width CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 305 of 1938

THROTTLE POSITION SENSOR (TPS)

The TPS mounts to the side of the throttle body

(Fig. 13).

The TPS connects to the throttle blade shaft. The

TPS is a variable resistor that provides the Power-

train Control Module (PCM) with an input signal

(voltage). The signal represents throttle blade posi-

tion. As the position of the throttle blade changes,

the resistance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.40 volt at minimum throttle

opening (idle) to a maximum of 3.80 volts at wide

open throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

LOCK KEY CYLINDER

The lock cylinder is inserted in the end of the

housing opposite the ignition switch. The ignition key

rotates the cylinder to 5 different detents (Fig. 14):

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

KNOCK SENSOR

The knock sensor threads into the side of the cyl-

inder block in front of the starter motor. When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increase, the knock

sensor output voltage also increases.

Fig. 12 Engine Coolant Temperature SensorÐ3.3/

3.8LFig. 13 Throttle Position Sensor and Idle Air Control

Motor

Fig. 14 Ignition Lock Cylinder Detents

NSIGNITION SYSTEM 8D - 7

GENERAL INFORMATION (Continued)

Page 314 of 1938

2.4L ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

CAMSHAFT POSITION SENSOR............ 17

CRANKSHAFT POSITION SENSOR.......... 16

FIRING ORDERÐ2.4L.................... 16

INTAKE AIR TEMPERATURE SENSORÐ2.4L . . . 17

REMOVAL AND INSTALLATION

CAMSHAFT POSITION SENSOR............ 19

CRANKSHAFT POSITION SENSOR.......... 19

ENGINE COOLANT TEMPERATURE SENSORÐ

2.4L................................. 20

IGNITION COILÐ2.4L..................... 18

INTAKE AIR TEMPERATURE SENSORÐ2.4L . . . 21KNOCK SENSORÐ2.4L................... 21

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSORÐ2.4/3.3/3.8L.................. 20

