steering wheel CHRYSLER VOYAGER 1996 Manual PDF

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 1000 of 1938

Component/

GroundColor Location Fig.

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorGY Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK RT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

Column at

Module11

Stop Lamp

SwitchGY Top of Brake

Pedal12

T05 BK LT Quarter

PanelN/S

T08 BK RT Quarter

PanelN/SComponent/

GroundColor Location Fig.

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7. 9

Transmission

Control

SolenoidsBK Front of

Transmission7, 9

Turbine Speed

SensorGY Front of

Transmission7, 9

Turn Signal/

Hazard SwitchBK Part of

Multifunction

Switch11

Upstream

Heated Oxygen

SensorGY Rear of Engine 5, 6, 7,

8, 9

Vehicle Speed

Control ServoBK LT Rear of

Engine

Compartment5, 6, 7,

8, 9

Vehicle Speed

SensorBK Rear of

Transmission5, 6, 8

Windshield

Wiper SwitchBK Part of

Multifunction

Switch11

Wiper Module BK LT Side of

Engine2

8W - 90 - 36 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 1076 of 1938

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect battery.

(3) Remove Air cleaner and hoses.

(4) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(5) Remove upper radiator hose and remove radia-

tor fans. Refer to Group 7, Cooling System for proce-

dure.

(6) Remove lower radiator hose.

(7) Disconnect automatic transmission cooler lines

and plug, if equipped.

(8) Disconnect transmission shift linkage.

(9) Disconnect throttle body linkage.

(10) Disconnect engine wiring harness.

(11) Disconnect heater hoses.

(12) Discharge Air Conditioning System. Refer to

Group 24, Air Conditioning for procedure.

(13) Hoist vehicle and remove right inner splash

shield. Remove wheels and tires.

(14) Loosen power steering belt for pump removal.

Refer to Group 7, Cooling System for procedure.

(15) Remove axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(16) Disconnect exhaust pipe from manifold.

(17) Remove front and rear engine mount brackets

from the body.

(18) Remove bending braces and front engine

mount bracket. Remove transmission inspection

cover.

(19) Mark flexplate to torque converter and

remove torque converter bolts.

(20) Install front engine mount bracket.

(21) Lower vehicle.

(22) Remove power steering pump. Set pump

aside.

(23) Remove A/C lines at compressor and cap.

(24) Remove ground straps to body.

(25) Raise vehicle enough to allow engine dolly

Special Tool 6135, cradle Special Tool 6710 with

Posts Special Tool 6848 and Adaptor Special Tool

8130 to be installed under vehicle (Fig. 27).

(26) Loosen cradle posts to allow movement for

proper positioning. Locate two rear posts (right side

of engine) into the holes on the engine bedplate.

Locate the two front posts (left side of engine) on the

front engine bracket and A/C compressor bracket

(Fig. 27). Lower vehicle and position cradle mounts

until the engine is resting on mounts. Tighten

mounts to cradle frame. This will keep mounts from

moving when removing or installing engine and

transmission.(27) Lower vehicle so the weight ofONLY THE

ENGINE AND TRANSMISSIONare on the cradle.

(28) Remove engine and transmission mount bolts.

(29) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly on the cradle

to allow for removal around the body.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Slowly raise vehicle enough to remove the

engine dolly and cradle Special Tools 6135 and 6710.

(4) Install axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(5) Install transmission and engine braces and

splash shields.

(6) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(7) Install power steering pump. Refer to Cooling

System Group 7, Accessory Drive Section for belt ten-

sion adjustment.

(8) Install A/C compressor hoses. Refer to Group

24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front and rear engine mounts. Refer to

this section for procedure.

(11) Install inner splash shield. Install wheels and

tires.

(12) Connect automatic transmission cooler lines,

and shift linkage. Refer to Group 21, Transmission

for procedures.

(13) Connect fuel line and heater hoses.

(14) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(15) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(16) Install radiator fans. Install radiator hoses.

Fill cooling system. Refer to Group 7, Cooling System

for filling procedure.

(17) Connect battery.

(18) Install air cleaner and hoses.

(19) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(20) Start engine and run until operating temper-

ature is reached.

(21) Adjust transmission linkage, if necessary.

9 - 26 2.4L ENGINENS

REMOVAL AND INSTALLATION (Continued)

Page 1223 of 1938

ENGINE DIAGNOSISÐMECHANICAL CONT.

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING OIL LOSS

(CONT.)6. Turbocharger leaking oil into the

air intake.6. Inspect air duct for evidence of oil

transfer.

7. Piston rings not sealing (oil being

consumed by the engine).7. Perform blow-by check. Repair as

required.

COMPRESSION KNOCKS 1. Air in fuel system. 1. Bleed the fuel system (refer to

Group 14, Fuel System).

2. Poor quality fuel or water/gasoline

contaminated fuel.2. Verify by operating from a

temporary tank with good fuel. Clean

and flush the fuel supply tank.

Replace fuel/water separator.

3. Engine Overloaded. 3. Verify the engine load rating is not

being exceeded.

