shaft CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1684 of 1938

NOTE: The input shaft is serviced as an assembly.

The only serviceable components of the input shaft

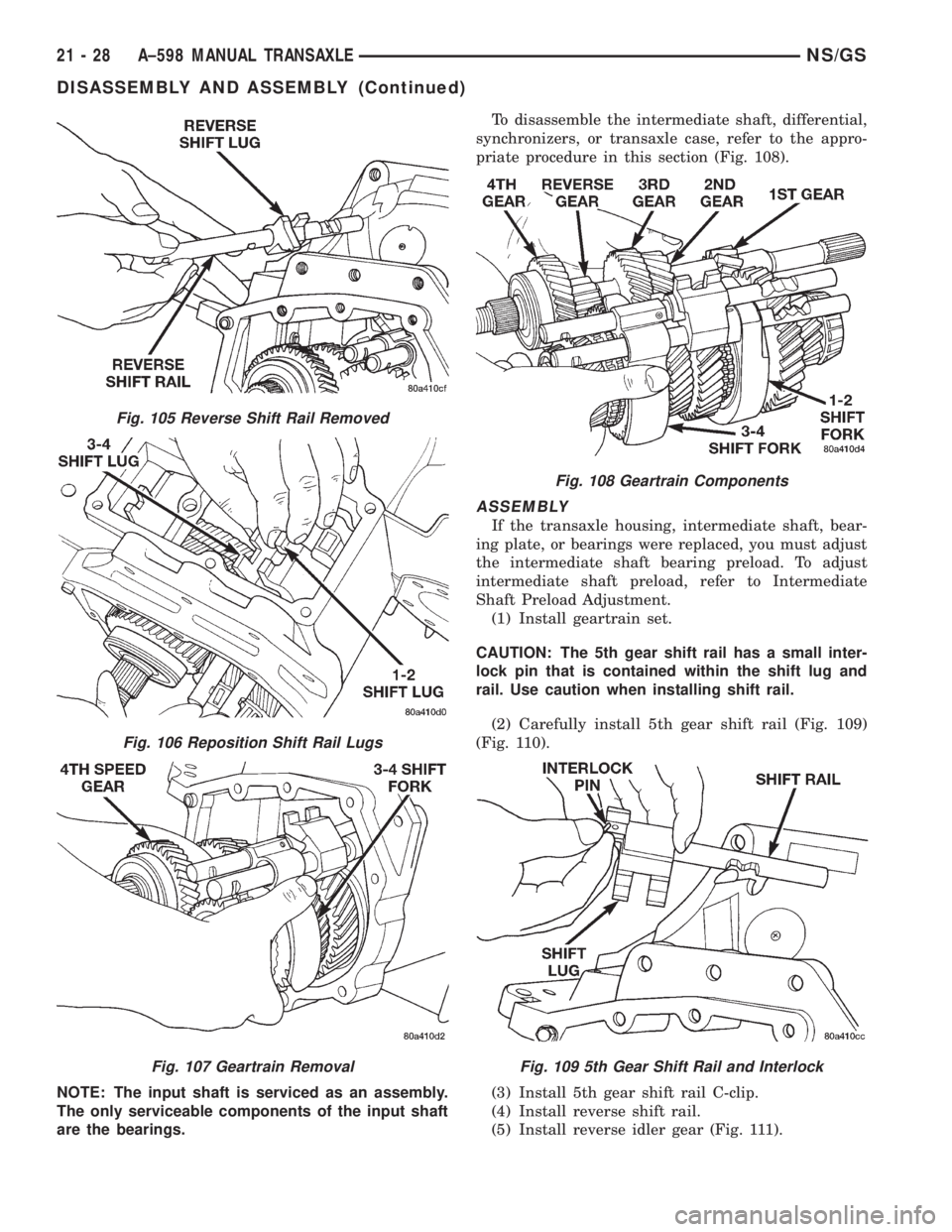

are the bearings.To disassemble the intermediate shaft, differential,

synchronizers, or transaxle case, refer to the appro-

priate procedure in this section (Fig. 108).

ASSEMBLY

If the transaxle housing, intermediate shaft, bear-

ing plate, or bearings were replaced, you must adjust

the intermediate shaft bearing preload. To adjust

intermediate shaft preload, refer to Intermediate

Shaft Preload Adjustment.

(1) Install geartrain set.

CAUTION: The 5th gear shift rail has a small inter-

lock pin that is contained within the shift lug and

rail. Use caution when installing shift rail.

(2) Carefully install 5th gear shift rail (Fig. 109)

(Fig. 110).

(3) Install 5th gear shift rail C-clip.

(4) Install reverse shift rail.

(5) Install reverse idler gear (Fig. 111).