SPARK PLUG CABLE SERVICEÐ2.4L........ 18

SPARK PLUG SERVICE................... 18

THROTTLE POSITION SENSOR............ 20

SPECIFICATIONS

IGNITION COIL......................... 22

SPARK PLUG CABLE RESISTANCEÐ2.4L..... 22

SPARK PLUG........................... 22

TORQUE.............................. 22

DESCRIPTION AND OPERATION

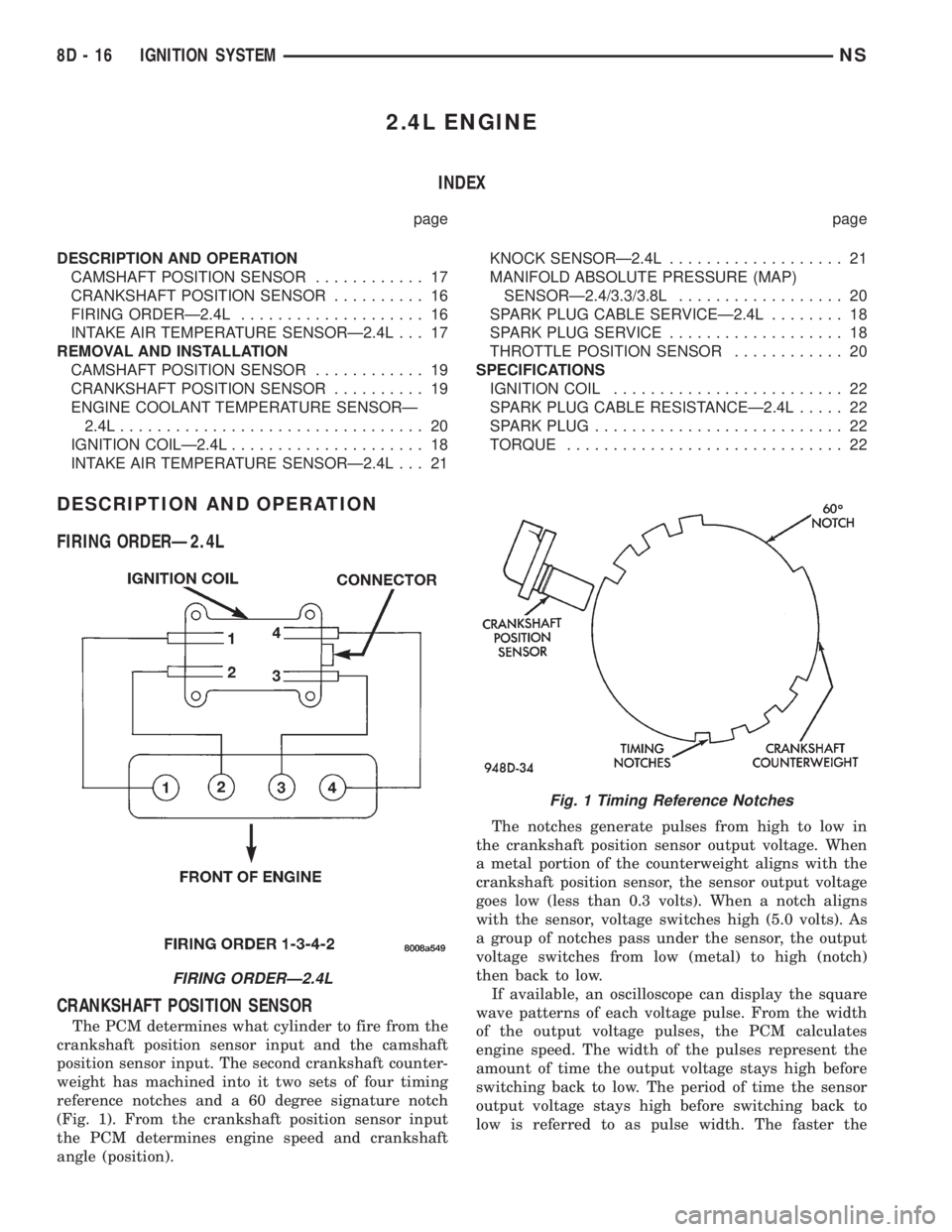

FIRING ORDERÐ2.4L

CRANKSHAFT POSITION SENSOR

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has machined into it two sets of four timing

reference notches and a 60 degree signature notch

(Fig. 1). From the crankshaft position sensor input

the PCM determines engine speed and crankshaft

angle (position).The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.3 volts). When a notch aligns

with the sensor, voltage switches high (5.0 volts). As

a group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulse. From the width

of the output voltage pulses, the PCM calculates

engine speed. The width of the pulses represent the

amount of time the output voltage stays high before

switching back to low. The period of time the sensor

output voltage stays high before switching back to

low is referred to as pulse width. The faster the

FIRING ORDERÐ2.4L

Fig. 1 Timing Reference Notches

8D - 16 IGNITION SYSTEMNS

Page 315 of 1938

engine is operating, the smaller the pulse width on

the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in each

set represents 9 degrees before top dead center

(TDC).

The timing reference notches are machined to a

uniform width representing 13.6 degrees of crank-

shaft rotation. From the voltage pulse width the

PCM tells the difference between the timing refer-

ence notches and the 60 degree signature notch. The

60 degree signature notch produces a longer pulse

width than the smaller timing reference notches. If

the camshaft position sensor input switches from

high to low when the 60 degree signature notch

passes under the crankshaft position sensor, the

PCM knows cylinder number one is the next cylinder

at TDC.

The crankshaft position sensor mounts to the

engine block behind the generator, near the oil filter

(Fig. 8).

CAMSHAFT POSITION SENSOR

The PCM determines fuel injection synchronization

and cylinder identification from inputs provided by

the camshaft position sensor and crankshaft position

sensor. From the two inputs, the PCM determines

crankshaft position.The camshaft position sensor attaches to the rear

of the cylinder head (Fig. 2). A target magnet

attaches to the rear of the camshaft and indexes to

the correct position (Fig. 3). The target magnet has

four different poles arranged in an asymmetrical pat-

tern. As the target magnet rotates, the camshaft

position sensor senses the change in polarity (Fig. 4).

The sensor output switch switches from high (5.0

volts) to low (0.30 volts) as the target magnet rotates.

When the north pole of the target magnet passes

under the sensor, the output switches high. The sen-

sor output switches low when the south pole of the

target magnet passes underneath.

INTAKE AIR TEMPERATURE SENSORÐ2.4L

The intake air temperature sensor measures the

temperature of the air as it enters the engine. The

sensor supplies one of the inputs the PCM uses to

determine injector pulse width and spark advance.

The intake air temperature sensor threads into the

intake manifold (Fig. 5).