4. Improperly operating injectors. 4. Check and replace injectors.

5. Fuel injection system defective. 5a. Instrumented injection. 5b. Timing

solenoid of the fuel pump. 5c. Pre

and post heat time of the glow plugs.

Check the fault codes in the ECU.

EXCESSIVE ENGINE NOISES 1. Drive belt squeal, insufficient

tension or abnormally high loading.1. Inspect the drive belts. Make sure

water pump pulley, generator and

power steering all turn freely.

2. Intake air and exhaust leak. 2. Refer to excessive exhaust smoke.

(Engine Diagnosis and Testing)

3. Excessive valve lash. 3. Make sure the rocker arms are not

bent. Defective hydraulic lash

adjuster.

4. Turbocharger noise. 4. Check turbocharger impeller and

turbine wheel for housing contact.

5. Power function knock. 5. Check and replace rod and main

bearings.

6. Fuel injection system defective. 6a. Instrumented injection. 6b. Timing

solenoid of the fuel pump. 6c. Pre

and post heat time of the glow plugs.

Check the fault codes in the ECU.

NS/GSENGINE 9 - 45

DIAGNOSIS AND TESTING (Continued)

Page 1239 of 1938

(3) Install cylinder head, intake manifold, and

exhaust manifold. Refer to cylinder head installation

in this section.

(4) Install push rods in original positions.

(5) Install rocker arms in original positions.

(6) Install cylinder head cover. Refer to cylinder

valve cover installation in this section.

(7) Start and operate engine. Warm up to normal

operating temperature.

CAUTION: To prevent damage to valve mechanism,

engine must not be run above fast idle until all

hydraulic tappets have filled with oil and have

become quiet.

VIBRATION DAMPER

REMOVAL

(1) Disconnect the battery cable.

(2) Raise vehicle on hoist.

(3) Remove right side lower splash shield.

(4) Remove generator, power steering belt. Refer to

Group 7, Cooling.

(5) Remove water pump belt. Refer to Group 7,

Cooling.

(6) Remove engine starter. Refer to Group, 8B for

procedure

(7) Install flywheel locking tool VM.1014 to pre-

vent engine rotation.

NOTE: Crankshaft damper nut is left handed

thread.

(8) Remove vibration damper nut.

(9) Remove vibration damper. No special tool is

needed for removal.

CAUTION: If thread sealant is used it is important

to remove all the old thread sealant from the

threads on the crankshaft.

INSTALLATION

NOTE: Before installing damper be sure the O-ring

inside the center of the damper is in its grove.

(1) Install vibration damper.

CAUTION: Correct torque on the vibration damper

nut is important or engine damage can occur.

(2) Install vibration damper nut and tighten to 441

N´m (325 ft. lbs.).

(3) Remove flywheel locking tool, and install

engine starter.(4) Install both accessary drive belts. Refer to

Group 7, Cooling.

(5) Install right splash shield.

(6) Lower vehicle.

(7) Connect the battery cable.