Fig. 105 Reverse Shift Rail Removed

Fig. 106 Reposition Shift Rail Lugs

Fig. 107 Geartrain Removal

Fig. 108 Geartrain Components

Fig. 109 5th Gear Shift Rail and Interlock

21 - 28 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1685 of 1938

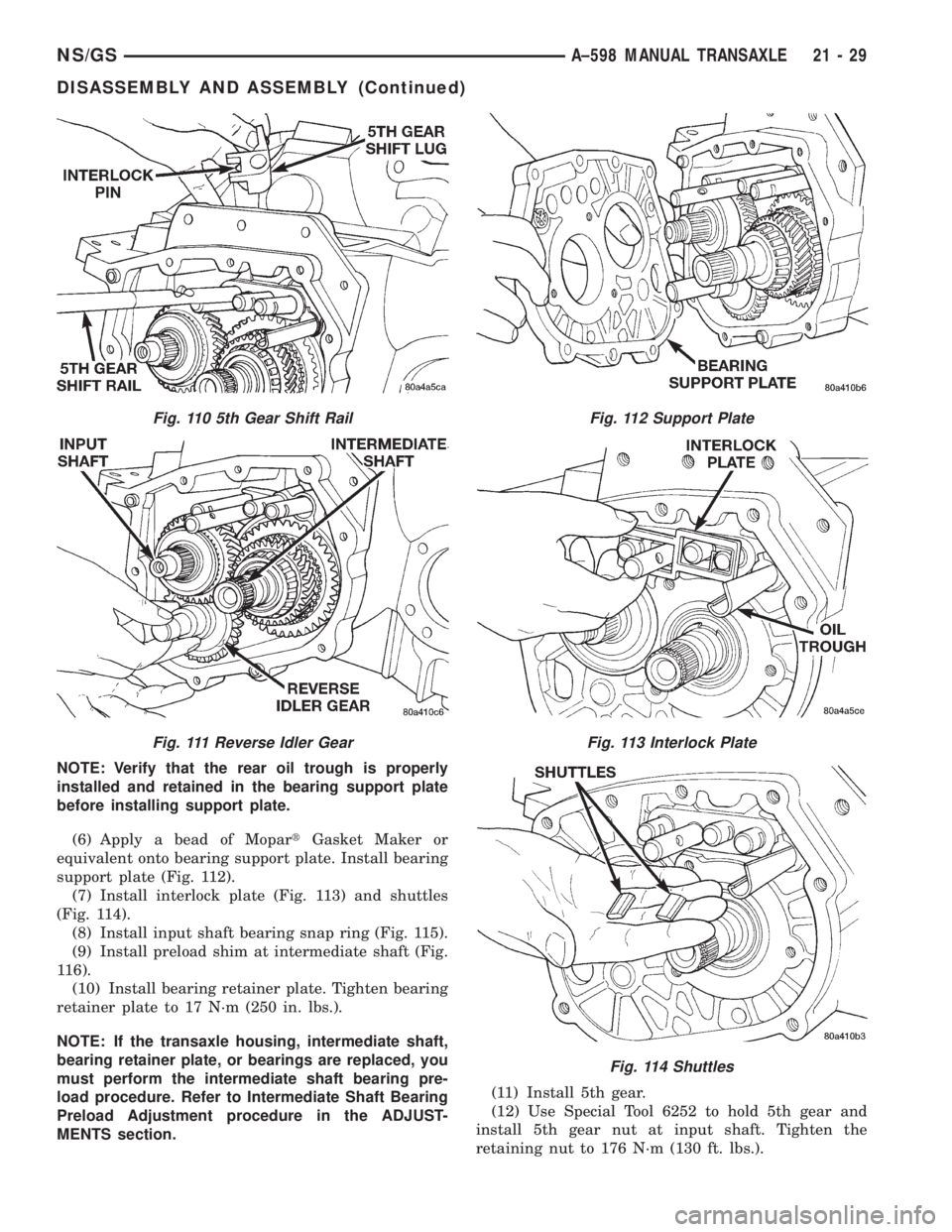

NOTE: Verify that the rear oil trough is properly

installed and retained in the bearing support plate

before installing support plate.

(6) Apply a bead of MopartGasket Maker or

equivalent onto bearing support plate. Install bearing

support plate (Fig. 112).

(7) Install interlock plate (Fig. 113) and shuttles

(Fig. 114).

(8) Install input shaft bearing snap ring (Fig. 115).

(9) Install preload shim at intermediate shaft (Fig.

116).

(10) Install bearing retainer plate. Tighten bearing

retainer plate to 17 N´m (250 in. lbs.).

NOTE: If the transaxle housing, intermediate shaft,

bearing retainer plate, or bearings are replaced, you

must perform the intermediate shaft bearing pre-

load procedure. Refer to Intermediate Shaft Bearing

Preload Adjustment procedure in the ADJUST-

MENTS section.(11) Install 5th gear.

(12) Use Special Tool 6252 to hold 5th gear and

install 5th gear nut at input shaft. Tighten the

retaining nut to 176 N´m (130 ft. lbs.).

