hood release CHRYSLER VOYAGER 1996 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1773 of 1938

(3) Install hood latch cable.

(4) Install lower steering column cover and knee

blocker reinforcement.

JACK STORAGE COVER

LONG WHEEL BASE

REMOVAL

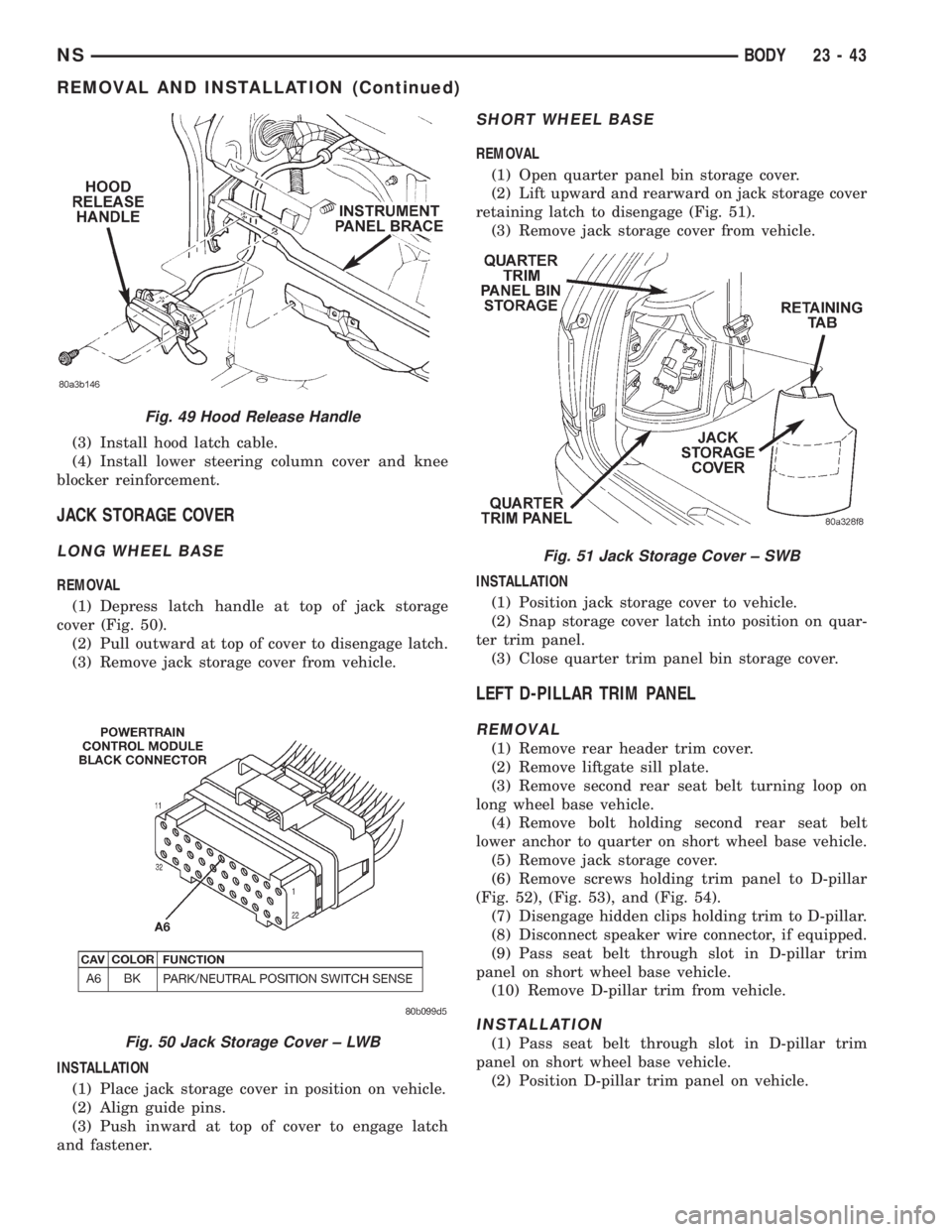

(1) Depress latch handle at top of jack storage

cover (Fig. 50).

(2) Pull outward at top of cover to disengage latch.

(3) Remove jack storage cover from vehicle.

INSTALLATION

(1) Place jack storage cover in position on vehicle.

(2) Align guide pins.

(3) Push inward at top of cover to engage latch

and fastener.

SHORT WHEEL BASE

REMOVAL

(1) Open quarter panel bin storage cover.

(2) Lift upward and rearward on jack storage cover

retaining latch to disengage (Fig. 51).

