torque CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1921 of 1938

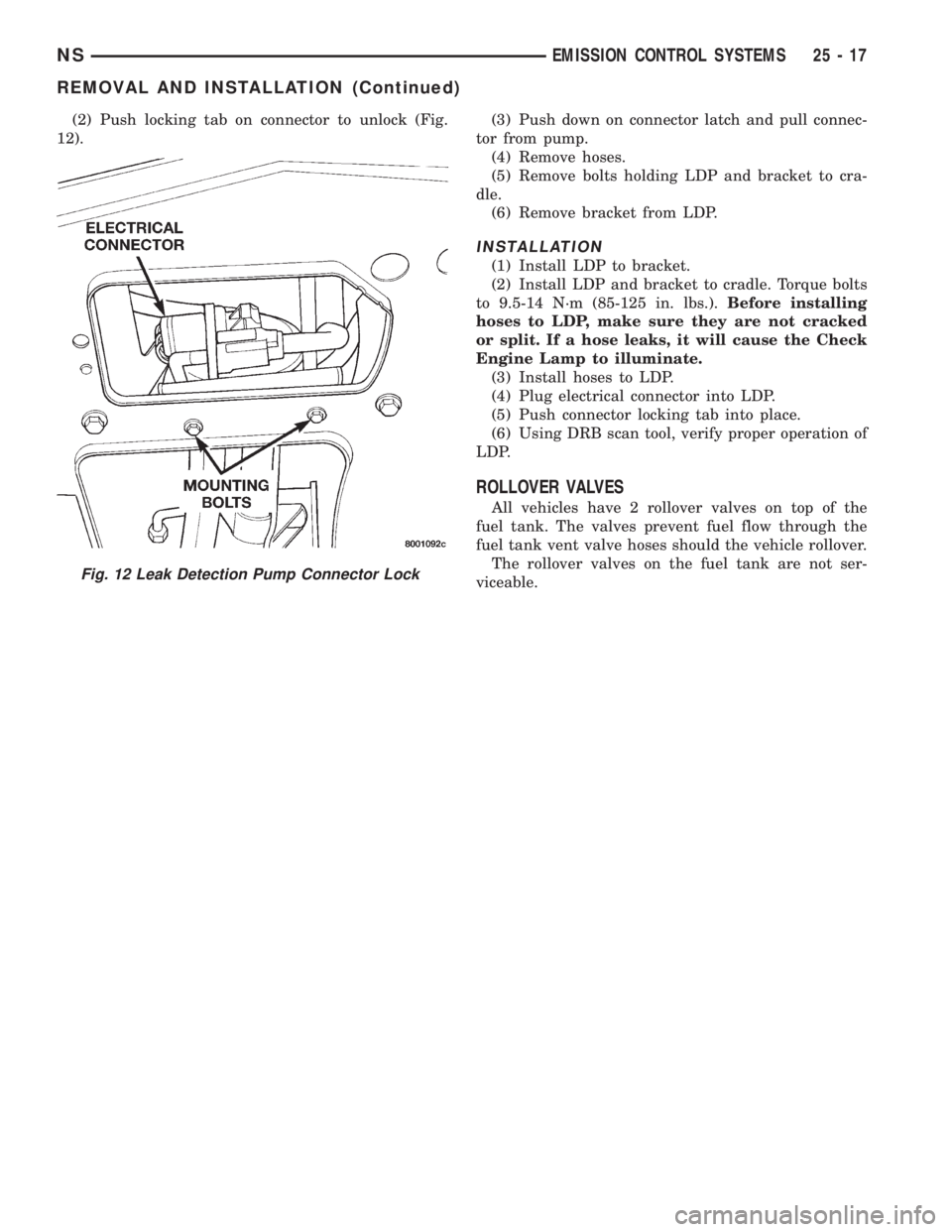

(2) Push locking tab on connector to unlock (Fig.

12).(3) Push down on connector latch and pull connec-

tor from pump.

(4) Remove hoses.

(5) Remove bolts holding LDP and bracket to cra-

dle.

(6) Remove bracket from LDP.

INSTALLATION

(1) Install LDP to bracket.

(2) Install LDP and bracket to cradle. Torque bolts

to 9.5-14 N´m (85-125 in. lbs.).Before installing

hoses to LDP, make sure they are not cracked

or split. If a hose leaks, it will cause the Check

Engine Lamp to illuminate.

(3) Install hoses to LDP.

(4) Plug electrical connector into LDP.

(5) Push connector locking tab into place.

(6) Using DRB scan tool, verify proper operation of

LDP.

ROLLOVER VALVES

All vehicles have 2 rollover valves on top of the

fuel tank. The valves prevent fuel flow through the

fuel tank vent valve hoses should the vehicle rollover.

The rollover valves on the fuel tank are not ser-

viceable.

Fig. 12 Leak Detection Pump Connector Lock

NSEMISSION CONTROL SYSTEMS 25 - 17

REMOVAL AND INSTALLATION (Continued)

Page 1925 of 1938

ulated shop air to the metal back- pressure fitting on

the EGR valve.

(6) By hand, open the throttle to the wide open

position. AirSHOULD NOT BE HEARDemitting

from the intake manifold while applying air pressure

at the back-pressure fitting.

(7) If airCAN BE HEARDemitting from the

intake manifold, the poppet valve (Fig. 4) is leaking

at the bottom of the EGR valve. Replace the EGR

valve. Note: The EGR valve, valve control and

attaching hoses are serviced as one assembly. Refer

to EGR Valve Removal/Installation in this group. Do

not attempt clean the old EGR valve.

EGR VALVE CONTROL (TRANSDUCER) TEST

TESTING ELECTRICAL SOLENOID PORTION

OF VALVE

This is not to be used as a complete test of the

EGR system.

Electrical operation of the valve should be checked

with the DRB scan tool. Refer to the appropriate

Powertrain Diagnostic Procedures service manual for

operation of the DRB scan tool. Replace solenoid if

necessary, unit serviced only as an assembly.

TESTING VACUUM TRANSDUCER PORTION

OF VALVE

The first part of this test will determine if the

transducer diaphragm at the back-pressure side of

the valve has ruptured or is leaking. The second part

of the test will determine if engine vacuum (full-man-

ifold) is flowing from the inlet to the outlet side of

the valve. This is not to be used as a complete test of

the EGR system.

(1) Disconnect the rubber back-pressure hose from

the fitting at the bottom of EGR valve (Fig. 4).

(2) Connect a hand-held vacuum pump to this fit-

ting.

(3) Apply 10 inches of vacuum to this fitting.

(4) If vacuum falls off, the valve diaphragm is

leaking.