Fig. 110 5th Gear Shift Rail

Fig. 111 Reverse Idler Gear

Fig. 112 Support Plate

Fig. 113 Interlock Plate

Fig. 114 Shuttles

NS/GSA±598 MANUAL TRANSAXLE 21 - 29

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1686 of 1938

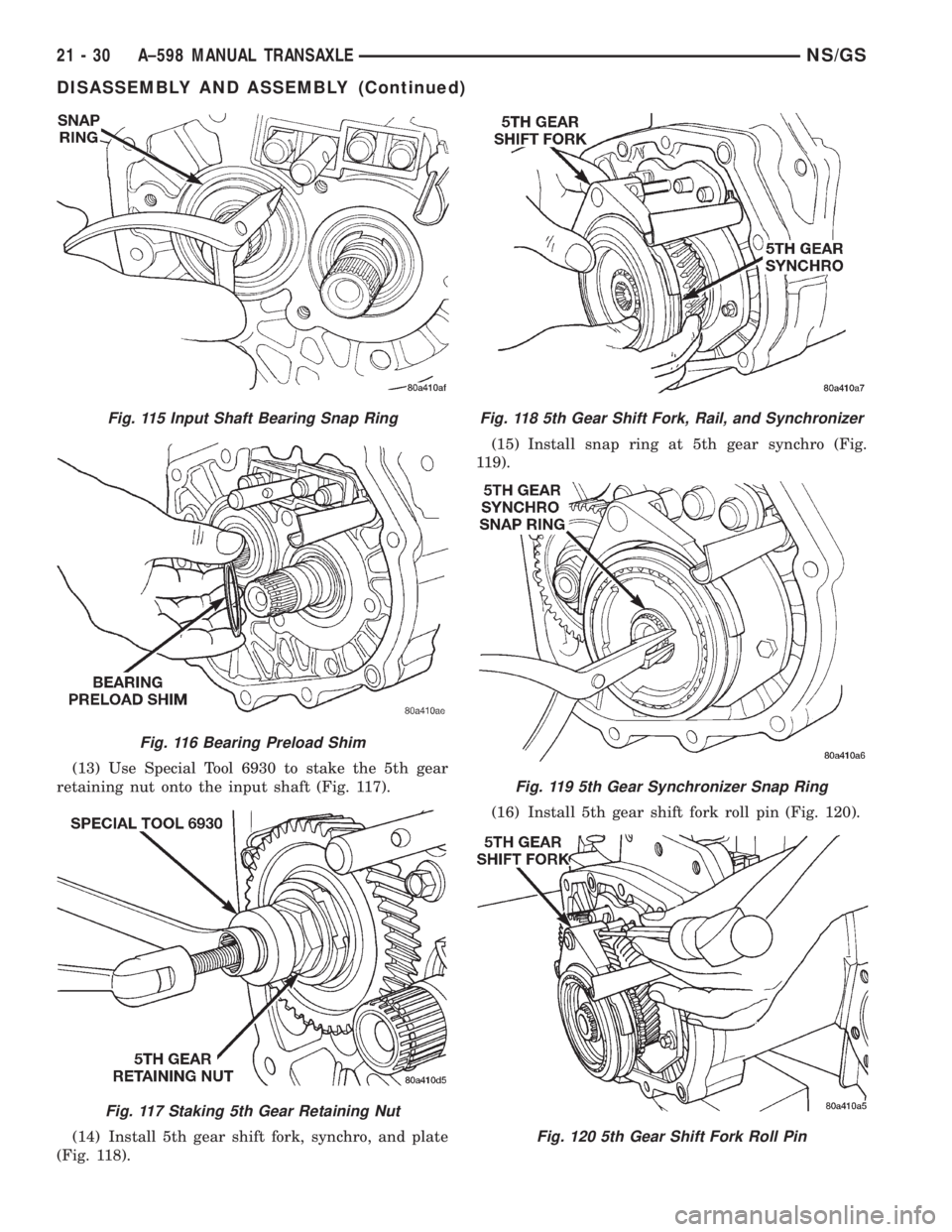

(13) Use Special Tool 6930 to stake the 5th gear

retaining nut onto the input shaft (Fig. 117).

(14) Install 5th gear shift fork, synchro, and plate

(Fig. 118).(15) Install snap ring at 5th gear synchro (Fig.

119).

(16) Install 5th gear shift fork roll pin (Fig. 120).

Fig. 115 Input Shaft Bearing Snap Ring

Fig. 116 Bearing Preload Shim

Fig. 117 Staking 5th Gear Retaining Nut

Fig. 118 5th Gear Shift Fork, Rail, and Synchronizer

Fig. 119 5th Gear Synchronizer Snap Ring

Fig. 120 5th Gear Shift Fork Roll Pin

21 - 30 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1688 of 1938

NOTE: Two of the bolts retaining the shift cover are

shouldered (Fig. 127).

(23) Apply a bead of MopartGasket Maker or

equivalent onto shift cover. Line up the shift detent

springs so the springs are aligned with the shift

cover spring pockets. Install shift cover. Tighten shift

cover bolts to 28 N´m (250 in. lbs.).

(24) Install differential assembly.

(25) Apply a bead of MopartGasket Maker or

equivalent onto differential cover. Install differential

cover. Tighten differential cover bolts to 61 N´m (45

ft. lbs.).

(26) Apply a bead of RTV silicone to the differen-

tial bearing retainer. Install differential bearing

retainer. Tighten differential bearing retainer bolts to

61 N´m (45 ft. lbs.).

(27) Apply a bead of RTV silicone to the extension

housing. Install extension housing. Tighten extension

housing bolts to 28 N´m (250 in. lbs.).

(28) Install engine mount bracket.

