fuel pressure CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 19 of 1938

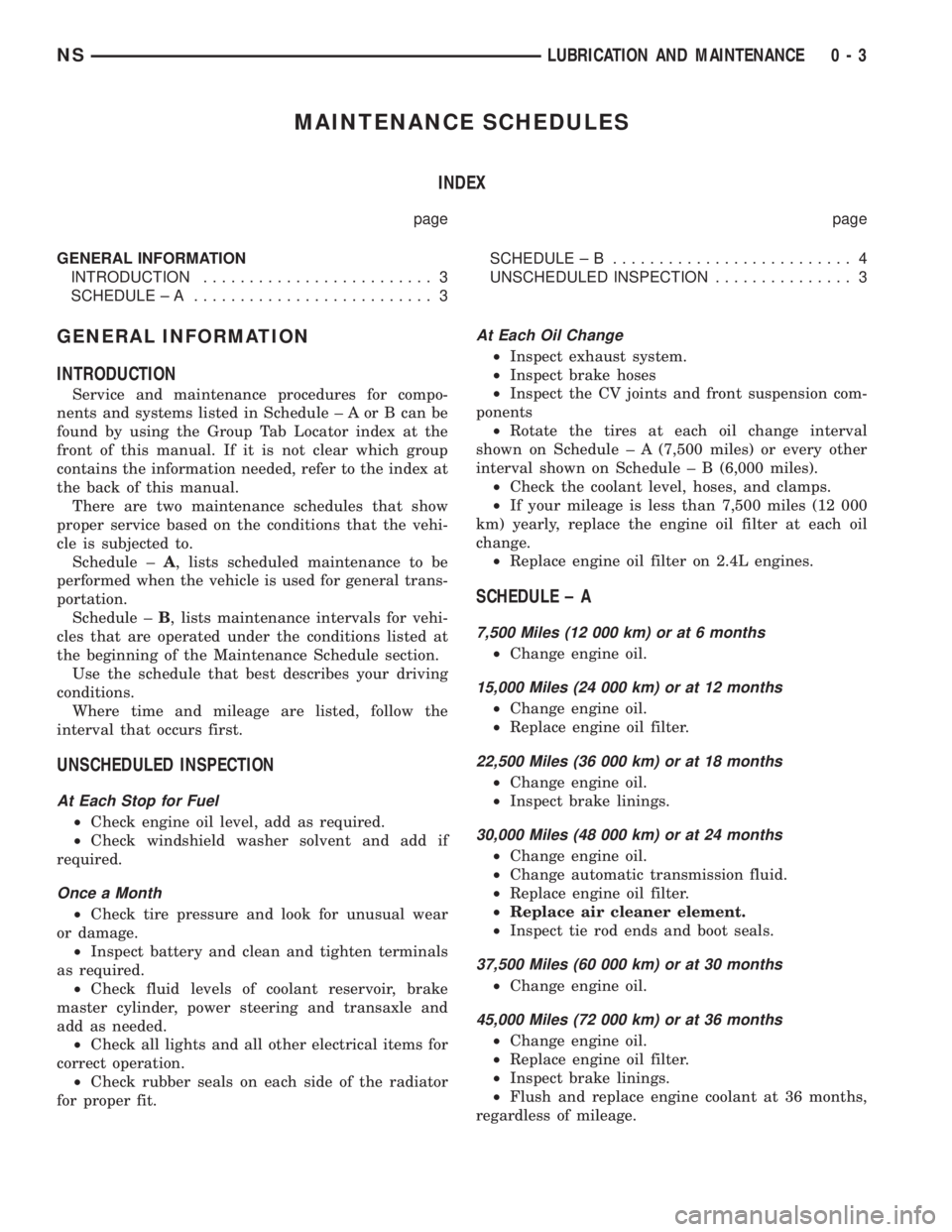

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to.

Schedule ±A, lists scheduled maintenance to be

performed when the vehicle is used for general trans-

portation.

Schedule ±B, lists maintenance intervals for vehi-

cles that are operated under the conditions listed at

the beginning of the Maintenance Schedule section.

Use the schedule that best describes your driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on Schedule ± B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter on 2.4L engines.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect brake linings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Change automatic transmission fluid.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect tie rod ends and boot seals.

37,500 Miles (60 000 km) or at 30 months

²Change engine oil.

45,000 Miles (72 000 km) or at 36 months

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

²Flush and replace engine coolant at 36 months,

regardless of mileage.

