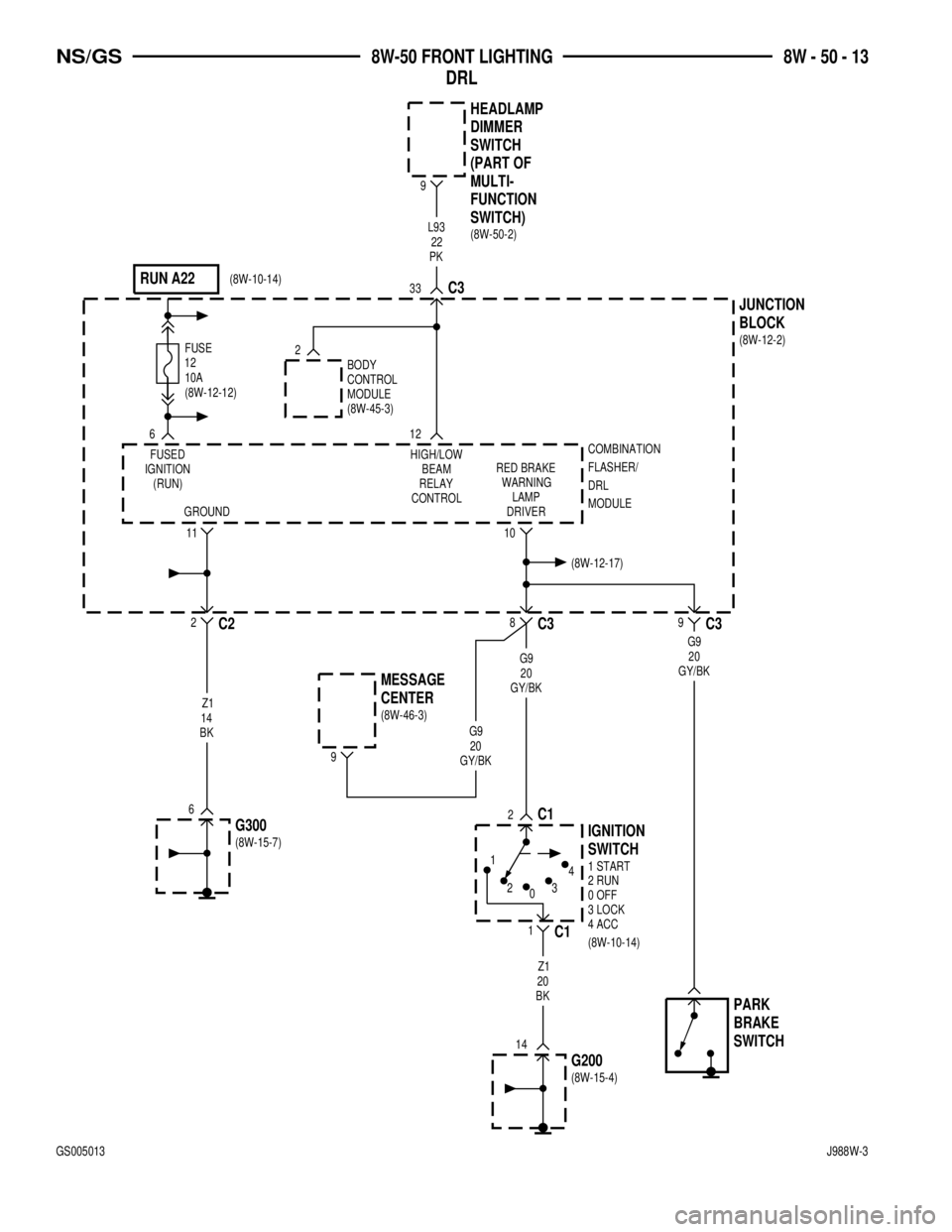

G300

6

4 ACC 0 OFF

3 LOCK 2 RUN 1 START

4

2

03

GY/BK20 G9

GY/BK20 G9MESSAGE

CENTER

9

BK20Z1PARK

BRAKE

SWITCH

14

G200

IGNITION

SWITCH

2C1

1C1 C3

89C3

10DRIVERLAMP WARNING RED BRAKE

1

COMBINATION

FLASHER/

DRL

MODULE

11

10A

FUSE

122BODY

CONTROL

MODULE

33C3

9

SWITCH) FUNCTION

MULTI-

(PART OF

SWITCH

DIMMER

HEADLAMPL93

22

PK

RUN A22

612

HIGH/LOW

BEAM

RELAY

CONTROL FUSED

IGNITION

(RUN)

