engine CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 144 of 364

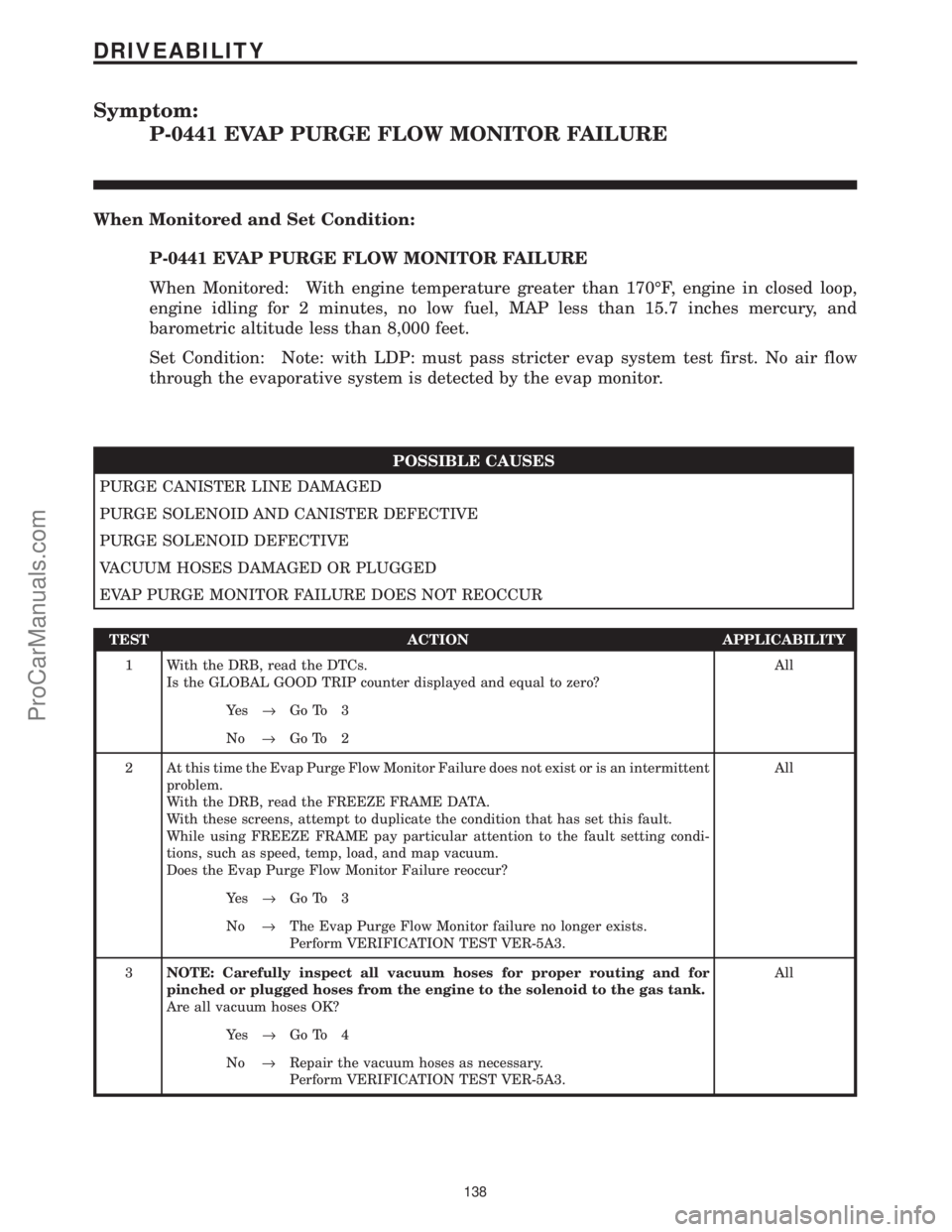

Symptom:

P-0441 EVAP PURGE FLOW MONITOR FAILURE

When Monitored and Set Condition:

P-0441 EVAP PURGE FLOW MONITOR FAILURE

When Monitored: With engine temperature greater than 170ÉF, engine in closed loop,

engine idling for 2 minutes, no low fuel, MAP less than 15.7 inches mercury, and

barometric altitude less than 8,000 feet.