(5) Replace the EGR valve assembly. Proceed to

next step for further testing.

(6) Remove the rubber hose at the vacuuminlet

fitting (Fig. 4) on the EGR valve.

(7) Connect a vacuum gauge to this disconnected

hose.

(8) Start the engine and bring to operating tem-

perature. Hold engine speed at approximately 1500

rpm.

(9) Check for steady engine vacuum (full-manifold)

at this hose.

(10) If engine vacuum (full-manifold) is not

present, check vacuum line to engine and repair as

necessary before proceeding to next step.(11) Reconnect the rubber hose to the vacuum

inletfitting (Fig. 4) on the EGR valve.

(12) Disconnect the rubber hose at the vacuum

outletfitting (Fig. 4) on the EGR valve.

(13) Connect a vacuum gauge to this fitting.

(14) Disconnect the electrical connector (Fig. 4) at

the valve control. This will simulate an open circuit

(no ground from the PCM) at the valve.

(15) Start the engine and bring to operating tem-

perature.

(16) Hold the engine speed to approximately 2000

rpm while checking for engine vacuum (full-manifold)

at this fitting.To allow full manifold vacuum to

flow through the valve, exhaust back-pressure

must be present at valve. It must be high

enough to hold the bleed valve in the trans-

ducer portion of the valve closed.Have a helper

momentarily (a second or two) hold a rag over the

tailpipe opening to build some exhaust back-pressure

while observing the vacuum gauge. Heavy gloves

should be worn.Do not cover the tailpipe open-

ing for an extended period of time as damage to

components or overheating may result.

(17) As temporary back-pressure is built, full man-

ifold vacuum should be observed at the vacuum out-

let fitting. Without back-pressure, and engine at

approximately 2000 rpm, the gauge reading will be

low. This low reading is normal. At idle speed, the

gauge reading will be erratic. This is also normal.

(18) If full manifold vacuum is not present at the

outlet fitting, but was present at the inlet fitting,

replace the valve. Note: The EGR valve, valve control

and attaching hoses are serviced as one assembly.

Refer to EGR Valve Removal/Installation in this

group.

REMOVAL AND INSTALLATION

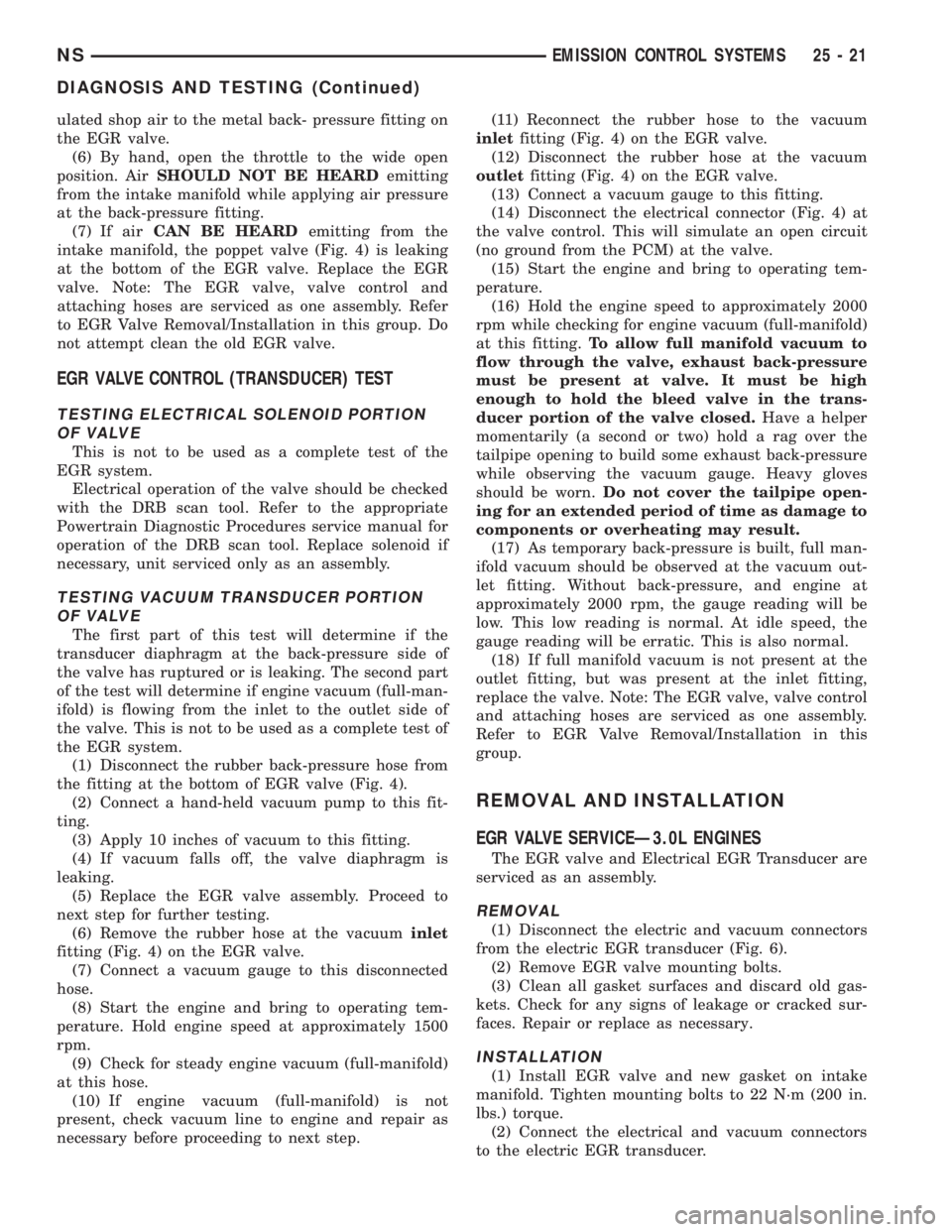

EGR VALVE SERVICEÐ3.0L ENGINES

The EGR valve and Electrical EGR Transducer are

serviced as an assembly.

REMOVAL

(1) Disconnect the electric and vacuum connectors

from the electric EGR transducer (Fig. 6).

(2) Remove EGR valve mounting bolts.

(3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Install EGR valve and new gasket on intake

manifold. Tighten mounting bolts to 22 N´m (200 in.

lbs.) torque.

(2) Connect the electrical and vacuum connectors

to the electric EGR transducer.

