shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1713 of 1938

been replaced, you must perform the differential

bearing preload shim adjustment. If the transaxle

case has been replaced, you must perform both pro-

cedures.

GENERAL RULES ON SERVICING BEARINGS

(1) Use extreme care when removing and install-

ing bearing cups and cones. Burrs or nicks on the

bearing seat will give a false end play reading while

gauging for proper shims. Improperly seated bearing

cups and cones are subject to low±mileage failure.

(2) Bearing cups and cones should be replaced if

they show signs of pitting or heat distress. If distress

is seen on either the cup or bearing rollers, both cup

and cone must be replaced.(3) Bearing preload and drag torque specifications

must be maintained to avoid premature bearing fail-

ures. Used (original) bearings may lose up to 50% of

their original drag torque after break in. All bearing

adjustments must be made with no other component

interference or gear intermesh.

(4) Replace bearings as a pair: If one differential

bearing is defective, replace both differential bear-

ings.

(5) Bearing cones must not be reused if removed.

(6) Turning torque readings should be obtained

while smoothly rotating in either direction.

INTERMEDIATE SHAFT BEARING PRELOAD

The intermediate shaft preload must be checked if

the housing, intermediate shaft, bearing plate, bear-

ings, or transaxle case are replaced.

The intermediate shaft bearing preload procedure

must be done with the transaxle out of the vehicle

and on a bench.

(1) Remove end cover (Fig. 226).

(2) Remove 5th shift fork roll pin (Fig. 227).

(3) Use Special Tool 6252 to hold 5th gear. Remove

input shaft 5th gear nut (Fig. 228).

(4) Remove 5th gear synchro snap ring (Fig. 229).

(5) Remove 5th gear synchro, synchro plate, and

fork.

(6) Remove 5th drive gear off of the input shaft

(Fig. 230).

(7) Remove bearing retainer plate (Fig. 231).

(8) Remove bearing preload shim (Fig. 232).

(9) Bolt down the bearing support plate in two

places (verify dowels are in place).

(10) Seat the intermediate bearing cup against the

bearing.

(11) Measure depth of intermediate bearing cup

with dial depth gauge (Fig. 233).

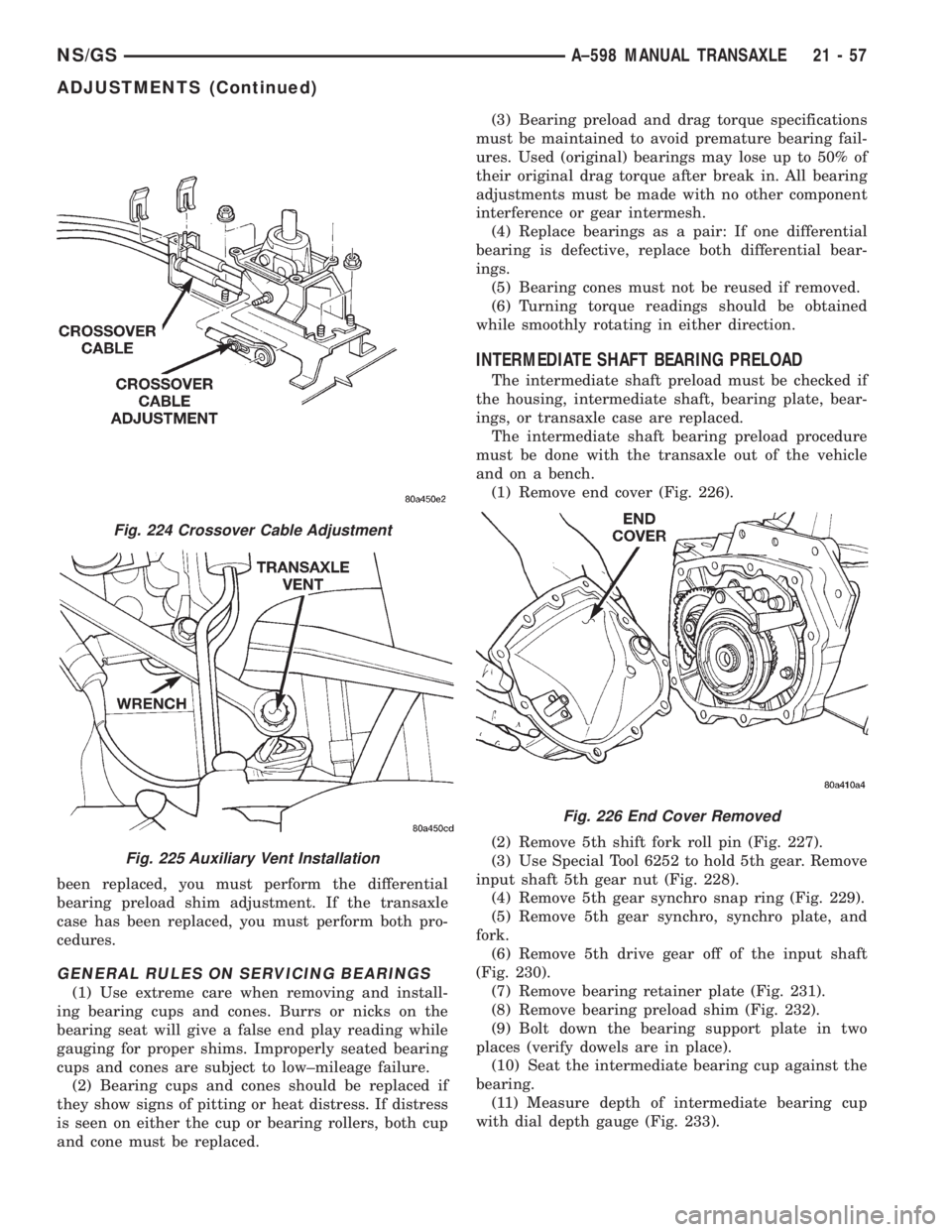

Fig. 224 Crossover Cable Adjustment

Fig. 225 Auxiliary Vent Installation

Fig. 226 End Cover Removed

NS/GSA±598 MANUAL TRANSAXLE 21 - 57

ADJUSTMENTS (Continued)

Page 1715 of 1938

(14) Apply a bead of MopartGasket Maker or

equivalent onto bearing support plate. Install bearing

support plate.

(15) Install necessary shim calculated from Step

12

(16) Install bearing retainer plate. Tighten bearing

retainer plate to 17 N´m (250 in. lbs.).

(17) Install 5th drive gear onto the input shaft.

(18) Install 5th gear, synchro, fork, and plate.

(19) Install 5th gear synchro snap ring.

(20) Install 5th gear shift fork roll pin.

(21) Use Special Tool 6252 to hold 5th gear and

install new 5th gear nut at input shaft. Tighten the

retaining nut to 176 N´m (130 ft. lbs.).