Set Condition: Note: with LDP: must pass stricter evap system test first. No air flow

through the evaporative system is detected by the evap monitor.

POSSIBLE CAUSES

PURGE CANISTER LINE DAMAGED

PURGE SOLENOID AND CANISTER DEFECTIVE

PURGE SOLENOID DEFECTIVE

VACUUM HOSES DAMAGED OR PLUGGED

EVAP PURGE MONITOR FAILURE DOES NOT REOCCUR

TEST ACTION APPLICABILITY

1 With the DRB, read the DTCs.

Is the GLOBAL GOOD TRIP counter displayed and equal to zero?All

Ye s®Go To 3

No®Go To 2

2 At this time the Evap Purge Flow Monitor Failure does not exist or is an intermittent

problem.

With the DRB, read the FREEZE FRAME DATA.

With these screens, attempt to duplicate the condition that has set this fault.

While using FREEZE FRAME pay particular attention to the fault setting condi-

tions, such as speed, temp, load, and map vacuum.

Does the Evap Purge Flow Monitor Failure reoccur?All

Ye s®Go To 3

No®The Evap Purge Flow Monitor failure no longer exists.

Perform VERIFICATION TEST VER-5A3.

3NOTE: Carefully inspect all vacuum hoses for proper routing and for

pinched or plugged hoses from the engine to the solenoid to the gas tank.

Are all vacuum hoses OK?All

Ye s®Go To 4

No®Repair the vacuum hoses as necessary.

Perform VERIFICATION TEST VER-5A3.

