shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1647 of 1938

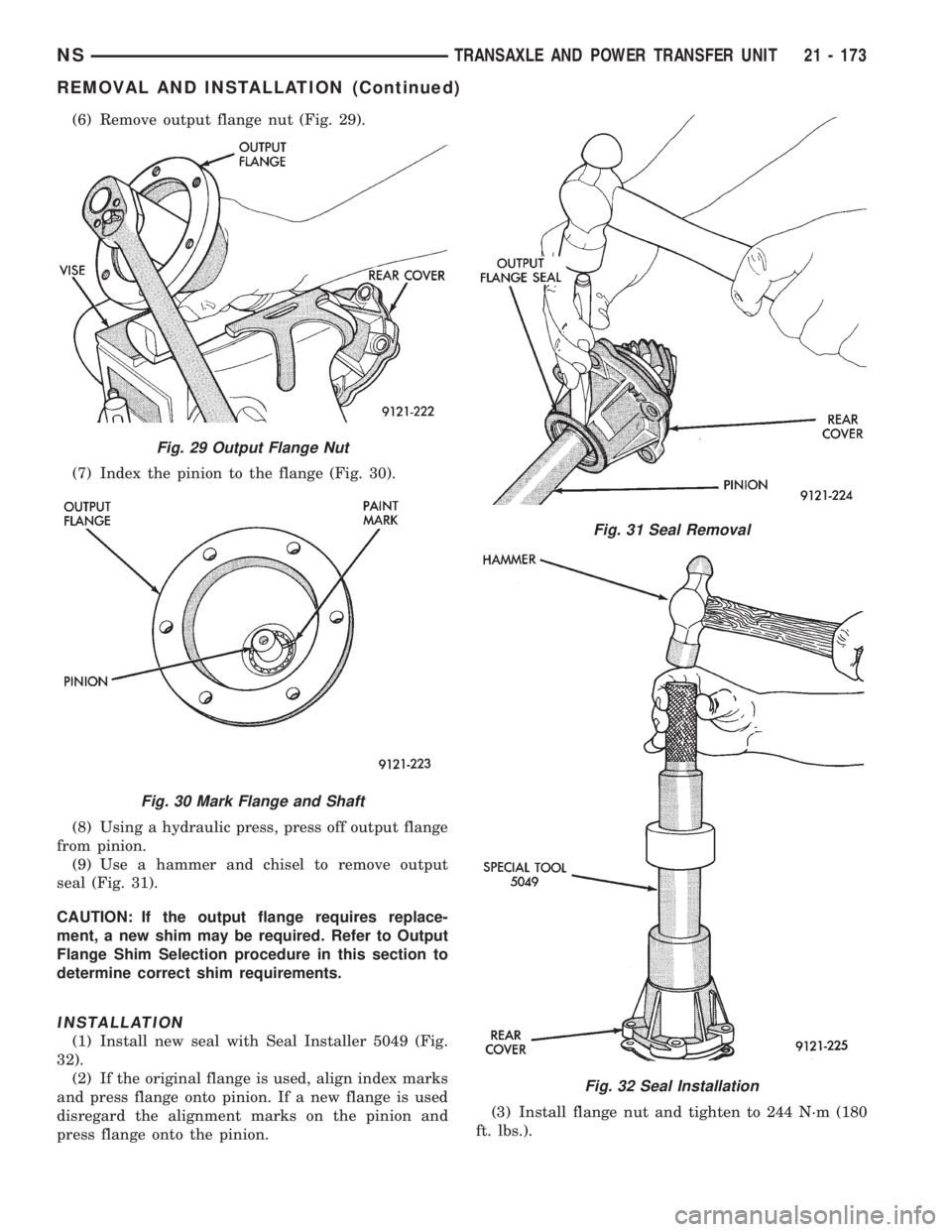

(6) Remove output flange nut (Fig. 29).

(7) Index the pinion to the flange (Fig. 30).

(8) Using a hydraulic press, press off output flange

from pinion.

(9) Use a hammer and chisel to remove output

seal (Fig. 31).

CAUTION: If the output flange requires replace-

ment, a new shim may be required. Refer to Output

Flange Shim Selection procedure in this section to

determine correct shim requirements.

INSTALLATION

(1) Install new seal with Seal Installer 5049 (Fig.

32).

(2) If the original flange is used, align index marks

and press flange onto pinion. If a new flange is used

disregard the alignment marks on the pinion and

press flange onto the pinion.(3) Install flange nut and tighten to 244 N´m (180

ft. lbs.).

Fig. 29 Output Flange Nut

Fig. 30 Mark Flange and Shaft

Fig. 31 Seal Removal

Fig. 32 Seal Installation

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 173

REMOVAL AND INSTALLATION (Continued)

Page 1648 of 1938

(4) Install rear cover. Use care not to cut rear

cover O-Ring when installing rear cover into P.T.U.

housing.

(5) Install rear cover retaining bolts and tighten to

28 N´m (250 in. lbs.).

(6) Install propeller shaft.

(7) Check and fill fluids as required.