GROUND

2C2

Z1

14

BK

G9

20

GY/BK

BLOCK JUNCTION

(8W-15-7)(8W-46-3)

(8W-15-4)(8W-10-14) (8W-12-12)

(8W-45-3)(8W-50-2)

(8W-10-14)

(8W-12-2)

(8W-12-17)

NS/GS8W-50 FRONT LIGHTING

DRL8W - 50 - 13

GS005013J988W-3

Page 1226 of 1938

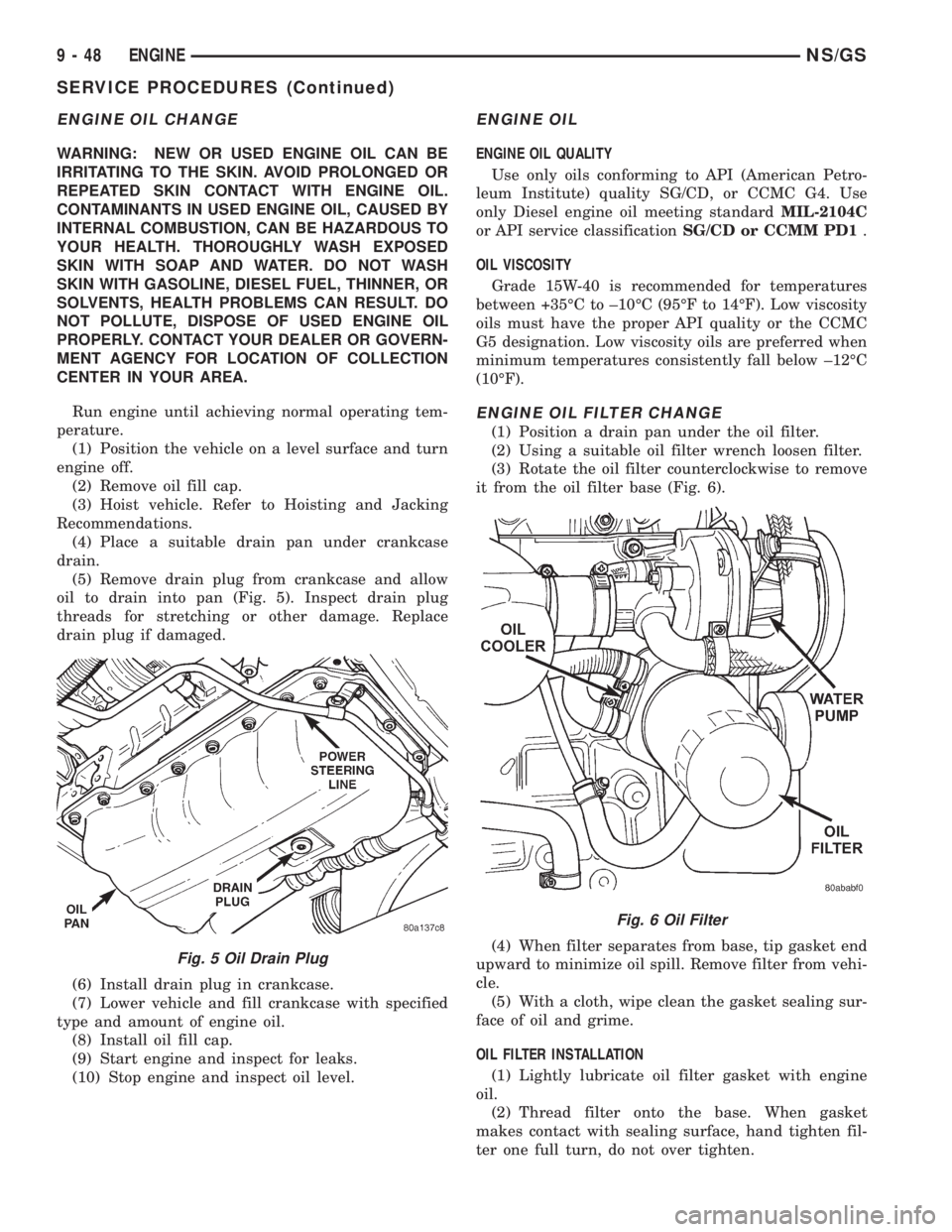

ENGINE OIL CHANGE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Remove oil fill cap.