(22) Use Special Tool 6930 to stake the 5th gear

retaining nut onto the input shaft (Fig. 234).

(23) Apply a bead of MopartGasket Maker or

equivalent onto end cover. Install 5th gear/synchro

end cover. Tighten bolts to 28 N´m (250 in. lbs.).

SPECIFICATIONS

A-598 (T-750) MANUAL TRANSAXLE

DESCRIPTION TORQUE

Back-up Lamp Switch..........27N´m(20ft.lbs.)

Bearing Retainer Plate........28N´m(250 in. lbs.)

Crossover Cable Adj. Screw......8N´m(70in.lbs.)

Drain Plug..................23N´m(17ft.lbs.)

Differential Housing...........54N´m(40ft.lbs.)

Diff. Bearing Retainer.........61N´m(45ft.lbs.)

Diff. Ring Gear Bolts..........94N´m(70ft.lbs.)

End Cover Bolts..............28N´m(21ft.lbs.)

Extension Housing...........28N´m(250 in. lbs.)

Gearshift Housing...........28N´m(250 in. lbs.)

*Input Gear Nut............176 N´m (130 ft. lbs.)

Input Retainer..............28N´m(250 in. lbs.)

Reverse Blocker.............12N´m(105 in. lbs.)

Transaxle Case Bolts..........29N´m(21ft.lbs.)

Vehicle Speed Sensor...........7N´m(60in.lbs.)

Vent........................6N´m(60in.lbs.)

NOTE: *The 5th/input gear is torqued to specifica-

tion and then staked in two places using Special

Tool 6930.

NOTE: Bolts that have thread sealer or torque lock

patches should not be reused. Always install new

bolts in these applications.

A-558 MANUAL TRANSAXLEÐRHD VEHICLES

DESCRIPTION TORQUE

Back-up Lamp Switch..........27N´m(20ft.lbs.)

Bearing Retainer Plate........28N´m(250 in. lbs.)

Crossover Cable Adj. Screw......8N´m(70in.lbs.)

Drain Plug..................23N´m(17ft.lbs.)

Modular Clutch to Drive

Plate Bolts................74N´m(55ft.lbs.)

Transaxle Case Bolts..........29N´m(21ft.lbs.)

Vehicle Speed Sensor...........7N´m(60in.lbs.)

Vent........................6N´m(60in.lbs.)

Fig. 233 Measure Depth Of Cup

Fig. 234 Staking 5th Gear Retaining Nut

NV T750 (A-598) MANUAL TRANSAXLE FLUID

FILL

TRANSAXLEMETRIC MEA-

SUREU.S. MEASURE

NV T750 1.9-2.2 Liters 2.0-2.3 Quarts

NS/GSA±598 MANUAL TRANSAXLE 21 - 59

ADJUSTMENTS (Continued)

Page 1750 of 1938

POWER SEAT SWITCH

Diagnostic information for power seat switch is

located in Group 8R, Power Seats.

REMOVAL

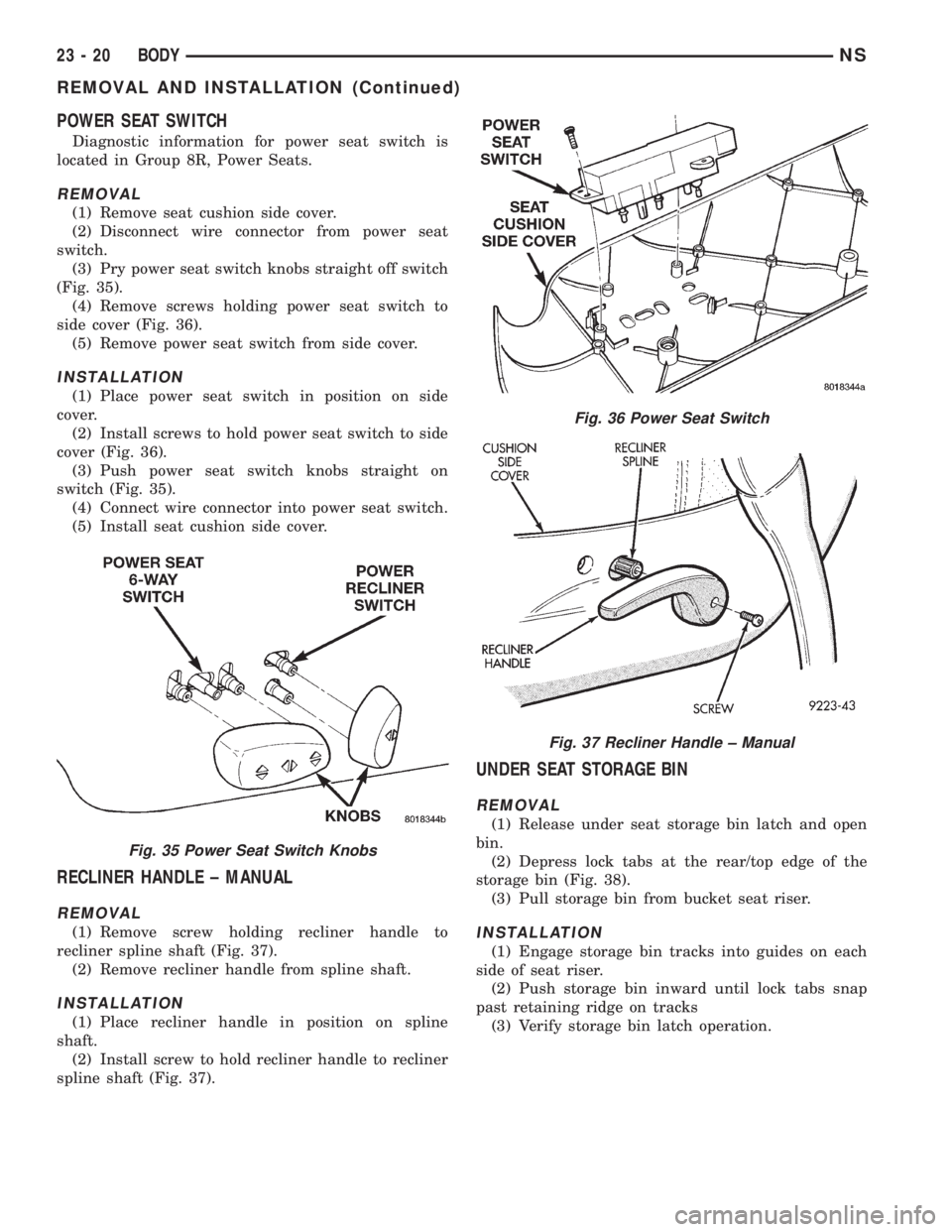

(1) Remove seat cushion side cover.

(2) Disconnect wire connector from power seat

switch.

(3) Pry power seat switch knobs straight off switch

(Fig. 35).

(4) Remove screws holding power seat switch to

side cover (Fig. 36).