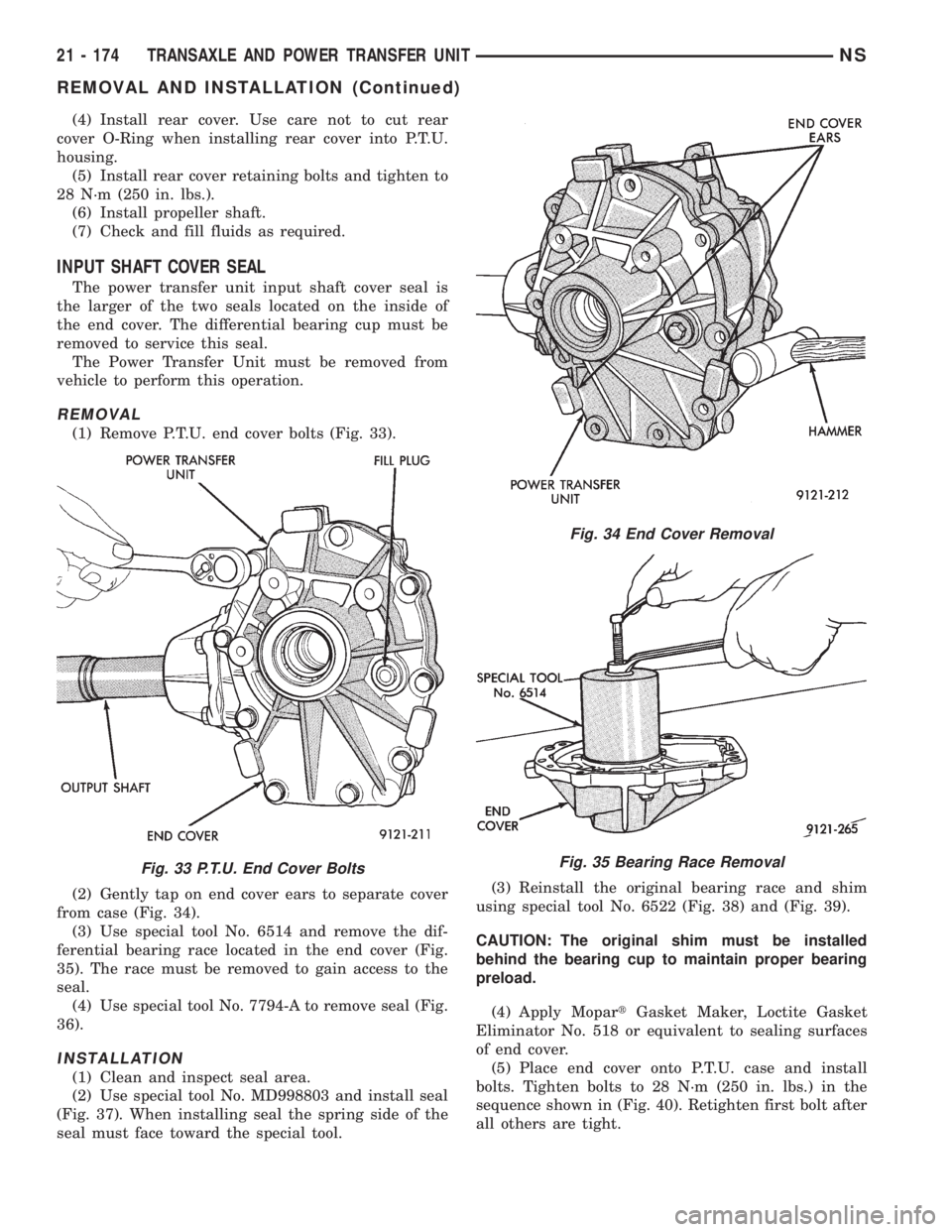

INPUT SHAFT COVER SEAL

The power transfer unit input shaft cover seal is

the larger of the two seals located on the inside of

the end cover. The differential bearing cup must be

removed to service this seal.

The Power Transfer Unit must be removed from

vehicle to perform this operation.

REMOVAL

(1) Remove P.T.U. end cover bolts (Fig. 33).

(2) Gently tap on end cover ears to separate cover

from case (Fig. 34).

(3) Use special tool No. 6514 and remove the dif-

ferential bearing race located in the end cover (Fig.

35). The race must be removed to gain access to the

seal.

(4) Use special tool No. 7794-A to remove seal (Fig.

36).

INSTALLATION

(1) Clean and inspect seal area.

(2) Use special tool No. MD998803 and install seal

(Fig. 37). When installing seal the spring side of the

seal must face toward the special tool.(3) Reinstall the original bearing race and shim

using special tool No. 6522 (Fig. 38) and (Fig. 39).

CAUTION: The original shim must be installed

behind the bearing cup to maintain proper bearing

preload.

(4) Apply MopartGasket Maker, Loctite Gasket

Eliminator No. 518 or equivalent to sealing surfaces

of end cover.

(5) Place end cover onto P.T.U. case and install

bolts. Tighten bolts to 28 N´m (250 in. lbs.) in the

sequence shown in (Fig. 40). Retighten first bolt after

all others are tight.