NSEMISSION CONTROL SYSTEMS 25 - 21

DIAGNOSIS AND TESTING (Continued)

Page 1926 of 1938

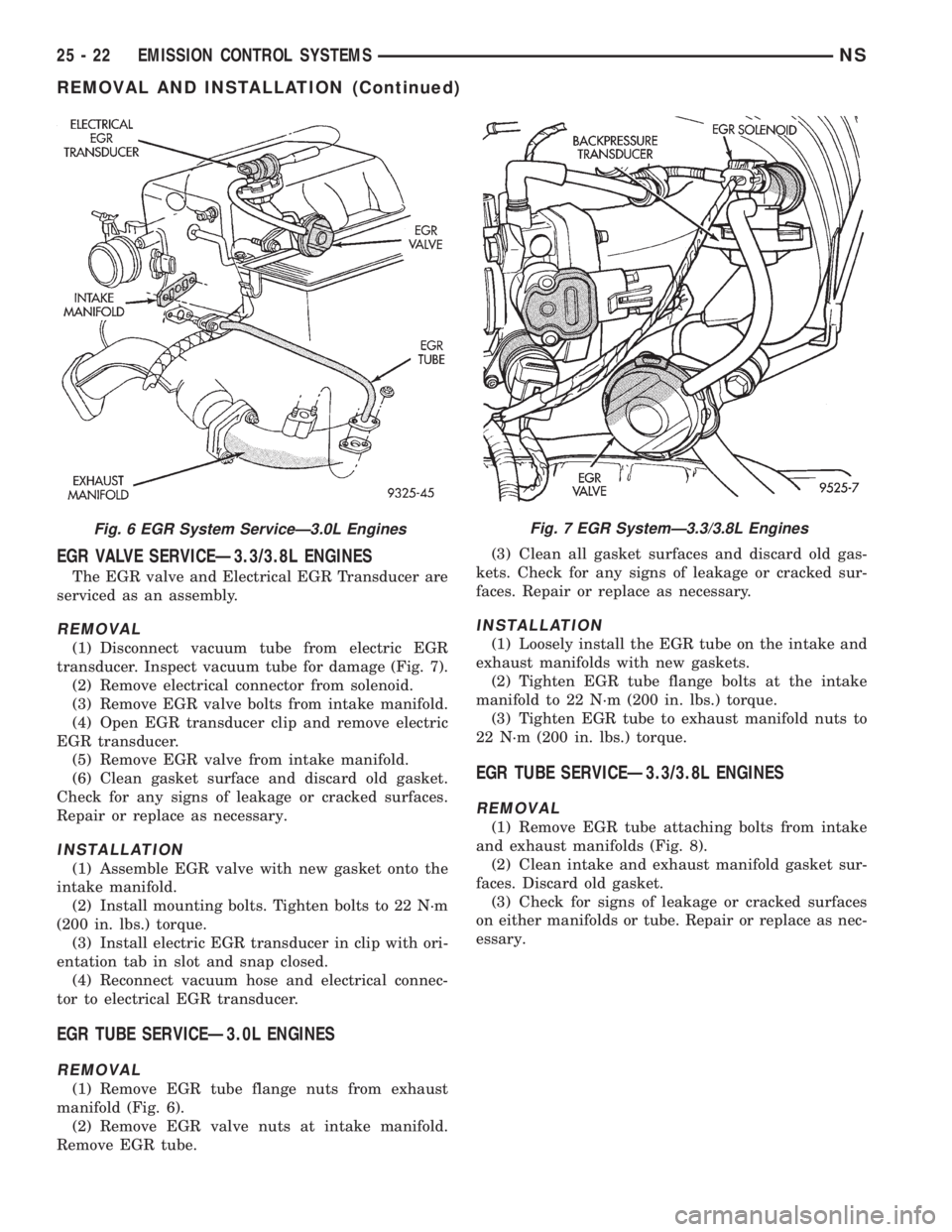

EGR VALVE SERVICEÐ3.3/3.8L ENGINES

The EGR valve and Electrical EGR Transducer are

serviced as an assembly.

REMOVAL

(1) Disconnect vacuum tube from electric EGR

transducer. Inspect vacuum tube for damage (Fig. 7).

(2) Remove electrical connector from solenoid.

(3) Remove EGR valve bolts from intake manifold.

(4) Open EGR transducer clip and remove electric

EGR transducer.

(5) Remove EGR valve from intake manifold.

(6) Clean gasket surface and discard old gasket.

Check for any signs of leakage or cracked surfaces.

Repair or replace as necessary.

INSTALLATION

(1) Assemble EGR valve with new gasket onto the

intake manifold.

(2) Install mounting bolts. Tighten bolts to 22 N´m

(200 in. lbs.) torque.

(3) Install electric EGR transducer in clip with ori-

entation tab in slot and snap closed.

(4) Reconnect vacuum hose and electrical connec-

tor to electrical EGR transducer.

EGR TUBE SERVICEÐ3.0L ENGINES

REMOVAL

(1) Remove EGR tube flange nuts from exhaust

manifold (Fig. 6).

(2) Remove EGR valve nuts at intake manifold.

Remove EGR tube.(3) Clean all gasket surfaces and discard old gas-

kets. Check for any signs of leakage or cracked sur-

faces. Repair or replace as necessary.

INSTALLATION

(1) Loosely install the EGR tube on the intake and

exhaust manifolds with new gaskets.

(2) Tighten EGR tube flange bolts at the intake

manifold to 22 N´m (200 in. lbs.) torque.