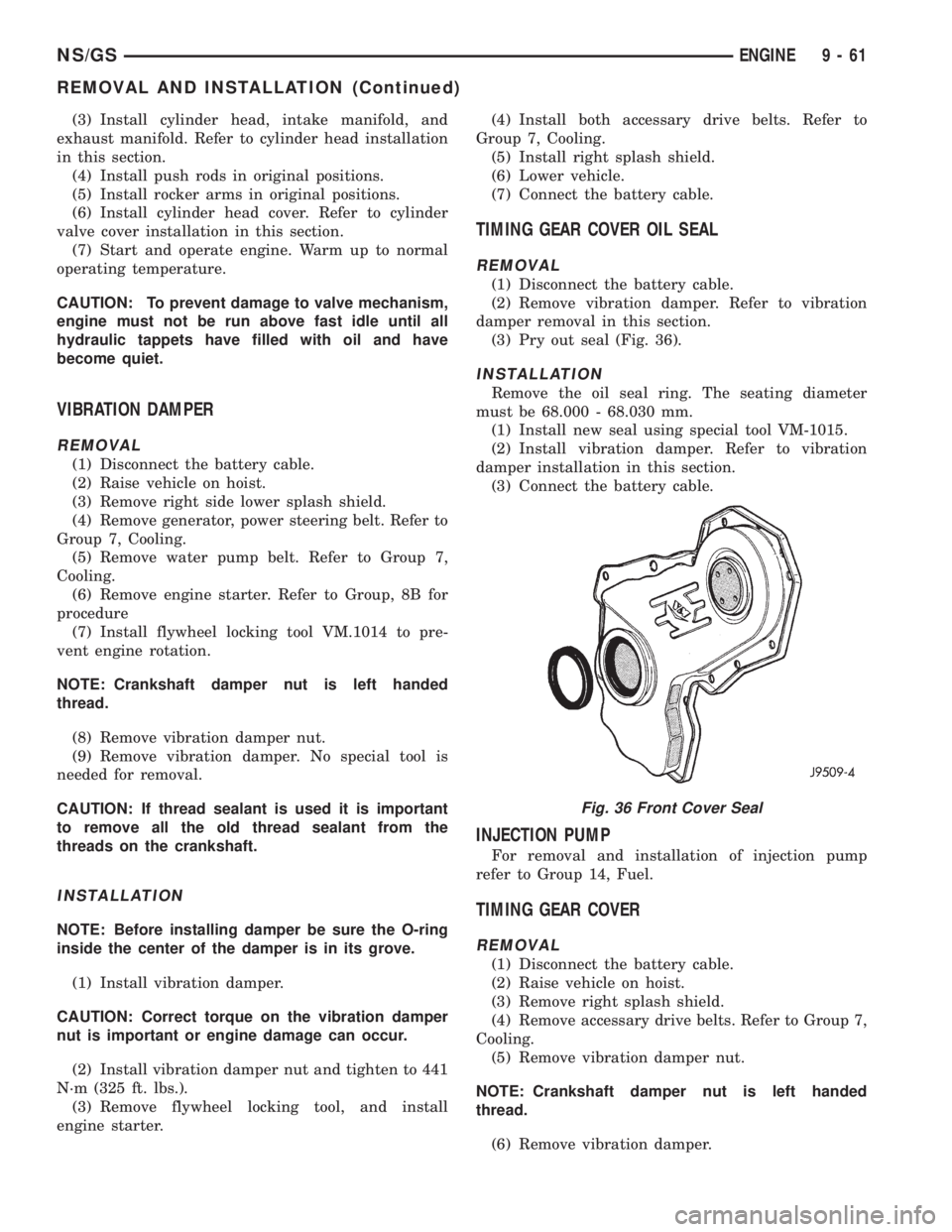

TIMING GEAR COVER OIL SEAL

REMOVAL

(1) Disconnect the battery cable.

(2) Remove vibration damper. Refer to vibration

damper removal in this section.

(3) Pry out seal (Fig. 36).

INSTALLATION

Remove the oil seal ring. The seating diameter

must be 68.000 - 68.030 mm.

(1) Install new seal using special tool VM-1015.

(2) Install vibration damper. Refer to vibration

damper installation in this section.

(3) Connect the battery cable.

INJECTION PUMP

For removal and installation of injection pump

refer to Group 14, Fuel.

TIMING GEAR COVER

REMOVAL

(1) Disconnect the battery cable.

(2) Raise vehicle on hoist.

(3) Remove right splash shield.

(4) Remove accessary drive belts. Refer to Group 7,

Cooling.

(5) Remove vibration damper nut.

NOTE: Crankshaft damper nut is left handed

thread.

(6) Remove vibration damper.

Fig. 36 Front Cover Seal

NS/GSENGINE 9 - 61

REMOVAL AND INSTALLATION (Continued)

Page 1283 of 1938

FRAME

INDEX

page page

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER MOUNT BUSHINGS . . . 5

FRONT CROSSMEMBER................... 3SPECIFICATIONS

FRAME AND BODY OPENING DIMENSIONS.... 5

REMOVAL AND INSTALLATION

FRONT CROSSMEMBER

The front suspension crossmember must be

installed in the design location to achieve proper

front end suspension alignment. If the crossmember

is removed without applying reference marks on the

frame rails, align the crossmember according to the

dimensions provided in this group.

NOTE: If the caged nuts in the frame rails become

damaged and cannot be reused, a replacement nut

can be obtained through a MoparTParts supplier.