Fig. 33 P.T.U. End Cover Bolts

Fig. 34 End Cover Removal

Fig. 35 Bearing Race Removal

21 - 174 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1649 of 1938

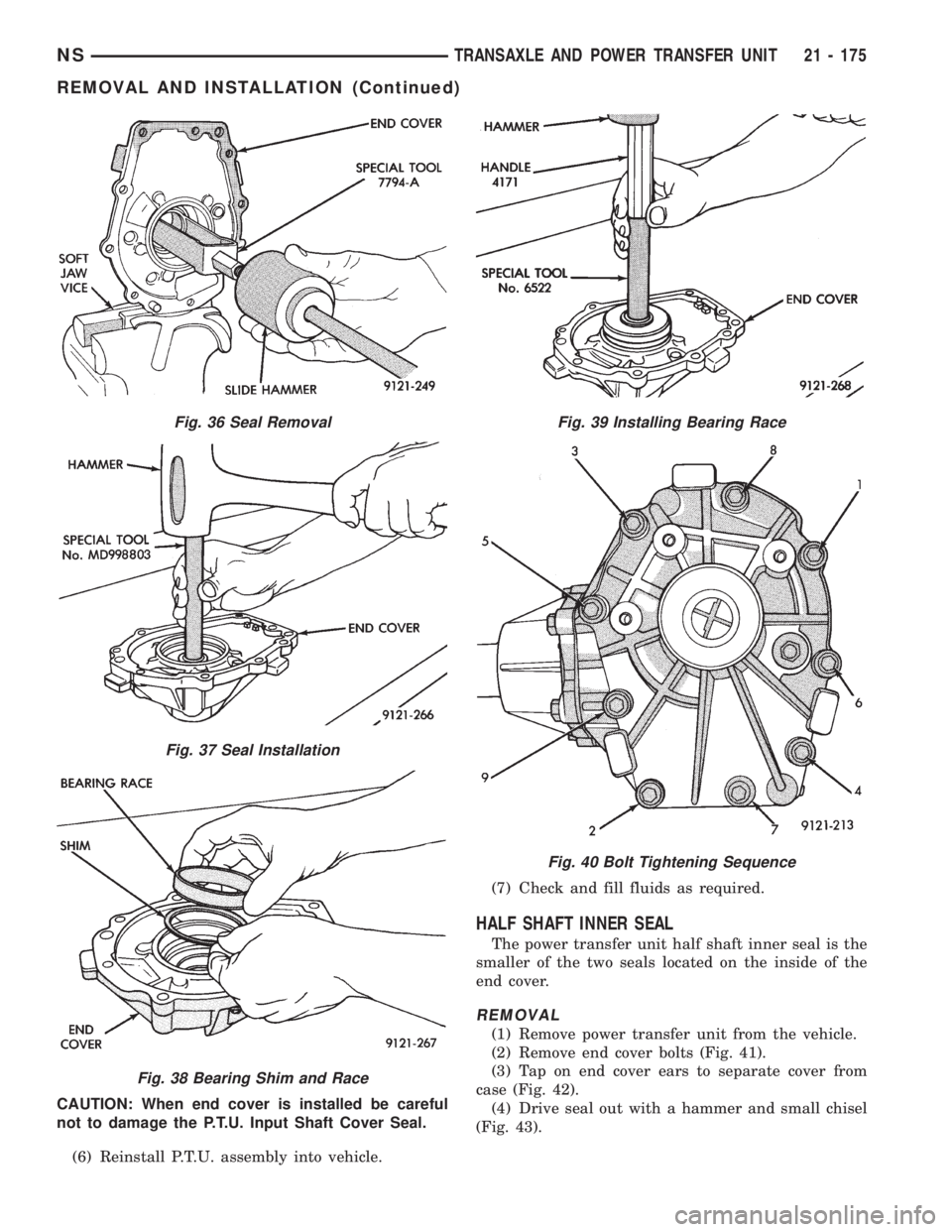

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.

(6) Reinstall P.T.U. assembly into vehicle.(7) Check and fill fluids as required.

HALF SHAFT INNER SEAL

The power transfer unit half shaft inner seal is the

smaller of the two seals located on the inside of the

end cover.

REMOVAL

(1) Remove power transfer unit from the vehicle.

(2) Remove end cover bolts (Fig. 41).

(3) Tap on end cover ears to separate cover from

case (Fig. 42).

(4) Drive seal out with a hammer and small chisel

(Fig. 43).

Fig. 36 Seal Removal

Fig. 37 Seal Installation

Fig. 38 Bearing Shim and Race

Fig. 39 Installing Bearing Race

Fig. 40 Bolt Tightening Sequence

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 175

REMOVAL AND INSTALLATION (Continued)

Page 1651 of 1938

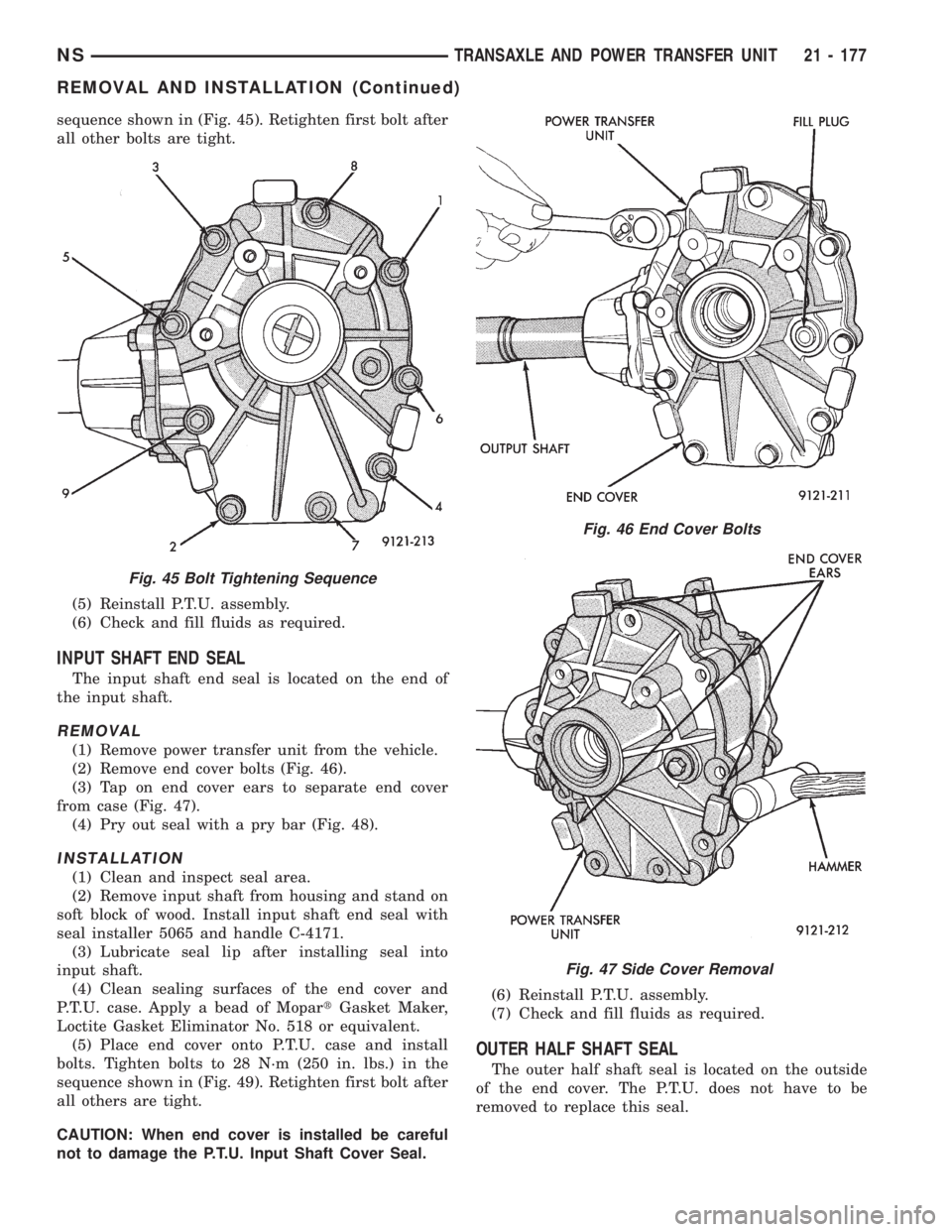

sequence shown in (Fig. 45). Retighten first bolt after

all other bolts are tight.