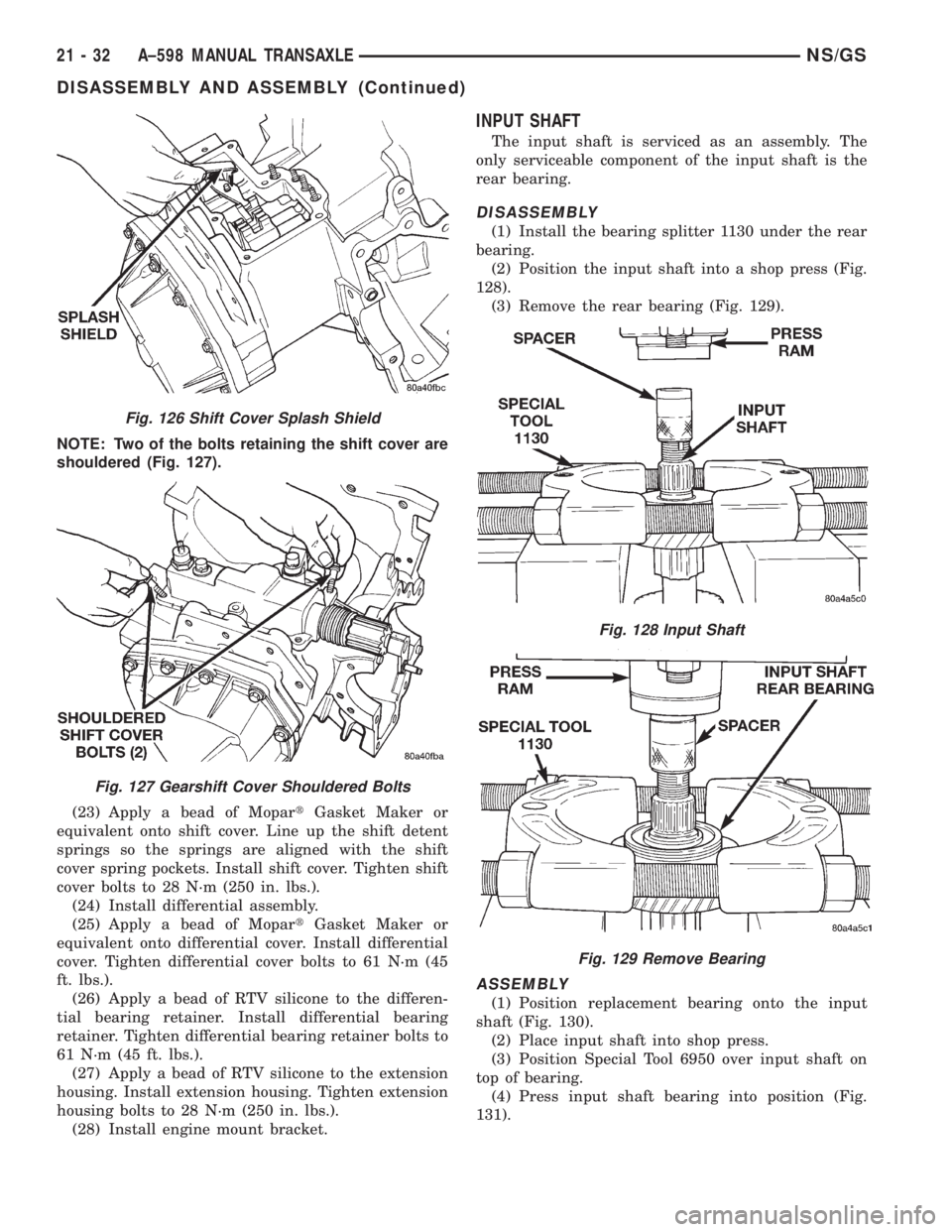

INPUT SHAFT

The input shaft is serviced as an assembly. The

only serviceable component of the input shaft is the

rear bearing.

DISASSEMBLY

(1) Install the bearing splitter 1130 under the rear

bearing.

(2) Position the input shaft into a shop press (Fig.

128).

(3) Remove the rear bearing (Fig. 129).

ASSEMBLY

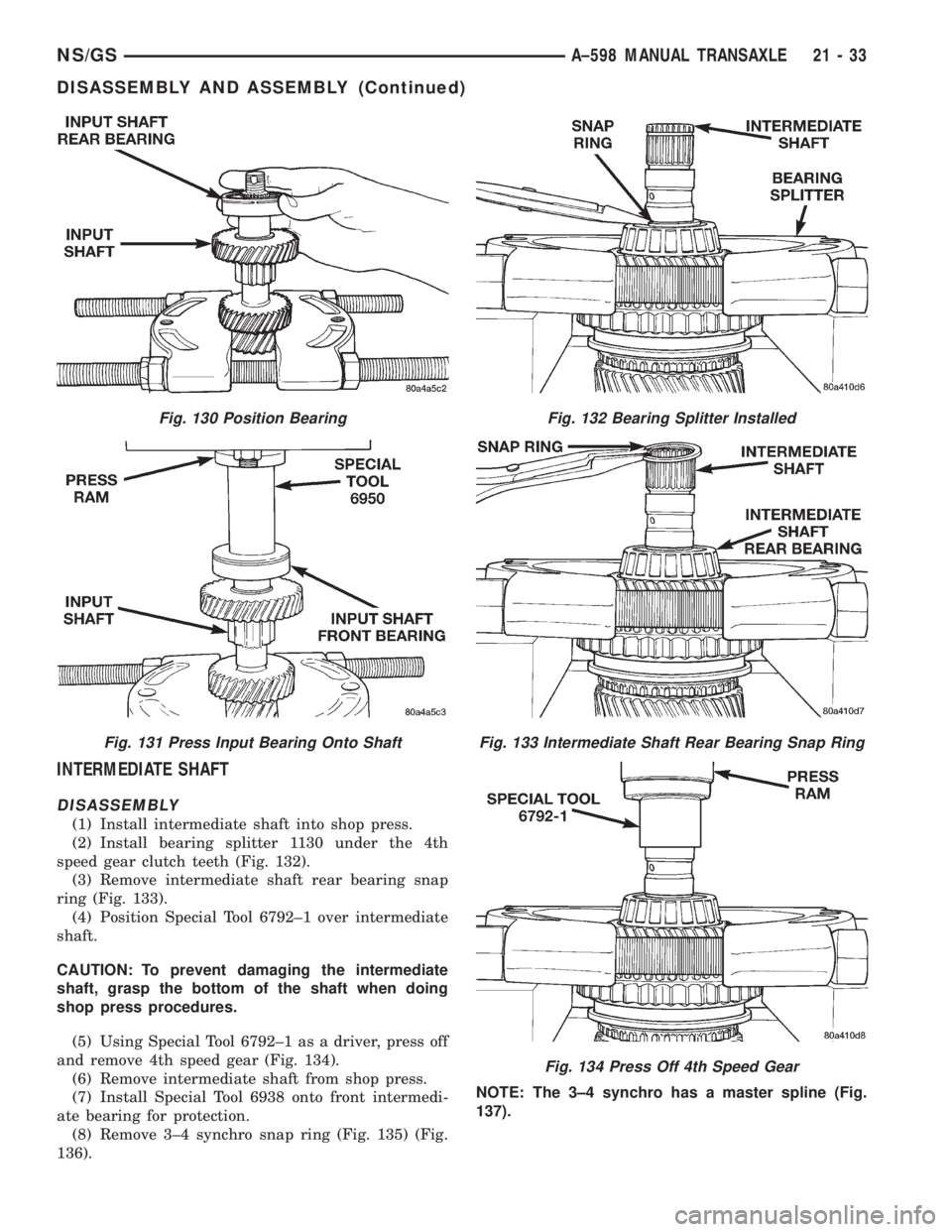

(1) Position replacement bearing onto the input

shaft (Fig. 130).

(2) Place input shaft into shop press.

(3) Position Special Tool 6950 over input shaft on

top of bearing.

(4) Press input shaft bearing into position (Fig.

131).

Fig. 126 Shift Cover Splash Shield

Fig. 127 Gearshift Cover Shouldered Bolts

Fig. 128 Input Shaft

Fig. 129 Remove Bearing

21 - 32 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1689 of 1938

INTERMEDIATE SHAFT

DISASSEMBLY

(1) Install intermediate shaft into shop press.

(2) Install bearing splitter 1130 under the 4th

speed gear clutch teeth (Fig. 132).

(3) Remove intermediate shaft rear bearing snap

ring (Fig. 133).

(4) Position Special Tool 6792±1 over intermediate

shaft.

CAUTION: To prevent damaging the intermediate

shaft, grasp the bottom of the shaft when doing

shop press procedures.

(5) Using Special Tool 6792±1 as a driver, press off

and remove 4th speed gear (Fig. 134).

(6) Remove intermediate shaft from shop press.

(7) Install Special Tool 6938 onto front intermedi-

ate bearing for protection.