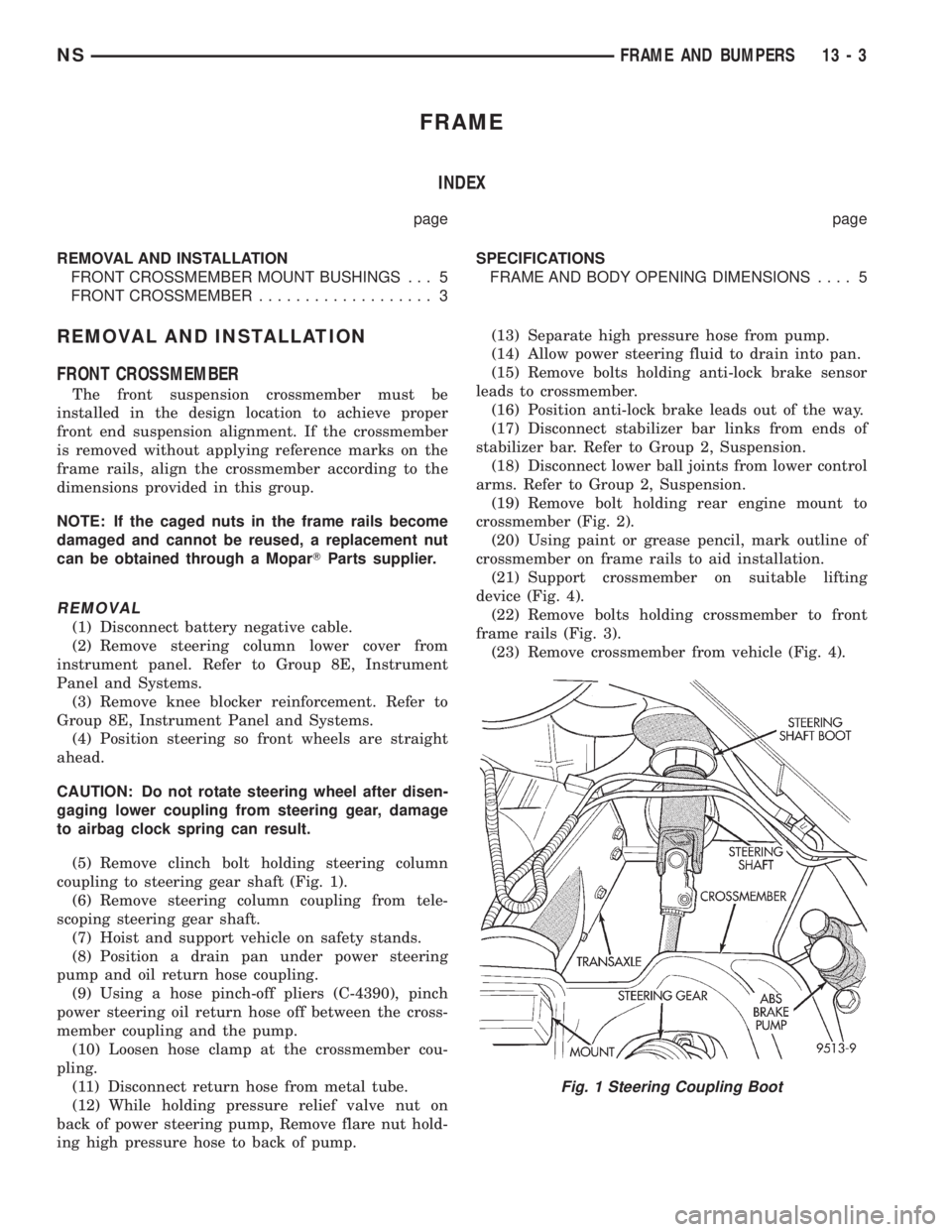

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(3) Remove knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(4) Position steering so front wheels are straight

ahead.

CAUTION: Do not rotate steering wheel after disen-

gaging lower coupling from steering gear, damage

to airbag clock spring can result.

(5) Remove clinch bolt holding steering column

coupling to steering gear shaft (Fig. 1).

(6) Remove steering column coupling from tele-

scoping steering gear shaft.

(7) Hoist and support vehicle on safety stands.

(8) Position a drain pan under power steering

pump and oil return hose coupling.

(9) Using a hose pinch-off pliers (C-4390), pinch

power steering oil return hose off between the cross-

member coupling and the pump.

(10) Loosen hose clamp at the crossmember cou-

pling.

(11) Disconnect return hose from metal tube.

(12) While holding pressure relief valve nut on

back of power steering pump, Remove flare nut hold-

ing high pressure hose to back of pump.(13) Separate high pressure hose from pump.

(14) Allow power steering fluid to drain into pan.

(15) Remove bolts holding anti-lock brake sensor

leads to crossmember.

(16) Position anti-lock brake leads out of the way.

(17) Disconnect stabilizer bar links from ends of

stabilizer bar. Refer to Group 2, Suspension.

(18) Disconnect lower ball joints from lower control

arms. Refer to Group 2, Suspension.

(19) Remove bolt holding rear engine mount to

crossmember (Fig. 2).

(20) Using paint or grease pencil, mark outline of

crossmember on frame rails to aid installation.

(21) Support crossmember on suitable lifting

device (Fig. 4).

(22) Remove bolts holding crossmember to front

frame rails (Fig. 3).

(23) Remove crossmember from vehicle (Fig. 4).

Fig. 1 Steering Coupling Boot

NSFRAME AND BUMPERS 13 - 3

Page 1285 of 1938

(7) Connect lower ball joints to lower control arms.

Refer to Group 2, Suspension.

(8) Connect stabilizer bar links to ends of stabi-

lizer bar. Refer to Group 2, Suspension.

(9) Install bolts to hold anti-lock brake sensor

leads to crossmember.

(10) Install high pressure hose to pump.

(11) Connect return hose to metal tube.

(12) Tighten hose clamp at the crossmember cou-

pling.

(13) Remove pinch-off pliers.

(14) Position steering so front wheels are straight

ahead.

(15) Install steering column coupling to telescoping

steering gear shaft.

(16) Install clinch bolt to hold steering column cou-

pling to steering gear shaft.

(17) Install knee blocker reinforcement. Refer to

Group 8E, Instrument Panel and Systems.

(18) Install steering column lower cover from

instrument panel. Refer to Group 8E, Instrument

Panel and Systems.

(19) Connect battery negative cable.

FRONT CROSSMEMBER MOUNT BUSHINGS

REMOVAL

(1) Using paint or grease pencil, mark outline of

crossmember on frame rails.

(2) Loosen bolts holding crossmember to frame

rails.

(3) Remove bolt on bushing that requires replace-

ment.

(4) Allow crossmember to drop down enough to

gain clearance for bushing removal.

(5) Remove bushing from vehicle.

INSTALLATION

(1) Apply rubber lube or soap to replacement bush-

ing.(2) Insert lower half of bushing into square hole in

crossmember.