(5) Reinstall P.T.U. assembly.

(6) Check and fill fluids as required.

INPUT SHAFT END SEAL

The input shaft end seal is located on the end of

the input shaft.

REMOVAL

(1) Remove power transfer unit from the vehicle.

(2) Remove end cover bolts (Fig. 46).

(3) Tap on end cover ears to separate end cover

from case (Fig. 47).

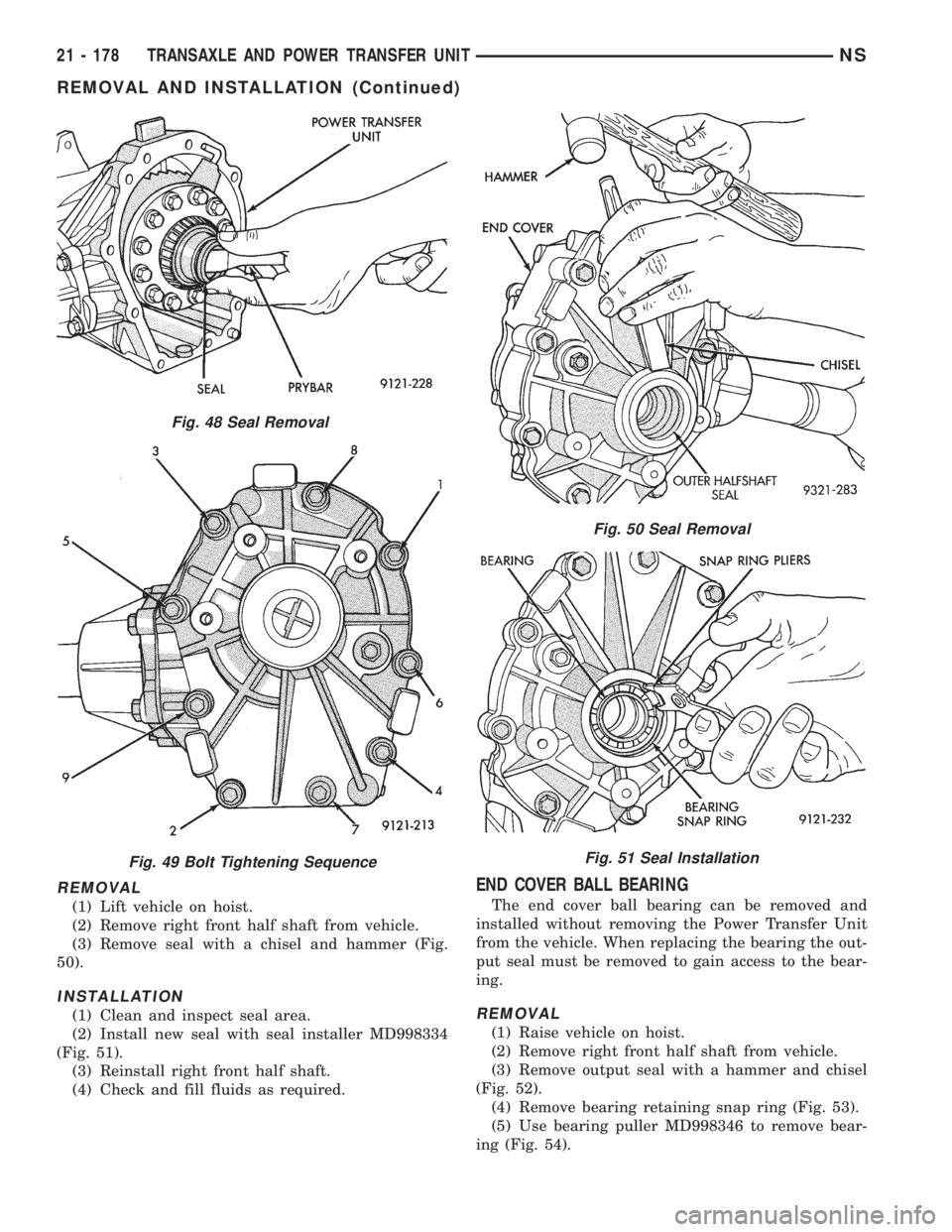

(4) Pry out seal with a pry bar (Fig. 48).

INSTALLATION

(1) Clean and inspect seal area.

(2) Remove input shaft from housing and stand on

soft block of wood. Install input shaft end seal with

seal installer 5065 and handle C-4171.

(3) Lubricate seal lip after installing seal into

input shaft.

(4) Clean sealing surfaces of the end cover and

P.T.U. case. Apply a bead of MopartGasket Maker,

Loctite Gasket Eliminator No. 518 or equivalent.

(5) Place end cover onto P.T.U. case and install

bolts. Tighten bolts to 28 N´m (250 in. lbs.) in the

sequence shown in (Fig. 49). Retighten first bolt after

all others are tight.

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.(6) Reinstall P.T.U. assembly.

(7) Check and fill fluids as required.

OUTER HALF SHAFT SEAL

The outer half shaft seal is located on the outside

of the end cover. The P.T.U. does not have to be

removed to replace this seal.

Fig. 45 Bolt Tightening Sequence

Fig. 46 End Cover Bolts

Fig. 47 Side Cover Removal

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 177

REMOVAL AND INSTALLATION (Continued)