(5) Remove power seat switch from side cover.

INSTALLATION

(1) Place power seat switch in position on side

cover.

(2) Install screws to hold power seat switch to side

cover (Fig. 36).

(3) Push power seat switch knobs straight on

switch (Fig. 35).

(4) Connect wire connector into power seat switch.

(5) Install seat cushion side cover.

RECLINER HANDLE ± MANUAL

REMOVAL

(1) Remove screw holding recliner handle to

recliner spline shaft (Fig. 37).

(2) Remove recliner handle from spline shaft.

INSTALLATION

(1) Place recliner handle in position on spline

shaft.

(2) Install screw to hold recliner handle to recliner

spline shaft (Fig. 37).

UNDER SEAT STORAGE BIN

REMOVAL

(1) Release under seat storage bin latch and open

bin.

(2) Depress lock tabs at the rear/top edge of the

storage bin (Fig. 38).

(3) Pull storage bin from bucket seat riser.

INSTALLATION

(1) Engage storage bin tracks into guides on each

side of seat riser.

(2) Push storage bin inward until lock tabs snap

past retaining ridge on tracks

(3) Verify storage bin latch operation.

Fig. 35 Power Seat Switch Knobs

Fig. 36 Power Seat Switch

Fig. 37 Recliner Handle ± Manual

23 - 20 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1766 of 1938

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

FRONT DOOR WEATHER-STRIP

REMOVAL

(1) Open front door.

(2) Using fork tool (C-4829), remove push-in fas-

teners holding front door weather-strip to end frames

and bottom of door (Fig. 30).

(3) Pull weather-strip from retaining channel

around window frame.

(4) Remove weather-strip from vehicle.

INSTALLATION

For installation, reverse the above procedures.

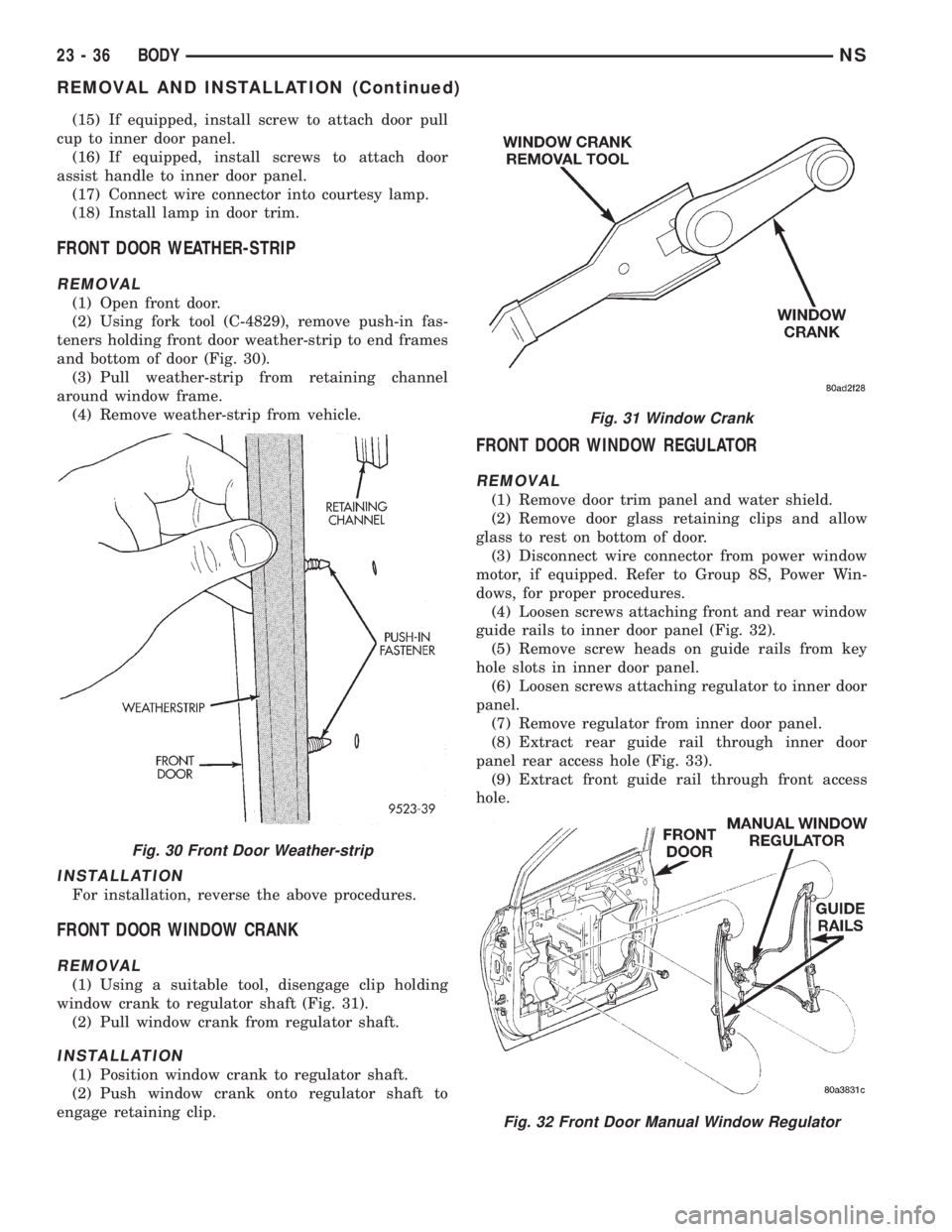

FRONT DOOR WINDOW CRANK

REMOVAL

(1) Using a suitable tool, disengage clip holding

window crank to regulator shaft (Fig. 31).

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Position window crank to regulator shaft.

(2) Push window crank onto regulator shaft to

engage retaining clip.

FRONT DOOR WINDOW REGULATOR

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove door glass retaining clips and allow

glass to rest on bottom of door.

(3) Disconnect wire connector from power window

motor, if equipped. Refer to Group 8S, Power Win-

dows, for proper procedures.

(4) Loosen screws attaching front and rear window

guide rails to inner door panel (Fig. 32).

(5) Remove screw heads on guide rails from key

hole slots in inner door panel.

(6) Loosen screws attaching regulator to inner door

panel.

(7) Remove regulator from inner door panel.

(8) Extract rear guide rail through inner door

panel rear access hole (Fig. 33).

(9) Extract front guide rail through front access

hole.