NSLUBRICATION AND MAINTENANCE 0 - 3

Page 28 of 1938

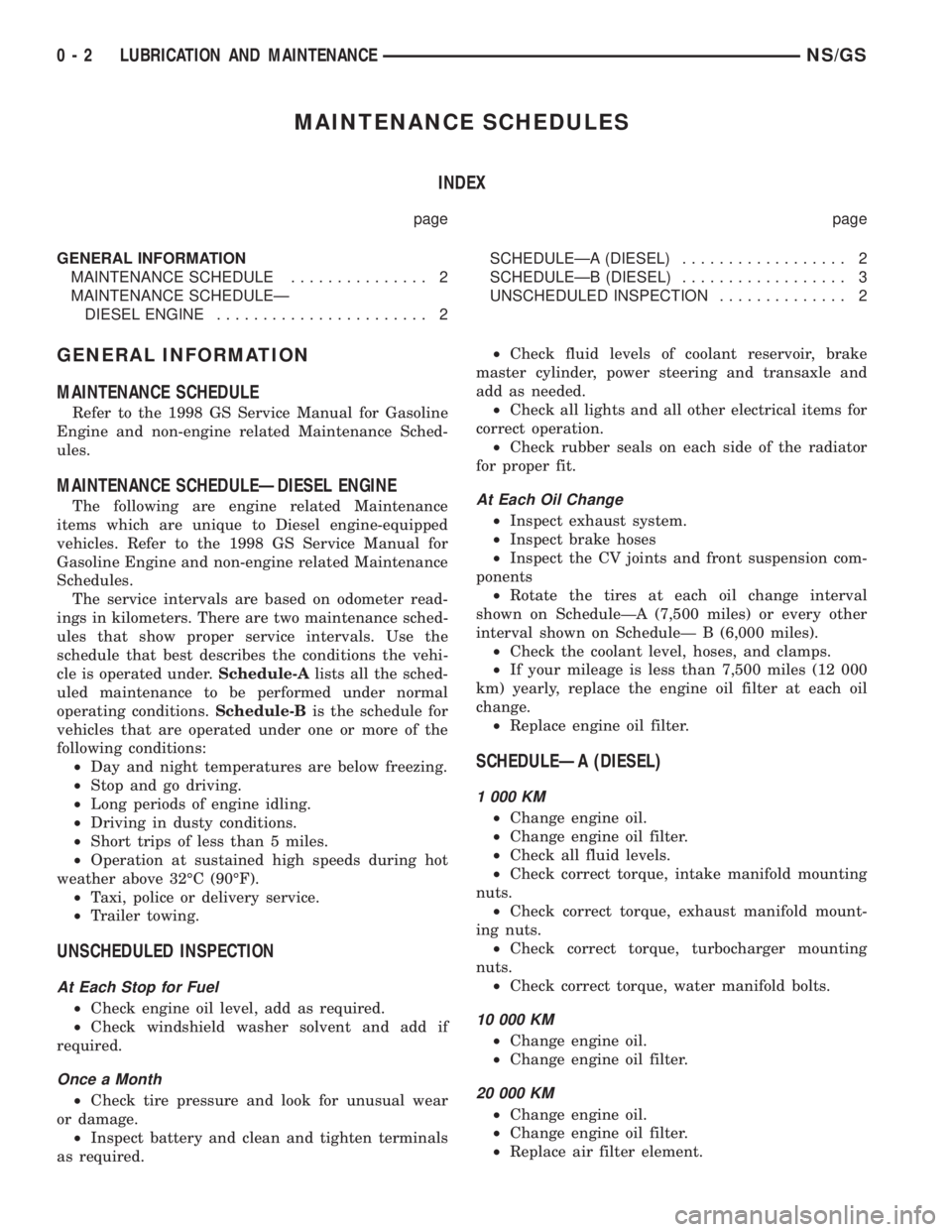

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

MAINTENANCE SCHEDULE............... 2

MAINTENANCE SCHEDULEÐ

DIESEL ENGINE....................... 2SCHEDULEÐA (DIESEL).................. 2

SCHEDULEÐB (DIESEL).................. 3

UNSCHEDULED INSPECTION.............. 2

GENERAL INFORMATION

MAINTENANCE SCHEDULE

Refer to the 1998 GS Service Manual for Gasoline

Engine and non-engine related Maintenance Sched-

ules.

MAINTENANCE SCHEDULEÐDIESEL ENGINE

The following are engine related Maintenance

items which are unique to Diesel engine-equipped

vehicles. Refer to the 1998 GS Service Manual for

Gasoline Engine and non-engine related Maintenance

Schedules.

The service intervals are based on odometer read-

ings in kilometers. There are two maintenance sched-

ules that show proper service intervals. Use the

schedule that best describes the conditions the vehi-

cle is operated under.Schedule-Alists all the sched-

uled maintenance to be performed under normal

operating conditions.Schedule-Bis the schedule for

vehicles that are operated under one or more of the

following conditions:

²Day and night temperatures are below freezing.

²Stop and go driving.

²Long periods of engine idling.

²Driving in dusty conditions.

²Short trips of less than 5 miles.

²Operation at sustained high speeds during hot

weather above 32ÉC (90ÉF).

²Taxi, police or delivery service.

²Trailer towing.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on ScheduleÐA (7,500 miles) or every other

interval shown on ScheduleÐ B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter.

SCHEDULEÐA (DIESEL)

1 000 KM

²Change engine oil.

²Change engine oil filter.

²Check all fluid levels.

²Check correct torque, intake manifold mounting

nuts.

²Check correct torque, exhaust manifold mount-

ing nuts.

²Check correct torque, turbocharger mounting

nuts.

²Check correct torque, water manifold bolts.

10 000 KM

²Change engine oil.

²Change engine oil filter.