Page 1652 of 1938

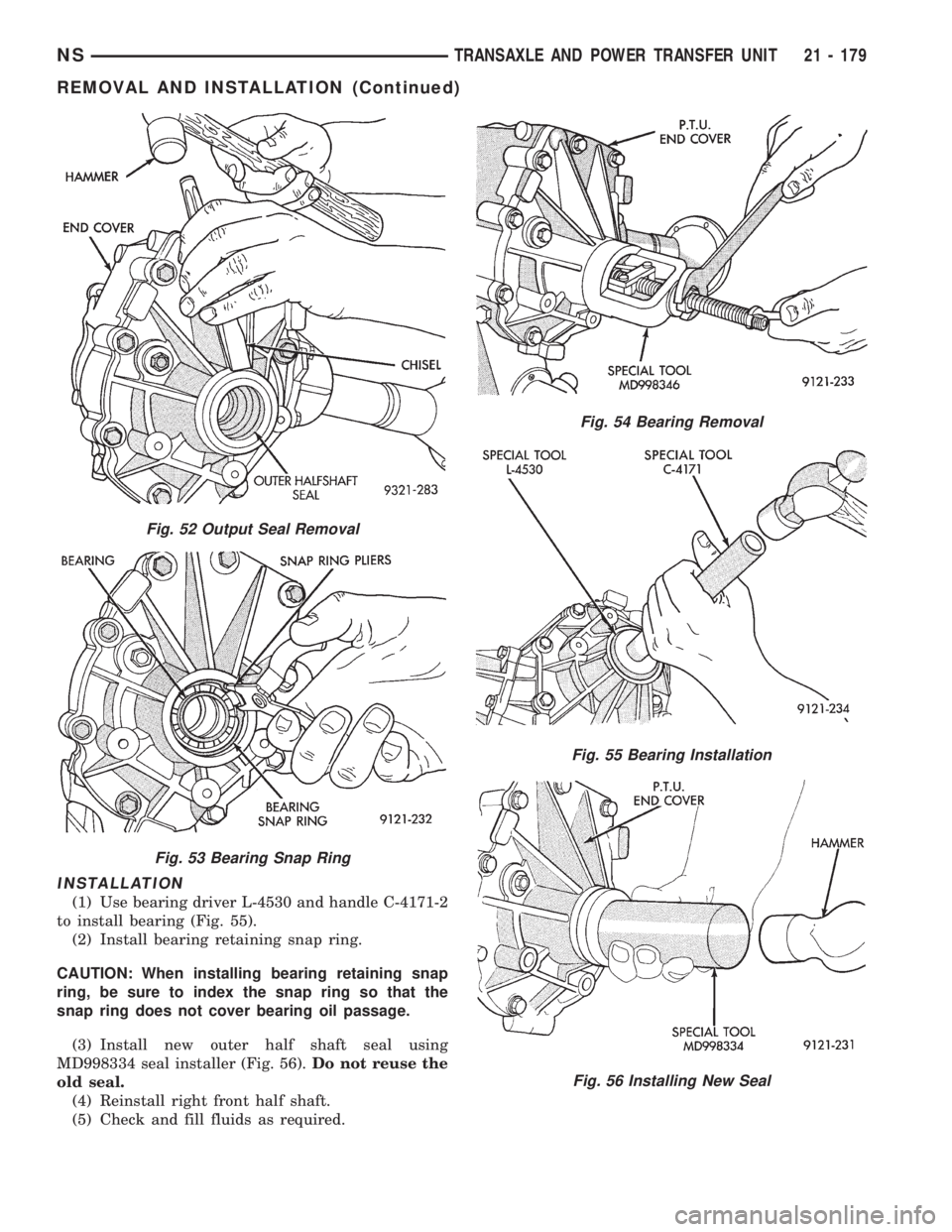

REMOVAL

(1) Lift vehicle on hoist.

(2) Remove right front half shaft from vehicle.

(3) Remove seal with a chisel and hammer (Fig.

50).

INSTALLATION

(1) Clean and inspect seal area.

(2) Install new seal with seal installer MD998334

(Fig. 51).

(3) Reinstall right front half shaft.

(4) Check and fill fluids as required.

END COVER BALL BEARING

The end cover ball bearing can be removed and

installed without removing the Power Transfer Unit

from the vehicle. When replacing the bearing the out-

put seal must be removed to gain access to the bear-

ing.

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove right front half shaft from vehicle.

(3) Remove output seal with a hammer and chisel

(Fig. 52).

(4) Remove bearing retaining snap ring (Fig. 53).

(5) Use bearing puller MD998346 to remove bear-

ing (Fig. 54).

Fig. 48 Seal Removal

Fig. 49 Bolt Tightening Sequence

Fig. 50 Seal Removal

Fig. 51 Seal Installation

21 - 178 TRANSAXLE AND POWER TRANSFER UNITNS

REMOVAL AND INSTALLATION (Continued)

Page 1653 of 1938

INSTALLATION

(1) Use bearing driver L-4530 and handle C-4171-2

to install bearing (Fig. 55).

(2) Install bearing retaining snap ring.

CAUTION: When installing bearing retaining snap

ring, be sure to index the snap ring so that the

snap ring does not cover bearing oil passage.

(3) Install new outer half shaft seal using

MD998334 seal installer (Fig. 56).Do not reuse the

old seal.

(4) Reinstall right front half shaft.

(5) Check and fill fluids as required.

Fig. 52 Output Seal Removal

Fig. 53 Bearing Snap Ring

Fig. 54 Bearing Removal

Fig. 55 Bearing Installation

Fig. 56 Installing New Seal

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 179

REMOVAL AND INSTALLATION (Continued)