(3) Tighten EGR tube to exhaust manifold nuts to

22 N´m (200 in. lbs.) torque.

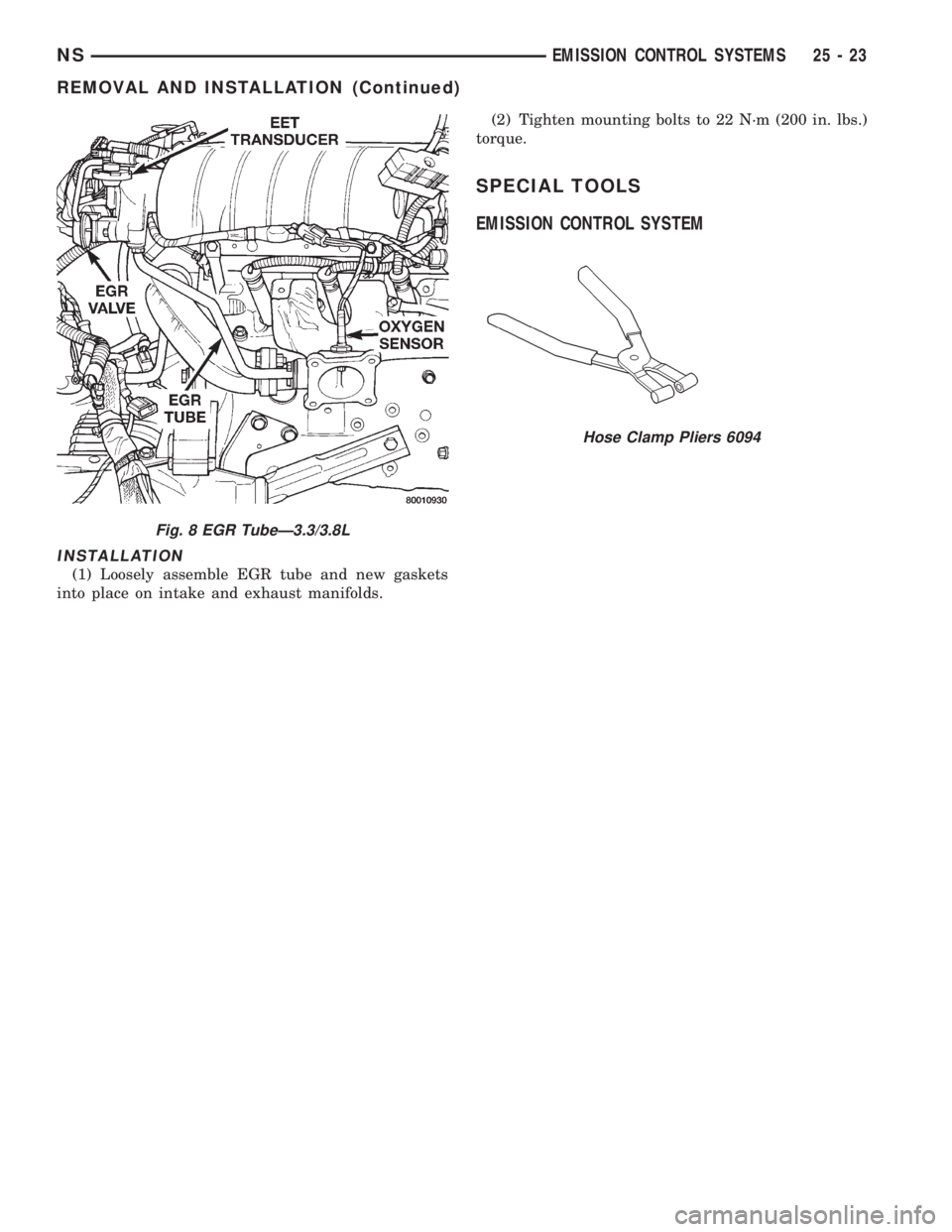

EGR TUBE SERVICEÐ3.3/3.8L ENGINES

REMOVAL

(1) Remove EGR tube attaching bolts from intake

and exhaust manifolds (Fig. 8).

(2) Clean intake and exhaust manifold gasket sur-

faces. Discard old gasket.

(3) Check for signs of leakage or cracked surfaces

on either manifolds or tube. Repair or replace as nec-

essary.

Fig. 6 EGR System ServiceÐ3.0L EnginesFig. 7 EGR SystemÐ3.3/3.8L Engines

25 - 22 EMISSION CONTROL SYSTEMSNS

REMOVAL AND INSTALLATION (Continued)

Page 1927 of 1938

INSTALLATION

(1) Loosely assemble EGR tube and new gaskets

into place on intake and exhaust manifolds.(2) Tighten mounting bolts to 22 N´m (200 in. lbs.)

torque.

SPECIAL TOOLS

EMISSION CONTROL SYSTEM

Fig. 8 EGR TubeÐ3.3/3.8L

Hose Clamp Pliers 6094

NSEMISSION CONTROL SYSTEMS 25 - 23

REMOVAL AND INSTALLATION (Continued)

Page 1933 of 1938

EXHAUST EMISSION CONTROLSÐ2.5L DIESEL ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM............................. 5

VACUUM HOSE ROUTING SCHEMATIC...... 5

DIAGNOSIS AND TESTING

EGR GAS FLOW TEST................... 6

ELECTRIC VACUUM MODULATOR (EVM)

