steering wheel CHRYSLER VOYAGER 1996 Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 501 of 1938

CLOCKSPRING

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the ACM to discharge.

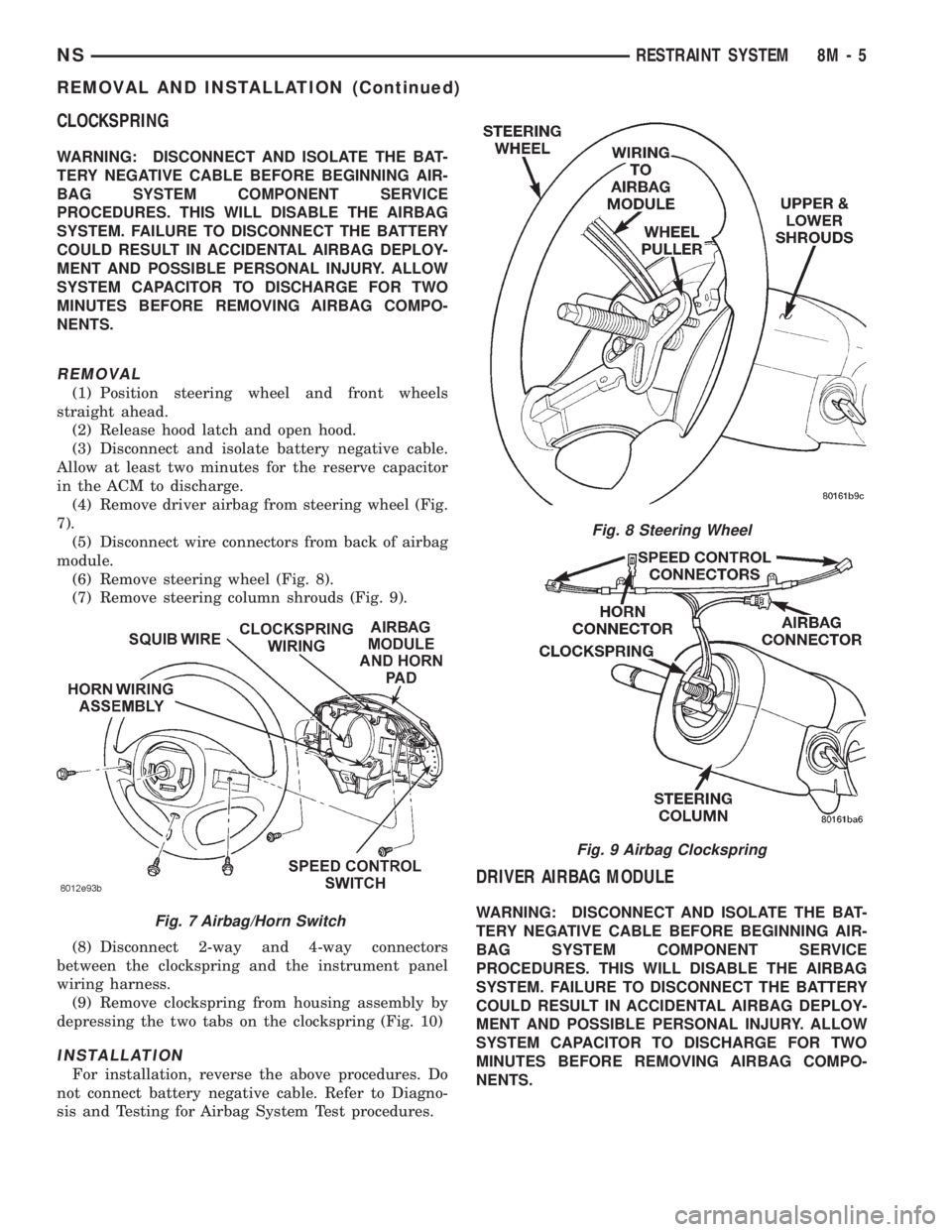

(4) Remove driver airbag from steering wheel (Fig.

7).

(5) Disconnect wire connectors from back of airbag

module.