Fig. 2 Crankshaft Position Sensor

Fig. 3 Target Magnet

Fig. 4 Target Magnet Polarity

NSIGNITION SYSTEM 8D - 17

DESCRIPTION AND OPERATION (Continued)

Page 676 of 1938

POWERTRAIN

CONTROL

MODULE C2

68

PK/BK18 K52

CONTROL SOLENOID EVAP/PURGE

2

1

SOLENOID

PURGE

EVAP/

57C2C249C248C258 3

4

MOTOR CONTROL

AIR

IDLEMOTOR

NO.1

DRIVER

2

1

K39

18

GY/RDK60

18

YL/BKK40

18

BR/WTK59

18

VT/BK

C270K70

18

VT/RD

CONTROLAIR IDLE IDLE

AIR

CONTROL

DRIVERNO.2 MOTORIDLE

AIR

CONTROL

DRIVERNO.3 MOTORIDLE

AIR

CONTROL

DRIVERNO.4 MOTOR

MOTOR

NO.4

DRIVER CONTROLAIR IDLE

MOTOR

NO.3

DRIVER CONTROLAIR IDLE

MOTOR

NO.2

DRIVER CONTROLAIR IDLE IDLE

AIR

DRIVERNO.1 MOTOR CONTROL MODULATED

PURGE

CURRENT

SENSEWIDTH PULSE

8W - 30 - 12 8W-30 FUEL/IGNITION SYSTEM

2.0LNS/GS

J988W-3GS003012

Page 682 of 1938

POWERTRAIN

CONTROL

MODULE

9A

PTC

1

C268

PK/BK18 K52

ST-RUN A21

JUNCTION

BLOCK

30C1

F87

18

WT/BK

POWER

DISTRIBUTION

CENTER

6C2

6C6

F87

18

WT/BK

2

1

SOLENOID PURGE

EVAP/

E69

F09

7

K52

18

PK/BK

ES07

F87

18

WT/BK

GY/YL18 K35

1

2

EGR

SOLENOID

CONTROL 40

C1 C272

PUMP DETECTION

LEAK

EVAP

3

1

K107

18

YL/BK

WT/BK18 F87

WT/DG18 K106

2

77

C2

PUMP DETECTIONLEAK

SENSE SWITCH SOLENOID

CONTROLLEAK

DETECTION

PUMP (ST-RUN)IGN. FUSE

SOLENOID

CONTROL SENSE SWITCH

57

C2C249C248C258 3

4

MOTOR CONTROL

AIR

IDLEMOTOR

NO. 1

DRIVER

2

1

K39

18

GY/RDK60

18

YL/BKK40

18

BR/WTK59

18

VT/BK

70

C2

6

K70

18

VT/RD

K70

18

VT/RD

(MTX) SOLENOID

EGR

EVAP/

PURGE

SOLENOID

CONTROL PURGE MODULATEDWIDTH PULSECONTROLAIR IDLE

DRIVERNO. 2 MOTOR CONTROLAIR IDLE

DRIVERNO. 3 MOTOR CONTROLAIR IDLE

DRIVERNO. 4 MOTOR CONTROLAIR IDLE

IDLE

AIR

CONTROL

MOTOR

NO. 4

DRIVER IDLE

AIR

CONTROL

MOTOR

NO. 3

DRIVER IDLE

AIR

CONTROL

MOTOR

NO. 2

DRIVER IDLE

AIR

DRIVERNO. 1 MOTOR CONTROL

CURRENT

SENSEPUMP DETECTIONLEAK

DETECTIONLEAK

PUMP

BUILT-UP

-EXPORT) (EXCEPT

(8W-12-13)(8W-10-16)

(8W-12-2)

(8W-10-29)

(8W-12-13)