Fig. 30 Front Door Weather-strip

Fig. 31 Window Crank

Fig. 32 Front Door Manual Window Regulator

23 - 36 BODYNS

REMOVAL AND INSTALLATION (Continued)

Page 1839 of 1938

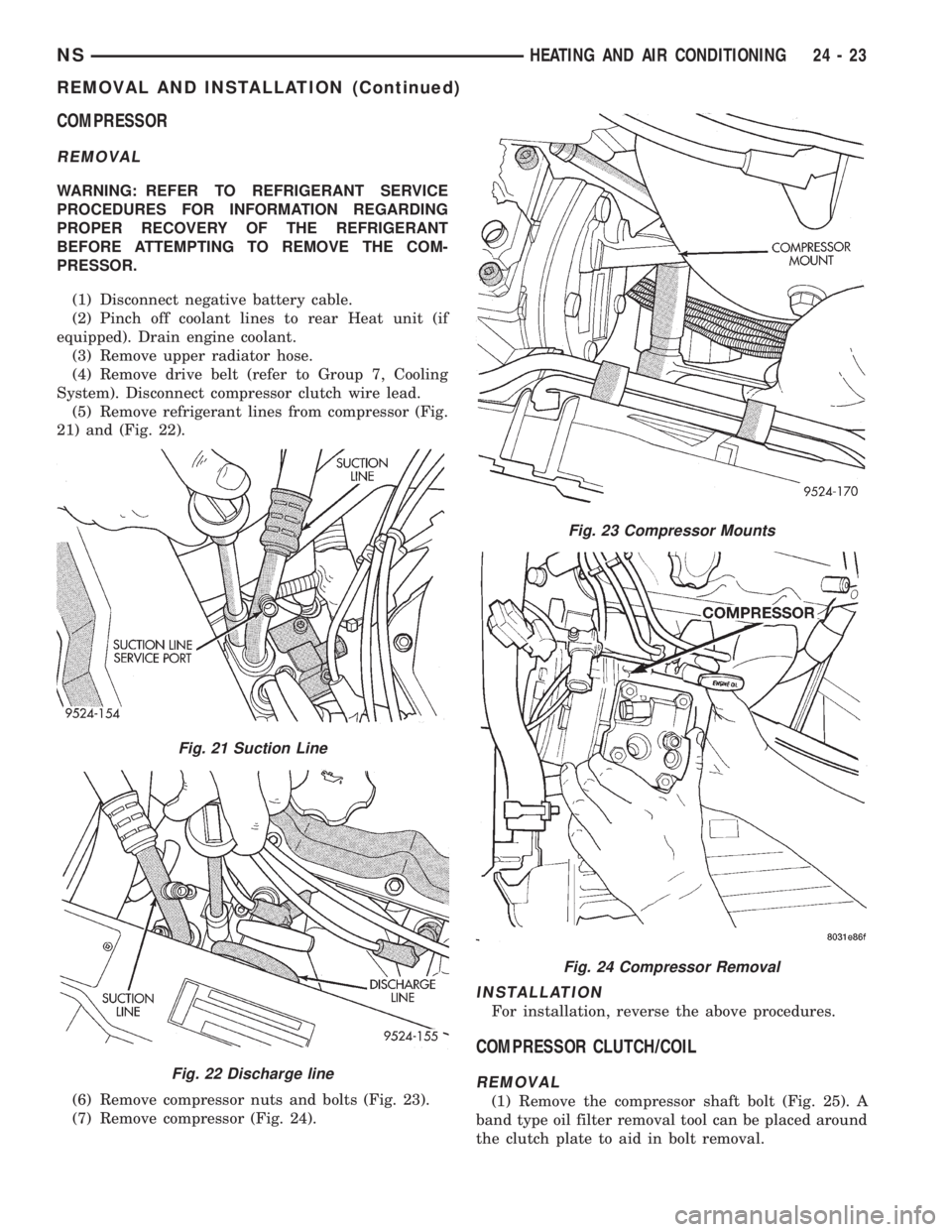

COMPRESSOR

REMOVAL

WARNING: REFER TO REFRIGERANT SERVICE

PROCEDURES FOR INFORMATION REGARDING

PROPER RECOVERY OF THE REFRIGERANT

BEFORE ATTEMPTING TO REMOVE THE COM-

PRESSOR.

(1) Disconnect negative battery cable.

(2) Pinch off coolant lines to rear Heat unit (if

equipped). Drain engine coolant.

(3) Remove upper radiator hose.

(4) Remove drive belt (refer to Group 7, Cooling

System). Disconnect compressor clutch wire lead.

(5) Remove refrigerant lines from compressor (Fig.

21) and (Fig. 22).

(6) Remove compressor nuts and bolts (Fig. 23).

(7) Remove compressor (Fig. 24).

INSTALLATION

For installation, reverse the above procedures.