(3) Hoist vehicle. Refer to Hoisting and Jacking

Recommendations.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan (Fig. 5). Inspect drain plug

threads for stretching or other damage. Replace

drain plug if damaged.

(6) Install drain plug in crankcase.

(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

ENGINE OIL

ENGINE OIL QUALITY

Use only oils conforming to API (American Petro-

leum Institute) quality SG/CD, or CCMC G4. Use

only Diesel engine oil meeting standardMIL-2104C

or API service classificationSG/CD or CCMM PD1.

OIL VISCOSITY

Grade 15W-40 is recommended for temperatures

between +35ÉC to ±10ÉC (95ÉF to 14ÉF). Low viscosity

oils must have the proper API quality or the CCMC

G5 designation. Low viscosity oils are preferred when

minimum temperatures consistently fall below ±12ÉC

(10ÉF).

ENGINE OIL FILTER CHANGE

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the oil filter base (Fig. 6).

(4) When filter separates from base, tip gasket end

upward to minimize oil spill. Remove filter from vehi-

cle.

(5) With a cloth, wipe clean the gasket sealing sur-

face of oil and grime.

OIL FILTER INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil.

(2) Thread filter onto the base. When gasket

makes contact with sealing surface, hand tighten fil-

ter one full turn, do not over tighten.

Fig. 5 Oil Drain Plug

Fig. 6 Oil Filter

9 - 48 ENGINENS/GS

SERVICE PROCEDURES (Continued)