8W - 30 - 18 8W-30 FUEL/IGNITION SYSTEM

2.4LNS/GS

J988W-3GS003018

Page 690 of 1938

POWERTRAIN

CONTROL

MODULE

9A

PTC

1

C268

PK/BK18 K52

SOLENOIDPURGEEVAP/

ST-RUN A21

JUNCTION

BLOCK

30C1

F87

18

WT/BK

POWER

DISTRIBUTION

CENTER

6C2

6C6

F87

18

WT/BK

2

1

SOLENOID PURGE

EVAP/

ES07

C2

72

PUMP DETECTION

LEAK

EVAP

3

1

K107

18

DB/WT

WT/BK18 F87

WT/DG18 K106

2

77

C2

(ST-RUN)IGN. FUSE

SOLENOID

CONTROL SENSE SWITCH

57

C2C249C248C258 3

4

MOTOR CONTROL

AIR

IDLEMOTOR

NO. 1

DRIVER

2

1

K39

18

GY/RDK60

18

YL/BKK40

18

BR/WTK59

18

VT/BK

SENSE SWITCHPUMP DETECTIONLEAK

LEAK

DETECTION

PUMP

SOLENOID

CONTROL PULSE

WIDTH

MODULATED

PURGE

70C2BUILT-UP

-EXPORT) (EXCEPT

K70

18

VT/RD

CONTROLCONTROLAIR IDLE IDLE

AIR

CONTROL

NO. 2 MOTOR MOTOR

NO. 4 CONTROLAIR IDLE IDLE

AIR

CONTROL

NO. 3 MOTOR

PUMP DETECTIONLEAK

PUMP DETECTIONLEAK

MOTOR

NO. 3 CONTROLAIR IDLE IDLE

AIR

CONTROL

NO. 4 MOTOR MOTOR

NO. 2 CONTROLAIR IDLE IDLE

AIR

CONTROL

DRIVERNO. 1 MOTOR

CURRENTDRIVER DRIVER DRIVER

DRIVER DRIVER DRIVER SENSE(8W-12-13)(8W-10-16)

(8W-12-2)

(8W-10-29)

(8W-12-13)