Page 1657 of 1938

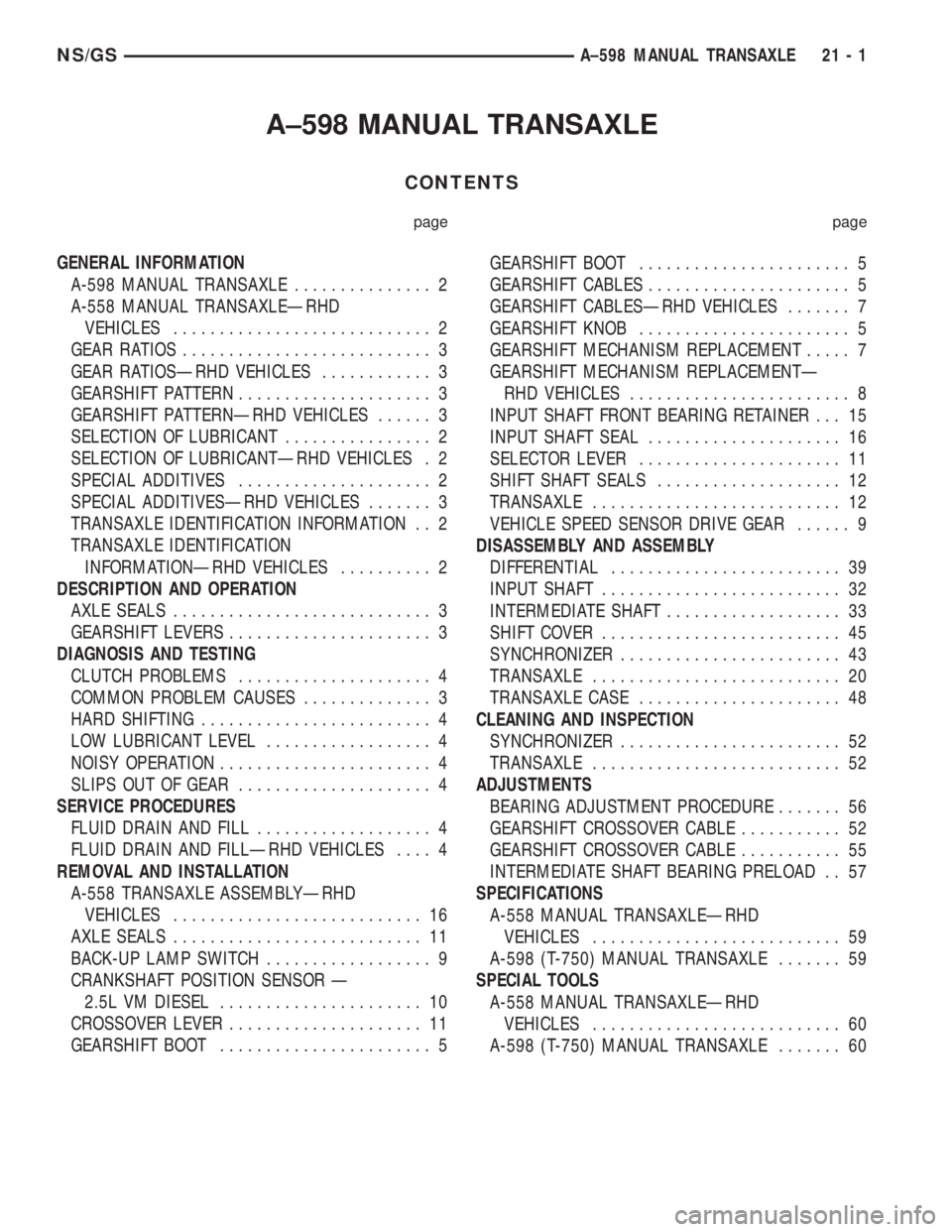

A±598 MANUAL TRANSAXLE

CONTENTS

page page

GENERAL INFORMATION

A-598 MANUAL TRANSAXLE............... 2

A-558 MANUAL TRANSAXLEÐRHD

VEHICLES............................ 2

GEAR RATIOS........................... 3

GEAR RATIOSÐRHD VEHICLES............ 3

GEARSHIFT PATTERN..................... 3

GEARSHIFT PATTERNÐRHD VEHICLES...... 3

SELECTION OF LUBRICANT................ 2

SELECTION OF LUBRICANTÐRHD VEHICLES . 2

SPECIAL ADDITIVES..................... 2

SPECIAL ADDITIVESÐRHD VEHICLES....... 3

TRANSAXLE IDENTIFICATION INFORMATION . . 2

TRANSAXLE IDENTIFICATION

INFORMATIONÐRHD VEHICLES.......... 2

DESCRIPTION AND OPERATION

AXLE SEALS............................ 3

GEARSHIFT LEVERS...................... 3

DIAGNOSIS AND TESTING

CLUTCH PROBLEMS..................... 4

COMMON PROBLEM CAUSES.............. 3

HARD SHIFTING......................... 4

LOW LUBRICANT LEVEL.................. 4

NOISY OPERATION....................... 4

SLIPS OUT OF GEAR..................... 4

SERVICE PROCEDURES

FLUID DRAIN AND FILL................... 4

FLUID DRAIN AND FILLÐRHD VEHICLES.... 4

REMOVAL AND INSTALLATION

A-558 TRANSAXLE ASSEMBLYÐRHD

VEHICLES........................... 16

AXLE SEALS........................... 11

BACK-UP LAMP SWITCH.................. 9

CRANKSHAFT POSITION SENSOR Ð

2.5L VM DIESEL...................... 10

CROSSOVER LEVER..................... 11

GEARSHIFT BOOT....................... 5GEARSHIFT BOOT....................... 5

GEARSHIFT CABLES...................... 5

GEARSHIFT CABLESÐRHD VEHICLES....... 7

GEARSHIFT KNOB....................... 5

GEARSHIFT MECHANISM REPLACEMENT..... 7

GEARSHIFT MECHANISM REPLACEMENTÐ

RHD VEHICLES........................ 8

INPUT SHAFT FRONT BEARING RETAINER . . . 15

INPUT SHAFT SEAL..................... 16

SELECTOR LEVER...................... 11

SHIFT SHAFT SEALS.................... 12

TRANSAXLE........................... 12

VEHICLE SPEED SENSOR DRIVE GEAR...... 9

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL......................... 39

INPUT SHAFT.......................... 32

INTERMEDIATE SHAFT................... 33

SHIFT COVER.......................... 45

SYNCHRONIZER........................ 43

TRANSAXLE........................... 20

TRANSAXLE CASE...................... 48

CLEANING AND INSPECTION

SYNCHRONIZER........................ 52

TRANSAXLE........................... 52

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURE....... 56

GEARSHIFT CROSSOVER CABLE........... 52

GEARSHIFT CROSSOVER CABLE........... 55

INTERMEDIATE SHAFT BEARING PRELOAD . . 57

SPECIFICATIONS

A-558 MANUAL TRANSAXLEÐRHD

VEHICLES........................... 59

A-598 (T-750) MANUAL TRANSAXLE....... 59

SPECIAL TOOLS

A-558 MANUAL TRANSAXLEÐRHD

VEHICLES........................... 60

A-598 (T-750) MANUAL TRANSAXLE....... 60

NS/GSA±598 MANUAL TRANSAXLE 21 - 1

Page 1659 of 1938

sealers should be avoided, since they may adversely

affect seals.

SPECIAL ADDITIVESÐRHD VEHICLES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes to

aid in detecting fluid leaks. The use of transmission

sealers should be avoided, since they may adversely

affect seals.