(8) Remove 3±4 synchro snap ring (Fig. 135) (Fig.

136).NOTE: The 3±4 synchro has a master spline (Fig.

137).

Fig. 130 Position Bearing

Fig. 131 Press Input Bearing Onto Shaft

Fig. 132 Bearing Splitter Installed

Fig. 133 Intermediate Shaft Rear Bearing Snap Ring

Fig. 134 Press Off 4th Speed Gear

NS/GSA±598 MANUAL TRANSAXLE 21 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1692 of 1938

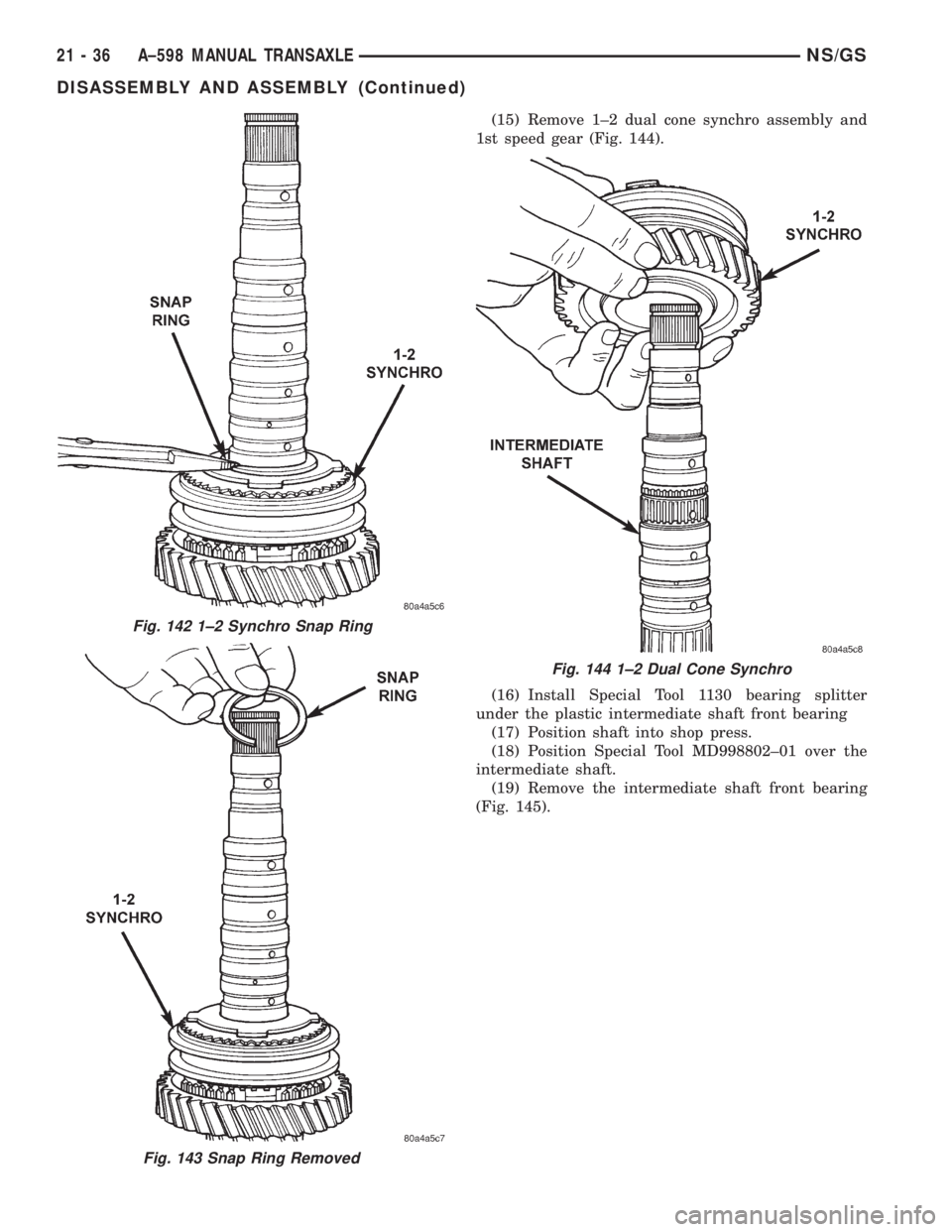

(15) Remove 1±2 dual cone synchro assembly and

1st speed gear (Fig. 144).

(16) Install Special Tool 1130 bearing splitter

under the plastic intermediate shaft front bearing

(17) Position shaft into shop press.

(18) Position Special Tool MD998802±01 over the

intermediate shaft.

(19) Remove the intermediate shaft front bearing

(Fig. 145).