TEST............................... 7REMOVAL AND INSTALLATION

EGR TUBE............................. 7

EGRVALVE ............................ 7

ELECTRIC VACUUM MODULATOR (EVM)..... 7

SPECIFICATIONS

TORQUE CHARTÐ2.5L DIESEL............ 8

DESCRIPTION AND OPERATION

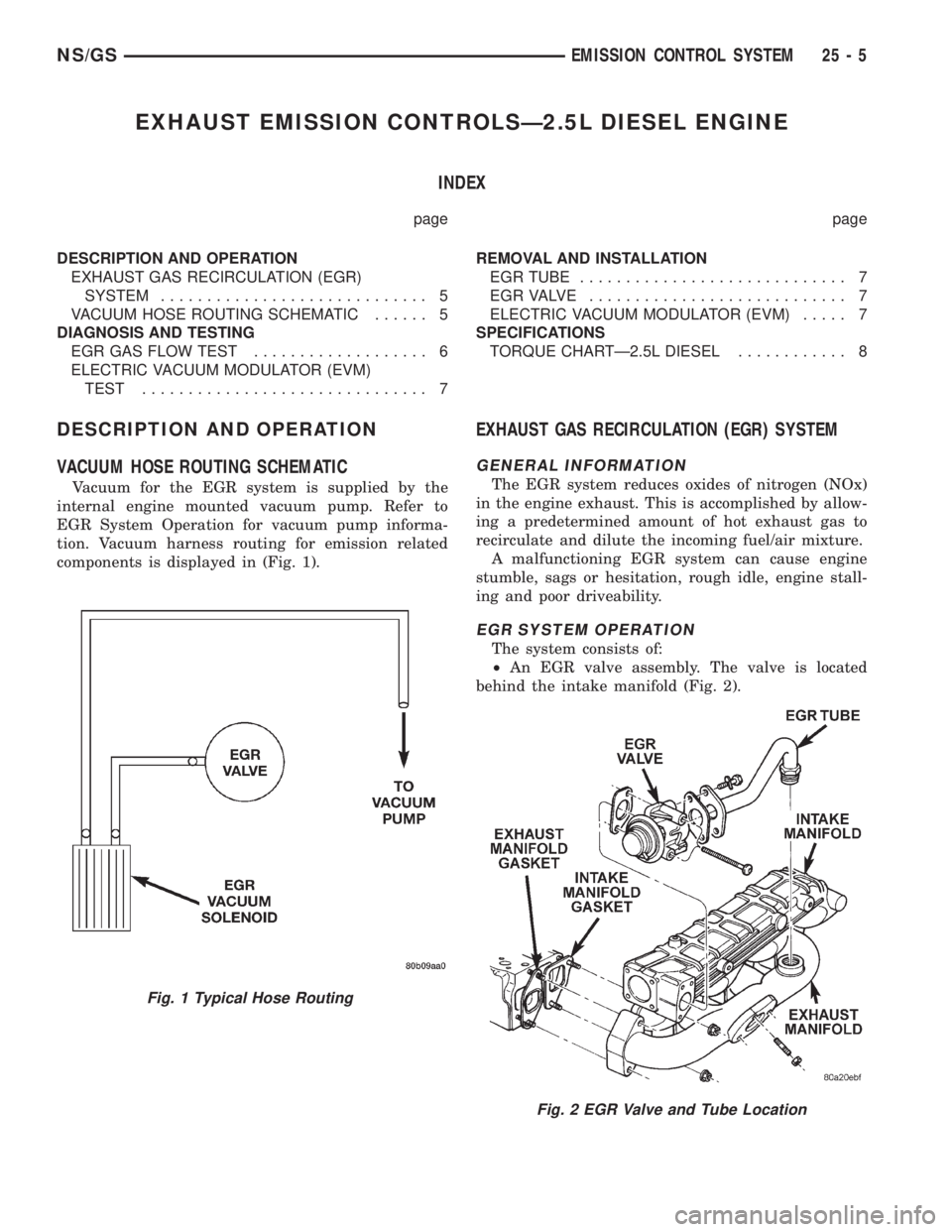

VACUUM HOSE ROUTING SCHEMATIC

Vacuum for the EGR system is supplied by the

internal engine mounted vacuum pump. Refer to

EGR System Operation for vacuum pump informa-

tion. Vacuum harness routing for emission related

components is displayed in (Fig. 1).

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

GENERAL INFORMATION

The EGR system reduces oxides of nitrogen (NOx)

in the engine exhaust. This is accomplished by allow-

ing a predetermined amount of hot exhaust gas to

recirculate and dilute the incoming fuel/air mixture.

A malfunctioning EGR system can cause engine

stumble, sags or hesitation, rough idle, engine stall-

ing and poor driveability.

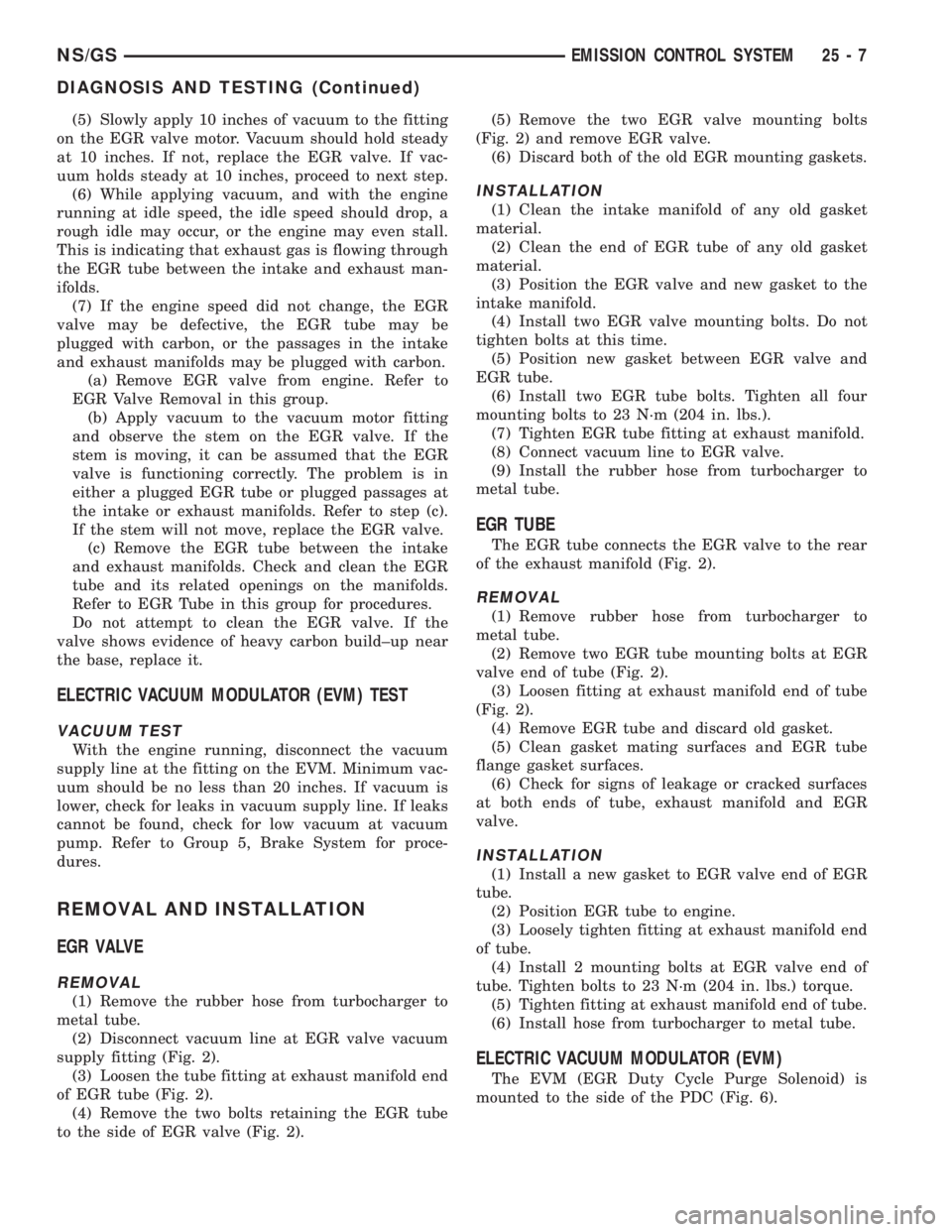

EGR SYSTEM OPERATION

The system consists of:

²An EGR valve assembly. The valve is located

behind the intake manifold (Fig. 2).

Fig. 1 Typical Hose Routing

Fig. 2 EGR Valve and Tube Location

NS/GSEMISSION CONTROL SYSTEM 25 - 5

Page 1935 of 1938

(5) Slowly apply 10 inches of vacuum to the fitting

on the EGR valve motor. Vacuum should hold steady

at 10 inches. If not, replace the EGR valve. If vac-

uum holds steady at 10 inches, proceed to next step.

(6) While applying vacuum, and with the engine

running at idle speed, the idle speed should drop, a

rough idle may occur, or the engine may even stall.

This is indicating that exhaust gas is flowing through

the EGR tube between the intake and exhaust man-

ifolds.