GEAR RATIOS

Gear ratios for the 2.4L gasoline engine and 2.5L

Turbo Diesel MTX are as follows:

²1stÐ3.36

²2ndÐ1.90

²3rdÐ1.28

²4thÐ0.92

²5thÐ0.71

²ReverseÐ3.17

Final drive ratio of 3.88 was selected for maximum

performance. All forward gears are synchronized.

Gear ratios for the 2.0L GAS MTX are as follows:

²1stÐ3.69

²2ndÐ2.24

²3rdÐ1.45

²4thÐ1.03

²5thÐ0.81

²ReverseÐ3.17

Final drive ratio of 4.08 was selected for maximum

performance. All forward gears are synchronized.

GEAR RATIOSÐRHD VEHICLES

Gear ratios for the 2.0L GAS MTX are as follows:

²1stÐ3.69

²2ndÐ2.24

²3rdÐ1.45

²4thÐ0.1.03

²5thÐ0.81

²ReverseÐ3.17

Final drive ratio of 4.08 was selected for maximum

performance. All forward gears are synchronized.

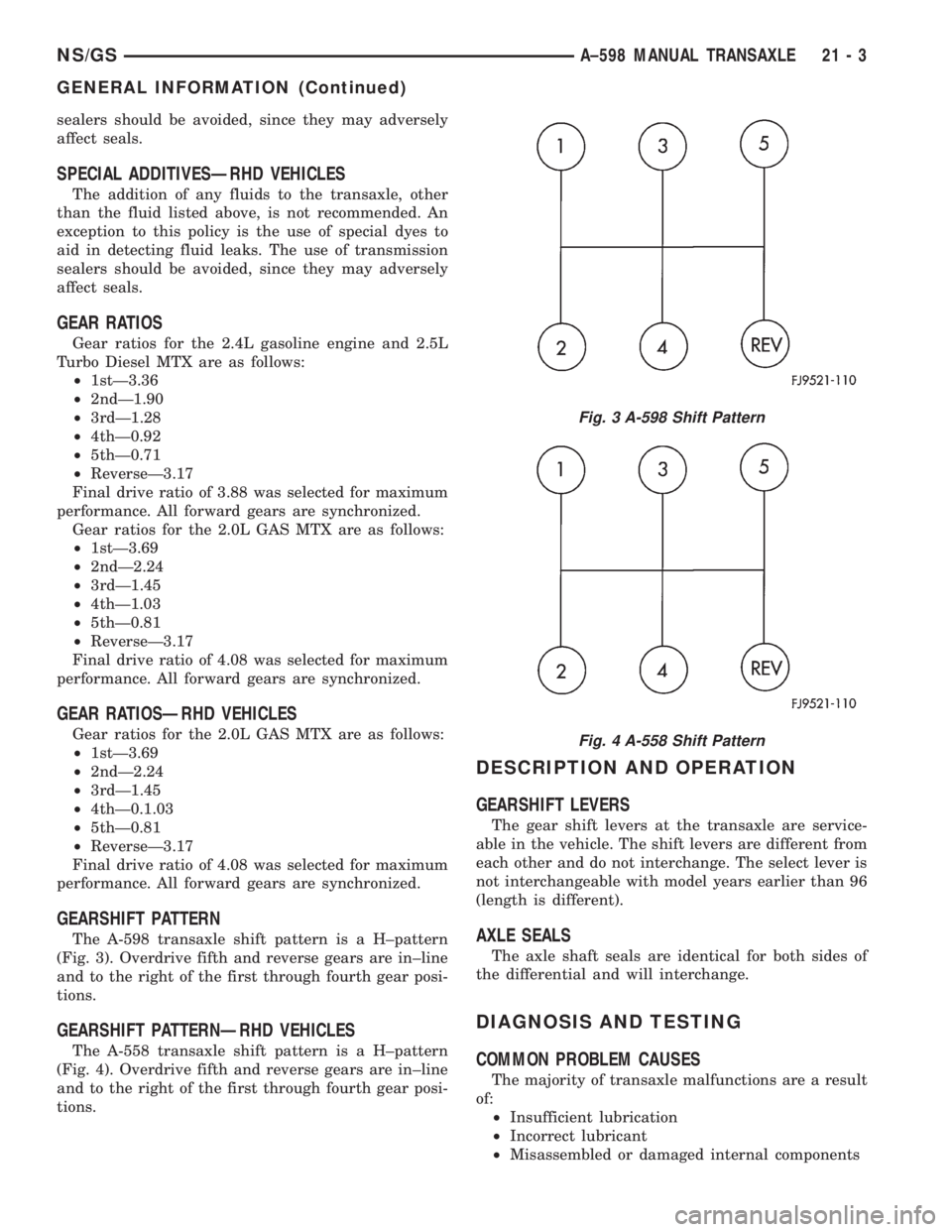

GEARSHIFT PATTERN

The A-598 transaxle shift pattern is a H±pattern

(Fig. 3). Overdrive fifth and reverse gears are in±line

and to the right of the first through fourth gear posi-

tions.

GEARSHIFT PATTERNÐRHD VEHICLES

The A-558 transaxle shift pattern is a H±pattern

(Fig. 4). Overdrive fifth and reverse gears are in±line

and to the right of the first through fourth gear posi-

tions.

DESCRIPTION AND OPERATION

GEARSHIFT LEVERS

The gear shift levers at the transaxle are service-

able in the vehicle. The shift levers are different from

each other and do not interchange. The select lever is

not interchangeable with model years earlier than 96

(length is different).

AXLE SEALS

The axle shaft seals are identical for both sides of

the differential and will interchange.