(3) Place upper half of bushing on top of cross-

member aligned to receive square tube protruding

upward from lower bushing half.

(4) Squeeze bushing halves together to ensure they

are properly mated.

(5) Lift crossmember upward to close gap between

the bushing and frame.

(6) Verify that lower bushing is fully seated into

crossmember and upper bushing.

(7) Install bolt to hold bushing and crossmember

to frame rail hand tight.

(8) Align crossmember to reference marks on

frame rails.

(9) Tighten crossmember to frame rails attaching

bolts to 163 N´m (120 ft. lbs.) torque.

SPECIFICATIONS

FRAME AND BODY OPENING DIMENSIONS

Frame dimensions are listed in metric scale. All

dimensions are from center to center of Principal

Locating Point (PLP), or from center to center of PLP

and fastener location.

VEHICLE PREPARATION

Position the vehicle on a frame alignment rack,

refer to instructions provided with equipment being

used. Adjust the vehicle PLP heights to the specified

dimension above the work surface (datum line). Ver-

tical dimensions can be taken from the datum line to

the locations indicated were applicable. Refer to (Fig.

5), (Fig. 6), (Fig. 7), (Fig. 8), (Fig. 9), (Fig. 10) and

(Fig. 11) for proper dimensions.

NSFRAME AND BUMPERS 13 - 5

REMOVAL AND INSTALLATION (Continued)

Page 1427 of 1938

STEERING

CONTENTS

page page

GENERAL INFORMATION................... 1

POWER STEERING GEAR.................. 26POWER STEERING PUMP.................. 9

STEERING COLUMN...................... 36

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION......................... 1DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS..... 2

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION

The power steering system consists of these four

major components. Power Steering Pump, Power

Steering Gear, Pressure Hose, and Return Line.

Turning of the steering wheel is converted into linear

travel through the meshing of the helical pinion

teeth with the rack teeth. Power assist steering is

provided by an open center, rotary type control valve.

It is used to direct oil from the pump to either side of

the integral steering rack piston.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As requiredsteering effort increases, as in a turn, the torsion bar

twists, causing relative rotary motion between the

rotary valve body and the valve spool. This move-

ment directs oil behind the integral rack piston,

which, in turn, builds up hydraulic pressure and

assists in the turning effort.

Drive tangs on the power steering gear pinion

shaft, mate loosely with the shaft of the steering

gear. This is to allow manual steering control to be

maintained, if the drive belt on the power steering

pump should break. However, under these conditions,

steering effort will significantly increase.