20 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

0 - 2 LUBRICATION AND MAINTENANCENS/GS

Page 36 of 1938

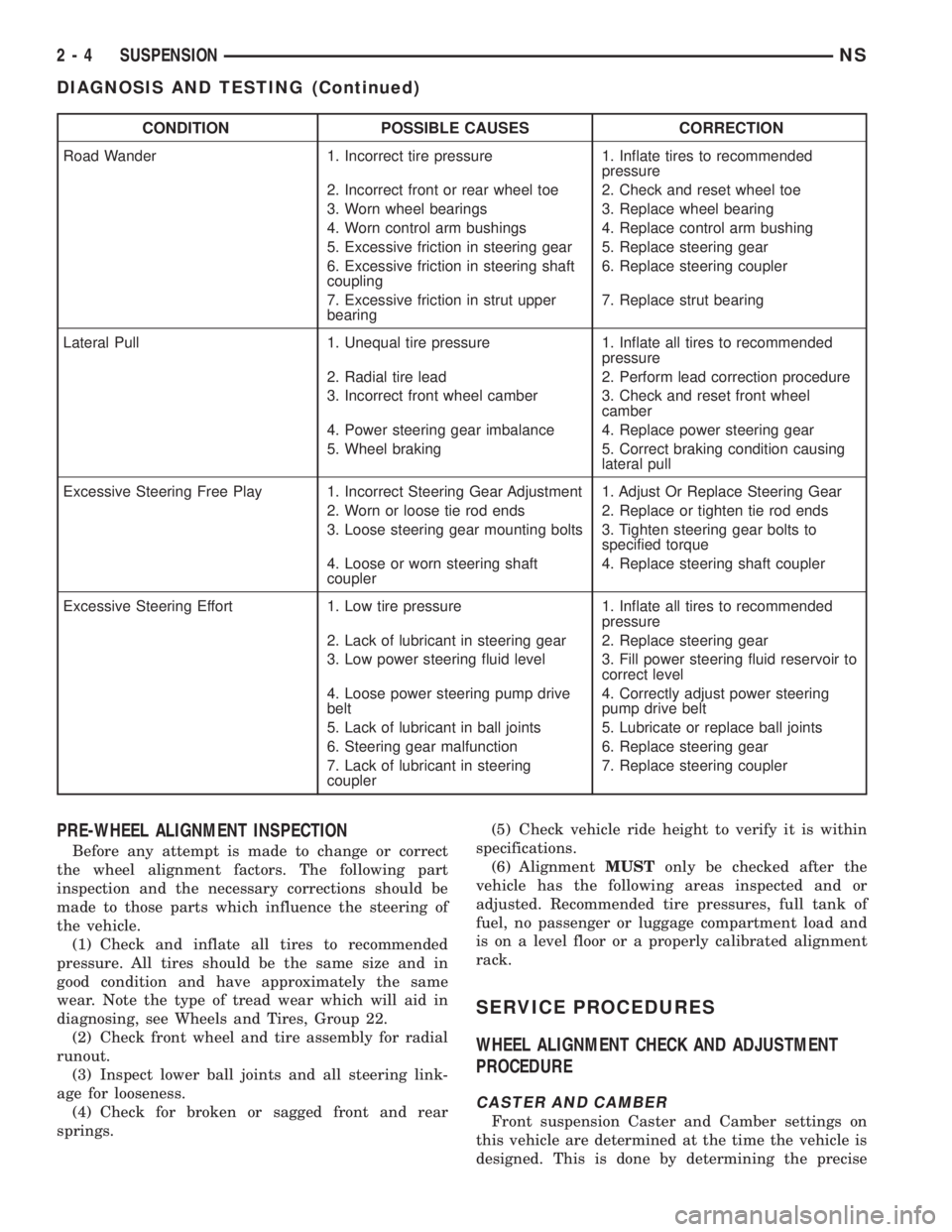

CONDITION POSSIBLE CAUSES CORRECTION

Road Wander 1. Incorrect tire pressure 1. Inflate tires to recommended

pressure

2. Incorrect front or rear wheel toe 2. Check and reset wheel toe

3. Worn wheel bearings 3. Replace wheel bearing

4. Worn control arm bushings 4. Replace control arm bushing

5. Excessive friction in steering gear 5. Replace steering gear

6. Excessive friction in steering shaft

coupling6. Replace steering coupler

7. Excessive friction in strut upper

bearing7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel

camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

Excessive Steering Free Play 1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to

specified torque

4. Loose or worn steering shaft

coupler4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering

pump drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering

coupler7. Replace steering coupler

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment factors. The following part

inspection and the necessary corrections should be

made to those parts which influence the steering of

the vehicle.

(1) Check and inflate all tires to recommended

pressure. All tires should be the same size and in

good condition and have approximately the same

wear. Note the type of tread wear which will aid in

diagnosing, see Wheels and Tires, Group 22.

(2) Check front wheel and tire assembly for radial

runout.

(3) Inspect lower ball joints and all steering link-

age for looseness.

(4) Check for broken or sagged front and rear

springs.(5) Check vehicle ride height to verify it is within

specifications.

(6) AlignmentMUSTonly be checked after the

vehicle has the following areas inspected and or

adjusted. Recommended tire pressures, full tank of

fuel, no passenger or luggage compartment load and

is on a level floor or a properly calibrated alignment

rack.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER AND CAMBER

Front suspension Caster and Camber settings on

this vehicle are determined at the time the vehicle is

designed. This is done by determining the precise

2 - 4 SUSPENSIONNS

DIAGNOSIS AND TESTING (Continued)