8W - 30 - 26 8W-30 FUEL/IGNITION SYSTEM

3.3L/3.8LNS/GS

J988W-3GS003026

Page 948 of 1938

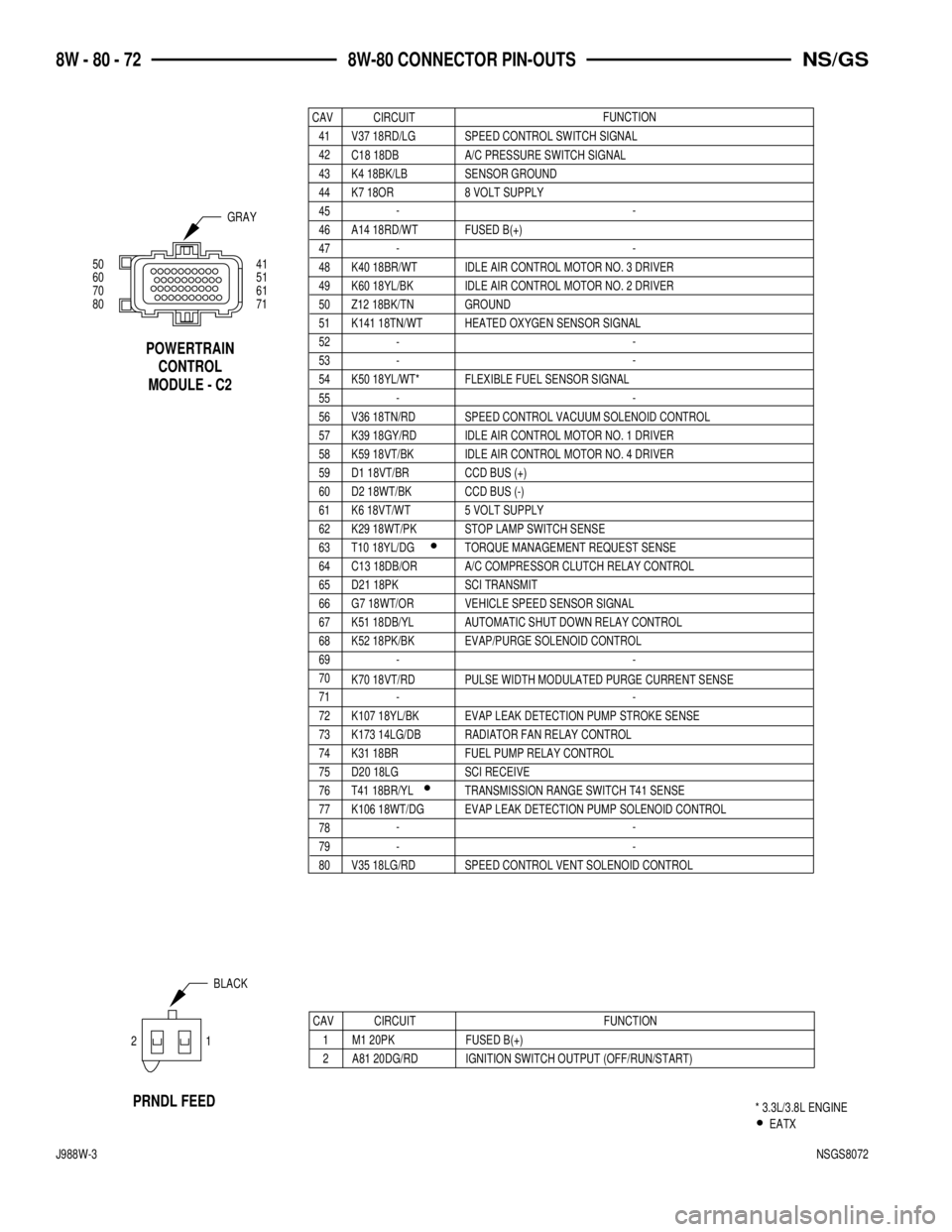

MODULE - C2CONTROL POWERTRAIN

K70 18VT/RD PULSE WIDTH MODULATED PURGE CURRENT SENSE- -

80 7161 51 41

70 60 50GRAY

V35 18LG/RD K106 18WT/DG T41 18BR/YL D20 18LG K31 18BR

K173 14LG/DB K107 18YL/BK K52 18PK/BK K51 18DB/YL G7 18WT/OR D21 18PK C13 18DB/OR T10 18YL/DG K29 18WT/PK

K6 18VT/WT D2 18WT/BK D1 18VT/BR

K59 18VT/BK K39 18GY/RD V36 18TN/RD K141 18TN/WT Z12 18BK/TN

K60 18YL/BK K40 18BR/WT A14 18RD/WT K7 18OR K4 18BK/LB C18 18DB V37 18RD/LG

80 79 78

77 76 75

74 73 72

71 70 69

68 67 66 65 64 63

62 61 60

59 58 57

56 55 54

53 52 51

50 49 48

47 46 45

44 43 42

41 CAV SPEED CONTROL VENT SOLENOID CONTROL EVAP LEAK DETECTION PUMP SOLENOID CONTROL TRANSMISSION RANGE SWITCH T41 SENSE SCI RECEIVE FUEL PUMP RELAY CONTROL

RADIATOR FAN RELAY CONTROL EVAP LEAK DETECTION PUMP STROKE SENSE EVAP/PURGE SOLENOID CONTROL AUTOMATIC SHUT DOWN RELAY CONTROL VEHICLE SPEED SENSOR SIGNAL SCI TRANSMIT A/C COMPRESSOR CLUTCH RELAY CONTROL TORQUE MANAGEMENT REQUEST SENSE STOP LAMP SWITCH SENSE

5 VOLT SUPPLY CCD BUS (-) CCD BUS (+)

IDLE AIR CONTROL MOTOR NO. 4 DRIVER IDLE AIR CONTROL MOTOR NO. 1 DRIVER SPEED CONTROL VACUUM SOLENOID CONTROL HEATED OXYGEN SENSOR SIGNAL GROUND

IDLE AIR CONTROL MOTOR NO. 2 DRIVER IDLE AIR CONTROL MOTOR NO. 3 DRIVER FUSED B(+) 8 VOLT SUPPLY SENSOR GROUND A/C PRESSURE SWITCH SIGNAL SPEED CONTROL SWITCH SIGNAL

- - - - - - - CIRCUIT

- - - - - - - FUNCTION

EATX

- -

* 3.3L/3.8L ENGINE K50 18YL/WT* FLEXIBLE FUEL SENSOR SIGNAL

FUNCTION

CIRCUIT

FUSED B(+)

IGNITION SWITCH OUTPUT (OFF/RUN/START)CAV

1

2M1 20PK

A81 20DG/RD

BLACK

21

PRNDL FEED

8W - 80 - 72 8W-80 CONNECTOR PIN-OUTSNS/GS

J988W-3NSGS8072

Page 1051 of 1938

ENGINE

CONTENTS

page page

2.4L ENGINE............................ 14

3.0L ENGINE............................ 61

3.3/3.8L ENGINE........................ 93ENGINE DIAGNOSIS....................... 7

STANDARD SERVICE PROCEDURES.......... 1

STANDARD SERVICE PROCEDURES

INDEX

page page

GENERAL INFORMATION

CRANKSHAFT SPROCKET BOLT ACCESS

PLUG................................ 2

ENGINE CORE PLUGS.................... 2

ENGINE OIL SERVICE..................... 5

ENGINE OIL............................. 5

ENGINE PERFORMANCE.................. 2FORM-IN-PLACE GASKETS................. 1

HONING CYLINDER BORES................ 3

HYDROSTATIC LOCKED ENGINE............ 5

MEASURING MAIN BEARING AND

CONNECTING ROD BEARING

CLEARANCES......................... 3

REPAIR OF DAMAGED OR WORN THREADS . . . 4

GENERAL INFORMATION

FORM-IN-PLACE GASKETS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets.Do not use

form-in-place gasket material unless specified.