COMPRESSOR CLUTCH/COIL

REMOVAL

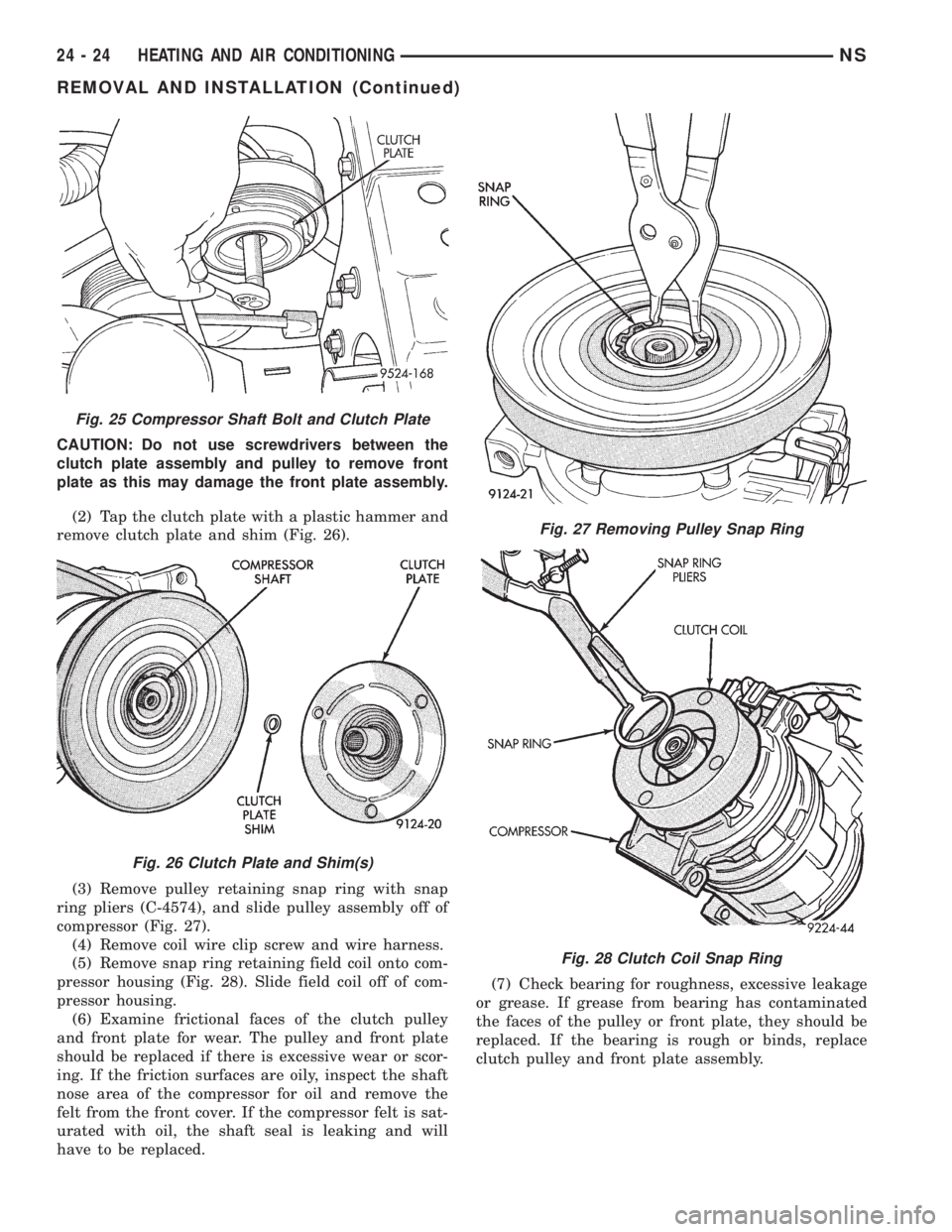

(1) Remove the compressor shaft bolt (Fig. 25). A

band type oil filter removal tool can be placed around

the clutch plate to aid in bolt removal.

Fig. 21 Suction Line

Fig. 22 Discharge line

Fig. 23 Compressor Mounts

Fig. 24 Compressor Removal

NSHEATING AND AIR CONDITIONING 24 - 23

REMOVAL AND INSTALLATION (Continued)

Page 1840 of 1938

CAUTION: Do not use screwdrivers between the

clutch plate assembly and pulley to remove front

plate as this may damage the front plate assembly.

(2) Tap the clutch plate with a plastic hammer and

remove clutch plate and shim (Fig. 26).

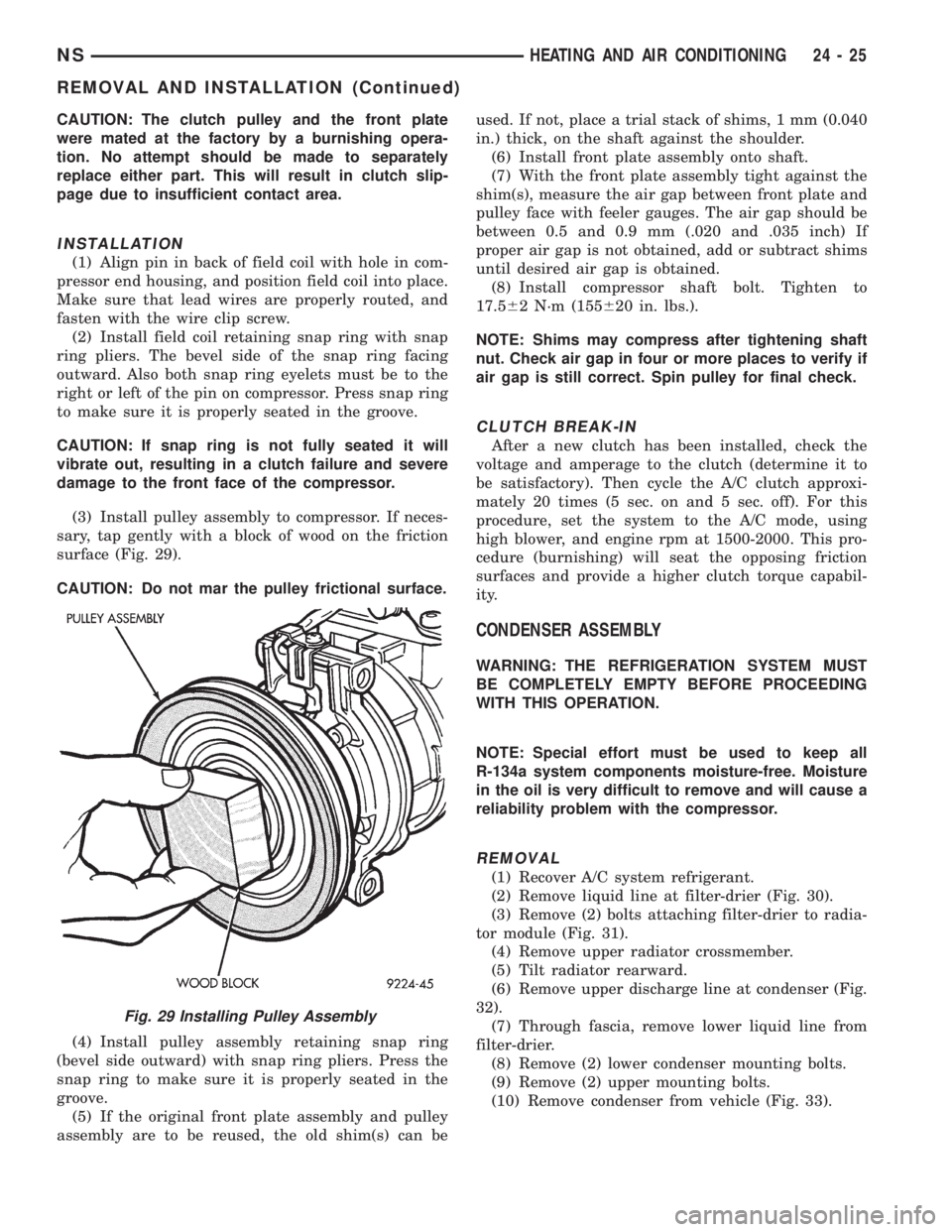

(3) Remove pulley retaining snap ring with snap

ring pliers (C-4574), and slide pulley assembly off of

compressor (Fig. 27).

(4) Remove coil wire clip screw and wire harness.

(5) Remove snap ring retaining field coil onto com-

pressor housing (Fig. 28). Slide field coil off of com-

pressor housing.

(6) Examine frictional faces of the clutch pulley

and front plate for wear. The pulley and front plate

should be replaced if there is excessive wear or scor-

ing. If the friction surfaces are oily, inspect the shaft

nose area of the compressor for oil and remove the

felt from the front cover. If the compressor felt is sat-

urated with oil, the shaft seal is leaking and will

have to be replaced.(7) Check bearing for roughness, excessive leakage

or grease. If grease from bearing has contaminated

the faces of the pulley or front plate, they should be

replaced. If the bearing is rough or binds, replace

clutch pulley and front plate assembly.

Fig. 25 Compressor Shaft Bolt and Clutch Plate

Fig. 26 Clutch Plate and Shim(s)

Fig. 27 Removing Pulley Snap Ring

Fig. 28 Clutch Coil Snap Ring

24 - 24 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1841 of 1938

CAUTION: The clutch pulley and the front plate

were mated at the factory by a burnishing opera-

tion. No attempt should be made to separately

replace either part. This will result in clutch slip-

page due to insufficient contact area.