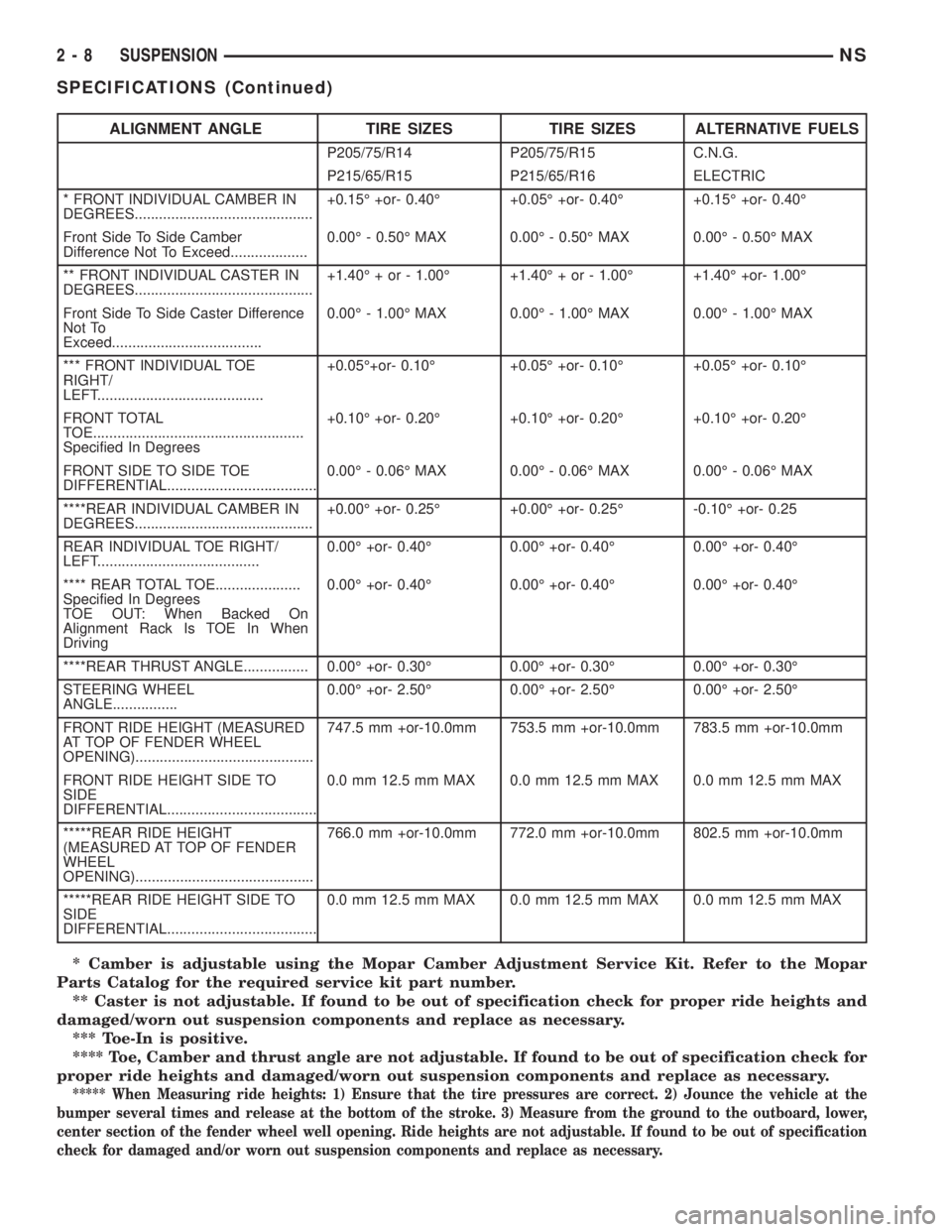

Page 40 of 1938

* Camber is adjustable using the Mopar Camber Adjustment Service Kit. Refer to the Mopar

Parts Catalog for the required service kit part number.

** Caster is not adjustable. If found to be out of specification check for proper ride heights and

damaged/worn out suspension components and replace as necessary.

*** Toe-In is positive.

**** Toe, Camber and thrust angle are not adjustable. If found to be out of specification check for

proper ride heights and damaged/worn out suspension components and replace as necessary.

***** When Measuring ride heights: 1) Ensure that the tire pressures are correct. 2) Jounce the vehicle at the

bumper several times and release at the bottom of the stroke. 3) Measure from the ground to the outboard, lower,

center section of the fender wheel well opening. Ride heights are not adjustable. If found to be out of specification

check for damaged and/or worn out suspension components and replace as necessary.

ALIGNMENT ANGLE TIRE SIZES TIRE SIZES ALTERNATIVE FUELS

P205/75/R14 P205/75/R15 C.N.G.

P215/65/R15 P215/65/R16 ELECTRIC

* FRONT INDIVIDUAL CAMBER IN

DEGREES............................................+0.15É +or- 0.40É +0.05É +or- 0.40É +0.15É +or- 0.40É

Front Side To Side Camber

Difference Not To Exceed...................0.00É - 0.50É MAX 0.00É - 0.50É MAX 0.00É - 0.50É MAX

** FRONT INDIVIDUAL CASTER IN

DEGREES............................................+1.40É + or - 1.00É +1.40É + or - 1.00É +1.40É +or- 1.00É

Front Side To Side Caster Difference

Not To

Exceed.....................................0.00É - 1.00É MAX 0.00É - 1.00É MAX 0.00É - 1.00É MAX

*** FRONT INDIVIDUAL TOE

RIGHT/

LEFT.........................................+0.05É+or- 0.10É +0.05É +or- 0.10É +0.05É +or- 0.10É

FRONT TOTAL

TOE....................................................

Specified In Degrees+0.10É +or- 0.20É +0.10É +or- 0.20É +0.10É +or- 0.20É

FRONT SIDE TO SIDE TOE

DIFFERENTIAL.....................................0.00É - 0.06É MAX 0.00É - 0.06É MAX 0.00É - 0.06É MAX

****REAR INDIVIDUAL CAMBER IN

DEGREES............................................+0.00É +or- 0.25É +0.00É +or- 0.25É -0.10É +or- 0.25

REAR INDIVIDUAL TOE RIGHT/

LEFT........................................0.00É +or- 0.40É 0.00É +or- 0.40É 0.00É +or- 0.40É

**** REAR TOTAL TOE.....................

Specified In Degrees

TOE OUT: When Backed On

Alignment Rack Is TOE In When

Driving0.00É +or- 0.40É 0.00É +or- 0.40É 0.00É +or- 0.40É

****REAR THRUST ANGLE................ 0.00É +or- 0.30É 0.00É +or- 0.30É 0.00É +or- 0.30É

STEERING WHEEL

ANGLE................0.00É +or- 2.50É 0.00É +or- 2.50É 0.00É +or- 2.50É

FRONT RIDE HEIGHT (MEASURED

AT TOP OF FENDER WHEEL

OPENING)............................................747.5 mm +or-10.0mm 753.5 mm +or-10.0mm 783.5 mm +or-10.0mm

FRONT RIDE HEIGHT SIDE TO

SIDE

DIFFERENTIAL.....................................0.0 mm 12.5 mm MAX 0.0 mm 12.5 mm MAX 0.0 mm 12.5 mm MAX

*****REAR RIDE HEIGHT

(MEASURED AT TOP OF FENDER

WHEEL

OPENING)............................................766.0 mm +or-10.0mm 772.0 mm +or-10.0mm 802.5 mm +or-10.0mm

*****REAR RIDE HEIGHT SIDE TO

SIDE

DIFFERENTIAL.....................................0.0 mm 12.5 mm MAX 0.0 mm 12.5 mm MAX 0.0 mm 12.5 mm MAX

2 - 8 SUSPENSIONNS

SPECIFICATIONS (Continued)

Page 171 of 1938

fluid accumulators temporarily store brake fluid that

is decayed from the wheel brakes during an ABS

cycle. This stored brake fluid is then used by the

pump in the HCU to provide build pressure for the

brake hydraulic system.

Additionally on vehicles that are equipped with

only ABS (non-traction control vehicles) there is a

mini brake fluid accumulator on the secondary

hydraulic circuit which protects the master cylinder's

seals during an ABS stop. There is also a noise

damping chamber on the primary hydraulic circuit.

On ABS equipped vehicles with traction control, in

addition to the brake fluid accumulators there are

also two noise damping chambers in the HCU.