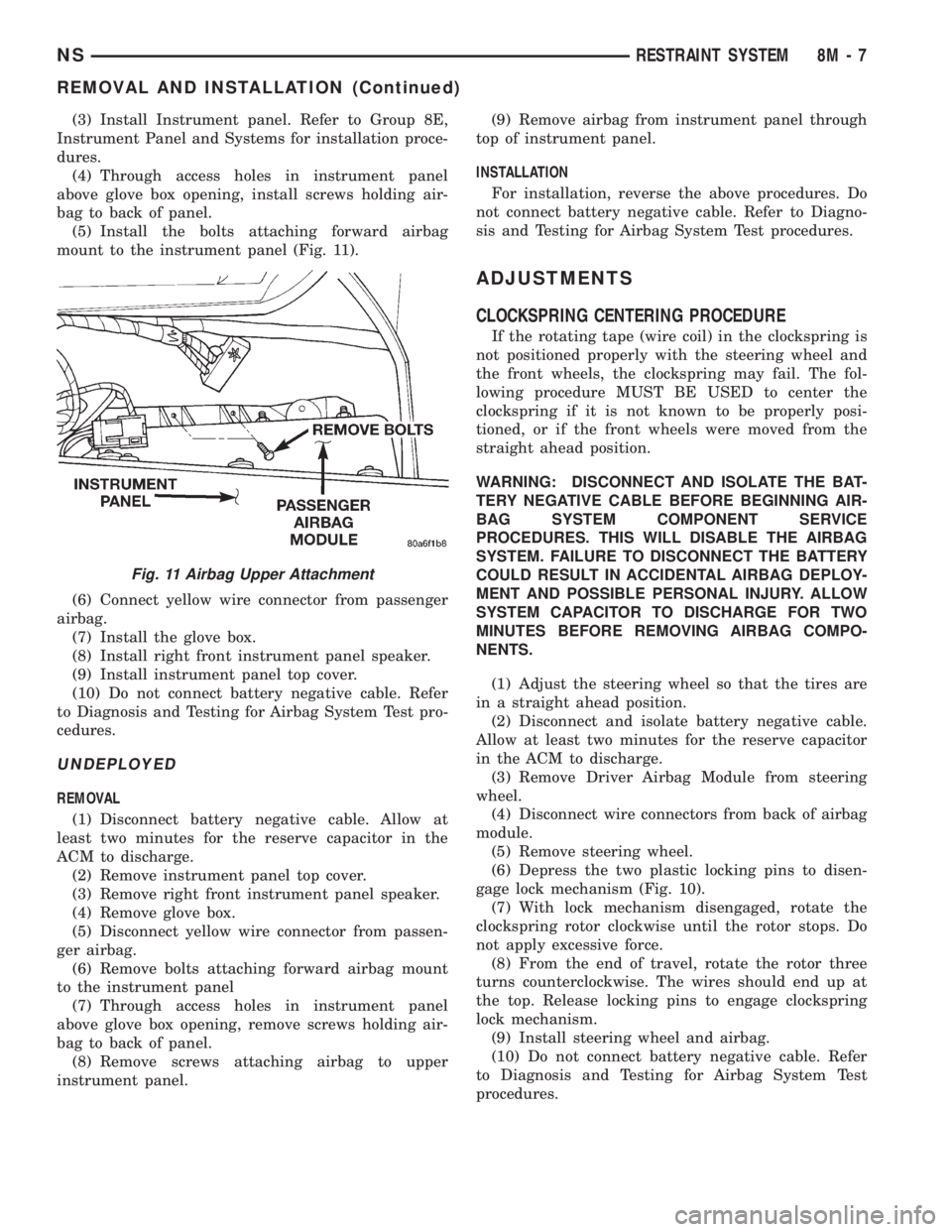

(6) Remove steering wheel (Fig. 8).

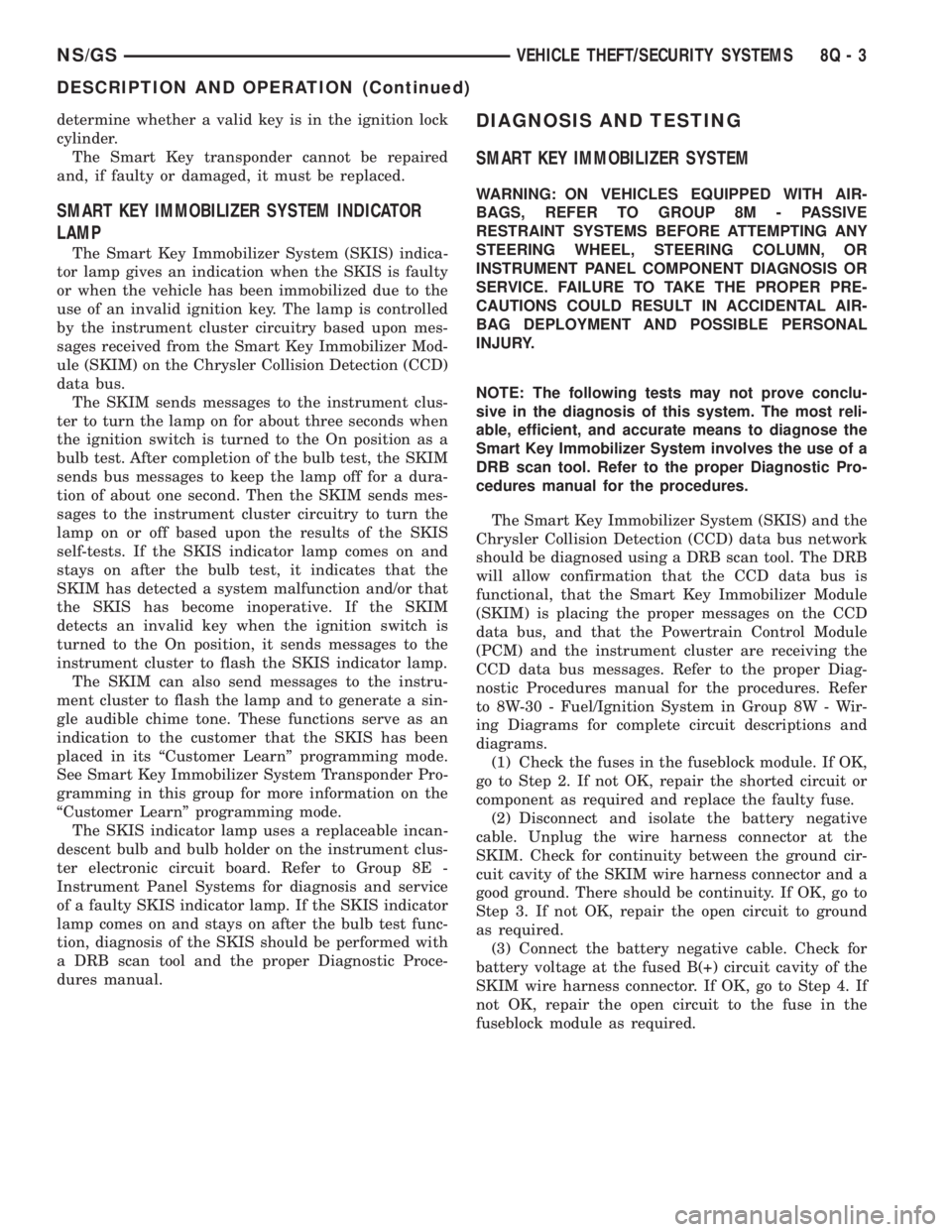

(7) Remove steering column shrouds (Fig. 9).

(8) Disconnect 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness.

(9) Remove clockspring from housing assembly by

depressing the two tabs on the clockspring (Fig. 10)

INSTALLATION

For installation, reverse the above procedures. Do

not connect battery negative cable. Refer to Diagno-

sis and Testing for Airbag System Test procedures.

DRIVER AIRBAG MODULE

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.Fig. 7 Airbag/Horn Switch

Fig. 8 Steering Wheel

Fig. 9 Airbag Clockspring

NSRESTRAINT SYSTEM 8M - 5

REMOVAL AND INSTALLATION (Continued)

Page 502 of 1938

DEPLOYED MODULE

The Driver Airbag Module and Driver Airbag Cov-

er/Horn Pad are serviced separately from eachother.

REMOVAL

(1) Disconnect battery negative cable. Allow at

least two minutes for the reserve capacitor in the

ACM to discharge.

(2) Clean powder residue from interior of vehicle,

refer to Cleanup Procedure.

(3) Remove three screws attaching Driver Airbag

Module to steering wheel (Fig. 7).

(4) Remove airbag module from steering wheel.

(5) Disconnect wire connectors from Airbag Mod-

ule, horn switch, and speed control switches.

(6) Adjust the steering wheel so that the tires are

in a straight ahead position. Remove steering wheel

(Fig. 8), refer to Group 19, Steering for proper proce-

dure.

(7) Disconnect the 2-way and 4-way connectors

between the clockspring and the instrument panel

wiring harness.

(8) Remove upper and lower steering column

shrouds.

(9) Remove clockspring from the housing assembly

by depressing the 2 tabs on the clockspring (Fig. 10).