(7) If the engine speed did not change, the EGR

valve may be defective, the EGR tube may be

plugged with carbon, or the passages in the intake

and exhaust manifolds may be plugged with carbon.

(a) Remove EGR valve from engine. Refer to

EGR Valve Removal in this group.

(b) Apply vacuum to the vacuum motor fitting

and observe the stem on the EGR valve. If the

stem is moving, it can be assumed that the EGR

valve is functioning correctly. The problem is in

either a plugged EGR tube or plugged passages at

the intake or exhaust manifolds. Refer to step (c).

If the stem will not move, replace the EGR valve.

(c) Remove the EGR tube between the intake

and exhaust manifolds. Check and clean the EGR

tube and its related openings on the manifolds.

Refer to EGR Tube in this group for procedures.

Do not attempt to clean the EGR valve. If the

valve shows evidence of heavy carbon build±up near

the base, replace it.

ELECTRIC VACUUM MODULATOR (EVM) TEST

VACUUM TEST

With the engine running, disconnect the vacuum

supply line at the fitting on the EVM. Minimum vac-

uum should be no less than 20 inches. If vacuum is

lower, check for leaks in vacuum supply line. If leaks

cannot be found, check for low vacuum at vacuum

pump. Refer to Group 5, Brake System for proce-

dures.

REMOVAL AND INSTALLATION

EGR VALVE

REMOVAL

(1) Remove the rubber hose from turbocharger to

metal tube.

(2) Disconnect vacuum line at EGR valve vacuum

supply fitting (Fig. 2).

(3) Loosen the tube fitting at exhaust manifold end

of EGR tube (Fig. 2).

(4) Remove the two bolts retaining the EGR tube

to the side of EGR valve (Fig. 2).(5) Remove the two EGR valve mounting bolts

(Fig. 2) and remove EGR valve.

(6) Discard both of the old EGR mounting gaskets.

INSTALLATION

(1) Clean the intake manifold of any old gasket

material.

(2) Clean the end of EGR tube of any old gasket

material.

(3) Position the EGR valve and new gasket to the

intake manifold.

(4) Install two EGR valve mounting bolts. Do not

tighten bolts at this time.

(5) Position new gasket between EGR valve and

EGR tube.

(6) Install two EGR tube bolts. Tighten all four

mounting bolts to 23 N´m (204 in. lbs.).

(7) Tighten EGR tube fitting at exhaust manifold.

(8) Connect vacuum line to EGR valve.

(9) Install the rubber hose from turbocharger to

metal tube.

EGR TUBE

The EGR tube connects the EGR valve to the rear

of the exhaust manifold (Fig. 2).

REMOVAL

(1) Remove rubber hose from turbocharger to

metal tube.

(2) Remove two EGR tube mounting bolts at EGR

valve end of tube (Fig. 2).

(3) Loosen fitting at exhaust manifold end of tube

(Fig. 2).

(4) Remove EGR tube and discard old gasket.

(5) Clean gasket mating surfaces and EGR tube

flange gasket surfaces.

(6) Check for signs of leakage or cracked surfaces

at both ends of tube, exhaust manifold and EGR

valve.

INSTALLATION

(1) Install a new gasket to EGR valve end of EGR

tube.

(2) Position EGR tube to engine.

(3) Loosely tighten fitting at exhaust manifold end

of tube.

(4) Install 2 mounting bolts at EGR valve end of

tube. Tighten bolts to 23 N´m (204 in. lbs.) torque.

(5) Tighten fitting at exhaust manifold end of tube.

(6) Install hose from turbocharger to metal tube.

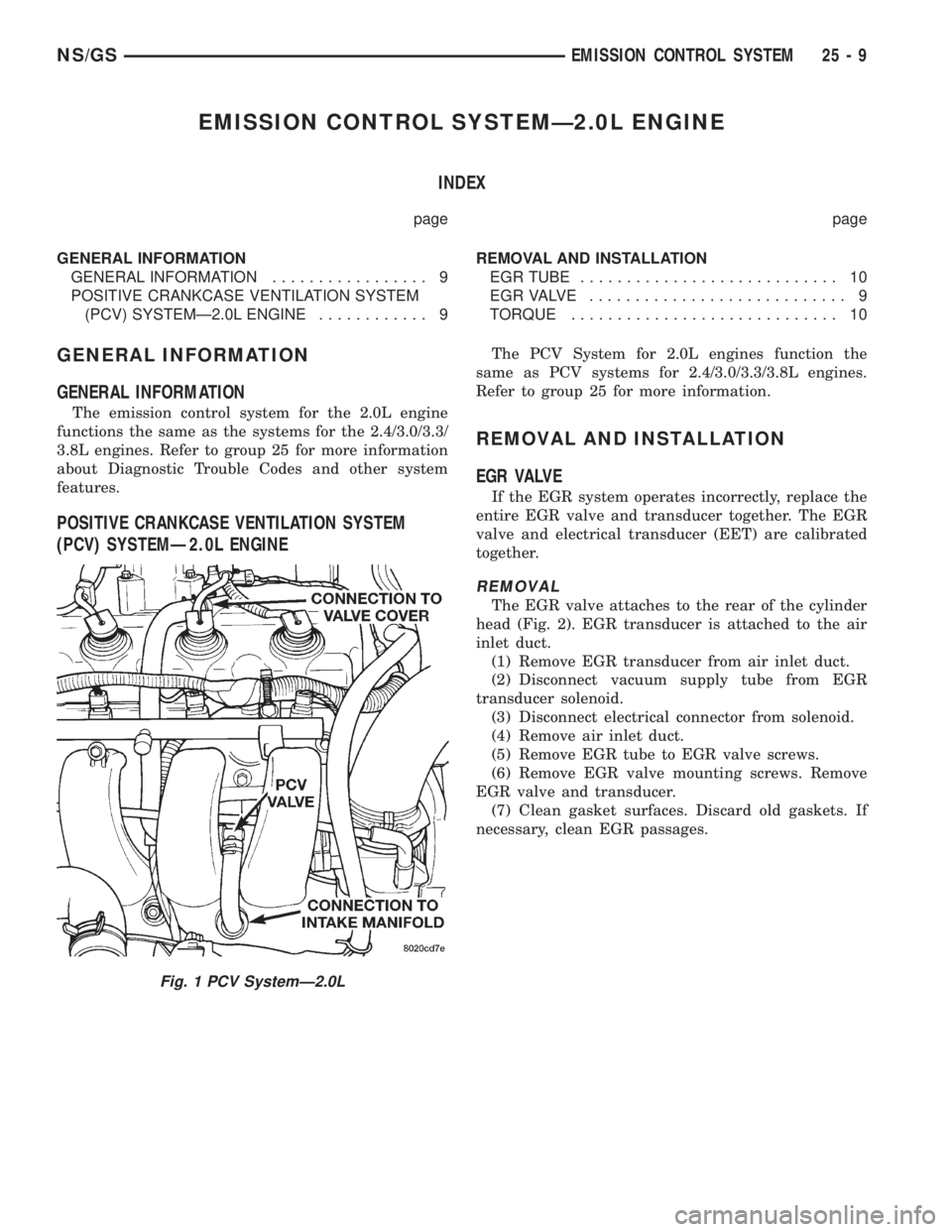

ELECTRIC VACUUM MODULATOR (EVM)

The EVM (EGR Duty Cycle Purge Solenoid) is

mounted to the side of the PDC (Fig. 6).