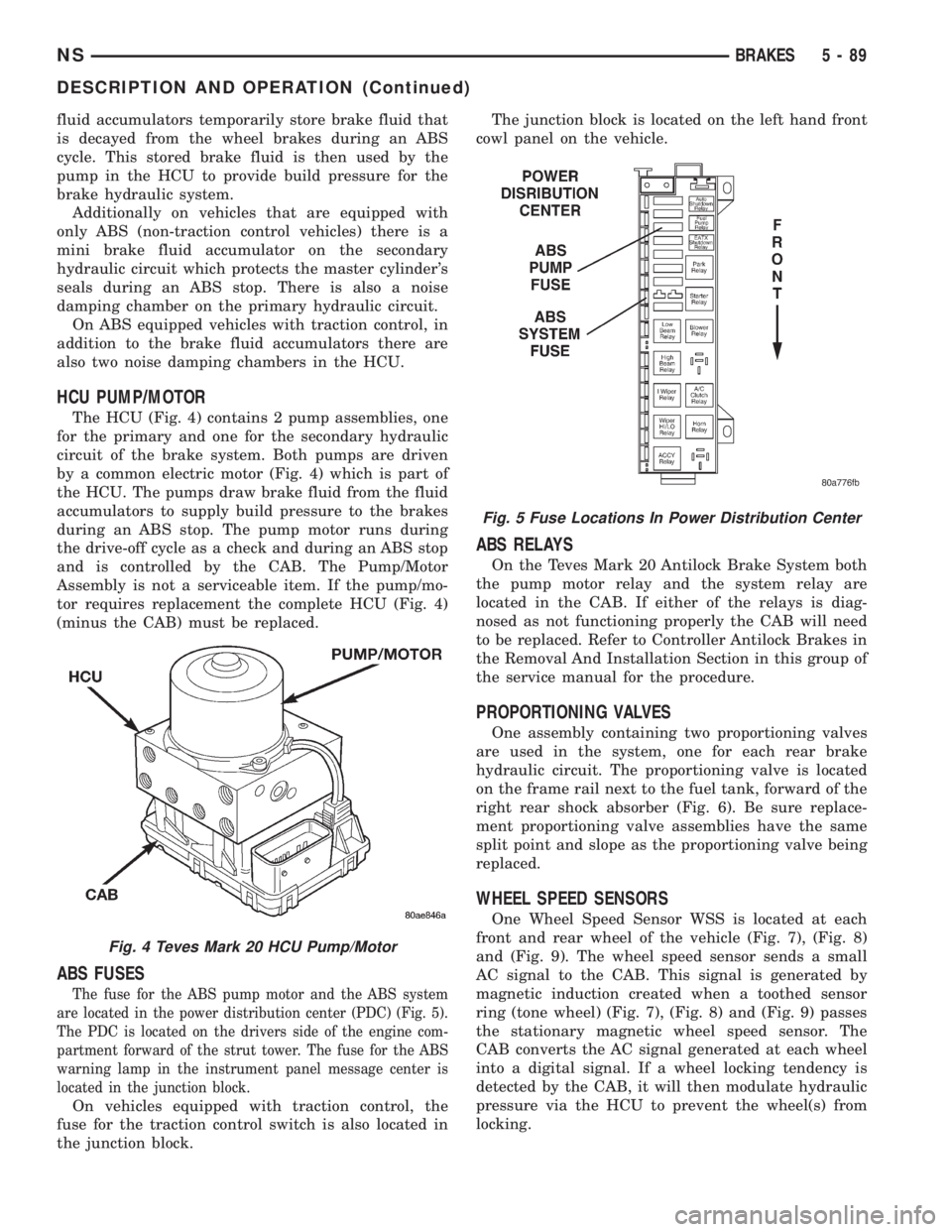

HCU PUMP/MOTOR

The HCU (Fig. 4) contains 2 pump assemblies, one

for the primary and one for the secondary hydraulic

circuit of the brake system. Both pumps are driven

by a common electric motor (Fig. 4) which is part of

the HCU. The pumps draw brake fluid from the fluid

accumulators to supply build pressure to the brakes

during an ABS stop. The pump motor runs during

the drive-off cycle as a check and during an ABS stop

and is controlled by the CAB. The Pump/Motor

Assembly is not a serviceable item. If the pump/mo-

tor requires replacement the complete HCU (Fig. 4)

(minus the CAB) must be replaced.

ABS FUSES

The fuse for the ABS pump motor and the ABS system

are located in the power distribution center (PDC) (Fig. 5).

The PDC is located on the drivers side of the engine com-

partment forward of the strut tower. The fuse for the ABS

warning lamp in the instrument panel message center is

located in the junction block.

On vehicles equipped with traction control, the

fuse for the traction control switch is also located in

the junction block.The junction block is located on the left hand front

cowl panel on the vehicle.

ABS RELAYS

On the Teves Mark 20 Antilock Brake System both

the pump motor relay and the system relay are

located in the CAB. If either of the relays is diag-

nosed as not functioning properly the CAB will need

to be replaced. Refer to Controller Antilock Brakes in

the Removal And Installation Section in this group of

the service manual for the procedure.

PROPORTIONING VALVES

One assembly containing two proportioning valves

are used in the system, one for each rear brake

hydraulic circuit. The proportioning valve is located

on the frame rail next to the fuel tank, forward of the

right rear shock absorber (Fig. 6). Be sure replace-

ment proportioning valve assemblies have the same

split point and slope as the proportioning valve being

replaced.

WHEEL SPEED SENSORS

One Wheel Speed Sensor WSS is located at each

front and rear wheel of the vehicle (Fig. 7), (Fig. 8)

and (Fig. 9). The wheel speed sensor sends a small

AC signal to the CAB. This signal is generated by

magnetic induction created when a toothed sensor

ring (tone wheel) (Fig. 7), (Fig. 8) and (Fig. 9) passes

the stationary magnetic wheel speed sensor. The

CAB converts the AC signal generated at each wheel

into a digital signal. If a wheel locking tendency is

detected by the CAB, it will then modulate hydraulic

pressure via the HCU to prevent the wheel(s) from

locking.