(10) Remove screws holding speed control switches

to airbag cover and remove, if equipped.

INSTALLATION

For installation, reverse the above procedures. Do

not connect battery negative cable. Refer to Diagno-

sis and Testing for Airbag System Test procedures.

UNDEPLOYED

REMOVAL

(1) Disconnect battery negative cable. Allow at

least two minutes for the reserve capacitor in the

Airbag Control Module (ACM) to discharge.

(2) Remove screws attaching airbag/horn switch to

steering wheel (Fig. 7).

(3) Remove Driver Airbag Module from steering

wheel.

(4) Disconnect wire connectors from airbag mod-

ule, horn switch, and speed control switches, if

equipped.

(5) Remove screws holding vehicle speed control

switches to airbag cover and remove.

INSTALLATION

For installation, reverse the above procedures and

do not connect battery negative cable. Do not connect

battery negative cable. Refer to Diagnosis and Test-

ing for Airbag System Test procedures.

PASSENGER AIRBAG

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

DEPLOYED MODULE

REMOVAL

(1) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the Airbag Control Module to discharge.

(2) Clean powder residue from interior of vehicle,

refer to Cleanup Procedure in this section.

(3) Remove instrument panel, refer to Group 8E,

Instrument Panel and Systems for proper proce-

dures.

(4) Remove all reusable components from the

upper instrument panel.

INSTALLATION

Transfer all reusable components to the new the

upper instrument panel.

(1) Install new Passenger Airbag Module into

instrument panel.

(2) Install airbag module attaching screws to the

instrument panel.

Fig. 10 Clockspring Locking Tabs

8M - 6 RESTRAINT SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 503 of 1938

(3) Install Instrument panel. Refer to Group 8E,

Instrument Panel and Systems for installation proce-

dures.

(4) Through access holes in instrument panel

above glove box opening, install screws holding air-

bag to back of panel.

(5) Install the bolts attaching forward airbag

mount to the instrument panel (Fig. 11).

(6) Connect yellow wire connector from passenger

airbag.

(7) Install the glove box.

(8) Install right front instrument panel speaker.

(9) Install instrument panel top cover.

(10) Do not connect battery negative cable. Refer

to Diagnosis and Testing for Airbag System Test pro-

cedures.

UNDEPLOYED

REMOVAL

(1) Disconnect battery negative cable. Allow at

least two minutes for the reserve capacitor in the

ACM to discharge.

(2) Remove instrument panel top cover.

(3) Remove right front instrument panel speaker.

(4) Remove glove box.

(5) Disconnect yellow wire connector from passen-

ger airbag.

(6) Remove bolts attaching forward airbag mount

to the instrument panel

(7) Through access holes in instrument panel

above glove box opening, remove screws holding air-

bag to back of panel.

(8) Remove screws attaching airbag to upper

instrument panel.(9) Remove airbag from instrument panel through

top of instrument panel.

INSTALLATION

For installation, reverse the above procedures. Do

not connect battery negative cable. Refer to Diagno-

sis and Testing for Airbag System Test procedures.

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE

If the rotating tape (wire coil) in the clockspring is

not positioned properly with the steering wheel and

the front wheels, the clockspring may fail. The fol-

lowing procedure MUST BE USED to center the

clockspring if it is not known to be properly posi-

tioned, or if the front wheels were moved from the

straight ahead position.

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE CABLE BEFORE BEGINNING AIR-

BAG SYSTEM COMPONENT SERVICE

PROCEDURES. THIS WILL DISABLE THE AIRBAG

SYSTEM. FAILURE TO DISCONNECT THE BATTERY

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT AND POSSIBLE PERSONAL INJURY. ALLOW

SYSTEM CAPACITOR TO DISCHARGE FOR TWO

MINUTES BEFORE REMOVING AIRBAG COMPO-

NENTS.

(1) Adjust the steering wheel so that the tires are

in a straight ahead position.

(2) Disconnect and isolate battery negative cable.

Allow at least two minutes for the reserve capacitor

in the ACM to discharge.

(3) Remove Driver Airbag Module from steering

wheel.

(4) Disconnect wire connectors from back of airbag

module.

(5) Remove steering wheel.

(6) Depress the two plastic locking pins to disen-

gage lock mechanism (Fig. 10).

(7) With lock mechanism disengaged, rotate the

clockspring rotor clockwise until the rotor stops. Do

not apply excessive force.

(8) From the end of travel, rotate the rotor three

turns counterclockwise. The wires should end up at

the top. Release locking pins to engage clockspring

lock mechanism.

(9) Install steering wheel and airbag.

(10) Do not connect battery negative cable. Refer

to Diagnosis and Testing for Airbag System Test

procedures.

Fig. 11 Airbag Upper Attachment

NSRESTRAINT SYSTEM 8M - 7

REMOVAL AND INSTALLATION (Continued)

Page 521 of 1938

determine whether a valid key is in the ignition lock

cylinder.

The Smart Key transponder cannot be repaired

and, if faulty or damaged, it must be replaced.

SMART KEY IMMOBILIZER SYSTEM INDICATOR

LAMP

The Smart Key Immobilizer System (SKIS) indica-

tor lamp gives an indication when the SKIS is faulty

or when the vehicle has been immobilized due to the

use of an invalid ignition key. The lamp is controlled

by the instrument cluster circuitry based upon mes-

sages received from the Smart Key Immobilizer Mod-

ule (SKIM) on the Chrysler Collision Detection (CCD)

data bus.

The SKIM sends messages to the instrument clus-

ter to turn the lamp on for about three seconds when

the ignition switch is turned to the On position as a

bulb test. After completion of the bulb test, the SKIM

sends bus messages to keep the lamp off for a dura-

tion of about one second. Then the SKIM sends mes-

sages to the instrument cluster circuitry to turn the

lamp on or off based upon the results of the SKIS

self-tests. If the SKIS indicator lamp comes on and

stays on after the bulb test, it indicates that the

SKIM has detected a system malfunction and/or that

the SKIS has become inoperative. If the SKIM

detects an invalid key when the ignition switch is

turned to the On position, it sends messages to the

instrument cluster to flash the SKIS indicator lamp.

The SKIM can also send messages to the instru-

ment cluster to flash the lamp and to generate a sin-

gle audible chime tone. These functions serve as an

indication to the customer that the SKIS has been

placed in its ªCustomer Learnº programming mode.

See Smart Key Immobilizer System Transponder Pro-

gramming in this group for more information on the

ªCustomer Learnº programming mode.