NS/GSEMISSION CONTROL SYSTEM 25 - 7

DIAGNOSIS AND TESTING (Continued)

Page 1936 of 1938

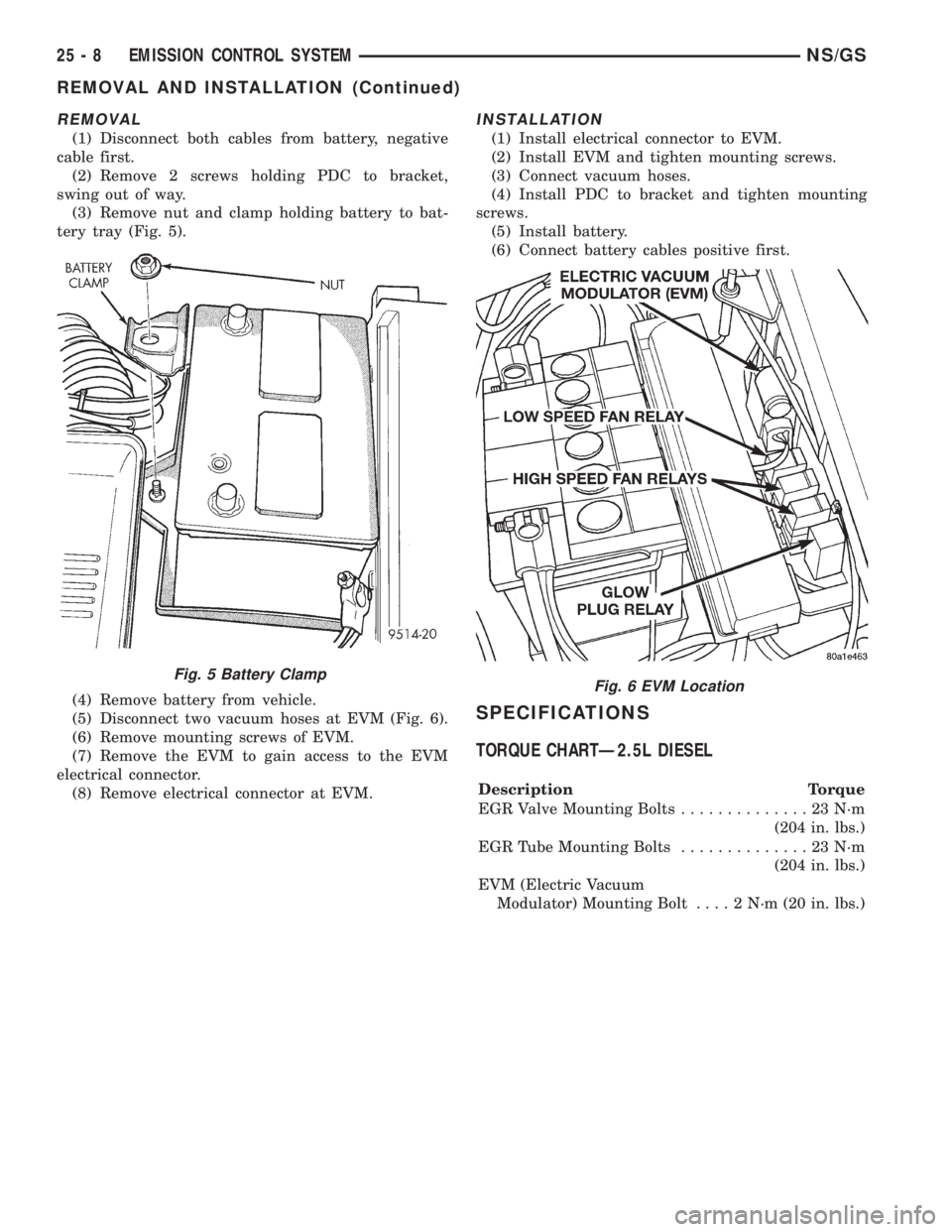

REMOVAL

(1) Disconnect both cables from battery, negative

cable first.

(2) Remove 2 screws holding PDC to bracket,

swing out of way.

(3) Remove nut and clamp holding battery to bat-

tery tray (Fig. 5).

(4) Remove battery from vehicle.

(5) Disconnect two vacuum hoses at EVM (Fig. 6).

(6) Remove mounting screws of EVM.

(7) Remove the EVM to gain access to the EVM

electrical connector.

(8) Remove electrical connector at EVM.

INSTALLATION

(1) Install electrical connector to EVM.

(2) Install EVM and tighten mounting screws.

(3) Connect vacuum hoses.

(4) Install PDC to bracket and tighten mounting

screws.

(5) Install battery.

(6) Connect battery cables positive first.

SPECIFICATIONS

TORQUE CHARTÐ2.5L DIESEL

Description Torque

EGR Valve Mounting Bolts..............23N´m

(204 in. lbs.)

EGR Tube Mounting Bolts..............23N´m

(204 in. lbs.)

EVM (Electric Vacuum

Modulator) Mounting Bolt. . . . 2 N´m (20 in. lbs.)

Fig. 5 Battery ClampFig. 6 EVM Location

25 - 8 EMISSION CONTROL SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1937 of 1938

EMISSION CONTROL SYSTEMÐ2.0L ENGINE

INDEX

page page

GENERAL INFORMATION

GENERAL INFORMATION................. 9

POSITIVE CRANKCASE VENTILATION SYSTEM

(PCV) SYSTEMÐ2.0L ENGINE............ 9REMOVAL AND INSTALLATION

EGR TUBE............................ 10

EGRVALVE ............................ 9

TORQUE............................. 10

GENERAL INFORMATION

GENERAL INFORMATION

The emission control system for the 2.0L engine

functions the same as the systems for the 2.4/3.0/3.3/

3.8L engines. Refer to group 25 for more information

about Diagnostic Trouble Codes and other system

features.