Fig. 143 Snap Ring Removed

Fig. 142 1±2 Synchro Snap Ring

Fig. 144 1±2 Dual Cone Synchro

21 - 36 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1693 of 1938

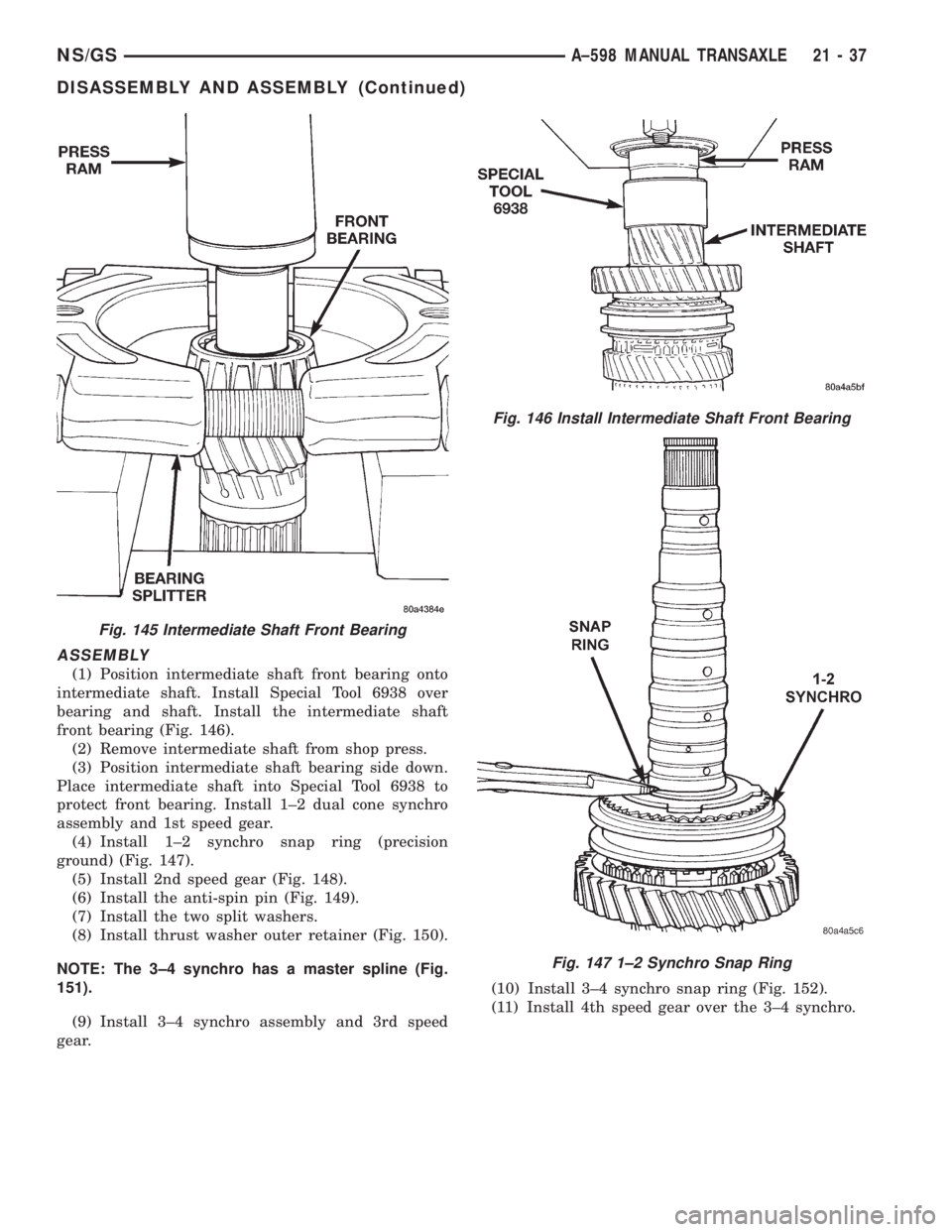

ASSEMBLY

(1) Position intermediate shaft front bearing onto

intermediate shaft. Install Special Tool 6938 over

bearing and shaft. Install the intermediate shaft

front bearing (Fig. 146).

(2) Remove intermediate shaft from shop press.

(3) Position intermediate shaft bearing side down.

Place intermediate shaft into Special Tool 6938 to

protect front bearing. Install 1±2 dual cone synchro

assembly and 1st speed gear.

(4) Install 1±2 synchro snap ring (precision

ground) (Fig. 147).

(5) Install 2nd speed gear (Fig. 148).

(6) Install the anti-spin pin (Fig. 149).

(7) Install the two split washers.

(8) Install thrust washer outer retainer (Fig. 150).

NOTE: The 3±4 synchro has a master spline (Fig.

151).

(9) Install 3±4 synchro assembly and 3rd speed

gear.(10) Install 3±4 synchro snap ring (Fig. 152).

(11) Install 4th speed gear over the 3±4 synchro.