The SKIS indicator lamp uses a replaceable incan-

descent bulb and bulb holder on the instrument clus-

ter electronic circuit board. Refer to Group 8E -

Instrument Panel Systems for diagnosis and service

of a faulty SKIS indicator lamp. If the SKIS indicator

lamp comes on and stays on after the bulb test func-

tion, diagnosis of the SKIS should be performed with

a DRB scan tool and the proper Diagnostic Proce-

dures manual.

DIAGNOSIS AND TESTING

SMART KEY IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Smart Key Immobilizer System involves the use of a

DRB scan tool. Refer to the proper Diagnostic Pro-

cedures manual for the procedures.

The Smart Key Immobilizer System (SKIS) and the

Chrysler Collision Detection (CCD) data bus network

should be diagnosed using a DRB scan tool. The DRB

will allow confirmation that the CCD data bus is

functional, that the Smart Key Immobilizer Module

(SKIM) is placing the proper messages on the CCD

data bus, and that the Powertrain Control Module

(PCM) and the instrument cluster are receiving the

CCD data bus messages. Refer to the proper Diag-

nostic Procedures manual for the procedures. Refer

to 8W-30 - Fuel/Ignition System in Group 8W - Wir-

ing Diagrams for complete circuit descriptions and

diagrams.

(1) Check the fuses in the fuseblock module. If OK,

go to Step 2. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(2) Disconnect and isolate the battery negative

cable. Unplug the wire harness connector at the

SKIM. Check for continuity between the ground cir-

cuit cavity of the SKIM wire harness connector and a

good ground. There should be continuity. If OK, go to

Step 3. If not OK, repair the open circuit to ground

as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the

fuseblock module as required.

NS/GSVEHICLE THEFT/SECURITY SYSTEMS 8Q - 3

DESCRIPTION AND OPERATION (Continued)

Page 522 of 1938

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKIM wire

harness connector. If OK, use a DRB scan tool and

the proper Diagnostic Procedures manual to complete

the diagnosis of the SKIS. If not OK, repair the open

circuit to the fuse in the fuseblock module as

required.

SERVICE PROCEDURES

SMART KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING

Two programmed Smart Key transponders are

included with the Smart Key Immobilizer System

(SKIS) when it is shipped from the factory. The

Smart Key Immobilizer Module (SKIM) can be pro-

grammed to recognize up to six additional transpon-

ders, for a total of eight Smart Keys. The following

ªCustomer Learnº programming procedure for the

programming of additional transponders requires

access to at least two of the valid Smart Keys. If two

valid Smart Keys are not available, Smart Key pro-

gramming will require the use of a DRB scan tool

and the proper Diagnostic Procedures manual.

PROGRAMMING THE SKIM MODULE WITH

THE DRBIII

(1) Turn the ignition on. Transmission must be in

park or neutral. Alarm set lamp will flash.

(2) Use the DRBIII and select ªSKIMº under the

ªMISCELLANEOUSº menu.

(3) Select ªPROGRAM PINº and enter the cus-

tomer 4±digit PIN number.

(4) Select ªUPDATE VINº. The SKIM module will

learn the VIN from the PCM in gasoline engine vehi-

cles, and from the BCM in diesel engine vehicles.

(5) Select ªCOUNTRY CODEº and enter the cor-

rect country.

(6) Select ªPROGRAM NEW EMSº. The SKIM

module will send the ªsecret keyº data to the PCM.

(7) Program ignition keys to the SKIM module.

PROGRAMMING IGNITION KEYS WITH THE

DRBIII

(1) Turn ignition on. Transmission must be in park

or neutral. Alarm set lamp will flash.

(2) Use the DRBIII and select ªSKIMº under the

ªMISCELLANEOUSº menu.

(3) Select ªLEARN NEW KEYº. Alarm Set lamp

will begin flashing.

NOTE: The PIN must be re-entered each time an

additional key is learned.(4) Insert key into ignition switch. Once the key

has been learned, the Alarm Set lamp will turn off.

REMOVAL AND INSTALLATION

SMART KEY IMMOBILIZER MODULE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the knee blocker from the instrument

panel. See Knee Blocker in Group 8E - Instrument

Panel Systems for the procedures.