POSITIVE CRANKCASE VENTILATION SYSTEM

(PCV) SYSTEMÐ2.0L ENGINE

The PCV System for 2.0L engines function the

same as PCV systems for 2.4/3.0/3.3/3.8L engines.

Refer to group 25 for more information.

REMOVAL AND INSTALLATION

EGR VALVE

If the EGR system operates incorrectly, replace the

entire EGR valve and transducer together. The EGR

valve and electrical transducer (EET) are calibrated

together.

REMOVAL

The EGR valve attaches to the rear of the cylinder

head (Fig. 2). EGR transducer is attached to the air

inlet duct.

(1) Remove EGR transducer from air inlet duct.

(2) Disconnect vacuum supply tube from EGR

transducer solenoid.

(3) Disconnect electrical connector from solenoid.

(4) Remove air inlet duct.

(5) Remove EGR tube to EGR valve screws.

(6) Remove EGR valve mounting screws. Remove

EGR valve and transducer.

(7) Clean gasket surfaces. Discard old gaskets. If

necessary, clean EGR passages.

Fig. 1 PCV SystemÐ2.0L

NS/GSEMISSION CONTROL SYSTEM 25 - 9

Page 1938 of 1938

INSTALLATION

(1) Loosely install EGR valve with new gaskets.

(2) Finger tighten EGR tube fasteners.

(3) Tighten EGR tube fasteners to 11 N´m (95 in.

lbs.) torque.

(4) Tightening EGR valve mounting screws to 22

N´m (200 in. lbs.) torque.

(5) Install air inlet duct.

(6) Connect vacuum supply tube to solenoid.

(7) Attach electrical connector to solenoid.

(8) Install EGR transducer onto air inlet duct.

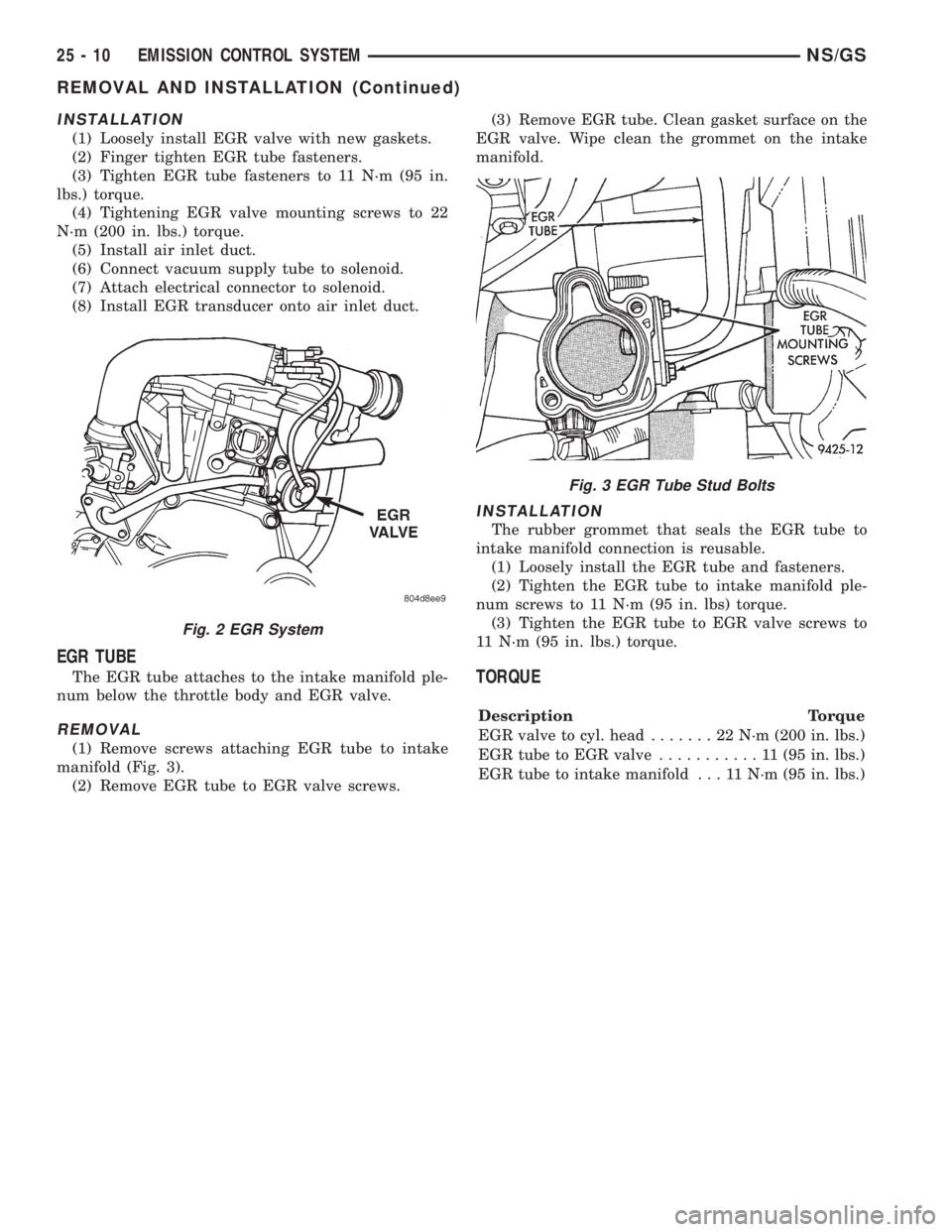

EGR TUBE

The EGR tube attaches to the intake manifold ple-

num below the throttle body and EGR valve.

REMOVAL

(1) Remove screws attaching EGR tube to intake

manifold (Fig. 3).

(2) Remove EGR tube to EGR valve screws.(3) Remove EGR tube. Clean gasket surface on the

EGR valve. Wipe clean the grommet on the intake

manifold.

INSTALLATION

The rubber grommet that seals the EGR tube to

intake manifold connection is reusable.

(1) Loosely install the EGR tube and fasteners.

(2) Tighten the EGR tube to intake manifold ple-

num screws to 11 N´m (95 in. lbs) torque.

(3) Tighten the EGR tube to EGR valve screws to

11 N´m (95 in. lbs.) torque.

TORQUE

Description Torque

EGR valve to cyl. head.......22N´m(200 in. lbs.)

EGR tube to EGR valve...........11(95in.lbs.)

EGR tube to intake manifold . . . 11 N´m (95 in. lbs.)

Fig. 2 EGR System

Fig. 3 EGR Tube Stud Bolts

25 - 10 EMISSION CONTROL SYSTEMNS/GS

REMOVAL AND INSTALLATION (Continued)