NSSTEERING 19 - 1

Page 1428 of 1938

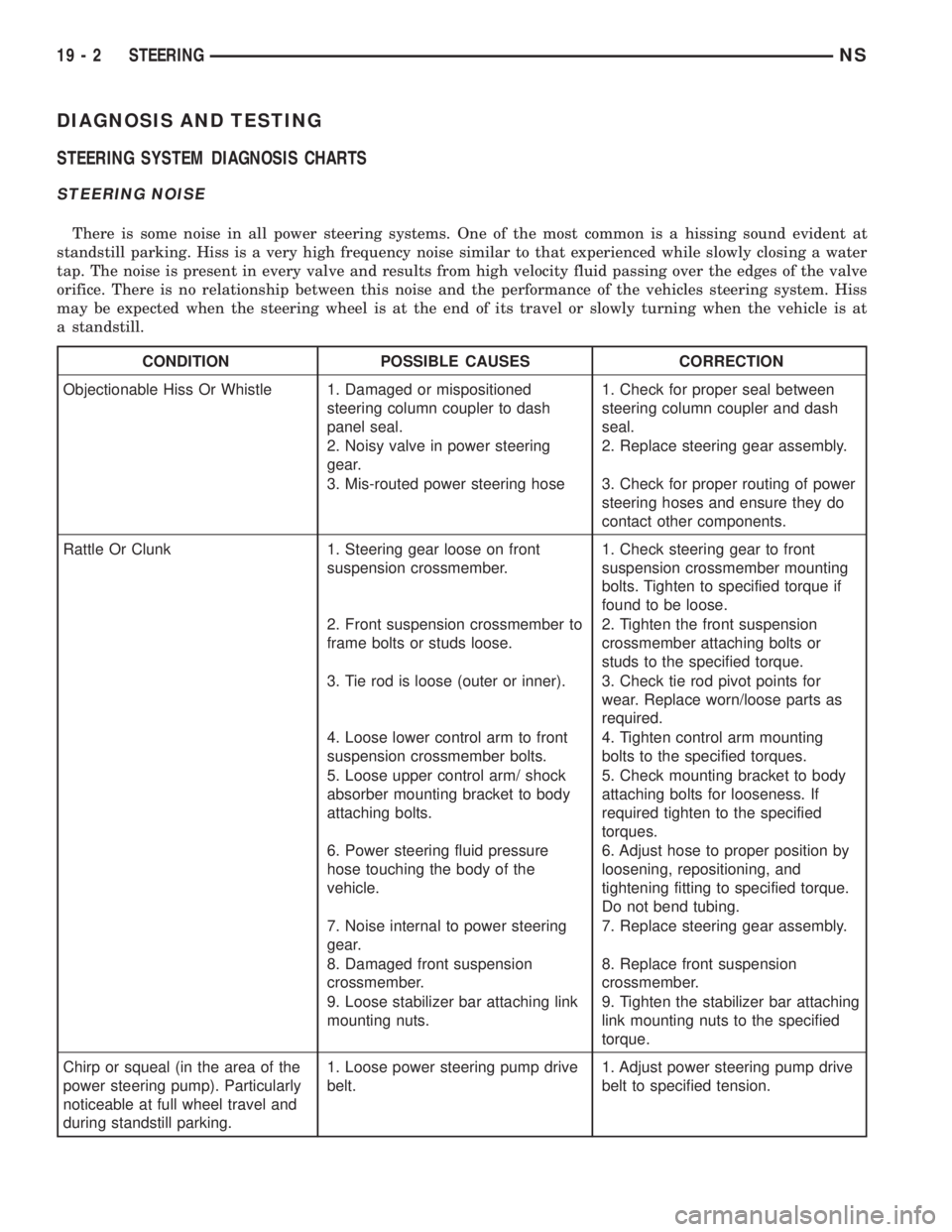

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS

STEERING NOISE

There is some noise in all power steering systems. One of the most common is a hissing sound evident at

standstill parking. Hiss is a very high frequency noise similar to that experienced while slowly closing a water

tap. The noise is present in every valve and results from high velocity fluid passing over the edges of the valve

orifice. There is no relationship between this noise and the performance of the vehicles steering system. Hiss

may be expected when the steering wheel is at the end of its travel or slowly turning when the vehicle is at

a standstill.

CONDITION POSSIBLE CAUSES CORRECTION

Objectionable Hiss Or Whistle 1. Damaged or mispositioned

steering column coupler to dash

panel seal.1. Check for proper seal between

steering column coupler and dash

seal.

2. Noisy valve in power steering

gear.2. Replace steering gear assembly.

3. Mis-routed power steering hose 3. Check for proper routing of power

steering hoses and ensure they do

contact other components.

Rattle Or Clunk 1. Steering gear loose on front

suspension crossmember.1. Check steering gear to front

suspension crossmember mounting

bolts. Tighten to specified torque if

found to be loose.

2. Front suspension crossmember to

frame bolts or studs loose.2. Tighten the front suspension

crossmember attaching bolts or

studs to the specified torque.

3. Tie rod is loose (outer or inner). 3. Check tie rod pivot points for

wear. Replace worn/loose parts as

required.

4. Loose lower control arm to front

suspension crossmember bolts.4. Tighten control arm mounting

bolts to the specified torques.

5. Loose upper control arm/ shock

absorber mounting bracket to body

attaching bolts.5. Check mounting bracket to body

attaching bolts for looseness. If

required tighten to the specified

torques.

6. Power steering fluid pressure

hose touching the body of the

vehicle.6. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing.

7. Noise internal to power steering

gear.7. Replace steering gear assembly.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

9. Loose stabilizer bar attaching link

mounting nuts.9. Tighten the stabilizer bar attaching

link mounting nuts to the specified

torque.

Chirp or squeal (in the area of the

power steering pump). Particularly

noticeable at full wheel travel and

during standstill parking.1. Loose power steering pump drive

belt.1. Adjust power steering pump drive

belt to specified tension.