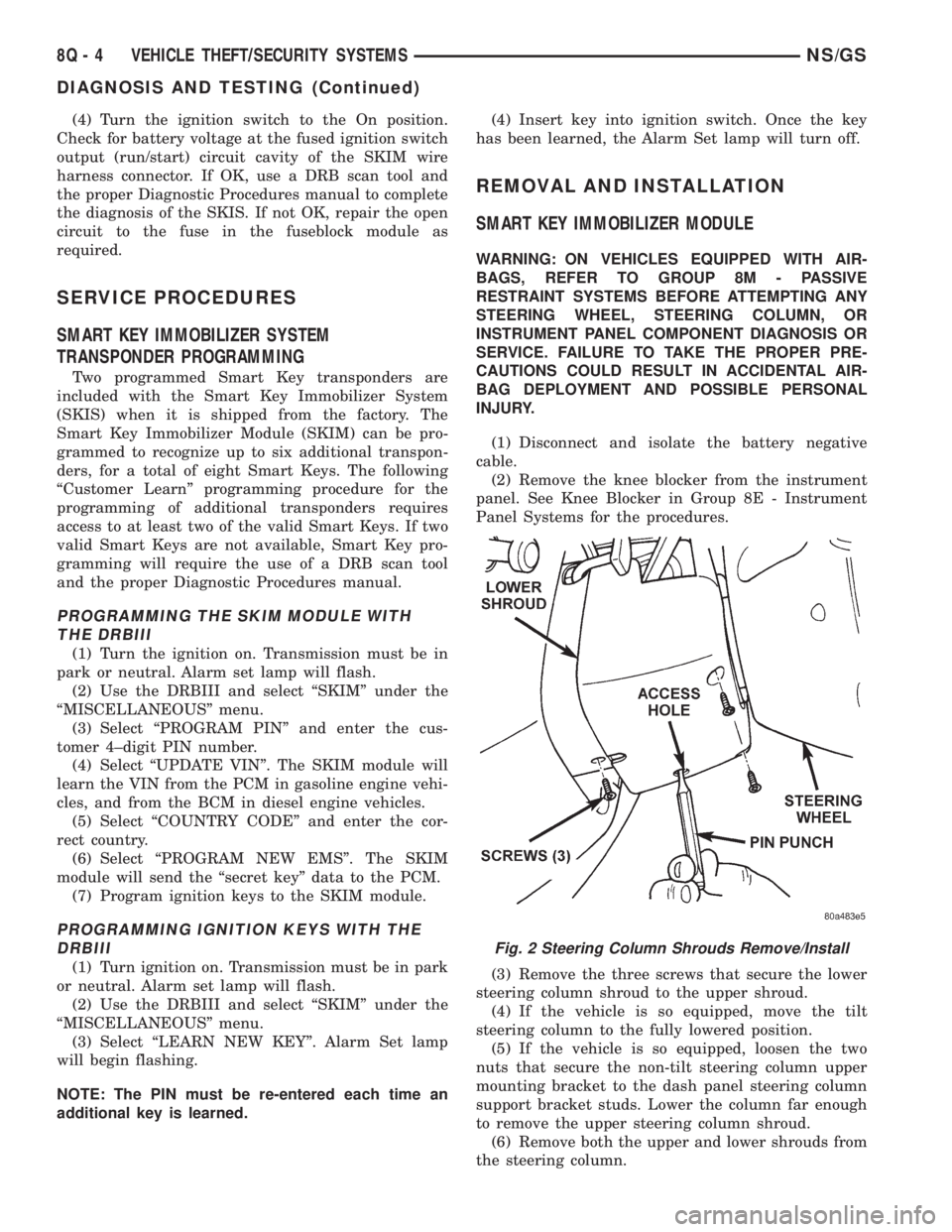

(3) Remove the three screws that secure the lower

steering column shroud to the upper shroud.

(4) If the vehicle is so equipped, move the tilt

steering column to the fully lowered position.

(5) If the vehicle is so equipped, loosen the two

nuts that secure the non-tilt steering column upper

mounting bracket to the dash panel steering column

support bracket studs. Lower the column far enough

to remove the upper steering column shroud.

(6) Remove both the upper and lower shrouds from

the steering column.

Fig. 2 Steering Column Shrouds Remove/Install

8Q - 4 VEHICLE THEFT/SECURITY SYSTEMSNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 965 of 1938

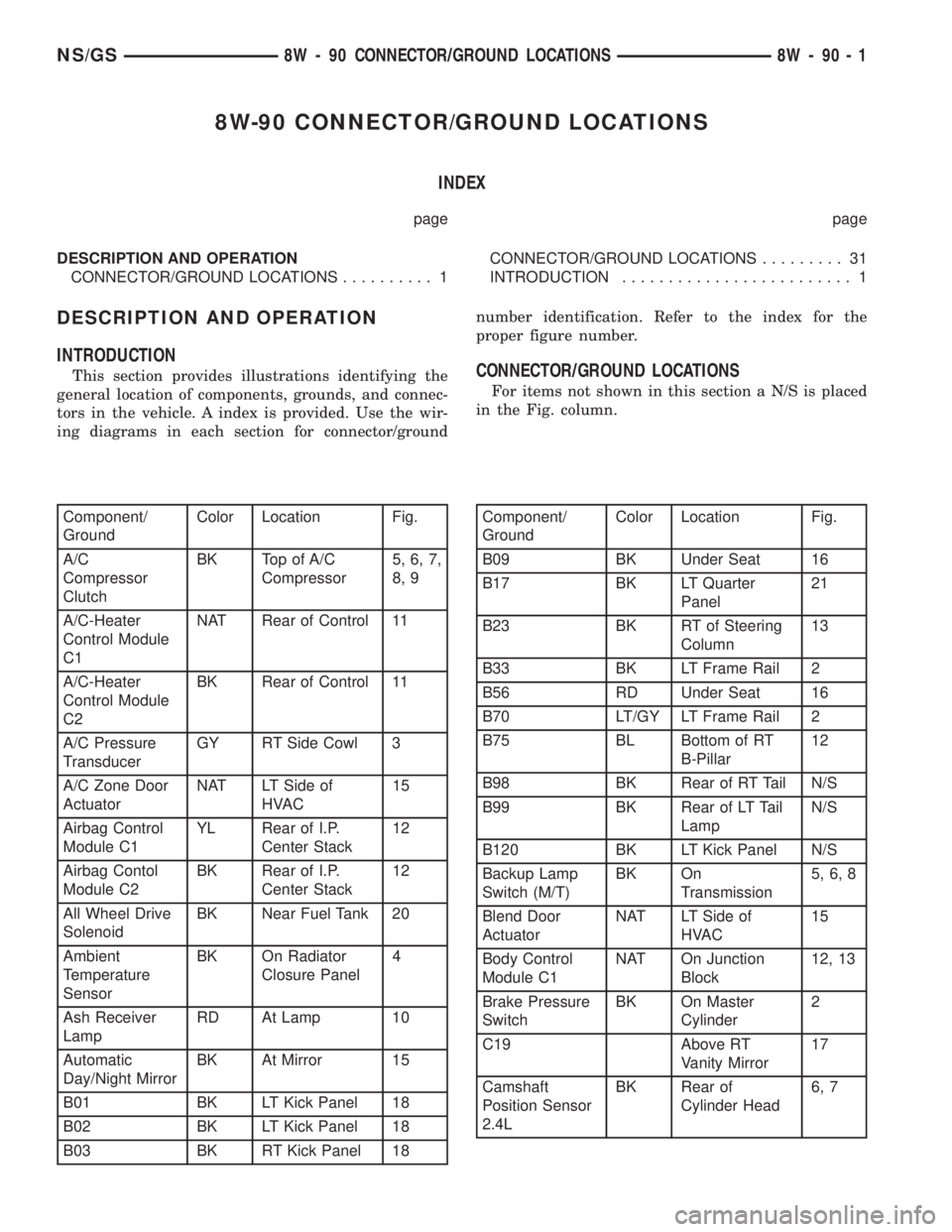

8W-90 CONNECTOR/GROUND LOCATIONS

INDEX

page page

DESCRIPTION AND OPERATION

CONNECTOR/GROUND LOCATIONS.......... 1CONNECTOR/GROUND LOCATIONS......... 31

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

INTRODUCTION

This section provides illustrations identifying the

general location of components, grounds, and connec-

tors in the vehicle. A index is provided. Use the wir-

ing diagrams in each section for connector/groundnumber identification. Refer to the index for the

proper figure number.CONNECTOR/GROUND LOCATIONS

For items not shown in this section a N/S is placed

in the Fig. column.

Component/

GroundColor Location Fig.

A/C

Compressor

ClutchBK Top of A/C

Compressor5, 6, 7,

8, 9

A/C-Heater

Control Module

C1NAT Rear of Control 11

A/C-Heater

Control Module

C2BK Rear of Control 11

A/C Pressure

TransducerGY RT Side Cowl 3

A/C Zone Door

ActuatorNAT LT Side of

HVAC15

Airbag Control

Module C1YL Rear of I.P.