138

DRIVEABILITY

ProCarManuals.com

Page 147 of 364

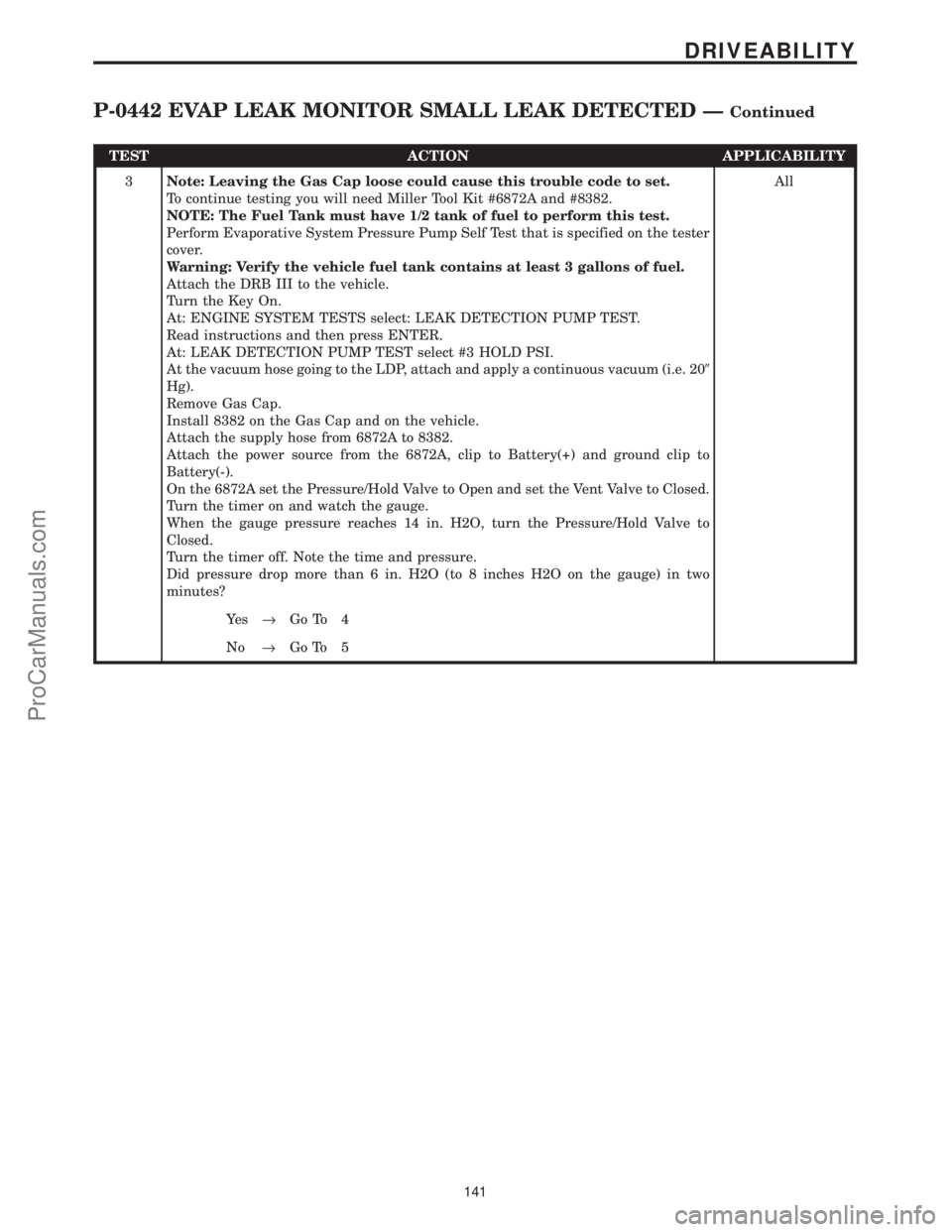

TEST ACTION APPLICABILITY

3Note: Leaving the Gas Cap loose could cause this trouble code to set.

To continue testing you will need Miller Tool Kit #6872A and #8382.

NOTE: The Fuel Tank must have 1/2 tank of fuel to perform this test.

Perform Evaporative System Pressure Pump Self Test that is specified on the tester

cover.

Warning: Verify the vehicle fuel tank contains at least 3 gallons of fuel.

Attach the DRB III to the vehicle.

Turn the Key On.

At: ENGINE SYSTEM TESTS select: LEAK DETECTION PUMP TEST.

Read instructions and then press ENTER.

At: LEAK DETECTION PUMP TEST select #3 HOLD PSI.

At the vacuum hose going to the LDP, attach and apply a continuous vacuum (i.e. 209

Hg).

Remove Gas Cap.

Install 8382 on the Gas Cap and on the vehicle.

Attach the supply hose from 6872A to 8382.

Attach the power source from the 6872A, clip to Battery(+) and ground clip to

Battery(-).

On the 6872A set the Pressure/Hold Valve to Open and set the Vent Valve to Closed.

Turn the timer on and watch the gauge.

When the gauge pressure reaches 14 in. H2O, turn the Pressure/Hold Valve to

Closed.

Turn the timer off. Note the time and pressure.