INSTALLATION

(1) Align pin in back of field coil with hole in com-

pressor end housing, and position field coil into place.

Make sure that lead wires are properly routed, and

fasten with the wire clip screw.

(2) Install field coil retaining snap ring with snap

ring pliers. The bevel side of the snap ring facing

outward. Also both snap ring eyelets must be to the

right or left of the pin on compressor. Press snap ring

to make sure it is properly seated in the groove.

CAUTION: If snap ring is not fully seated it will

vibrate out, resulting in a clutch failure and severe

damage to the front face of the compressor.

(3) Install pulley assembly to compressor. If neces-

sary, tap gently with a block of wood on the friction

surface (Fig. 29).

CAUTION: Do not mar the pulley frictional surface.

(4) Install pulley assembly retaining snap ring

(bevel side outward) with snap ring pliers. Press the

snap ring to make sure it is properly seated in the

groove.

(5) If the original front plate assembly and pulley

assembly are to be reused, the old shim(s) can beused. If not, place a trial stack of shims, 1 mm (0.040

in.) thick, on the shaft against the shoulder.

(6) Install front plate assembly onto shaft.

(7) With the front plate assembly tight against the

shim(s), measure the air gap between front plate and

pulley face with feeler gauges. The air gap should be

between 0.5 and 0.9 mm (.020 and .035 inch) If

proper air gap is not obtained, add or subtract shims

until desired air gap is obtained.

(8) Install compressor shaft bolt. Tighten to

17.562 N´m (155620 in. lbs.).

NOTE: Shims may compress after tightening shaft

nut. Check air gap in four or more places to verify if

air gap is still correct. Spin pulley for final check.

CLUTCH BREAK-IN

After a new clutch has been installed, check the

voltage and amperage to the clutch (determine it to

be satisfactory). Then cycle the A/C clutch approxi-

mately 20 times (5 sec. on and 5 sec. off). For this

procedure, set the system to the A/C mode, using

high blower, and engine rpm at 1500-2000. This pro-

cedure (burnishing) will seat the opposing friction

surfaces and provide a higher clutch torque capabil-

ity.

CONDENSER ASSEMBLY

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

NOTE: Special effort must be used to keep all

R-134a system components moisture-free. Moisture

in the oil is very difficult to remove and will cause a

reliability problem with the compressor.

REMOVAL

(1) Recover A/C system refrigerant.

(2) Remove liquid line at filter-drier (Fig. 30).

(3) Remove (2) bolts attaching filter-drier to radia-

tor module (Fig. 31).

(4) Remove upper radiator crossmember.

(5) Tilt radiator rearward.

(6) Remove upper discharge line at condenser (Fig.

32).

(7) Through fascia, remove lower liquid line from

filter-drier.

(8) Remove (2) lower condenser mounting bolts.

(9) Remove (2) upper mounting bolts.

(10) Remove condenser from vehicle (Fig. 33).

Fig. 29 Installing Pulley Assembly

NSHEATING AND AIR CONDITIONING 24 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1846 of 1938

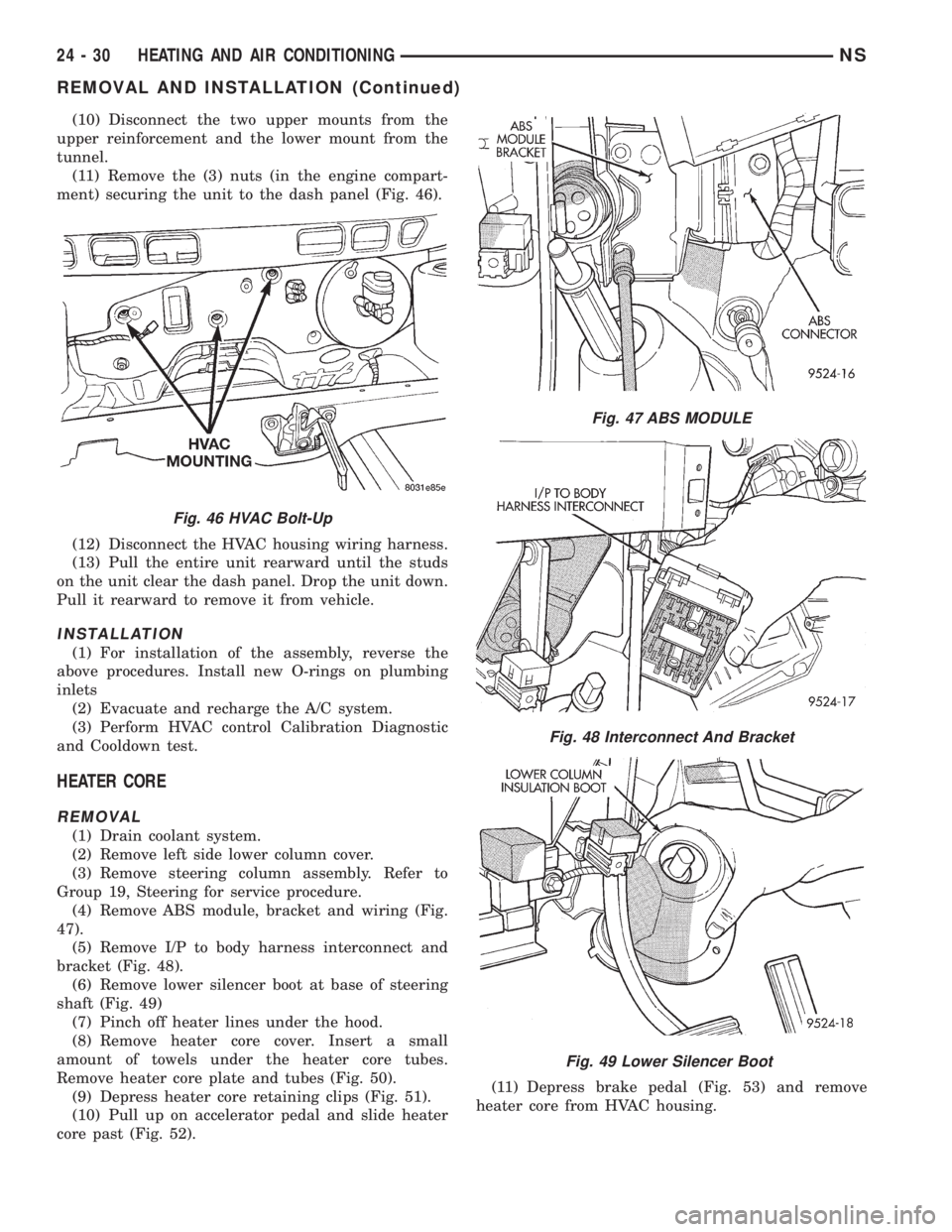

(10) Disconnect the two upper mounts from the

upper reinforcement and the lower mount from the

tunnel.