Center Stack12

Airbag Contol

Module C2BK Rear of I.P.

Center Stack12

All Wheel Drive

SolenoidBK Near Fuel Tank 20

Ambient

Temperature

SensorBK On Radiator

Closure Panel4

Ash Receiver

LampRD At Lamp 10

Automatic

Day/Night MirrorBK At Mirror 15

B01 BK LT Kick Panel 18

B02 BK LT Kick Panel 18

B03 BK RT Kick Panel 18Component/

GroundColor Location Fig.

B09 BK Under Seat 16

B17 BK LT Quarter

Panel21

B23 BK RT of Steering

Column13

B33 BK LT Frame Rail 2

B56 RD Under Seat 16

B70 LT/GY LT Frame Rail 2

B75 BL Bottom of RT

B-Pillar12

B98 BK Rear of RT Tail N/S

B99 BK Rear of LT Tail

LampN/S

B120 BK LT Kick Panel N/S

Backup Lamp

Switch (M/T)BK On

Transmission5, 6, 8

Blend Door

ActuatorNAT LT Side of

HVAC15

Body Control

Module C1NAT On Junction

Block12, 13

Brake Pressure

SwitchBK On Master

Cylinder2

C19 Above RT

Vanity Mirror17

Camshaft

Position Sensor

2.4LBK Rear of

Cylinder Head6, 7

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 1

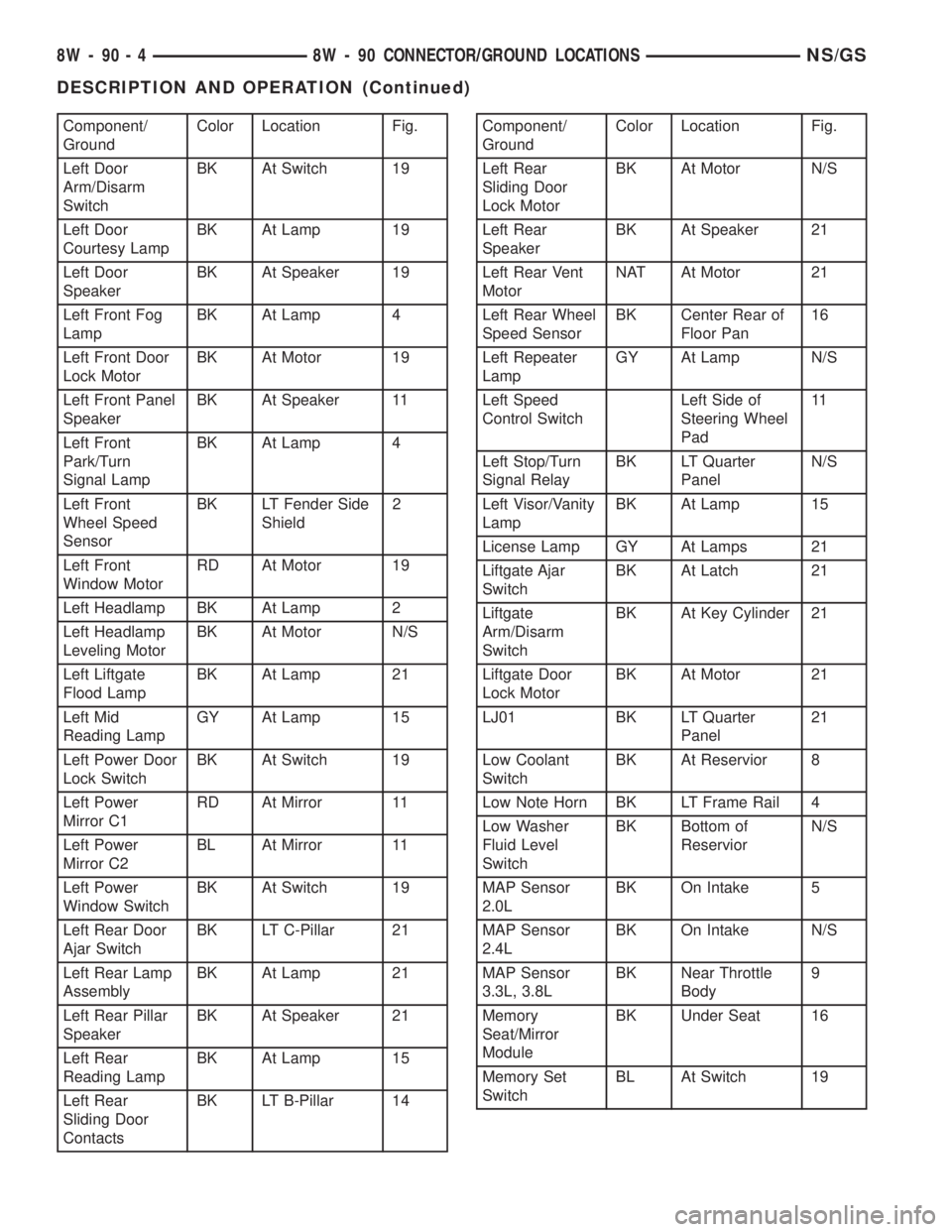

Page 968 of 1938

Component/

GroundColor Location Fig.

Left Door

Arm/Disarm

SwitchBK At Switch 19

Left Door

Courtesy LampBK At Lamp 19

Left Door

SpeakerBK At Speaker 19

Left Front Fog

LampBK At Lamp 4

Left Front Door

Lock MotorBK At Motor 19

Left Front Panel

SpeakerBK At Speaker 11

Left Front

Park/Turn

Signal LampBK At Lamp 4

Left Front

Wheel Speed

SensorBK LT Fender Side

Shield2

Left Front

Window MotorRD At Motor 19

Left Headlamp BK At Lamp 2

Left Headlamp

Leveling MotorBK At Motor N/S

Left Liftgate

Flood LampBK At Lamp 21

Left Mid

Reading LampGY At Lamp 15

Left Power Door

Lock SwitchBK At Switch 19

Left Power

Mirror C1RD At Mirror 11

Left Power

Mirror C2BL At Mirror 11

Left Power

Window SwitchBK At Switch 19

Left Rear Door

Ajar SwitchBK LT C-Pillar 21

Left Rear Lamp

AssemblyBK At Lamp 21

Left Rear Pillar

SpeakerBK At Speaker 21

Left Rear

Reading LampBK At Lamp 15

Left Rear

Sliding Door

ContactsBK LT B-Pillar 14Component/

GroundColor Location Fig.