Did pressure drop more than 6 in. H2O (to 8 inches H2O on the gauge) in two

minutes?All

Ye s®Go To 4

No®Go To 5

141

DRIVEABILITY

P-0442 EVAP LEAK MONITOR SMALL LEAK DETECTED ÐContinued

ProCarManuals.com

Page 148 of 364

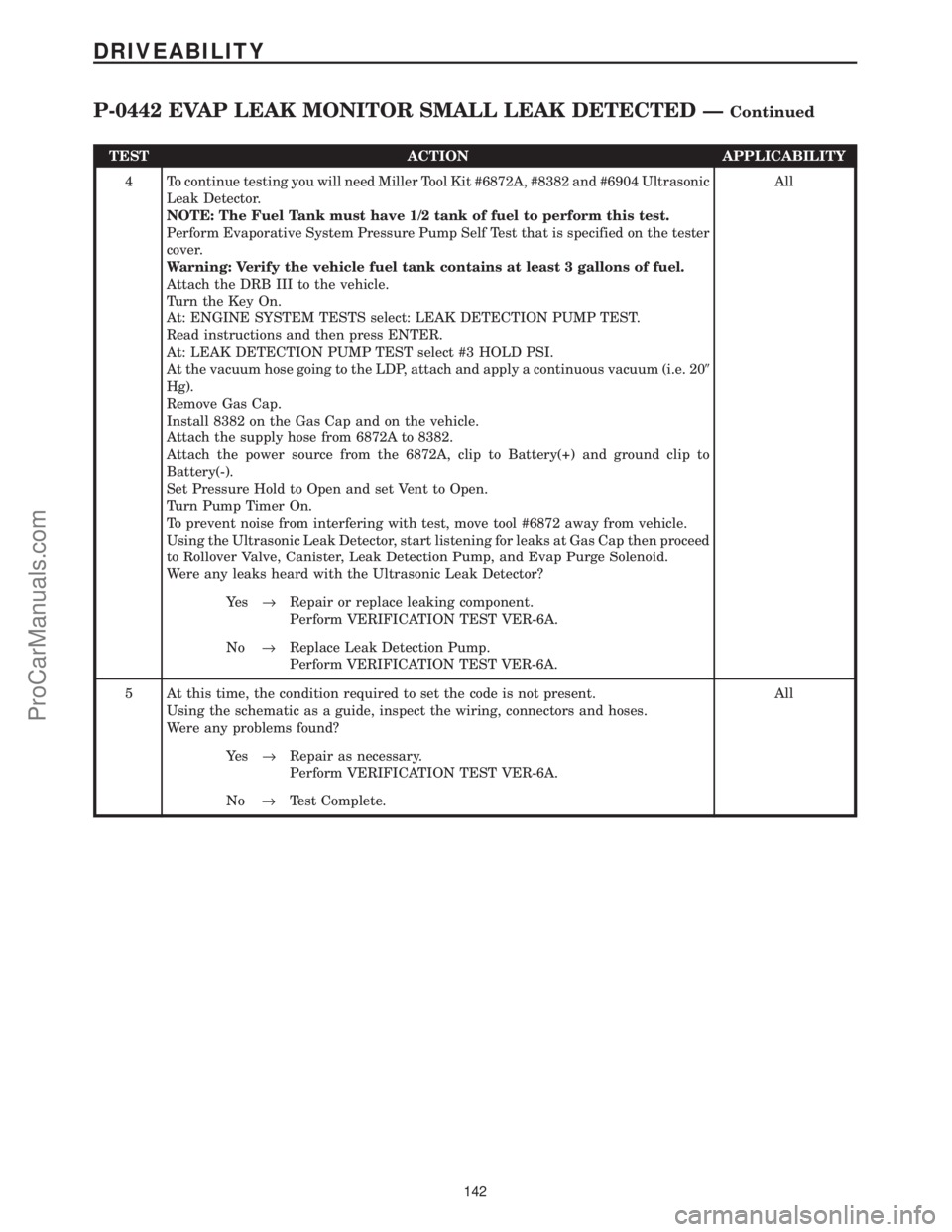

TEST ACTION APPLICABILITY

4 To continue testing you will need Miller Tool Kit #6872A, #8382 and #6904 Ultrasonic

Leak Detector.

NOTE: The Fuel Tank must have 1/2 tank of fuel to perform this test.

Perform Evaporative System Pressure Pump Self Test that is specified on the tester

cover.

Warning: Verify the vehicle fuel tank contains at least 3 gallons of fuel.

Attach the DRB III to the vehicle.

Turn the Key On.

At: ENGINE SYSTEM TESTS select: LEAK DETECTION PUMP TEST.

Read instructions and then press ENTER.

At: LEAK DETECTION PUMP TEST select #3 HOLD PSI.

At the vacuum hose going to the LDP, attach and apply a continuous vacuum (i.e. 209

Hg).

Remove Gas Cap.

Install 8382 on the Gas Cap and on the vehicle.

Attach the supply hose from 6872A to 8382.

Attach the power source from the 6872A, clip to Battery(+) and ground clip to

Battery(-).

Set Pressure Hold to Open and set Vent to Open.

Turn Pump Timer On.

To prevent noise from interfering with test, move tool #6872 away from vehicle.

Using the Ultrasonic Leak Detector, start listening for leaks at Gas Cap then proceed

to Rollover Valve, Canister, Leak Detection Pump, and Evap Purge Solenoid.

Were any leaks heard with the Ultrasonic Leak Detector?All

Ye s®Repair or replace leaking component.

Perform VERIFICATION TEST VER-6A.

No®Replace Leak Detection Pump.

Perform VERIFICATION TEST VER-6A.