DIAGNOSIS AND TESTING

COMMON PROBLEM CAUSES

The majority of transaxle malfunctions are a result

of:

²Insufficient lubrication

²Incorrect lubricant

²Misassembled or damaged internal components

Fig. 3 A-598 Shift Pattern

Fig. 4 A-558 Shift Pattern

NS/GSA±598 MANUAL TRANSAXLE 21 - 3

GENERAL INFORMATION (Continued)

Page 1666 of 1938

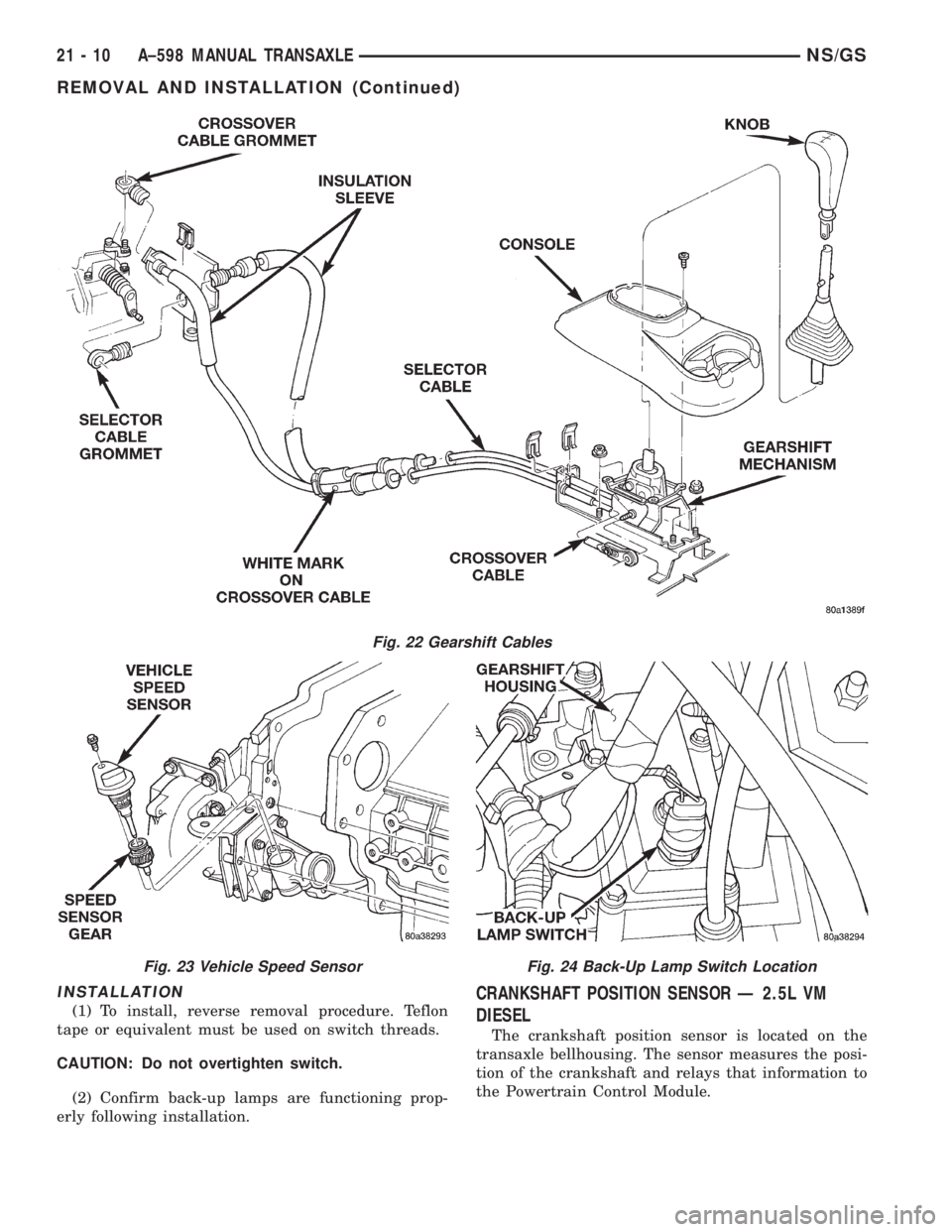

INSTALLATION

(1) To install, reverse removal procedure. Teflon

tape or equivalent must be used on switch threads.

CAUTION: Do not overtighten switch.

(2) Confirm back-up lamps are functioning prop-

erly following installation.

CRANKSHAFT POSITION SENSOR Ð 2.5L VM

DIESEL

The crankshaft position sensor is located on the

transaxle bellhousing. The sensor measures the posi-

tion of the crankshaft and relays that information to

the Powertrain Control Module.

Fig. 22 Gearshift Cables

Fig. 23 Vehicle Speed SensorFig. 24 Back-Up Lamp Switch Location

21 - 10 A±598 MANUAL TRANSAXLENS/GS

REMOVAL AND INSTALLATION (Continued)

Page 1667 of 1938

REMOVAL

(1) Remove electrical connector at crankshaft posi-

tion sensor (Fig. 25).

(2) Remove screw retaining the crankshaft position

sensor to the bellhousing.

(3) Remove the crankshaft position sensor.

INSTALLATION

(1) For installation, reverse removal procedure.

CROSSOVER LEVER

REMOVAL

(1) Remove crossover cable. Refer to Gearshift

Cable removal.

(2) Using a pin punch, remove the crossover roll

pin from lever.

(3) Pull up and remove the crossover lever from

the transaxle crossover shaft.

INSTALLATION

(1) For installation, reverse removal procedure.

Replace the roll pin that was removed with a new

one.

SELECTOR LEVER

REMOVAL

(1) Remove the selector cable. Refer to Gearshift

Cable removal.

(2) Using a pin punch, remove the roll pin from

the lever.

(3) Remove the selector lever from the transaxle

selector shaft

INSTALLATION

(1) For installation, reverse removal procedure.

Replace the roll pin with a new one.

AXLE SEALS

The axle shaft seals are identical for both sides of

the differential and will interchange.

EXTENSION HOUSING AXLE SEAL

REMOVAL

(1) Remove axle shaft. Refer to Group 2, Suspen-

sion and Driveshafts for service procedures.

(2) Insert a flat±blade pry tool into the axle seal

bore (Fig. 26).

(3) Using the pry tool, carefully pop out the seal

taking care not to nick the seal bore.

INSTALLATION

(1) Clean axle shaft seal bore of any excess seal-

ant.

(2) Align axle shaft seal with axle shaft seal bore.

(3) Position axle seal at extension housing.

(4) Using Tool L-4520 and Tool C-4171, tap seal

into position (Fig. 27).

Fig. 25 Crankshaft Position Sensor

Fig. 26 Extension Housing Axle Seal

Fig. 27 Install Seal

NS/GSA±598 MANUAL TRANSAXLE 21 - 11

REMOVAL AND INSTALLATION (Continued)