(3) Remove jack storage cover from vehicle.

INSTALLATION

(1) Position jack storage cover to vehicle.

(2) Snap storage cover latch into position on quar-

ter trim panel.

(3) Close quarter trim panel bin storage cover.

LEFT D-PILLAR TRIM PANEL

REMOVAL

(1) Remove rear header trim cover.

(2) Remove liftgate sill plate.

(3) Remove second rear seat belt turning loop on

long wheel base vehicle.

(4) Remove bolt holding second rear seat belt

lower anchor to quarter on short wheel base vehicle.

(5) Remove jack storage cover.

(6) Remove screws holding trim panel to D-pillar

(Fig. 52), (Fig. 53), and (Fig. 54).

(7) Disengage hidden clips holding trim to D-pillar.

(8) Disconnect speaker wire connector, if equipped.

(9) Pass seat belt through slot in D-pillar trim

panel on short wheel base vehicle.

(10) Remove D-pillar trim from vehicle.

INSTALLATION

(1) Pass seat belt through slot in D-pillar trim

panel on short wheel base vehicle.

(2) Position D-pillar trim panel on vehicle.

Fig. 49 Hood Release Handle

Fig. 50 Jack Storage Cover ± LWB

Fig. 51 Jack Storage Cover ± SWB

NSBODY 23 - 43

REMOVAL AND INSTALLATION (Continued)