5 At this time, the condition required to set the code is not present.

Using the schematic as a guide, inspect the wiring, connectors and hoses.

Were any problems found?All

Ye s®Repair as necessary.

Perform VERIFICATION TEST VER-6A.

No®Test Complete.

142

DRIVEABILITY

P-0442 EVAP LEAK MONITOR SMALL LEAK DETECTED ÐContinued

ProCarManuals.com

Page 149 of 364

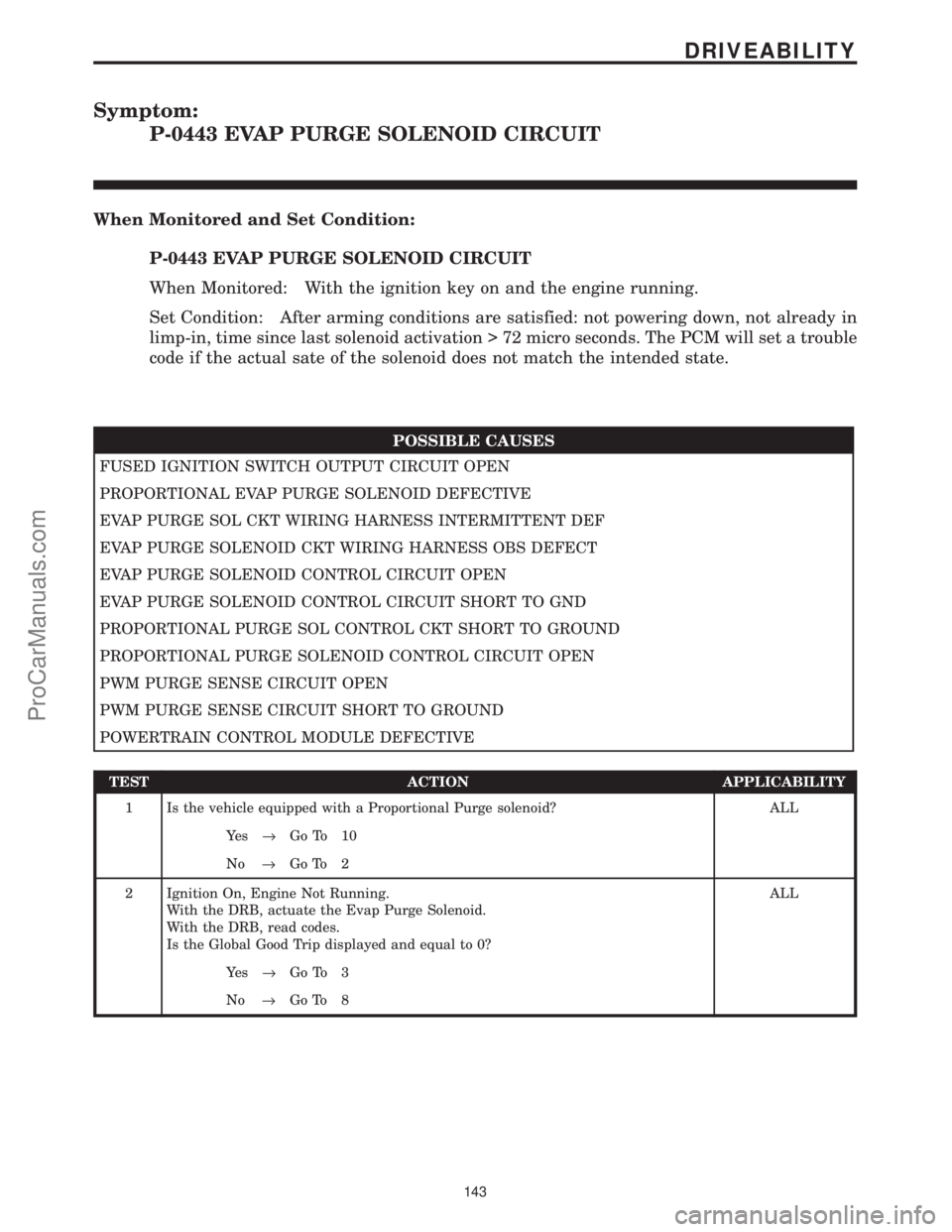

Symptom:

P-0443 EVAP PURGE SOLENOID CIRCUIT

When Monitored and Set Condition:

P-0443 EVAP PURGE SOLENOID CIRCUIT

When Monitored: With the ignition key on and the engine running.