Fig. 4 Teves Mark 20 HCU Pump/Motor

Fig. 5 Fuse Locations In Power Distribution Center

NSBRAKES 5 - 89

DESCRIPTION AND OPERATION (Continued)

Page 300 of 1938

²available manifold vacuum

²barometric pressure

²engine coolant temperature

²engine RPM

²intake air temperature (2.4L only)

²throttle position

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

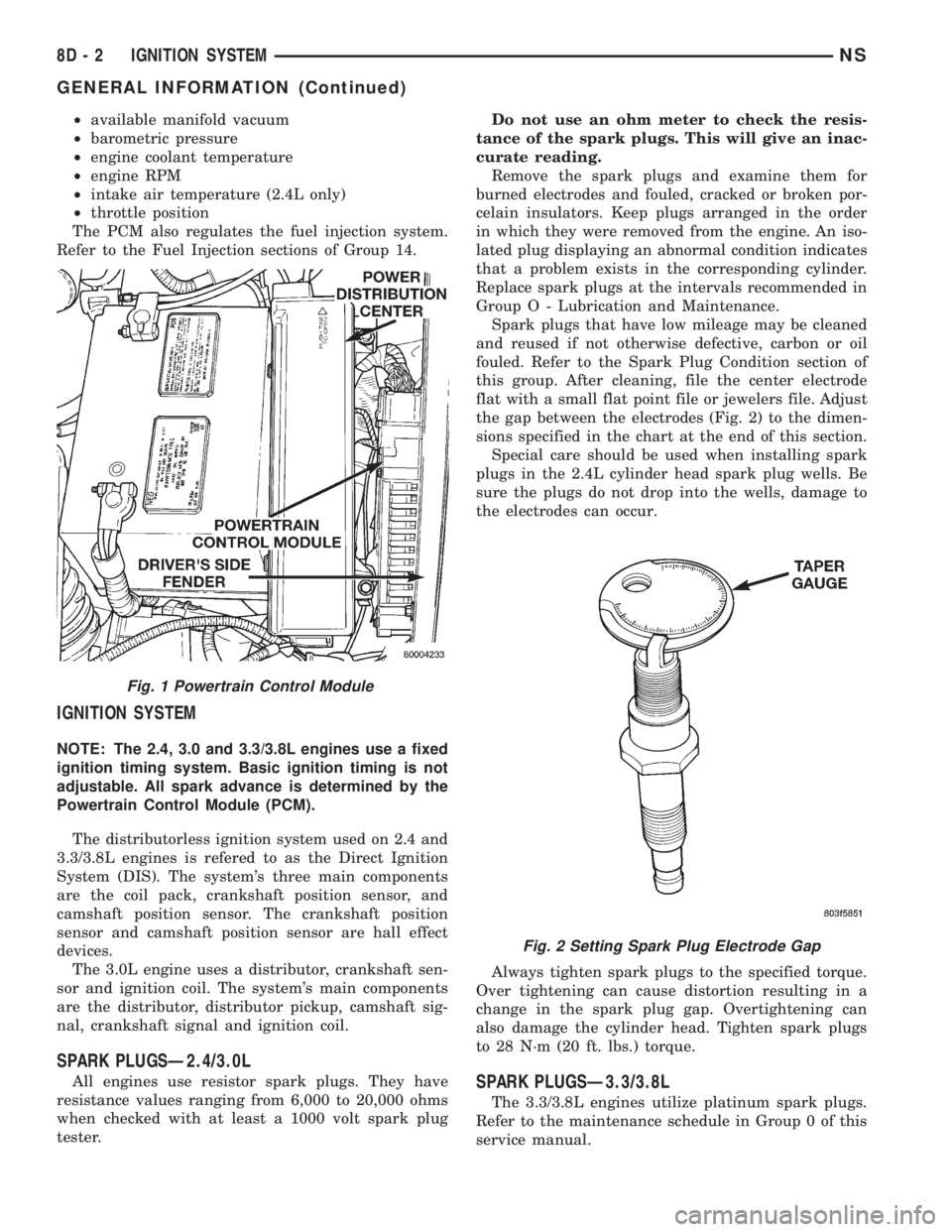

IGNITION SYSTEM

NOTE: The 2.4, 3.0 and 3.3/3.8L engines use a fixed

ignition timing system. Basic ignition timing is not

adjustable. All spark advance is determined by the

Powertrain Control Module (PCM).

The distributorless ignition system used on 2.4 and

3.3/3.8L engines is refered to as the Direct Ignition

System (DIS). The system's three main components

are the coil pack, crankshaft position sensor, and

camshaft position sensor. The crankshaft position

sensor and camshaft position sensor are hall effect

devices.

The 3.0L engine uses a distributor, crankshaft sen-

sor and ignition coil. The system's main components

are the distributor, distributor pickup, camshaft sig-

nal, crankshaft signal and ignition coil.

SPARK PLUGSÐ2.4/3.0L

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O - Lubrication and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective, carbon or oil

fouled. Refer to the Spark Plug Condition section of

this group. After cleaning, file the center electrode

flat with a small flat point file or jewelers file. Adjust

the gap between the electrodes (Fig. 2) to the dimen-

sions specified in the chart at the end of this section.

Special care should be used when installing spark

plugs in the 2.4L cylinder head spark plug wells. Be

sure the plugs do not drop into the wells, damage to

the electrodes can occur.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion resulting in a

change in the spark plug gap. Overtightening can

also damage the cylinder head. Tighten spark plugs

to 28 N´m (20 ft. lbs.) torque.SPARK PLUGSÐ3.3/3.8L

The 3.3/3.8L engines utilize platinum spark plugs.

Refer to the maintenance schedule in Group 0 of this

service manual.

Fig. 1 Powertrain Control Module

Fig. 2 Setting Spark Plug Electrode Gap

8D - 2 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)

Page 304 of 1938

cylinder 4 crankshaft timing marks follow. One cam-

shaft pulse after the 3 pulses indicates cylinder 5.

The 2 camshaft pulses after cylinder 5 signals cylin-

der 6 (Fig. 10). The PCM can synchronize on cylin-

ders1or4.

When metal aligns with the sensor, voltage goes

low (less than 0.3 volts). When a notch aligns with

the sensor, voltage switches high (5.0 volts). As a

group of notches pass under the sensor, the voltage

switches from low (metal) to high (notch) then back

to low. The number of notches determine the amount

of pulses. If available, an oscilloscope can display the

square wave patterns of each timing event.

Top Dead Center (TDC) does not occur when

notches on the camshaft sprocket pass below the cyl-

inder. TDC occurs after the camshaft pulse (or

pulses) and after the 4 crankshaft pulses associated

with the particular cylinder. The arrows and cylinder

call outs on Figure 4 represent which cylinder the

flat spot and notches identify, they do not indicate

TDC position.