Fig. 145 Intermediate Shaft Front Bearing

Fig. 146 Install Intermediate Shaft Front Bearing

Fig. 147 1±2 Synchro Snap Ring

NS/GSA±598 MANUAL TRANSAXLE 21 - 37

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1695 of 1938

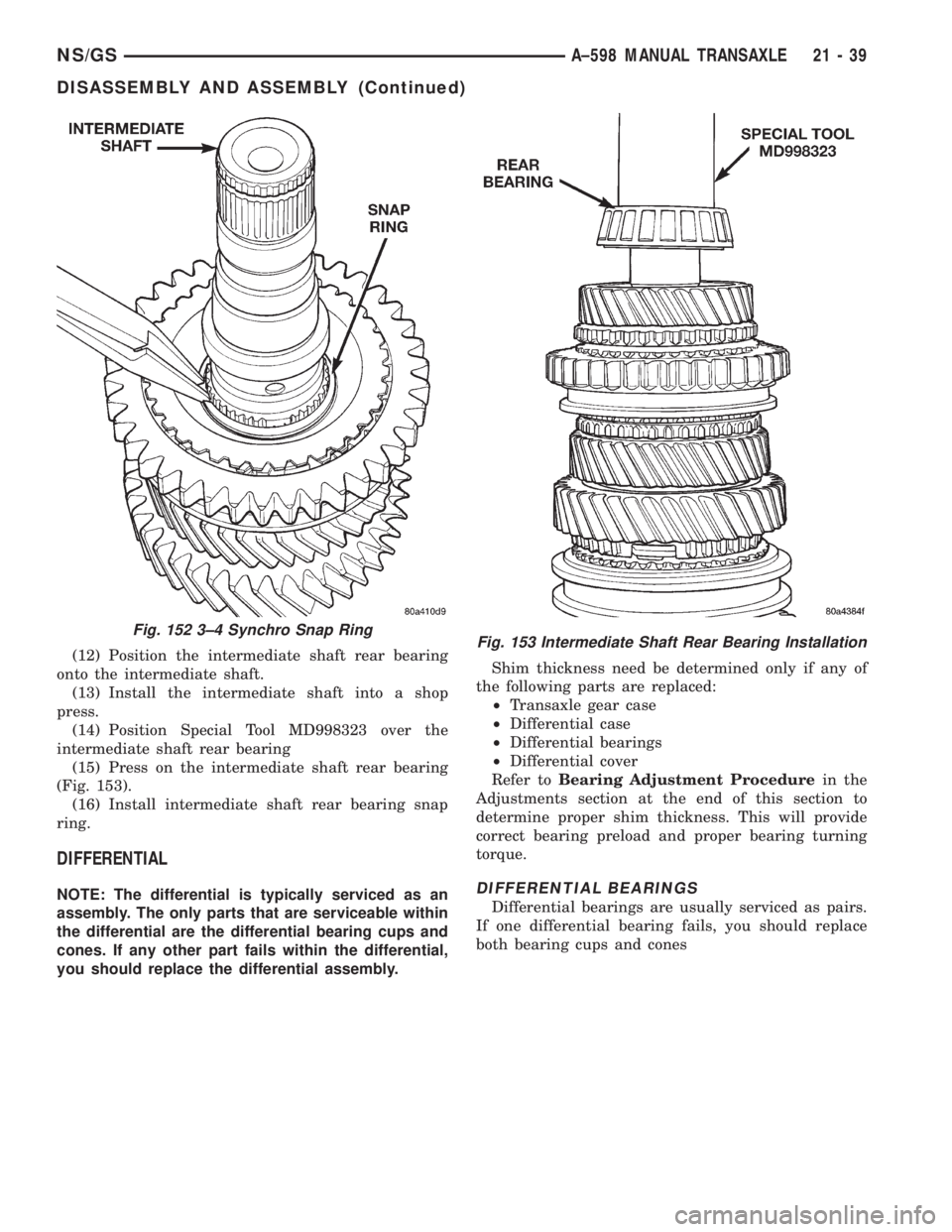

(12) Position the intermediate shaft rear bearing

onto the intermediate shaft.

(13) Install the intermediate shaft into a shop

press.

(14) Position Special Tool MD998323 over the

intermediate shaft rear bearing

(15) Press on the intermediate shaft rear bearing

(Fig. 153).

(16) Install intermediate shaft rear bearing snap

ring.

DIFFERENTIAL

NOTE: The differential is typically serviced as an

assembly. The only parts that are serviceable within

the differential are the differential bearing cups and

cones. If any other part fails within the differential,

you should replace the differential assembly.Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle gear case

²Differential case

²Differential bearings

²Differential cover

Refer toBearing Adjustment Procedurein the

Adjustments section at the end of this section to

determine proper shim thickness. This will provide

correct bearing preload and proper bearing turning

torque.DIFFERENTIAL BEARINGS

Differential bearings are usually serviced as pairs.

If one differential bearing fails, you should replace

both bearing cups and cones

Fig. 152 3±4 Synchro Snap RingFig. 153 Intermediate Shaft Rear Bearing Installation

NS/GSA±598 MANUAL TRANSAXLE 21 - 39

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1698 of 1938

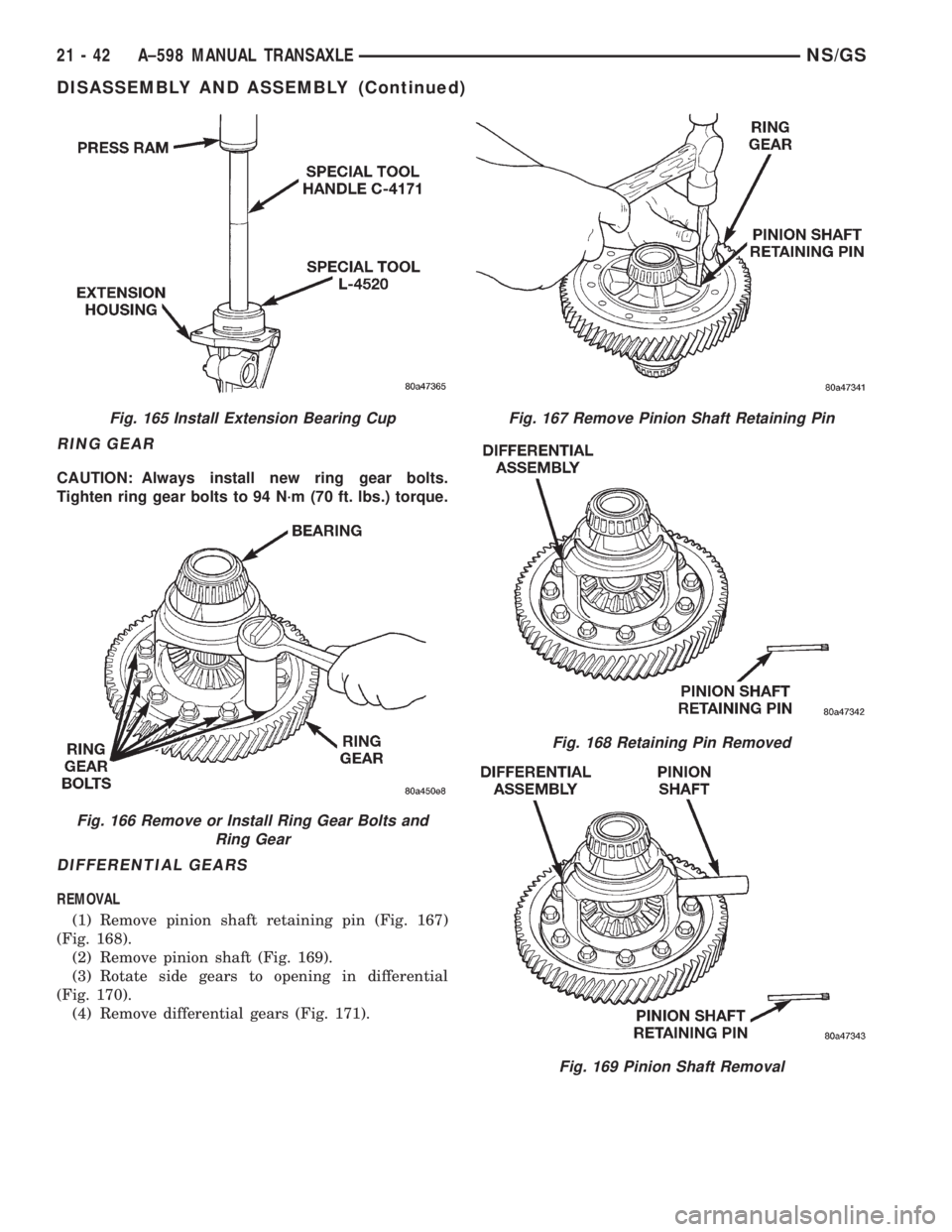

RING GEAR

CAUTION: Always install new ring gear bolts.