Set Condition: After arming conditions are satisfied: not powering down, not already in

limp-in, time since last solenoid activation > 72 micro seconds. The PCM will set a trouble

code if the actual sate of the solenoid does not match the intended state.

POSSIBLE CAUSES

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

PROPORTIONAL EVAP PURGE SOLENOID DEFECTIVE

EVAP PURGE SOL CKT WIRING HARNESS INTERMITTENT DEF

EVAP PURGE SOLENOID CKT WIRING HARNESS OBS DEFECT

EVAP PURGE SOLENOID CONTROL CIRCUIT OPEN

EVAP PURGE SOLENOID CONTROL CIRCUIT SHORT TO GND

PROPORTIONAL PURGE SOL CONTROL CKT SHORT TO GROUND

PROPORTIONAL PURGE SOLENOID CONTROL CIRCUIT OPEN

PWM PURGE SENSE CIRCUIT OPEN

PWM PURGE SENSE CIRCUIT SHORT TO GROUND

POWERTRAIN CONTROL MODULE DEFECTIVE

TEST ACTION APPLICABILITY

1 Is the vehicle equipped with a Proportional Purge solenoid? ALL

Ye s®Go To 10

No®Go To 2

2 Ignition On, Engine Not Running.

With the DRB, actuate the Evap Purge Solenoid.

With the DRB, read codes.

Is the Global Good Trip displayed and equal to 0?ALL

Ye s®Go To 3

No®Go To 8

143

DRIVEABILITY

ProCarManuals.com

Page 151 of 364

TEST ACTION APPLICABILITY

8 Ignition On, Engine Not Running.

With the DRB, read codes.

With the DRB, actuate the Evap Purge Solenoid.

Wiggle Wiring Harness from the Solenoid to PCM.

Does the Evap Purge Solenoid Control Circuit code return?ALL

Ye s®Repair as necessary where wiggling caused problem to appear.

Perform Powertrain Verification Test VER-5A.

No®Go To 9

9 Ignition Off.

Using the Schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?ALL

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 10

10 Check the freeze frame data to determine the conditions when code was set.

Attempt duplication of 'freeze frame' conditions for added diagnostics.

If there are no other possible causes remaining there is assumed to be an9intermit-

tent9problem with a Wiring Harness Connector or Wire.

View repair options.ALL

Repair

Visually inspect related Wire Harness Connectors and Harnesses.

Look for broken, bent, pushed out, or corroded terminals and for

chafed, pierced, or partiallly broken wire, respectively. Refer to

any hotlines or technical service bulletins that apply.

11 Ignition On, Engine Not Running.

With the DRB, actuate the Evap Purge Solenoid.

With the DRB, read codes.

Is the Global Good Trip displayed and equal to 0?ALL

Ye s®Go To 12

No®Go To 18

12 Ignition Off.

Disconnect Proportional Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of the Proportional Purge Solenoid.

Is the resistance 14.2 ohms +/- 1.4?ALL

Ye s®Go To 13

No®Replace the open Proportional Purge Solenoid.

Perform Powertrain Verification Test VER-5A.

145

DRIVEABILITY

P-0443 EVAP PURGE SOLENOID CIRCUIT ÐContinued

ProCarManuals.com

Page 153 of 364

TEST ACTION APPLICABILITY

16 Ignition Off.

Disconnect Proportional Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the battery.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Using and Ohmmeter, measure the PWM Purge Sense Circuit PCM to Solenoid

Connector.

Is the resistance below 5.0 ohms?ALL

Ye s®Go To 17

No®Repair the open PWM Purge Sense Circuit.

Perform Powertrain Verification Test VER-5A.

17 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.ALL

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

18 Ignition On, Engine Not Running.

With the DRB, actuate the Evap Purge Solenoid.

With the DRB, read codes.

Wiggle Wiring Harness from the Solenoid to PCM.