(11) Remove the (3) nuts (in the engine compart-

ment) securing the unit to the dash panel (Fig. 46).

(12) Disconnect the HVAC housing wiring harness.

(13) Pull the entire unit rearward until the studs

on the unit clear the dash panel. Drop the unit down.

Pull it rearward to remove it from vehicle.

INSTALLATION

(1) For installation of the assembly, reverse the

above procedures. Install new O-rings on plumbing

inlets

(2) Evacuate and recharge the A/C system.

(3) Perform HVAC control Calibration Diagnostic

and Cooldown test.

HEATER CORE

REMOVAL

(1) Drain coolant system.

(2) Remove left side lower column cover.

(3) Remove steering column assembly. Refer to

Group 19, Steering for service procedure.

(4) Remove ABS module, bracket and wiring (Fig.

47).

(5) Remove I/P to body harness interconnect and

bracket (Fig. 48).

(6) Remove lower silencer boot at base of steering

shaft (Fig. 49)

(7) Pinch off heater lines under the hood.

(8) Remove heater core cover. Insert a small

amount of towels under the heater core tubes.

Remove heater core plate and tubes (Fig. 50).

(9) Depress heater core retaining clips (Fig. 51).

(10) Pull up on accelerator pedal and slide heater

core past (Fig. 52).(11) Depress brake pedal (Fig. 53) and remove

heater core from HVAC housing.

Fig. 46 HVAC Bolt-Up

Fig. 47 ABS MODULE

Fig. 48 Interconnect And Bracket

Fig. 49 Lower Silencer Boot

24 - 30 HEATING AND AIR CONDITIONINGNS

REMOVAL AND INSTALLATION (Continued)

Page 1855 of 1938

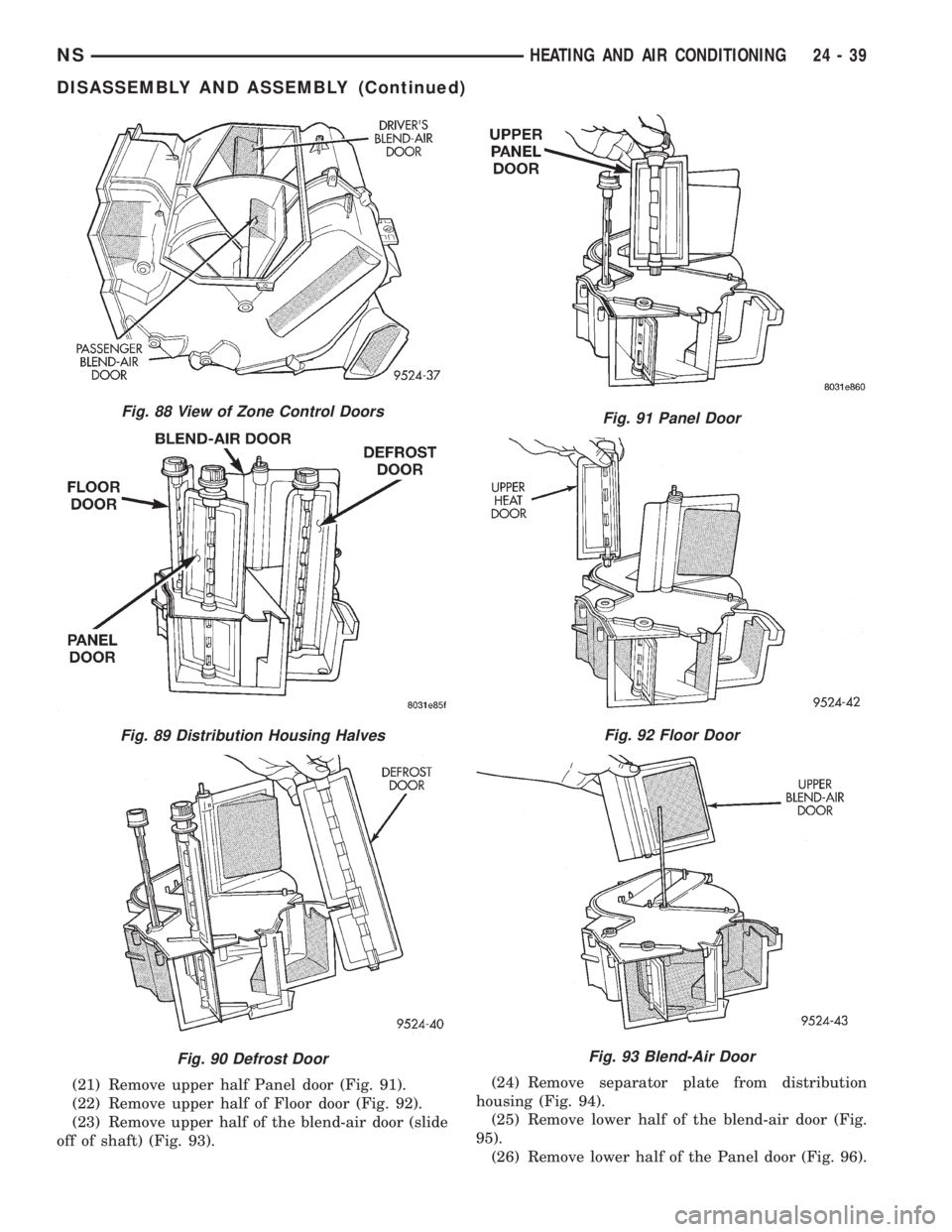

(21) Remove upper half Panel door (Fig. 91).

(22) Remove upper half of Floor door (Fig. 92).

(23) Remove upper half of the blend-air door (slide

off of shaft) (Fig. 93).(24) Remove separator plate from distribution

housing (Fig. 94).

(25) Remove lower half of the blend-air door (Fig.

95).

(26) Remove lower half of the Panel door (Fig. 96).

Fig. 88 View of Zone Control Doors

Fig. 89 Distribution Housing Halves

Fig. 90 Defrost Door

Fig. 91 Panel Door

Fig. 92 Floor Door

Fig. 93 Blend-Air Door

NSHEATING AND AIR CONDITIONING 24 - 39

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1892 of 1938

(2) Hand-start the stud into the expansion valve

and torque to7-11N´m(64-96in.lbs.).

(3) Carefully install the expansion valve to the

sealing plate. Install the two screws and tighten 8 to

14 N´m (70 to 130 in. lbs.) torque.

(4) Carefully install the refrigerant lines and seal-

ing plate to the expansion valve. Install the nut and

tighten 20 to 26 N´m (170 to 230 in. lbs.) torque.

(5) Install the ground wire at dash panel.

(6) Pull generator back into the proper position for

bracket mounting.