Page 1231 of 1938

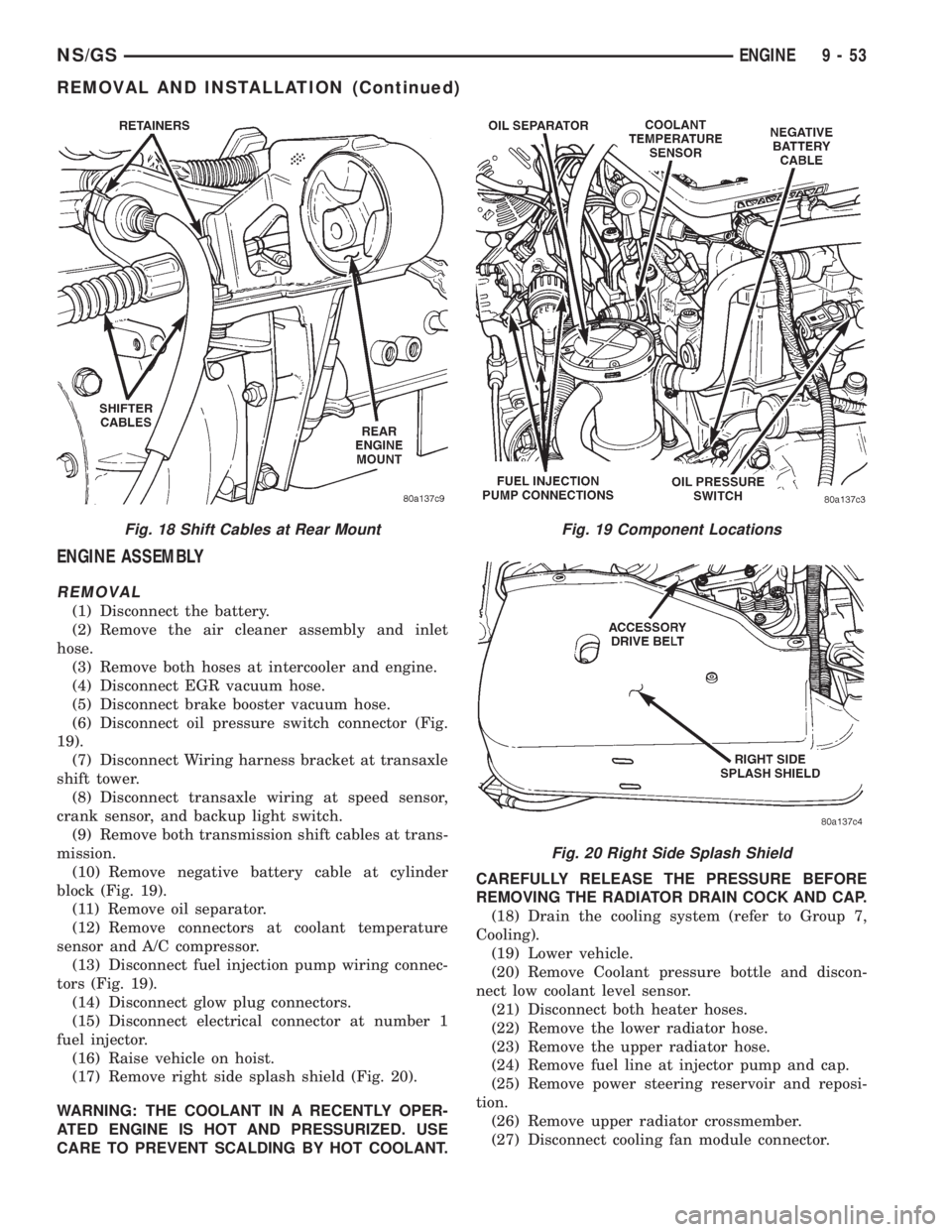

ENGINE ASSEMBLY

REMOVAL

(1) Disconnect the battery.

(2) Remove the air cleaner assembly and inlet

hose.

(3) Remove both hoses at intercooler and engine.

(4) Disconnect EGR vacuum hose.

(5) Disconnect brake booster vacuum hose.

(6) Disconnect oil pressure switch connector (Fig.

19).

(7) Disconnect Wiring harness bracket at transaxle

shift tower.

(8) Disconnect transaxle wiring at speed sensor,

crank sensor, and backup light switch.

(9) Remove both transmission shift cables at trans-

mission.

(10) Remove negative battery cable at cylinder

block (Fig. 19).

(11) Remove oil separator.

(12) Remove connectors at coolant temperature

sensor and A/C compressor.

(13) Disconnect fuel injection pump wiring connec-

tors (Fig. 19).

(14) Disconnect glow plug connectors.

(15) Disconnect electrical connector at number 1

fuel injector.

(16) Raise vehicle on hoist.

(17) Remove right side splash shield (Fig. 20).

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED. USE

CARE TO PREVENT SCALDING BY HOT COOLANT.CAREFULLY RELEASE THE PRESSURE BEFORE

REMOVING THE RADIATOR DRAIN COCK AND CAP.

(18) Drain the cooling system (refer to Group 7,

Cooling).

(19) Lower vehicle.

(20) Remove Coolant pressure bottle and discon-

nect low coolant level sensor.

(21) Disconnect both heater hoses.

(22) Remove the lower radiator hose.

(23) Remove the upper radiator hose.

(24) Remove fuel line at injector pump and cap.

(25) Remove power steering reservoir and reposi-

tion.

(26) Remove upper radiator crossmember.

(27) Disconnect cooling fan module connector.

Fig. 18 Shift Cables at Rear MountFig. 19 Component Locations

Fig. 20 Right Side Splash Shield

NS/GSENGINE 9 - 53

REMOVAL AND INSTALLATION (Continued)