Does the Evap Purge Solenoid Control Circuit code return?ALL

Ye s®Repair as necessary where wiggling caused problem to appear.

Perform Powertrain Verification Test VER-5A.

No®Go To 19

19 Ignition Off.

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?ALL

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 20

20 Check the freeze frame data to determine the conditions when code was set.

Attempt duplication of 'freeze frame' conditions for added diagnostics.

If there are no other possible causes remaining there is assumed to be an9intermit-

tent9problem with a Wiring Harness Connector or Wire.

View repair options.ALL

Repair

Visually inspect related Wire Harness Connectors and Harnesses.

Look for broken, bent, pushed out, or corroded terminals and for

chafed, pierced, or partiallly broken wire, respectively. Refer to

any hotlines or technical service bulletins that apply.

147

DRIVEABILITY

P-0443 EVAP PURGE SOLENOID CIRCUIT ÐContinued

ProCarManuals.com

Page 159 of 364

Symptom:

P-0500 NO VEHICLE SPEED SENSOR SIGNAL

When Monitored and Set Condition:

P-0500 NO VEHICLE SPEED SENSOR SIGNAL

When Monitored: For 3 Speed: With engine running, transmission not in park or neutral,

brakes not applied, engine rpm greater than 1500. For 4 Speed: With the engine running,

transmission not in park or neutral, brakes not applied, engine rpm greater than 1500.

Set Condition: For 3 Speed: No signal from the vehicle speed sensor for more than 11

seconds for 2 consecutive trips. For 4 Speed: No signal from the vehicle speed sensor (TCM)

is present for more than 11 seconds for 2 consecutive trips.

POSSIBLE CAUSES

ELECTRONIC AUTO TRANSAXLE TROUBLE CODES PRESENT

8-VOLT SUPPLY CIRCUIT OPEN

PCM DEF (NO VSS SIGNAL CKT)

PCM TERMINAL DEFECTIVE

VEHICLE SPEED SENSOR GROUND CIRCUIT OPEN

VEHICLE SPEED SENSOR SIGNAL CIRCUIT WIRING HARNESS OBSERVABLE DEFECT

PINION GEAR DEFECTIVE

OUTPUT SPEED SENSOR CIRCUIT OPEN

OUTPUT SPEED SENSOR CIRCUIT SHORTED TO GROUND

VEHICLE SPEED SENSOR SIGNAL CIRCUIT OPEN

VSS SIGNAL CIRCUIT SHORTED TO GROUND

OUTPUT SPEED SENSOR DEFECTIVE

OUTPUT SPEED SENSOR DEFECTIVE (RES > 5.0)

PCM DEFECTIVE (NO VSS SIGNAL CKT)

PCM DEFECTIVE (NO VSS SIGNAL CKT)

TCM DEFECTIVE (VSS SIG CKT)

VSS DEFECTIVE

153

DRIVEABILITY

ProCarManuals.com

Page 160 of 364

TEST ACTION APPLICABILITY

1 Ignition Off

Raise the Drive Wheels off the ground.

Warning: Be sure to keep hands and feet clear of rotating wheels.

Start Engine.

With DRB, read the Vehicle Speed Sensor.

Put Transmission on any forward gear.

Does the DRB show above zero MPH?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Go To 2

No®Go To 3

2 Ignition off.

Using the Schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?ENGINE -2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Test Complete.

3 Ignition Off

Disconnect the VSS Connector.

Note: Check connectors - Clean/repair as necessary.

Key On

Using a Voltmeter, probe the 8-Volt Power Supply Circuit.

Is the voltage above 7.0 volts?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Go To 4

No®Repair the open 8-volt Supply Circuit.

Perform Powertrain Verification Test VER-5A.

4 Ignition Off

Disconnect the VSS Connector.

Note: Check connectors - Clean/repair as necessary.

Key On.

Using a Voltmeter, Probe the Vehicle Speed Sensor Signal.

Is the voltage above 4.0 volts?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Go To 5

No®Go To 11

5 Ignition Off

Disconnect the VSS Connector.

Note: Check connectors - Clean/repair as necessary.

Connect a jumper wire from the Sensor Signal to the Sensor Ground Circuit.