19 - 2 STEERINGNS

Page 1429 of 1938

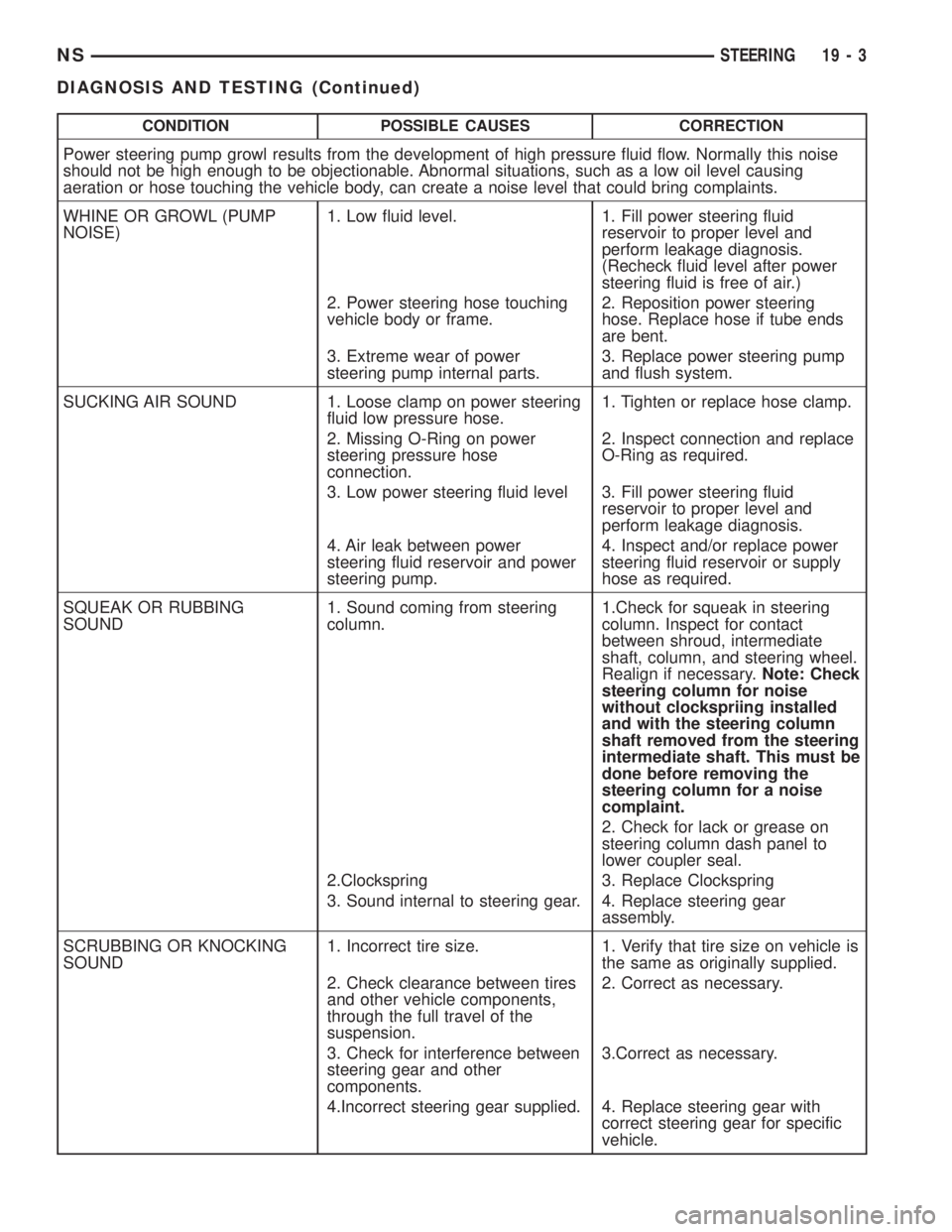

CONDITION POSSIBLE CAUSES CORRECTION

Power steering pump growl results from the development of high pressure fluid flow. Normally this noise

should not be high enough to be objectionable. Abnormal situations, such as a low oil level causing

aeration or hose touching the vehicle body, can create a noise level that could bring complaints.

WHINE OR GROWL (PUMP

NOISE)1. Low fluid level. 1. Fill power steering fluid

reservoir to proper level and

perform leakage diagnosis.

(Recheck fluid level after power

steering fluid is free of air.)

2. Power steering hose touching

vehicle body or frame.2. Reposition power steering

hose. Replace hose if tube ends

are bent.

3. Extreme wear of power

steering pump internal parts.3. Replace power steering pump

and flush system.

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid low pressure hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power

steering pressure hose

connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level 3. Fill power steering fluid

reservoir to proper level and

perform leakage diagnosis.

4. Air leak between power

steering fluid reservoir and power

steering pump.4. Inspect and/or replace power

steering fluid reservoir or supply

hose as required.

SQUEAK OR RUBBING

SOUND1. Sound coming from steering

column.1.Check for squeak in steering

column. Inspect for contact

between shroud, intermediate

shaft, column, and steering wheel.

Realign if necessary.Note: Check

steering column for noise

without clockspriing installed

and with the steering column

shaft removed from the steering

intermediate shaft. This must be

done before removing the

steering column for a noise

complaint.

2. Check for lack or grease on

steering column dash panel to

lower coupler seal.

2.Clockspring 3. Replace Clockspring

3. Sound internal to steering gear. 4. Replace steering gear

assembly.

SCRUBBING OR KNOCKING

SOUND1. Incorrect tire size. 1. Verify that tire size on vehicle is

the same as originally supplied.

2. Check clearance between tires

and other vehicle components,

through the full travel of the

suspension.2. Correct as necessary.

3. Check for interference between

steering gear and other

components.3.Correct as necessary.

4.Incorrect steering gear supplied. 4. Replace steering gear with

correct steering gear for specific

vehicle.

NSSTEERING 19 - 3

DIAGNOSIS AND TESTING (Continued)