Page 1783 of 1938

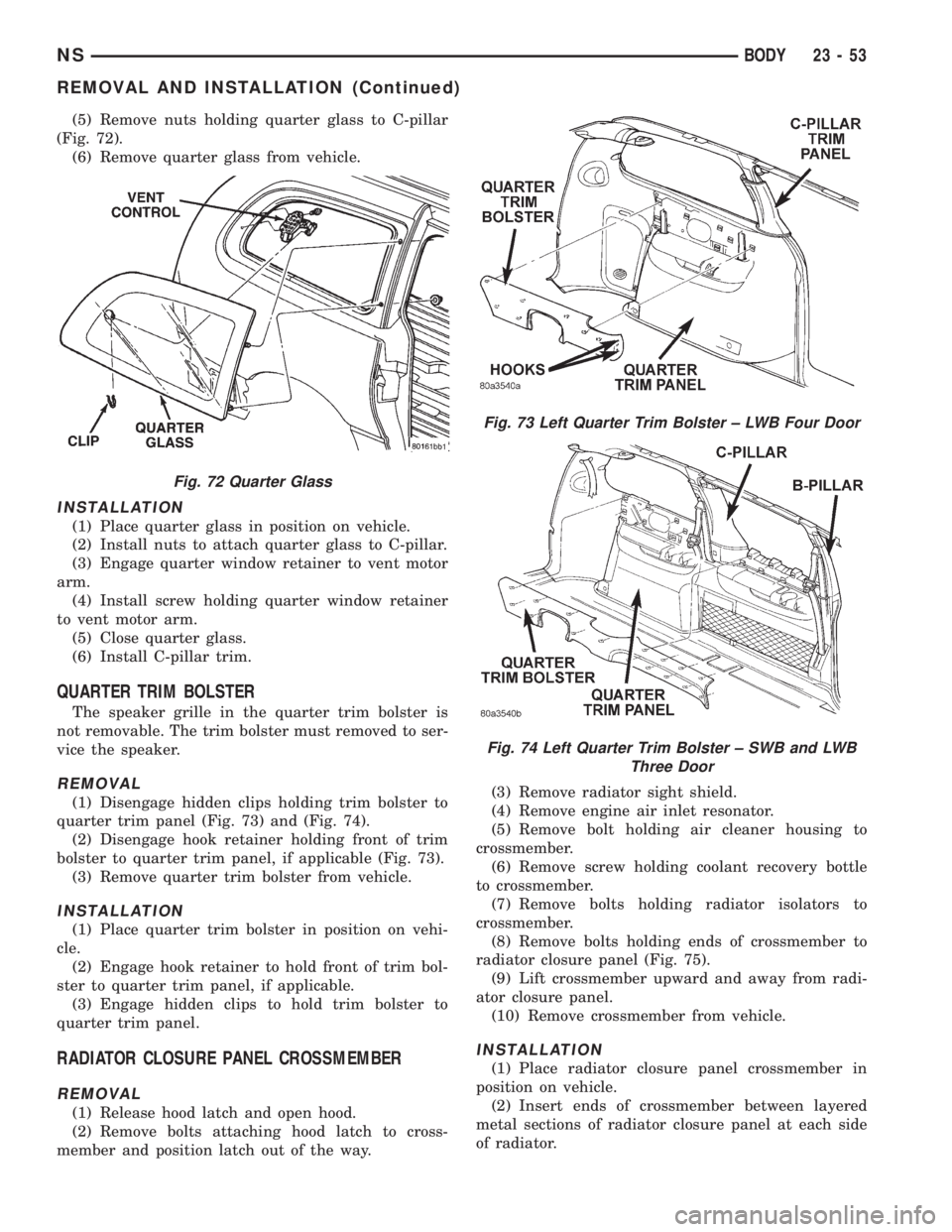

(5) Remove nuts holding quarter glass to C-pillar

(Fig. 72).

(6) Remove quarter glass from vehicle.

INSTALLATION

(1) Place quarter glass in position on vehicle.

(2) Install nuts to attach quarter glass to C-pillar.

(3) Engage quarter window retainer to vent motor

arm.

(4) Install screw holding quarter window retainer

to vent motor arm.

(5) Close quarter glass.

(6) Install C-pillar trim.

QUARTER TRIM BOLSTER

The speaker grille in the quarter trim bolster is

not removable. The trim bolster must removed to ser-

vice the speaker.

REMOVAL

(1) Disengage hidden clips holding trim bolster to

quarter trim panel (Fig. 73) and (Fig. 74).

(2) Disengage hook retainer holding front of trim

bolster to quarter trim panel, if applicable (Fig. 73).

(3) Remove quarter trim bolster from vehicle.

INSTALLATION

(1) Place quarter trim bolster in position on vehi-

cle.

(2) Engage hook retainer to hold front of trim bol-

ster to quarter trim panel, if applicable.

(3) Engage hidden clips to hold trim bolster to

quarter trim panel.

RADIATOR CLOSURE PANEL CROSSMEMBER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching hood latch to cross-

member and position latch out of the way.(3) Remove radiator sight shield.

(4) Remove engine air inlet resonator.

(5) Remove bolt holding air cleaner housing to

crossmember.

(6) Remove screw holding coolant recovery bottle

to crossmember.

(7) Remove bolts holding radiator isolators to

crossmember.

(8) Remove bolts holding ends of crossmember to

radiator closure panel (Fig. 75).

(9) Lift crossmember upward and away from radi-

ator closure panel.

(10) Remove crossmember from vehicle.

INSTALLATION

(1) Place radiator closure panel crossmember in

position on vehicle.

(2) Insert ends of crossmember between layered

metal sections of radiator closure panel at each side

of radiator.

Fig. 72 Quarter Glass

Fig. 73 Left Quarter Trim Bolster ± LWB Four Door

Fig. 74 Left Quarter Trim Bolster ± SWB and LWB

Three Door

NSBODY 23 - 53

REMOVAL AND INSTALLATION (Continued)