Left Rear

Sliding Door

Lock MotorBK At Motor N/S

Left Rear

SpeakerBK At Speaker 21

Left Rear Vent

MotorNAT At Motor 21

Left Rear Wheel

Speed SensorBK Center Rear of

Floor Pan16

Left Repeater

LampGY At Lamp N/S

Left Speed

Control SwitchLeft Side of

Steering Wheel

Pad11

Left Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Left Visor/Vanity

LampBK At Lamp 15

License Lamp GY At Lamps 21

Liftgate Ajar

SwitchBK At Latch 21

Liftgate

Arm/Disarm

SwitchBK At Key Cylinder 21

Liftgate Door

Lock MotorBK At Motor 21

LJ01 BK LT Quarter

Panel21

Low Coolant

SwitchBK At Reservior 8

Low Note Horn BK LT Frame Rail 4

Low Washer

Fluid Level

SwitchBK Bottom of

ReserviorN/S

MAP Sensor

2.0LBK On Intake 5

MAP Sensor

2.4LBK On Intake N/S

MAP Sensor

3.3L, 3.8LBK Near Throttle

Body9

Memory

Seat/Mirror

ModuleBK Under Seat 16

Memory Set

SwitchBL At Switch 19

8W - 90 - 4 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

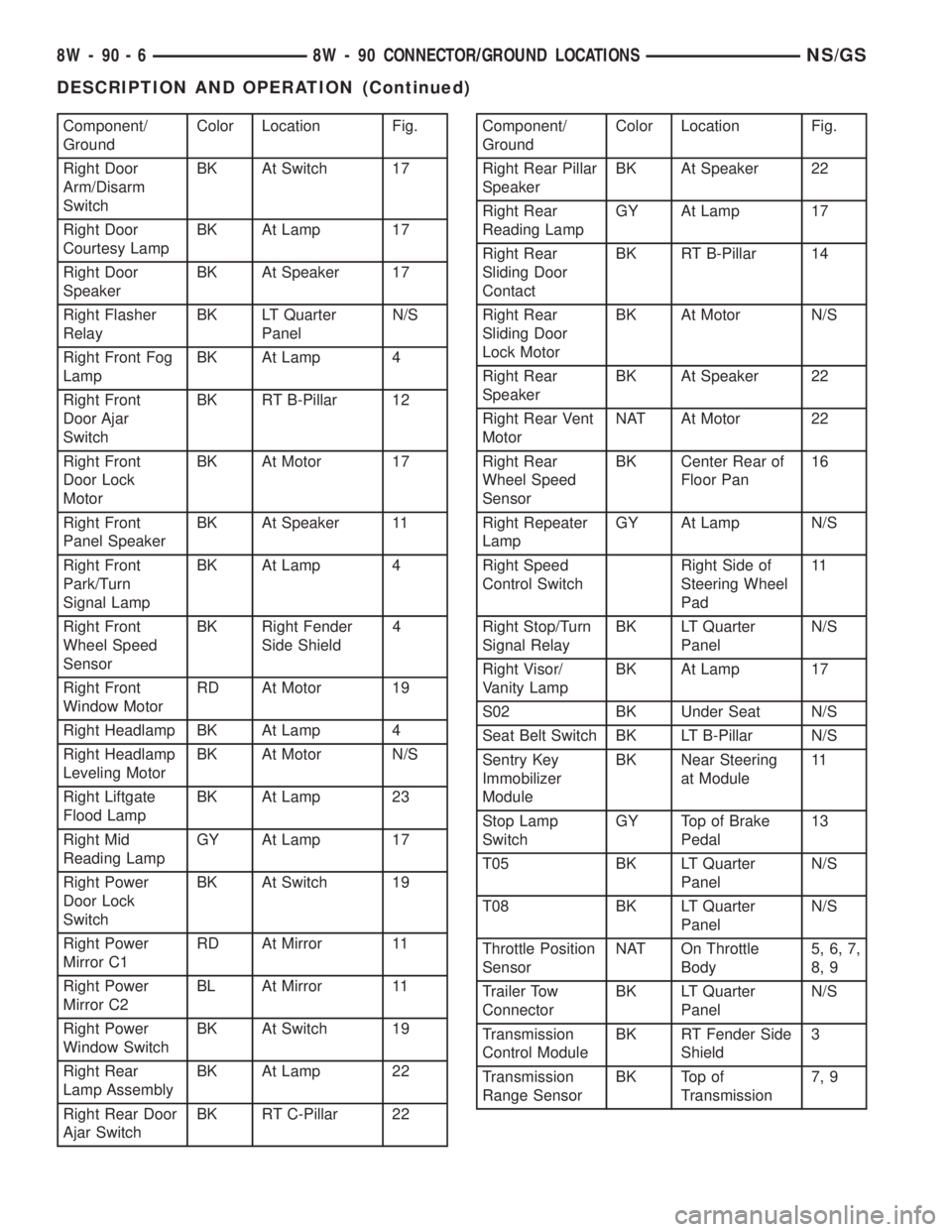

Page 970 of 1938

Component/

GroundColor Location Fig.

Right Door

Arm/Disarm

SwitchBK At Switch 17

Right Door

Courtesy LampBK At Lamp 17

Right Door

SpeakerBK At Speaker 17

Right Flasher

RelayBK LT Quarter

PanelN/S

Right Front Fog

LampBK At Lamp 4

Right Front

Door Ajar

SwitchBK RT B-Pillar 12

Right Front

Door Lock

MotorBK At Motor 17

Right Front

Panel SpeakerBK At Speaker 11

Right Front

Park/Turn

Signal LampBK At Lamp 4

Right Front

Wheel Speed

SensorBK Right Fender

Side Shield4

Right Front

Window MotorRD At Motor 19

Right Headlamp BK At Lamp 4

Right Headlamp

Leveling MotorBK At Motor N/S

Right Liftgate

Flood LampBK At Lamp 23

Right Mid

Reading LampGY At Lamp 17

Right Power

Door Lock

SwitchBK At Switch 19

Right Power

Mirror C1RD At Mirror 11

Right Power

Mirror C2BL At Mirror 11

Right Power

Window SwitchBK At Switch 19

Right Rear

Lamp AssemblyBK At Lamp 22

Right Rear Door

Ajar SwitchBK RT C-Pillar 22Component/

GroundColor Location Fig.