Page 1430 of 1938

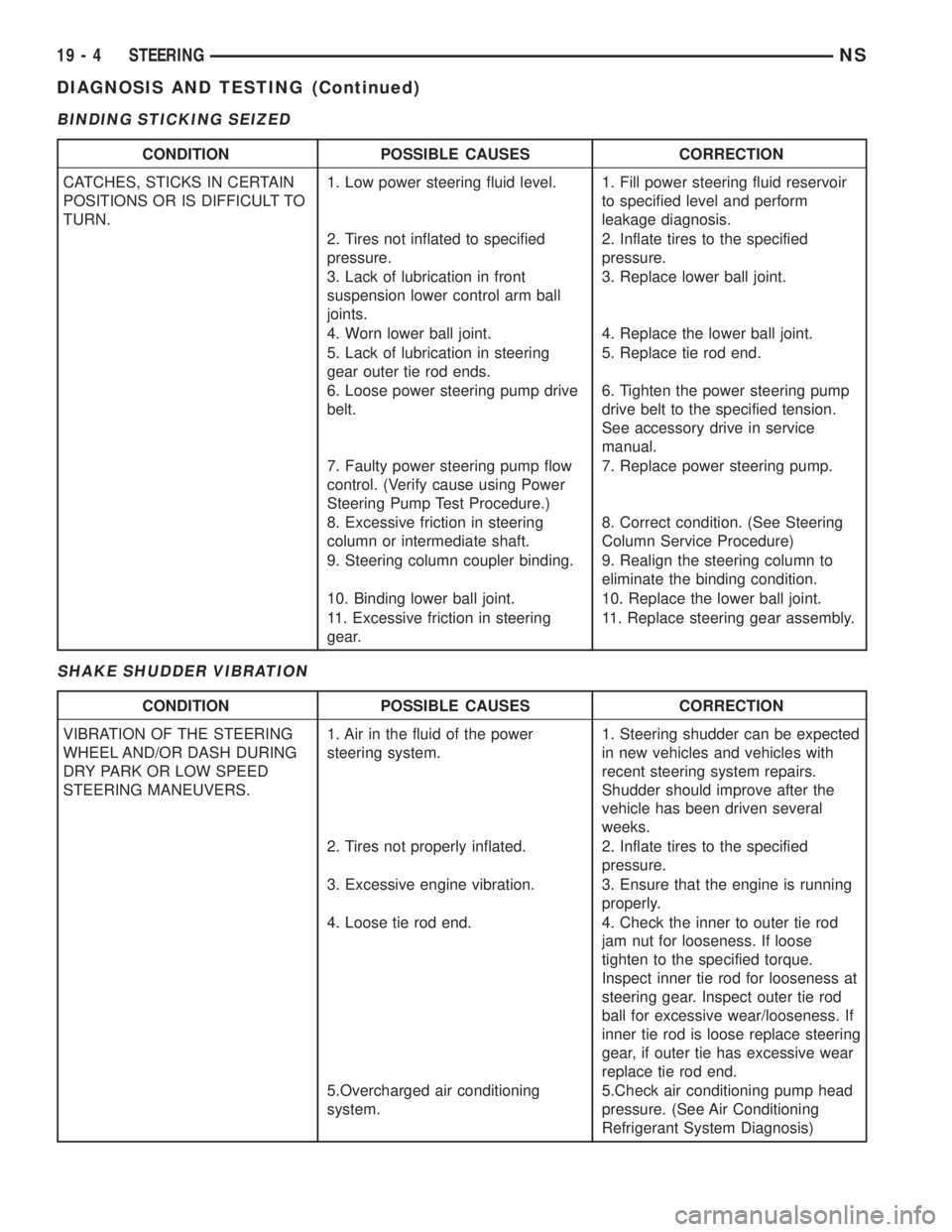

BINDING STICKING SEIZED

SHAKE SHUDDER VIBRATION

CONDITION POSSIBLE CAUSES CORRECTION

CATCHES, STICKS IN CERTAIN

POSITIONS OR IS DIFFICULT TO

TURN.1. Low power steering fluid level. 1. Fill power steering fluid reservoir

to specified level and perform

leakage diagnosis.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified

pressure.

3. Lack of lubrication in front

suspension lower control arm ball

joints.3. Replace lower ball joint.

4. Worn lower ball joint. 4. Replace the lower ball joint.

5. Lack of lubrication in steering

gear outer tie rod ends.5. Replace tie rod end.

6. Loose power steering pump drive

belt.6. Tighten the power steering pump

drive belt to the specified tension.

See accessory drive in service

manual.

7. Faulty power steering pump flow

control. (Verify cause using Power

Steering Pump Test Procedure.)7. Replace power steering pump.

8. Excessive friction in steering

column or intermediate shaft.8. Correct condition. (See Steering

Column Service Procedure)

9. Steering column coupler binding. 9. Realign the steering column to

eliminate the binding condition.

10. Binding lower ball joint. 10. Replace the lower ball joint.

11. Excessive friction in steering

gear.11. Replace steering gear assembly.

CONDITION POSSIBLE CAUSES CORRECTION

VIBRATION OF THE STEERING

WHEEL AND/OR DASH DURING

DRY PARK OR LOW SPEED

STEERING MANEUVERS.1. Air in the fluid of the power

steering system.1. Steering shudder can be expected

in new vehicles and vehicles with

recent steering system repairs.

Shudder should improve after the

vehicle has been driven several

weeks.

2. Tires not properly inflated. 2. Inflate tires to the specified

pressure.

3. Excessive engine vibration. 3. Ensure that the engine is running

properly.

4. Loose tie rod end. 4. Check the inner to outer tie rod

jam nut for looseness. If loose

tighten to the specified torque.

Inspect inner tie rod for looseness at

steering gear. Inspect outer tie rod

ball for excessive wear/looseness. If

inner tie rod is loose replace steering

gear, if outer tie has excessive wear

replace tie rod end.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure. (See Air Conditioning

Refrigerant System Diagnosis)

19 - 4 STEERINGNS

DIAGNOSIS AND TESTING (Continued)