Page 1833 of 1938

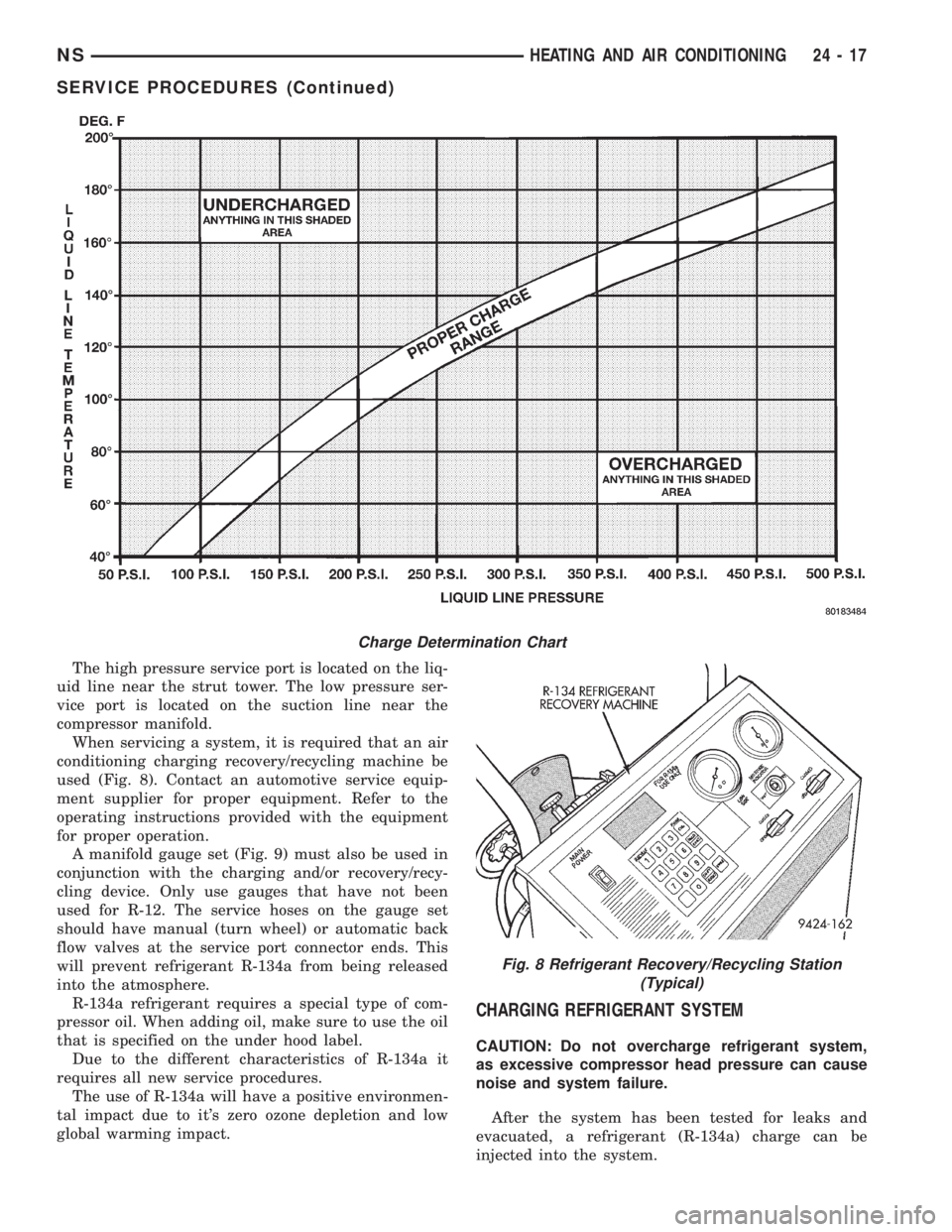

The high pressure service port is located on the liq-

uid line near the strut tower. The low pressure ser-

vice port is located on the suction line near the

compressor manifold.

When servicing a system, it is required that an air

conditioning charging recovery/recycling machine be

used (Fig. 8). Contact an automotive service equip-

ment supplier for proper equipment. Refer to the

operating instructions provided with the equipment

for proper operation.

A manifold gauge set (Fig. 9) must also be used in

conjunction with the charging and/or recovery/recy-

cling device. Only use gauges that have not been

used for R-12. The service hoses on the gauge set

should have manual (turn wheel) or automatic back

flow valves at the service port connector ends. This

will prevent refrigerant R-134a from being released

into the atmosphere.

R-134a refrigerant requires a special type of com-

pressor oil. When adding oil, make sure to use the oil

that is specified on the under hood label.

Due to the different characteristics of R-134a it

requires all new service procedures.

The use of R-134a will have a positive environmen-

tal impact due to it's zero ozone depletion and low

global warming impact.

CHARGING REFRIGERANT SYSTEM

CAUTION: Do not overcharge refrigerant system,

as excessive compressor head pressure can cause

noise and system failure.

After the system has been tested for leaks and

evacuated, a refrigerant (R-134a) charge can be

injected into the system.

Charge Determination Chart

Fig. 8 Refrigerant Recovery/Recycling Station

(Typical)

NSHEATING AND AIR CONDITIONING 24 - 17

SERVICE PROCEDURES (Continued)