Page 1307 of 1938

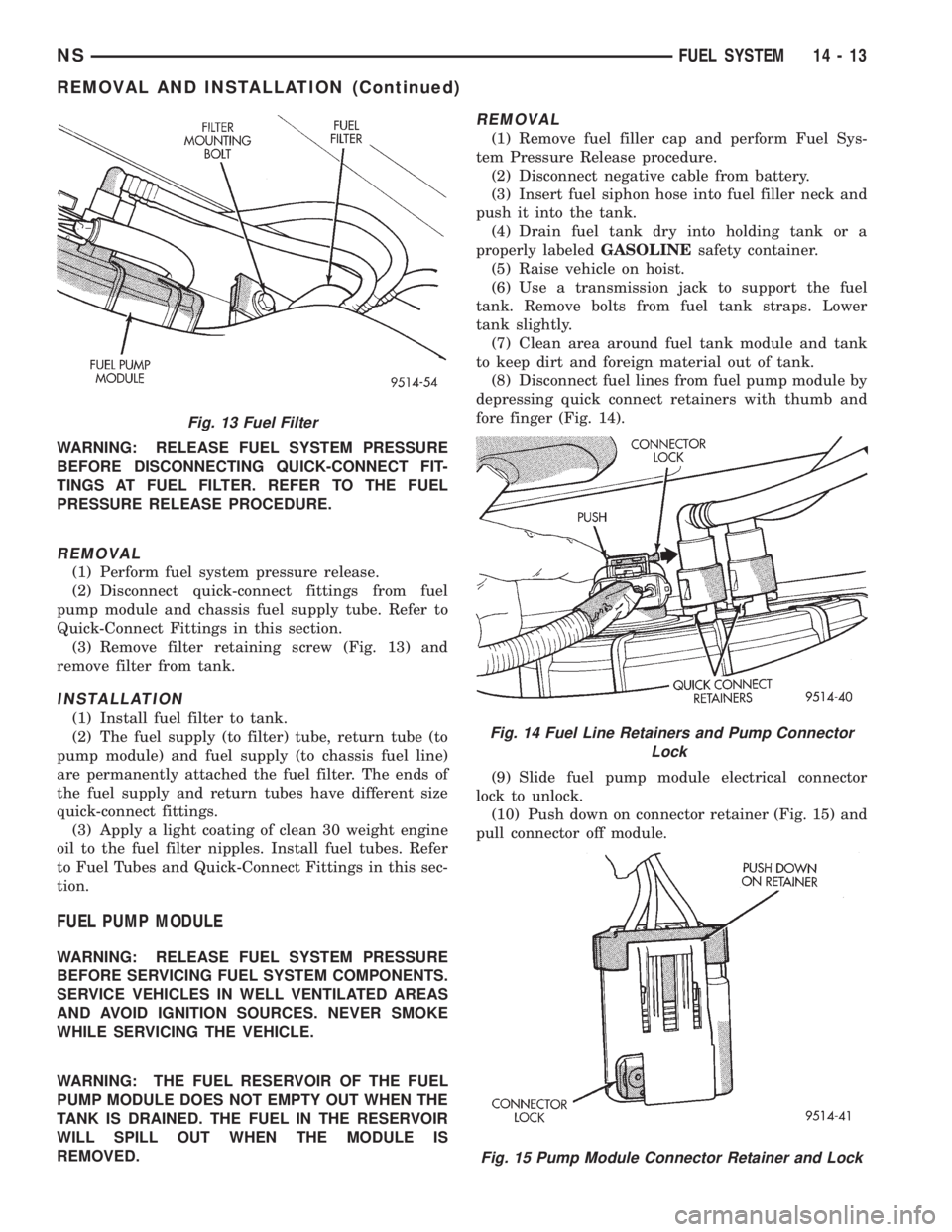

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING QUICK-CONNECT FIT-

TINGS AT FUEL FILTER. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE.

REMOVAL

(1) Perform fuel system pressure release.

(2) Disconnect quick-connect fittings from fuel

pump module and chassis fuel supply tube. Refer to

Quick-Connect Fittings in this section.

(3) Remove filter retaining screw (Fig. 13) and

remove filter from tank.

INSTALLATION

(1) Install fuel filter to tank.

(2) The fuel supply (to filter) tube, return tube (to

pump module) and fuel supply (to chassis fuel line)

are permanently attached the fuel filter. The ends of

the fuel supply and return tubes have different size

quick-connect fittings.

(3) Apply a light coating of clean 30 weight engine

oil to the fuel filter nipples. Install fuel tubes. Refer

to Fuel Tubes and Quick-Connect Fittings in this sec-

tion.

FUEL PUMP MODULE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

WILL SPILL OUT WHEN THE MODULE IS

REMOVED.

REMOVAL

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable from battery.

(3) Insert fuel siphon hose into fuel filler neck and

push it into the tank.

(4) Drain fuel tank dry into holding tank or a

properly labeledGASOLINEsafety container.

(5) Raise vehicle on hoist.

(6) Use a transmission jack to support the fuel

tank. Remove bolts from fuel tank straps. Lower

tank slightly.

(7) Clean area around fuel tank module and tank

to keep dirt and foreign material out of tank.

(8) Disconnect fuel lines from fuel pump module by

depressing quick connect retainers with thumb and

fore finger (Fig. 14).

(9) Slide fuel pump module electrical connector

lock to unlock.

(10) Push down on connector retainer (Fig. 15) and

pull connector off module.

Fig. 13 Fuel Filter

Fig. 14 Fuel Line Retainers and Pump Connector

Lock

Fig. 15 Pump Module Connector Retainer and Lock

NSFUEL SYSTEM 14 - 13

REMOVAL AND INSTALLATION (Continued)