(7) Install generator field wire connector.

(8) Install the upper generator bracket.

(9) Install accessory drive belt.

(10) Evacuate and recharge system.

(11) After expansion valve is installed, the system

is charged, and leaks have checked repeat the A/C

performance check.

FILTER-DRIER ASSEMBLY

REMOVAL

WARNING: THE REFRIGERATION SYSTEM MUST

BE COMPLETELY EMPTY BEFORE PROCEEDING

WITH THIS OPERATION.

(1) Recover A/C system refrigerant.

(2) Remove liquid line at filter-drier (Fig. 21).

(3) Remove the (2) bolts holding filter-drier bracket

to radiator fan module bracket.

(4) Remove the lower liquid line at condenser.

(5) Remove the upper radiator crossmember.

(6) Pull up on radiator and slide filter-drier from

the mounting location.

INSTALLATION

(1) Before installation, replace both refrigerant

line O-rings. Then reverse the above procedures.

(2) Evacuate and recharge system.

HEATER A/C UNIT HOUSING

REMOVAL

WARNING: IF EQUIPPED WITH AIR CONDITIONING,

THE REFRIGERATION SYSTEM MUST BE COM-

PLETELY EMPTY BEFORE PROCEEDING.

(1) Set parking brake.

(2) Disconnect battery negative cable.

(3) Using a refrigerant recovery machine, remove

refrigerant from the A/C system.

(4) Remove wiper module. Refer to Group 8K,

Windshield Wipers and Washers.

(5) Drain engine coolant. Remove heater hoses at

the heater core, refer to Heater Hoses Removal and

Installation procedures. Plug coolant lines.(6) Remove suction and liquid lines at the expan-

sion valve (Fig. 27).

(7) Remove the Instrument Panel Assembly. Refer

to Group 8E, Instrument Panel and Systems.

(8) Remove heater ducts.

(9) Disconnect the two upper mounts from the

upper reinforcement and the lower mount from the

tunnel.

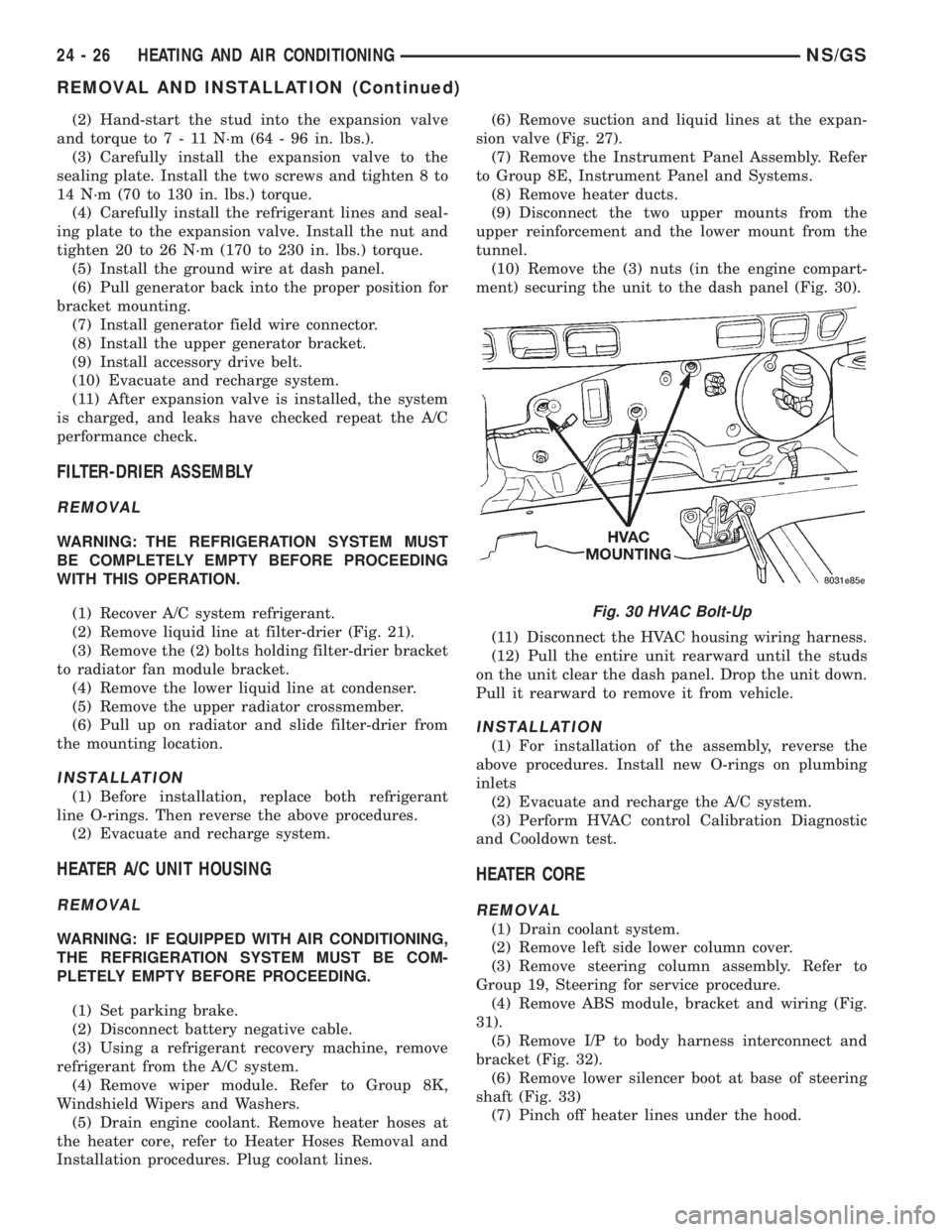

(10) Remove the (3) nuts (in the engine compart-

ment) securing the unit to the dash panel (Fig. 30).

(11) Disconnect the HVAC housing wiring harness.

(12) Pull the entire unit rearward until the studs

on the unit clear the dash panel. Drop the unit down.

Pull it rearward to remove it from vehicle.

INSTALLATION

(1) For installation of the assembly, reverse the

above procedures. Install new O-rings on plumbing

inlets

(2) Evacuate and recharge the A/C system.

(3) Perform HVAC control Calibration Diagnostic

and Cooldown test.

HEATER CORE

REMOVAL

(1) Drain coolant system.

(2) Remove left side lower column cover.

(3) Remove steering column assembly. Refer to

Group 19, Steering for service procedure.

(4) Remove ABS module, bracket and wiring (Fig.

31).

(5) Remove I/P to body harness interconnect and

bracket (Fig. 32).

(6) Remove lower silencer boot at base of steering

shaft (Fig. 33)

(7) Pinch off heater lines under the hood.

Fig. 30 HVAC Bolt-Up

24 - 26 HEATING AND AIR CONDITIONINGNS/GS

REMOVAL AND INSTALLATION (Continued)