The camshaft position sensor is mounted in the

front of the timing case cover (Fig. 11).

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

Powertrain Control Module (PCM). As engine load

changes, manifold pressure varies. The changes in

engine load cause the MAP sensors resistance to

change. The change in MAP sensor resistance results

in a different input voltage to the PCM.

The input voltage level supplies the PCM with

information relating to ambient barometric pressure

during engine start-up (cranking) and engine load

while its operating. Based on MAP sensor voltage

and inputs from other sensors, the PCM adjusts

spark advance and the air-fuel mixture.

ENGINE COOLANT TEMPERATURE (ECT) SENSOR

The ECT sensor is located next to the thermostat

housing (Fig. 12). The sensor provides an input volt-

age to the Powertrain Control Module (PCM). Thesensor is a variable resistance (thermistor) with a

range of -40ÉF to 265ÉF. As coolant temperature var-

ies, the sensors resistance changes, resulting in a dif-

ferent input voltage to the PCM.

The PCM contains different spark advance sched-

ules for cold and warm engine operation. The sched-

ules reduce engine emission and improve driveability.

When the engine is cold, the PCM will demand

slightly richer air-fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

The ECT sensor input is also used for cooling fan

control.

Fig. 9 Camshaft Position Sensor

Fig. 10 Camshaft Sprocket

Fig. 11 Camshaft Position Sensor Location

8D - 6 IGNITION SYSTEMNS

GENERAL INFORMATION (Continued)

Page 309 of 1938

either the crankshaft position sensor/camshaft posi-

tion sensor 8 volt supply circuit, or the camshaft

position sensor output or ground circuits. Use the

DRB scan tool to test the camshaft position sensor

and the sensor circuits. Refer to the appropriate Pow-

ertrain Diagnostics Procedure Manual. Refer to the

wiring diagrams section for circuit information.

IGNITION TIMING PROCEDURE

The engines for this vehicle, use a fixed ignition

system. The PCM regulates ignition timing. Basic

ignition timing is not adjustable.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

Refer to Group 14, Fuel System for Diagnosis and

Testing.

CAMSHAFT POSITION SENSOR AND CRANKSHAFT

POSITION SENSOR

The output voltage of a properly operating cam-

shaft position sensor or crankshaft position sensor

switches from high (5.0 volts) to low (0.3 volts). By

connecting an Moper Diagonostic System (MDS) and

engine analyzer to the vehicle, technicians can view

the square wave pattern.

ENGINE COOLANT TEMPERATURE SENSOR

Refer to Group 14, Fuel System for Diagnosis and

Testing.

INTAKE AIR TEMPERATURE SENSOR

Refer to Group 14, Fuel System, for Diagnosis and

Testing.

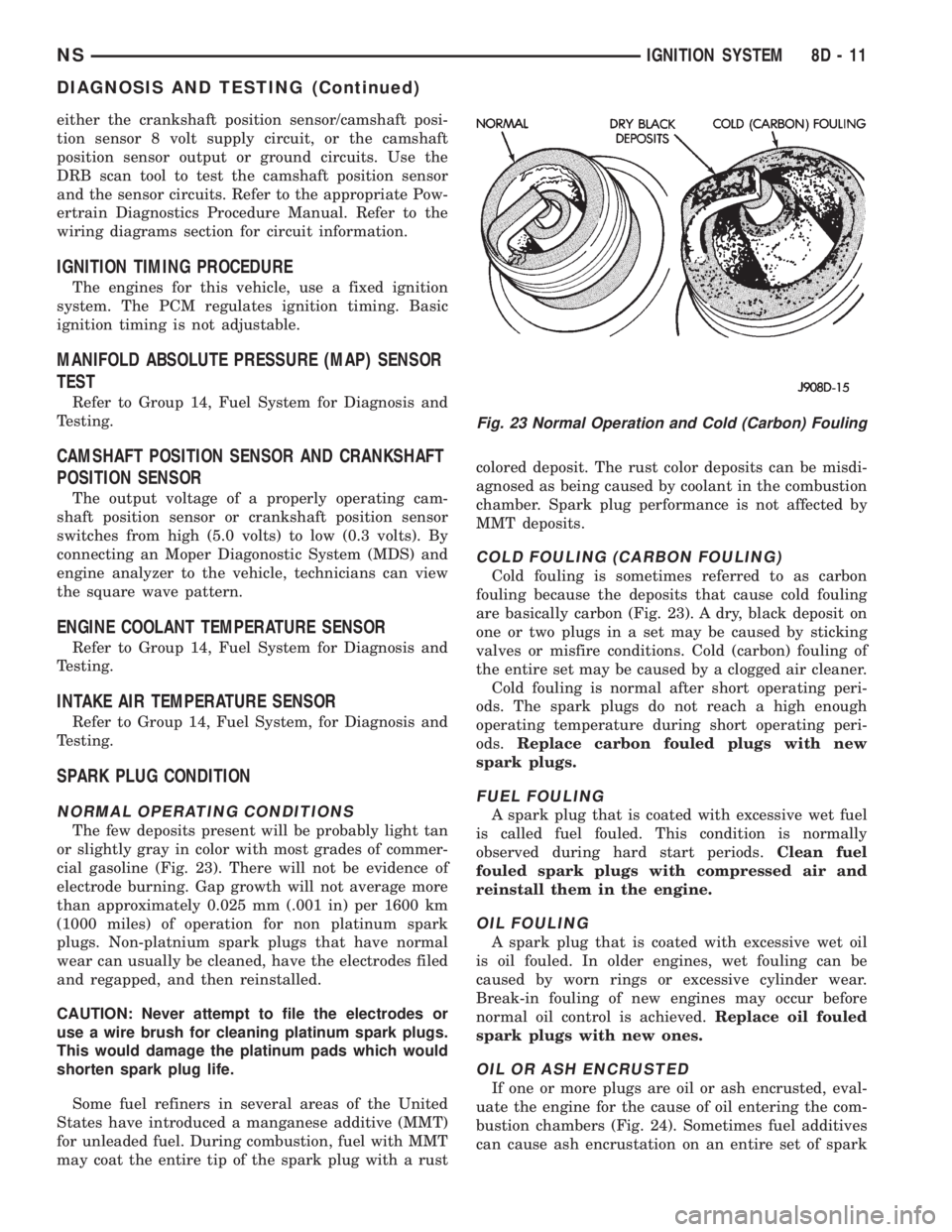

SPARK PLUG CONDITION

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 23). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation for non platinum spark

plugs. Non-platnium spark plugs that have normal

wear can usually be cleaned, have the electrodes filed

and regapped, and then reinstalled.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum spark plugs.