Right Rear Pillar

SpeakerBK At Speaker 22

Right Rear

Reading LampGY At Lamp 17

Right Rear

Sliding Door

ContactBK RT B-Pillar 14

Right Rear

Sliding Door

Lock MotorBK At Motor N/S

Right Rear

SpeakerBK At Speaker 22

Right Rear Vent

MotorNAT At Motor 22

Right Rear

Wheel Speed

SensorBK Center Rear of

Floor Pan16

Right Repeater

LampGY At Lamp N/S

Right Speed

Control SwitchRight Side of

Steering Wheel

Pad11

Right Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Right Visor/

Vanity LampBK At Lamp 17

S02 BK Under Seat N/S

Seat Belt Switch BK LT B-Pillar N/S

Sentry Key

Immobilizer

ModuleBK Near Steering

at Module11

Stop Lamp

SwitchGY Top of Brake

Pedal13

T05 BK LT Quarter

PanelN/S

T08 BK LT Quarter

PanelN/S

Throttle Position

SensorNAT On Throttle

Body5, 6, 7,

8, 9

Trailer Tow

ConnectorBK LT Quarter

PanelN/S

Transmission

Control ModuleBK RT Fender Side

Shield3

Transmission

Range SensorBK Top of

Transmission7, 9

8W - 90 - 6 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)

Page 995 of 1938

CONNECTOR/GROUND LOCATIONS

For items not shown in this section a N/S is placed

in the Fig. column.

Component/

GroundColor Location Fig.

A/C

Compressor

ClutchBK Top of A/C

Compressor5, 6, 7,

8, 9

A/C-Heater

Control Module

C1NAT Rear of Control 11

A/C-Heater

Control Module

C2BK Rear of Control 11

A/C Pressure

TransducerGY RT Side Cowl 3

A/C Zone Door

ActuatorNAT LT Side of

HVAC15

Airbag Control

Module C1YL Rear of I.P.

Center Stack12

Airbag Contol

Module C2BK Rear of I.P.

Center Stack12

All Wheel Drive

SolenoidBK Near Fuel Tank 20

Ambient

Temperature

SensorGY On Radiator

Closure Panel4

Ash Receiver

LampRD At Lamp 10

Automatic

Day/Night MirrorBK At Mirror 17

B01 BK RT Kick Panel 18

B02 BK RT Kick Panel 18

B03 BK LT Kick Panel 18

B09 BK Under Seat 16

B17 BK LT Quarter

Panel21

B23 BK RT of Steering

Column13

B33 BK LT Frame Rail 2

B56 BK Under Seat 16

B70 LT/GY LT Frame Rail 2

B75 BL Bottom of RT

B-Pillar14

B98 BK Rear of RT Tail

LampN/SComponent/

GroundColor Location Fig.

B99 BK Rear of LT Tail

LampN/S

B120 BK LT Kick Panel N/S

Backup Lamp

Switch (M/T)BK On

Transmission5, 6, 8

Blend Door

ActuatorNAT LT Side of

HVAC15

Body Control

Module C1NAT On Junction

Block12

Body Control

Module C2NAT On Junction

Block12

Brake Pressure

SwitchBK On Master

Cylinder2

C19 At Top Center

of Windshield17

C20 Bottom of RT

B-PillarN/S

Camshaft

Position Sensor

2.4LBK Rear of

Cylinder Head6, 7

Camshaft

Position Sensor

3.3L, 3.8LBK RT Side of

Engine9

Center Dome

LampBK At Lamp N/S

CHMSL RD Rear of CHMSL 23

Clockspring C1 YL Rear of

Clockspring11

Clockspring C2 NAT Rear of

Clockspring11

Clutch Switch BK Top of Clutch

Pedal13

Controller

Anti-Lock BrakeBK LT Side of

Engine

CompartmentN/S

Crankshaft

Position SensorBK Rear of Engine 5, 6, 7,

9

D01 BK On Kick Panel 19

D02 BK On Kick Panel 19

Data Link

ConnectorBK LT of Steering

Column12

NS/GS8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 31

DESCRIPTION AND OPERATION (Continued)

Page 998 of 1938

Component/

GroundColor Location Fig.

Left Rear

Reading LampGY At Lamp 17

Left Rear

Sliding Door

ContactBK LT B-Pillar 14

Left Rear

Sliding Door

Lock MotorBK At Motor N/S

Left Rear

SpeakerBK At Speaker 21

Left Rear Vent

MotorNAT At Motor 21

Left Rear Wheel

Speed SensorGY Center Rear of

Floor Pan16

Left Repeater

LampGY At Lamp N/S

Left Speed

Control SwitchLeft Side of

Steering Wheel

Pad11

Left Stop/Turn

Signal RelayBK LT Quarter

PanelN/S

Left Visor/Vanity

LampBK At Lamp 17

License Lamp GY At Lamps 23

Liftgate Ajar

SwitchBK At Latch 23

Liftgate

Arm/Disarm

SwitchGY At Key Cylinder 23

Liftgate Lock

MotorBK At Motor 23

LJ01 BK LT Quarter

Panel21

Low Note Horn BK LT Frame Rail 4

Low Washer

Fluid Level

SensorBK Bottom of

Reservior4

MAP Sensor

2.4LBK On Intake N/S

MAP Sensor

3.3L, 3.8LBK Near Throttle

Body9

Memort

Seat/Mirror

ModuleBK RT Front of

Floor Pan16

Memory Set

SwitchBL At Switch 19Component/

GroundColor Location Fig.

Message Center BL Rear of

Message

Center11

Mode Door

ActuatorBK LT Side of

HVAC15

Multi Function

SwitchBK Rear of Switch 11

Name Brand

Speaker RelayLT/GY LT of Steering

ColumnN/S

Output Shaft

Speed SensorGY Front of

Transmission7, 9

Overhead

ConsoleRD Front of

Console17

P18 GY RT of Steering

Column12

P30 BK RT Side of

HVAC10

P34 GY RT of Steering

Column12

P50 NAT Right Side of

HVAC Taped to

Harness10

Park Brake

SwitchNAT Top of Park

BrakeN/S

Park/Neutral

Positon SwitchBK Front of

TransmissionN/S

Passenger

AirbagYL Rear of Airbag 11

PDC C1 NAT Bottom of PDC 2

PDC C2 OR Bottom of PDC 2

PDC C3 DK/

GNBottom of PDC 2

PDC C4 BK Bottom of PDC 2

PDC C5 LT/GY Bottom of PDC 2

PDC C6 LT/GN Bottom of PDC 3

PDC C7 LT/GY Bottom of PDC 3

PDC C8 BL Bottom of PDC 3

Power Folding

Mirror SwitchBK At Switch N/S

Power Mirror

SwitchBK Rear of Switch 11

Power Steering

Pressure SwitchBK RT Side of

Engine

CompartmentN/S

8W - 90 - 34 8W - 90 CONNECTOR/GROUND LOCATIONSNS/GS

DESCRIPTION AND OPERATION (Continued)