Bead size, continuity, and location are of great impor-

tance. Too thin a bead can result in leakage while too

much can result in spill-over, a continuous bead of

the proper width is essential to obtain a leak-free

joint.

Two types of form-in-place gasket materials are

used in the engine.MopartSilicone Rubber Adhe-

sive Sealant andMopartGasket Maker, (anaerobic)

each have different properties and cannot be used

interchangeably.

CAUTION: Silicone sealer and anaerobic sealers

each will inhibit the cure of the other and care

should be taken to keep usages separated as much

as possible.

MOPARTSILICONE RUBBER ADHESIVE

SEALANT

MopartSilicone Rubber Adhesive Sealant or

equivalent, normally black in color, is available in

three ounce tubes. Moisture in the air causes the

MopartSilicone Rubber Adhesive Sealant material

to cure. This material is normally used on flexible

metal flanges. It has a shelf life of one year and will

not properly cure if over age. Always inspect the

package for the expiration date before use.

MOPARTGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material normally red in color. The material cures in

the absence of air when squeezed between two metal-

lic surfaces. It will not cure if left in the uncovered

tube. It is normally red in color. The anaerobic mate-

rial is for use between two machined surfaces. Do not

use on flexible metal flanges.

MOPARTTORQUE CURE GASKET MAKER

MopartTorque Cure Gasket Maker is a unique

anaerobic type gasket material to be usedONLY

between the bedplate and engine block. The material

cures in the absence of air when torqued between

two metallic surfaces. It will not cure if left in the

uncovered tube. This anaerobic material is specially

NSENGINE 9 - 1

Page 1054 of 1938

ENGINE WITH 5 MAIN BEARINGS

²When checking #1 main bearing shim #2 main

bearing.

²When checking #2 main bearing shim #1 & 3

main bearing.

²When checking #3 main bearing shim #2 & 4

main bearing.

²When checking #4 main bearing shim #3 & 5

main bearing.

²When checking #5 main bearing shim #4 main

bearing.

ENGINE WITH 4 MAIN BEARING

²When checking #1 main bearing shim # 2 main

bearing.

²When checking #2 main bearing shim #1 & #3

main bearing.

²When checking #3 main bearing shim #2 & #4

main bearing.

²When checking #4 main bearing shim #3 main

bearing.

NOTE: REMOVE ALL SHIMS BEFORE REASSEM-

BLING ENGINE

ALTERNATIVE METHOD

The weight of the crankshaft can be supported by a

jack under the counterweight adjacent to the bearing

being checked.

PLASTIGAGE PROCEDURE

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 3). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage (Fig. 4) with the

metric scale provided on the package. Locate the

band closest to the same width. This band shows theamount of clearance in thousandths of a millimeter.

Differences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Refer to Engine Specifications.Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage or equivalent. The

following is the recommended procedure for the use

of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is at the bottom of its stroke.

(2) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole (Fig. 3). In addition, suspect areas can be

checked by placing plastigage in the suspect area.

(4) Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque.Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.

(5) Remove the bearing cap and compare the

width of the flattened Plastigage (Fig. 4) with the

scale provided on the package. Locate the band clos-

est to the same width. This band indicates the

amount of oil clearance. Differences in readings

between the ends indicate the amount of taper

present. Record all readings taken. Refer to Engine

Specifications.Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale. If the bearing clearance

exceeds 0.076 mm (0.003 in.) replace bearing.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

REPAIR OF DAMAGED OR WORN THREADS

Damaged or worn threads (including aluminum

head spark plug threads) can be repaired. Essen-

tially, this repair consists of drilling out worn or

damaged threads, tapping the hole with a special

Heli-Coil Tap, (or equivalent) and installing an insert

into the tapped hole. This brings the hole back to its

original thread size.