Key On

With the DRB, read the VSS Signal.

While observing display, tap other end of jumper to VSS Signal Circuit.

Does the display show more than 0 MPH?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Go To 6

No®Go To 8

154

DRIVEABILITY

P-0500 NO VEHICLE SPEED SENSOR SIGNAL ÐContinued

ProCarManuals.com

Page 161 of 364

TEST ACTION APPLICABILITY

6 Ignition Off

Remove the Vehicle Speed Sensor. Inspect the Speedometer Pinion Gear.

Is the Pinion Gear okay?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Go To 7

No®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

7 If there are no potential causes remaining, the Vehicle Speed Sensor is assumed to be

defective.

View repair options.ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Repair

Replace the VSS.

Perform Powertrain Verification Test VER-5A.

8 Ignition Off

Disconnect the VSS Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure between the Sensor Ground Circuit and Engine

Ground.

Is the resistance below 5.0 ohms?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Go To 9

No®Repair the open Sensor Ground Circuit.

Perform Powertrain Verification Test VER-5A.

9 Ignition Off

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Is any Terminal damaged, pushed out or miswired?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 10

10 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Repair

Replace the PCM.

Perform Powertrain Verification Test VER-5A.

11 Ignition Off

Disconnect the VSS Connector.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the VSS Signal Circuit from the PCM to the VSS

Connector.

Is the resistance below 5.0 ohms?ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Go To 12

No®Repair the open Speed Sensor Signal Circuit.

Perform Powertrain Verification Test VER-5A.

155

DRIVEABILITY

P-0500 NO VEHICLE SPEED SENSOR SIGNAL ÐContinued

ProCarManuals.com

Page 162 of 364

TEST ACTION APPLICABILITY

12 Ignition Off

Disconnect the VSS Connector.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

With the DRB in Ohmmeter mode, measure between the VSS Signal Circuit in the

Powertrain Control Module Connector.

Is the resistance below 5.0 ohms?ENGINE -2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX

Ye s®Repair the Speed Sensor Signal Circuit for a short to ground.

Perform Powertrain Verification Test VER-5A.

No®Go To 13

13 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.ENGINE - 2.0L,

2.4L I-4 DOHC

and/or ENGINE -

3.0L V6 w/o EATX Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

14 Ignition Off

Raise the Drive Wheels off the ground.

Warning: Be sure to keep hands and feet clear of rotating wheels.

Start Engine.

With DRB, read the Vehicle Speed Sensor.

Put Transmission on any forward gear.

Does the DRB show above zero MPH?ENGINE -2.0L,

2.4L, 3.3L V6 FFV

and/or ENGINE -

3.3L V6 and/or EN-

GINE - 3.8L V6

w/EATX

Ye s®Go To 15

No®Go To 16

15 Ignition off.

Using the Schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?ENGINE - 2.0L,

2.4L, 3.3L V6 FFV

and/or ENGINE -

3.3L V6 and/or EN-

GINE - 3.8L V6

w/EATX Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Test Complete.

16 Ignition On, Engine Not Running

With the DRB, read the EATX Trouble Codes.

Are any codes P0731- P0734, P0736, P0715, P0720, P1794 present or Pinion Factor

not programmed?ENGINE - 2.0L,

2.4L, 3.3L V6 FFV

and/or ENGINE -

3.3L V6 and/or EN-

GINE - 3.8L V6

w/EATX Ye s®Refer to the symptom list for problems related to Transmission.

No®Go To 17

17 Ignition Off

Disconnect the Transmission Control Module.

Note: Check connectors - Clean/repair as necessary.

Connect a Jumper Wire to the VSS Signal Circuit.

Key on.

With the DRB, read the VSS Signal.

While observing display, tap the other end of Jumper to ground.

Does the display show above zero MPH?ENGINE - 2.0L,

2.4L, 3.3L V6 FFV

and/or ENGINE -

3.3L V6 and/or EN-

GINE - 3.8L V6

w/EATX

Ye s®Go To 18

No®Go To 25

156

DRIVEABILITY

P-0500 NO VEHICLE SPEED SENSOR SIGNAL ÐContinued

ProCarManuals.com