Page 1882 of 1938

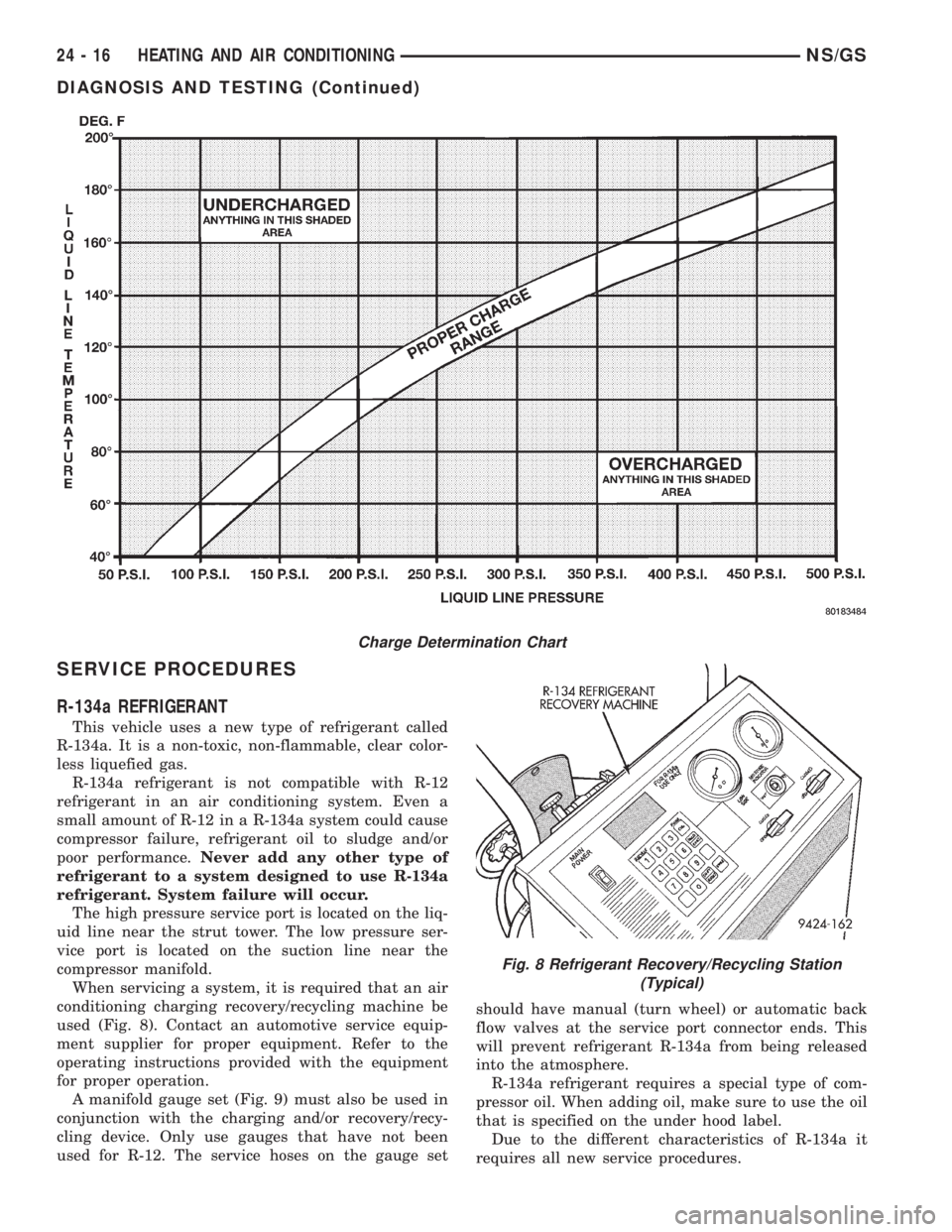

SERVICE PROCEDURES

R-134a REFRIGERANT

This vehicle uses a new type of refrigerant called

R-134a. It is a non-toxic, non-flammable, clear color-

less liquefied gas.

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 in a R-134a system could cause

compressor failure, refrigerant oil to sludge and/or

poor performance.Never add any other type of

refrigerant to a system designed to use R-134a

refrigerant. System failure will occur.

The high pressure service port is located on the liq-

uid line near the strut tower. The low pressure ser-

vice port is located on the suction line near the

compressor manifold.

When servicing a system, it is required that an air

conditioning charging recovery/recycling machine be

used (Fig. 8). Contact an automotive service equip-

ment supplier for proper equipment. Refer to the

operating instructions provided with the equipment

for proper operation.

A manifold gauge set (Fig. 9) must also be used in

conjunction with the charging and/or recovery/recy-

cling device. Only use gauges that have not been

used for R-12. The service hoses on the gauge setshould have manual (turn wheel) or automatic back

flow valves at the service port connector ends. This

will prevent refrigerant R-134a from being released

into the atmosphere.

R-134a refrigerant requires a special type of com-

pressor oil. When adding oil, make sure to use the oil

that is specified on the under hood label.

Due to the different characteristics of R-134a it

requires all new service procedures.

Charge Determination Chart

Fig. 8 Refrigerant Recovery/Recycling Station

(Typical)

24 - 16 HEATING AND AIR CONDITIONINGNS/GS

DIAGNOSIS AND TESTING (Continued)