Fig. 4 Clearance Measurement

9 - 4 ENGINENS

GENERAL INFORMATION (Continued)

Page 1063 of 1938

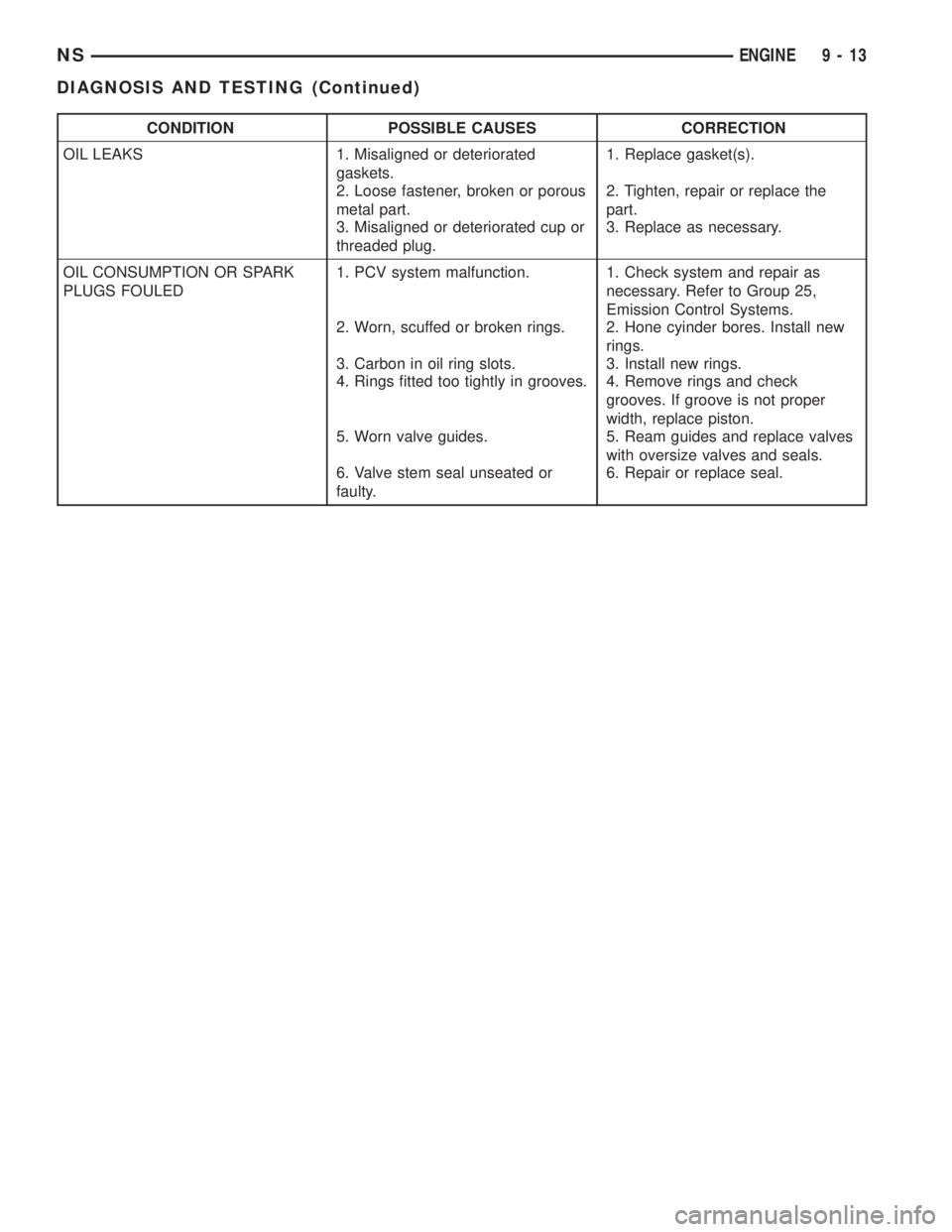

CONDITION POSSIBLE CAUSES CORRECTION

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

OIL CONSUMPTION OR SPARK

PLUGS FOULED1. PCV system malfunction. 1. Check system and repair as

necessary. Refer to Group 25,

Emission Control Systems.

2. Worn, scuffed or broken rings. 2. Hone cyinder bores. Install new

rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check

grooves. If groove is not proper

width, replace piston.

5. Worn valve guides. 5. Ream guides and replace valves

with oversize valves and seals.

6. Valve stem seal unseated or

faulty.6. Repair or replace seal.

NSENGINE 9 - 13

DIAGNOSIS AND TESTING (Continued)