Tighten ring gear bolts to 94 N´m (70 ft. lbs.) torque.

DIFFERENTIAL GEARS

REMOVAL

(1) Remove pinion shaft retaining pin (Fig. 167)

(Fig. 168).

(2) Remove pinion shaft (Fig. 169).

(3) Rotate side gears to opening in differential

(Fig. 170).

(4) Remove differential gears (Fig. 171).

Fig. 165 Install Extension Bearing Cup

Fig. 166 Remove or Install Ring Gear Bolts and

Ring Gear

Fig. 167 Remove Pinion Shaft Retaining Pin

Fig. 168 Retaining Pin Removed

Fig. 169 Pinion Shaft Removal

21 - 42 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1699 of 1938

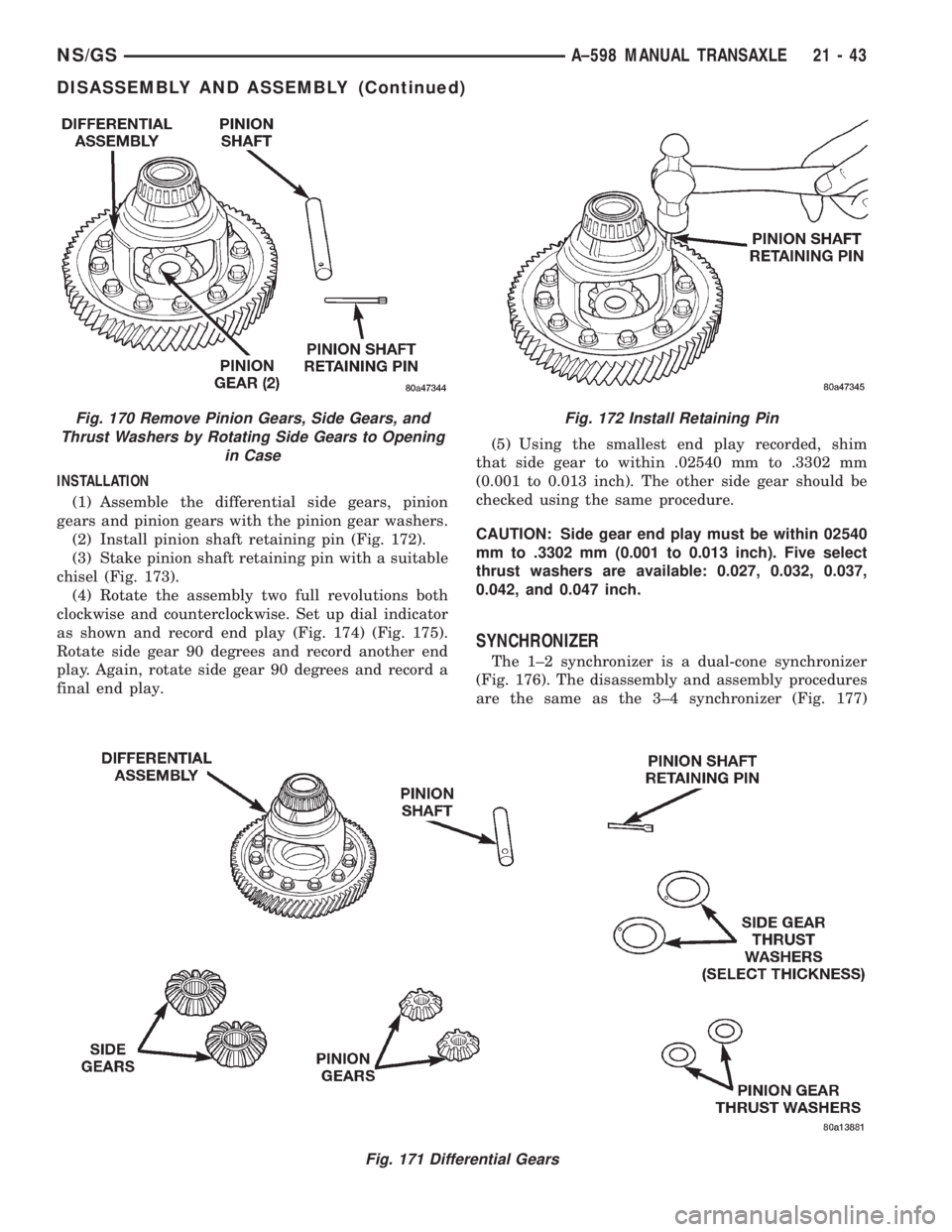

INSTALLATION

(1) Assemble the differential side gears, pinion

gears and pinion gears with the pinion gear washers.

(2) Install pinion shaft retaining pin (Fig. 172).

(3) Stake pinion shaft retaining pin with a suitable

chisel (Fig. 173).

(4) Rotate the assembly two full revolutions both

clockwise and counterclockwise. Set up dial indicator

as shown and record end play (Fig. 174) (Fig. 175).

Rotate side gear 90 degrees and record another end

play. Again, rotate side gear 90 degrees and record a

final end play.(5) Using the smallest end play recorded, shim

that side gear to within .02540 mm to .3302 mm

(0.001 to 0.013 inch). The other side gear should be

checked using the same procedure.

CAUTION: Side gear end play must be within 02540

mm to .3302 mm (0.001 to 0.013 inch). Five select

thrust washers are available: 0.027, 0.032, 0.037,

0.042, and 0.047 inch.

SYNCHRONIZER

The 1±2 synchronizer is a dual-cone synchronizer

(Fig. 176). The disassembly and assembly procedures

are the same as the 3±4 synchronizer (Fig. 177)

Fig. 171 Differential Gears

Fig. 170 Remove Pinion Gears, Side Gears, and

Thrust Washers by Rotating Side Gears to Opening

in CaseFig. 172 Install Retaining Pin

NS/GSA±598 MANUAL TRANSAXLE 21 - 43

DISASSEMBLY AND ASSEMBLY (Continued)