This would damage the platinum pads which would

shorten spark plug life.

Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rustcolored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling

are basically carbon (Fig. 23). A dry, black deposit on

one or two plugs in a set may be caused by sticking

valves or misfire conditions. Cold (carbon) fouling of

the entire set may be caused by a clogged air cleaner.

Cold fouling is normal after short operating peri-

ods. The spark plugs do not reach a high enough

operating temperature during short operating peri-

ods.Replace carbon fouled plugs with new

spark plugs.

FUEL FOULING

A spark plug that is coated with excessive wet fuel

is called fuel fouled. This condition is normally

observed during hard start periods.Clean fuel

fouled spark plugs with compressed air and

reinstall them in the engine.

OIL FOULING

A spark plug that is coated with excessive wet oil

is oil fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur before

normal oil control is achieved.Replace oil fouled

spark plugs with new ones.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or ash encrusted, eval-

uate the engine for the cause of oil entering the com-

bustion chambers (Fig. 24). Sometimes fuel additives

can cause ash encrustation on an entire set of spark

Fig. 23 Normal Operation and Cold (Carbon) Fouling

NSIGNITION SYSTEM 8D - 11

DIAGNOSIS AND TESTING (Continued)

Page 318 of 1938

(1) Install target magnet in end of camshaft.

Tighten mounting screw to 5.65 N´m (50 in. lbs.)

torque.

(2) Install a new O-ring on sensor.

(3) Install camshaft position sensor. Tighten sensor

mounting screws to 9.6 N´m (85 in. lbs.) torque.

(4) Attach engine harness connector to camshaft

position sensor.

(5) Install air cleaner inlet tube and filtered air

tube.

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ2.4/3.3/3.8L

REMOVAL

(1) Disconnect electrical connector from MAP sen-

sor (Fig. 12).

(2) Remove two screws holding sensor to the

intake manifold.

INSTALLATION

(1) Reverse the above procedure for installation.

THROTTLE POSITION SENSOR

Refer to Group 14, Fuel Injection Section, for

Removal/Installation.

ENGINE COOLANT TEMPERATURE SENSORÐ2.4L

The coolant sensor threads into the top of the ther-

mostat housing (Fig. 13). New sensors have sealant

applied to the threads.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE COOLANT TEMPERATURE SENSOR.

REFER TO GROUP 7- COOLING.

Fig. 10 Target Magnet

Fig. 11 Target Magnet Installation

Fig. 12 Map Absolute Pressure Sensor

Fig. 13 Engine Coolant Temperature SensorÐ2.4L

8D - 20 IGNITION SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 321 of 1938

3.0L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

CAMSHAFT POSITION SENSOR............ 23

FIRING ORDERÐ3.0L.................... 23

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR............................. 23

REMOVAL AND INSTALLATION

CRANKSHAFT POSITION SENSOR.......... 25

ENGINE COOLANT TEMPERATURE SENSORÐ

3.0L................................. 25

IGNITION COILÐ3.OL.................... 24

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ3.0L........................ 24SPARK PLUG SERVICE................... 24

THROTTLE POSITION SENSOR............ 25

DISASSEMBLY AND ASSEMBLY

DISTRIBUTORÐ3.0L..................... 26

CLEANING AND INSPECTION

DISTRIBUTOR CAP...................... 26

DISTRIBUTOR ROTORÐ3.0L............... 27

SPECIFICATIONS

SPARK PLUG CABLE RESISTANCEÐ3.0L..... 27

SPARK PLUG........................... 27

TORQUE.............................. 27

DESCRIPTION AND OPERATION

FIRING ORDERÐ3.0L

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

The MAP sensor reacts to absolute pressure in the

intake manifold and provides an input voltage to the

Powertrain Control Module (PCM). As engine load

changes, manifold pressure varies. The changes in

engine load cause the MAP sensors resistance to

change. The change in MAP sensor resistance results

in a different input voltage to the PCM.

The input voltage level supplies the PCM with

information relating to ambient barometric pressure

during engine start-up (cranking) and engine load

while its operating. Based on MAP sensor voltage

and inputs from other sensors, the PCM adjusts

spark advance and the air-fuel mixture.

CAMSHAFT POSITION SENSOR

The PCM determines fuel injection synchronization

and cylinder identification from inputs provided by

the camshaft position sensor and crankshaft position

sensor. From the two inputs, the PCM determines

crankshaft position.

The 3.0L engine is equipped with a camshaft

driven mechanical distributor, containing a shaft

driven distributor rotor. The distributor is also

equipped with an internal camshaft position (fuel

sync) sensor (Fig. 1). This sensor provides fuel injec-

tion synchronization and cylinder identification to

the PCM.

The camshaft position sensor contains a hall effect

device callled a sync signal generator. This sync sig-

nal generator detects a rotating pulse ring (shutter)

on the distributor shaft. The pulse ring rotates 180

through the sync signal generator. Its signal is used

in conjunction with the crankshaft position sensor to

differentiate between fuel injection and spark events.

It is also used to synchronize the fuel injectors with

their respective cylinders.

When the leading edge of the shutter enters the

sync signal generator, the interruption of magnetic

field causes the voltage to switch high. This causes a

sync signal of approximately 5 volts.

When the trailing edge of the shutter leaves the

sync signal generator, the change of magnetic field

causes the sync signal voltage to switch low to 0

volts.

Since the shutter rotates at half crankshaft speed,

it may take 1 engine revolution during cranking for

the PCM to determine the position of piston number

6.

SPARK PLUG WIRE ROUTINGÐ3.0L ENGINE

NSIGNITION SYSTEM 8D - 23